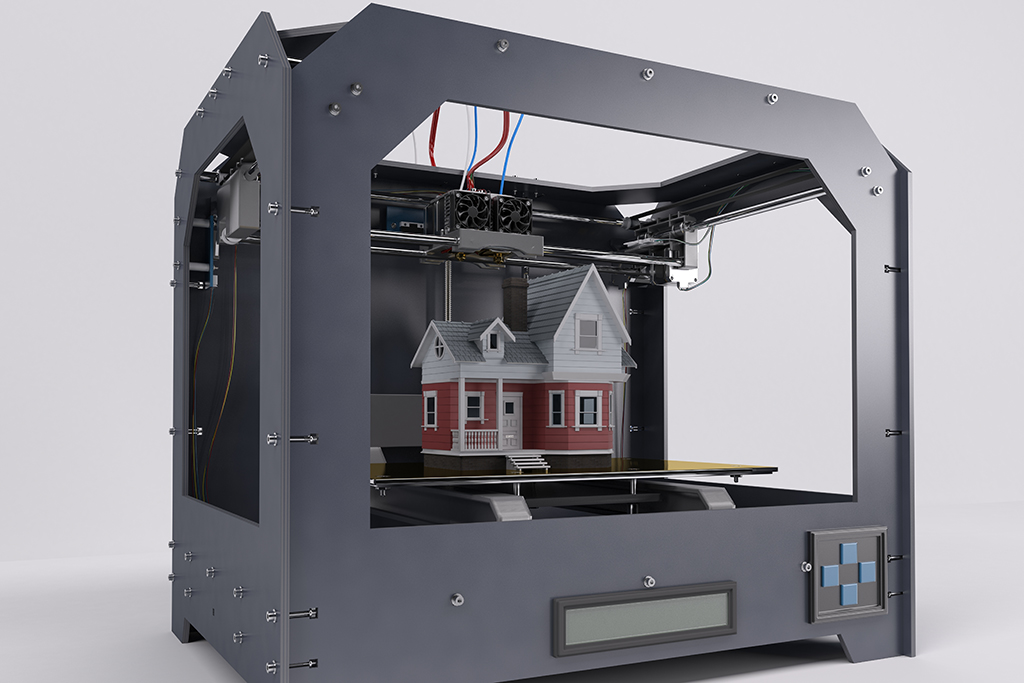

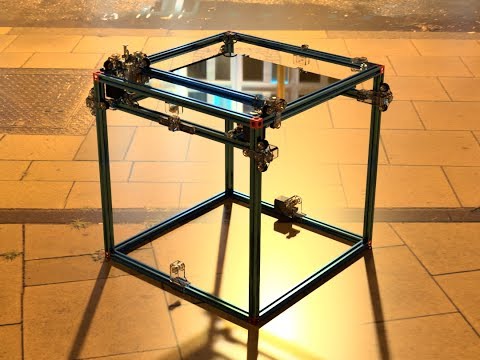

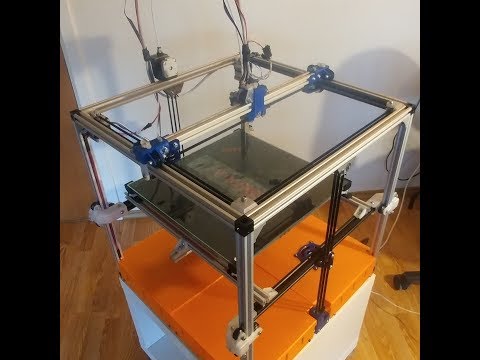

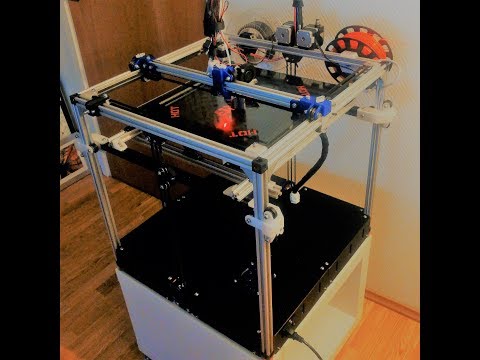

Vking 3d printer

V-King CoreXY – Viking 3D Printers

All that is special to the V-King CoreXY 3d Printer

You find your juction deviation number from using this formula: You can read more about it here: Calculating Juction Deviation

By Roy Berntsen, ago

There is a Google Spreadsheet with all parts for the V-king. If you wish to use it to keep track of what parts you have printed, you have to make a copy of the spreadsheet. Click here to have a look at the spreadsheet.

By Thomas Edvardsen, ago

Calibrate your printer This article will try to show you the best ways to calibrate your printer, and how to fine-tune your slicer settings for your chosen filament. Calibrate extruder steps/mmShould be done into the air with no nozzle pressure. Teaching Tech has described how to do this here. Level Read more…

By Thomas Edvardsen, ago

The community has created several components for the V-King printer. Below is an unverified list: Here is also a github community repository https://github.com/RoyBerntsenDesign/Vking-Community-Files V-King Enclosure Panels https://www.thingiverse.com/thing:3623752 V-King WyzeCam V2 Cover https://www.thingiverse.com/thing:3623734 V-King Panel Due 7i Enclosure https://www.thingiverse.com/thing:3583124 V-King Conduit https://www.thingiverse.com/thing:3583098 V-King Top Corner Cover https://www.thingiverse.com/thing:3510808 V-King Bottom Corner Cover Read more…

By kelly stephenson, ago

App for tuning: I use this app for tuning the belts: https://play. google.com/store/apps/details?id=com.stonekick.tuner For XY! Try using the note A1to B1 as a start and tension from there. Remember that too tens belts are worse than loose Try to get both sides same note but it is more important that the Read more…

google.com/store/apps/details?id=com.stonekick.tuner For XY! Try using the note A1to B1 as a start and tension from there. Remember that too tens belts are worse than loose Try to get both sides same note but it is more important that the Read more…

By Roy Berntsen, ago

How to place the idlers on a CoreXY 3d Printer? So since we are dealing with smooth and toothed idlers it is important to place them correctly inside the X-Idler brackets on the X axis Here is how it looks like seen from the motor side of the printer – Read more…

By Roy Berntsen, ago

Explaining X0, Y0 I drew up this to explain what is where on a CoreXY 3d printer It has no X or Y motor as they both work together and there is no front, left, right or rear on this printer as you choose this yourself X0, Y0 is always Read more…

By Roy Berntsen, ago

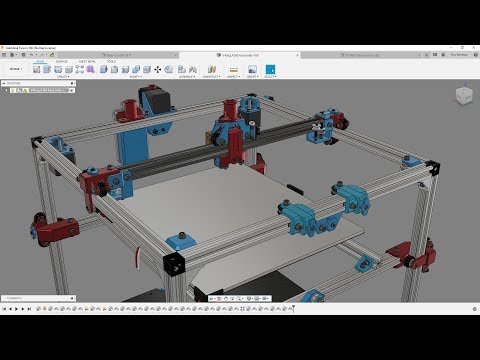

YouTube Playlists: The Complete Animation Playlist Live Build Video Playlist A360 3D Viewing Links: V-King Top Assembly The X-Carrier

By Roy Berntsen, ago

Optical Endstop Setup The same should apply to other type of 3 wire endstop like mechanical ones Make sure V from end-stop goes to 5V on board, G to GND and S to Dx (x is a number on the pinout) Endstop and Flag Placement

By Roy Berntsen, ago

Project Valkyrie – Viking 3D Printers

High Temp – DIY 3D Printer

Valkyrie – High Temp – Liquid Cooled – DIY 3D Printer- Frame footprint – 500X520X750

- Print volume – 310X310X300

- Weight ~45Kg

- Extruder Temp < 450C (stage 1)

- Bed Temp < 150C (stage 1)

- Chamber Temp < 80C (Stage 1)

- Drybox Temp < 70C (Stage 1)

File repository here: Project Valkyrie

Join our Discord Server for all updates. Join the Facebook group here. View the CAD here

Join the Facebook group here. View the CAD here

- Advanced Kinematics with independent triple Z axis

- Fully automated bed leveling

- Inverted CoreXY for minimal friction – only 2 toothed idlers vs 6

- XUV Triple Z True Bed Leveling with the precis Maxwell Coupling as the Z lift

- Stall-detection homing on all 2+3 – XY+ZUV axis

- Light tool-head riding on carbon X with MGN9h

- All XYZ stepper motors all located outside the heated chamber

- Temperature Controlled Heated Chamber up to 80C+

- Active heated chamber using a fan and the bedheater as the heater source

- Engineered insulation options for high level of safety and minimal thermal loss

- High end ACM Outer Paneling

- Double glazed window for inside viewing and good insulation

- Integrated Temperature Controlled Heated Dry-box

- Filament weight control by load-cell

- Dry-box temp control up to 70C

- Dry-box humidity sensor

- Advanced Firmware add-ons

- Chamber temp controls and display

- Dry-box temp control and display

- Dry-box humidity display

- Filament weight display

- Extruder motor temp sensor and display

- Water-cooled hotend

- Option to water-cool extruder stepper motor

Product Choice

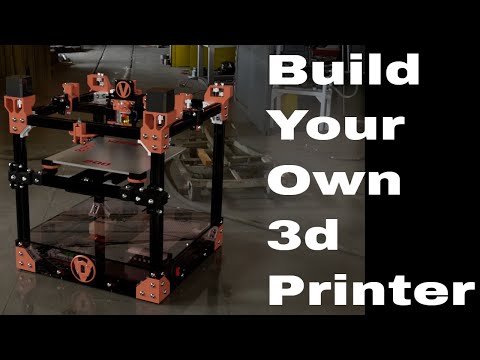

The aim is to develop a Premium DIY FDM 3d printer for the DIY 3d printer community

- Safety features must be very high

- Fully automated bed leveling

- Engineered advanced Z lift with kinematic coupling

- Integrated dry-box filament container

- We want to be able to print high temp materials

- The project will be open source

- Size should be scalable < 500

- Standard alu profiles.

2040 and 2020

2040 and 2020 - Belted Z drive

- Advanced Firmware options

- Enclosed chamber with engineered insulation for <80C Chamber temp

Function Choices

The machine should have all the functions needed for a trouble-free user experience. The goal is to implement all basic functions plus any feature that is making an advanced high temp premium 3d printer

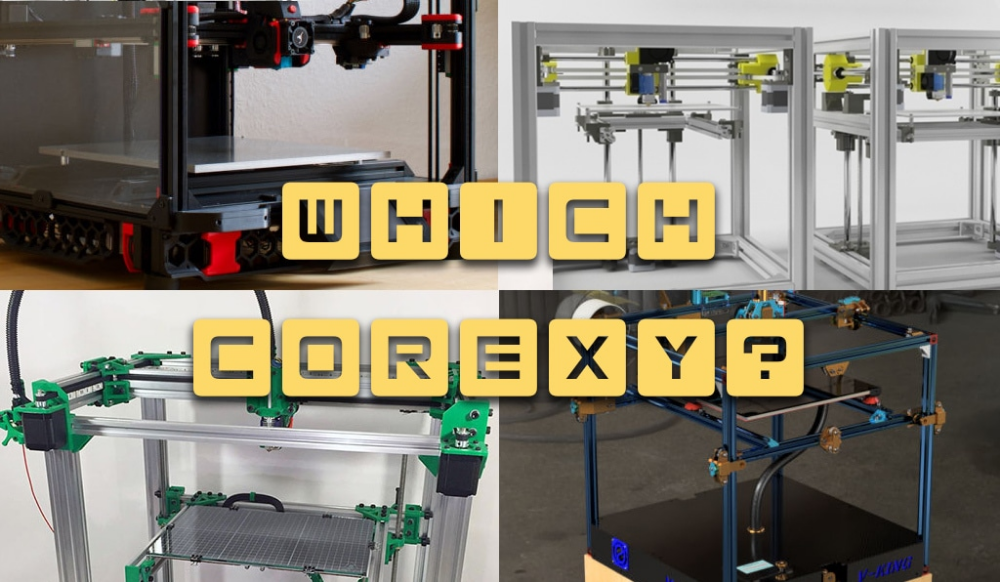

DIY Type Projects – No High Temp options can be found

- Ratrig V-Core 3

- Hevort

- Voron

- BLV MGN Cube

- VZBot

Comparable Industrial Grade

- Bambu X1 Carbon

- FUNMAT HT

- CreatBot F160

- VM 22 IDEX

Roy Berntsen – Norway – Lead Engineering Designer

Mark Bridgewater – New Zealand – Mechatronics Design

Cris Lombardi – USA – Firmware, Design and Advanced features

3D Printer Sharebot VIKING | Machine World

3D Printers & Scanners / 3D Printers / Resin Printers / 3D Printer Sharebot VIKING

Service

Taiwanese equipment is highly reliable, well-proven components are used in its production.

The warranty period for equipment is 1 year from the date of signing the acceptance certificate. In the event of a warranty case, spare parts and repairs are absolutely free for the customer. Troubleshooting is carried out by the own service department World of the Machine Tool. The main spare parts are in our warehouse, repairs take a short time. nine0003

Leasing

We have extensive experience in supplying equipment to Leasing. Contact us for details.

Warranty

The warranty period for the equipment is 1 year from the date of signing the acceptance certificate. In the event of a warranty case, spare parts and repairs are absolutely free for the customer.

Tools and accessories

Our technologists and programmers will work out the technology for free and write control programs for the manufacture of your parts. Including we can supply equipment with technology and production of a batch of parts. You pay for equipment, tooling and tools. The Machine Tool World is an official dealer of the leading tool manufacturers, so we can offer competitive prices and delivery times. nine0003

You pay for equipment, tooling and tools. The Machine Tool World is an official dealer of the leading tool manufacturers, so we can offer competitive prices and delivery times. nine0003

Writing control programs

Our software engineers will write control programs for your details. He has experience in implementing complex projects in the defense and aviation industries. When you purchase a tool from us, the service is free.

Commissioning

Commissioning of the equipment takes place in several stages: installation of equipment, accuracy check and signing of the accuracy check certificate, manufacturing of parts and signing of the equipment acceptance certificate. Training of your employees takes place simultaneously with commissioning and launch of parts. nine0003

Delivery

Delivery time for most items is 10-12 calendar days. Warehouse items are delivered within 1-2 working days from the date of payment of the invoice. When invoicing, our process engineer without fail checks the availability of items in the warehouse and informs you. Delivery is carried out by courier service at our expense.

When invoicing, our process engineer without fail checks the availability of items in the warehouse and informs you. Delivery is carried out by courier service at our expense.

Writing control programs

Our software engineers will write control programs for your details. He has experience in implementing complex projects in the defense and aviation industries. When you purchase a tool from us, the service is free. nine0003

Warranty

We guarantee the correct selection of tools and accessories, corresponding to your tasks. Free replacement in case of error.

Price on request

Op. Zone-190x120x200 mm

Technology-LCD

Type-Professional

Material-Photopolymer

Service

0068

Product Description

Sharebot Viking is a photopolymer 3D printer with a large build chamber and resin series available for any application.

It is used both for making jewelry and for creating any other models, from mechanics to prototyping. A wide range of resins makes it possible to obtain finished models with a variety of structural characteristics, suitable for any sector of use and production.

Sharebot Viking is very easy to use and comes with Pyramis, a 3D printing management software that provides optimal model support. nine0003

Specifications

| Technology | LCD |

| Platform dimensions | 190 x 120 x 200 mm |

| Z resolution | 50 – 100 µm |

| XY plane accuracy | 75 µm |

| Approval | 37. 5 µm 5 µm |

| Print speed | Max. 15 mm/h (depending on photopolymer) |

| Firmware | Pyramis |

| Wave length | 405 mm |

| Connection | USB - WIFI - Ethernet |

| Display | 3. 5” touch screen 5” touch screen |

| Dimensions | 390 x 270 x 470 mm |

| Weight | 21 kg |

Tasks

Direct production of end product and tooling

Production of functional prototypes and visual models

Research work and educational tasks

Foundry processes

industries

Medicine

Jewelry

Education

Consumables

S-TUGH 9000 G-Model 9000 G-STRONG 9000 S -HARD

S-CLEAR

S-WAX

Media

Photopolymer

Accessories

Sharebot DUC 9 ultrasonic cleaner0007 Sharebot UCB curing chamber

Warranty

1 year

Brochure with tech.

Features

Features Yes

Scroll Up

3D print in 1-2 days! White photopolymer

What do you get?

- Material: white photopolymer

- Printing accuracy: 100 microns

- 3D printers: Sharebot VIKING, Protofab SLA 600, Voxeljet VX500

- Max. model dimensions: 600 × 600 × 400 mm

- Technology. Stereolithography (SLA) - layer-by-layer curing of a liquid material under the action of a laser beam

- We work with companies and individuals

- Convenient geographical location of the production premises - Moscow (10 minutes from Kuntsevskaya metro station)

request a call

All you need is...

nine0002 3D model in .STL format.No .STL file?

We will help you scan the product to create a 3D model

submit your applicationImportant information

- What if I need to print not just one product, but a whole series?

- For small-scale production, we recommend using photopolymer resin printing.

nine0260

nine0260

Ready to discuss all your questions!

Fill out the form or call +7 (495) 223 01 21

Request a call

Additional services

3D scanning

leave a request

Plastic injection molding

Submit a request more

nine0088 Examples of our workThe most interesting orders of our clients in various industries

see all works

Obtaining a 3D support bearing

- #3D Scan

more details

Mercedes car scan for video tour

- #3D scan

more

Aircraft 3D scan

- #3D scan

more details

Creating a NURBS model of rubber car mats

- #3D modeling

more details

3D-modeling and control of deviations of the mechanism body part

- #3D-modeling

more details

3D simulation of lifting unit

- #3D simulation

more details

Three-dimensional jewelry stencils

- #3D print

more details

3D print car headlight

- #3D print

more details

3D printing of a combine part from casting wax

- #3D printing

more

BIM model for restoration of a cultural heritage site

- #BIM modeling

more

BIM model for church restoration

- #BIM modeling

more details

Construction control of a building in Khimki

- #BIM-modeling

more details

Fork production

- #Plastic molding

more details

Measurements of the facade of the fashion house Dior

- #Measurements

more

Scanning the interior of the apartment

- #Measuring work

details

Scanning a church in the Tver region to obtain data for restoration

- #Measuring works

details

Our clients

Aluminum and alumina production

Russian state company. Operator of the Russian railway network

Operator of the Russian railway network

Manufacture of military and civil aircraft. Flight personnel training

Russian airline. Domestic and international passenger air transportation

R&D in the field of nanotechnology, robotics, space activities, ammunition

Design and manufacture of equipment for thermal, nuclear and hydroelectric power plants

Defense enterprise. Military-technical cooperation of the Russian Federation with foreign partners

Russia's leading design bureau for submarine shipbuilding

Design, manufacture and after-sales service of aircraft

Development and production of complexes, systems and communications for the Armed Forces of the Russian Federation

Leading university of the Upper Volga region

002 Engineering University. One of the nine backbone universities in RussiaLeading enterprise in Russia for the production of metal spans of bridges

Russian instrument-making concern. Manufacture of electronic equipment for the Russian Navy

Manufacture of electronic equipment for the Russian Navy

Creation of equipment for control systems of aviation and rocket technology, as well as for gas and oil pipelines

The largest research institute in the country, solving problems of defense, scientific and national economic importance

Development, manufacture and maintenance of engines for the aerospace industry

Development, production, testing, operation support, maintenance of aircraft equipment

Creation and maintenance of the aerospace defense system in the interests of the security of the Russian Federation and civil aviation

Manufacture of equipment for post-harvest processing, drying and storage of grain

Equipment park

- Sharebot VIKING

- Protofab SLA 600

- Voxeljet VX500

Sharebot VIKING

Technology: LCD/ UV Resins nine0003

Material: photopolymer

Max. model dimensions: 190 x 120 x 200 mm

model dimensions: 190 x 120 x 200 mm

Layer thickness: Z resolution 50 - 100 µm, XY accuracy 75 µm

Protofab SLA 600

Technology: Stereolithography (SLA) is a layer-by-layer laser-assisted curing of a liquid material. Suitable for creating mock-ups, tooling and burn-out models for casting. nine0003

Material: photopolymer

Max. model dimensions: 600 × 600 × 400 mm

Layer thickness: 0.05 - 0.25 mm

Voxeljet VX500

Technology: Powder Binder Jetting (PBJ)

Material: PMMA - Modified Polymethyl Methacrylate Powder (PBJ)

Max. model dimensions: 500 x 400 x 300 mm

Layer thickness: 70 µm

Photopolymer characteristics

White (can be changed)

Density

1. 21 g/cm³ (at 25°C)

21 g/cm³ (at 25°C)

Tensile strength, MPa

43-48 MPa

Thermal deformation temperature

56-60°C

Shore D, %

81-85%

nine0088 Material3D printing sla, or photopolymer printing, is a technology for manufacturing three-dimensional objects using layer-by-layer photopolymerization under the action of a laser beam. With its help, a three-dimensional object created on a computer is synthesized from a liquid polymer in successive thin layers of 0.05-0.2 mm, formed under the action of laser radiation on a moving platform.

The materials used in photopolymer 3d printing are very diverse and are considered universal. So, products made from them can be transparent, colored, matte, rigid, resistant to high temperatures and even biocompatible. nine0003

They are used in modern 3D prototyping, 3D master model making and end products. Also, such 3D products are suitable for experiments and functional tests.

Services

-

making master patterns for casting two-component polyurethanes into silicone

-

creation of burnout patterns for metal casting in mechanical engineering and jewelry

nine0070 -

manufacture of dental prototypes, prostheses, crowns, elements of the bones of the skull and jaw

-

creation of master models, fully functional prototypes

-

manufacture of end products

Advantages of laser stereolithography technology

- impressive precision

- the ability to create geometrically complex, smallest and thin-walled objects

- light post-processing

- perfect surface finish

- the best choice for subsequent low-volume production using vacuum casting technology in silicone molds

- good moisture resistance

- high speed additive systems

Resin specifications

- Standard

Characterized by increased strength and flexibility.

It makes it possible to produce parts with a flat and smooth surface.

It makes it possible to produce parts with a flat and smooth surface. - Robust

The material is very similar to ABS and has maximum strength and good toughness and ductility relative to other resins.

- Rigid

It has the characteristics of both durable and standard resin. It has increased tensile strength. nine0070 - Heat resistant

Due to its high melting point, which can reach up to 238°C, the resin is ideal for parts requiring high temperature resistance.

- Ceramic

A very rigid material that does not warp, making it possible to create parts with thin walls and a polished surface.

nine0087

3D services using SLA technology at TWIZE

We provide sla 3d printing services in Moscow, and we also deliver finished prototypes to all cities of the Russian Federation and CIS countries. Our specialists will print your model with an accuracy of up to 100 microns in just 1-2 days.