3D printer graphics

Uses of 3D printing in graphic design and visual communication -

3D printing involves making things – 3 dimensional objects – which is generally not what most people think graphic designers do. However, graphic designers have actually been designing 3D objects since the early days of visual communication – from books and brochures through to signs, packaging, merchandise, folders, cards and advertising hoardings. The question is, will 3D printing have a role to play in visual communication? Will it change the solutions we design, or the way we design them?

Collaboration across design disciplines

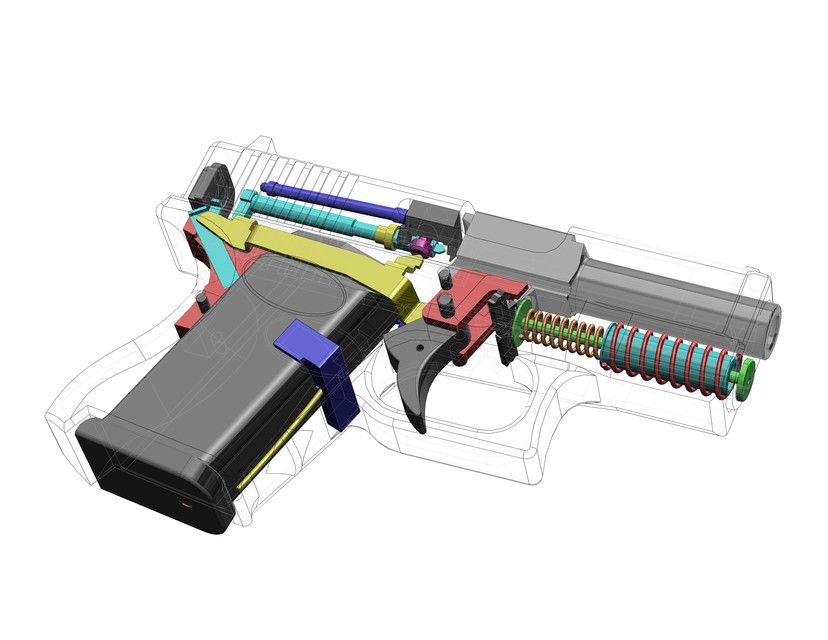

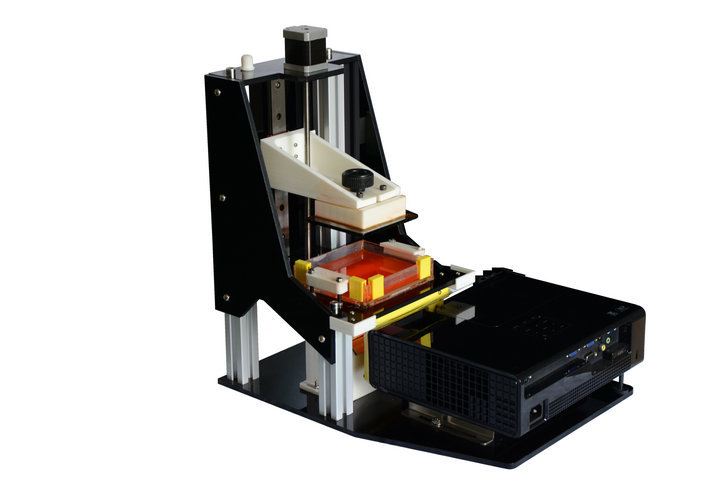

Most current applications of 3D printing involve making parts or prototypes for everything from consumer products to medical prosthetics, architecture and machinery. Forbes’ article The State of 3D Printing, 2018 quotes research by Sculpteo that says the most popular applications of 3D printing are prototyping, production and proof of concept models. Graphic designers often work with product designers, architects and business clients, so to collaborate effectively they need to keep up with industry developments in 3D printing and related technologies.

3D topographic maps

Topographic model of Wilpena Pound, South Australia Topography and Bathymetry of New Zealand Topgraphic model of Yosemite National Park, USAThe examples above are from Thingiverse, which has thousands of 3D designs uploaded by users. The topographic map of Yosemite was generated via the handy Terrain2STL tool.

Information design and data visualisation

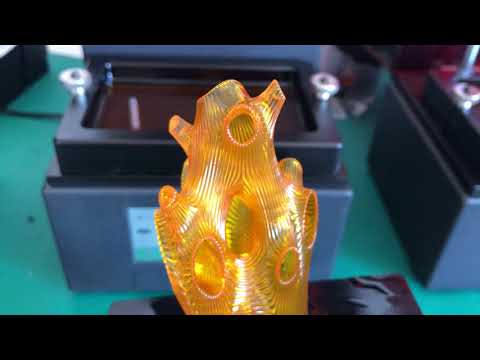

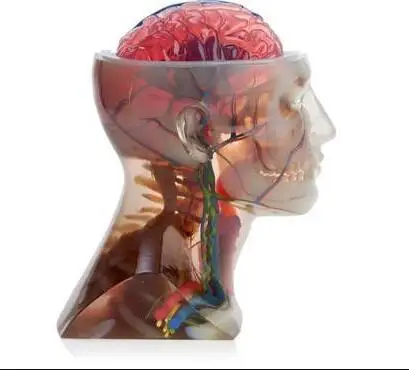

Complex data means nothing unless you can understand it! ‘Big data’ can sometimes be made more understandable using 3D modelling. The article How 3-D Printing is Revolutionizing the Display of Big Data explains how a translucent 3D-printed model is combined with coloured lights to enhance meaning and convey information.

3D printed model to explain a maths concept 3D flight map graphic 3D campus model with lighting

Typography

Complete typefaces are being developed for 3D, just as they are for print and screen use.

Business cards

Packaging

3D printing can be used to create prototype or small run packaging designs, and enables more complex shapes than some alternative methods.

Packaging prototypes Packaging prototypes Packaging productionThe above examples are just a few of the areas of visual communication where 3D printing is being used. Some other areas include signage, branding and education. As the technology develops, 3D printing is likely to be used in ways we can’t yet anticipate, especially if it reaches widespread use in the home and a wider range of materials (particularly eco-friendly materials) are available for everyday use.

<< back to Enhanced Design Tools index

500+ 3D Printing Pictures [HD]

500+ 3D Printing Pictures [HD] | Download Free Images on Unsplash- A framed photoPhotos 7.

2k

2k - A stack of photosCollections 10k

- A group of peopleUsers 6

3d printer

machine

person

electronic

computer

technology

keyboard

hardware

computer keyboard

computer hardware

Hd modern wallpapersmenequipment

seoul대한민국factory

berlintechnologyprusa mini

Hd computer wallpapersemployment and laborukraine

orthoticscast

barcelonaespanyaarchitecture

oldenburgdeutschlandwork in progress

3d printerchessfilament

Hd 3d wallpapersdigital imagerender

germanymakersprusa

–––– –––– –––– – –––– – –––– –– – –– –––– – – –– ––– –– –––– – –.

englanduknophead

laserwood engravinglaser cutter

cnc millingstem3d print

swedenmalmöplastic

Hd design wallpapersadditive manufactureengineering

orthopedicscustom-madewellbeing

Hd grey wallpapersbracecasts

machinemachiningprototyping

orthosesultimakerneck

Related collections

3D Printing

9 photos · Curated by Marc Hartkopf3D printing

12 photos · Curated by Gaëlle Dufour3D Printing

7 photos · Curated by Sonja Perduefrancetoulouseadditive manufacturing

Hd modern wallpapersmenequipment

berlintechnologyprusa mini

swedenmalmöplastic

barcelonaespanyaarchitecture

Hd grey wallpapersbracecasts

orthosesultimakerneck

englanduknophead

cnc millingstem3d print

orthoticscast

orthopedicscustom-madewellbeing

3d printerchessfilament

machinemachiningprototyping

francetoulouseadditive manufacturing

–––– –––– –––– – –––– – –––– –– – –– –––– – – –– ––– –– –––– – –.

seoul대한민국factory

laserwood engravinglaser cutter

Hd computer wallpapersemployment and laborukraine

Hd design wallpapersadditive manufactureengineering

Related collections

3D Printing

9 photos · Curated by Marc Hartkopf3D printing

12 photos · Curated by Gaëlle Dufour3D Printing

7 photos · Curated by Sonja Perdueoldenburgdeutschlandwork in progress

Hd 3d wallpapersdigital imagerender

germanymakersprusa

Unsplash logoUnsplash+

In collaboration with Getty Images

Unsplash+

Unlock

Hd modern wallpapersmenequipment

Gavin Allanwood

englanduknophead

–––– –––– –––– – –––– – –––– –– – –– –––– – – –– ––– –– –––– – –.

Minku Kang

seoul대한민국factory

Opt Lasers

laserwood engravinglaser cutter

Kadir Celep

berlintechnologyprusa mini

ZMorph All-in-One 3D Printers

cnc millingstem3d print

Unsplash logoUnsplash+

In collaboration with Getty Images

Unsplash+

Unlock

Hd computer wallpapersemployment and laborukraine

Karl Hörnfeldt

swedenmalmöplastic

Tom Claes

orthoticscast

Rob Wingate

Hd design wallpapersadditive manufactureengineering

Andrea G

barcelonaespanyaarchitecture

Tom Claes

orthopedicscustom-madewellbeing

NEW DATA SERVICES

oldenburgdeutschlandwork in progress

Tom Claes

Hd grey wallpapersbracecasts

Osman Talha Dikyar

3d printerchessfilament

SIMON LEE

Hd 3d wallpapersdigital imagerender

ZMorph All-in-One 3D Printers

machinemachiningprototyping

Kadir Celep

germanymakersprusa

Tom Claes

orthosesultimakerneck

eMotion Tech

francetoulouseadditive manufacturing

Browse premium images on iStock | 20% off at iStock

Unsplash logoMake something awesome

3D Modeling Basics for 3D Printing / Habr

KolianM

Working with 3D graphics *Prototyping *DIY or DIY 3D printers

casting or milling. This is due to the technical features of the 3D printer, from which you need to either squeeze the maximum benefit, or adjust to the disadvantages of printing.

From the reservations, I note that these recommendations relate mainly to the FDM (FFF) 3D printing method, in which a plastic rod is heated by a moving extruder that forms the part layer by layer.

3D model development starts with a sketch. It can be a drawing on paper, a material prototype, a mental image, etc. What is important to pay attention to when creating such a sketch and the model itself, we will analyze in detail.

Part strength

Here and further down the text there are several sub-points that must be taken into account at the same time, kept in mind from the very beginning. nine0005

nine0005

- Be aware of the layering or anisotropy of the material: it is much easier to break a part in layers than across. This must be taken into account in advance, given the location of the 3D model on the 3D printer table.

- Add fillets. The leg of the stool and the tabletop at the junction should have a rounded corner. At the same time, the larger the radius of curvature, the stronger the leg will be fixed on the table top. Similarly for various body parts. Modeling a box All right angles are rounded. It doesn't matter what plane they are in. Even where a right angle is needed, we make a radius of 0.5 mm. The printer will pass through such a section more easily than an unrounded one, there will be no impact from a sharp stop of the extruder, the part will not sway, and other pluses. nine0013

- Wall thickness and filling. The maximum strength at 100% infill is a fact, but if you need to lighten the part or save plastic, you can make a much larger wall thickness in the print settings, while setting the infill much lower.

This works with parts that have holes for fasteners. When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

This works with parts that have holes for fasteners. When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

- Support. This element affects the strength in that the layers supported by the support are not always ideal in structure. This can be solved by increasing the wall thickness, filling, but it is better not to do support at all. Support is added by the slicer depending on the angle between the part wall and the table plane. Often the default is 60 degrees, sometimes 45. This setting is selected experimentally for each 3D printer. You can check this with the help of special test parts. For example, https://www.thingiverse.com/thing:2806295 - do not forget to turn off support to check the real quality of 3D printing in its absence. For example, you need to print a T-piece for tubes. Cast products are made in a T-shape. 3D printing makes the product L or even Λ-shaped.

In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes. We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print. nine0013

In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes. We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print. nine0013

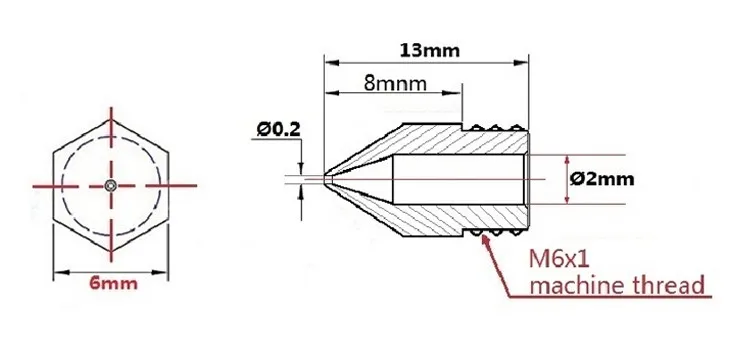

Geometric restrictions

- The wall thickness is limited from below by the size of the 3D printer nozzle. Its diameter is constant and in the vast majority of cases it is 0.4 mm. Smaller thickness - long 3D printing for most parts. The larger the nozzle, the bonds between the layers are less strong, the steps between the layers are more visible. And in general, the wall thickness should be a multiple of 0.4 mm, then the 3D printer will be able to accurately make the wall in two passes (0.8 mm), in 3 passes (1.2 mm), etc. Other thicknesses will cause the 3D printer to leave a gap or overflow, which negatively affects the strength and appearance of the printed part.

nine0013

nine0013

- 3D printing of thin cylinders and "needles". For 3D printing of such products, special 3D printer settings are needed: low 3D printing speed, allow time for cooling, otherwise such a structure will bend. Vertically standing thin elements are best avoided at all costs. Even if they are printed, they will be very fragile. It makes sense to leave them only for decorative purposes, but you must be prepared that their quality will be worse than the quality of other elements of the 3D part.

- 3D printed holes. I note that if the hole is straight and through, then it can be drilled, if it is curved and requires support, then it may turn out that it will be impossible to get support.

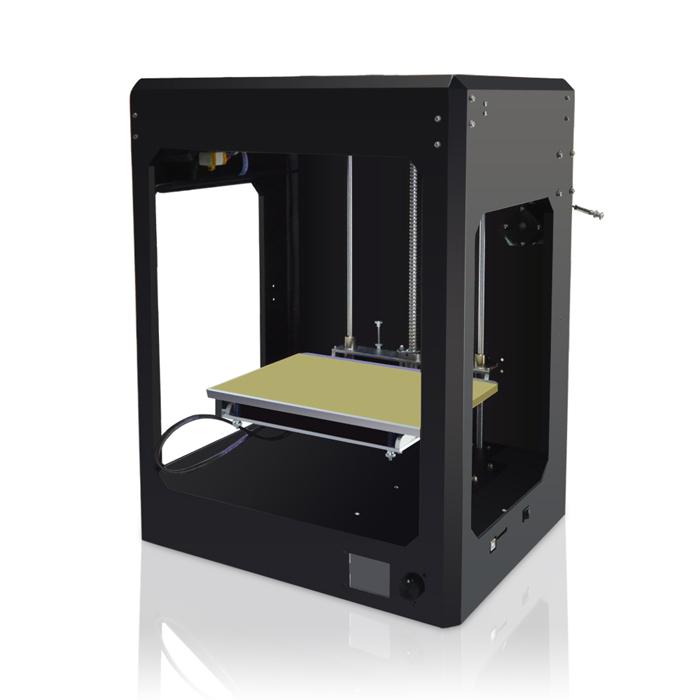

- When 3D modeling, it is important to consider the overall dimensions of the 3D printer. We use convenient 3D printers, table 250x250 mm, diagonal 353 mm. This is where you need to enter the dimensions, if possible. Otherwise, you need to order either an industrial 3D printer with a large print area, or use gluing, but assembly is better, so the assembly process will be controlled by the developer, and not by the 3D printing master.

nine0013

nine0013

- Large footprint may cause edges to peel off the table. We use special glue, but this does not always help. We are periodically approached with a complaint about colleagues in the shop that for them such “minor” defects as a folded edge are not a reason to restart 3D printing, take it as it is. But an engineer who 3D models a part can take this into account in his work and make either assemblies or thin-walled flat 3D parts that “do not have enough strength” to compress the outer contour and, as a result, raise the edge. nine0013

- Tall and thin "towers" may not work well due to vibrations that occur when the 3D printer is running closer to the top, and layer shifts are also possible.

Dimensional stability, accuracy

- Precise 3D printing is quite rare. I don’t want to speak in engineering terms here, but the likelihood that a complex composite structure will assemble the first time is very low.

Here, rather, you need to take into account the fact that you can then mechanically refine the details. nine0013

- Holes for fasteners are best done with a margin of 0.5 mm in diameter. This will not reduce strength, the fasteners will also not dangle due to tightening forces, but if you do it without a margin, you will definitely have to drill it out. Reducing the size of a large shaft, >10mm sandpaper is much easier than making a hole, which requires a huge drill that cuts into the plastic walls and breaks the part, or gets stuck in it. It is also important to consider that when drilling, the plastic melts and the drill can melt into it so that it cannot be removed. There have been cases. nine0013

- Heat shrinkage is not always compensated, more precisely, it is very difficult to catch it, it is not the same in different directions, so it is extremely difficult to take it into account. It's easier to print a test version, and then make adjustments.

When appearance matters

- Think about how the craftsman will orient the part on the 3D printer table.

3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table. Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing. nine0013

3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table. Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing. nine0013

- Support. First, the surface it supports has significantly more defects than without it. Secondly, thin and high support is weak, wobbly, which leads to the fact that the supporting part may have serious defects, or not work at all.

- First layer quality improvement. You need to add a bevel. Even where a sharp corner is not needed, I recommend adding a chamfer of 0.5 mm. It will not be clearly visible, but the edge will be neat. nine0013

What you need to know in order not to make a mistake when ordering 3D printing

If appearance is important

- Placement of the part on the table.

Remember about anisotropy.

Remember about anisotropy.

- Wall thickness and filling. What you can run into here: the filling is 20% cells, which are either visible through a thin outer wall, or the filling slightly tightens the outer wall during shrinkage, but at the same time it is visually easy to determine that there is support inside. Here, first of all, an increase in the thickness of the outer wall, or an increase in the filling density, helps. Please take this into account when ordering. nine0013

Postprocessing

The elimination of stepping is achieved by mechanical and chemical methods. It is possible to use putty. Acrylic paint available. If the part has a complex color structure, then we use the ProJet 4500 printer, which works on a different technology. He glues the powder particles together with colored ink glue. It turns out well.

Morality

In conclusion, I would like to note that these recommendations and the accumulated experience will make it possible to produce parts by 3D printing, which in their properties will not be inferior to cast ones, which makes it possible to save significant funds in the presence of a customized printer and small production volumes. From my own experience, I note that fiddling with the printer, debugging it, knowing “all the cracks” is a separate topic, which I will talk about later. And in conclusion, I would like to ask the reader to express their opinion in the survey. nine0005

From my own experience, I note that fiddling with the printer, debugging it, knowing “all the cracks” is a separate topic, which I will talk about later. And in conclusion, I would like to ask the reader to express their opinion in the survey. nine0005

Only registered users can participate in the survey. Come in, please.

Do I need to buy a 3D printer, or should I outsource it?

66.67% It is better to control everything yourself, modeling and printing 60

21.11% I model, and let those who live it print 19

10% I prefer designing and printing to narrow-profile specialists 9

14.44% I don't believe in 3D printing, I try to avoid it altogether 13

90 users voted. 24 users abstained.

Tags:

- 3D-modeling

- 3D -ip

Habs:

- Work with 3D graphics

- Prototyping

- 3D prinches

- DIY or do

The use of a 3D printer in mechanical engineering and robotics

The use of a 3D printer in mechanical engineering and robotics Yeltsova Ekaterina Evgenievna

Stavropol State Pedagogical Institute

Abstract

This article is devoted to the study of the use of three-dimensional graphics, its application and printing on a 3D printer. We study the tasks, methods and necessity of using a 3D printer in mechanical engineering and robotics.

Keywords: 3D printer, graphics, mechanical engineering, robotics, three-dimensional graphics, three-dimensional printing 3D graphics. The use of a 3D printer in mechanical engineering and robotics // Modern scientific research and innovation. 2022. No. 7 [Electronic resource]. URL: https://web.snauka.ru/issues/2022/07/98644 (date of access: 12/18/2022).

Since the beginning of the new millennium, the concept of "3D" has firmly entered our daily lives. First of all, when we talk about it, we remember cinematography, photography or animation. But there is hardly a person now who has not heard about 3D printing at least once in his life. Nowadays, concepts such as 3D printing and 3D graphics cannot be imagined without each other [1]. But what new, interesting, and most importantly, useful has such a novelty brought and can bring to mankind? nine0005

But there is hardly a person now who has not heard about 3D printing at least once in his life. Nowadays, concepts such as 3D printing and 3D graphics cannot be imagined without each other [1]. But what new, interesting, and most importantly, useful has such a novelty brought and can bring to mankind? nine0005

Three-dimensional or 3D graphics - a section of computer graphics, a set of techniques and tools (both software and hardware) designed to ensure the spatio-temporal continuity of the resulting images. The process of creating a three-dimensional model includes three main steps:

Modeling - creating a model from nothing, using geometric shapes, setting dimensions, textures and lighting settings.

Rendering (Russian "visualization") - making the model look nice to the eye: rounding corners, displaying light and textures. nine0005

Model output. Print or monitor.

Advanced technologies do not stand still, scientists invent new technologies, and these include 3D monitors and 3D printers. A 3D screen or 3D monitor is a screen that creates the illusion of a three-dimensional image. Most often, such monitors require additional programs or special equipment. 3D printers are printers for creating three-dimensional objects according to a given model. 3D models are created in special programs. The most popular of them are 3DS Max, Maya, Newtek Lightwave, SoftImage XSI and so on. Such programs can be bundled with the printer, that is, a disk with the program, or installed separately. Often companies that produce 3D printers create their own application for creating and printing a model [3]. This is because not all programs can work well with this model. nine0005

A 3D screen or 3D monitor is a screen that creates the illusion of a three-dimensional image. Most often, such monitors require additional programs or special equipment. 3D printers are printers for creating three-dimensional objects according to a given model. 3D models are created in special programs. The most popular of them are 3DS Max, Maya, Newtek Lightwave, SoftImage XSI and so on. Such programs can be bundled with the printer, that is, a disk with the program, or installed separately. Often companies that produce 3D printers create their own application for creating and printing a model [3]. This is because not all programs can work well with this model. nine0005

So how can 3D printers help industries such as mechanical engineering and robotics?

The first and most obvious is the creation of prototype models for testing. After all, a person can spend weeks or even months on their creation. And with a 3D printer, everything will be ready in a few hours and will not require large expenditures in terms of materials. Therefore, if something does not go according to plan, the manufacturer will not suffer big losses, both financially and in terms of time spent. The use of 3D printing at the development stage or in the technological process allows you to create products of higher quality cheaper and faster [2]. nine0005

Therefore, if something does not go according to plan, the manufacturer will not suffer big losses, both financially and in terms of time spent. The use of 3D printing at the development stage or in the technological process allows you to create products of higher quality cheaper and faster [2]. nine0005

The second point is also quite obvious - this is the manufacture of parts that are unique in geometry, which are almost impossible to create using traditional methods. What seemed fantastic yesterday, today you can create in just a few hours on a 3D printer.

Eliminate the "human factor", reduce risks and errors. A product created using a 3D printer is 99% identical to a CAD model. But we must not forget that any technology has failures. Although manufacturers are trying to minimize this problem with 3D printers. Let's hope that soon all devices will work without the possibility of failures [4]. nine0005

Improving the parameters of finished products: weight reduction, increased accuracy and strength. 3D printer products have a number of advantages in properties. Plastic is one of the lightest materials, but it has fairly good strength and ductility.

3D printer products have a number of advantages in properties. Plastic is one of the lightest materials, but it has fairly good strength and ductility.

Ability to control the physical and mechanical properties of parts by mixing different materials (for example, alloys of different metals).

Thanks to the 3D printer, the introduction of robots into everyday life becomes less of an unimaginable task. After all, now every owner of certain knowledge in the field of programming and the coveted 3D printer can create his own assistant robot [5]. Robot toys have long been in the consumer goods market, with Sony's Aibo being re-released after an 11-year hiatus among the most popular models. The toy is now available for $1,800, but 3D printing and robotics enthusiasts have another option: they can make their own mechanical pet. This is exactly what a programmer from the USA did, who created a robot cat using his 3D printer. nine0005

References

- Adamadziev, K.

R. Computer modeling in economics: textbook / K.R. Adamadziev, A.K. Adamadziev; Ministry of Science and Higher Education of the Russian Federation, Dagestan State University. - 2nd ed., add. revised - Makhachkala: Publishing House of DSU, 2020. - 360 p. : ill., tab.; 21 cm; ISBN 978-5-9913-0201-2 : 50 copies

R. Computer modeling in economics: textbook / K.R. Adamadziev, A.K. Adamadziev; Ministry of Science and Higher Education of the Russian Federation, Dagestan State University. - 2nd ed., add. revised - Makhachkala: Publishing House of DSU, 2020. - 360 p. : ill., tab.; 21 cm; ISBN 978-5-9913-0201-2 : 50 copies - Antonova, P.V. Computer modeling: textbook / P.V. Antonova, A.V. Gerasimov, A.S. Titovtsev; Ministry of Science and Higher Education of the Russian Federation, Federal State Budgetary Educational Institution of Higher Education “Kazan National Research Technological University”. - Kazan: School, 2020. - 202 p. nine0024

- Bogatov, N.M. Computer graphics: workshop / N.M. Bogatov, L.R. Grigoryan, O.E. Mitina; Ministry of Education and Science of the Russian Federation, Kuban State University. - Krasnodar: Kuban State University, 2018. - 107 p. : col. ill.; ISBN 978-5-8209-1477-5 : 500 copies

- Garmashov, S.I. Computer modeling of physical and ecological systems: textbook / S.

Learn more