Who is making 3d printers

The World’s Largest 3D Printing Companies By Market Cap: 3D Systems & Xometry On Top

This is a list of the world’s largest 3D printing companies measured by market capitalisation. Thanks to their resources, these companies dominate the global 3D printing market. The listing is as per the data verified on 4th March 2022.

Contents

- 1 3D Systems (NASDAQ: DDD)

- 2 Xometry Inc. (NASDAQ: XMTR)

- 3 Stratasys Ltd. (NASDAQ: SSYS)

- 4 Protolabs (NASDAQ: PRLB)

- 5 Velo3D Inc. (NYSE: VLD)

- 6 Desktop Metal Inc. (NYSE: DM)

- 7 Materialise N.V. ADR (NASDAQ: MTLS)

- 8 Nano Dimension (NASDAQ: NNDM)

- 9 Markforged Holding Corp. (NYSE: MKFG)

- 10 Shapeways Holdings Inc.: (NYSE: SHPW)

- 11 MeaTech 3D Ltd. (NASDAQ: MITC)

- 12 Organovo Holding Inc. (NASDAQ: ONVO)

- 13 Voxeljet AG ADR (NASDAQ: VJET)

- 14 Final Thoughts

Market Capitalisation: $2. 2B

3D Systems is the most valuable and biggest 3D printing companies in the world, with a market capitalization of $2.2 billion. The company sells a variety of items, including 3D printers, printing materials, digital design tools, and more. Manufacturing, 3D scanning, and healthcare are among the industries where the company’s 3D printing services are used.

With the acquisitions of Titan Additive and Kumovis, it is now expanding into extrusion-based 3D printing technologies.

Share Price (March, 2022): $17

Xometry Inc. (NASDAQ: XMTR)

Market Capitalisation: $2.17B

Xometry, which debuted on the stock market less than a year ago in June 2021, is now second on the list of the top 3D printing companies. Xometry is an on-demand manufacturing company that was founded in 2013 as a convenient marketplace for products people to make and use. Xometry digitised manufacturing by starting from 3D printing but expanding to include much of the conventional manufacturing processes as well. Today, it is one the world’s biggest on-demand manufacturing platform. To understand Xometry better, think of it as the Airbnb of On-demand manufacturing.

Today, it is one the world’s biggest on-demand manufacturing platform. To understand Xometry better, think of it as the Airbnb of On-demand manufacturing.

Share Price (March, 2022): $49

Stratasys Ltd. (NASDAQ: SSYS)

Market Capitalisation: $1.55B

Israel-based Stratasys is on the third spot in the list of world’s largest 3D printing companies as per market capitalisation (rising from 5th position last year to the third position). It also ranks high among the biggest 3D printer companies across the world. With a market cap of $1.55 billion, the company is undeniably a force to be reckoned with in the global 3D printing market.

Share Price (March, 2022): $23.97

Protolabs (NASDAQ: PRLB)Above: Protolabs Corporate HQ Maple Plain, US/Image Credit: ProtolabsMarket Capitalisation: $1.51B

With a market cap of $1.51 billion Protolabs stands fourth in the list of largest companies in the global 3D printing market. Specialising in rapid prototyping, the company is known to offer the fastest source for and customised custom prototypes production parts. The company uses three additive processes namely stereolithography, selective laser sintering (SLS), and one of the metal 3D printing technologies such as direct metal laser sintering (DMLS). With more than half a dozen manufacturing locations across three continents, the company is known to produce and assemble custom parts in just one day.

Specialising in rapid prototyping, the company is known to offer the fastest source for and customised custom prototypes production parts. The company uses three additive processes namely stereolithography, selective laser sintering (SLS), and one of the metal 3D printing technologies such as direct metal laser sintering (DMLS). With more than half a dozen manufacturing locations across three continents, the company is known to produce and assemble custom parts in just one day.

Share Price (March, 2022): $54.93

Velo3D Inc. (NYSE: VLD)

Above: Velo3D team at the New York Stock Exchange/Image Source: Velo3DMarket Capitalisation: $1.47B

Velo3D is a new entrant to the list as it debut as a publicly-traded company in October 2021. Velo3D is a leading additive manufacturing technology company for mission-critical metal parts. It has quickly rose to prominence due to its proprietary Sapphire® system. Velo3D’s reputation can be gauged by the fact that its AM systems are used by some of the most innovative companies in the world, including SpaceX, Honeywell, Boom Supersonic and more. Velo3D is said to be effective in producing mission-critical parts and that too at fraction of time and cost required by conventional technologies.

Velo3D is said to be effective in producing mission-critical parts and that too at fraction of time and cost required by conventional technologies.

Share Price (March, 2022): $7.78

Desktop Metal Inc. (NYSE: DM)

Market Capitalisation: $1.27B

Desktop Metal became a publicly listed company on December 10, 2020 after going through a SPAC deal. There was much excitement as Desktop Metal went public but for multiple reasons the DM stock has continued to fall. From the stock hitting an all-time high of $35 per share last February, it has plummeted to $4 per share (March 3rd, 2022).

Though the picture seems dark, Desktop Metal is betting big on its flagship Production System P-50 printer. The company shipped its first P-50 printer on 28th February. So, there is something to look forward to.

Share Price (March, 2022): $4.03

Materialise N.V. ADR (NASDAQ:

MTLS)Image Source: MaterialiseMarket Capitalisation: $1. 17B

17B

With a market capitalisation of $1.17B, Belgium-based Materialise NV comes at number seven this year. The company has more than two decades of 3D printing experience and offers a host of software solutions and 3D printing services to a variety of industries such as automotive, art and design, consumer goods, and healthcare.

The Materialise stock is steady at $19 per share. Though it reached a 52-week high of $77 per share in February last year, but has seen a downturn since then.

Share Price (March, 2022): $19.34

Nano Dimension (NASDAQ: NNDM)Image Credit: Nano DimensionMarket Capitalisation: $890.02M

Israel-based Nano Dimension is the next on the list of the world’s largest 3D printing companies with a market cap of $890.02M. The company has registered exponential growth recently and has emerged as a leader in additive electronics and nanotechnology-based ink products. Its products include the award-winning DragonFly Pro 2020 3D printer known to 3D print a variety of functional electronics such as sensors, antennas, moulded connected devices, printed circuit boards, and other devices. By easing the process of manufacturing such complex electronic devices, the DragonFly 2020 Pro 3D printer is transforming the electronic additive manufacturing market and allowing companies to take charge of their entire development cycle.

By easing the process of manufacturing such complex electronic devices, the DragonFly 2020 Pro 3D printer is transforming the electronic additive manufacturing market and allowing companies to take charge of their entire development cycle.

Share Price (March, 2022): $3.41

Markforged Holding Corp. (NYSE: MKFG)

Image Source: MarkforgedMarket Capitalisation: $691.37M

Markforged is an American public additive manufacturing company that debuted on the NYSE last year in July 2021. It designs, develops, and manufactures The Digital Forge — an industrial platform of 3D printers, software and materials that enables manufacturers to print parts at the point-of-need.

Markforged was valued at $2.1 billion at the time of its debut but has seen a downfall in stock prices like almost every 3D printing company and especially those going public via SPAC deals. One of the reason for the fall in prices is likely due to the SPAC deals going out of favour among many other.

Share Price (March, 2022): $3.57

Shapeways Holdings Inc.: (NYSE: SHPW)

Market Capitalisation: $155.51M

Shapeways is the Dutch-New York counterpart of the Belgian Materialise. It is a digital manufacturing platform offering customers access to high-quality part manufacturing from a wide selection of processes and materials through automation, innovation and digitisation.

It also offer ready-made products from its marketplace like an E-commerce store catering to B2C clients who can place an order and get it delivered to their doorstep.

Share Price (March, 2022): $3.13

MeaTech 3D Ltd. (NASDAQ: MITC)

Market Capitalisation: $82.49M

MeaTech4D is also among the biggest 3D printing companies in the world. MeaTech 3D Ltd. is an Israeli food technology company, that promotes and focuses on developing alternative option to industrialised farming. It does this to circumvent the ethical and environmental issues surrounding conventional animal husbandry by developing an industrial cultured meat production process with integrated 3D printing technology. It aims to develop a customised process to manufacture protein without animal slaughter.

It aims to develop a customised process to manufacture protein without animal slaughter.

MeaTech was also among the companies that went public last year in 2021.

Share Price (March, 2022): $5.15

Organovo Holding Inc. (NASDAQ: ONVO)

Image Source: OrganovoMarket Capitalisation: $32.82M

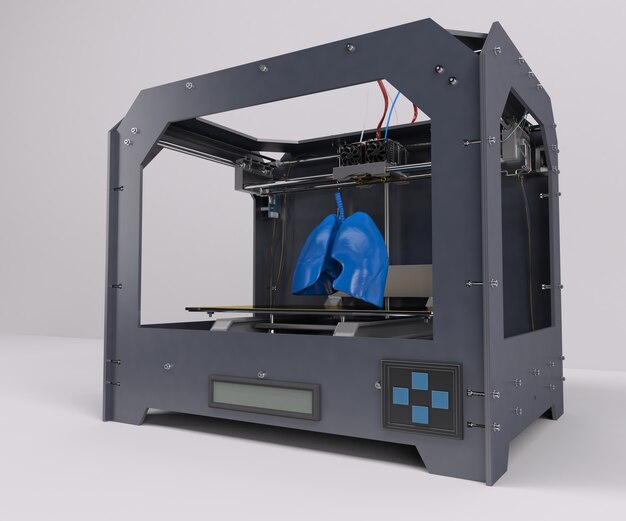

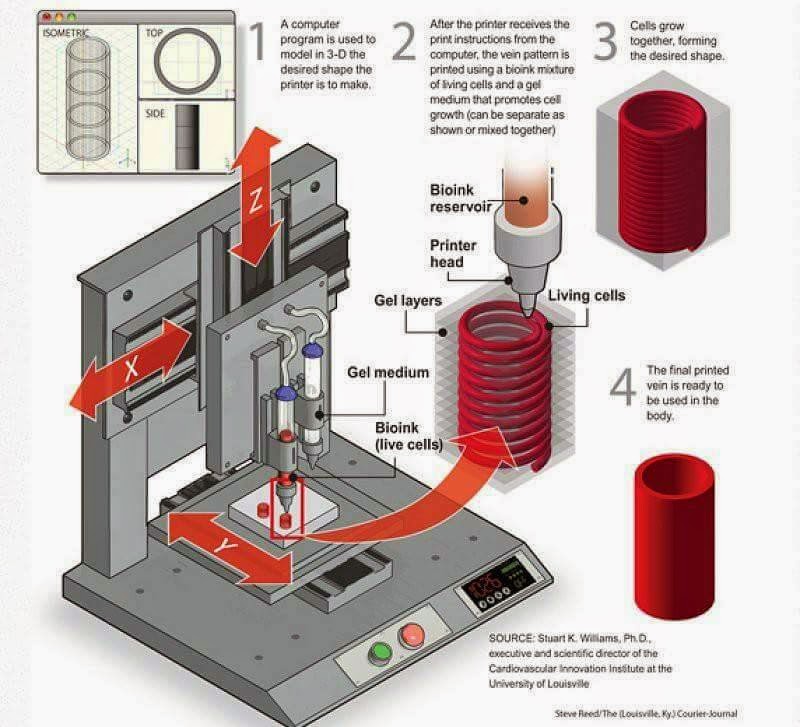

San Diego-based Organovo is at the 12th position in the list of the world’s largest 3D printing company with a market cap of $76.65 million. Known to transform the future of regenerative medicine with its 3D bioprinting technology, the company has partnered with several pharmaceuticals, medical centers and develops 3D human tissue models that could be used for different medical purposes such as biological research, predictive preclinical testing of drug compounds, therapeutic implants and even to treat damaged or degenerating tissues and organs.

Share Price (March, 2022): $4.67

Voxeljet AG ADR (NASDAQ: VJET)

Market Capitalisation: $30. 57M

57M

The next on this list of the world’s largest 3D printing companies with a market cap of $96.59 million is Voxeljet. A manufacturer of 3D printing systems for industrial applications, Voxeljet is known for its large-format production and a chemical 3D printing process. The company caters to industries that range from automotive, aerospace to architecture and design.

Share Price (March, 2022): $4.60

Final Thoughts

The list of 13 of the largest and the best 3D printing companies around the world also offer a great representation of the entire 3D printing ecosystem. This list has some of the biggest 3D printer manufacturers, 3D printing service providers, software manufacturers and also one of the top medical/healthcare 3D printing company.

Note: The article is for informational purposes only. Manufactur3D does not offer personalised investment recommendations or views about any particular company or stock of a company

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

5 Biggest 3D Printing Companies

DDD, PRLB, and FARO lead the 5 biggest 3D printing companies list

By

Nathan Reiff

Full Bio

Nathan Reiff has been writing expert articles and news about financial topics such as investing and trading, cryptocurrency, ETFs, and alternative investments on Investopedia since 2016.

Learn about our editorial policies

Updated August 01, 2022

Reviewed by

Thomas Brock

Reviewed by Thomas Brock

Full Bio

Thomas J. Brock is a CFA and CPA with more than 20 years of experience in various areas including investing, insurance portfolio management, finance and accounting, personal investment and financial planning advice, and development of educational materials about life insurance and annuities.

Brock is a CFA and CPA with more than 20 years of experience in various areas including investing, insurance portfolio management, finance and accounting, personal investment and financial planning advice, and development of educational materials about life insurance and annuities.

Learn about our Financial Review Board

The manufacturing process known as 3D printing is one of the most promising and rapidly developing technologies with applications across a multitude of industries. 3D printing involves the additive layering of thin sheets of material that are fused together to create a physical product from a digital design. While the industry is currently hampered by relatively slow production times, advocates believe that 3D printing ultimately will have the capability to mass produce everything from medical equipment to automotive parts to airline components. Below, we look at the 5 biggest 3D printing companies by 12-month trailing (TTM) revenue. This list is limited to companies that are publicly traded in the U. S. or Canada, either directly or through ADRs. Some foreign companies may report semiannually, and so may have longer lag times. All data are from YCharts as of September 8, 2020.

S. or Canada, either directly or through ADRs. Some foreign companies may report semiannually, and so may have longer lag times. All data are from YCharts as of September 8, 2020.

- Revenue (TTM): $566.6 million

- Net Income (TTM): -$78.4 million

- Market Cap: $632.3 million

- 1-Year Trailing Total Return: -24.6%

- Exchange: New York Stock Exchange

3D Systems invented 3D printing in 1989 with the development and patenting of its stereolithography technology, which uses ultraviolet lasers to help create highly precise parts. DDD built on that by developing new technologies, including selective laser sintering, multi-jet printing, film-transfer imaging, color jet printing, direct metal printing, and plastic jet printing. 3D Systems has three business units: products, materials, and services. The products category offers 3D printers and software and includes small desktop and commercial printers that print in plastics and other materials.

- Revenue (TTM): $451.0 million

- Net Income (TTM): $58.6 million

- Market Cap: $3.9 billion

- 1-Year Trailing Total Return: 58.2%

- Exchange: New York Stock Exchange

Proto Labs was founded in 1999 with a focus on building automated solutions to develop plastic and metal parts used in the manufacturing process. The company expanded to launch an industrial-grade 3D printing service that allowed developers and engineers to move prototypes into the production process. The company's primary business services include injection molding, sheet metal fabrication and 3D printing.

- Revenue (TTM): $334.7 million

- Net Income (TTM): -$79.7 million

- Market Cap: $1.0 billion

- 1-Year Trailing Total Return: 20.6%

- Exchange: NASDAQ

FARO specializes in 3D measurement and other services for the fields of architecture, engineering, and construction. With a 40-year history, FARO' began before the advent of 3D printing. The company's products include coordinate measuring machines, laser trackers and projectors, mappers, scanners, and software. FARO also serves the aerospace, automotive, and power generation industries.

The company's products include coordinate measuring machines, laser trackers and projectors, mappers, scanners, and software. FARO also serves the aerospace, automotive, and power generation industries.

- Revenue (TTM): $205.3 million

- Net Income (TTM): -$2.7 million

- Market Cap: $1.9 billion

- 1-Year Trailing Total Return: 94.8%

- Exchange: NASDAQ

Belgian company Materialise has a 30-year history providing 3D printing solutions and related software. It provides platforms to facilitate the development of 3D printing applications in industries such as healthcare, automotive, aerospace, and art and design. Some of the company's first 3D printing activities included anatomical models in both dental and hearing aid products. Materialise also produces eyewear and automobile products.

- Revenue (TTM): $52.9 million

- Net Income (TTM): -$14.5 million

- Market Cap: $238.2 million

- 1-Year Trailing Total Return: 48.

3%

3% - Exchange: NASDAQ

ExOne specializes in manufacturing 3D printing machines for customers across various industries. It also produces 3D printed products to specification for industrial customers. ExOne 3D printers utilize binder jetting technology, fusing powder particles of materials like metal or sand into molds, cores, and other products.

Article Sources

Investopedia requires writers to use primary sources to support their work. These include white papers, government data, original reporting, and interviews with industry experts. We also reference original research from other reputable publishers where appropriate. You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

YCharts. "YCharts."

3D Systems. "Our Story."

Materialise. "Timeline."

Top 10 3D printing companies listed on the stock exchange

So, we present to your attention the ranking of 3D printing companies in terms of annual turnover.

Stratasys: $750 million

Industry leader Stratasys grew 54% over the past year with sales exceeding $750 million. This is partly driven by demand for the new Object500 Connex3 model, as well as the traditionally popular PolyJet and industrial FDM 3D printers. Another growth driver was the acquisition of other companies such as Solid Concepts and Harvest Technologies (now part of Stratasys Direct Manufacturing). At the same time, the American-Israeli company (which includes, among other things, MakerBot Industries and SolidScape) recorded a net loss of $119 in its financial statements.million. This figure is more than four times higher than last year, which is also due to active acquisitions and investments. The forecast for 2015 is positive, it is expected that the revenue will be $940 million. If Stratasys manages to beat expectations by 6%, it could become the first pure 3D printing company to reach $1 billion in revenue.

3D Systems: $650 million

Although 3D Systems' revenue rose 27% to a record high, the company still lost the top spot to Stratasys last year. The head of the company, Avi Reichental, said he was not entirely satisfied with how the company realized the potential of its technology portfolio. 3D Systems has some of the most advanced 3D printing technology in the industry, but hasn't shown enough willingness to go mainstream. However, according to 3D Systems financial statements, the company turned out to be in positive territory with a net profit of $1.6 million at the end of the year. Although the forecast for 2015 is generally positive, it is likely that 3D Systems will again be behind Stratasys, with revenues of $850-900 million.

The head of the company, Avi Reichental, said he was not entirely satisfied with how the company realized the potential of its technology portfolio. 3D Systems has some of the most advanced 3D printing technology in the industry, but hasn't shown enough willingness to go mainstream. However, according to 3D Systems financial statements, the company turned out to be in positive territory with a net profit of $1.6 million at the end of the year. Although the forecast for 2015 is generally positive, it is likely that 3D Systems will again be behind Stratasys, with revenues of $850-900 million.

Materialize: $81 million

Materialize is one of Europe's leading 3D printing service providers and a developer of innovative 3D printing software. In 2014, the company's revenue amounted to $81 million, which is 18.4% more than last year. The company's net profit reached $1.8 million, half of what it was in 2013, but still significant. Materialize's core business is the development and sale of 3D printing software (22% of sales) and medical 3D printing services (37%). The industrial segment, including the i.materialise 3D printing service, generated 40% of the company's total revenue. Materialize is expected to grow by 20% next year and reach €100 million in annual turnover.

The industrial segment, including the i.materialise 3D printing service, generated 40% of the company's total revenue. Materialize is expected to grow by 20% next year and reach €100 million in annual turnover.

ExOne: $43.9 million

Last year, ExOne grew by 10% with revenues of approximately $43.9 million. The main contribution to this result was made by the fourth quarter, during which sales increased by 50%. This state of affairs resulted in a gross profit of $10 million, but ExOne's operating costs were $21 million. This was mainly due to investments in the expansion of the company (new production facilities in Russia and Italy), as well as research and development (more than $8 million). In addition, ExOne announced the creation of a new large-scale 3D printer, Exerial.

Arcam: $39 million

Arcam, a Swedish manufacturer of electron beam melting (EBM) systems, recorded revenues of approximately $39 million. Thus, sales grew by 70% in a year, and profits exceeded $6 million. However, it is likely that in the financial markets such results were considered too good to be true. Compared to a record high at the end of 2013, Arcam shares are down more than 70% and are now trading for around $17.

Thus, sales grew by 70% in a year, and profits exceeded $6 million. However, it is likely that in the financial markets such results were considered too good to be true. Compared to a record high at the end of 2013, Arcam shares are down more than 70% and are now trading for around $17.

SLM Solutions: $36 million

Germany's SLM Solutions posted similar results to Arcam, with record earnings of approximately $36 million and 56% growth in 2014. At the same time, the company's shares fell from a record high of €21 to €18. However, SLM Solutions boasts a more stable stock price than most other members of the 3D printing industry. At the moment, for the past period of 2015, SLM Solutions reports an increase in the number of orders twice year-on-year.

Alphaform: $30 million

German company Alphaform offers rapid prototyping services. Alphaform made its first steps in the consumer market as part of the Artshapes project to apply 3D printing to the arts. The company reported record revenue of $30 million in 2014, up 11.6%. While Alphaform lost more than $3 million in the same period, this is a significant improvement from $6.5 million in 2013.

The company reported record revenue of $30 million in 2014, up 11.6%. While Alphaform lost more than $3 million in the same period, this is a significant improvement from $6.5 million in 2013.

voxeljet: $17-18 million

Analysts have criticized the German company voxeljet for not selling enough devices while offering special deals to customers to increase orders. However, it should be taken into account that voxeljet manufactures large industrial equipment, the print volume of which reaches 8 cubic meters - in other words, the company occupies a very specific niche. Estimated revenue for 2014 (updated data will be available at the end of March) is $17-18 million. In addition, according to voxeljet forecasts, the company expects to grow by almost 50% this year.

Organovo: $0

Organovo is the only listed biomaterials 3D printing company. However, most of Organovo's activities are still research and the first commercial product, exVive3D human liver tissue, was released just recently. The company has created its own bioprinter and uses it to 3D print organic tissues, which it then sells to major pharmaceutical companies for research purposes. The company's annual operating costs are approximately $20 million. At the same time, Organovo is confident that its products can bring more than $100 million in profit in the foreseeable future.

The company has created its own bioprinter and uses it to 3D print organic tissues, which it then sells to major pharmaceutical companies for research purposes. The company's annual operating costs are approximately $20 million. At the same time, Organovo is confident that its products can bring more than $100 million in profit in the foreseeable future.

Renishaw: data not available

Rounding out the top ten was British company Renishaw, which recorded $520 million in revenue and $100 million in marginally lower profits. As of now, Renishaw has yet to disclose earnings for its 3D printing business, limiting itself to commenting that "demand has been solid." The stability of demand can be judged by the fact that, having entered the market with the AM250 device operating on SLM technology, in 2014 the company has already introduced a new EVO system.

Tags: Stratasys, 3D Systems, Materialize, ExOne, Arcam, SLM Solutions, Alphaform, voxeljet, Organovo, Renishaw

Possibilities of 3D printing in small-scale production

A bit of history

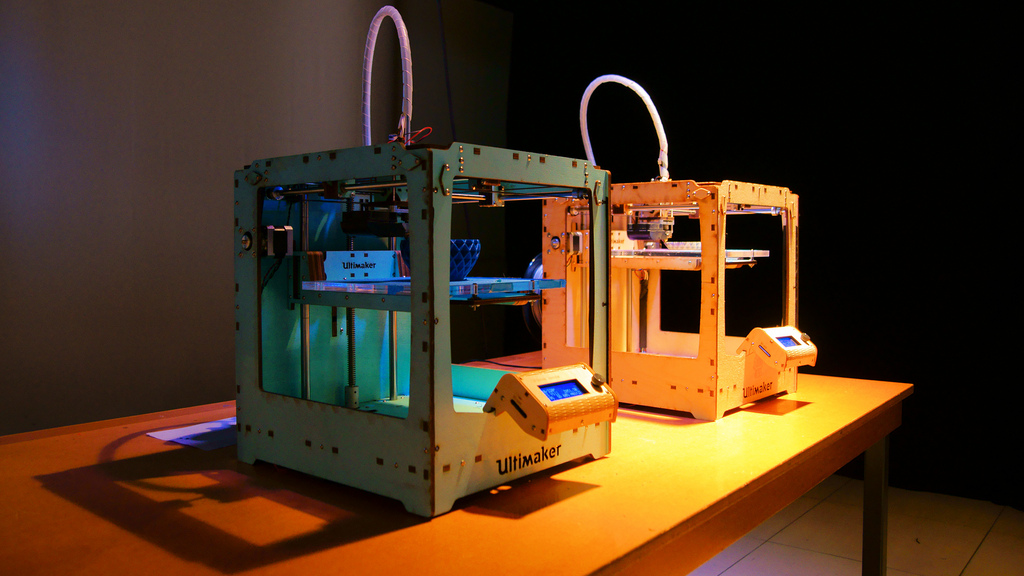

Modern desktop 3D printing began just over 10 years ago with the emergence of the RepRap enthusiast community. The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. The task was to small-scale production of 3D printers on the 3D printers themselves. This idea was picked up and developed by the Czech engineer and entrepreneur Josef Prusa. He created the largest 3D printing farm to print plastic parts produced by his 3D printer factory. The total number of printers in his factory reaches 1000 pieces, this achievement was even registered in the Guinness Book of Records.

The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. The task was to small-scale production of 3D printers on the 3D printers themselves. This idea was picked up and developed by the Czech engineer and entrepreneur Josef Prusa. He created the largest 3D printing farm to print plastic parts produced by his 3D printer factory. The total number of printers in his factory reaches 1000 pieces, this achievement was even registered in the Guinness Book of Records.

In this case, I would note Josef's marketing talent, because his company produces about 100 thousand printers a year and its production can hardly be called small-scale. However, he continues to print plastic components for his printers on them. Thus, their reliability is emphasized, because printing is part of the testing process, on the one hand, and on the other hand, it demonstrates to customers the quality of models made on a 3D printer. The effectiveness of this approach, from the point of view of the production itself, is negligible. One injection molding machine would do the job easily, saving a lot of space and electricity, and there would be no need for a large number of jobs.

One injection molding machine would do the job easily, saving a lot of space and electricity, and there would be no need for a large number of jobs.

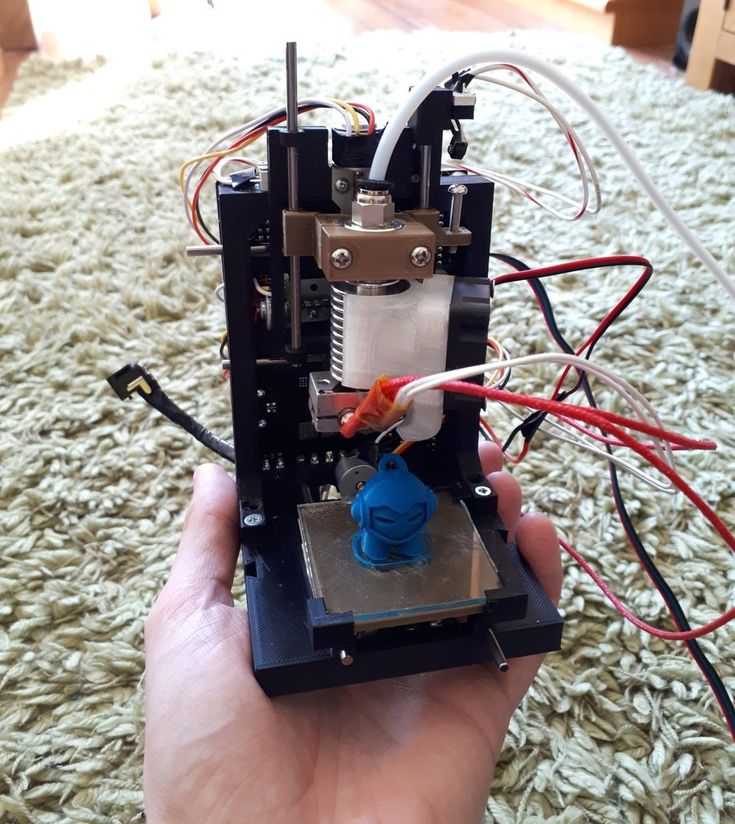

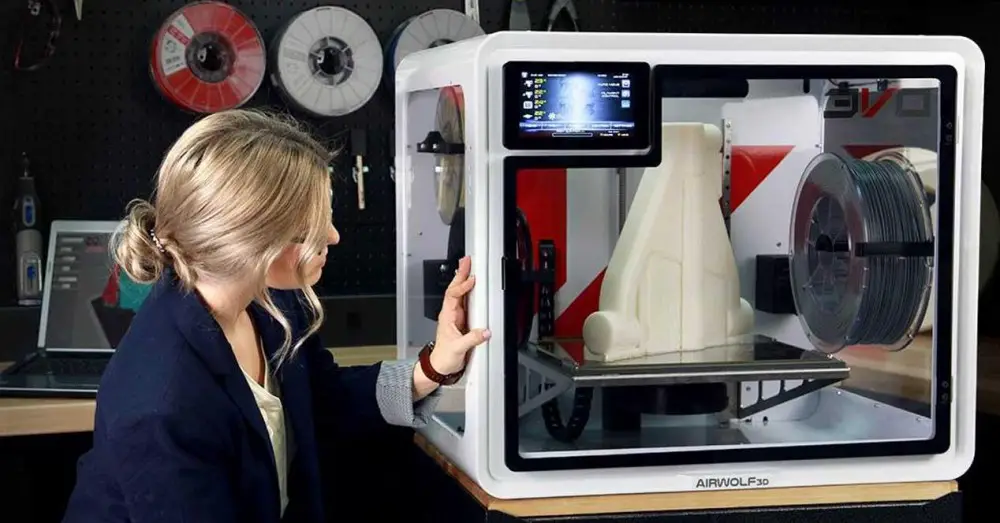

3D printing capabilities for low volume production

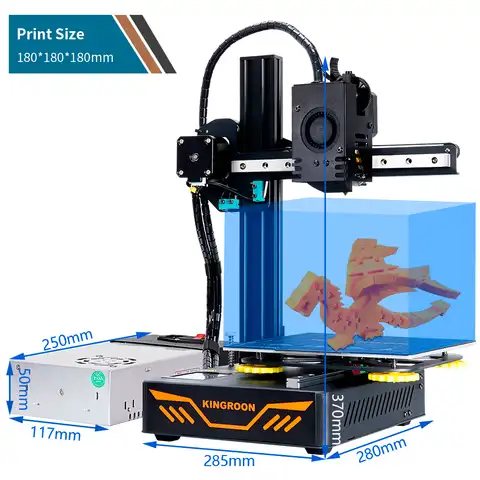

So what are the possibilities of desktop 3D printing for small-scale production? I note right away that this article is about desktop 3D printers. I will not consider industrial systems in it, since they are in a different price category, both for the equipment itself and for printing materials.

To begin with, it is worth talking about what can be produced on 3D printers. Usually we are talking about small plastic elements, plugs, clamps, housings, holders and other similar elements. The choice is to order a mold or 3D print these elements. It is easy to make such a choice by calculating the cost of the mold, the cost of products obtained on an injection molding machine and the cost of printing the same product on a 3D printer of the required circulation. You need to understand how many units of production per unit of time you need to produce and, accordingly, how many and which 3D printers will be needed for this task. Having made such an initial analysis and having previously understood that 3D printing is what suits you, you should carefully start choosing equipment.

You need to understand how many units of production per unit of time you need to produce and, accordingly, how many and which 3D printers will be needed for this task. Having made such an initial analysis and having previously understood that 3D printing is what suits you, you should carefully start choosing equipment.

If you already know what you will print, the choice becomes easier. If you plan to produce models with different tasks in the future, then before buying, you should carefully analyze the possible options. The main factor influencing the choice of equipment is the presence or absence of certain functionality in future models. The printer should print with materials that will ensure the functionality of your products. For example, a future part must withstand a certain heating or cooling temperature, be strong, rigid, wear and shock resistant, or, conversely, soft, rubber-like, elastic, flexible. The more versatile a 3D printer is, the more expensive it is. Indeed, for printing various types of plastic, printers are equipped with closed chambers, interchangeable extruders, perforated platforms, feed mechanisms with adjustable filament pressure, etc.

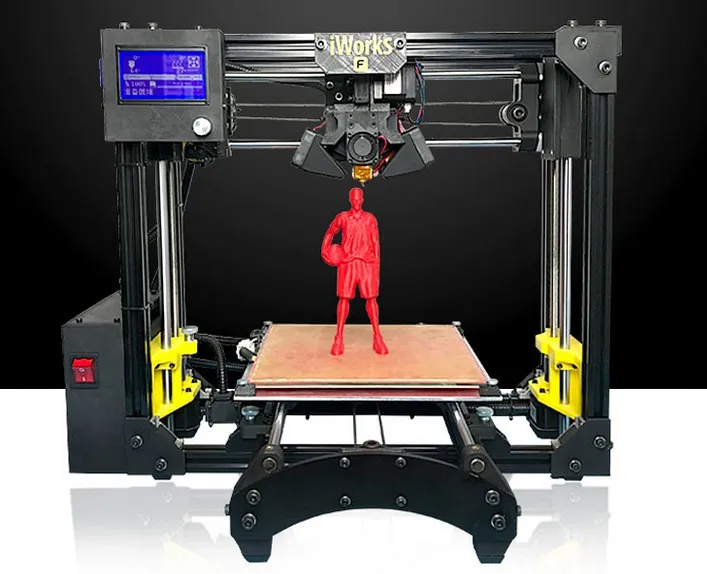

FDM/FFF solutions

This is the FDM/FFF printing technology most commonly used today for small-scale production. Let's look at a few technological solutions that manufacturers offer.

The most affordable and suitable for printing simple models from plastics such as PLA or PETG is a solution based on budget printers such as Creality Ender-3. These are very simple models that are installed on racks.

Pictured is a 3D printing farm in Creality3D

Among the advantages of this solution: the ability to quickly deploy it in almost any suitable place, quickly increase the number of printers to increase the productivity of the farm. Of the minuses: the impossibility of printing with engineering plastics, the need to manually remove models, as well as the impossibility of remote monitoring and control over printing.

The next level of organization of small-scale production is a farm of printers that can cope with the most diverse tasks. For example, a farm built on the basis of Raise3D Pro2 3D printers. Each such printer is equipped with two extruders, a closed camera and a built-in webcam for remote monitoring. On such printers, you can easily change the "manufactured" models. Today it can be simple plugs made of PLA plastic, and tomorrow it will be complex models made of carbon fiber or nylon gears. The disadvantages include only the high cost of equipment and the remaining need to shoot finished models manually.

For example, a farm built on the basis of Raise3D Pro2 3D printers. Each such printer is equipped with two extruders, a closed camera and a built-in webcam for remote monitoring. On such printers, you can easily change the "manufactured" models. Today it can be simple plugs made of PLA plastic, and tomorrow it will be complex models made of carbon fiber or nylon gears. The disadvantages include only the high cost of equipment and the remaining need to shoot finished models manually.

Pictured is a 3D printing farm at 2050.AT

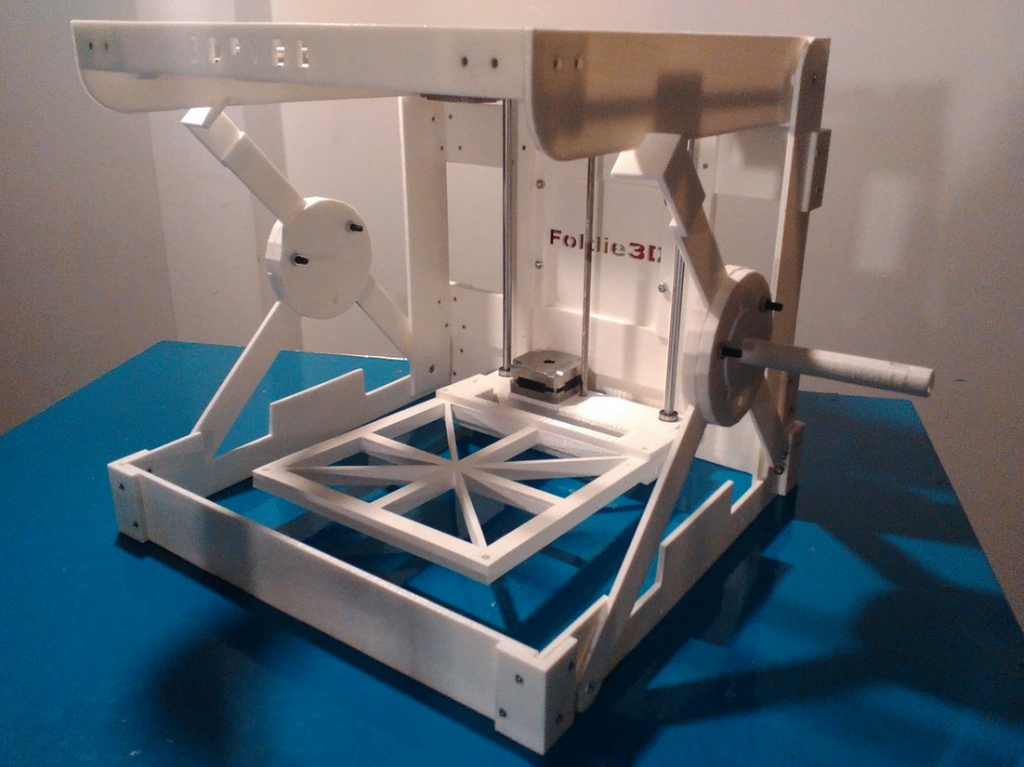

Another option for such a solution is a farm based on printers with two independent IDEX type extruders. In the photo below you can see a similar farm based on Raise3D E2 printers. The solution has the added benefit of increasing productivity: each printer can print two identical models at the same time instead of one. The disadvantages remain the same: the need to shoot models manually and the rather high cost of the printers themselves. The benefits are the same plus increased performance.

The benefits are the same plus increased performance.

Pictured is a 3D printing farm at 3D.RU

If for the previous solutions small-scale production is one of the possible applications, then the printer, which will be discussed further, is created specifically for this task. The TierTime X5 is a mini conveyor with 12 interchangeable pads for long, uninterrupted printing. After the printing of the model or models is completed, the platform moves off the platform, and a new one takes its place, after which printing can continue. In this case, both the same and different models can be printed. The printer also maintains a print queue, different employees can send jobs to it, and they will be executed as they arrive. Models from the sites will still have to be removed manually, so it’s too early to talk about full automation. Of the minuses, it is worth noting the high cost of equipment and its low productivity. For comparable money, you can buy up to 10 printers of the same level, but their performance will be 10 times greater. True, they will take up much more space, and it is much more difficult to monitor 10 printers than one. But at the same time, one must take into account that if one of the 10 printers breaks down, you still have 9 more. If the only printer breaks, you are left without your equipment for an indefinite period of time, depending on the timing of the repair.

True, they will take up much more space, and it is much more difficult to monitor 10 printers than one. But at the same time, one must take into account that if one of the 10 printers breaks down, you still have 9 more. If the only printer breaks, you are left without your equipment for an indefinite period of time, depending on the timing of the repair.

Another printer option designed specifically for low volume production is the Creality3D CR-30 PrintMill ribbon type model. This printer is created on the principle of a conveyor belt, models can be printed endlessly and fall into the box themselves, you just have to remember to change the plastic. Human participation is minimal, but due to the complex design, where printing is carried out at an angle of 45 ° C, there are many restrictions on the geometry of models, the location of supports and other nuances. But on the other hand, this is the most automated process of all possible today, especially given the modest budget for the purchase.

In an effort to fully automate small-scale production, manufacturers and builders of 3D printing factories or small-scale production add various equipment. In particular, to automate the removal of models, cobots (collaborative robots) are used, which are programmed to remove the platform along with the printed model and install a new printing platform, after which printing resumes. This is an insanely expensive solution that doesn't really improve productivity, and can only be justified in countries with incredibly high wages.

Pictured is a VooDoo Manufacturing 3D printing truss

Another possible solution for the complete automation of the small-scale production process using 3D printing was presented by the Latvian company Mass Portal. She created a portal system for this task. The printers are installed in a rack, where the manipulator arm removes the platforms with finished models and transfers them to a special storage rack. Such a solution almost completely automates the entire process, but its cost is so high, and the system itself is so cumbersome that it is not worth talking about its effectiveness for a wide range of tasks.

Such a solution almost completely automates the entire process, but its cost is so high, and the system itself is so cumbersome that it is not worth talking about its effectiveness for a wide range of tasks.

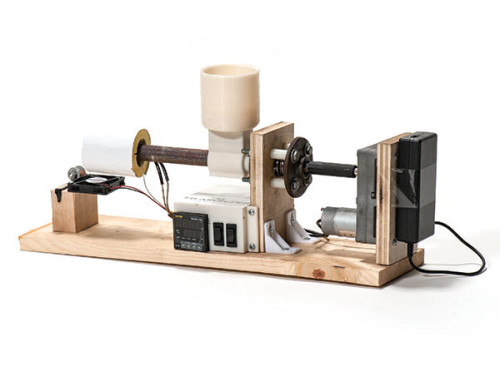

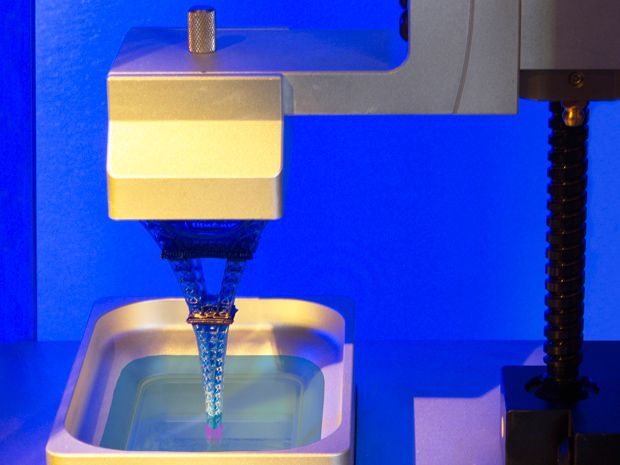

Photopolymer Solutions

All solutions discussed earlier in this article were created on the basis of FDM / FFF technology, which involves printing using molten plastic filament. But recently, photopolymer 3D printers are gaining more popularity, which print on the principle of forming a model from a liquid photopolymer. From the point of view of small-scale production, this technology has a number of advantages. First of all, performance. The technology allows you to illuminate the entire layer at once - in this way the printer spends the same time printing one or any other number of models that fit into the construction area. If earlier desktop photopolymer printers had modest pad sizes and, accordingly, their production potential was not very high, then this year a number of models with a large print area and high detail were introduced, for example, the Phrozen Sonic Mega 8K printer model.

Printing models on the photo lasted 3.5 hours. It is not difficult to calculate the performance of a printer. In this case, even one printer is a mini-factory and is capable of solving serious production problems. It is also important to note that unlike FDM/FFF printers, all photoresin 3D printers are inherently universal - you can print on them with any resins available on the market or even those that will appear in the future.

Not surprisingly, the creators of 3D printing trusses were inspired by the huge opportunities that were opening up, and many small-scale productions were created based on such equipment. For example, the British company Photocentric has opened the largest such center in Europe based on its LC Magna model. It came in handy during the pandemic, when it was necessary to urgently establish the production of elements necessary for the treatment of patients, for example, replaceable valves for ventilators.

Unfortunately, it is also not complete without significant disadvantages, but let's talk about everything in order. First of all, this is the process of post-processing of printed models, which consists of washing the models in alcohol and subsequent illumination in a UV camera. Without these procedures, the model will not acquire the final quality. These processes cannot be automated, they require a lot of labor, and this must be taken into account when choosing equipment. In addition, it should be taken into account that the cost of photopolymer resin is on average 3 times more than plastic for 3D printing, and, accordingly, the cost of the resulting products will be higher. Another factor to consider is the need for special preparation of the installation site for printers, the availability of high-quality ventilation and the possibility of waste disposal.

First of all, this is the process of post-processing of printed models, which consists of washing the models in alcohol and subsequent illumination in a UV camera. Without these procedures, the model will not acquire the final quality. These processes cannot be automated, they require a lot of labor, and this must be taken into account when choosing equipment. In addition, it should be taken into account that the cost of photopolymer resin is on average 3 times more than plastic for 3D printing, and, accordingly, the cost of the resulting products will be higher. Another factor to consider is the need for special preparation of the installation site for printers, the availability of high-quality ventilation and the possibility of waste disposal.

Totals

In summary, even a single 3D printer is a suitable solution for small-scale production. 3D printing is ideal for small-scale production. The main thing is to choose the right equipment, calculate its payback period and the cost of the final product.