What size 3d printer do i need

Shop the Best Large Format 3D Printers in 2022 (Including Best Large 500mm 3D Printer)

Welcome to the Thomas guide to the best large format 3D printer 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

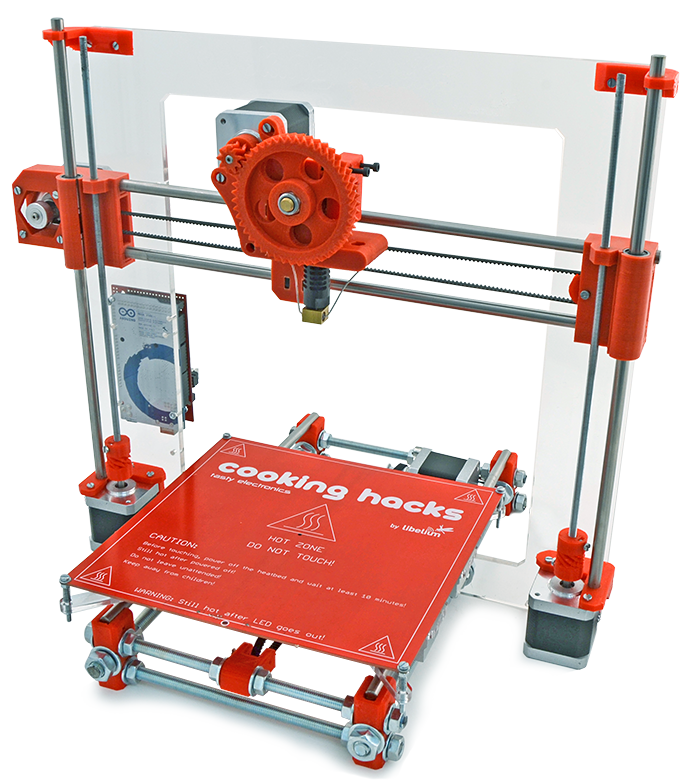

Printing larger items with most at-home or small-scale 3D printers is possible but consists of separately printing different parts of the project and then connecting them all together afterward to make the much larger finished product. In this way, many 3D printing enthusiasts, such as cosplayers, for instance, are able to get past the 3D printing size limitations and use their machines for much larger products than the print bed will allow.

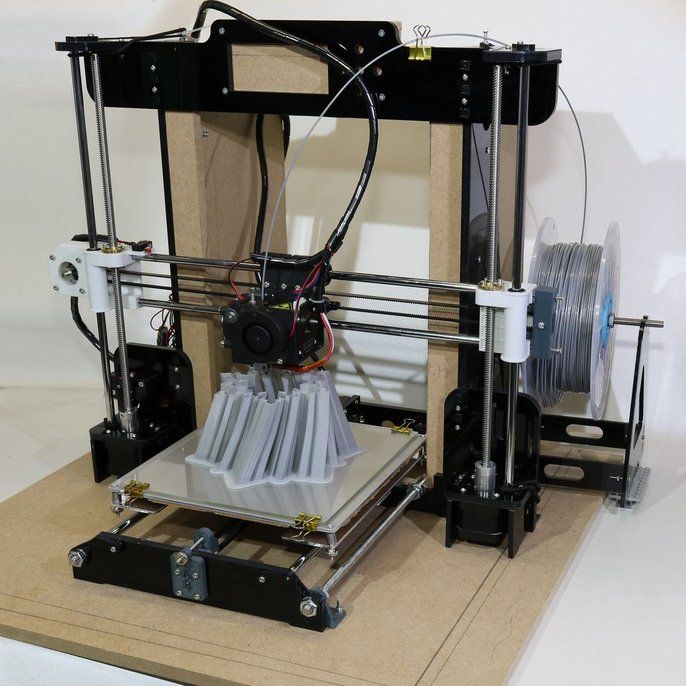

A large-format 3D printer in actionImage credit: Shutterstock/asharkyu

However, purchasing a large-format 3D printer can provide an increase in opportunities for creativity and a decrease in the amount of "putting together" necessary for those larger projects.

Large-Format 3D Printer—Buying Guide

With the average printing bed size of a 3D printer intended for general use being around 150–300mm, if you wanted to scale up the size of your 3D creations, a printer of 350mm–500mm would be ideal, and luckily, there are a few worthy large-scale models available on the market for you to choose from.

Benefits of a Large 3D Printer

Development in 3D printing technology means that we've recently been presented with 3D printed houses, cars, bikes, camper vans, life-size statues, and even sofas and other pieces of furniture.

Obviously, the "large format" we're referring to in this article is less about making grand-scale structures, and more about moving on from miniatures, ornaments, and other small objects or parts that an ordinary, non-industrial-sized 3D printer can produce.

Since you'll have a little more print bed area to play with, with a large-format 3D printer you can create detailed products that don't require a magnifying glass to really appreciate and also larger parts that would otherwise need to be printed in separate sections.

Thomas’ Top Picks for the Best Large Format 3D Printer 2022

If you're ready to step up your 3D printing game, and have a blast doing it, here are some of the best large format 3D printers currently available to buy now.

Best Large 500mm 3D Printer: Creality CR-10 S5 Plus 3D Printer | Buy Now Best Large 400mm 3D Printer: ANYCUBIC Chiron 3D Printer | Buy Now Best Large 3D Printer Under $1000: Creality Ender 5 Plus 3D Printer | Buy Now Best Industrial Large 3D Printer: Snapmaker 2.0 Modular 3-in-1 3D Printer | Buy Now Best Large 3D Printer under $500: SUNLU S8 3D Printer | Buy Now Best Cheap Large 3D Printer: LONGER LK1 3D Printer | Buy NowScroll down to see more on our top picks for the best large format 3D printer, according to many happy buyers.

*Prices listed in this article were as shown in US$ on Amazon. com (USA) and other online retailers as of February 2022

com (USA) and other online retailers as of February 2022

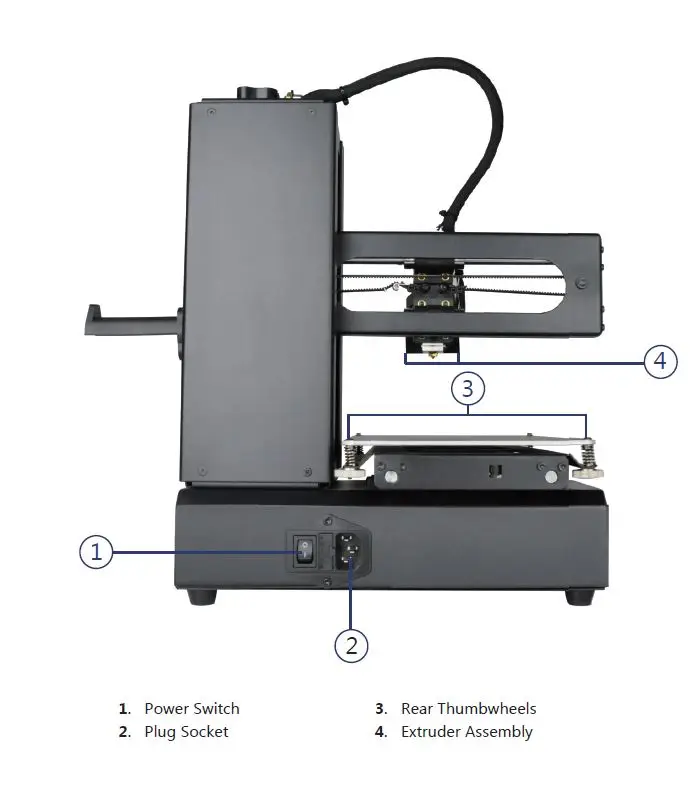

1. Best Large 500mm 3D Printer—Crealty Large 3D Printer 500x500x500mm

As one of the 3D printers with the largest printing beds currently available, the Creality CR-10 S5 3D printer has 500x500x500mm of printing space meaning you can really let your imagination run wild.

Installation is super quick and easy as the machine comes in three pre-assembled parts with clearly labeled wires and instructions. Other features include a resume-printing function in the event of loss of power, and you also get a one-year warranty from the manufacturer.

One buyer who gave this machine five stars helpfully mentioned that you need to have plenty of room to accommodate this huge printer, writing, "The main thing to consider is its sheer size. It requires over a yard, possibly a full meter of depth to move the build plate."

BUY NOW: US$719, Creality 3D2.

Best Large 400mm 3D Printer—ANYCUBIC 3D Printer 400x400x450mm

Best Large 400mm 3D Printer—ANYCUBIC 3D Printer 400x400x450mm A large-format 3D printer from a trusted brand, the ANYCUBIC Chiron is for anyone who doesn't mind spending some extra time and effort on leveling the bed or working out the settings.

Users have reported this as being rather tricky, but the trade-off is a great 400mm 3D printer with impressive capabilities, plus, a superb customer service department that helped with any and all issues pertaining to the printer, from setup to product completion. One fan wrote, "It took me a long time to dial in my settings and get high-quality prints but I was able to get the printer working and printing decent quality the same day I put it together."

Another happy user who has "completed more than 4,000 hours of printing" and "used many hundreds of rolls of filament," described, "The results I am getting are amazing even with some prints taking over 300 hours to complete. In fact, I have just started a seven-part 700-hour print which is going very well. "

"

3. Best Large 3D Printer Under $1000—Creality Ender 5 Plus 3D Printer 350x350x400mm

With pretty much the same capabilities as its equally highly-rated sister model, the Creality Ender 5 Pro, including an automatic bed leveling sensor, bed stabilizer, color touch screen, and easy assembly, the Ender 5 Plus has one major difference; its huge size which accommodates its large build plate.

This sturdy thing works straight out of the box, and in addition to great customer support, there is also a massive Creality community to quickly get any answers and assistance you may require.

"I have printed several large helmets with great results," one happy purchaser wrote, and another added, "I love having the bigger print bed for very big projects. There is some fine-tuning you will have to do but after that, you are ready to rock and roll."

BUY NOW: US$599 (Was US$649), Amazon4.

Best Industrial Large 3D Printer—Snapmaker 3-in-1 3D Printer 320x350x330mm

Best Industrial Large 3D Printer—Snapmaker 3-in-1 3D Printer 320x350x330mm For advanced hobbyists or pros who want to up their 3D printing game, the Snapmaker 2.0 will make a proud addition to your workspace and open up a world of 3D opportunity and creativity. In addition to its large printing capacity, it is fast, powerful, and also allows you to do much more than 3D printing, like engraving, cutting, and CNC carving.

At this price, it's a unit for those who are pretty serious about 3D printing, but for small businesses that rely on the craft, it will end up paying for itself in no time. One reviewer who bought this to enhance their graphic design business, wrote, "It's been a valuable asset so far. We are making our own business cards on metal which is super unique and our customers love the added services we can now offer."

Another happy buyer who raved about its versatility and build quality, added, "I have been making non-stop with this machine. .. [It] allows for the imagination to go absolutely wild with ideas!"

.. [It] allows for the imagination to go absolutely wild with ideas!"

5. Best Large 3D Printer under $500—SUNLU S8 3D Printer 310x310x400mm Upgraded

Another good printer with a large print bed, and a tiny price to boot, the upgraded SUNLO S8 only weighs around 26 pounds so is not as much of a task to move as some of the other large 3D printers.

At under US$300, you get many features like high stability, accurate printing, filament runout detection, a Z-axis dual linear rail, and simple assembly. There's also a resume printing function for power failures.

"This printer provides great value for the cost," one buyer explained. "Not only is the print size large enough to do just about anything you can think of, but at 310x310x400 it is the largest in its price class." Another happy customer wrote, "Awesome printer for the price. Can't beat it. It's open-source so it's super easy to add upgrades if you want. Huge build size."

Huge build size."

6. Best Cheap Large 3D Printer—LONGER LK1 3D Printer 300x300x400mm

With an even smaller price tag, the Longer LK1 3D printer is another option for those wanting to dabble in 3D printing but unsure whether to fork out the big bucks just yet.

It provides plenty of features to learn the art, and the customer service is helpful with any questions you may have. The leveling is not the best, but it is easy to assemble and users have been satisfied with the print quality.

"This is an awesome entry-level printer," one satisfied shopper explained. "I was pleasantly surprised, how easy it was to set up... If you're looking for bang for your buck and [to] familiarize yourself with 3D printing, then don't go wasting money on expensive printers; this one works great."

BUY NOW: US$270.39, WalmartThe Best Large Format 3D Printer—Summary

With one of the largest printing beds currently available for a non-industrial 3D printer, the Creality CR-10 S5 3D printer (US$719, Creality 3D) provides an impressive 500x500x500mm of printing space. The Anycubic Chiron (US$623.75, Amazon) is another large-format printer with impressive capabilities and has a superb customer service department too.

The Anycubic Chiron (US$623.75, Amazon) is another large-format printer with impressive capabilities and has a superb customer service department too.

We hope our review of the best large format 3D printer has been helpful. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

Other 3D Printing Articles- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

What manufacturers don't want you to know: The truth about 3D printer maximum print areas

One of the most fundamental decisions you can make when choosing a 3D printer is the size of the build area. While printer prices vary for many different reasons, it's pretty much a constant that the larger the build area, the more expensive the printer.

While printer prices vary for many different reasons, it's pretty much a constant that the larger the build area, the more expensive the printer.

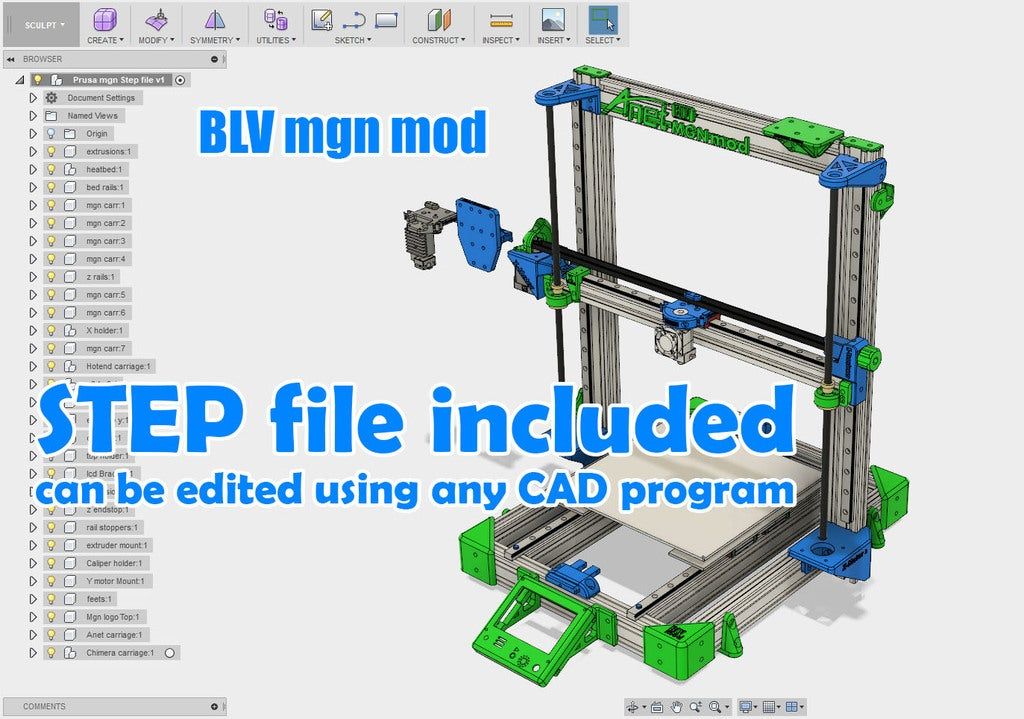

In this edition of DIY-IT's 3D Printing Discovery Series on ZDNet, we'll take a hard look at the different build areas available for different 3D printers and then I'll take you into the dark underbelly of the 3D printing world to show you what manufacturers don't want you to know: the truth about 3D printer build areas.

This was a much bigger and more complex project than I expected and it took a whole lot of filament to produce the build area samples used in my testing. So before I get started on the details, I'd like to shout out a thank you to the folks at ColorFabb for providing the filament used in these examples. I'd also like to shout out to MakerBot, Ultimaker, Lulzbot, Dreammaker, and New Matter for providing unrestricted access to their printers so I could perform these tests.

Put simply, when a manufacturer specifies a maximum print areas (also known as a build area), it's the maximum size of an object the printer can (theoretically) print. Technically, a 3D shape that's not equidistant on all sides isn't a cube, it's a cuboid or a convex polyhedron bounded by six quadrilateral faces.

Technically, a 3D shape that's not equidistant on all sides isn't a cube, it's a cuboid or a convex polyhedron bounded by six quadrilateral faces.

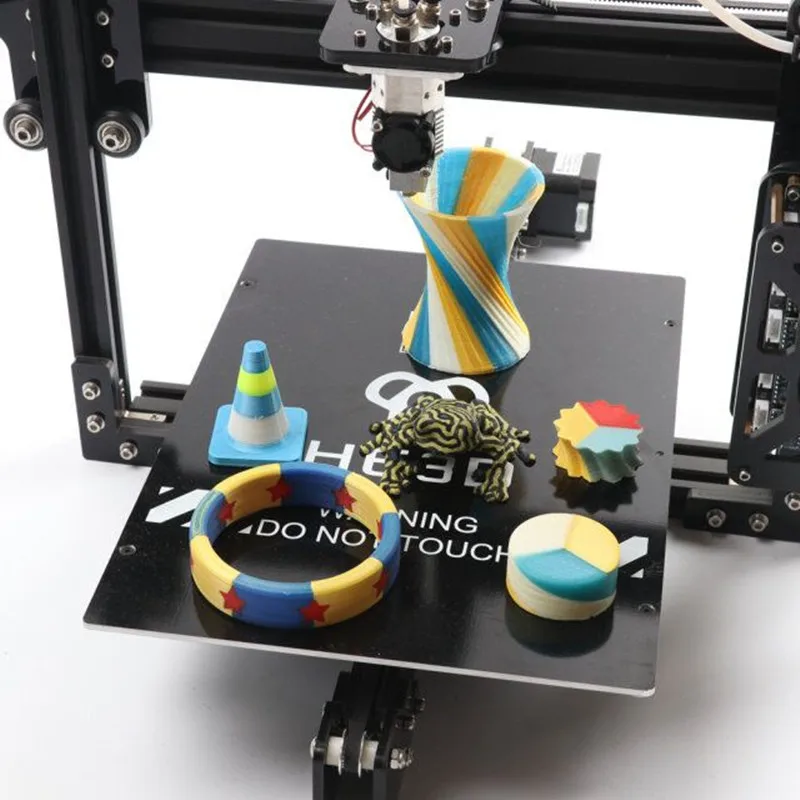

The accompanying video shows what the build areas look like for the five printers I have here in the shop. I designed and printed shapes that represent the maximum build areas for each of these printers. I've posted each of these on Thingiverse with links below, you can print your own sizing templates.

- MakerBot sizing template

- Ultimaker 3 sizing template

- LulzBot Mini sizing template

- Overlord Pro Plus sizing template

- New Matter MOD-t sizing template

Here they are in the printers. You can start to see how they relate to each other in size. From left to right, you're looking at the New Matter MOD-t (silver), the Dreammaker Overlord Pro Plus (blue), the LulzBot Mini (green), the Ultimaker 3 (white), and the MakerBot Replicator+ (red).

Image: David Gewirtz Another way to look at these is by stacking them together. In the video, you can really see how they differ in size when placed inside of each other.

In the video, you can really see how they differ in size when placed inside of each other.

Also, don't confuse what may look like available build area with actual, functional build area. For example, on the Overlord Pro, it looks like the model of the Vanderbilt Mansion would print. But if you compare the model with the actual buildable area, the mansion just won't fit. A mighty fine stack of three and half Yoda heads would easily fit in the Overlord's build area, but not the Vanderbilt Mansion. On the other hand, the mansion does easily fit in the build area of the Lulzbot.

As I alluded to at the beginning of this article, there's a lot about build areas that are misleading. Of the five vendors, not one specified a maximum print size that I was actually able to print.

On the MakerBot, the full cube I started to print began to disintegrate near the end, and I wasn't able to complete that print. On the Overlord, Cura wouldn't accept the dimensions specified on the Dreammaker site, except for the vertical Y-axis dimension. When I printed a test bar, the Overlord Pro wasn't able to actually meet that height and caused a very messy jam.

When I printed a test bar, the Overlord Pro wasn't able to actually meet that height and caused a very messy jam.

New Matter's slicer accepted a model for printing, but after two tries, you can see just how messy the results were. Once I reduced the model's size, it eventually printed. In the case of both the Lulzbot and the Ultimaker, Cura simply wouldn't accept a model sized for the maximum printable area described in the specs for each printer.

After a lot of test prints, here's what I found.

| Printer | Specified Width | Actual Width | Specified Depth | Actual Depth | Specified Height | Actual Height |

|---|---|---|---|---|---|---|

| MakerBot Replicator+ | 295 | 292 | 195 | 192 | 165 | 165 |

| Ultimaker 3 | 197 | 188 | 215 | 185 | 200 | 200 |

| LulzBot Mini | 152 | 152* | 152 | 152* | 158 | 158 |

| Dreammaker Overlord Pro Plus | 125 | 79 | 125 | 79 | 280 | 255 |

| New Matter MOD-t | 150 | 145 | 100 | 95 | 125 | 125 |

*There's a trick to making this work. See the article below.

See the article below.

On the MakerBot Replicator+, the specified maximum print size was 295 millimeters long by 195 millimeters deep by 165 millimeters high. Actual build area was 292 millimeters long by 192 millimeters deep by 165 millimeters high, so length and width were three millimeters smaller than specified.

On the Ultimaker 3, the specified maximum print size was 215 millimeters long by 215 millimeters deep by 200 millimeters high for a single extruder. This machine supports using two extruders at once. For a dual extruder setup, the specified maximum print size was 197 millimeters long by 215 millimeters deep by 200 millimeters high.

I tested with both extruders active, and my best results were 185 millimeters long by 188 millimeters deep by 200 millimeters high, so length and width were more than a centimeter smaller than specified, at least for a true rectangle. Ultimaker says that you can increase this a bit if you have longer areas in the middle, but you can't go all the way out in the corners. In any case, like the other vendors, the company didn't meet it's published spec.

In any case, like the other vendors, the company didn't meet it's published spec.

On the LulzBot Mini, the specified maximum print size was 152 millimeters long by 152 millimeters deep by 158 millimeters high. The actual max print area area allowed by Cura was 145 millimeters long by 145 millimeters deep by 158 millimeters high, so length and width were six millimeters smaller than specified.

UPDATE: The LulzBot folks reached out to me and described a trick (changing the Skirt Line Count in Cura) that lets it print to the full 152x152 spec. I tested it and it works. Here's a short video that shows how it's done. Very cool.

The Overlord is interesting, because the Delta architecture means it should print cylinders that have a large diameter than the length and width dimensions of a cuboid. That said, for consistency sake, I went with squared edges. Dreammaker specifies 125 millimeters long by 125 millimeters deep by 280 millimeters high. The width and height weren't even close, at 79 millimeters by 79 millimeters. Even though I'm using the taller Overlord Pro, this was the only printer that completely failed at its specified height. Instead of 280 millimeters, the best I got without making a mess was 255 millimeters. Essentially, the Overlord's maximum specified print area was about 25 percent more than reality.

The width and height weren't even close, at 79 millimeters by 79 millimeters. Even though I'm using the taller Overlord Pro, this was the only printer that completely failed at its specified height. Instead of 280 millimeters, the best I got without making a mess was 255 millimeters. Essentially, the Overlord's maximum specified print area was about 25 percent more than reality.

Finally, there's the New Matter MOD-t. Although the New Matter slicer accepted a print designed at its maximum print size of 150 millimeters long by 100 millimeters deep by 125 millimeters high, the results were a mess. I finally managed a print that was 145 millimeters long by 95 millimeters deep by 125 millimeters high, so the MOD-t lost about 5 millimeters off the X-and-Y axis.

What does it all mean?

So now that you've seen the results of my little study, what does it all mean?

My recommendation is that you do't freak out too much about the fact that the specified maximum build dimensions and the actual ones are slightly different. In most cases, the difference is a centimeter or less.

In most cases, the difference is a centimeter or less.

That said, if you're buying a 3D printer for a project that is tightly dependent on certain dimensions, you should make sure to factor into your decision the fact that the build area documented in the specs is lightly to be optimistic by about 5 or 10 percent. If you're particularly dependent on an exact size, ask the vendor to print a part sample to see what the machine will produce.

Beyond that, if you're in the market for a new 3D printer, think carefully about how much build area you really need. Since build area is one of the most fundamental drivers in printer price, you save money and get a lot more capabilities in a printer if you're willing to sacrifice some build area. Conversely, if you need to print larger objects, you'll definitely need to be aware that size does matter when it comes to your buying budget.

You can follow my day-to-day project updates on social media. Be sure to follow me on Twitter at @DavidGewirtz, on Facebook at Facebook. com/DavidGewirtz, on Instagram at Instagram.com/DavidGewirtz, and on YouTube at YouTube.com/DavidGewirtzTV.

com/DavidGewirtz, on Instagram at Instagram.com/DavidGewirtz, and on YouTube at YouTube.com/DavidGewirtzTV.

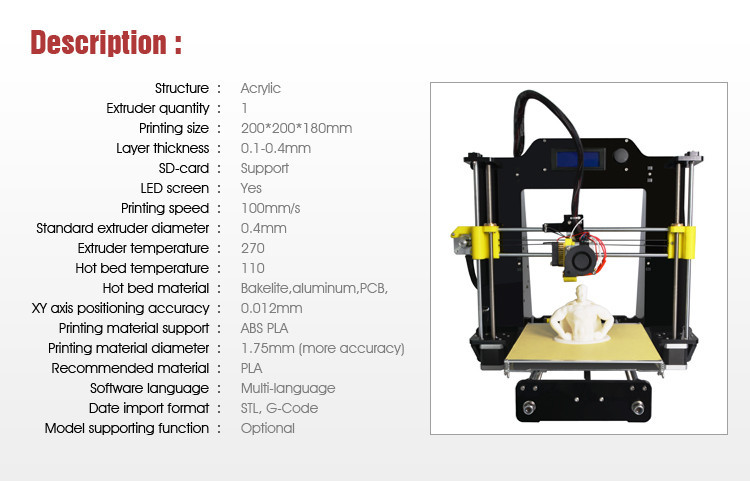

How to choose the nozzle size for a 3D printer? Pros and cons

3DPrintStory 3D printing process How to choose nozzle size for 3D printer? Advantages and disadvantages

When choosing your 3D printer, the nozzle size of your 3D printer may have been the last thing on your mind. This is a detail that is often overlooked. But depending on what you need to print, the wrong nozzle diameter can get in the way. nine0005

In this article, we'll take a look at the different 3D printer nozzle sizes and why you should consider this assembly, what materials it's made from, understand the relationship between nozzle size and layer height, and how to measure the actual nozzle diameter.

How does nozzle size affect 3D printing?

Nozzle diameter affects the extrusion width of the 3D printer line. This affects some elements of your model. If you are 3D printing for business (make a lot of orders), you need to make sure your extruder is feeding the right amount of material. If too much material is fed, then more filament is used than is actually required for successful 3D printing. Well, a smaller number can simply lead to marriage. nine0005

Or maybe you're printing different designs, some of them very detailed and intricate, and some more practical (like a replacement doorknob) that just needs to be printed quickly and with maximum durability.

In any case, you will need the correct setting to save time, material and ensure the normal quality of the 3D model.

There is no easy answer to what is the best nozzle size for a 3D printer. You need to weigh what you want to achieve and what elements of the 3D model are most important to you. nine0005

nine0005

Depending on your 3D printer, the nozzle can be quite easily replaced (most of them are mounted on screws), and buying a package with different sizes will cost you a lot.

Most common 3D printer nozzle options

The most common standard nozzle size is the 0.4mm (or 0.35mm) nozzle used by most modern 3D printer manufacturers. The reason for this is that it is a rather large and yet versatile nozzle size. This means that you can print with exceptional detail in no time. nine0005

With the 0.4 mm 3D printing nozzle you can print up to a layer thickness of only 0.1 mm or up to 0.3 mm. The lower the layer height, the better the detail (on the Z axis) and the larger the layer height, the faster your 3D print will be, but with worse detail quality.

A common misconception is that if someone doesn't get good enough 3D print quality on their printer with a 0.4mm nozzle, they immediately think they need a smaller 3D print nozzle.

Another common smaller size is 0. 25 mm. Some 3D printers offer 0.2mm, 0.15mm, and Mass Portal is even experimenting with 0.1mm 3D printer nozzles. And the experiments are really interesting. Thanks to this miniature nozzle, they were able to print the clock mechanism with excellent detail. nine0005

25 mm. Some 3D printers offer 0.2mm, 0.15mm, and Mass Portal is even experimenting with 0.1mm 3D printer nozzles. And the experiments are really interesting. Thanks to this miniature nozzle, they were able to print the clock mechanism with excellent detail. nine0005

How is nozzle diameter related to 3D printer resolution?

Theoretically, smaller 3D printer nozzles allow for greater precision. But for many 3D printers, especially cheaper or older models, a smaller extruder nozzle won't necessarily make a difference if your printer doesn't support the higher resolution you need. It's like putting low-profile, high-performance tires on an old classic car - it doesn't make it go faster, and it doesn't necessarily make it better cornering. nine0005

This is also similar to how the specifications of a 3D printer on paper (eg advertised resolution) do not always result in the best print quality of the finished product. Just like Ultimaker and Zortrax have very similar resolutions on paper, but in many actual tests, Zortrax produces better models than Ultimaker 2.

smaller nozzles as resolution across the board is getting better every day. nine0005

Let's look at the pros and cons of 3D printing with smaller nozzles. Some are less obvious than others. Next, we'll look at the larger, underpriced nozzles available. I hope after reading this article you will be able to answer the question: "What nozzle size should I print?".

You probably already guessed that the smaller the nozzle size in the extruder, the more detailed model you can get as a result of 3D printing. The thin nozzle is great for complex figures, or if you need to print very thin walls for aircraft skins, or high transparency models, etc. nine0005

The photo below shows the printed skin of a model aircraft, which was made with a standard 0.4 mm diameter nozzle. If the same skin is printed with a nozzle with a diameter of 0.2 mm, then the weight (and strength) would be halved.

It is worth noting that a 3D printer with a 0.2 mm nozzle feeds half as much material as a 0. 4 mm nozzle. And this actually leads to an increase in print time by the same two times. It should be noted that strength and detail are reciprocals of time. So to get high-quality 3D models using a thin nozzle and high resolution, you will have to be patient (2 times more than when printing with a standard 0.4 extruder :)). In some cases this is justified, in others it is a waste of time...

As a general rule, the smaller the nozzle size, the higher the chance of problems with the 3D printer. Especially if you are using cheap materials - they can work well with low models and thicker nozzles, but if you need detailed models that are printed using a thin nozzle, then you should also be puzzled by buying quality filaments for 3D printing.

Other factors are less obvious when 3D printing with a thin diameter nozzle - for example, protrusions can be problematic. This is because each layer has a smaller width for the next layer. Crossing bridges can also be difficult. nine0005

But there is good news too! Where overhangs form, the caliper material will be much easier to remove if printed with a thin nozzle. Due to the increased accuracy, your slicer can use a minimum amount of material between your model and supports, so they will break off more easily and have fewer damaged pads that need to be sanded.

Due to the increased accuracy, your slicer can use a minimum amount of material between your model and supports, so they will break off more easily and have fewer damaged pads that need to be sanded.

And finally, the most annoying thing about a thin nozzle is the ease with which it clogs. If you downsize to 0.2mm or even 0.1mm, you'll need a small particle to clog the hotend. You need to be very careful about the cleanliness of your 3D printing material and regularly clean the nozzle of your 3D printer. Otherwise, you will not end up with additional unnecessary problems. nine0005

It is also worth taking the time to understand the relationship between nozzle size and layer thickness. In short, the first parameter determines the horizontal detail (along the x and y axes), and the second adjusts the resolution along the vertical or z axis.

How to measure the nozzle size of a 3D printer?

Although the actual nozzle diameter should be engraved on the side of the nozzle, it is not always possible to read this value if it is already installed in the extruder or if you have been printing with it for some time. After all, there is the concept of wear and you may not be sure that the nozzle is the same size as before. nine0005

After all, there is the concept of wear and you may not be sure that the nozzle is the same size as before. nine0005

To determine what size your nozzle really is, very slowly extrude some material into the air (high speed may change shape or size) at the lowest setting you can feed material at (approximately 1 mm/s). Once cool, use a micrometer if you have one. They are generally more accurate than digital calipers. Keep in mind that the filament will probably expand after being extruded. Poor quality material or an extruder that is too hot (especially if you extrude at 1mm/s) will cause the material to expand more, resulting in inaccurate readings. nine0005

It can also be useful to know the size to which your material expands after extrusion if you are working on getting a really nice and accurate model. So feel free to experiment with higher speeds that are a bit more like your actual 3D printing.

What is the relationship between 3D print layer height and nozzle diameter?

In simple terms, this is the thickness of each line of extruded material that makes up each layer of your model. The thinner the layer height (or layer thickness), the finer the print detail in the Z-axis (the vertical dimension of your model), but the more layers will be required. Increases print time. nine0005

The thinner the layer height (or layer thickness), the finer the print detail in the Z-axis (the vertical dimension of your model), but the more layers will be required. Increases print time. nine0005

These characteristics are related, but not completely. For example, you can print using a thinner, thicker nozzle if vertical resolution is less important to you. Or you can use a thicker nozzle with a very small layer height. Although in this case, do not get too carried away. To maintain adequate pressure, your layer height should be at least 20% less than your nozzle width - and in most cases, for best 3D printing results, it should be around 50%. nine0005

How to determine the correct distance from the nozzle to the desktop of a 3D printer?

With the correct setting of the distance between the table and the nozzle, the base of the finished model should have an almost perfectly smooth, glassy surface. Many people assume that you need to use a stylus to properly set the distance between the nozzle and the 3D printer bed, but in fact, even that can be too thick. So it's worth thinking in the direction of the already proven table calibration with a piece of paper. You should use thin paper. For example, check paper is a great choice. Place the receipt paper under the nozzle and gradually lower the nozzle down until the receipt paper resists a little when you try to push it out. 3D printing at this height will give the bottom of the model a great look, and in the case of tall models, the print will definitely not go astray. nine0005

So it's worth thinking in the direction of the already proven table calibration with a piece of paper. You should use thin paper. For example, check paper is a great choice. Place the receipt paper under the nozzle and gradually lower the nozzle down until the receipt paper resists a little when you try to push it out. 3D printing at this height will give the bottom of the model a great look, and in the case of tall models, the print will definitely not go astray. nine0005

What is the maximum 3D print layer height compared to the nozzle size?

You don't necessarily need a layer height calculator on your 3D printer, but typically the maximum layer height is 50% of the nozzle width. In some cases, you can go higher (perhaps 75%), but in this case, you must be aware that you can sacrifice reliability.

It's best to experiment with the parameters of your model if you understand the relationship between the 3D printer's nozzle size and the layer height you'll be using to print. So for a 0.4mm nozzle, you will need to print with a layer height of 0.2mm, or up to 0.3mm. Your minimum should be around 0.1mm. If less, then in fact you just increase the waiting time without much benefit (on the same 0.4 mm nozzle). nine0005

So for a 0.4mm nozzle, you will need to print with a layer height of 0.2mm, or up to 0.3mm. Your minimum should be around 0.1mm. If less, then in fact you just increase the waiting time without much benefit (on the same 0.4 mm nozzle). nine0005

In most cases, it is worth printing thinner layers with smaller nozzle diameters and generally thicker layers with thicker nozzles. Just note that if you are printing with a thicker nozzle diameter and very thin layer height, you will need to lower the extrusion settings in your slicer to prevent overfeeding.

It's also worth noting that no matter the size, you should always make sure you always have a clean nozzle. One of the easiest ways to do this is to use a high quality cleaning floss. You only need to use a few grams of it each time you brush, but this will prevent carbon buildup over time. nine0005

So why should I use a 0.8mm nozzle or thicker?

Similar nozzle sizes were more common on older 3D printers but are making a comeback. It's all about using what you need and nothing more. For a large number of models, the 0.4mm headroom that your 3D printer probably comes with may be overkill in terms of detail.

It's all about using what you need and nothing more. For a large number of models, the 0.4mm headroom that your 3D printer probably comes with may be overkill in terms of detail.

If you need strength and speed, but detail is less important, then you should use a 0.8 mm or even 1.0 mm nozzle. And don't forget that models printed with a 0.8mm nozzle can be very detailed, as a lot depends on your 3D printer as well. nine0005

The only slight disadvantage may be that you use more material, but with thicker part walls you can probably compensate with less infill.

There is no single optimal nozzle size for all models, you just need to take all factors into account and decide which nozzle size is best for you.

What nozzle size should I use for composite materials?

It is worth noting that composite materials (any particulate filament such as wood filler, copper filler, carbon fiber nylon or glass reinforced nylon) will cause extrusion problems when using a thinner nozzle. nine0005

nine0005

This is because these filaments contain particles which, although nanosized, can cause problems when passing through nozzles smaller than 0.4 mm. For composite materials, it is better to use nozzles of at least 0.5 mm, and for any metal, glass or carbon fiber materials, you will need a hardened nozzle. The brass nozzle that comes with your 3D printer will most likely not last long and will increase in diameter after a few hours of printing.

A 0.5 mm stainless steel or tungsten nozzle will last much longer for composite materials, but will, of course, be more expensive.

So, if you're still wondering "What size extruder nozzle to choose?", here are the results for a nozzle with a diameter smaller than the standard 0.4 mm:

- worth using for small detailed models if your 3D printer supports high resolution;

- 3D printing can take significantly longer, thicker nozzles can significantly reduce print time; nine0005

- overhangs are more difficult to print, but supports break off more easily;

- you need material from a quality proven manufacturer, otherwise the nozzle can easily become clogged.

3D printer print size - 1.2 x 1.5 x 1.8 m. by Sprint 3D.

Rapid prototyping of large-scale art products

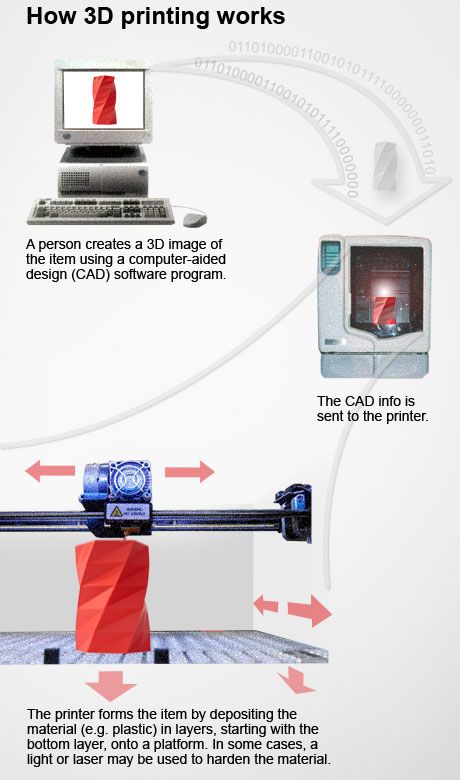

In the minds of many contemporaries, 3D printing is a technology capable of creating extremely small objects - spare parts, souvenirs, various kinds of models, and so on. Moreover, many believe that it takes many hours. In the meantime, a whole car has already been created through 3D printing. And it didn't take weeks. Let's consider which print size 3 D printer is possible today and what speed 3 D print is currently achieved. But first, a few words about prototyping.

Rapid prototyping of 3D models is a process of rapid creation of mock-ups of models (prototypes), which will later be used to improve and finalize design solutions. In some cases, such prototypes can also be used as finished products. nine0005

Satellite 3D Printer 500x500x800 cm

The Capabilities of Modern 3D Printers

3D printing equipment has made a huge leap forward in recent years. One of the brightest representatives of the new generation of printers for rapid prototyping of dimensional art products is the 3D printers that we use in our work.

One of the brightest representatives of the new generation of printers for rapid prototyping of dimensional art products is the 3D printers that we use in our work.

Main equipment features:

- Working area - up to 1.2 x 1.5 x 1.8 m.

How do you achieve high print speeds and the ability to produce large items? First of all, due to the use of special photopolymer gel compositions with a high degree of viscosity, as well as due to the rationalization of the placement of supporting structures. The so-called GDP-technology (Gel Dispensed Printing) is used. It is based on the use of liquid light-sensitive compounds that quickly harden under the influence of ultraviolet lamps. Those are located directly above the print heads and act directly on the material. This system ensures fast curing. nine0005

Due to the fact that the GDP technology cures faster than other technologies, it is not necessary to use supports for horizontal surfaces. Obviously this saves time. And at the same time, the materials of production.

Obviously this saves time. And at the same time, the materials of production.

We also note that 3D printer models and some analogues use two print heads that work independently of each other. This allows you to create two objects at the same time in one workspace or separate components of one large product. Accordingly, print size 3 D of printer in this case, when gluing, it increases at least twice and can exceed 3 meters.

Large-scale 3D printing: how much more difficult it is than small-sized

If in older models of printers there could be cases when the material clogged the nozzle and the work done simply went down the drain, then modern equipment is devoid of such shortcomings. You don’t have to worry that something will go wrong in the many hours of printing and you will have to redo everything from the beginning, wasting time and a lot of resources. nine0005

Separately, we note the simplicity of the post-processing process. After hardening, the gel lends itself perfectly to a wide variety of processing. It is perfectly painted and varnished, which opens up the widest possibilities for creating a wide variety of dimensional objects: stands, product models, models of equipment and much more. Everything is fast, convenient and at the same time quite inexpensive. The printing process itself and finished products meet the requirements of environmental friendliness and safety of use. During production, no harmful and dangerous substances are emitted, and the printed products fully comply with modern environmental standards and are hypoallergenic. This is a particularly important factor at the present time. nine0005

After hardening, the gel lends itself perfectly to a wide variety of processing. It is perfectly painted and varnished, which opens up the widest possibilities for creating a wide variety of dimensional objects: stands, product models, models of equipment and much more. Everything is fast, convenient and at the same time quite inexpensive. The printing process itself and finished products meet the requirements of environmental friendliness and safety of use. During production, no harmful and dangerous substances are emitted, and the printed products fully comply with modern environmental standards and are hypoallergenic. This is a particularly important factor at the present time. nine0005

How does 3D prototyping work? A physical structure is built according to a previously prepared mathematical model.

The advantages of prototyping are obvious:

1. Visibility of the whole process;

2. Minimization of the time required for preparation of production;

3.

Reduce engineering and design costs. nine0129

Reduce engineering and design costs. nine0129

The first step in prototyping is mathematical modeling, which creates a mathematical model in STL format. After that, prototypes are finalized to create the necessary surface textures. Prototyping also includes the development of technologies, the production of specific models and their finishing. Everything is almost identical to small-sized printing, although products are made with many times larger sizes.

Advantages of rapid prototyping in large-scale printing:

- Accurate and fast verification of the conformity, function and form of the printed design.

- Extensive design flexibility and versatility with the ability to quickly transition between different stages of production.

- Increased speed 3 D printing and no waste of materials that are already used in large quantities.

- The ability to quickly test the properties of specific products in order to further develop new materials and at the same time obtain new properties of finished products.

Learn more