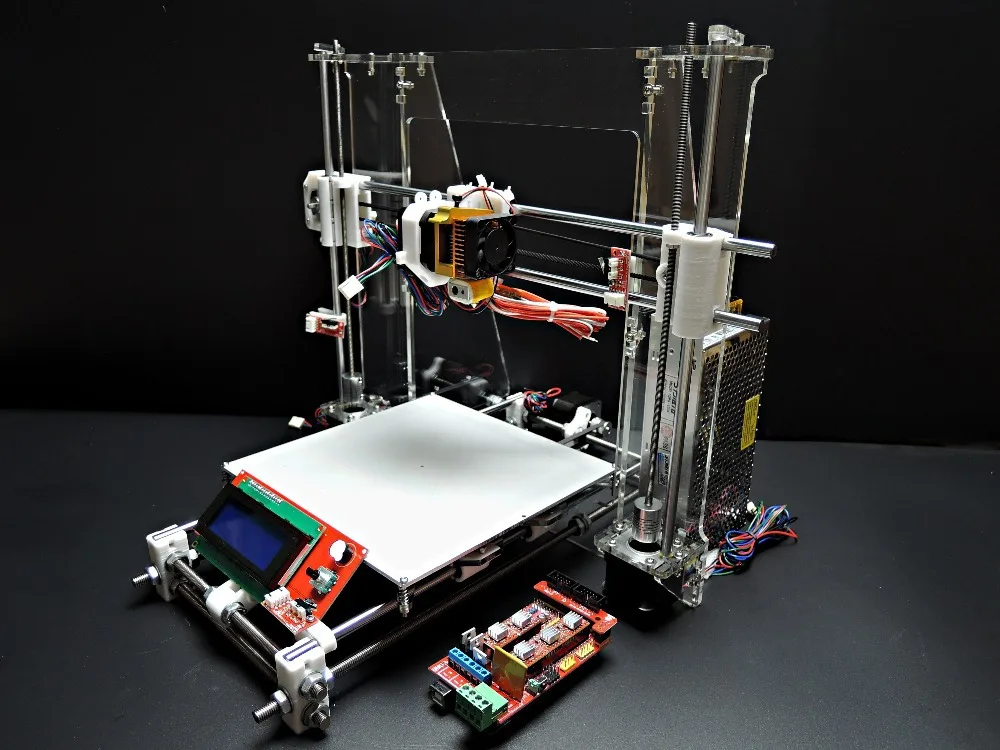

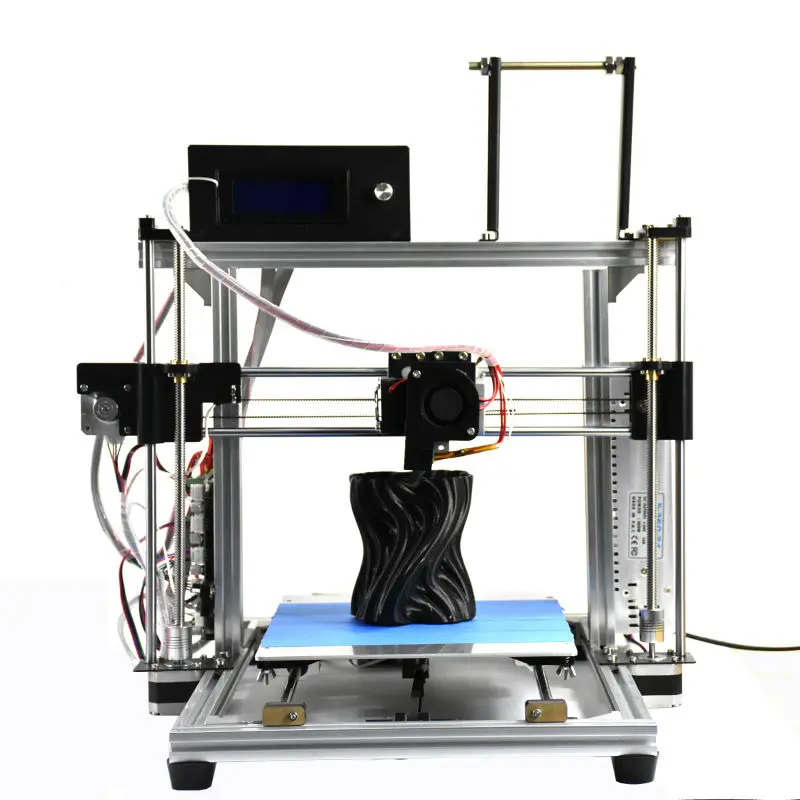

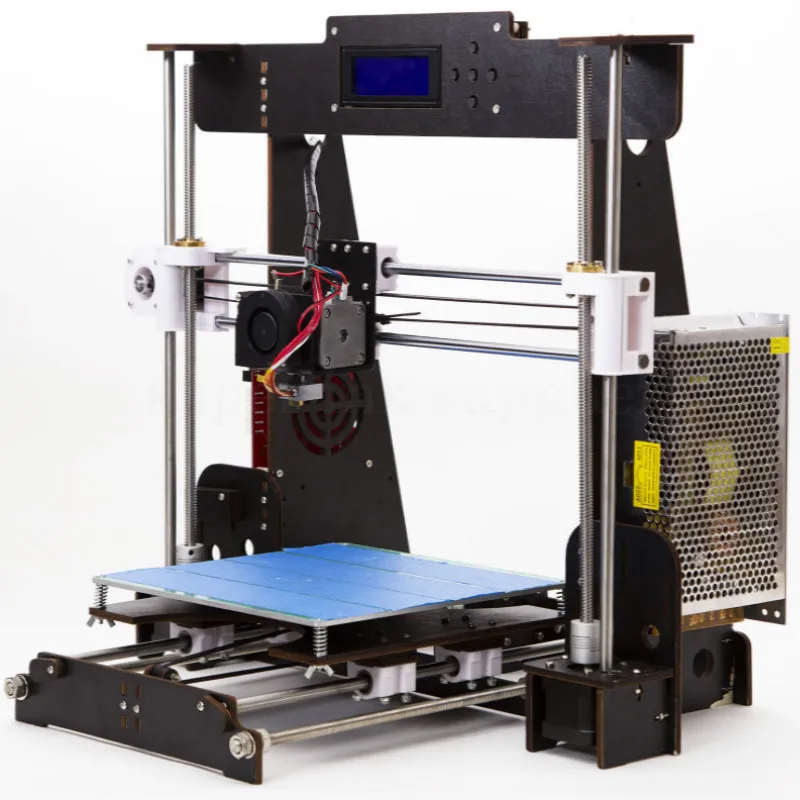

Rep rap 3d printer

Build a reprap - RepRap

This page has been flagged as containing duplicate material that PartsSupplies also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that Darwin/Buyers Guide also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that What Tooling Do You Have also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page is out of date --Sebastien Bailard 04:34, 31 October 2010 (UTC)

This page is not only out of date, but contains in part simply nonsense - especially the "Software installation" section. For the lack of editors, this page should be removed. --Traumflug 21:18, 13 April 2011 (UTC)

Contents

- 1 Build a RepRap

- 2 Overview

- 2.

1 Object Creation Software

- 2.2 System control Software

- 2.3 Installing the Software (experimental)

- 2.4 Thermoplast extruder

- 2.5 Positioning system

- 2.6 Shopping list

- 2.

There are multiple ways to build a RepRap or RepStrap; the method selected for these instructions has been chosen to minimize skills and tools needed. If you wish to explore other options click Alternative Build Documentation.

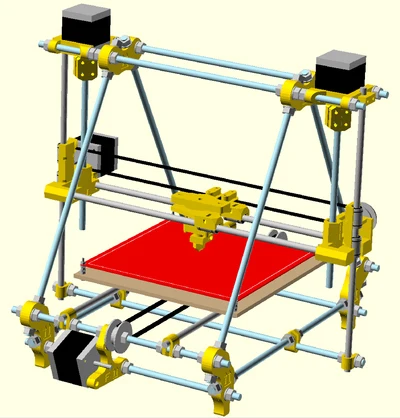

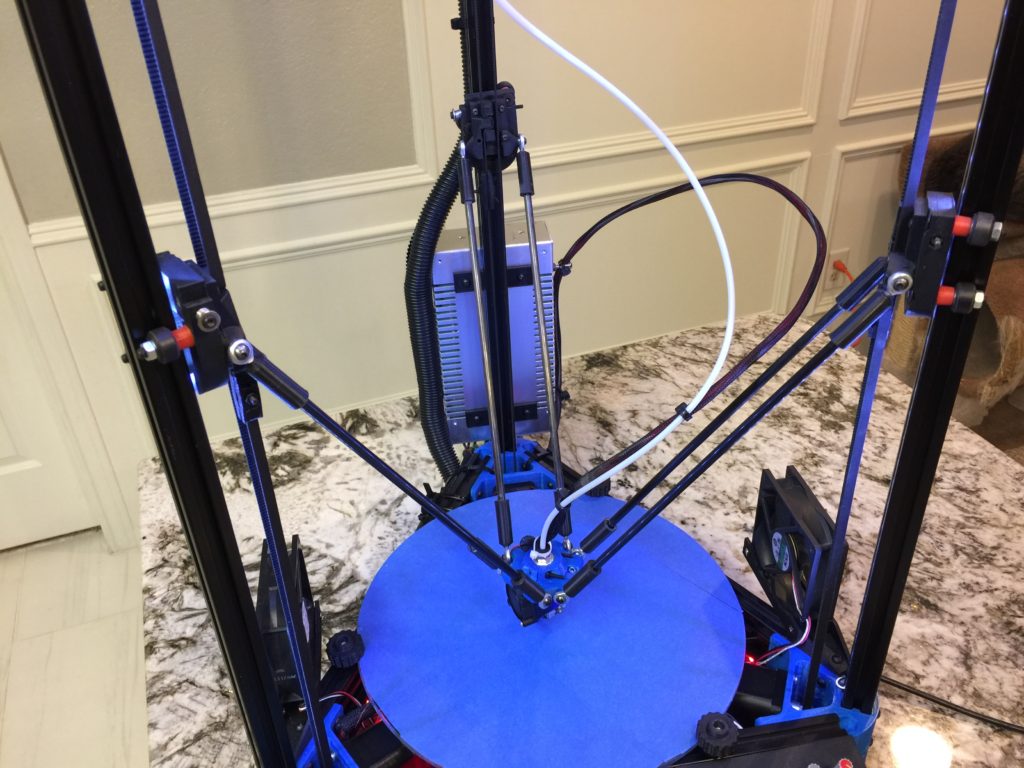

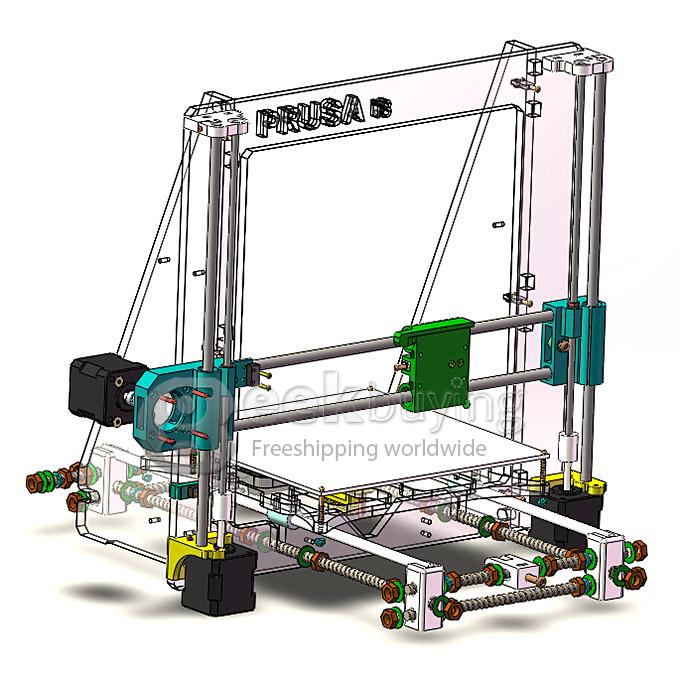

The Classic RepRap Design is "Darwin" pictured on the right. There are very full and accurate building instructions in Make Your Own RepRap.

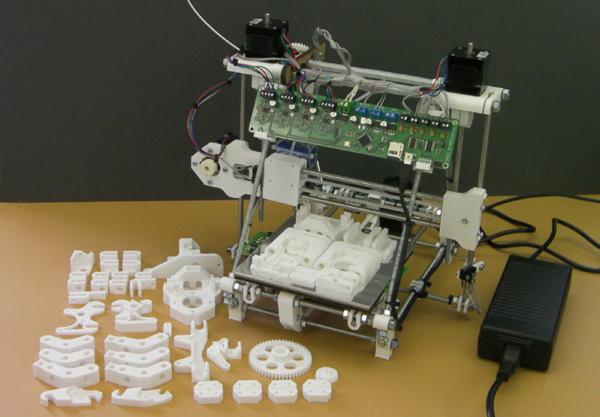

The RepRap was carefully designed to use only parts that can be made on a RepRap and other cheap parts that you can get anywhere. It was also designed to require few skills to assemble. The one snag is you have to find someone to supply you with the parts that must be made on a RepRap.

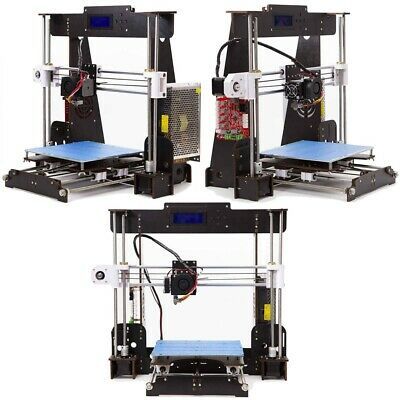

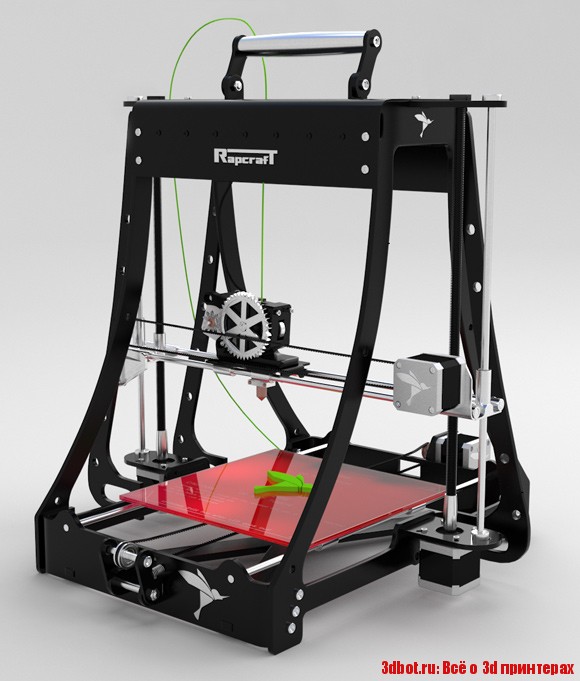

RepStrap Darwin Clones are RepRap designs which are fairly accurately copies of the Darwin design but the RepRapped parts are replaced by parts created some other way, Perhaps molded plastic or laser cut acrylic or plywood. Generally parts of one of these machines are interchangeable with RepRapped Darwin parts. Here are some Parts Suppliers.

Generally parts of one of these machines are interchangeable with RepRapped Darwin parts. Here are some Parts Suppliers.

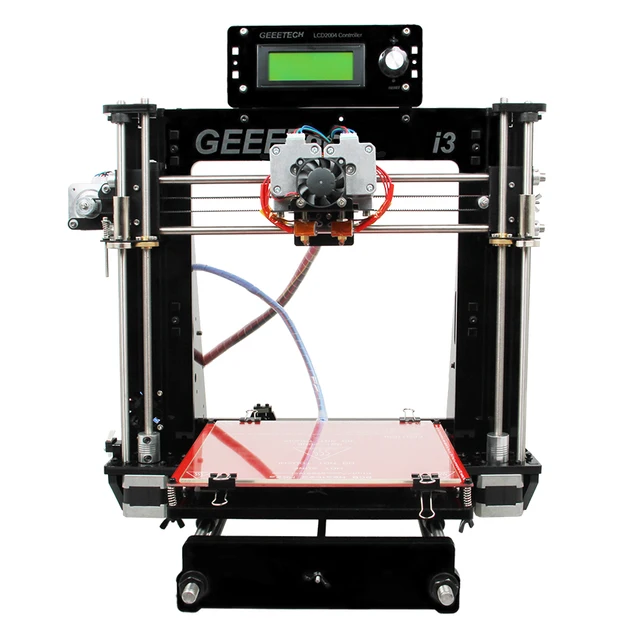

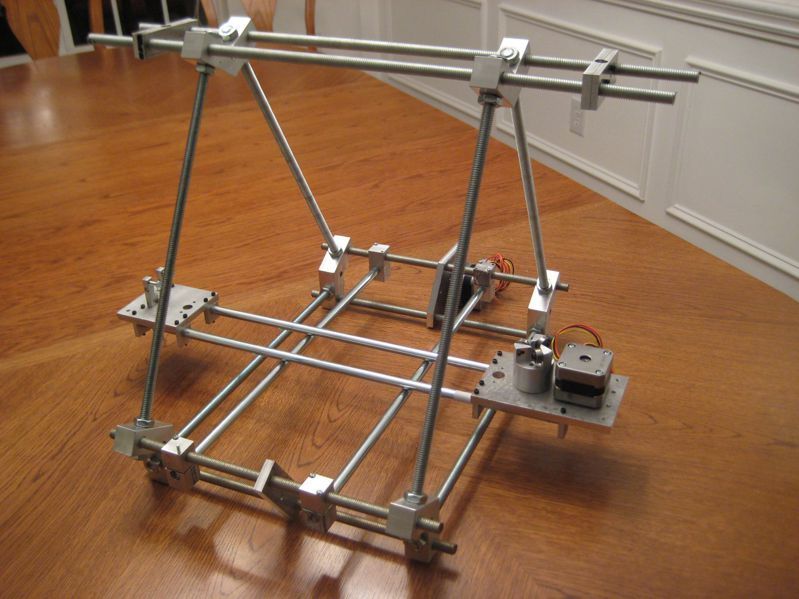

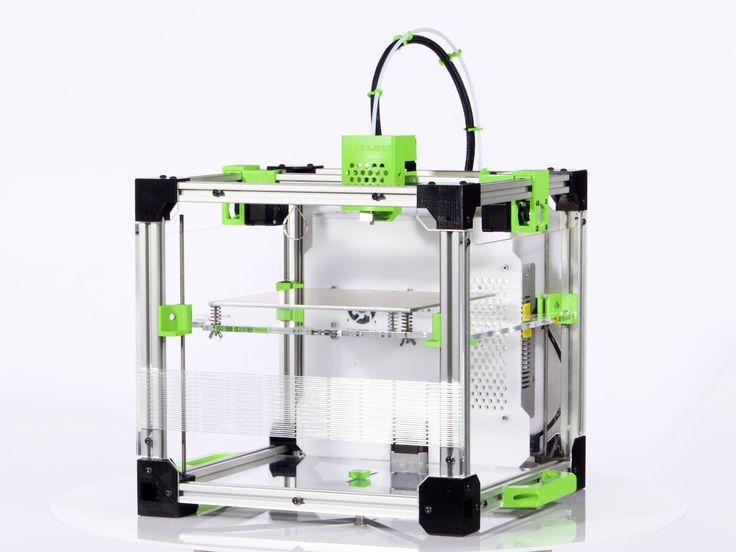

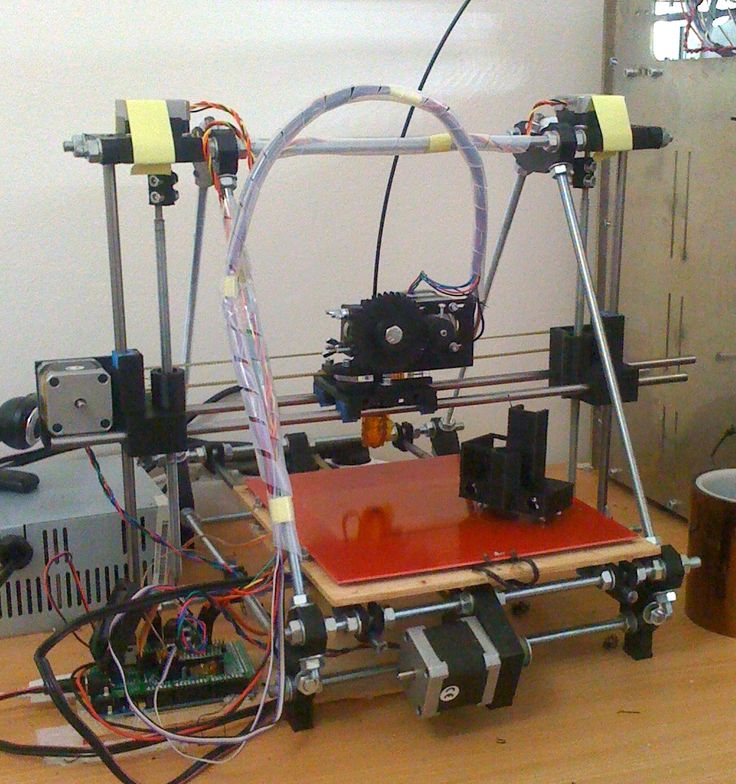

Other RepStraps, these are 3D printers capable of making RepRap (Darwin) parts but are not structurally similar to Darwin. These machines may vary a lot but may be separated into two kinds. Those like Darwin in which the extruder (print head) is moved in the x and y directions and the work is slowly lowered as the print progresses and others where the work is moved in the x and y directions under a stationary head which gradually moves upwards as the print progresses. Here are some references to various RepStrap Machines.

If this is your first RepRap that you are building, here is a basic guide of which build option you should choose:

- If you have a friend nearby that can print out the RepRap part on their RepRap or some other 3D printer. Choose the Classic Darwin

- If you don't have access to a 3d printer then you have 3 options.

- You can build a Classic Darwin, but this means you will have to use a commercial service to print out parts for you; it can easily cost over $1000 for just those parts depending on what deals you can get. This option is probably the most expensive option.

- You can build a RepStrap Darwin Clone. This means you can either buy a lasercut acrylic kit from Bits from Bytes or make some part yourself by machining them. This option is becoming the more common option especially because soon you will be able to buy a lasercut kit from Ponoko which has offices in the US. This is also usually cheaper than the first option.

- The third option is to build non-clone RepStrap that does not have the same frame as a Darwin, such as McWire which uses pipes for the frame. This option is usually the cheapest, but each RepStrap has it own weaknesses. The good thing is that when complete they can print out parts so that you can build a Classic Darwin. The electronics are compatible with Darwin so you only have to buy them once.

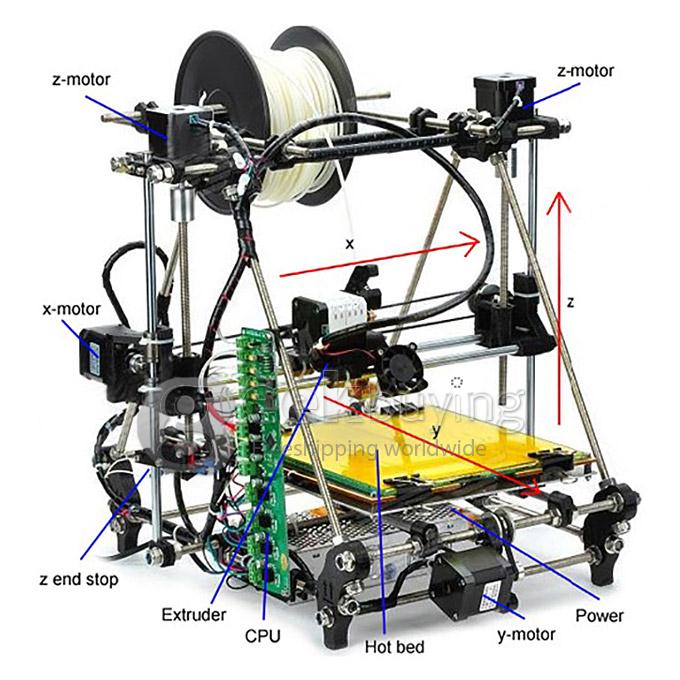

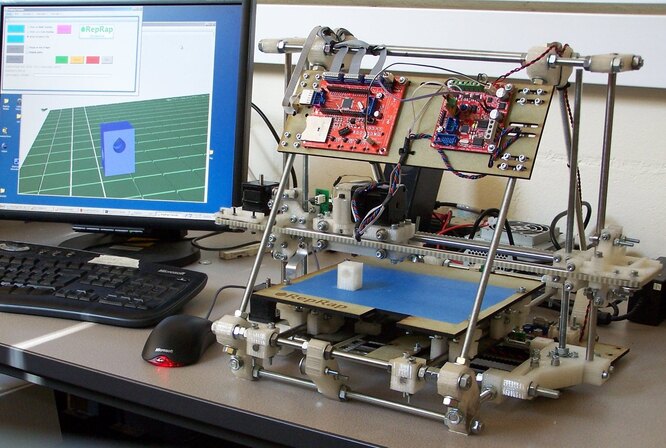

A RepRap or RepStrap (A RepRap can build itself, a RepStrap can build something that can build itself) can be divided into several key areas:

- Object creation Software

- System control Software

- Thermoplastic extruder

- Positioning system (the Cartesian Bot)

- The electronics to control the positioning system

Object Creation Software

Art of Illusion is currently the software most recommended for designing objects to be printed. It's not a CAD package but it is easy to use. The software allows you to create and manipulate 3D shapes. You can store these shapes in STL file format. STL files are object files that are used in Rapid Prototyping. These STL files can be printed off into real 3D objects using your 3D printer (RepRap).

The software is free (GNU GPL version 2) and it is available for Mac OS X, Windows and Linux. If you want to try it out without installing it's available bundled in the Linux distribution liveCD with the rest of the hosted software for the RepRap project.

System control Software

RepRap is controlled via USB or an RS232 interface. You may find a description or download from RepRap Host Software.

There is a RepRap variant which allows you to print an object from a file saved onto a SD card.

Installing the Software (experimental)

This set of instructions tells you how to set up all the software you need for a Reprap in one big blow under Linux Debian.

It involves 5 steps that anyone should be able to complete in a few hours of his/her spare time.

It's easy.

Really.

Warning: Proceed at your own risk. The instructions are not double checked yet.

Prerequisites

You'll need

- a PC (not too old)

- broadband internet access

- some time

Step 1: If you have Windows, go to [Here], get your copy of the Debian installer with one click and start it.

If you already have Linux: Install Debian Lenny some way or the other (you know how to do that ;-)) and continue with Step 3.

Step 2: Follow the instructions. I suggest installing on a 4GB USB stick - but you can also install it all on your hard disk. Be careful to select "testing" instead of stable - this installs Lenny instead of etch. Otherwise the standard settings should be ok in most cases. Don't say "yes" to things you might regret. After a while, a standard system should be installed. Don't forget to install the GRUB boot loader.

Step 3: Log in and say

sudo apt-get install firefox

on the command line.

Step 4: Start firefox and download this Media:Reprap_setup.sh script.

Step 5: Run the script from the shell with

sudo ./Reprap_setup.sh"

Now all the software specific to Reprap is retrieved and installed.

This includes the AVR-Tools, Subversion, Java3d, the Reprap-source tree etc. Installing all that will take some time.

Having successfully reached this point you should try to start the software in reprap-host with:

ant run

If you now see the main window of the host software, you're done.

Congrats! You have made it!

You still have to learn how to use it - but that is another story and another tutorial.

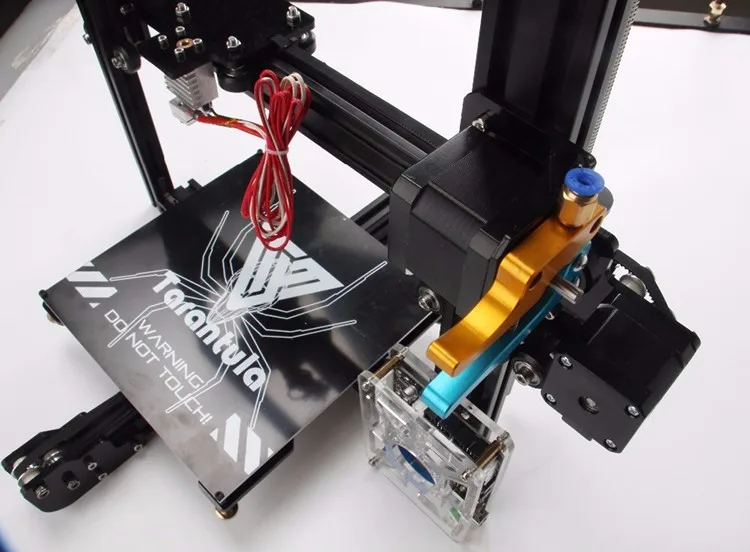

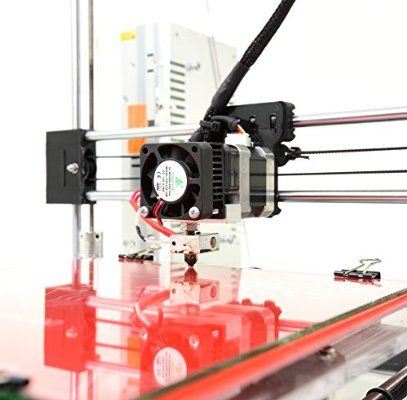

Thermoplast extruder

There are three different extruders all of which, in the end, perform the same function. There is the "official" extruder that can be made by another RepRap. Then there are the kits which are mass produced so it is easier to start printing your first parts. Both kits are designed to be interchangeable with the official extruder.

- RepRapable Thermoplast Extuder

Can be made by another RepRap or commercial rapid prototyper. These are not the only ways the parts can be made but are the easiest. Some builders have made them from machining aluminum or plastic. Others by making molds and casting from resin. This is only for the main pieces of the extruder. The drive screw and other mechanics must be bought or machined. - Kit from Bits from Bytes (laser cut acrylic)

There is an extruder kit currently available from Bits from Bytes who are based in the UK. The kit is part of the silver or gold kits and doesn't need ordering separately unless you want a spare. Assembly instructions are available on the Bits from Bytes website in the 'Assembly Instructions' area:

The kit is part of the silver or gold kits and doesn't need ordering separately unless you want a spare. Assembly instructions are available on the Bits from Bytes website in the 'Assembly Instructions' area:

Bits from Bytes Extruder Assembly instructions

Bits from Bytes Extruder 3d Model - the model requires a recent copy of Adobe Acrobat.

There are videos of the construction process, in the 'Tutorials' section of the website.

Bits from Bytes Heater Barrel Assembly

Bits from Bytes Extruder Drive Assembly

- Kit from Ponoko (laser cut plywood)

A kit will soon be available via Ponoko which has offices in the US.

Positioning system

The positioning system is the greatest part of the size of a RepRap. It is what moves the extruder head from place to place. Kits are available from Bits from Bytes, either the FULL Mechanical Kit - Silver or Gold contain all the components necessary to build a positioning system and extruder. Assembly instructions are available on the bits from bytes website in the 'Assembly Instructions' area:

Bits from Bytes Assembly Instructions

Shopping list

The following list contains all the components necessary to build a RepStrap and enough plastic to print a RepRap. Some handtools are required for assembly, but the only power tool used is a soldering iron.

Some handtools are required for assembly, but the only power tool used is a soldering iron.

Extruder and Positioning System

Bits from Bytes - FULL Mechanical Kit - Silver or Gold

Ponoko - coming soon

(only one required)

Electronics

Plastic

The extruders all use 3mm diameter plastic filament/wire. ABS is the recommended plastic for its combination of strength, availability and dimensional stability. Suitable plastic is available from RRRF in 5lb reels. It is also available by request from plasticweldingrod.com.

Total

Shipping and tax vary by country of order but $1000 total is a reasonable approximation.

About - RepRap

From RepRap

Jump to: navigation, search

About | Development | Community | RepRap Machines | Resources | Policy

an exhibition of repraped parts

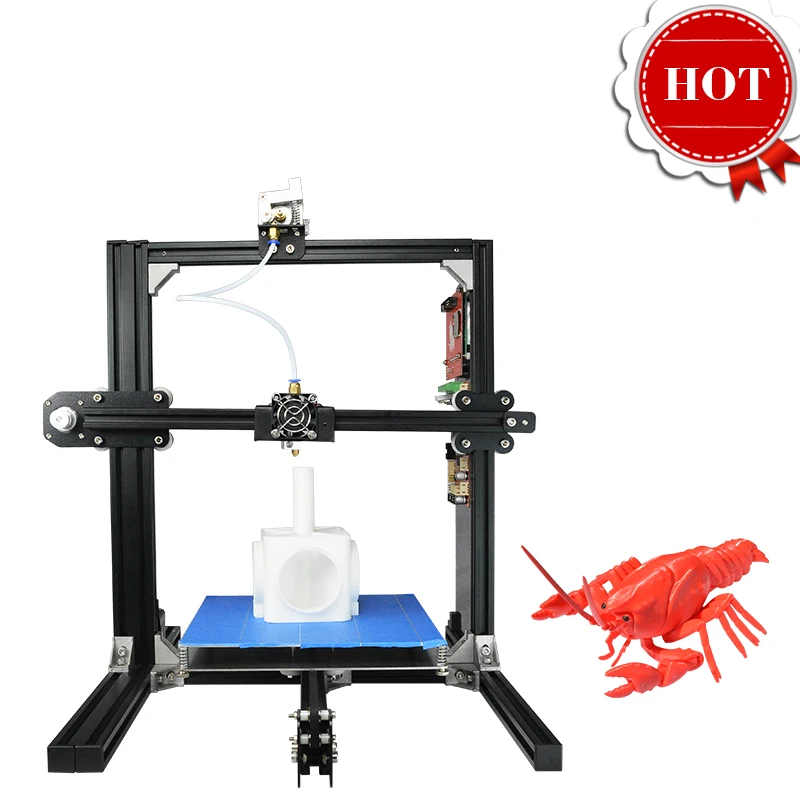

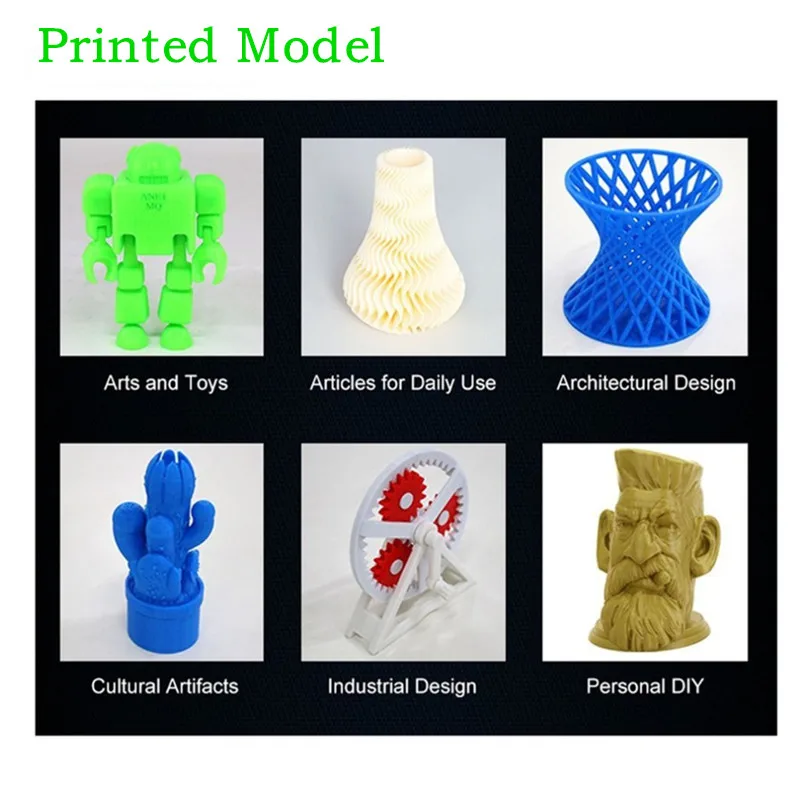

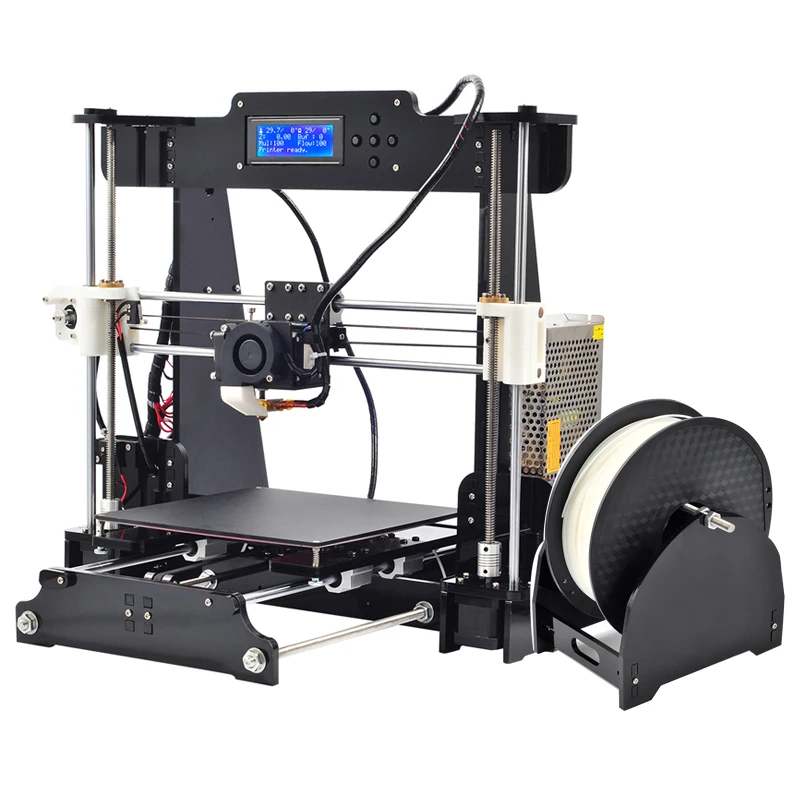

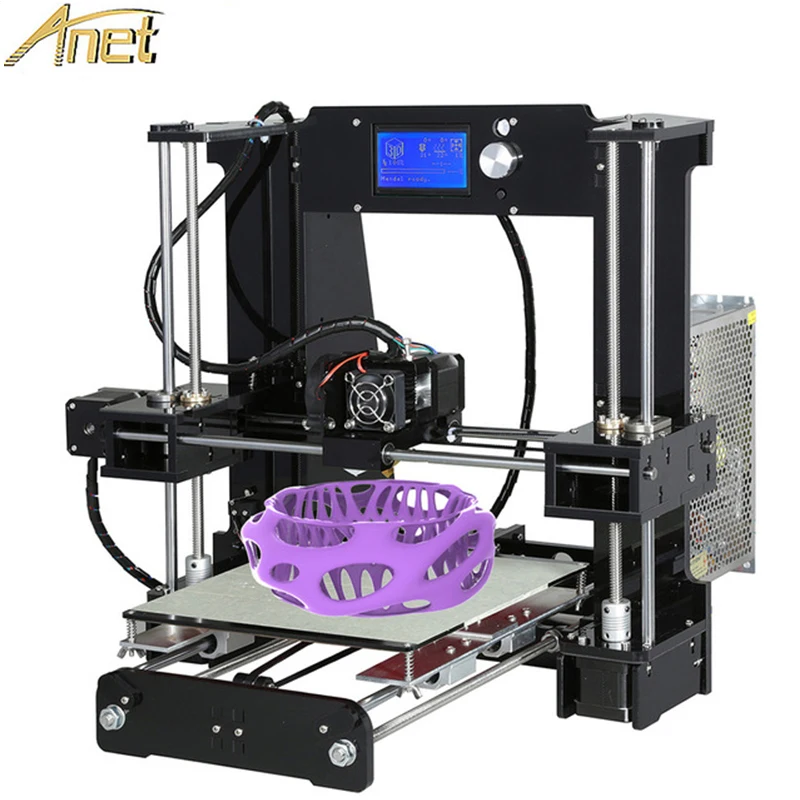

Look at your computer setup and imagine that you hooked up a 3D printer. Instead of printing on bits of paper this 3D printer makes real, robust, mechanical parts. To give you an idea of how robust, think Lego bricks and you're in the right area. You could make lots of useful stuff, but interestingly you could also make most of the parts to make another 3D printer. That would be a machine that could copy itself.

Instead of printing on bits of paper this 3D printer makes real, robust, mechanical parts. To give you an idea of how robust, think Lego bricks and you're in the right area. You could make lots of useful stuff, but interestingly you could also make most of the parts to make another 3D printer. That would be a machine that could copy itself.

Contents

- 1 The Realization

- 2 Machine Self-Replication

- 3 Scholarship and History

- 4 Spread the Word

- 5 Glossary

- 6 Also See

- 7 Longer Video

The Realization

RepRap was invented by Adrian Bowyer and the idea first appeared online in February 2004.

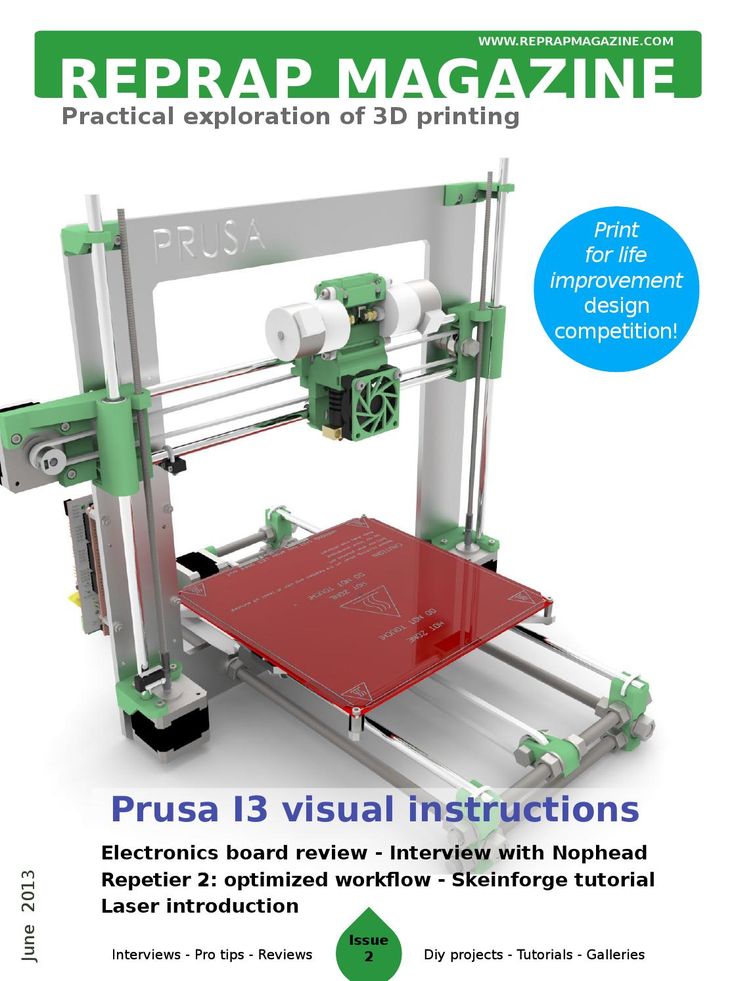

The word RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer introduced in the video on the left - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology existed before RepRap, but the cheapest commercial machine then would have cost you about €30,000. And it wasn't even designed so that it could make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €350). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under an open source license (the GNU General Public License). So, if you have a RepRap machine, you can use it to make another and give that one to a friend...

This technology existed before RepRap, but the cheapest commercial machine then would have cost you about €30,000. And it wasn't even designed so that it could make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €350). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under an open source license (the GNU General Public License). So, if you have a RepRap machine, you can use it to make another and give that one to a friend...

The RepRap project became widely known after a large press coverage in March 2005.

Machine Self-Replication

Not counting nuts and bolts the latest RepRap can make 70% of its parts; the other parts are designed to be cheaply available everywhere. The primary goal of the RepRap project is to create and to give away a makes-useful-stuff machine that, among other things, allows its owner cheaply and easily to make another such machine for someone else.

The primary goal of the RepRap project is to create and to give away a makes-useful-stuff machine that, among other things, allows its owner cheaply and easily to make another such machine for someone else.

To increase that 70%, future versions of RepRap will be able to make their own electric circuitry - a technology we have already proved experimentally - though not their electronic chips. After that we'll look to doing transistors with it, and so on...

Adrian Bowyer (left) and Vik Olliver (right) with a parent RepRap machine, made on a conventional rapid prototyper, and the first complete working child RepRap machine, made by the RepRap on the left. The child machine made its first successful grandchild part at 14:00 hours UTC on 29 May 2008 at Bath University in the UK, a few minutes after it was assembled.

Scholarship and History

Academics and others seeking peer-reviewed journal articles on RepRap may care to start with this paper in Robotica. The citation and link are:

The citation and link are:

- Jones, R., Haufe, P., Sells, E., Iravani, P., Olliver, V., Palmer, C., and Bowyer, A.,: RepRap - The Replicating Rapid Prototyper, Robotica (2011) volume 29, pp. 177–191. Cambridge University Press.

For great insight to RepRap as a self replictor see:

- Bowyer, A., 2014. 3D printing and humanity's first imperfect replicator. 3D Printing and Additive Manufacturing, 1(1), pp.4-5. https://www.liebertpub.com/doi/abs/10.1089/3dp.2013.0003

If you are interested in the legal aspects of this technology, then you may care to read this paper:

- Bradshaw, S., Bowyer, A. and Haufe, P.: The Intellectual Property Implications Of Low-Cost 3D Printing, ScriptEd, April 2010 pp.5-31. Also available here.

If you are interested in how the RepRap can be used to assist in sustainable development see:

- J. M. Pearce, C.M. Blair, K.J. Laciak, R. Andrews, A. Nosrat, and I. Zelenika-Zovko, 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development, Journal of Sustainable Development', 3(4), 17-29, 2010.

'

'

If you are interested in the economics of RepRap see:

- B.T. Wittbrodt, A.G. Glover, J. Laureto, G.C. Anzalone, D. Oppliger, J.L. Irwin, J.M. Pearce (2013), Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers, Mechatronics, 23 (2013), pp. 713-726. http://dx.doi.org/10.1016/j.mechatronics.2013.06.002 open access (self built Mendel)

- Emily E. Petersen and Joshua Pearce. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5(1), 7; doi:10.3390/technologies5010007 open access (commercial Lulzbot RepRap)

- Emily E. Petersen, Romain W. Kidd, Joshua M. Pearce, Impact of DIY Home Manufacturing with 3-D Printing on the Toy and Game Market. Technologies 2017, 5(3), 45; doi: 10.3390/technologies5030045 open access

- Aubrey L. Woern and Joshua M. Pearce. Distributed Manufacturing of Flexible Products: Technical Feasibility and Economic Viability, Technologies 2017, 5(4), 71; doi:10.

3390/technologies5040071 open access

3390/technologies5040071 open access - André O. Laplume, Bent Petersen, Joshua M. Pearce, Global value chains from a 3D printing perspective, Journal of International Business Studies 47(5), 595–609 (2016). doi:10.1057/jibs.2015.47 open access

If you are interested in the environmental benefits of RepRap see:

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Life Cycle Analysis of Distributed 3-D Printing and Conventional Manufacturing of Polymer Products, ACS Sustainable Chemistry & Engineering, Engineering, 1 (12), (2013) pp. 1511–1519DOI: 10.1021/sc400093k Open access

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Impacts of Distributed Manufacturing from 3-D Printing of Polymer Components and Products. MRS Online Proceedings Library, 1492, mrsf12-1492-g01-02 open access

There is also a study on the spread of RepRap and its population:

- Erik de Bruijn: On the viability of the open source development model for the design of physical objects, November 8th 2010, University of Tilburg, The Netherlands.

For a reasonably up-to-date literature review of RepRap technology see:

- RepRap Lit Review

To get a copy of the entire RepRap Blog from its very start as a single PDF file download this (41MB; thanks to Gary Hodgson). The images in the early posts of the online blog are broken, but they are all in that file.

There are many reports, student RepRap projects and theses that are available as PDF files from this site. They are all linked from relevant pages but in addition we should, perhaps, index them as well. In the mean time you can get a complete list of all of them by following this link.

The very first RepRap - the RepRap Darwin made by Adrian Bowyer and Ed Sells at Bath University - is now in the collection of the London Science Museum.

Spread the Word

You can freely use the RepRap Logo (see the licence terms on the left) and QR code:

Glossary

- RepRap - n. any free rapid prototyping machine that can manufacture a significant fraction of its own parts; v.

t. (in lower case: to reprap) to make something in a RepRap machine.

t. (in lower case: to reprap) to make something in a RepRap machine. - RepStrap - n. any free rapid prototyping machine that doesn't make its own parts, but is intended to make parts for a RepRap.

- reprapper - n. a person engaged in making or using RepRaps or RepStraps.

- reprapable - adj. capable of being made in a RepRap machine.

Also See

- Adrian Bowyer's One sheet Description of the RepRap Project

- Background

Longer Video

Here is a recent talk and Q&A by Adrian Bowyer about RepRap and self-replicating manufacturing machines.

How to turn your 3D printer into a laser engraver/cutter

3DPrintStory Reviews How to turn your 3D printer into a laser engraver/cutter

If you want to create something more than just 3D printed parts, or simply expand the range of materials you work with, laser cutting and engraving is a great choice. It allows you to work with other materials and does not require special experience. nine0005

It allows you to work with other materials and does not require special experience. nine0005

But perhaps the best part is that this technology can be easily used by upgrading your 3D printer. The motion system of 3D printers far exceeds the requirements for laser cutting, and laser diode modules can be as small as hot end nodes.

Converting a 3D printer into a laser cutter and engraver is a pretty big deal. In this article, we'll talk about laser technology in general, and then we'll discuss the main steps involved in converting your 3D printer. nine0005

What is laser cutting and engraving?

Laser cutting is a process in which a laser beam selectively removes material along a specific path by vaporizing it. Engraving is basically the same, but instead of removing material, it marks the surface, changing its appearance through oxidation.

Two laser technologies are mainly used for the manufacture of tabletop machines: CO2 and diode. CO2 lasers are powerful enough to cut most materials, including some metals, and are widely used in industry. nine0005

nine0005

However, CO2 laser machines are bulky and require rather expensive and fragile equipment such as CO2 tubes, mirrors and lenses. On the other hand, diode lasers are lightweight and relatively cheap, since they consist mainly of one small module.

Diode lasers are much less powerful than CO2 and are best suited for engraving and cutting thin sheets of balsa and plywood. In comparison, a CO2 laser can deliver up to 400W, while diode lasers can only deliver 10W maximum. nine0005

Do you need to convert your 3D printer to a laser engraver?

Converting a 3D printer to a CO2 laser machine can be quite a challenge given the size of the tubes and the complex system of mirrors. For this reason, it is much better to use diode lasers.

However, please note that these lasers can only cut certain materials such as paper, cardboard, balsa and plywood with a thickness of 3 to 5 mm. Due to the wavelength of the laser, it cannot cut or engrave transparent materials such as acrylic. nine0005

nine0005

Also be aware of the safety requirements when using lasers. Class 4 lasers are dangerous to the eyes, so the use of safety goggles is mandatory. In addition, the products of combustion emitted during the operation of the laser can be harmful to our health, so enclosure and proper ventilation are required.

Take all of this into account before deciding to convert your 3D printer to a laser machine. Given the risks involved, it is especially important to take precautions. nine0005

How to turn a 3D printer into a laser cutter/engraver?

The process of converting a 3D printer to a laser machine varies but usually involves the same steps.

First of all, we need to choose the laser module that best suits our requirements (eg functionality and price). Next, we need to figure out how to adapt it to the electronics and physical interface of the 3D printer.

Laser module

Powerful solid state lasers are a relatively recent development, but the market has quickly caught up with demand for diode laser modules. nine0005

nine0005

The laser power is always between 1 and 10 W. Some white label lasers you see online are listed as 30W or even 40W, but that is definitely not optical power output.

Power will determine which materials can be engraved and whether materials such as wood (and how thick) can be cut. Laser manufacturers usually provide a list of materials that can be engraved and cut, so be sure to check it out.

Variable focal length, which you sometimes see as an advertised feature, is not really important here, as the 3D printer's Z-axis can raise or lower the module to fit a fixed distance. nine0005

The air blower is an interesting feature as it blows air directly onto the surface to disperse particles that interfere with the laser, resulting in cleaner cuts. Some lasers have this feature built in.

Compatibility and connection

Most laser modules can be connected directly to the 3D printer control board. The partial cooling fan on a 3D printer requires an adjustable power output to control its speed, and it is this port that can power and drive the laser. nine0005

nine0005

Some lasers require a special 12V power input. This is usually via a separate driver board, which can be powered by either the printer's power supply or an external power supply. This setup also requires a connection to the printer through the fan port.

Refer to the laser manufacturer's documentation for correct connection instructions.

Installation

Installation and mounting of the laser module is perhaps the only major equipment change in the entire conversion process. Although some lasers come with non-standard brackets, some adaptation will always be required. nine0005

Fortunately, you already have a 3D printer, so anything is possible. You may be able to find suitable designs on sites like Thingiverse. Otherwise, it might be time to try some 3D modeling software like Tinkercad or similar. The model doesn't have to be fancy, just a joint between holes and screws that will be used to hold the hot end.

Once you've attached the laser module to your 3D printer, you're done! However, in order to start engraving or cutting, you may need a new firmware. nine0005

nine0005

Next steps

The laser cutter and engraver is one of the coolest machines we can have at home because it allows us to make things from a wider range of materials than extruded plastic filament. Converting a 3D printer to a laser printer is an inexpensive option, and you can always go back to 3D printing in the end.

By the way, for Ender and CR-10 users, Creality offers special laser kits to add (not replace) laser modules to these printers. nine0005

Be sure to check out some step-by-step guides online. For example, Instructables user Goss Adema has documented converting the Anet A8 to a laser cutter and engraver, and the TeachingTech YouTube channel has great step-by-step instructions on how to do it on any 3D printer.

How to convert a CNC machine into a 3D printer?

Before you start converting the CNC machine into a 3D printer, you first need to stock up on the necessary tools and materials. This is the most important and preparatory stage, where you can buy cheap used devices at a lower price. When planning to turn a CNC machine into a 3D printer, anyone can significantly expand the functionality of the equipment. In order to manage the transformed machine-printer in the future, it is recommended to use the Mach4 program. To print in 3D, you need to create a file in STL resolution. It is supported by most 3D printers. If you need to convert the file format, then you can use one of the following programs: Soildworks, google Sketchup and other programs. nine0005

When planning to turn a CNC machine into a 3D printer, anyone can significantly expand the functionality of the equipment. In order to manage the transformed machine-printer in the future, it is recommended to use the Mach4 program. To print in 3D, you need to create a file in STL resolution. It is supported by most 3D printers. If you need to convert the file format, then you can use one of the following programs: Soildworks, google Sketchup and other programs. nine0005

To print in 3D format on a desktop CNC machine, it is recommended to use a 3D printer extruder. The temperature sensor must first be replaced with a 3K thermocouple.

What to do

There is a myth that it is almost impossible to convert a CNC machine into a 3D printer without professional technical knowledge. However, if you use the ready-made instructions, select the necessary materials and tools, then everyone will be able to cope with the task. nine0005

To obtain a proper result, the following procedure is recommended:

• Remove the spindle holder. In the holes that have become free, it is necessary to fix the adapter-corner. It is necessary in order to install and fix the print head of the 3D printer;

In the holes that have become free, it is necessary to fix the adapter-corner. It is necessary in order to install and fix the print head of the 3D printer;

• To fix the spool of 3D printing thread, you need to assemble a stand made of aluminum profile. It is a resistant metal that is tolerated by almost any mechanical impact; nine0005

• on an existing CNC machine, you need to fix a special stand with a spool and thread for 3D printing;

• install additional software;

• Download the Mach4 program from the official website of the developer. It is worth noting that the program does not require heavy-duty hardware for normal operation. The package contains Skeinforge software, which enables the normal conversion of 3d files to G-code;

• In addition, you need to install the Russian-language interface. In this case, management becomes much easier; nine0005

• Mach4mill must be selected to run the Mach4 program. After the download comes to an end, you need to go to the menu and find "Wizards" select "Pick Wizard";

• double click on the button and select "Open STL File"print addon"";

• click on the file and find in English Open. It is necessary to wait until the program completes the creation of the 3D file, then the settings with printing in 3D format should open;

It is necessary to wait until the program completes the creation of the 3D file, then the settings with printing in 3D format should open;

• Next, you need to return to the Mach4 window, you must click on the Post Gcode to Mach4 button. The resulting code is easy to save. nine0005

After you manage to bring the print head to the starting print location, you need to erase or reset the coordinates of the tools.

Printing is started by simultaneously pressing the combination ALT + R.

What materials you can buy

To make your own 3D printer, you can alternatively purchase the following devices and materials:

• Arduino Mega 2560. This is the main element that will be responsible for the future control of the printer in 3D format. Can be purchased from the Chinese store Aliexpress; nine0005

• if you are planning to buy the brain offered above, then Mosfet transistors with any other powerful devices are best suited;

• foil fiberglass;

• M6 threaded stud in the amount of 3 pcs.