Maker bot 3d printer replicator

Professional 3D Printer Comparison | MakerBot

METHOD | REPLICATOR+ | REPLICATOR Z18 | |

|---|---|---|---|

CATEGORY | Performance | Desktop | Desktop Large Volume |

USES | Prototypes, manufacturing aids, and other parts that require complex assemblies, extreme geometries, and commercial precision. | Classroom lesson plans, STEM projects, design thinking exercises, and facilitation of 21st-century career skills. | Oversized models, housings, and structures that require a massive build volume. |

PRICE | $4,999 | $2,799 | $5,499 |

LAYER HEIGHTThe range of thicknesses of each printed layer measured in microns. | 20 - 400 microns Print Modes: | 100 - 400 microns Print Modes: | 100 - 400 microns Print Modes: |

COMPATIBLE EXTRUDERSMakerBot 3D printers utilize swappable extruders for flexibility of print options and convenience of maintainance. | Model 1 Performance Extruder, Model 2 Performance Extruder | Smart Extruder+ Tough Smart Extruder+ Experimental Extruder | Smart Extruder+ Tough Smart Extruder+ Experimental Extruder |

BUILD SPEEDMax Material Flow rate is the maximum speed material can be extruded. Print Head Travel Speed is the speed that extruder moves on the xy axis. | Max Material Flow Rate: ~50mm3/sec Print Head Travel Speed: 500 mm/sec | Max Material Flow Rate: ~15mm3/sec Print Head Travel Speed: Up to 175 mm/sec | Max Material Flow Rate: ~15mm3/sec Print Head Travel Speed: Up to 175 mm/sec |

PRINTER FRAME CONSTRUCTIONThe printer's frame connects the xy gantry to the z stage making it the essential structural component of the printer. | Ultra-Rigid Metal Frame | Injection Molded ABS with aluminum gantry-reinforcement | Injection Molded ABS with aluminum gantry-reinforcement |

BUILD VOLUMEThe maximum space available for 3D printing either your complete object or a component of your final, assembled object. | 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in single extrusion 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in dual extrusion | 29.5 L x 19.5 W x 16.0 H cm / 11.6 L x 7. | 30.0 L x 30.5 W x 45.7 H cm / 11.8 L x 12.0 W x 18.0 H in |

MATERIAL STORAGEMaterial storage location can improve the user experience, and a sealed storage compartment can significantly increase the "pristine" lifetime of material allowing for high print accuracy. | Dry-Sealed Material Bay | Open back loaded material drawer | Open bottom loaded material drawer |

COMPATIBLE MATERIALDifferent materials can be used for different applications. | MakerBot Precision PLA, MakerBot Precision Tough, MakerBot Precision PVA, MakerBot Specialty PETG | MakerBot PLA, Smart Extruder+. | MakerBot PLA, Smart Extruder+. MakerBot Tough, Tough Smart Extruder+. Additional materials such as bronzeFill, copperFill, and woodFill, Experimental Extruder. |

BUILD PLATFORMBuild surface and platform type | Factory-Leveled Spring Steel Build Plate with Reusable Grip Surface | Factory-Leveled Flex Build Plate with Reusable Grip Surface | Factory-Leveled ABS Build Plate with Reusable Grip Surface |

MEASURABLE DIMENSIONAL ACCURACY3D printed parts that consistently match CAD dimensions to within a published tolerance. | |||

DUAL EXTRUSIONTwo extruders provide the added ability to print with soluble support material alongside model material. | |||

ENCLOSED HEATED BUILD CHAMBERAn elevated 3D printing environmental temperature improves layer adhesion, reduces warping, and improves dimensional accuracy. | |||

SMART ASSIST MATERIAL LOADINGAn extra sensor and drive motor designed to automate the loading process from spool to extruder. | |||

SMART SPOOL COMPATIBILITYRFID Tag equipped spool providing real-time information on material type, color, and amount remaining. | |||

CAMERAOnboard camera for monitoring your print jobs and sharing pictures of your 3D prints. | |||

INTERFACEProvides easy, computer-free access to printing menus, commands, and your cloud storage library. | 5" Capacitive Touch Screen | 3.5" LCD Screen | 3.5" LCD Screen |

CONNECTIVITYOptions for connecting directly or remotely to the printer for from launching and monitoring prints, to adjusting settings and updating firmware. | WI-FI Ethernet USB Stick USB Cable | WI-FI Ethernet USB Stick USB Cable | WI-FI Ethernet USB Stick USB Cable |

| Shop Method | Shop Replicator+ | Shop Replicator Z18 |

MakerBot Replicator 5th Generation Review

3. 3

See Price

MakerBot’s Replicator is among the top well-known 3D printers on the market. There are various different versions available, but it goes without saying that some are better than others. Today, we’ll be taking a closer look at one of the lesser-known models – the Replicator 5th Generation.

We’ll be keeping an eye out for any strengths or weaknesses this printer might have. Who knows – while it’s been replaced by the Replicator+, maybe it has benefits that later models don’t. You’ll have to read our full review below to find out.

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Supported Materials | PLA |

| Connectivity | USB, WiFi |

| Printing Speed | 150mm/s |

| Build Volume | 9.92 in x 7.83 in x 5.9” |

Table of ContentsShow

Design

It’s easy to be intimidated by the large, looming frame of the 5th Generation. However, it’s designed to be accessible and easy to use. Take the chassis, for instance. It’s built to accommodate an enclosure, in case you’re having difficulty maintaining a consistent temperature during a print.

Of course, because of the printer’s size, the build area looks relatively small. In actuality, it’s larger than most, except for when it comes to depth. Still, there’s a lot of potential here, especially if you’d like to print models larger than most 3D printers will allow.

Let’s be clear: this printer is probably too big for your desktop. It’s pretty clearly designed for professionals, so you’re really expected to have a designated printing area set up. Since the extruder can move up to 150mm/s, you can expect it to be a little louder than most, too.

Printing

Overall, the Replicator 5th Generation has average-to-good print quality. We were a little underwhelmed by the 0.5mm minimum layer size, but for general day-to-day printing, it’ll do just fine. The problem is that this printer is intended for experienced users, yet offers very little to draw these people in.

For instance, you’re limited to PLA filament. We’ve seen open-source, $200 printers that can handle more materials than this one, and for a company like MakerBot, that’s just embarrassing. Its speed might have helped redeem it, but 150mm per second hardly makes it the fastest printer around.

For what it’s worth, it does replicate models pretty well. Mechanical gears, for instance, rarely need any post-processing in order to work properly. That said, at this price, you really expect it to excel in some way, and that’s simply not the case.

Features

It’s not all bad, though. The LCD screen is an absolute joy to use, with clean, well-organized menus and a control dial to save space on the unit itself. There are even WiFi capabilities so you can print while away from the machine. There’s also the option to print from a USB stick, but not an SD card.

We’d be remiss if we didn’t mention the smart extruder. The Replicator series claims to be the only range of printers with a hot-swappable extruder, meaning if one stops working, you don’t have to halt production. It’s also more reliable than traditional extruders, which can only be a good thing.

The print bed, unfortunately, isn’t heated. This means that you’ll be relying on tape or other sticky surfaces to keep your prints stable. We were pleased to see that there is an automatic leveling function, though, so you don’t have to waste time getting set up for a print every single time.

Cost

So far, the Replicator 5th Generation sounds decent for a mid-range printer. There’s an issue, though: it’s priced like a premium one. While it’s no longer available directly from MakerBot, it retails on third-party sites for around $2000. Even after a couple of years, this price stays too high to be viable.

On the plus side, PLA is about as cheap a filament as you can get. You can actually use a third-party filament, but you might have to download a user-created print mode in order to do so. It’s a bit of a shame: if users can build these on their own, MakerBot could easily have just included them as standard. Of course, this would hurt their bottom line, so they didn’t.

The Replicator 5th Generation really struggles to justify its high price. It has decent performance across the board, but nothing particularly stands out about it. If you’re a collector or 3D printing enthusiast, by all means, buy one, but most people can find something better at a lower price.

Support

MakerBot’s website has tutorials and support for all of its printers… except for the 5th Generation. If you need help, you can search for general information using keywords, or you can call them on the phone during office hours. There used to be email support, but we’ve heard reports that they no longer reply.

There’s a little confusion regarding this product’s warranty, too. In the user manual, it claims that the 5th Generation is covered by a limited warranty and links to the terms. However, while most other printers are referred to specifically, there’s no mention of this one. You should still qualify for some kind of third-party warranty, but it might be worth trying your luck regardless.

This simply isn’t good enough. Even for a model that’s no longer actively sold, users should know up front if they’re protected should something go wrong. While we can overlook this from smaller manufacturers, MakerBot has the money and legal resources to take better care of its legacy customers.

Not the MakerBot 3D printer that you want? Check our review about the MakerBot Replicator 2, this one might be the one that you’re looking for.

MakerBot Replicator 3D Printerfrom MakerBot Industries, LLC The Makerbot Replicator is one of the most popular desktop 3D printers and has spawned many imitations around the world. Since its inception, the design of the printer has been constantly improved: the fifth generation of the popular device is currently being released.

About the MakerBot Replicator

MakerBot welcomed 2014 with a new range officially classified as "5th Generation". This includes the new compact MakerBot Mini printer, its exact opposite of the MakerBot Z18 (the name directly refers to the height of the working area of 18 inches, i.e. 455mm) for printing large objects and, of course, the updated flagship and golden mean - MakerBot Replicator.

Here it is, handsome

Don't be confused by the name of the model - the new Replicator is the development of the Replicator 2 printer. The company deliberately did not call it Replicator 3, but instead introduced the concept of generations. Thus, the Replicator 2 belongs to the fourth generation, and the new printer - to the fifth.

This option has a lot of interesting and quite rational ideas, although the result can hardly be called ideal. So:

Design

The appearance of the printer gives the impression of a high-tech gadget, which is what the Replicator is. While maintaining the black, matte severity of the Replicator 2, the new device was “licked” - the panels disappeared, the supporting steel frame was hidden in a smoothed plastic lining. The first optimization is visible to the naked eye: the control module has moved from its usual place in the lower right corner to the top, which makes its use much more convenient. Despite rumors about the touch screen, the display remained just liquid crystal, but color. But the large rotary knob is very convenient, reminiscent of the smoothness of the volume controls on expensive stereos.

Smart extruder mounted on magnets

The new version of the extruder has become "smart": built-in electronic components allow the printer to detect when the consumable is running out and warn the user about it. This moment alone deserves huge praise for the designers. No printing "over the air" and decommissioned semi-finished models - received a warning, changed the coil, continued printing. Amazing.

The “jumping nozzle” is also interesting: when changing the horizontal position without printing (for example, when layering individual fragments on the same level), the platform movement is no longer required to distance the layer from the nozzle and prevent smearing of freshly applied plastic. Instead of a platform, the nozzle itself comes into motion. The extrusion stops, the nozzle rises, separating from the applied plastic, the print head moves to a new position, the nozzle lowers and printing continues. This approach theoretically allows for higher Z-axis accuracy and higher print speeds. As for the mechanism of movement of the nozzle, it is extremely simple: the feed mechanism simply turns on the “reverse speed”, and the plastic thread pulls the nozzle up with it.

The third interesting element was the Hall sensor built into the print head. The platform calibration procedure has become much easier. Now tilt adjustment is carried out using two large, comfortable handles. The sensor in the head tells you when one or another edge of the platform reaches the optimal position. The light came on - it means that the slope is eliminated. The same for the perpendicular axis, and the calibration is complete. But why not put two servomotors instead of handles and make the process fully automatic?

The downside of the new extruder is its relative complexity. In fact, it is not designed to be repaired on its own. If the nozzle becomes clogged, then the entire extruder will most likely have to be replaced with a new one or the old one should be sent to a service center, which is a problem in Russia. The good news is that detaching the assembly is exceptionally simple: the extruder is held in place with fairly powerful magnets. You just need to apply enough force, and the whole assembly separates. I stuck a new extruder in its place, threaded the thread, continued working.

Glass platform covered with blue masking tape. An illuminated light near the nozzle indicates that the stage is properly calibrated. MakerBot deliberately sticks to the flagship concept of printing with one filament and one extruder. On the one hand, this allows you to slightly increase the size of the working area while maintaining the dimensions of the printer - after all, the more extruders, the larger the printed assembly. On the other hand, polylactide is one of the easiest materials to print, does not suffer from high shrinkage and does not emit harmful fumes due to its organic origin. Since PLA plastic is almost not subject to deformation during curing, the Replicator is not equipped with a heated platform. On the other hand, fans of "replicators" often misuse these printers, printing with ABS plastic, polystyrene, nylon and other alternative materials. Many of them require platform heating. Fortunately, purchasing such an upgrade from a third-party manufacturer is quite simple. The previous model used an acrylic worktop, but on the new version, the designers decided to use glass. In principle, both options are excellent for printing with polylactide.

Built-in camera allows you to transfer images of the printing process to remote computers and mobile devices

Finally, for the first time, the "replicator" was equipped with a camera. The idea is to be able to control the printing process remotely. What if there's a crash? To receive images and control using a mobile device, you will have to connect the printer to the network, for which an Ethernet interface was provided. The USB port remained in place and became multifunctional, as the developers abandoned the use of memory cards in favor of flash drives. By the way, branded flash drives, as in the case of CubeX, are not required. Any drive with standard formatting will do. True, the drive is not supplied in the kit. Remote control is carried out using the MakerBot Mobile mobile application or the standard MakerBot Desktop software, and within the office, you can also use a Wi-Fi connection.

Plastic filament spools have been resized. All fifth generation MakerBot printers use thinner, larger diameter spools. This was done so that the coils fit more ergonomically into the dimensions of the devices themselves, because they are stored inside. You don't have to turn the entire printer around to change the spool: the spool slides into a drawer at the back of the printer with the mount facing forward. After installing the spool, the section drops down and the printer looks neat.

Spools of filament are inserted into the drawer

Of course, no one else, except MakerBot, produces such spools. But! The company does not break the hands of users by forcing them to use branded cartridges, as 3D Systems did. Those who wish can use standard coils, they just have to be installed outside the printer. And the drawer section, with the guide tube attached, has a latch that holds it in the raised position. It will not look particularly attractive, but the functionality is provided. Branded thread is sold at a price of about $40 per kilogram, which is about 20% more expensive than consumer goods. But the quality is guaranteed - no dust or oval profile. Unfortunately, a rather complicated filament feed path, coupled with a narrow nozzle, creates an additional load on the pulling mechanism of the extruder. Although the designers have spring-loaded the roller, there are times when the printer simply cannot grab onto the filament. As a rule, such problems do not appear immediately.

Despite all the tricks, such as optimizing algorithms, using an ARM9 processor and a jumping nozzle, the new printer is noticeably slower than the Replicator 2. In one of the comparative tests, the task was to print a Lego brick. The Replicator 2 completed the task in 18 minutes, while the 5th generation "replicator" took 25! Even the inclusion process is quite long - the download takes about three minutes.

Not practical, but glamorous!

And yet, if everything works as expected, the Replicator is pleased with the good quality of the models. The printer allows you to print with a resolution of 100 microns vertically, although the thickness of the applied layer can be increased to speed up the process. Back at the office, the MakerBot team prints mostly in 200-micron layers, which is enough for most tasks, according to CEO Bree Pettis. Positioning accuracy has remained at the level of the fourth generation printers, which is good in itself: 11 microns in the X and Y axes, 2.5 microns in the Z axis.

And yes, the new Replicator informs you about the progress of the print and estimates the remaining time. This feature has been enabled due to persistent user requests. As Pettis explained, there was simply no room for it on the old hardware.

The platform has undergone significant changes. The dimensions have changed: the area of the table has slightly increased and become “square”: 252x199mm versus 285x153mm for the Replicator 2. The material of the table has been replaced with more and more popular glass, and the table itself is now attached to the platform using skids instead of clips. So it's safer and more convenient. For better adhesion of plastic to the table, a time-tested solution is used - masking tape.

Software

MakerBot Desktop software. The status bar at the bottom indicates that the model being printed is 98 percent complete.

The software used is the MakerBot Desktop software package. This includes MakerWare, which made its debut on the Replicator 2 and is responsible for model processing, slicing, and other functions and settings related directly to printing. In addition, networking features have been added, including access to the Thingiverse website, which features many digital models, including free ones, uploading your own digital designs for the benefit of the community, the ability to order additional consumables, and more and more. With it, you can also receive pictures from the built-in camera or remotely control the printer. To use the software, you will have to open an account on Thingiverse, but it is not at all difficult and completely free.

The MakerBot Digitizer Desktop 3D Scanner and MakerBot Replicator Printer is a Chinese engineer's dream. Copy, copy!

It's worth noting that MakerBot is seriously aiming to create a 3D "ecosystem" tested by 3D Systems. This means the integration of hardware, software and networking into a single whole. If in the case of 3D Systems the ecosystem consists of Cube 3D printers, Sense 3D scanner and Cubify online service, then in the case of MakerBot we have Replicator, Digitizer and Thingiverse, respectively. Adding to the intrigue is the fact that MakerBot is actually an independent division of 3D Systems' main competitor, Stratasys.

Summary

The new "replicator" has become friendlier due to an optimized design and user-friendly software. It's still a favorite of seasoned 3D enthusiasts, but the new version is easy enough to use for inexperienced users. A lot of convenient innovations and improvements are pleasantly surprising. Unfortunately, the first batches of delivered printers clearly showed the dampness of the design: there were problems with the extruder, bugs in the firmware, and a surprisingly slow print speed, which, on the contrary, should have increased. If the designers bring this wonderful machine to mind, then it will have every right to the title of "best among equals." The cost of the device is high, although this printer is primarily intended for serious users and design companies, for which the manufacturer's selling price of almost three thousand dollars will not be prohibitive.

Benefits

- Stylish, ergonomic design

- Convenient control module and software

- High print quality

- MakerBot 3D Ecosystem Integration

Shortcomings

- Fairly large number of shortcomings

- Slow print speed

- High price

Detailed view of the MakerBot Replicator Plus

3D Printer3DPrintStory Reviews Detailed review of the 3D printer MakerBot Replicator Plus

The MakerBot Replicator Plus has received improvements in terms of design, speed and many other features compared to previous models. This time around, MakerBot tried to attract a professional audience to 3D printing, and it succeeded. This 3D printer is quieter and has many other advanced features that make it one of the strongest 3D printers in its price range.

MakerBot Replicator Plus 3D Printer Specifications

Let's take a look at the MakerBot Replicator Plus features that make this 3D printer a real gem. It has a few limitations and is expensive. But the implementation of the rest of the nodes of this 3D printer makes it easy to neglect these shortcomings. Overall, this 3D printer has been and remains very popular among 3D printers.

The MakerBot Replicator Plus is all black and looks great thanks to its rugged design. The company has increased the dimensions of this 3D printer compared to its predecessor, which is 410 x 440 x 525 mm. The weight is about 18 kg. Nozzle diameter 0.4 mm.

The build volume of the 3D printer is 165 x 290 x 190 mm. Open frame design. It is open at the top, front and sides, providing a great view for those who like to follow the 3D printing process.

MakerBot boasts many updates that have been implemented in this 6th generation released by the company. All new features are worthy of attention. This model would be a great option for teaching the basics of 3D printing or for those who want to start a small 3D printing business. With 25% more workspace and 30% faster 3D printing than the previous version, the MakerBot Replicator Plus is a clear improvement over its predecessor.

The price of the MakerBot Replicator Plus 3D printer

MakerBot succeeded in many ways in terms of quality, but not in terms of price... The MakerBot Replicator Plus is expensive. $2,499 is a hefty amount of money for most people, especially if someone is just getting started with 3D printers.

Although the company intended to target the professional and educational sector, the price was even by that measure. There are many professional 3D printers with comparable features at a lower price.

The price of the MakerBot Replicator Plus certainly limits its availability to most users. But as the 3D printing community grows, the number of those who can pay that price has also increased. This way, MakerBot will have no problem selling its item, given that its features are worthy for this price. Let's now dig deeper to see what exactly this 3D printer delivers at such an indiscreet price.

MakerBot Replicator Plus 9 First Impressions0115

The first impression of the MakerBot Replicator Plus is the same 3D printer as its predecessor, with a slightly expanded 3D print workspace. In fact, it has the same metal case with plastic containers. Like most older versions, the model is sleek and durable. The open design makes this model suitable for any lab or garage. This same openness makes the MakerBot Replicator Plus a great option for training centers.

However, when you start setting up this 3D printer and start 3D printing, you will realize that many changes have been made to the functionality of the previous version.

Size is the first thing people pay attention to. Once you start plugging this model into an outlet, you will realize that it is nothing like the fifth generation version. If not for the biting price, then the MakerBot Replicator Plus is a great choice for a desktop 3D printer.

Setting Up the MakerBot Replicator Plus 3D Printer

Setting up the MakerBot Replicator Plus is simple, but the instructions could be better illustrated. To set up, you need to connect to WIFI and download the mobile phone app. There is no mention of which OS version is compatible with the mobile phone app. Doesn't work with old version.

Problems may occur if your phone's OS is not updated to the latest version. However, this is not a big problem and it can be fixed. But at some point, the instructions will continue to be confusing. Setup can be done via the USB connector on the back of the 3D printer. There is no mention of this in the instructions. You can also use an Ethernet cable for the necessary settings.

You also need to create an account with MakerBot before starting setup. This gives you the added benefit of remote viewing and 3D printing.

In addition, the mobile phone app is quite easy to use and even beginners will find it useful when setting up a 3D printer.

MakerBot Replicator Plus 3D Printing

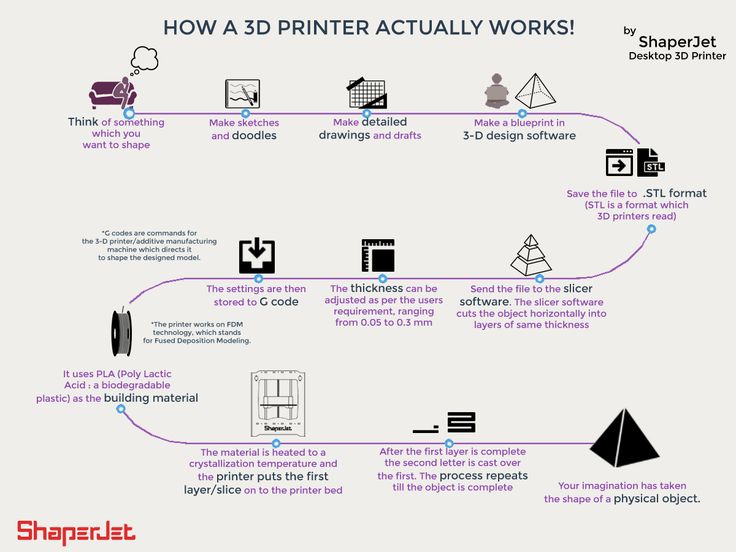

This 3D printer is based on the FDM process. The material is heated and extruded to be deposited layer by layer on the worktable. After each layer cools and solidifies, another layer of molten material is applied to the previous layer. This way the whole part will be printed.

Controls and User Interface : Controls are placed at eye level in front of the 3D printer body. Thanks to a clear interface, you can choose between different setting options. The display can be navigated using one button wheel and two more buttons. You can also preview the model before 3D printing. This is a great feature as you can use this 3D printer without a desktop computer via the USB port to preview your model before starting 3D printing.

Material Storage : MakerBot has made major changes to the material storage system. Unlike many other options available on the market where the spool storage is located outside, the MakerBot's plastic spool storage is hidden in the back of the 3D printer. This allows you to control the remaining material. Loading material is also simple and convenient. MakerBot didn't mention it directly, but you are forced to use only MakerBot stuff. This is noted in the 3D Printing Materials Warning from other manufacturers, which states that the warranty may be voided if other materials are used. The material offered by MakerBot is as expensive as their 3D printer itself. Coil of PLA plastic weighing 0.9kg will cost from 48 to 65 dollars. Available in about 30 different shades and types of materials.

3D Printing Process : Although printing with this 3D printer is effortless, you may have to work a little to remove parts from the desktop when printing is complete. Before printing details, you need to adjust the layer height. After that, a file for 3D printing is generated and sent to the printer for direct printing. After starting 3D printing, you can turn off your computer or control the printing process by turning it on.

3D print speed : The company claims that this version prints 30% faster than the previous model. And this 3D printer is really faster.

Extruder : MakerBot offers a "smart" extruder, available at an additional cost, that is designed to use 1.75mm PLA. It can detect when material is running low and immediately pause 3D printing. It also notifies the user to submit material in order to start 3D printing again.

MakerBot Replicator Plus 3D Print Quality

MakerBot Plus 3D print quality is better than most professional 3D printers. However, at $2,499 you can expect better results. Perhaps the company could work a little more on print quality in the context of the overpriced.

With this 3D printer, you can print fine details in decent quality. However, there are a few problems, such as the tendency of this 3D printer to leave filaments between voids. Although they are removable, they still leave traces and in fact the print is not perfect.

Smooth and beautiful curves can be printed. This 3D printer allows you to create curves with fine details. However, the print speed will have to be reduced to improve detail and accuracy.

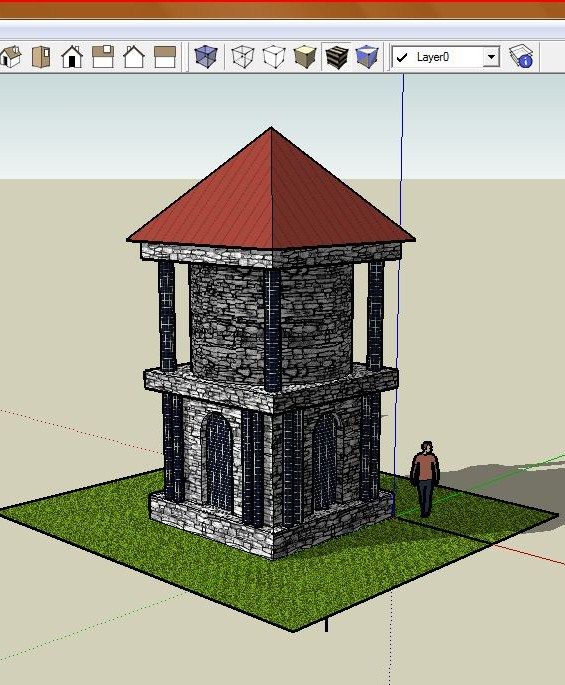

Geometric prints are also great, though not as dramatic. The MakerBot Replicator Plus can create bevelled edges with fine detail. This 3D printer does an excellent job of making sculptures and geometric shapes. However, don't expect perfectly sharp corners. Remains of material between the voids will also show up in similar 3D models.

You can also try printing assembled gears. However, when 3D printing sets of gears, the amount of post-processing work increases.

The biggest flaw that calls into question the quality of this 3D printer is desktop without heating . ..

MakerBot Replicator Plus 3D printer software

The MakerBot Print application compatible with this model can be considered almost flawless. With simple commands, you can start the 3D printing process in seconds. Just open the printable file and send it for 3D printing. You can even export files to USB or other external drives. The application can be used with a mobile phone or tablet. Thus, you can send a 3D print command over Wi-Fi or even remotely.

MakerBot Help Desk

The company offers good customer support. Your inquiries will only be welcome, and you can get feedback from the manufacturer pretty quickly.

MakerBot Replicator Plus performance evaluation

Before buying a 3D printer, the user looks at various parameters. Based on these parameters, there are a few things you can consider before making your final decision.

MakerBot Replicator Plus 9 Cost0162 : 3D printer is expensive. Since professional 3D printers start at a lower range, there are many options available at a lower price point. The price also looks higher compared to the quality that this 3D printer provides. What's more, FDM 3D printers are available for as little as $200... However, they won't give you the power that the MakerBot Replicator Plus provides.

3D Print Quality MakerBot Replicator Plus : Expect decent 3D print quality with minor to minor flaws.

3D print speed MakerBot Replicator Plus : 3D print speed is excellent. However, there are some issues with creating finer details at high settings.

3D printer capabilities MakerBot Replicator Plus: 3D printer capabilities are enormous. You can use this printer for both complex geometric shapes and regular models. However, you are limited to using PLA.

Practical 3D printer MakerBot Replicator Plus : This 3D printer is not designed for high end 3D printing. It is designed for professionals who use 3D printers for general purpose printing and especially for educational purposes.