Petg 3d printer

Everything you need to know about PETG 3D printing

Before you get started with PETG 3D Printing, we’ve compiled some of the basic information you’ll need to know. Read on to learn the advantages, disadvantages, history and applications of PETG 3D printing.

PETG Filament and 3D Printed Vacuum Nozzle

FDM (fused deposition modeling) 3D printing is one of the most practical and popular 3D printing technologies today due to its ability to print a wide range of materials (i.e., polymers, composites, metals). One such material is PET, a polymer most notably used to make plastic bottles, among other consumer packaging products, making it one of the world’s most-used plastics. Due to its adaptability, PET has become popular as an FDM 3D printing material in the modified version called PETG.

PETG is a reliable and affordable material with a lot to offer for designers and engineers, among other users. Through this article, you will find more information about this versatile filament, including benefits, drawbacks and how to get the best results for PETG 3D printing.

PET AND PETG - VERSATILE POLYMERS

Chemical Composition

PET (polyethylene terephthalate) is a transparent and lightweight thermoplastic polymer resin part of the polyester family that is derived from petroleum. First synthesized by the DuPont Company in the 1940’s, PET has become the world’s most used plastic. PET can be easily modified for use in a wide range of applications with the modifier being identified as a suffix letter in the name.

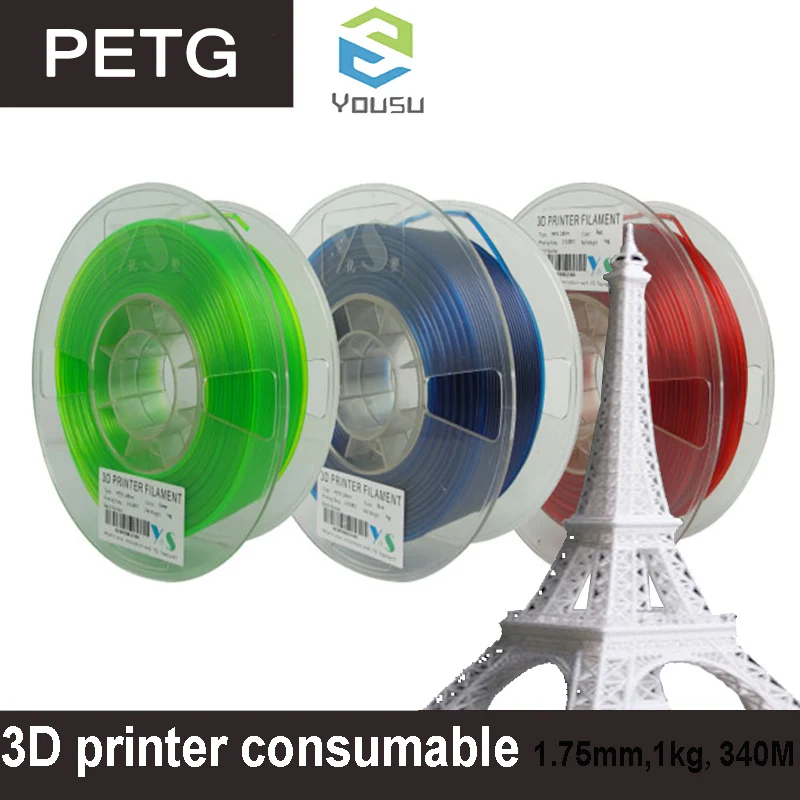

PETG is a modified version of PET, with the “G” standing for “Glycol,” a molecule added during the polymerization process to make it less fragile, more durable and easier to use. This version is preferred for FDM filaments used in additive manufacturing and is generally translucent but also available in a range of colors. PETG exhibits excellent mechanical properties and also boasts resistance to moisture, chemicals and heat, particularly when compared to PLA.

Applications of PET

Food and beverage packaging often takes advantage of PET in the form of PETE due to its limited reactivity to moisture and chemicals. PETE is one of the most commonly recycled types of plastic due to its sheer volume of production.

PETE is one of the most commonly recycled types of plastic due to its sheer volume of production.

Source: Coca-Cola

Packaging for consumer products other than foods such as cosmetics, soaps and detergents, and various other reactive chemicals are used by major consumer products companies like Procter & Gamble and Colgate-Palmolive.

Source: Colgate-Palmolive

The textiles industry utilizes PET in both new and recycled form to create polyester fabrics. These textiles products can range greatly - from fleece jackets to sleeping bags to dog beds and much more.

Source: Patagonia

In dentistry and orthodontics, PETG is used for dental aligners with some of the more recent brands, like Invisalign and Smile-Direct Club, creating plastic, form molded alternatives to traditional metal braces.

Source: Invisalign

PETG 3D PRINTING

Applications of PETG 3D Printing

PETG is now widely available as a filament for FDM 3D printers and, thanks to its material properties, has become popular in a number of different professional applications.

When working on new concepts, designers and engineers can take advantage of its transparency, moisture and chemical resistance to make great functional prototypes such as containers for liquids, signage and graphic displays, enclosures for electrical equipment, etc. The most obvious use of PETG 3D printing is for the design and prototyping of the packaging for consumer products that will be later made out of some form of PET when it enters mass production.

Also suited for more demanding environments, where heat and chemical resistance is required in addition to mechanical resistance, machinists and manufacturing engineers can use PETG to create durable custom parts such as manufacturing tools and aids, testing components or robotic end effectors.

Additionally, because PETG remains a durable and performant polymer, engineers and machinists can create true end-use parts including snap fits and living hinges, protective guards or custom machine parts.

MakerBot PETG Material

Tips for PETG 3D Printing

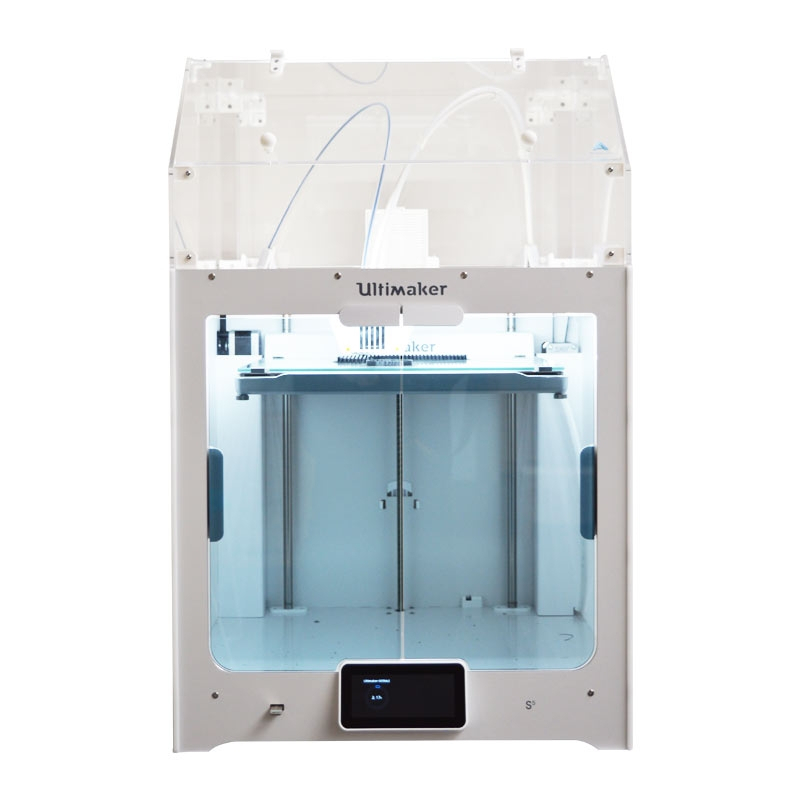

The material properties for PETG vary depending on the material grade or producer, so it is best to follow the manufacturer’s recommendations first and foremost (MakerBot PETG, for example, is optimized and tested to work with METHOD and thus the default settings will yield optimal results).

Generally, PETG’s melting point is around 260°C, and it starts transitioning to a more liquid state at about 230°C. Don’t forget to ensure your FDM extruder and nozzle are able to heat up to temperatures in this range. Additionally for best results, it is recommended to use an FDM 3D printer with a heated print bed or, even better, a heated build chamber with a temperature setting somewhere around 60°C-80°C. This will enable better temperature control when the polymer starts to solidify and minimize the risk of warpage.

For optimal adhesion of the part in PETG 3D printing, it is highly recommended to use a build plate adhesive – a regular old glue stick will work for this. This will help prevent the print from curling off of the print bed which can be a common occurrence in PETG 3D printing.

| PARAMETER | Imperial | Metric |

|---|---|---|

| Moisture Resistance (ISO 62) | 1,104 ppm | 1,104 ppm |

| Heat Deflection (ASTM 648, 66 psi) | 158°F | 70°C |

| Flexural Strength (ISO 178) | 10,007 psi | 69 MPa |

| Flexural Modulus (ISO 178) | 297,327 psi | 2,050 MPa |

| Tensile Strength at Yield (ISO 527) | 7,251 psi | 50 MPa |

| Tensile Modulus (ISO 527) | 292,976 psi | 2,020 MPa |

| Strain at Yield - Elongation (ISO 527) | 6% | 6% |

| Notched Impact Strength (Charpy Method 23C) | 3. 85 ft-lb/in² 85 ft-lb/in² | 8.1 kJ/m² |

Specifications for MakerBot PETG

Ultimate Materials Guide - Tips for 3D Printing with PETG

Overview

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear. The material also benefits from great thermal characteristics, allowing the plastic to cool efficiently with almost negligible warpage. There are several variations of this material in the market including PETG, PETE, and PETT. The tips in this article will apply to all of these PET-based filaments.

- Glossy and smooth surface finish

- Adheres well to the bed with negligible warping

- Mostly odorless while printing

- Poor bridging characteristics

- Can produce thin hairs on the surface from stringing

Hardware Requirements

Before 3D printing with PET / PETG make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 75-90 °C

Heated Bed Recommended

Enclosure Not Required

Build Surface

Glue Stick

Painter’s tape

Extruder

Temperature: 230-250 °C

No special hot-end required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PET / PETG such as stringing, oozing, and poor bed adhesion.

Invest In a Good Build Surface

Some 3D printers come with a glass bed or blue painter’s tape installed on the bed. Although these surfaces might work fine for PETG, we recommend using a heated build platform for best results. The heated bed can significantly improve the first layer adhesion, making things much easier for future prints. Many of these heated beds come with a glass surface, allowing you to print directly on the bed without needing to apply any additional layers of tape or glue.

Calibrate Retraction Settings to Reduce Stringing

One of the few common issues that we see with PETG is stringing. These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model.

These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model. If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

Optimize Extruder Settings to Prevent Blobs and Zits

When 3D printing at higher temperatures associated with PETG, you may notice small blobs or zits on the surface of your model. These print defects typically occur at the beginning or end of each segment, where the extruder has to suddenly start or stop extruding plastic. There are several ways to eliminate these print defects such as enabling “Extra Restart Distance” or “Coasting” options located in the Extruder tab. Simplify3D also includes an option to perform a dynamic retraction, where the filament is retracted while the extruder is still moving. This completely eliminates blobs that are typically formed from a stationary retraction. To learn more about these features and other tips for reducing blobs on the surface of your print, please refer to our Print Quality Guide.

Pro-Tips

- The glossy surface of PETG is especially useful when using rafts. The part separates easily from the raft and maintains a clean surface finish.

- Try disabling your part cooling fan for the first few layers of the print to prevent warping. This trick especially works well for larger prints.

Get Started with PET / PETG

Now that you are ready to start printing with PET / PETG, here are a few ideas to help you get started – from common applications to popular filament brands.

Common Applications

- Water proof applications

- Snap fit components

- Planter Pot

Sample Projects

- Self-watering Planter

- Water Bottle

- Snap Fit Parts

Popular Brands

- ColorFabb PETG

- eSun PETG

- E3D Spoolworks Edge

- Hatchbox PETG

- HobbyKing PETG

PETG 3D Printing Filament - Details & Comparison

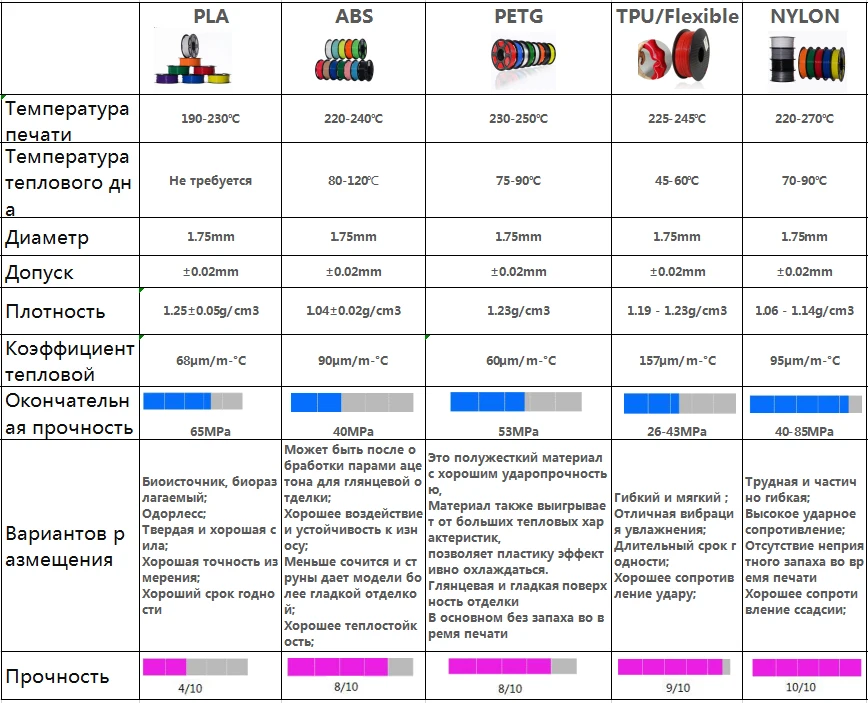

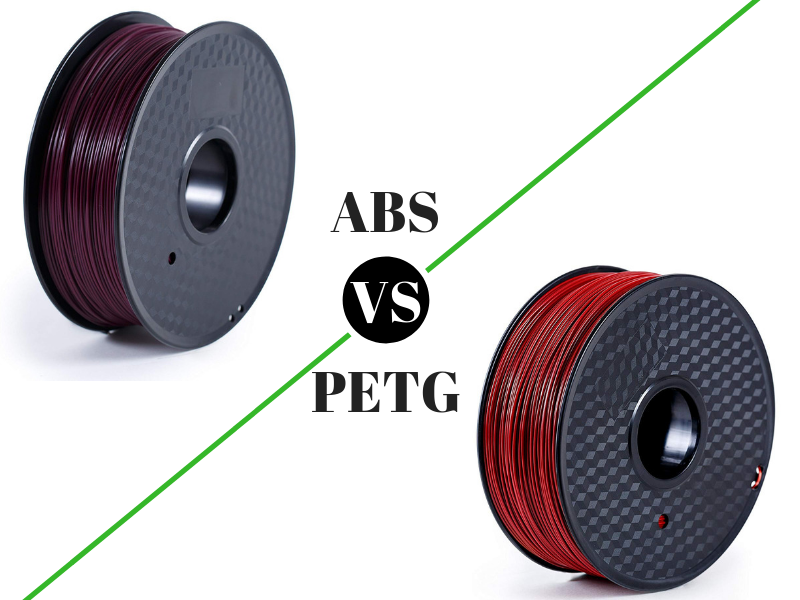

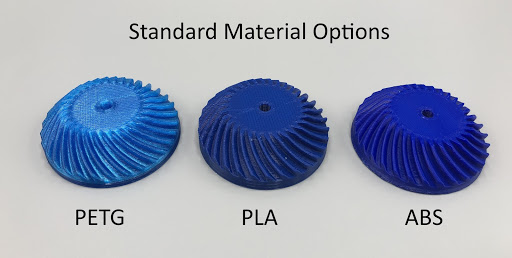

PETG is said to combine the advantages of ABS - strength, heat resistance, durability - and PLA - ease of use.

Advantages of PETG over other materials

- PETG is considered to combine the advantages of ABS (strength, heat resistance, durability) and PLA (ease of use).

- Layer fusion is generally excellent.

- Low heat shrink. You can not be so afraid of distortions in the size of printouts.

Differences between PET and PETG

PET (polyethylene glycol terephthalate) is a plastic resin. It is the most used plastic in the world. Its fibers can be found in clothing, food containers, industrial plastic sheets, and in combination with fiberglass for technical resins. Thousands of types of goods, food and beverages are supplied and packaged in this material. nine0003

PETG (also called copolyester PET) is a modified version of PET. The modification consists in adding a second glycol tail during polymerization. It turns out an irregular molecular structure, the plastic is clean and amorphous, the glass transition temperature is about 88 °C.

The main advantages of PETG over PET are as follows:

- It is more durable. If you heat regular PET too much, it becomes cloudy and brittle. What doesn't happen with PETG: The added glycol prevents crystallization and breakage. The new material also has impressive impact-resistant properties. nine0010

- Unlike PET, it is UV-impermeable.

- It can be professionally printed and can be sterilized.

Is PETG food safe?

Yes, it is considered as such in almost all countries. Just in case, it is worth checking the specifications provided by the manufacturer.

What are the disadvantages of PETG?

There are not many of them. First, this plastic scratches more easily than PET. In addition, under the influence of ultraviolet light, its structure becomes weaker. Some manufacturers claim that this is not the easiest material to print and that you need to find a middle ground when using it. nine0003

What is the optimal temperature and speed for 3D printing PETG?

Most manufacturers recommend a hot end temperature of 200 to 230°C. It is convenient to start the first printout at 210–220 °C.

It is convenient to start the first printout at 210–220 °C.

Look at the first layers: if the material extrudes sluggishly, the temperature should be raised a little. You can also start at a low speed, say 15 mm/s, and increase it until you get the best result.

Is table heating required?

Preheating is optional, but may be useful, especially if large parts are distorted. It is quite possible to print without heating, but you will have to tinker with the settings a bit. nine0003

Some manufacturers claim that standard hairspray and masking tape tricks don't work with this plastic.

Please use the temperature of the substrate specified in the specification: if it is not indicated, try 80 °C and make sure that the first layer adheres to the substrate.

How to store PETG?

In a dry place. Dampness changes this filament, as a result of which it may turn out that it is impossible to print with it or all sorts of nonsense is obtained. nine0003

nine0003

Fortunately, both PET and PETG are virtually unaffected by normal ambient humidity, so printing and storage are no problem. And yet, it is good that the filament is stored in as dry a place as possible, next to the silicate bags.

If you often have problems with 3D printing, read the article about filament storage

PETG plastic - optimal 3D printer settings 3DPrintStory

3D printing process PETG plastic - optimal 3D printer settings One of the positive things about FDM 3D printing is the huge variety of materials you can work with. There are flexible materials, those that mimic the finish of wood, and some even have some degree of electrical conductivity. nine0003

There are flexible materials, those that mimic the finish of wood, and some even have some degree of electrical conductivity. nine0003

The downside of having all of these filament options is that each of them requires some specific usage. In this article, we will look at how to get good quality 3D prints using PETG plastic, which, judging by the trends, will soon become one of the most popular. What 3D printer settings are best for PETG? What problems can you face when printing PETG plastic?

What is PETG?

PETG is a derivative of the extremely popular polyethylene terephthalate (PET). The "G" in PETG stands for "high glycol". The addition of a glycol group makes PETG slightly stronger and less brittle. It also has better optical properties and is easier to work with than PET. It has excellent chemical resistance and is a good moisture barrier. nine0003

In the world of 3D printing, PETG is often touted as the best of the two most popular materials, PLA and ABS. It prints at high temperatures, which provides good heat resistance. However, it does not have a high shrinkage ratio and has better adhesion between layers, which means that it does not have major warping problems. It also does not emit harmful gases during printing, which is one of the worst aspects of printing with ABS.

It prints at high temperatures, which provides good heat resistance. However, it does not have a high shrinkage ratio and has better adhesion between layers, which means that it does not have major warping problems. It also does not emit harmful gases during printing, which is one of the worst aspects of printing with ABS.

So PETG gives you almost all of the mechanical and chemical benefits of ABS with the same ease of processing as PLA. It is a good choice for functional parts that must withstand constant movement or pressure. Using PETG plastic, you can get almost completely transparent products, which makes it an excellent material for decorative elements. nine0003

Set up the 3D printer table

If you've ever printed with ABS, you know how difficult it is to get the first layer of an ABS model to grip the table. PETG also has some problems, but the reverse is that it sticks too well. If you do not take the necessary measures, you may end up with a finished model that cannot be removed from the table without damage.

Because of the high printing temperatures of PETG, you still need a heated bed. A sudden drop in temperature will almost certainly cause warping if your 3D printing table is too cold. For PETG plastic, it is recommended to set the table temperature between 70° and 80° C. If you still have problems with adhesion to the layer at these settings, you can gradually increase the temperature up to 100° C.

To ensure that the 3D printed model comes off easily enough, it is recommended to use an adhesive that will come off with the model, such as glue stick or hairspray. Do not print directly on the glass to avoid scratching the table surface. Don't use BuildTak as every time you work with PETG you will almost certainly damage the BuildTak surface (which can be quite expensive).

Since PETG has no adhesion problems, it is not necessary to set the nozzle too low for the base coat. This is a technique used to "press" the first layer onto the table and improve the adhesion of the base layer. If you already have a run-in nozzle height setting for ABS or PLA, you can safely set a value that is two or three times higher for PETG. To improve aesthetics, it is worth using as high values as possible, so you can start with the maximum values and gradually lower them if you have any problems with adhesion. nine0003

If you already have a run-in nozzle height setting for ABS or PLA, you can safely set a value that is two or three times higher for PETG. To improve aesthetics, it is worth using as high values as possible, so you can start with the maximum values and gradually lower them if you have any problems with adhesion. nine0003

If you want to accurately calibrate the nozzle height, a setting of 0.02-0.05 mm nozzle to table is a good starting point. You can set this to both the initial height of the nozzle and the height for the rest of the 3D model.

3D printing temperature, speed and retract

The main reason PETG is compared to ABS is that it prints at relatively high temperatures. A range of 220° to 265° C is commonly used, but your plastic manufacturer's recommendations may vary slightly. While PETG virtually eliminates any kink issues, you still run into other issues. nine0003

The first thing you need to do is determine if your 3D printer is capable of reaching the required temperatures. Some 3D printers provide 250°C, especially those that use PTFE tubing inside the extruder assembly. If you try to print with the wrong equipment, you will end up ruining not only your model, but also your extruder.

Some 3D printers provide 250°C, especially those that use PTFE tubing inside the extruder assembly. If you try to print with the wrong equipment, you will end up ruining not only your model, but also your extruder.

Setting the 3D print speed is a matter of getting the balance right, which should also consider the 3D print temperature. Printing at high speed, if your temperature is too low, can cause "overshoot" in the extruder because the material is not soft enough to come out of the nozzle. However, fast printing at very high temperatures can cause material residue to form between the voids in the model. nine0003

Start with a relatively moderate speed of 25 mm/s. If there are no problems with this setting, then you increase the speed to 50 mm/s. This should be enough to get a good PETG model without spending too much time. You can see information about printing PETG at 60 mm/s, but this is probably the absolute maximum if you do not want to have problems with material residue between the walls of the model.

Dealing with plastic residue between the walls of model

One of the most common problems when using high temperature materials is the aforementioned plastic residue, cobwebs between the walls. This occurs when molten material seeps out of the nozzle as the print head moves. These plastic residues are particularly troublesome when using PETG, as the material is strong and difficult to remove.

Unfortunately, the material that melts at high temperatures also has a low viscosity, which makes it even more prone to web formation. If you're having this problem when 3D printing PETG plastic, the first step is to lower the temperature and print speed a bit, although this will definitely reduce the overall time it takes to print any model. nine0003

Another option is to enable retract on your 3D printer, if possible. The retract allows the extruder mechanism to "pull in" a small amount of material to relieve pressure on the molten material that is right at the tip of the nozzle. You can refine some parameters, such as retraction distance or speed, until there are no signs of plastic residue.

You can refine some parameters, such as retraction distance or speed, until there are no signs of plastic residue.

Turning down the cooling fan speed

PETG prints great and maintains a good level of detail without a cooling fan. Lack of cooling will also lead to better adhesion between coats. Printing PETG with the cooling fan turned off is perfectly normal. nine0003

Some users find it not worth using the fan only for the first two layers and then printing with the fan at 100%. This can be a good case if your 3D model has a lot of bridges and protrusions, or if you want your product to be as detailed as possible. In any case, watch out for any signs of cracks or layers peeling off during 3D printing, as PETG prints at high temperatures and doesn't like sudden changes in temperature. nine0003

The key to success is experimentation

PETG can be easier to work with than ABS, but if you're just getting started with it, it's worth learning about its features. Different grades of PETG materials can also behave differently and unpredictably. It may take some time to properly adjust the 3D print temperature, bed temperature, print speed, and retract settings. But once you find that sweet spot, you can enjoy all the benefits of PETG without the many problems that other plastics have. nine0003

Different grades of PETG materials can also behave differently and unpredictably. It may take some time to properly adjust the 3D print temperature, bed temperature, print speed, and retract settings. But once you find that sweet spot, you can enjoy all the benefits of PETG without the many problems that other plastics have. nine0003

When buying, you should choose polyethylene terephthalate filament from a reliable manufacturer and work only with it without changing the manufacturer. Before you can get the optimal settings, you will probably have to print a few unsuccessful models. But don't despair, keep optimizing your settings and after a while working with PETG will become easier.

Conclusions

Many 3D printing professionals have long brag about PETG because of its potential to dethrone ABS from the Big Two position. After all, it has comparable properties, but it's not that hard to work with. nine0003

To say that PETG is as easy to work with as PLA is an overstatement.