Waterproof 3d print

9 Ways How to Make Your 3D Prints Waterproof & Airtight – 3D Printerly

Creating 3D prints that are waterproof and airtight is something that many people try to achieve, or even wonder if they can do it in the first place. It’s definitely possible to make your 3D printed objects watertight when you follow the right directions.

3D printing models with a flow rate of 150%, a large layer height and a wide nozzle diameter works very well to create waterproof and airtight models. Increase your printing temperature to help layers adhere and seal up potential gaps. Seal the final model with an epoxy resin for better results.

The rest of this article will detail the process and tips on how you can get some of the best waterproof 3D prints out there, so keep reading to find out more.

Is 3D Printing Waterproof & Airtight? Can 3D Prints Hold Water?

It is possible to 3D print a waterproof and airtight object which can hold water for long periods of time without leaking. Generally, 3D prints created normally are not waterproof because there are many small gaps throughout an object due to the nature of 3D printing. You also need to have a model which is optimized to be airtight.

Most 3D prints are not going to be watertight because 3D printing creates several layers on top of each other, and in many instances, your nozzle can get slightly clogged during printing leading to imperfections in prints.

These imperfections can lead to sections having small or large holes in the model. The larger your layer height, the less dimensionally accurate your models will be which is another factor which can create a 3D print that is not waterproof or airtight.

In order to make your 3D prints waterproof and watertight, there are steps you can follow which go from picking a good model, to adjusting your slicer settings, to post-print treatment of the model itself.

The next section will go into some more details to set you on the right path to making your 3D prints waterproof, whether it is PLA, ABS or another type of filament.

How Do You Waterproof PLA 3D Prints & Containers?

To waterproof your 3D prints you should:

- Use a known water-resistant filament which can withstand water easily and be affected by it negatively

- Change your print settings to print larger layers

- Increase the thickness of the exterior, otherwise known as walls or perimeters

- Increase your flow rate/extrusion multiplier to over extrude the amount of plastic to fill up those gaps

- Increase your printing for better layer adhesion

- Use a wider 3D printing nozzle such as a 0.6mm or even a 1mm nozzle

- Increase your infill percentage/density to fill the model more

- Apply a coat of epoxy resin to seal any gaps or holes in your 3D print

- For ABS, do some acetone vapor smoothing to smooth out any holes or gaps

Using these strategies is going to lead you to a much better path to finally create some real waterproof 3D prints, whether PLA or ABS.

It’s all geared towards reducing how many holes, gaps, and layer separations we get during the printing process, then doing some post-processing to get of any holes that may have got through the FDM, layer-by-layer process.

One amazing product to seal your 3D prints that not many people know about is the MG Chemicals Silicone Conformal Coating from Amazon.

It’s an aerosol spray which people usually use to waterproof their electronics, even having great corrosion resistance when tested in a salt spray environment. Many people use it for their 3D prints to seal PLA and ABS models.

One user said he applies 4 coats, letting each coat dry for 30 minutes before applying the next. It’s really easy to use and only requires thin coats. One of the best things is how it has no weird smell or look after it dries.

Ensure you spray in a well-ventilated area.

Now let’s get into the rest of the strategies.

Use a Water-Resistant Filament

Although you can use filament that isn’t water-resistant like PLA or ABS, you would be best off picking a filament which is.

Some good water-resistant filament to use for waterproof 3D prints are:

- PETG

- Polypropylene (PP)

- GF30-PP (Polypropylene with glass fibers)

These filaments are known to hold water nicely and have a good amount of chemical and impact resistance. Polypropylene is even hydrophobic and repels water, so it’s a great choice to go with.

Increase Your Layer Height

Printing with a thicker layer height leads to fewer spaces for there to be gaps and holes in your 3D models. It essentially squishes together and makes it more likely that your prints will be airtight and waterproof, reducing your chances of experiencing leaks.

Increase Wall Thickness or Perimeters

The outer layers, or the exterior of your model are where your 3D prints will have any gaps, so ensuring that you add more material to these sections means you can make models more waterproof.

A good rule of thumb for a good airtight 3D print is to have around 2 or 3 walls/perimeters, making sure you also have a good wall thickness of at least 1. 7mm. This would mean you would have around a 3.4-5.1mm external barrier to keep that water or liquid inside.

7mm. This would mean you would have around a 3.4-5.1mm external barrier to keep that water or liquid inside.

You should also have 4-6 top and bottom layers to provide even more of a solid exterior.

Increase Flow Rate/Extrusion Multiplier

Another great way to make your 3D prints waterproof and airtight is to increase the flow rate or extrusion multiplier in your slicer. This has similar results to some of the methods above, which extrudes more material to reduce the spaces between layers.

Each layer of your 3D model should have better adhesion since there is more pressure and material coming out the nozzle to connect with the previous layer.

Since we are increasing the amount of material coming out the nozzle, you would usually compensate by either reducing your printing speed, increasing your printing temperature, or both!

A flow rate of 150% should work well for making your prints watertight.

Increase Printing Temperature

As mentioned above, you can increase your printing temperature to add to the necessary element of good layer adhesion between every layer. When you have a relatively lower temperature, layers may not bond as well as they need to.

When you have a relatively lower temperature, layers may not bond as well as they need to.

Use a Wider Nozzle Diameter

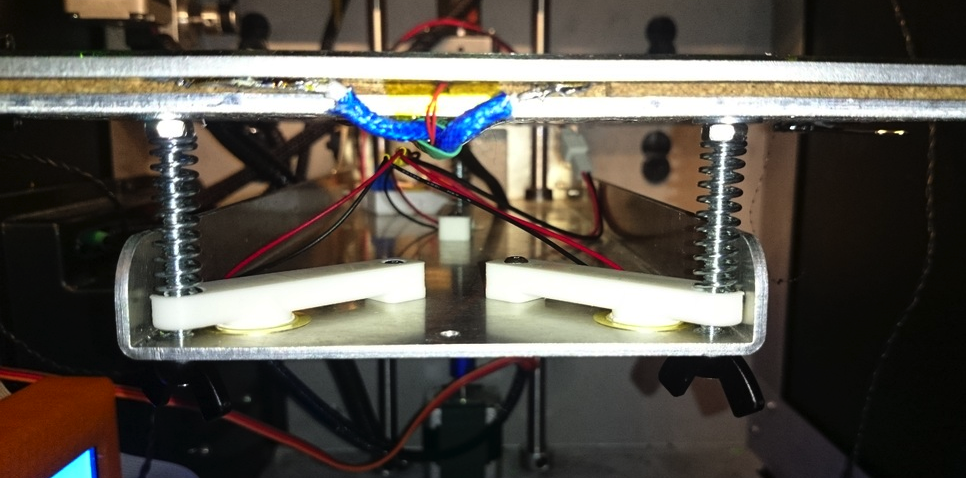

Increasing your nozzle diameter is one of the best ways of improving the reliability of waterproof and airtight 3D prints. It relates to increasing the flow rate and reducing the spaces between each layer.

Your layers will extrude much faster and thicker, meaning that it takes longer to cool down. This leads to better layer bonding because the filament is in more in the “liquid-state”.

I’d recommend a nozzle diameter of between 0.6mm and 1mm for the most optimal option.

Increase Infill Density Percentage

When you have a higher infill density, it reduces the presence of gaps in your model. This is a great way of ensure that your 3D prints are more waterproof, so use an infill density of 40-100%.

Apply a Coat of Epoxy Resin or Clear Coat

This is a great method of post-processing that clears up any slight failures in the printing process, because 3D printers aren’t perfect! By applying a smooth, clear coat of epoxy resin, it provides a thick protection against any smaller gaps or holes in your model.

People tend to apply a coat of XTC Smooth-On High Performance 3D Print Coating (Amazon) on the inside of their model to make it waterproof, then letting it dry. Once it’s dried, you should have a 3D print which is optimized for holding water or any liquids you choose to use.

It has a great rating of 4.4/5.0 on Amazon at time of writing and not only does it help with waterproofing your 3D prints, but it also provides a glossy shine to any of your models to make them pop.

When you sand your 3D models then apply a coat of this stuff, you can really get some professional looking 3D objects that you’ll be impressed with.

Do Acetone Vapor Smoothing

Creating waterproof 3D models with ABS is a lot easier due to the acetone smoothing technique. This works because acetone is a known solvent for ABS, and in some cases PLA depending on the brand and manufacturing methods.

The preferred way to smooth ABS prints with acetone is to create an environment where the ABS vapor can slowly work on dissolving each layer of the model and close up any gaps that may be present.

Use SLA 3D Printing

SLA or resin 3D printing provides a better alternative for making waterproof 3D prints due to its very fine layer heights of 0.01mm or just 10 microns. A 3D printed vase at 50 microns on an SLA 3D printer should be enough to provide you with a waterproof 3D print.

Since FDM works on heat and extrusion, the dimensional accuracy are much lesser, and presence of gaps are are much more prominant.

How Do You Waterproof a Vase?

If you have a vase made out of ABS, you can use acetone to slightly melt/dissolve the surface and clear up any small gaps where water might leak out.

Another great method that works to waterproof a vase for other materials is by using an aerosol spray. Many people have had success with the Performix Multi-Purpose Rubber Coating Aerosol from Amazon.

Many people have had success with the Performix Multi-Purpose Rubber Coating Aerosol from Amazon.

It is an air-dry special rubber coating spray which is flexible, non-slip, and provides an amazing durable finish.

The best thing is how it will remain flexible and not crack or become brittle regardless of any extreme conditions, even proven to work in temperatures from -30°F to 200°F.

One user got great results with printing a vase by setting extrusion width to 30% bigger than the nozzle diameter, using two perimeters with overlap (Skin Overlap Percentage) of more than 30% to completely seal the perimeters.

Best Water-Resistant & Moisture Resistant 3D Printing Filament

Every thermoplastic is reasonably waterproof as long as the manufacturing method is sound. One user who put a PLA piece in their aquarium did a 2 year update and found that it held up without showing any signs of degradation or damage.

PLA would do fine underwater, but it’s likely going to become brittle over time.

In terms of some of the best water-resistant and moisture resistant 3D printing filament out there, I’d recommend:

- PETG

- ABS

- Polycarbonate

- ABS (acetone smoothed)

How to 3D print waterproof parts

Arun Chapman1 March 2022

Guide

3D printers promise endless applications. However, sometimes reality gets in the way of that promise. One example of where that can happen is when trying to print something that needs to hold water, only to watch it leak like a sieve. Read on to find out to avoid such a tragic waste of liquid.

Is it possible to print waterproof and watertight parts?

Yes, it can be done but it’s not always easy. To get the best results, you need to pay special attention to both the material and the settings you use. And even then, some post-processing may also be needed to get a part that is truly and reliably waterproof.

It is also worth talking about what we mean when we say waterproof. When talking about clothing or electronics, the word waterproof is usually used to indicate that an object is capable of keeping water out. For anything that needs to keep water in such as a vase, a more appropriate description would be watertight. Some industries like electronics also use the term water-resistant to describe something that can water out, up to a limit. Such as a phone which is only waterproof up to a certain depth.

When talking about clothing or electronics, the word waterproof is usually used to indicate that an object is capable of keeping water out. For anything that needs to keep water in such as a vase, a more appropriate description would be watertight. Some industries like electronics also use the term water-resistant to describe something that can water out, up to a limit. Such as a phone which is only waterproof up to a certain depth.

In this article, we will use waterproof as an umbrella term to include all the above. The steps you take to make a print waterproof will also help it to be watertight and water-resistant. Although, most parts will not meet the same criteria that your waterproof phone is held to so it’s probably best not to go deep-water diving while relying on a printed part to protect anything sensitive.

How do you print waterproof parts?

To get waterproof parts, there are three areas that are important. The material used, your slicer settings, and post-processing.

It is possible to print waterproof parts with a variety of different 3D printing technologies. Some industrial printers with six-figure price tags are even capable of making extremely reliable waterproof parts with robust materials like metal. However, most people don’t have access to those printers so for this article, we will be focusing on the most common and accessible 3D printing technology, FFF printing.

Materials for printing waterproof parts

Most FFF filaments are thermoplastics. Plastics are generally good at being waterproof which is why most water bottles are made of plastic. Plastics are also not normally degraded or damaged by water which is also why so many of those plastic bottles end up in the ocean and are likely to stay for a long time to come. However, there are a lot of different types of thermoplastics and all of them have different properties which are worth knowing before you try to print your waterproof parts.

A note on swelling: Many 3D printing materials are hygroscopic, meaning they absorb water. Some are worse than others (PETG, Nylon, PLA) and some are better (ABS, PP) but most absorb water to some extent. The result is, if you leave a part in contact with water for a long time it may start to swell. The amount of swelling is usually small, but it can deform your part and even cause it to split or break in a way that stops it from being waterproof or watertight. The swelling will not continue indefinitely or cause the part to degrade completely like it would with untreated wood. Instead, the part will likely swell up to a certain point (depending on the material) and then stop. If you have ever printed a part that was initially waterproof but started leaking over time, this was probably why. It should be possible to dry your part to remove the swelling but allowing a part to swell and then drying it repeatedly may cause increasingly more damage.

Some are worse than others (PETG, Nylon, PLA) and some are better (ABS, PP) but most absorb water to some extent. The result is, if you leave a part in contact with water for a long time it may start to swell. The amount of swelling is usually small, but it can deform your part and even cause it to split or break in a way that stops it from being waterproof or watertight. The swelling will not continue indefinitely or cause the part to degrade completely like it would with untreated wood. Instead, the part will likely swell up to a certain point (depending on the material) and then stop. If you have ever printed a part that was initially waterproof but started leaking over time, this was probably why. It should be possible to dry your part to remove the swelling but allowing a part to swell and then drying it repeatedly may cause increasingly more damage.

PLA

PLA is one of the cheapest and most common FFF printing materials. PLA can be used to create waterproof parts, but it does have some disadvantages. As mentioned above PLA can be prone to absorbing water and swelling.

As mentioned above PLA can be prone to absorbing water and swelling.

PLA is also biodegradable. Meaning that (under the right circumstances) it can be composted. This is not an issue if it’s only exposed to perfectly clean water, but if you were to leave a PLA printed part submerged for an extended period in a body of water that contains microorganisms, like a pond, there is a chance that your part could start to degrade. Albeit slowly.

Lastly, PLA has low heat resistance. Meaning that if you wanted to use a printed part to hold hot water, it would likely deform. This can be solved by heat treating your part after printing. Heat treating is explained more later in this article.

PETG

PETG is another common and affordable FFF material. PETG is particularly hygroscopic meaning it’s prone to swelling. On the flipside, PETG has a high heat resistance so printed parts can be kept outside in direct sunlight without issue, and they can stand up to hot (although not boiling) water.

PP

PP is one of the better options for printing waterproof parts. It is less prone to swelling than PLA or PETG and it is chemical resistant. PP can also be used to print flexible parts that hold their shape and do not break after repeated bending.

ABS

ABS is a decent option for printing waterproof parts. It has a high heat resistance and is not as hygroscopic as many other materials. The best reason to use ABS, though, is that you can use Acetone to vapor-smooth parts printed in ABS. Vapor-smoothing will be talked about more in the post-processing section.

PVB

PolySmooth is a PVB-based material made by PolyMaker that is easy to print and has mechanical properties similar to PETG. The big advantage of PolySmooth for printing waterproof parts is that it can be vapor smoothed using isopropyl alcohol. The process is similar to how ABS is smoothed using acetone but isopropyl alcohol is much safer and easier to handle than acetone.

Which settings to use for printing waterproof parts?

Just as important as the material you choose, is the settings you use. FFF printing works by stacking layers of material on top of each other, one at a time. The problem with that is that each layer has a chance of leaving a small gap between itself and the layer below. The following settings are mostly aimed at avoiding those gaps or mitigating their effect:

FFF printing works by stacking layers of material on top of each other, one at a time. The problem with that is that each layer has a chance of leaving a small gap between itself and the layer below. The following settings are mostly aimed at avoiding those gaps or mitigating their effect:

Wall line count

Wall line count is the setting that determined how many layers thick the outer wall of your print is. Generally, more wall lines will increase the chance of your part being waterproof. The reason is that they reduced the chance of water having a direct path through all the walls present. If under extrusion or some other issue has caused a small gap in one wall, the next wall acts as a backup to plug that gap.

A wall line count of 3 is normally a good place to start. It’s worth noting that increasing the wall line count for thin parts will have no effect. There is also one situation where a single wall is the best option, and that’s when using vase mode.

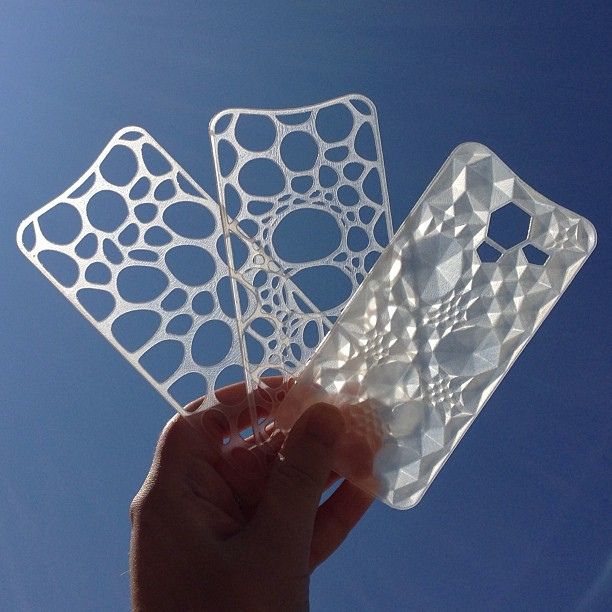

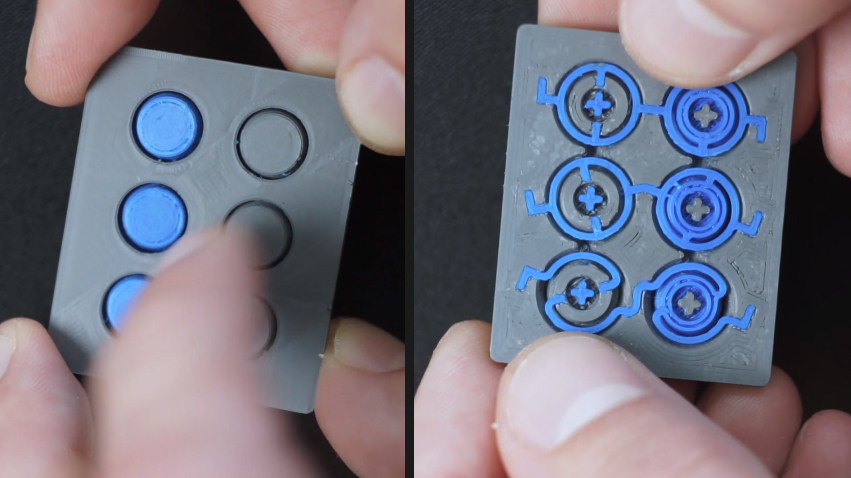

Spiralize outer contour (vase mode)

Spiralize outer contour (also known as vase mode) is a setting that enables smooth printing of objects with a single wall thickness. It turns the print into one continuous print path which means there are no retractions between layers and therefore no Z seam.

It turns the print into one continuous print path which means there are no retractions between layers and therefore no Z seam.

That is the biggest benefit of vase mode. The Z seam is one of the most common areas for gaps in your printed part to occur. Removing that seam makes parts with even a single wall capable of being waterproof. However, this setting is not suitable for most parts as it requires a very specific geometry. Vases, cups, and bowls are the kinds of prints that can be printed using vase mode.

Temperature

Gaps can appear when one layer is not properly bonded to the layer below. A higher printing temp is one way to increase layer adhesion. It’s generally best to print at as high a temp as your material will allow. Beware that when you print at too high a temp, the material can boil as it comes out of the nozzle, leading to more issues and potential gaps.

Flow rate

Under-extrusion is a major cause of gaps in your part. Even well-tuned print profiles can suffer from under-extrusion at times as they normally prioritize high dimensional accuracy, structural strength, or visual fidelit over other considerations. A slight increase to flow rate should be enough to see an improvement. Start with 105% and increase until you see diminishing returns.

A slight increase to flow rate should be enough to see an improvement. Start with 105% and increase until you see diminishing returns.

How to post-process a part to make it waterproof

Ideally, you should be able to pull a printed part off the build plate and have it be completely waterproof. However, sometimes a bit of post-processing is needed to shore up an almost waterproof part. Here are some of the main methods you can use:

Apply a waterproof coating

This is the easiest and most straightforward way to waterproof an otherwise leaky part. Applying a waterproofing spray, a clear coat, or even just water-resistant paint can help plug up any tiny gaps in your part. Multiple coats may be needed depending on the part and the coating used.

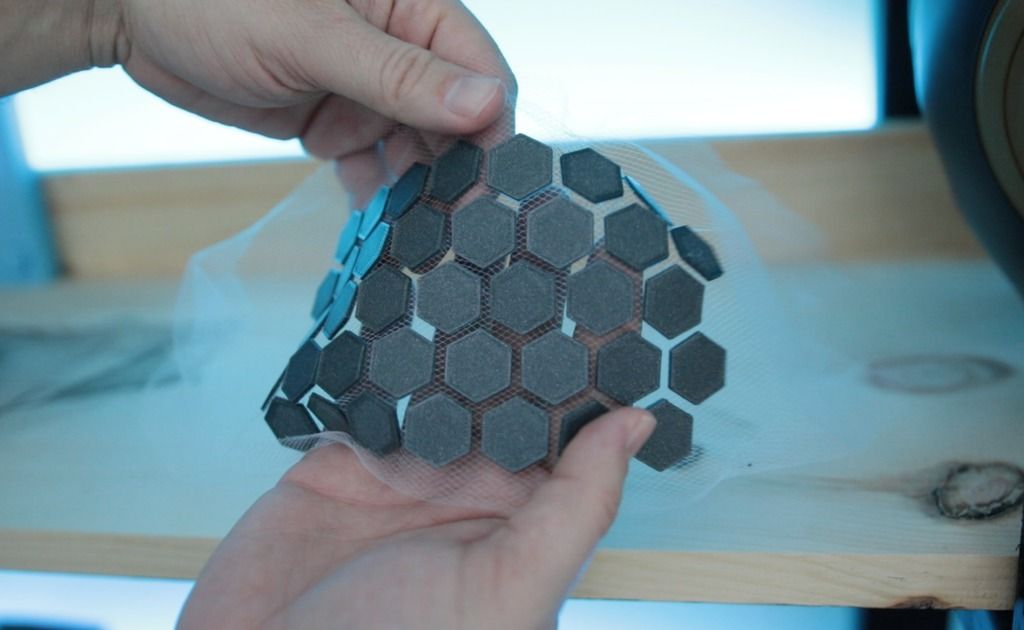

Vapor smoothing

Vapor smoothing using acetone for ABS or isopropanol for PVB is a great way to make a part more waterproof. Vapor smoothing is the process of using a chemical to melt the outer surface of a printed part just enough that it smooths out the part and removes the layer lines that are synonymous with FFF printed parts. Vapor smoothing is normally done to make a part look better but since it fuses the layers of a printed part together, it’s also a great way to fill gaps and make a part more waterproof.

Vapor smoothing is normally done to make a part look better but since it fuses the layers of a printed part together, it’s also a great way to fill gaps and make a part more waterproof.

Temperature treatment

Temperature treatment can be done in two ways and for two very different goals. The first is to apply heat to the outside of a print (usually with a heat gun) so that the outer surface melts just enough to fuse the layers together in order to remove the layer lines. This works in the same way as vapor smoothing and it helps remove gaps in the surface of a part and therefore makes it more waterproof.

The second is to heat soak a part over an extended period in an oven or other heated chamber. This process is called annealing. Annealing a part allows the layers of the entire part (even the interior) to bond together more strongly. This increases the strength of the part and makes it more temperature resistant in the future. This can result in PLA parts that have equal or higher temperature resistance to that of ABS or PETG parts.

What are the applications for waterproof parts?

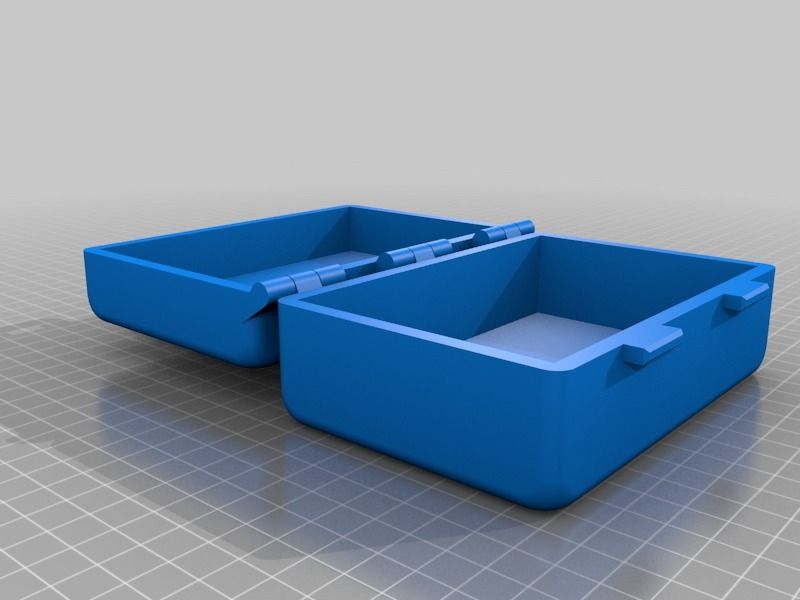

Once you have perfected printing waterproof parts, there is a whole world of possible applications. One obvious area is food and drinks related prints like bowls, cups, or water bottles. While all these prints are possible, we would advise against it as FFF prints are often not food safe and the process for assuring they are is beyond the scope of this article.

However, there are plenty of other applications for waterproof parts. Some examples are:

Scientific research

3D printed parts can be perfect for helping in scientific research related to fluid dynamics and microfluidics. An example of this in practice are the researchers at Cardiff University using 3D printed parts to study microfluidics in a way that is cheaper and more flexible than traditional alternatives.

Watch the videoGardening

Plant pots, composting containers, and hydroponics are just a few areas that are ripe for 3D printing to help with gardening. Beware that if you are using a printed part outside then you should make sure the material you use is suitable to the climate and environmental conditions. More robust materials like PETG and ABS might be a better choice than PLA, for example.

Beware that if you are using a printed part outside then you should make sure the material you use is suitable to the climate and environmental conditions. More robust materials like PETG and ABS might be a better choice than PLA, for example.

Water features

3D printed water features can be perfect for your pond or fish tank. And with the complete creative freedom that 3D printing provides, there’s no reason you can’t create an epic rube Goldberg-style water feature that fills your whole house with the soothing sound of gently flowing water.

We hope you enjoyed learning about how to print waterproof parts. If you found these tips valuable, you might be interested to know that a lot of the same techniques apply when trying to print transparent parts. To learn more, check out the blog post we did on the topic.

Read blog

Waterproof for high resolution 3D printing

Share to:

- Description

- Reviews (0)

- Delivery and payment

- Bulk request

Descriptions

Durable 100% polyester fabric, soft to the touch, with durable rust-resistant metal eyelets and high-strength plastic hooks. Water repellent, quick dry, mildew resistant, antibacterial, odorless, eco-friendly. High quality 3D printing with modern stylish designs, decorate your bathroom with artistic sense. Machine washable, no fading, easy cleaning

Water repellent, quick dry, mildew resistant, antibacterial, odorless, eco-friendly. High quality 3D printing with modern stylish designs, decorate your bathroom with artistic sense. Machine washable, no fading, easy cleaning

Datasheet

Design

Your shower curtain is the largest decorative element in your bathroom, so we put extra care into the design and craftsmanship of each piece. Choose from a wide variety of raw material, prints and textures in colorful fabric or waterproof PEVA.

Adds real value and depth to your bathroom decoration, high resolution pictures bring a 3D like realistic experience to your life.

It's a quick and luxurious way to refresh and completely change the appearance of a bathroom without a big expense.

Mildew Free

Mildew-resistant,odorless eco friendly,anti-bacteria keeps your curtain looking clean and fresh longer.

Soft Fabric

Durable 100 percent polyester fabric that is soft to the touch what are with rust proof reinforced buttonholes and high strength plastic hooks - these fabric shower curtains have no scent, unlike their vinyl counterparts.

Water-Repellent, Quick-Dry

Durable 100 percent polyester fabric is coated to allow water to easily glide off and resist soaking. Keeps water in the shower, Water glides off and the curtain dries quickly.

Machine Washable

Cleaning and maintenance are easy! Just toss it in the washing machine.

More Application

Except can be used as shower curtain,but also can be used in fitting room in dress shop,shelter and decorate your room.

Either a gift to your family or friend, relative or boyfriend girlfriend, or to yourself, it should be interesting and authentic. They will be shocked by the superior quality of the item when they open the present.

They will be shocked by the superior quality of the item when they open the present.

[Product Show]

- All (0)

- Photo (0)

- Video (0)

- Sort by: All

All Popularity Most Helpful Most Recent

-

Translate to English

Get G points! Be the first to write a review!

Do you want to buy in bulk? Please submit your wholesale inquiry below. Please note that we don't usually provide free shipping on bulk orders, but the wholesale price will be a big deal.

Your target price:

Ordered quantity:

Country

Your name:

Your phone:

Your email address:

Company name:

Detailed information about Request:

Your recently viewed goods

Pre-Sales Support

STL file Waterproof door・3D printing design for download・Cults

crane Abeille flandre

0,50 €

boat recovery

1. 50 €

50 €

Magnetic compass

4 €

Foghorn

4 €

Radar

0,50 €

Antenna

0.50 €

water bottle hook

3 €

boat recovery

1.50 €

crane Abeille flandre

0,50 €

Watertight door

0.50 €

Scale

0.50 €

bin

0.50 €

Best 3D printer files in Game category

Flying submarine

5 €

Elephant 3-layered-animal cnc/laser

Free

Dagger inspired by the Elder Scroll universe

7,90 €

Jumping Kangaroo

3 €

Deactivated

Thyrik, Hill Dwarf Sorcerer (28mm/Heroic scale)

Free

Benchus Maximus - Benchi Combiner

1. 73 €

73 €

Animal Crossing Fossil!

€10.61

Bestsellers in the Game category

Heavily armored warriors Catafrac - set of limbs

1,85 €

Savages Fotianna

9.65 €

Chopper motorcycle print-in-place

1 €

GIANT CROCODILE HINGED

4.28 €

Divisions Hrafnagud and ROKSS

9.65 €

Octopus 2.0

3.85 €

USS EnterSurprise - Play container for tiny F14 jet fighters

3.85 €

Snake and rattlesnake

3.85 €

Fighting director

1. 45 €

45 €

Voidwalker Exosuits Truescale

14.83 €

Healer Conversion Kit SM

6 €

Flying unicorn

1.05 €

Exolotreftes Truescal

5 €

Space Dwarf All - terrain vehicle

15.44 €

Bicycle

1.40 €

Champion Alteyra

4.83 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.