Why do 3d printers take so long

9 Reasons Why Your 3D Prints Take So Long – Printing It 3D

Print times can be incredibly frustrating to deal with, especially if you are printing for commercial reasons. 3D printers are notorious for taking a very long time to create a piece, which can put a dent in plans or put you under a time crunch.

Here are 9 reasons your 3D prints might be taking so long:

- You’re using complicated fill patterns.

- Your print has a high fill density.

- Your prints have thicker walls.

- High resolution can slow down print time.

- Generating more supports can take longer.

- You’re heating different printing materials.

- The print head travel speed is set low.

- A better quality print takes longer to produce.

- The size of your piece can increase print time.

Read on for more explanations and tips about how you can increase your print speed.

1. You’re Using Complicated Fill Patterns

Complicated fill patterns take a lot longer to print than simple ones. Fill patterns are a way to make the center of a printed piece strong but also not solid.

Solid pieces are made of solid printing material, but they take a very long time to complete. If you lower the density and use a complicated fill pattern, you can cut down on time and make a strong piece.

However, sometimes, the fill pattern still takes a long time to print.

If there is a complicated series of hatches and lines through the center of the piece, it will take a long time to fill. Many different types of fill patterns can be used for various purposes, and they all take different times to print.

For example:

- Low strength fills for models and figurines

- ‘Standard’ 3D prints with medium strength

- Functional or practical prints with high strength

- Flexible 3D prints that need to bend

All of these require different types of fill patterns, and they take different times to print. Some are complicated hexagonal patterns, others are simple lines, but all have different print times.

Some are complicated hexagonal patterns, others are simple lines, but all have different print times.

Zig zag fill patterns typically are the fastest, but they offer little internal support. Grids and other connected shapes are more effective and can stop vibration while also being quicker. The more unique the form, like a hexagon, the longer the process will take, but it can help the piece’s stability.

To understand why these take so long, you need to understand fill density and how that factors into your prints.

2. Your Print Has a High Fill Density

If your print has a high fill density, it can take a lot longer to print as well. This means that you have a much denser fill pattern, and the piece is more solid.

Dense fill patterns are great if you need the object to be sturdy. Dense objects can handle impact damage more and are less likely to break if they are used.

This is important for things you are using every day or that are expected to do specific things. For example, if you have printed a piece of tubing for a device or pipe system, you need to make the density strong and handle what the tube is pushing around.

For example, if you have printed a piece of tubing for a device or pipe system, you need to make the density strong and handle what the tube is pushing around.

This density takes time and will extend the active printer period. The printer head has to go over every single line in the printing pattern.

If you want to lower your print time, you can reduce the density. However, it would help if you kept in mind how much you want the item to be used and how strong it needs to be.

3. Your Prints Have Thicker Walls

Thick print walls are also essential to make sturdy pieces. These make sure that your item won’t break and you can’t punch through it quickly.

Wall thickness is the actual width of the outer shell of the item you’ve printed. The wall is what the internal fill will be constructed against, and it’s essential to have a thick wall as good support.

Thick walls take longer to print. They add a different section of the piece that has to be shaped, and the fill pattern has to develop with it.

You can technically lower wall thickness to get a faster print time, but it is not recommended. You need to check the stability of your printed piece before lowering the wall thickness.

Some prints that aren’t going to be used daily (like models or display figures) can be safely made with lower wall thickness. Other things like pipes or multi-function items may need a thicker print wall.

4. Higher Resolution Can Slow Down Print Time

Using a higher resolution is another reason why your prints might be taking longer.

Resolution is a word for image quality. This is what makes an image blurry or pixelated or what makes it high definition. This same premise can be applied to 3D printed pieces.

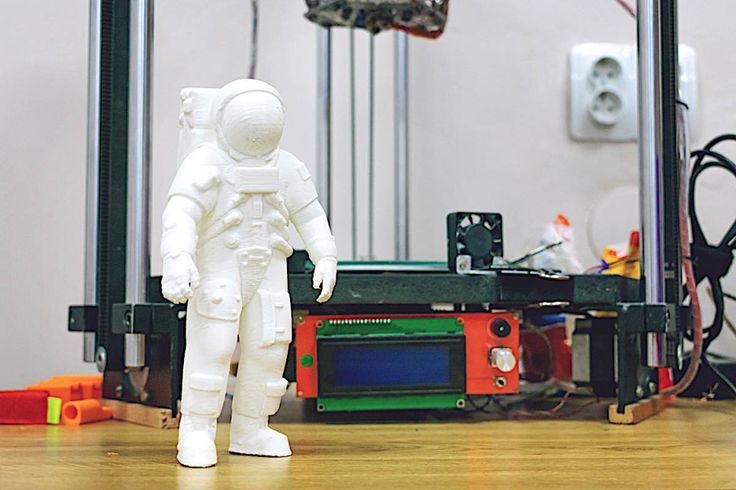

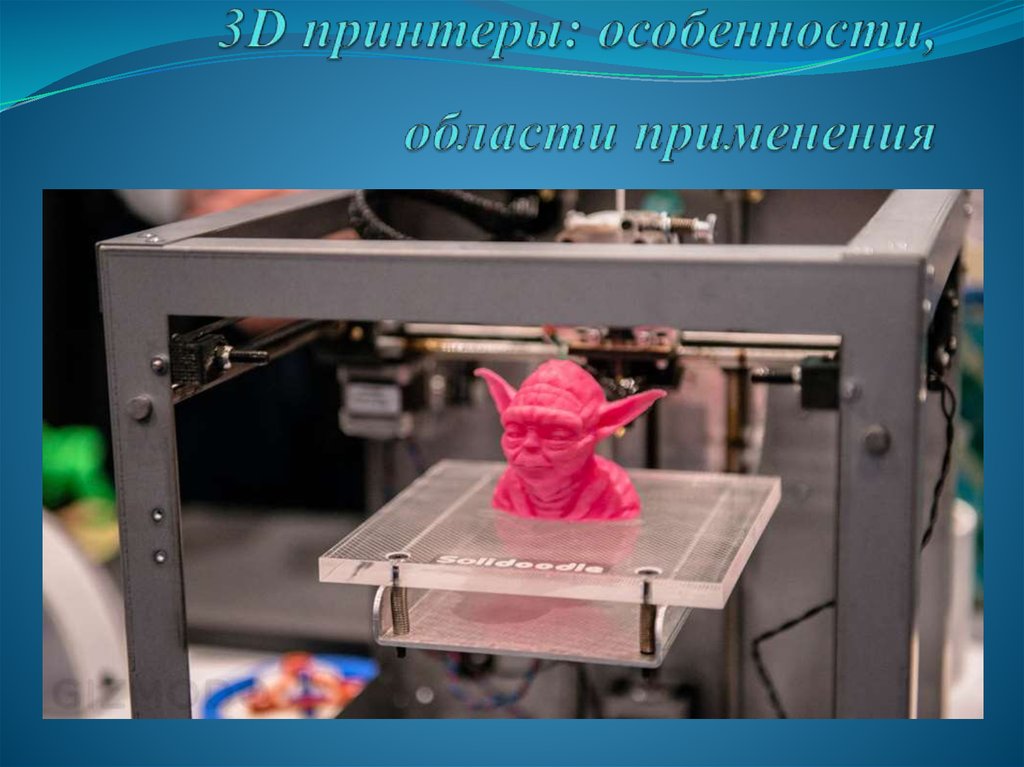

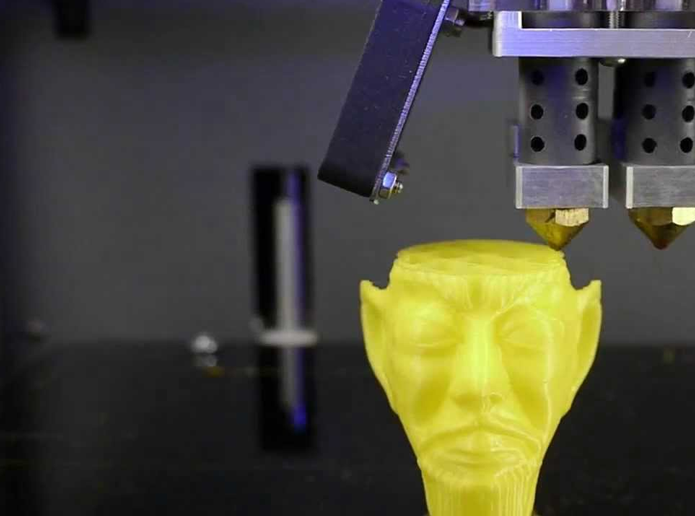

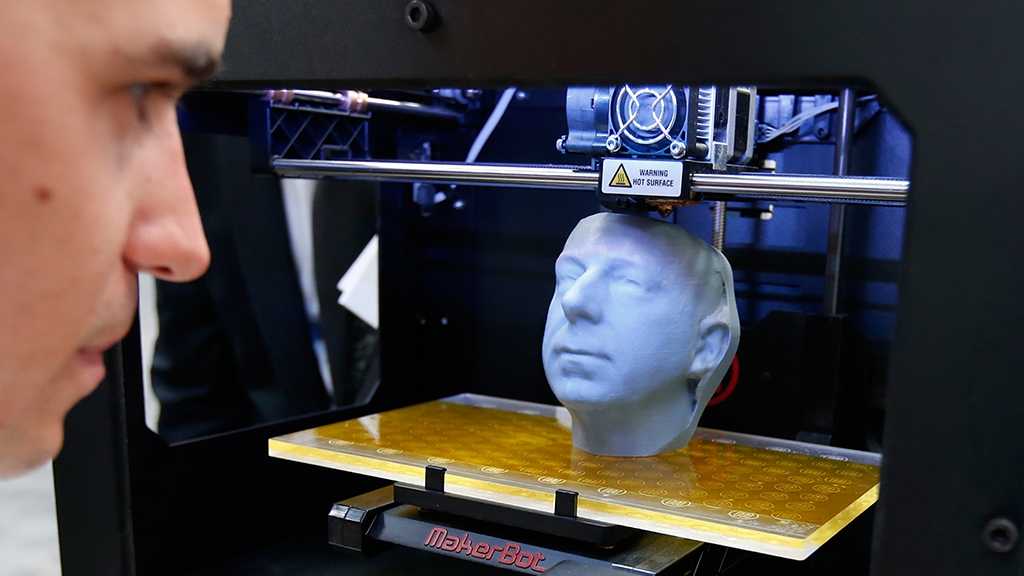

For example, if you want to make a replica of your favorite TV or video game character, there are a lot of pieces from their costume and associated props that are small, fine details. You need a higher resolution to capture them.

Higher resolution means that these details are being printed better, and the final piece will look better overall. They can capture incredibly tiny details, like single buttons on a figure’s jacket or curl definition in hair.

They can capture incredibly tiny details, like single buttons on a figure’s jacket or curl definition in hair.

The way that printers naturally try to improve resolution is by decreasing the layer height.

Decreasing the number of layers improves the resolution by making the printer produce more of them. However, more layers, especially thin ones, will dramatically increase the print time. Every new layer is another time that the print head has to go over the piece.

If you lower the layer count, you can reduce the print time. However, you will miss out on the fine details that 3D printers can make. This may cause your print to look pixelated or almost blurry.

This is also what gives many 3D-printed objects their lined look. The lines mean that the printer used a low layer count for what the thing is.

These lines can be sanded down and modified to improve the physical appearance, but that is more work you have to do later after the print has thoroughly cooled. Increasing the layer count reduces the work and makes it even easier to prep the object later.

Increasing the layer count reduces the work and makes it even easier to prep the object later.

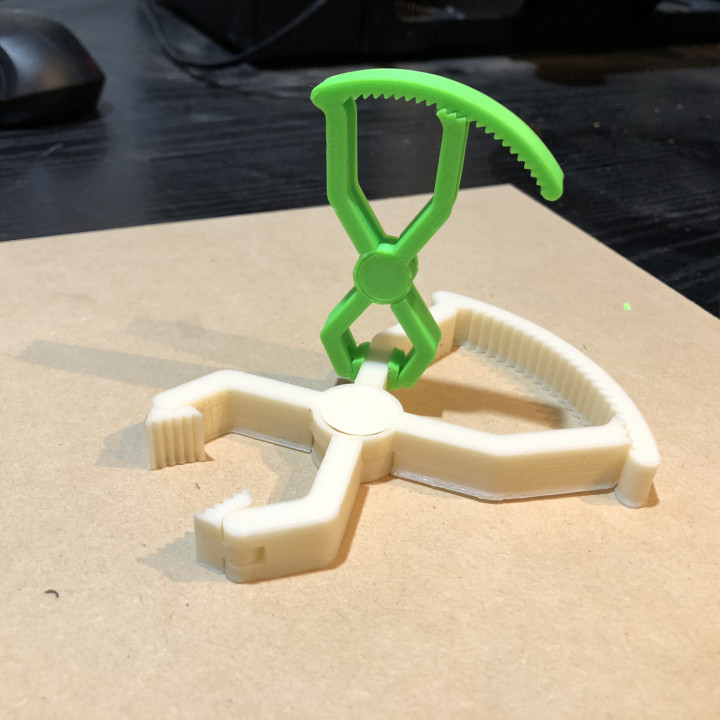

5. Generating More Supports Can Take Longer

Your print could also be taking a long time because it needs a lot of supports.

Supports are small, thin bits of printed material that suspended parts of a print are built on top of. They make sure the printer moves evenly over each layer and give the printer head a space to build on.

Let’s say you are making a model of a TV character waving. A line from the ground does not support their arms. The 3D printer needs a place to start constructing the arm from. Otherwise, the print material will fall to the ground.

Supports fix that problem. If you have an object that needs a lot of supports, this can drastically add more print time.

If a piece needs a lot of supports, it requires a lot of supports. This means that you can’t always cut down on the build time by messing around with supports. Sometimes you just have to suck it up and sink the time.

However, you can change the settings to make sure your piece is being printed with the least number of supports possible, and you can change the thickness of the supports.

This will cut down on time and lower your overall waste. Supports take a lot of extra material and can be a big waste, especially if you use an expensive filament.

Supports can also take a lot more time after the piece has been fully printed. Supports need to be carefully removed and can take a lot of time to sand traces away. Sanding can also wear down the wall thickness of your print and cause structural issues.

It’s recommended that you use a cutter or snipper to get the cleanest cuts on both your supports and filaments. A clean-cut will save you even more time and get into small places your fingers cannot.

This Flush Cutter from BLEDS on Amazon.com is a great choice and a necessary tool for anyone doing a lot of 3D printing. Using the fine tip of the cutter will reduce stress on your piece and get a cleaner cut, so you don’t have to sand as much.

6. You’re Heating Different Printing Materials

Different printing materials take different times to heat up and move through the feeder tubes. This means that a printer may need time to prepare the fibers for extrusion properly.

If you want to work with more difficult filaments, you need to consider how long the preparation process will take. You can’t necessarily cut down on this time, but you can prepare for it, so you aren’t strapped for time.

On the other side of this, materials also need different times to cool down properly. Removing a print from the platform too soon can damage it and warp the plastic. You have to give your print time to cool before removing it.

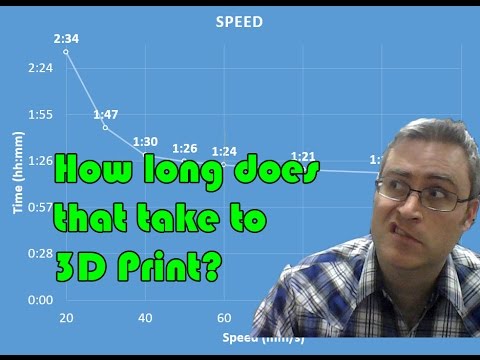

7. The Print Head Travel Speed Is Set Low

Print head travel speed is another reason a print might be taking longer.

The print head is programmed to travel at a certain speed depending on the filament, the thickness of certain sections and avoid putting extra stress on the device. They are also very heavy, and it can be difficult for them to pick up speed.

They are also very heavy, and it can be difficult for them to pick up speed.

Changing printer speed can speed up the process, but you may lose quality. Slowly increase the speed over several different prints to see if you lose quality. Look at the little details in your print and see if they are visible.

If you don’t, then you can enjoy the higher speed and cut down on print time! If you do lose quality, you should slow the speed down until you find the sweet spot.

8. A Better Quality Print Takes Longer To Produce

If you want a higher quality print, it will take more time. All of the other factors outlined above impact the print time, and it could affect the actual longevity of the piece.

If you want a huge and accurate piece, it’s going to take a while to complete. The printing process is long, and if you want it done right, you need to be patient. The layers need to be thin, and it has to have enough time to cool.

Rushing the process can ruin a piece, and it won’t turn out the way you want. There are also concerns about structural stability because a piece that hasn’t adequately cooled and has improper fill patterns can easily break.

There are also concerns about structural stability because a piece that hasn’t adequately cooled and has improper fill patterns can easily break.

Fill patterns need to be built carefully to make sure your piece doesn’t collapse in on itself. Fill patterns make sure your piece isn’t going to snap and break at the lowest amount of pressure. Giving the printer time to arrange them properly is crucial to creating a long-lasting piece.

In addition, speed can leave many sharp corners on your piece that will need to be sanded. They may also be in a place where you can’t remove them. Ouch!

9. The Size of Your Piece Can Increase Print Time

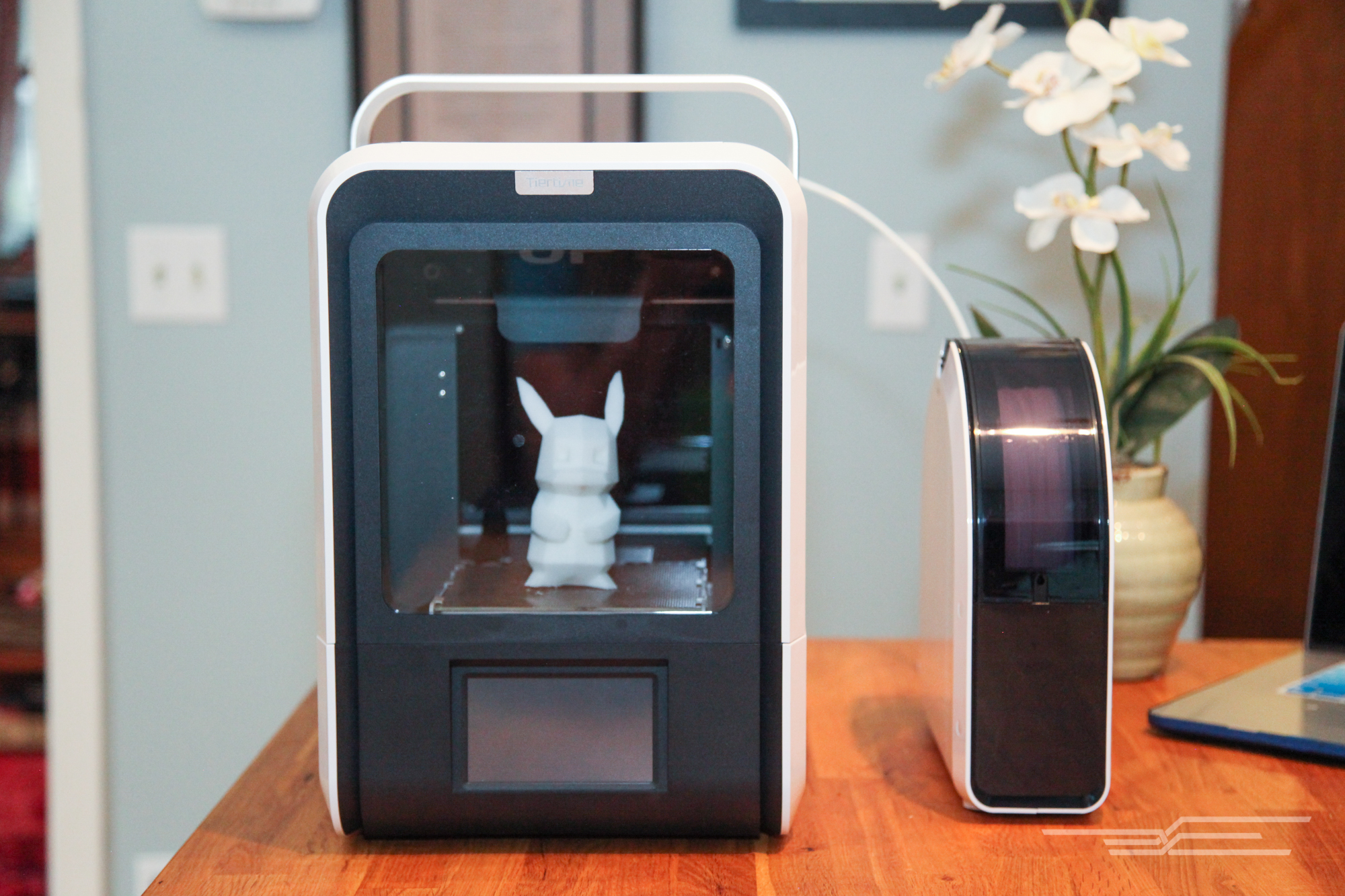

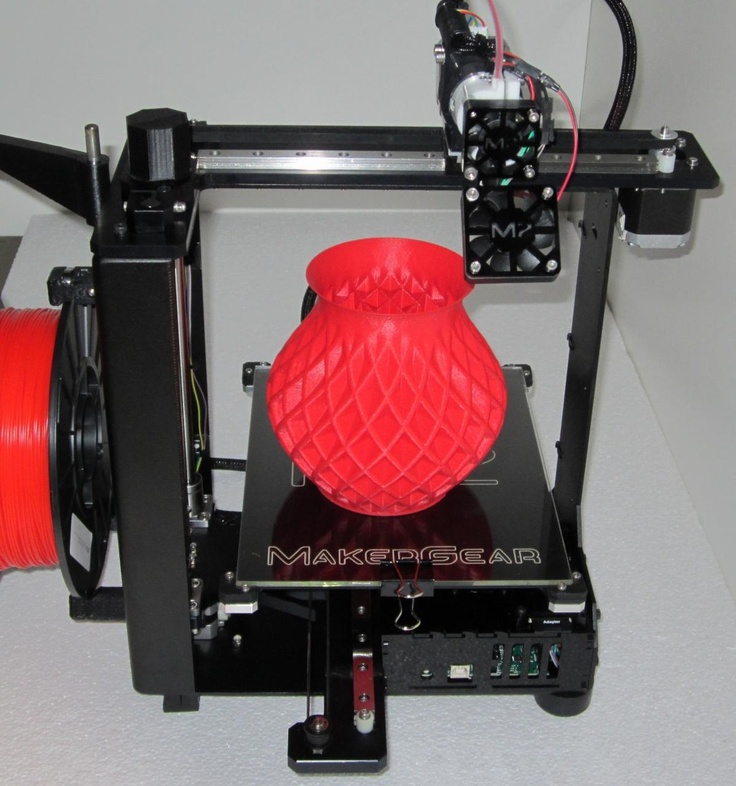

The size of the piece you’re printing is also going to determine the printing time. Smaller pieces take less time to print overall.

However, smaller pieces lose resolution unless you have a very fine printer tip. These can be very expensive, and in general, the larger the piece, the more accurate the resolution can be.

Larger pieces take time, more materials, and they can be very long to print. The amount of space alone can be a challenge, so you may have to turn to a part-based system to fit everything onto one printer platform.

The amount of space alone can be a challenge, so you may have to turn to a part-based system to fit everything onto one printer platform.

The benefits can’t be understated, though. You can get exponentially more resolution on larger prints than smaller ones.

Not only that but using a part-based system can take the stress off your printer. Taking a larger project piece by piece means allowing your printer to cool down between parts. Not forcing it to finish a large piece in one go will make your printer last a lot longer.

Why Are 3D Printers So Slow?

3D printing has become cheap and reliable over the years. Beginner-friendly materials such as PLA and PETG have made home manufacturing more accessible than before. Unfortunately, the actual 3D printing process remains excruciatingly slow, in many cases requiring several days' worth of printing.

Why do 3D printers still go about their business at a glacial pace, when they have been available to consumers for over a decade?

The answer lies in the engineering and production challenges behind making 3D printing commercially viable. Let’s take a look at these challenges and a promising technology that could make 3D printing faster for everyone.

Let’s take a look at these challenges and a promising technology that could make 3D printing faster for everyone.

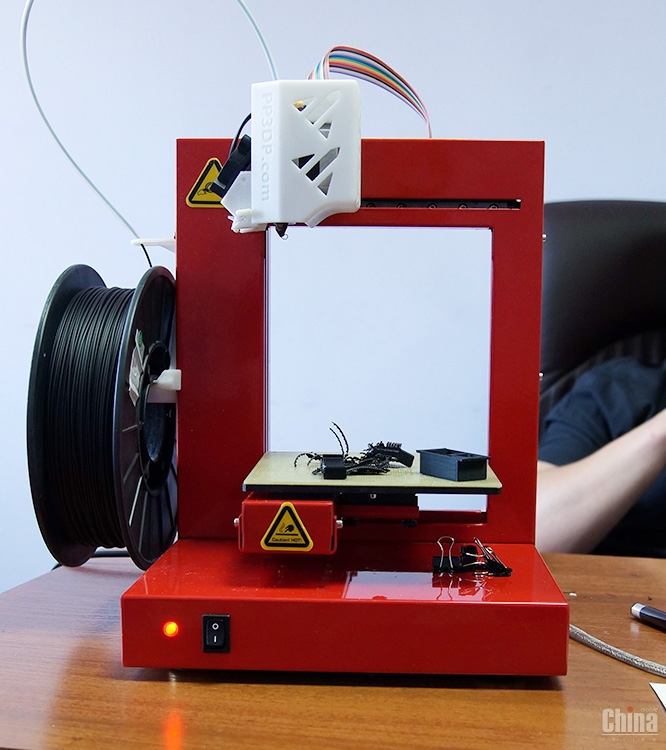

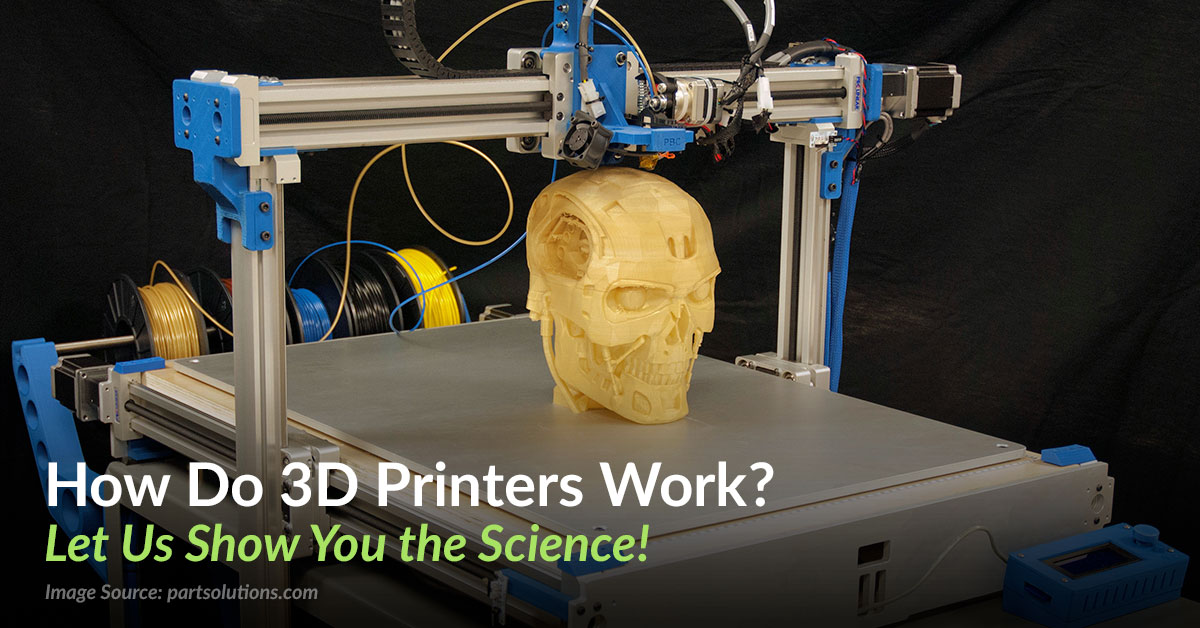

Bed-Slingers Don’t Like Moving Fast

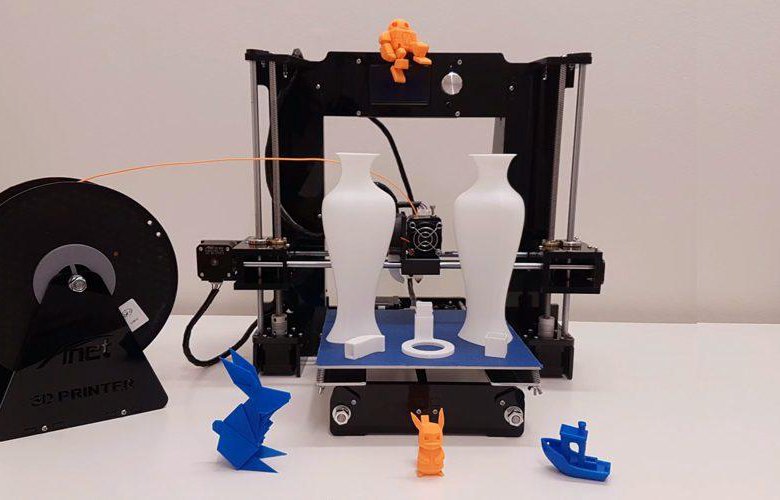

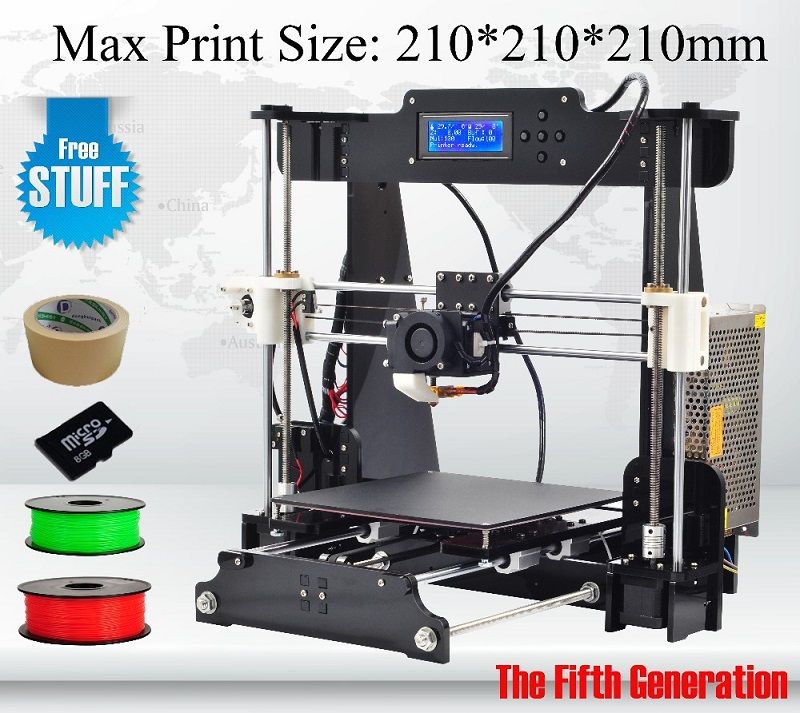

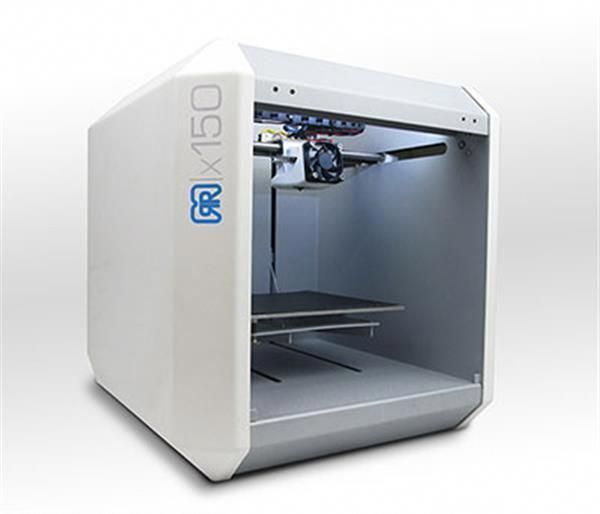

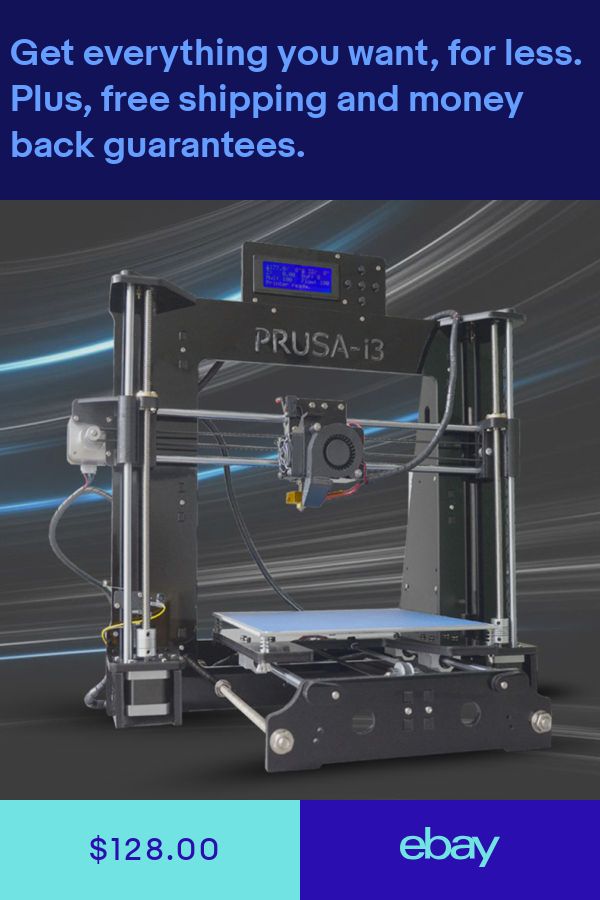

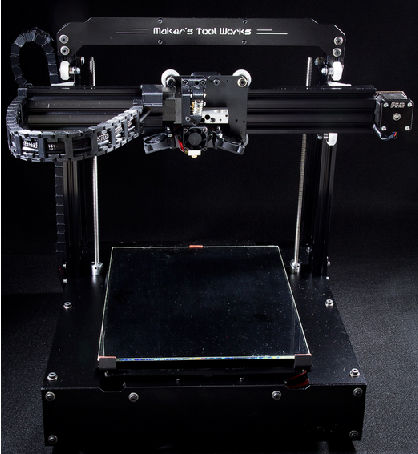

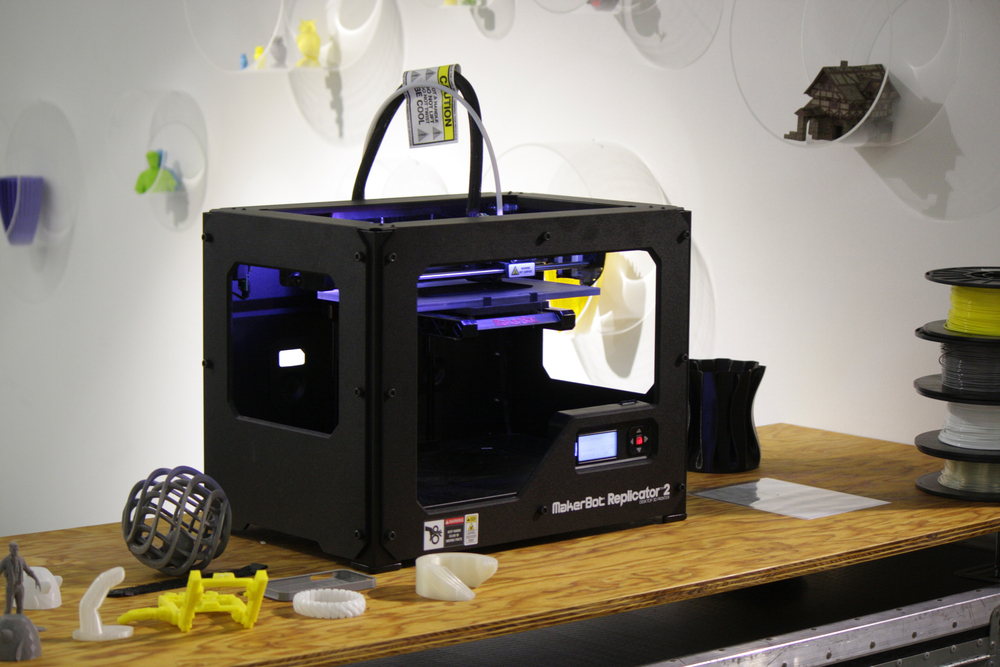

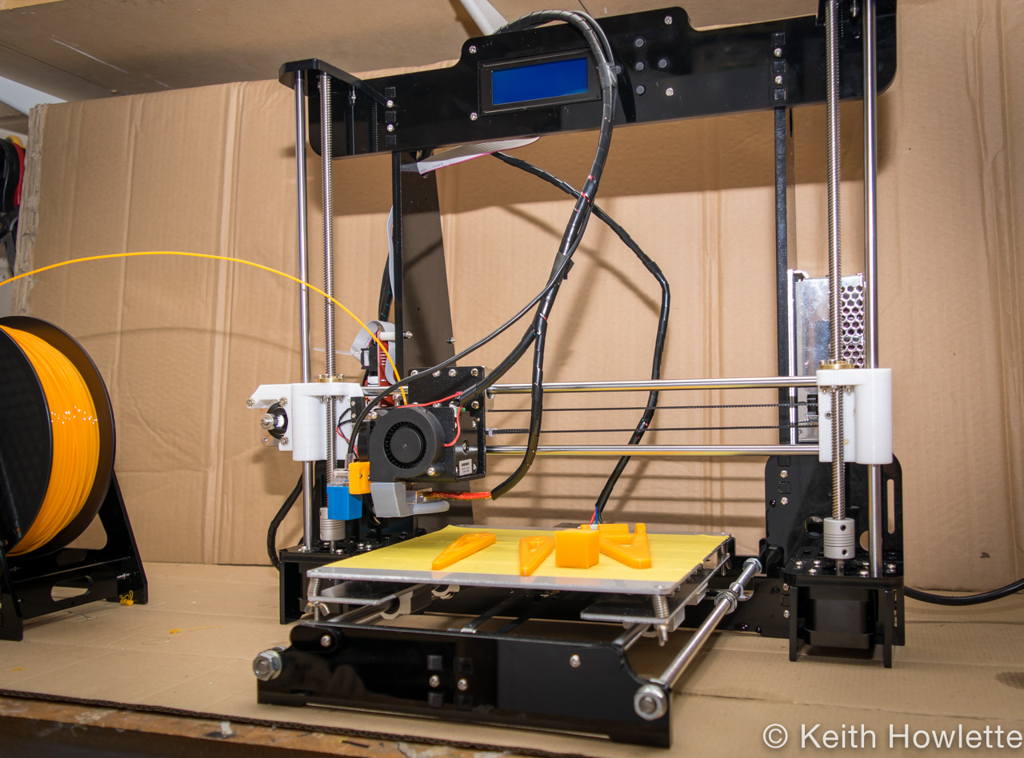

The first clue lies in a typical consumer 3D printer’s appearance itself. Searching Amazon for 3D printers yields results that look virtually indistinguishable from one another. That’s an unfortunate by-product of consumer 3D printers being based on the Prusa i3 design. There’s apparently no better approach to mass manufacturing cheap printers. Unfortunately, this pursuit of cost-efficiency comes at the cost of speed.

Let’s take a quick look at the Prusa i3 motion system to understand why that’s the case.

Your average consumer-grade 3D is cheap primarily because it is uncomplicated. This simplicity extends to their motion system as well. The X-axis, for example, comprises the print head moving along a length of V-slot aluminum extrusion. The Z-axis, in turn, moves the entire X-axis assembly up and down. That might seem like a lot of weight, but it isn’t a major concern because 3D printers move along the Z-axis infrequently and only a fraction of a millimeter at a time.

That might seem like a lot of weight, but it isn’t a major concern because 3D printers move along the Z-axis infrequently and only a fraction of a millimeter at a time.

However, the Y-axis setup of such printers is definitely suboptimal. This poor axis is tasked with the Herculean task of moving the entire bed, which also happens to be the heaviest component in a 3D printer. To print fast, you ideally want the moving components to be as light as possible. It is already tricky to quickly move a print head weighing 150 grams, while maintaining micrometer precision.

Now, imagine doing the same with a 1.5kg bed instead. Not surprisingly, 3D printers employing the Prusa i3 design are colloquially named bed-slingers for this reason.

What Happens When You Print Fast Anyway?

We have figured out why your average 3D printer is slow. But what if we were to disable firmware limits on print speed and acceleration to print fast anyway? The cost of moving too fast goes beyond putting tremendous stress on the stepper motors and causing them to overheat. Print quality is the first casualty in the fight between a weak motor and stubborn mass of a heavy bed. This manifests as ringing or ghosting caused by excessive vibration associated with printing fast.

Print quality is the first casualty in the fight between a weak motor and stubborn mass of a heavy bed. This manifests as ringing or ghosting caused by excessive vibration associated with printing fast.

In extreme cases, the 3D printer components can shake themselves loose over time. Although it is easy to re-tighten screws, printing fast on Prusa i3-style often leads to irreversible wear on the motion components. The worst hit are the cheap V-slot rollers used in the motion system of such printers. The plastic wheels running along V-shaped tracks on aluminum extrusions wear out significantly when subjected to fast printing speeds.

The typical 3D printer based on the Prusa i3 design can’t print fast with any degree of quality or long-term reliability. But what about printers based on different designs. There should be some viable alternatives suitable for printing fast, right?

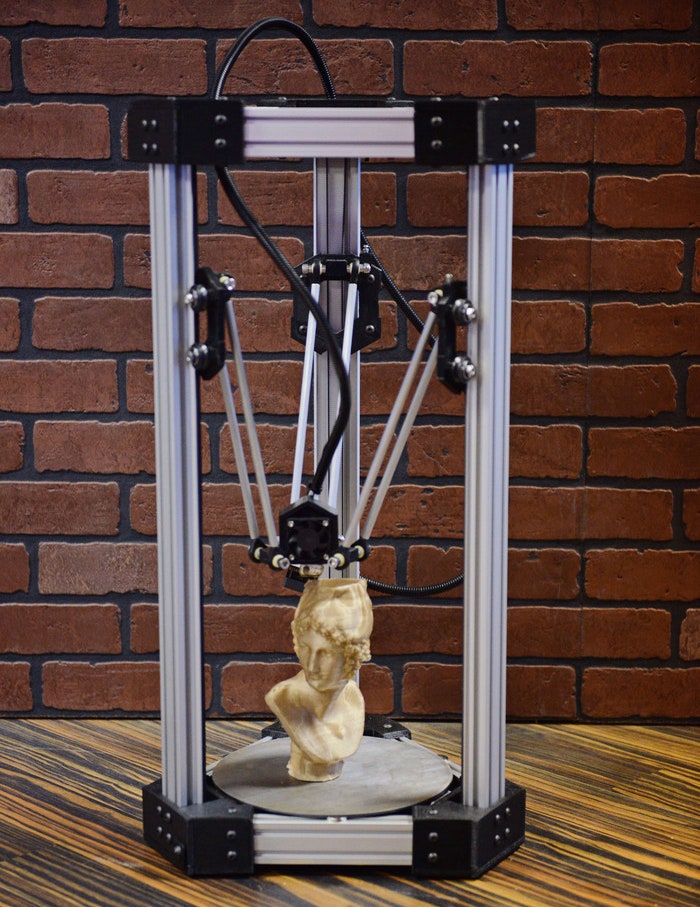

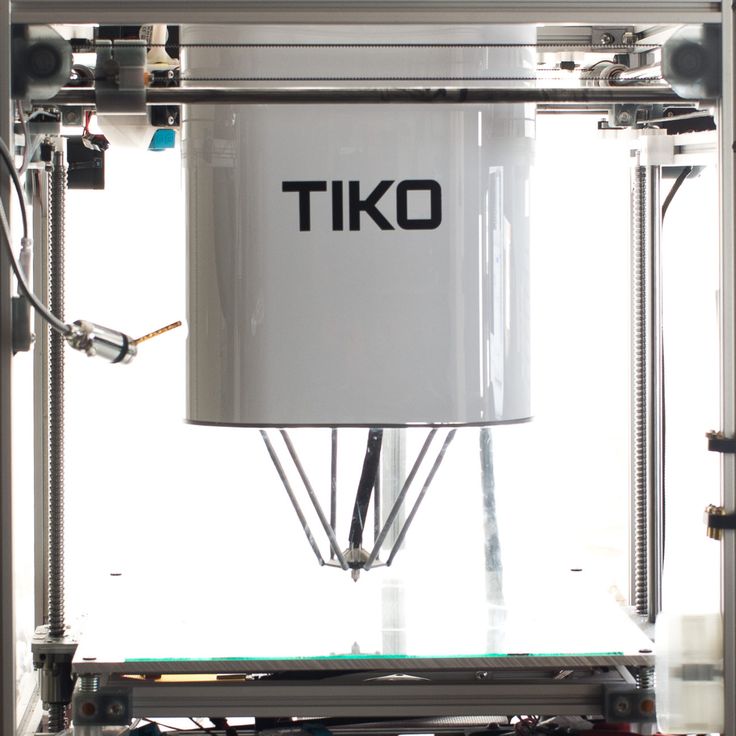

Delta Printers: Cheap and Fast, but Inaccurate

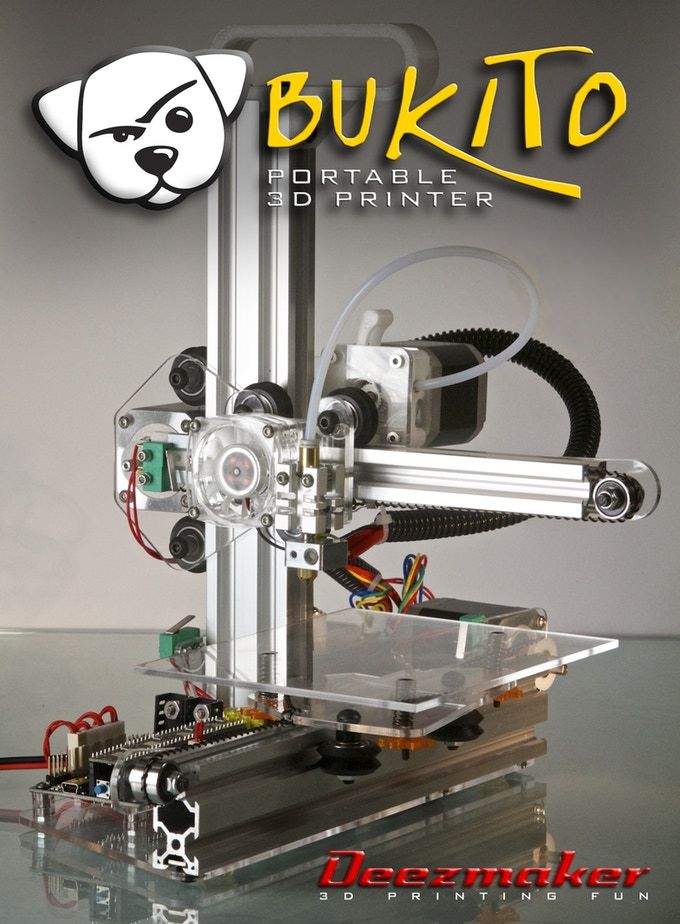

Delta 3D printers are designed from the ground up to be fast. Their light print head is quicker and more controllable due to its inherently lower momentum. Moreover, the Delta design uses fewer components than its bed-slinger counterpart, which makes it even cheaper to manufacture. Printers that are cheap as well as fast sound perfect, but then why don’t we see enough of them?

Their light print head is quicker and more controllable due to its inherently lower momentum. Moreover, the Delta design uses fewer components than its bed-slinger counterpart, which makes it even cheaper to manufacture. Printers that are cheap as well as fast sound perfect, but then why don’t we see enough of them?

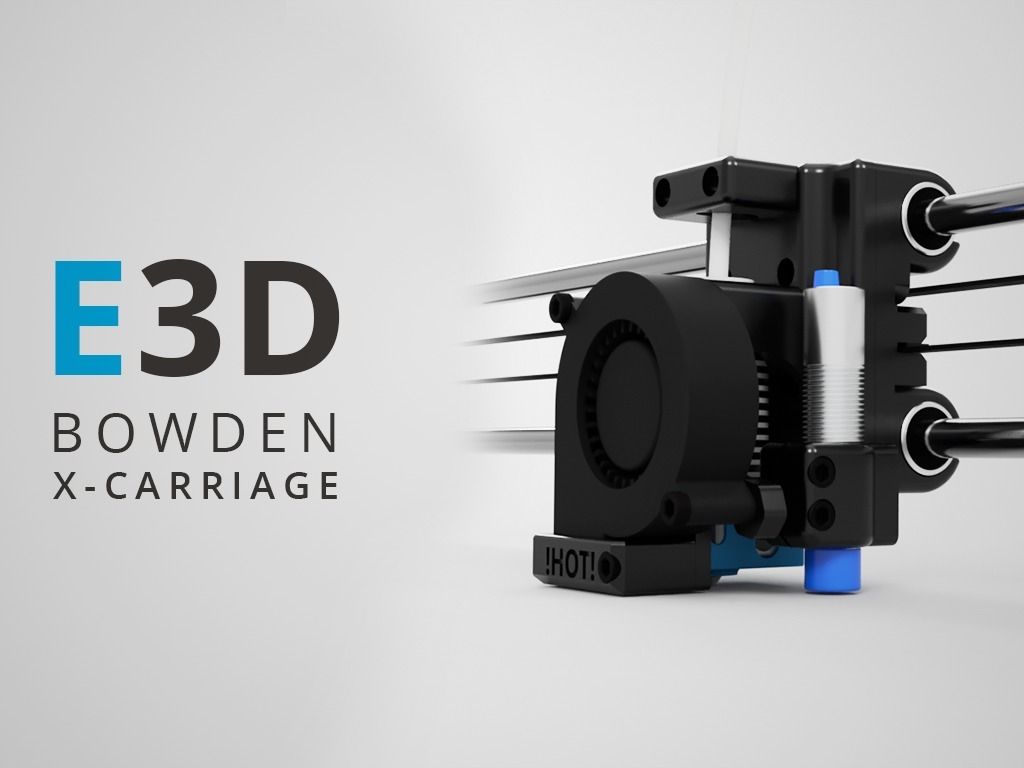

Printers based on the Delta design compromise a lot in their pursuit of speed. Their compact and lightweight print heads make it impossible to implement a direct drive extruder. Learn more about this technology in our direct drive extruder guide. Meanwhile, this Bowden-only extruder restriction makes Delta printers incapable of handling flexible filaments, which hurts their versatility.

However, their biggest compromise comes in the form of reduced print quality, especially while printing large models that are spread out horizontally. Furthermore, the surface print quality achieved by a Delta isn’t comparable to bed-slingers. This is further exacerbated by the circular bed that limits build volume, and their general propensity to excel only at tall prints.

This is further exacerbated by the circular bed that limits build volume, and their general propensity to excel only at tall prints.

These limitations are severe enough for the consumer 3D printing industry to have relegated Delta printers to a niche despite their impressive speed and cost-effectiveness.

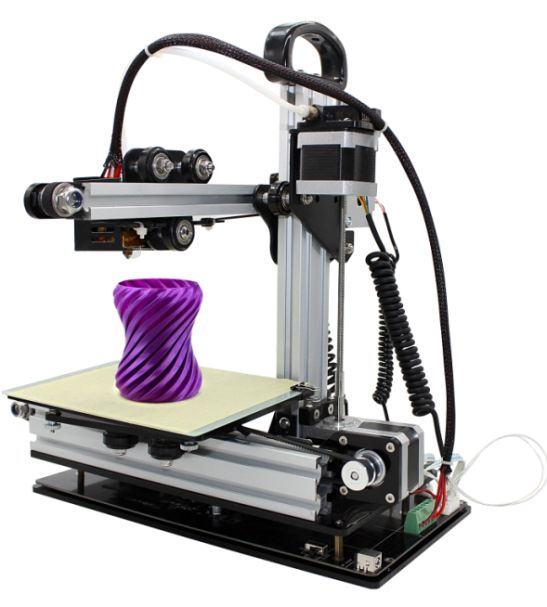

CoreXY Printers: Speed Comes at a Price

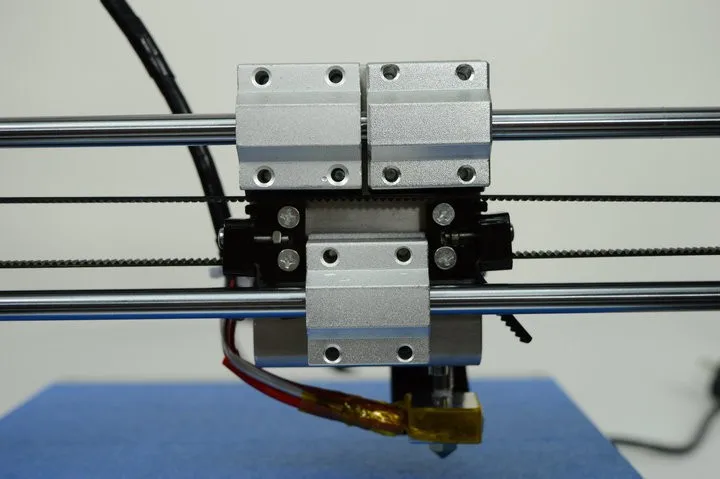

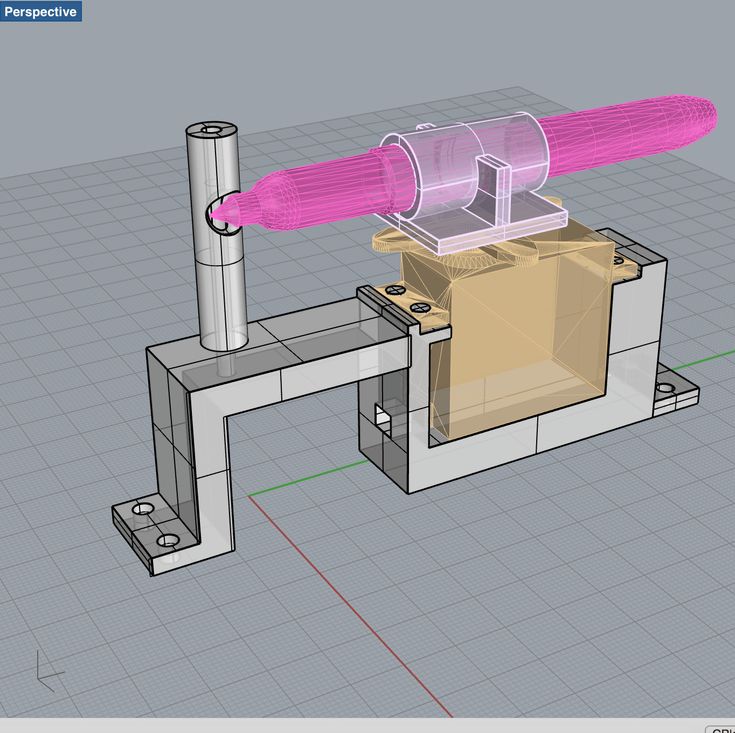

The quickest printers around are based on CoreXY kinematics, as explained in our beginner’s guide to Voron 3D printers. This is a sophisticated motion system where the bed is largely stationary, but the significantly lighter print head is moved at lightning quick speeds. Unlike Delta printers, the CoreXY design maintains quality while allowing the use of direct drive extruders.

Image Credit: Paul Nokel/Voron Design The only problem is that the extreme complexity and high costs involved make these printers unviable for consumer 3D printing. As such, CoreXY printers remain restricted to niche open-source projects aimed at 3D printing enthusiasts. That isn’t surprising considering how the average CoreXY 3D printer costs anywhere between $1000 and $2000 in parts alone.

That isn’t surprising considering how the average CoreXY 3D printer costs anywhere between $1000 and $2000 in parts alone.

Consumer 3D printer manufacturers still haven’t figured out how to make this technology cheap and approachable enough for mainstream users.

Speed Is a Luxury 3D Printers Can’t Afford

To sum this up, fast 3D printing is an expensive affair. You can either have a cheap Delta printer that goes quick at the cost of quality and build volume, or you can spend a fortune on a CoreXY machine. Neither of these extremes sit well with consumers.

And that’s why virtually every consumer 3D printer is based on the Prusa i3 design. These printers might be slow, but they nevertheless strike a good balance between price, features, and performance. Speed is an unfortunate casualty of manufacturing 3D printers with mass market appeal.

Why mass 3D printing is still not a trend

Photo: asharkyu / Shutterstock, Chris McGrath / Getty Images

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When the problem of shortage of personal protective equipment (PPE) for doctors became acute, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization Challenges

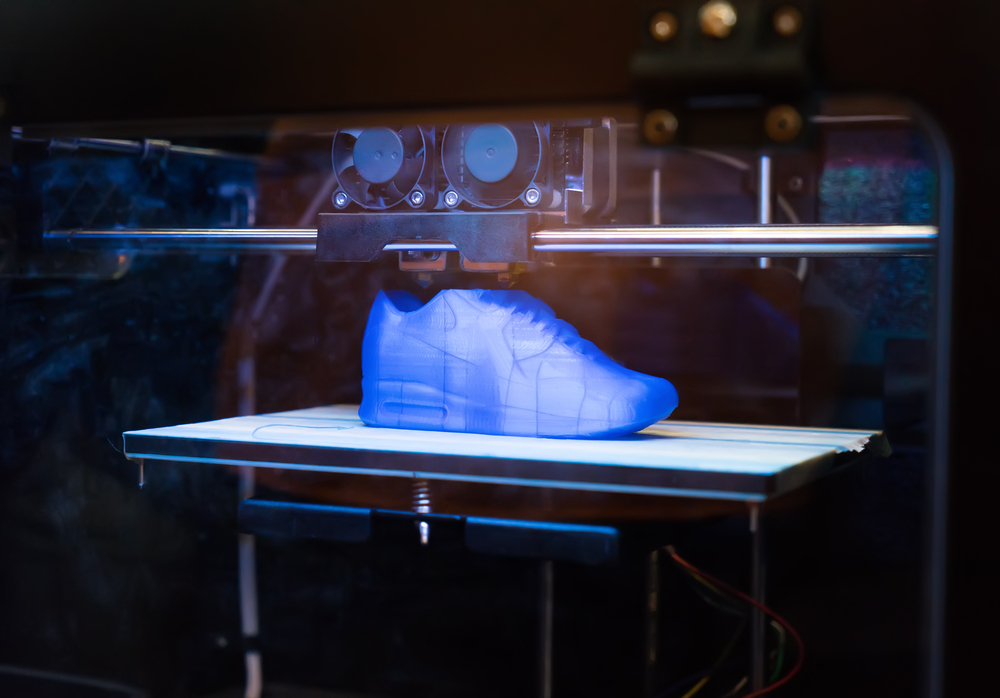

Nike and Adidas have been experimenting with 3D printing for sneakers since 2012. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020 these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay for customized sneakers many times more expensive when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production.”

Denis Alekseev, Head of R&D and Production at JSC ROBBO (educational robotics, Skolkovo resident), is confident that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

-

low production speed;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

The main question is: who will buy it?

Entrepreneurs will be able to develop the production of personalized goods if they find the answer to the question: who will buy them? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand. It is almost impossible to guess - you need to be sure of the demand.

Artur Gerasimov notes that small-scale production is promising for business development using additive technologies. One of the areas of work of his company Innovax is the production of parts and mechanisms by order of industrial enterprises from the automotive industry, instrument making, and the aerospace industry.

A customization boom will occur when a customer can get a personalized product at the same price and as quickly as a mass product. Therefore, it is up to the development of technologies and services.

Therefore, it is up to the development of technologies and services.

Subscribe to the RBC Trends Telegram channel and stay up to date with current trends and forecasts about the future of technology, economics, education and innovation.

Fixing the 20 Most Common 3D Printing Problems

3DPrintStory 3D printing process Fixing the 20 Most Common 3D Printing Problems

3D printing allows you to create amazing models. But everyone faces unpleasant moments when even a simple model does not print well.

You've checked the model, making sure that many have already printed it and had no problems. What are you doing wrong?

This article has collected 20 of the most common 3D printing problems. We hope that the article will help you quickly identify the problem and find a solution for it. In addition, the article details the causes of problems during 3D printing, which will help you avoid them in the future.

We hope that the article will help you quickly identify the problem and find a solution for it. In addition, the article details the causes of problems during 3D printing, which will help you avoid them in the future.

Model tearing off

Problem description

At the base, the model rises up relative to the table (English - warping). In addition to the quality of the manufactured part, this problem can prevent the printing of tall parts that can finally fall off the table.

What causes this problem during 3D printing?

Part breakage is a very common problem due to the nature of the printable plastic. As the ABS or PLA plastic cools, it begins to make poor contact with the surface, so the "warping" effect occurs when the plastic cools too quickly.

Solving the problem: part tearing off

- Use a heated table. The simplest solution is to use a heated table slightly below the melting point of the plastic.

If the temperature is set correctly, the first layer will be in firm contact with the table. Most often, the platform temperature is set in the program to generate the g code for the model. The recommended temperature is often indicated on plastic packaging.

If the temperature is set correctly, the first layer will be in firm contact with the table. Most often, the platform temperature is set in the program to generate the g code for the model. The recommended temperature is often indicated on plastic packaging. - Use glue. If your model still wraps in the corners, apply some glue to the print bed.

- Try another table. Replace your print bed with a model that offers better adhesion. Manufacturers such as Lulzbot use PEI (Polyetherimide) surfaces. XYZPrinting add special tape to the printer box and that works great too (but they don't have heated tables). Zortrax 3D 3D printers solve the problem differently - with the help of small holes in the table.

- Level the print table. The print bed may need to be calibrated. During calibration, make sure that the tip of the extruder is at a suitable, uniform height from the stage along its entire plane.

- Reinforce contact.

Increasing the contact between the model and the print bed is another easy way. Most 3D printing software has the ability to add additional layers to the base.

Increasing the contact between the model and the print bed is another easy way. Most 3D printing software has the ability to add additional layers to the base. - Play around with the temperature. If none of the above work, try increasing the print bed temperature in 5-degree increments. Also pay attention to the operating modes of the coolers. Usually coolers start to work at full capacity when the model height is about 0.5 mm. Try increasing this height to 0.75mm so that the base layers have more time to cool naturally.

And finally - even if you have a heated table, applying a little glue is unlikely to hurt.

3D Printing Problem Checklist: Part 9 Tear Off0104

- Use a heated bed

- Add glue to the print bed

- Use a high-adhesion bed from quality manufacturers

- Calibrate the bed

- Add extra layers to the model base in your 3D printing software

- Play around with temperature and settings cooler

Elephant leg

Description of the problem

The base of the model is printed with a distinct indentation to the outside. It is called - “elephant's foot”

It is called - “elephant's foot”

What causes this problem during 3D printing?

This undesirable effect is caused by the mass of the model itself, which presses on the first, insufficiently cooled layers. In particular, this problem occurs if you have a heated table.

Solve the problem: "Elephant's foot"

- Correct balance. In order to avoid this problem, it is necessary to properly cool the layers at the base of the model. The base layers must be able to support the mass of the part, but not overcool, so that the part does not start to come off the table. Finding the right balance can be tricky. Start by lowering the table temperature in 5 degree increments (within +/- 20 degrees from the recommended temperature). If your bottom and top layers are set to 0.6mm, start cooling earlier.

- Level the table. Most 3D printing problems are caused by improper table alignment. Start with calibration recommendations from your printer manufacturer.

After that, print a square for calibration and evaluate how the plastic lays down. After printing, you will be able to see how evenly the plastic lays down depending on the height of the extruder relative to the table.

After that, print a square for calibration and evaluate how the plastic lays down. After printing, you will be able to see how evenly the plastic lays down depending on the height of the extruder relative to the table. - Raise the extruder. A simple increase in the distance between the extruder and the table can help. But if the distance is too large, the plastic will not stick to the table.

- Chamfer the base of the model. If none of the above work, you can chamfer the base of your model. Of course, this is only possible if you developed the print model yourself or have access to the original file. Start with a 5mm 45º bevel and experiment for the best result.

3D Printing Problem Checklist: Elephant Leg

- Adjust Table Temperature and Cooler Speed

- Calibrate Table

- Check the distance between the extruder and the table

- Chamfer the base of the model

If you are interested in more detailed information on this problem, we recommend that you read our detailed material on eliminating the "elephant leg" problem.

Other first layer problems

Description of the problem

The first layer does not adhere well to the table and some parts come off. Unwanted lines appear at the base of the model.

What causes this problem during 3D printing?

Such problems are a sign that the table has not been correctly calibrated (table calibration on the example of the Anet A8 3D printer). If the extruder is too far from the table, unwanted lines appear on the base and/or the first layer does not stick. If the extruder is too close, voids may appear.

Important: The print bed should be as clean as possible. Even fingerprints can cause the model to come off.

Solve the problem: The remaining problems of the first layer

- Calibrate the table. Each printer has its own table calibration features. For example, the latest Lulzbot models have an automatic calibration system. Ultimaker 3D printers are configured manually according to the corresponding guide.

With Prusa i3 printers, you have to tinker a little longer and think for yourself.

With Prusa i3 printers, you have to tinker a little longer and think for yourself. - Adjust the distance between the extruder and the table. If the extruder is too high, the plastic will not grip the platform. If too low, you may damage the table.

- Clean the print table. It is advisable to clean the table before each new print. Especially if you are using glue. Fingerprints and adhesive residue may cause the model to come off.

- Add glue. A small layer of adhesive can greatly improve adhesion. But do not forget that if you do not clean the table, then the use of glue can lead to the opposite effect.

- Special tape for non-heated table. If you are using an unheated platform, try applying tape to improve the contact between the base of the model and the table.

Solving the problem: Layer mismatch

- Check the belts. Start by checking belt tension.

You should feel resistance as you bring them together with your fingers. If the top of the belt is stiffer than the bottom, this is a clear sign that they need to be tightened.

You should feel resistance as you bring them together with your fingers. If the top of the belt is stiffer than the bottom, this is a clear sign that they need to be tightened. - Check table top plate. Check the top plate and screw sets in the printer. Make sure everything is taut and aligned where needed.

- Check the Z-axis screws. Most 3D printers use a screw-nut pair instead of a ball screw. In general, this does not particularly affect the print quality, but over time, the screw may deform. Do not disassemble the printer to check the screws. It is enough to use a program like ‘Printrun’ and move the extruder up and down. If one of the screws is deformed, you will notice it. Unfortunately, it's almost impossible to fix this. But, on the other hand, this is a great chance to modify your 3D printer and replace the screws with screw-nut pairs.

Checount of 3D Problems: mismatch of layers

- Check belt tension

- Check the reliability of the top of the top of the printing table

- Clear that the zans of the Z axis are not deformed

0 9000 903

the model has voids because some layers were simply skipped (partially or completely).

What causes this problem during 3D printing?

The printer did not feed the required amount of plastic. This may be due to problems with the plastic (for example, it has a different diameter), the extruder, or the plastic feed mechanism.

Friction has caused the table to stop temporarily. The reason may be that the vertical screws are not calibrated.

There is a problem with one of the screws or the Z-axis nut. For example, the screw is damaged, dirty, or not well lubricated.

Troubleshooting: Missing layers

- Mechanics check. A 3D printer, like any other piece of equipment, needs maintenance. If you have this problem, this is a clear sign that you should pay attention to its service. Start by checking the screws. Make sure they are well seated in the bearings/holes, with no undue misalignment.

- Screw alignment check. Check that all screws are aligned and not bent. You can appreciate this by turning off the power and carefully moving the extruder along the coordinate axes (depending on the layout of your 3D printer).

If you feel resistance, then something is wrong.

If you feel resistance, then something is wrong. - Damaged bearings. Damage to the bearings is manifested in the characteristic vibration during the operation of the 3D printer. If you notice vibrations, turn off the power and manually move the carriage with the extruder to find exactly where the bearing failed.

- Check lubrication. Many people forget about the lubrication of joints. But this is a very important point for the correct operation of your 3D printer. Regular machine oil is inexpensive and is great for maintaining printer connections. Before lubricating, check the guides. They must not be dirty. You need to apply a little oil. If you have applied too much lubricant, simply wipe off the excess with a rag. Naturally, after lubrication, check that the carriages run smoothly.

- Plastic feed problem. The last possible problem is insufficient plastic supply. The solution to this problem may not be simple, so it is considered separately below.

3D Printing Issue Checklist: Missing Layers

- Check mechanics and make sure all screws are tight

- Check screw alignment

- Check bearings

- Add lubricant

7

Problem description

Dimples form on the sides of the model, especially on tall models. One of the most unexpected problems, the solution to which is usually not where you are looking for it.

What causes this problem during 3D printing?

In higher layers, the material cools faster because the heating from the table does not reach this height. Because of this, adhesion on higher layers is lower.

Problem Solving: Dimples on tall models

- Extruder temperature. Start by raising the extruder temperature in 10ºC increments. The specifications for your plastic should list operating temperatures. Try to keep the temperature within the specified range.

- Cooler direction and speed.

Check the coolers, make sure they work and point to the model. If so, try reducing their speed.

Check the coolers, make sure they work and point to the model. If so, try reducing their speed.

3D Printing Problem Checklist: Dimples on Tall Models

- Check extruder temperature and raise it in 10 degree increments

- Check the location and speed of the coolers aimed at the 3D model

Dimples, holes on the top of the model

Description of the problem

Dimples or even holes form on the top of the model.

What causes this problem during 3D printing?

The two most common causes are improper cooling of the top layer or insufficient thickness of the top layer.

Solving the problem:

hollows, holes on the top of model- Printable plastic diameter. Most common when printing with 1.75 plastic. Similar problems can appear in any 3D printer, but most often they appear when using plastic with a diameter of 1.75 mm, not 2.85.

- Check cooler location.

Any cooling problems are naturally related to coolers. At the start of printing, the coolers run slowly or turn off altogether, but after the first coat they should work much harder. Be sure to rate the performance of the coolers at the end of the print. If everything works, just in case, check the direction of their rotation. Cold air should flow to the model, and not vice versa.

Any cooling problems are naturally related to coolers. At the start of printing, the coolers run slowly or turn off altogether, but after the first coat they should work much harder. Be sure to rate the performance of the coolers at the end of the print. If everything works, just in case, check the direction of their rotation. Cold air should flow to the model, and not vice versa. - Set the fan speed in G-code. As the last layers of the model are formed, the cooling must be very intense so that the plastic does not fall into the holes of your mesh in the model. Cooler speed can be configured in G-code. The standard code for an on cooler is M106 and M107 for off. That is, adjust the maximum speed for the upper layers. An example would be a 1 cm by 1 cm cube with a layer thickness of 0.1 mm. In this case, the G-code obtained from CURA for the Prusa i3 3D printer will be 97 layers. Knowing that we have the 'Bottom / Top Thickness' settings set to 0.6mm, we can look at ;LAYER:91 and add M106 S255 at the end of the line.

The M106 kicks off the cooler, while the S255 makes it run at full capacity.

The M106 kicks off the cooler, while the S255 makes it run at full capacity. - Increase the thickness of the top layer. The simplest solution is to increase the thickness of the top layer. In most applications, this can be done in the advanced settings under ‘Bottom / Top Thickness’. It is desirable to form a minimum of 6 layers and 8 for extruders with a smaller nozzle diameter and, accordingly, a smaller plastic diameter. So if the layer height is 0.1mm, set ‘Bottom / Top Thickness’ to 0.6mm. If this does not help, increase the thickness to 0.8 mm.

3D printing problem checklist:

hollows, holes on the top of the model- Increase the diameter of the printing plastic

- Check that the coolers are correctly installed and working

- Specify the speed of the cooler in manual mode - in G-code Increase top layer thickness

Plastic residue

Problem description

Unwanted plastic residue forms between model parts.

What causes this problem during 3D printing?

When the extruder is moving and not printing (in idle mode), plastic residue is still coming in.

Solving the problem:

plastic residue (more detailed article on troubleshooting plastic residue between parts of the 3D model)- Activate the Retraction option. Retraction is a very useful option, especially when it comes to finishing. It works very simply - before the print head begins to move, the plastic flows back into the extruder, and is not fed. Thus, the problem can be nipped in the bud.

- One-click backfeed activation. Most apps like Cura offer a one-click option to activate this option. The default settings are used, which is sufficient for most cases. However, if you want more flexibility, there should be other options. For example, you can set the minimum printhead path before activating plastic backfeed.

- Minimum travel (mm).

Reducing the minimum path is usually the quickest fix if the standard retraction settings didn't help. Decrease this value by 0.5 mm until the problem goes away. By the way, activating reverse feed will increase the speed of 3D printing.

Reducing the minimum path is usually the quickest fix if the standard retraction settings didn't help. Decrease this value by 0.5 mm until the problem goes away. By the way, activating reverse feed will increase the speed of 3D printing. - Just cut off the rest of the plastic. This is not the most elegant solution, but by far the easiest and fastest.

Cheklist of 3D Problem:

Residues of plastic- Turn on the return supply of plastic (RETRACTION option)

- Set up the minimum path before the feedback

- describing the 1st with a knife

The 3D printer cannot feed the required amount of plastic (or at the required speed). As a result, thin layers are formed, layers with unwanted depressions or layers are completely absent.

What causes this problem during 3D printing?

There may be several reasons. The first is that the diameter of the plastic for printing does not match the diameter specified in the software for forming layers.

The second - the amount of plastic supplied is insufficient, due to incorrect settings in the software. Well, perhaps your extruder is very dirty.

The second - the amount of plastic supplied is insufficient, due to incorrect settings in the software. Well, perhaps your extruder is very dirty. Solving the problem: Insufficient supply of plastic

- Check the diameter of the plastic. Start with the simplest case - check the plastic diameter settings in your software. If you are not sure about the correct diameter, it and the temperature are usually indicated on the packaging of the plastic.

- Measure the plastic diameter. If the problem still persists, measure the plastic diameter manually and enter more precise settings in your G-code generation software.

- Check print head. In most printers, the print head is retracted from the print table. Check extruder. There should be no obvious contamination on it.

- Set the extrusion ratio. If there is no difference between the actual plastic diameter and the settings in the software, check the extrusion coefficient (extrusion multiplier or flow rate or flow compensation).

Perhaps these settings are too small. Each program handles these settings differently, but the principle is the same - increase the value in the settings by 5% and restart 3D printing.

Perhaps these settings are too small. Each program handles these settings differently, but the principle is the same - increase the value in the settings by 5% and restart 3D printing.

In Simplify3D open Edit Process Settings and go to Extruder tab - extrusion ratio set to 1.0 corresponds to 100%; If you are using Cura, open the Material tab and increase the Flow setting (you may need to activate the Flow settings in the Preferences panel).

3D Printing Problem Checklist: Plastic Underfeed

- Check Print Plastic Diameter

- Manually Check Plastic Diameter

- Check Extruder Cleanliness

- Increase the extrusion ratio by 5%

Too much plastic feeding

Problem description

Your 3D printer is feeding too much plastic. Because of this, the material peels off at the edges of the model.

What causes this problem during 3D printing?

This is usually caused by the Extrusion multiplier or Flow in your G-code generation software being set too high (see section above).

Solve the problem: Too much plastic feed

- Extrusion ratio. Open your model layering software and make sure the correct extrusion factor is set.

- Delivery settings. If the previous point did not help, reduce the flow value (Flow).

3D printing problem checklist: too much plastic feed

- Check extrusion ratio settings

- Decrease plastic feed value

Layer misalignment

Problem description

Bottom and top layers move relative to each other during 3D printing. Usually the offset is not as large as in the figure, but the above case can also occur.

What causes this problem during 3D printing?

Layer misalignment can occur for a variety of reasons, including a blow to the printer during printing! This problem may manifest itself due to incorrect belt tension or misalignment of screws. Or due to the fact that the extruder hooked the model and it shifted a little right during printing.

Solving the problem: Layer misalignment

- Check the stability of the printer. The 3D printer must be placed on a stable surface. Even slight shocks can cause the layers to shift.

- Check table stability. Most 3D printers have removable tables. Although this is convenient in terms of replacing it, over time the mounting screws can loosen. So it's worth checking them periodically.

- Check the under layers. If you print at high quality, the underlying layers may break off due to cooling. If a break occurs, the plastic rises and the extruder can hit it. In most cases, the model will come off the table, but if there is no lift, the powerful motors can push the model and the table. So if you have problems with the first layers, try reducing the rotation speed of the coolers.

- The print speed is too fast. By increasing the temperature and increasing the feed rate, 3D printing can be accelerated.

However, even though the plastic will feed properly, your printer may not be able to handle the selected mode. If you hear clicks while printing, this is a sure sign that the printer is running at too fast speeds. In this case, check if the plastic breaks in the extruder itself, and then go to the settings for the actual speed of the 3D printer. The speed can be adjusted in your software to generate the g-code. If you are using Simply 3D go to ‘Other > Default Printing Speed (mm/min)’, if Cura go to ‘Basic > Print Speed (mm/s)’.

However, even though the plastic will feed properly, your printer may not be able to handle the selected mode. If you hear clicks while printing, this is a sure sign that the printer is running at too fast speeds. In this case, check if the plastic breaks in the extruder itself, and then go to the settings for the actual speed of the 3D printer. The speed can be adjusted in your software to generate the g-code. If you are using Simply 3D go to ‘Other > Default Printing Speed (mm/min)’, if Cura go to ‘Basic > Print Speed (mm/s)’. - Check the belts. If the layers are still shifting, it's time to check the belts. The tension of all belts must be the same. Timing belts tend to stretch over time (this is clearly manifested when the belts begin to slip on the pulleys). If the tension is very weak, you should consider replacing them. Strong belt tension can also be a problem. But usually this is a problem with DIY 3D printers. Some 3D printers (such as the Prusa i3) have special screws to adjust the tension.

- Guide shafts must be clean and lubricated. Over time, the guides become covered with dirt in places with maximum friction. This, in turn, can cause problems when moving and shifting layers. A quick cleaning and lubrication usually solves the problem.

- Curved or misaligned rails. If you notice that the printhead positioning error occurs in a certain place, this may be a sign that one of the guides is deformed. You can check this by turning off the 3D printer and moving the print head along the coordinate axes. Check axle alignment. If everything is in order, remove the guides and lay them on a flat surface. If there is a bend, you will immediately see it.

3D Printing Problem Checklist: Layer Misalignment

- Check the stability of the 3D printer base.

- Check table stability.

- The first layers of the model should not form breaks.

- The print speed is too fast.

- Check belts.

- Guide shafts must be clean and lubricated.

- Curved or misaligned rails.

Blocked plastic feed mechanism

Problem description

You start 3D printing, but no plastic comes out of the extruder. You took the rod out of the extruder, put it back in, but it didn't work.

What causes this problem during 3D printing?

After replacing the plastic, a small piece of bar remained in the feed mechanism. Most often, the break occurs at the very end. When you insert a new rod, the remnants of the old one block the flow of plastic.

The second option - the remnants of the old plastic dried up at the end of the extruder. In this case, the remnants of the frozen plastic must be removed manually.

Solve the problem: blocked plastic feed mechanism

- Unlock with a needle. If you're lucky, unlocking the feed mechanism is quick and easy. Start by removing the plastic. After that, on the control panel, select the option “heat up nozzle” (heat up the extruder) and increase the temperature to the level of plastic melting.

If you have an Ultimaker 2 3D printer, go to Maintenance > Heat Up nozzle. For PLA plastic, set the temperature to 220 C. When the extruder is hot, use a needle or something with a small diameter and clean the hole (be careful not to burn your hands!). By the way, it is useful to clean the outside of the extruder.

If you have an Ultimaker 2 3D printer, go to Maintenance > Heat Up nozzle. For PLA plastic, set the temperature to 220 C. When the extruder is hot, use a needle or something with a small diameter and clean the hole (be careful not to burn your hands!). By the way, it is useful to clean the outside of the extruder. - Push the old plastic through. If the extruder is still blocked, you may be able to push the stuck plastic through with a new rod. Remove the plastic supply tube from the print head. Preheat the extruder to 220 C for PLA plastic and then, using a new rod, try to push the stuck plastic through the extruder. It may take some effort, but be careful not to bend the printer's horizontal guides. After that, you can clean the nozzle with a needle in accordance with the instructions from point 1.

- Remove and reassemble the extruder. In extreme cases, you will have to disassemble and reassemble the plastic feed mechanism. If you've never done this before, consider taking photos or recording your every step as you take apart the feed mechanism, as you'll need to put it back together afterwards.

First remove the plastic bar. After that, read the instructions for dismantling the print head in the instructions for your 3D printer. Wear gloves while doing this, as the nozzle will be hot. Let's take a closer look at the Ultimaker 2 3D printer as an example. Move the print head to the center of the printer. Loosen the four screws on the print head. Preheat the nozzle to 220 C (for PLA). When the extruder reaches the desired temperature, turn off the power. Holding the cooler's plastic case, remove the rest of the interfering plastic. Clean the nozzle with a needle. You can also clean its outer surface. When the nozzle is cool, assemble the extruder, turn on the 3D printer and load the new plastic.

First remove the plastic bar. After that, read the instructions for dismantling the print head in the instructions for your 3D printer. Wear gloves while doing this, as the nozzle will be hot. Let's take a closer look at the Ultimaker 2 3D printer as an example. Move the print head to the center of the printer. Loosen the four screws on the print head. Preheat the nozzle to 220 C (for PLA). When the extruder reaches the desired temperature, turn off the power. Holding the cooler's plastic case, remove the rest of the interfering plastic. Clean the nozzle with a needle. You can also clean its outer surface. When the nozzle is cool, assemble the extruder, turn on the 3D printer and load the new plastic.

3D printing problem checklist: blocked plastic feed mechanism

- Warm up the nozzle and clean it inside and out with a needle.

- Remove the plastic feed tube and try pushing through the remaining plastic with a new rod.

- Disassemble the feed mechanism and try to remove any remaining plastic.

Faulty plastic

Problem description

The plastic looks normal, is properly seated in the feed mechanism, and exits the nozzle when printing. This happens most often in Bowden-feed 3D printers rather than straight-feed 3D printers, as the plastic isn't visible or noticeable when it's broken.

What causes this problem during 3D printing?

Printing plastic breakage can occur for a variety of reasons, but mostly because the plastic is old or cheap. Most plastics like PLA and ABS last a long time, but if stored in poor conditions (such as direct sunlight), they can become brittle. If you use such plastic, no settings will help.

The second possible reason is the bar diameter, which may vary slightly depending on the manufacturer. And if the pressure in the feed mechanism is too high, it can break.

Solving the problem: broken plastic

- Remove the plastic. The first thing to do is to remove the plastic from the 3D printer.

If you are using Ultimaker, you can use the Maintenance and Change Material option. Heat up the extruder and remove the plastic.

If you are using Ultimaker, you can use the Maintenance and Change Material option. Heat up the extruder and remove the plastic. - Try another plastic. If the problem persists after reinstalling the plastic, try a different one to make sure the media quality is not the problem.

- Reduce feeder pressure. If the new plastic also breaks, loosen the pressure on the feed mechanism. Start 3D printing and increase the pressure until the slip is complete.

- Check nozzle. Check nozzle for cleanliness.

- Check flow and temperature. If problem persists, check nozzle heating. Also make sure the pitch is 100% and no more.

3D Printing Problem Checklist: Plastic Breakage

- Check the shelf life of plastic

- check the diameter of plastic

- Set up the pressure in the supply mechanism

- Check the cleanliness of the nozzle and its temperature

- set the supply to 100%

PROTOSKED PACK 3D printing stage.

And it does not depend on the type of plastic. As a result, no plastic is fed.

And it does not depend on the type of plastic. As a result, no plastic is fed. What causes this problem during 3D printing?

Clogged nozzle, insufficient feed force, incorrect nozzle temperature. As the motor rotor rotates, the small wheel that normally grips and feeds the plastic will pinch the bar and prevent it from being printed.

Solve the problem: bar slippage

- Help the feed system. If the plastic has just begun to slip, this will show up as a characteristic noise. Try applying some pressure to the bar to get this section through. This often helps and the 3D printer continues to print well.

- Adjust the feed force. Start by depressurizing. After that, start increasing the force until the bar stops slipping. Heads vary in diameter, so some require fine tuning.

- Remove the plastic. More one solution is to remove and reload the plastic into the feed mechanism.

After removing the bar, cut off the plastic over the place where the slip marks are visible and reload it into the feeder. If slippage remains, try this operation again. If that doesn't help, replace the plastic as this one is most likely no longer printable.

After removing the bar, cut off the plastic over the place where the slip marks are visible and reload it into the feeder. If slippage remains, try this operation again. If that doesn't help, replace the plastic as this one is most likely no longer printable. - Check nozzle temperature. If you have installed new plastic and the problem persists, or vice versa, check the temperature of the nozzle.

Checount of 3D Problems: slippage of the rod

- Help the supply mechanism with an additional effort

- Set up the force in the mechanism of the supply

- Moving the plastic and load the surge

Description of the problem

The printed product is missing an internal grid or it is obviously incorrect

What causes this problem during 3D printing?

There can be several reasons why the internal structure of the 3D model does not print well.

The most common is incorrect settings in your software for generating a G-code. It may turn out that the problem is a clogged nozzle.

The most common is incorrect settings in your software for generating a G-code. It may turn out that the problem is a clogged nozzle. Solving the problem: Poor 3D printing of the inner mesh

- Check the fill factor. This is checked in your software. A value of about 20% is quite acceptable. If less, problems may arise. This parameter should be increased for large models.

- Speed for printing inner layers. The speed at which printing takes place can have a direct effect on the quality of the inner mesh. If you see problems, try reducing the print speed of the inner mesh.

- Change the mesh configuration. Most programs allow you to change the grid configuration. Squares, triangles, hexagons, etc. Experiment with these settings.

- Check nozzle. It may be that the cause is a clogged nozzle. At the same time, the outer parts of the model will be printed well, since plastic is fed more intensively on them.

3D printing problem checklist: Poor 3D printing of inner mesh

- Check and adjust fill ratio of model

- Reduce print speed of inner mesh

- Change mesh configuration

- Check for clogged nozzle 89 Inner mesh showing through

Description of the problem

The printed model generally looks normal, but the inner mesh is showing through the outer walls of the model.

What causes this problem during 3D printing?

See-through problem occurs when your model has thin walls and the internal structure intersects with the outer wall line.

Normally the outer wall thickness should be proportional to the nozzle diameter. That is, if your nozzle diameter is 0.4 mm, the wall thickness of the model should be 0.5, 0.8, 0.12 mm, etc. If the proportion is not maintained, the effects of the clearance of the internal structure may occur.

Solving the problem: the inner mesh is showing through

- Check the thickness of the outer wall of your 3D model.

Check that the wall thickness value is proportional to the nozzle diameter.

Check that the wall thickness value is proportional to the nozzle diameter. - Thicken the outer wall. The simplest solution is to increase the wall thickness. Doubling the thickness will most likely help solve the clearance problem.

- Use the filling option after the walls have been formed. Most g-code programs have the ability to generate the internal structure after printing the outer walls.

- In Cura open 'Expert Settings' and in the Infill section activate the option 'Infill prints after perimeters'

- In Simply3D click on 'Edit Process Settings', then select 'Layer' and in 'Layer Settings' select 'Outside-in' next to 'Outline Direction'.

- Check the print table. Examine the printed model. If the effect is more on one of the sides, the cause may be in the calibration. If so, calibrate.

- Use this effect to your advantage. Depending on the task, you can use the print sequence to your advantage.

If you need a model of high quality, with a good outer surface and at the same time the rigidity of the model is not critical, choose Outside-in printing (first the outer layer, then the inner filling). If the rigidity of the model is important, print inside-out, doubling the wall thickness.

If you need a model of high quality, with a good outer surface and at the same time the rigidity of the model is not critical, choose Outside-in printing (first the outer layer, then the inner filling). If the rigidity of the model is important, print inside-out, doubling the wall thickness.

3D printing problem checklist: inner mesh shows through

- Check the outer wall thickness of the model.

- Thicken the outer wall.

- Use the filling option after wall formation.

- Check print bed and calibrate if necessary.

- Use this effect to your advantage.

Gaps between inner mesh and outer walls

Problem Description

If you look at the bottom or top surfaces of the model, you will see gaps between the inner mesh and outer walls.

What causes this problem during 3D printing?

Gaps between the outer wall and the inner mesh used to be a common problem, but with the increasing accuracy of 3D printers, this is now a rare bug.

However, there are new materials for 3D printing that can cause this problem again.

However, there are new materials for 3D printing that can cause this problem again. The most common cause of these gaps is that your software does not have an overlap of the mesh and outer walls set, or this value is set to "0". Your 3D printer considers this so that the wall and mesh should not intersect, and gaps may occur.

Another possible reason is the sequence in which you set the printing of the inner mesh and the outer wall. If you print the outer wall first, there may be no or minimal overlap. Accordingly, there is a chance of occurrence of these gaps.

Solving the problem:

gaps between the inner mesh and the outer walls of the 3D model- Check the parameter of the intersection of the walls and the inner mesh of the model. This is the most common problem and is very easy to fix. Find the "Infill Overlap" option in your gcode generation software and increase this value.

- Cura defaults to 15%.

Increase it to 30%.

Increase it to 30%. - In Simplify3D these settings are in the 'Edit Process Settings > Infill > Outline Overlap' tab. Again, increase this value. This setting is directly related to the thickness of your head. So the % value will be % of the bar thickness to be printed. When tuning, do not set this value above 50%, as you will go beyond the walls.

- Cura defaults to 15%.

- Form the inner mesh before printing the walls. If at the same time the inner mesh starts to show through, increase the thickness of the outer wall of the model as indicated in the section above.

- Increase extruder temperature. Some newer 3D printing materials (eg XT-CF20) may require finer temperature settings. Try increasing the extruder temperature by 5-10º. It might work.

- Reduce speed. You probably want to print your model faster, but faster speeds can cause a lot of problems. Especially if the 3D printer is not perfectly calibrated.

If print speed is still important to you, try lowering it for the top layer only.

If print speed is still important to you, try lowering it for the top layer only.

3D printing problem checklist: gaps between inner mesh and outer walls of the 3D model

- Check the intersection parameter between the walls and the inner mesh of the model.

- Print the inner mesh first and then move on to the outer walls.

- Increase extruder temperature.

- Reduce the print speed.

Object intersection

Problem description

Parts of the model are missing or the final model is not rigid enough. The finished product and the 3D model are different and there are incomprehensible errors in the geometry of the printed product.

What causes this problem during 3D printing?

Virtual walls are one of the most common causes. Vertical walls only exist in 3D space, not in the real world.

For example, if you have two cubes in the real world and you try to match them, it won't work because the outer walls will not allow the two objects to intersect.

In the 3D world you can combine two objects and still exist as two separate objects and your slicing program will also allow them to intersect in the virtual world.

In the 3D world you can combine two objects and still exist as two separate objects and your slicing program will also allow them to intersect in the virtual world. For correct printing, these two objects must be combined into one, so that the inner walls disappear and one object remains.

Another possible problem - for example, you have a cube object and you have deleted one of its surfaces. In fact, you have an object with a hole. It may look like a 3D correct object, but it only exists as such in 3D space. Such an object cannot exist in the real world.

Deleting one of the surfaces leaves only two coordinates. The wall thickness, the third coordinate, has no dimension in the real world. We only see it in 3D modeling software. And when we start to form the layers of the model, the program will try to fix this bug and add the third coordinate. However, in more complex models, this can lead to unpredictable effects.

Solving the problem: object intersection

- Use the latest slicing software.

Most recent versions of slicing programs support automatic correction of intersecting objects, but it's still better to make sure that your 3D model is formed correctly.

Most recent versions of slicing programs support automatic correction of intersecting objects, but it's still better to make sure that your 3D model is formed correctly. - Set the Fix Horrible settings in Cura. In Cura, open the Expert Settings tab and have the Match All (Type-A) option selected in the ‘Fix Horrible’ settings.

- Set Silmplify3D's Non-manifold settings. In the 'Process settings' select the 'Advanced' menu and then 'Heal' next to Non-manifold.

- Use layered representation. Use the layer view in your slicing software to check for problem areas in your model. A superficial view of the layers can help you quickly identify problem areas and fix the problem.

- Use your software to fix object intersections. One of the easiest solutions is to use additional software to solve the problem. Blender and Meshmixer have built-in mechanisms for identifying problems and fixing the 3D model before slicing.

- Merge objects. It's better to fix your 3D model before importing it into the slicing software. When doing this, make sure that if your two objects intersect or overlap, you use the appropriate intersect, merge, or subtract function.

3D Printing Problem Checklist: Object Intersection

- Please use the latest version of the slicing software.

- Use the “Fix Horrible” option (in Cura).

- Use the “Fix Non-manifold” option (in Simplify3D).

- Use layered view to identify the problem.

- To fix errors, use additional software like Blender or Meshmixer.

- Merge objects.

No base for next layers

Description of the problem

You have loaded your 3D model into the slicing software and everything looks good. We started printing and as a result part of the model was printed well, and some parts - badly. This is a fairly common problem in 3D printing.

What causes this problem during 3D printing?

During 3D printing, each layer is built on top of the previous one.

Naturally, if your model has a part that does not have plastic underneath (for example, as shown in the figure above - horizontally outstretched arms), printing problems will arise.

Naturally, if your model has a part that does not have plastic underneath (for example, as shown in the figure above - horizontally outstretched arms), printing problems will arise. Ideally, the slicing software should somehow detect and point out this problem. However, in most cases, the programs will let us print without indicating that additional supports are needed for the model.

Problem solved: no base for next layers

- Add supports. The quickest and easiest solution is to add calipers. In most programs, this is done quite simply. For example, in Simplify3D go to Edit Process Settings > Support > Generate support material; you can customize the quantity, shape and specify other caliper settings. If you are using Cura, just select Support type in the Basic settings.

- Make your own calipers. Software generated calipers may not suit you, so you can create your own in the base 3D model. This will require a little more skill, but can give fantastic results.

- Add an additional object to your 3D model. Most often, problems occur when printing hands and similar details. In this case, adding supports from the base of the model to the arm can also result in a problem, since the distance can be quite large. Considering that the calipers should be easy to remove, the high height may prevent them from being printed correctly. You can get around this by adding an additional object to your model (a piece of wall, a bench, a box, a flower, etc.) and printing an additional rack already from this object.

- Change the angle. For example, models of people whose arms are raised at 45º will print well and it is absolutely impossible to print arms stretched horizontally at 90º relative to the body.

- Divide the model into separate parts. Another option is to divide the model into separate parts and print two pieces instead of one. The only problem that will need to be solved is how to combine the resulting parts into one model after printing.

3D printing problem checklist: no base for next layers

- Add sapphops for SLISING SLISING

- Add calipers in the original model

- Add an object that can serve as a replacement for the caliper

- Change the location of the problem node

- Separate the parts separately

problemsAs the model builds, the layers begin to shift. As a result, instead of a straight vertical model, displacements appear. In this case, the offsets are not the same over the entire height of the model. The offset can increase/decrease at different heights.

What causes this problem during 3D printing?

The reason is quite simple. One of the belts connected to the stepper motor has lost tension. To eliminate model drift, it is enough to check the tension of the belts and the pulleys that keep the belts in tension.

At first glance, the solution to the problem is simple. However, before you fix it, you should find out which belt is causing it, as getting to the belt can be a difficult task.

Learn more

- Check the thickness of the outer wall of your 3D model.

- Check the belts. Start by checking belt tension.