Variquest 3d printer

VariQuest Blog | VariQuest Tools: Trifecta 800 3D Printer

VariQuest Tools: Design Center Software | VariQuest Tools: Perfecta 2400 | VariQuest Tools: Cutout Maker 1800 | VariQuest Tools: Cold Laminator 2510 | VariQuest Tools: Trifecta 800 3D Printer | Kinesthetic Learning | VariQuest Tools: Motiva 400 | VariQuest Tools: Perfecta 2400STP | VariQuest Tools: Perfecta 3600STP

By: VariQuest Visual and Kinesthetic Learning Suite

March 11th, 2020

At VariQuest, we offer many tools and resources to help you enhance the learning environment in your classroom. Our interactive learning tools for teachers and students are highly effective for helping children flourish in the classroom and increase in their knowledge and comprehension of different subjects. With the latest trends in classroom technology, teachers are turning more to interactive methods of teaching, and using the various tools that make this way of relating information, data, concepts, and ideas possible. Educators have numerous opportunities to present information in a fun and engaging way through interactive learning.

Read More

STEM | Academic Subject: STEM | Featured Topics: Student Engagement | VariQuest Tools: Trifecta 800 3D Printer | 3D Printing | Trifecta™ 800 3D Printer | Kinesthetic Learning | Project-based Learning | Makerspace

By: VariQuest Visual and Kinesthetic Learning Suite

December 10th, 2019

40 years ago, would you have predicted that every household in America would have a need for a computer? 20 years ago, would you have predicted that every person would need to surf the internet on a phone - a mobile phone? Probably not. It's hard to imagine a world where every household would have a 3D printer, but that time could feasibly come sooner than we think.

It's hard to imagine a world where every household would have a 3D printer, but that time could feasibly come sooner than we think.

Read More

How to Write a Grant eBook

This helpful guide includes an explanation of the grant process, including a checklist (with samples!), and useful links and resources to find funding!

Lessons/Activities/Templates | VariQuest Product Updates | Featured Topics: Industry News and Trends | VariQuest Tools: Cutout Maker 1800 | VariQuest Tools: Cold Laminator 2510 | Featured Topics: Templates for FREE download | VariQuest Tools: Trifecta 800 3D Printer | VariQuest Tools: Motiva 400 | VariQuest Tools: Perfecta 2400STP | VariQuest Tools: Perfecta 3600STP

By: VariQuest Visual & Kinesthetic Learning Tools

August 8th, 2019

In the spring of 2019, we made a big commitment to our customers. We promised LOTS of new and revised content and we're happy to report - we've delivered. Just in time for back-to-school! We are thrilled to announce that our VariQuest® Design Center Software v8.0 is now available for download - packed with over 900 NEW templates, cutouts, graphics, fonts, and collections - bringing our grand total to over 19,000 content options for our nation's best educators to create with. And it's FREE for our customers!

We promised LOTS of new and revised content and we're happy to report - we've delivered. Just in time for back-to-school! We are thrilled to announce that our VariQuest® Design Center Software v8.0 is now available for download - packed with over 900 NEW templates, cutouts, graphics, fonts, and collections - bringing our grand total to over 19,000 content options for our nation's best educators to create with. And it's FREE for our customers!

Read More

VariQuest Tools: Cutout Maker 1800 | Featured Topics: Funding | VariQuest Tools: Trifecta 800 3D Printer | VariQuest Tools: Motiva 400 | VariQuest Tools: Perfecta 2400STP | VariQuest Tools: Perfecta 3600STP

By: VariQuest Visual & Kinesthetic Learning Tools

February 4th, 2019

According to the U. S. Department of Education website, the Title I Grant program is meant to provide funding to disadvantaged Local Educational Agencies (LEAs) to improve their academic achievement. The most common of these, Title I - Part A, "...provides financial assistance to LEAs and schools with high numbers or high percentages of children from low-income families to help ensure that all children meet challenging state academic standards." As these funds are meant to improve instruction and provide additional academic support and learning opportunities, they are often allocated towards reading or mathematics curriculum, supplemental programs to reinforce and extend the regular school curriculum, or additional staff members to lead and teach the students. And as we look at the bright future of the job market as it relates to STEM and 21st Century skills, we'd like to give you some ideas for tools that Title I Funding can be used for!

S. Department of Education website, the Title I Grant program is meant to provide funding to disadvantaged Local Educational Agencies (LEAs) to improve their academic achievement. The most common of these, Title I - Part A, "...provides financial assistance to LEAs and schools with high numbers or high percentages of children from low-income families to help ensure that all children meet challenging state academic standards." As these funds are meant to improve instruction and provide additional academic support and learning opportunities, they are often allocated towards reading or mathematics curriculum, supplemental programs to reinforce and extend the regular school curriculum, or additional staff members to lead and teach the students. And as we look at the bright future of the job market as it relates to STEM and 21st Century skills, we'd like to give you some ideas for tools that Title I Funding can be used for!

Read More

Lessons/Activities/Templates | Common Core | Grade Level: Secondary (7-12) | Grade Level: Intermediate (3-6) | Featured Topics: Classroom Celebrations/Holidays | Featured Topics: Common Core | VariQuest Tools: Cold Laminator 2510 | Featured Topics: Lessons and Activities | Academic Subject: Mathematics | VariQuest Tools: Trifecta 800 3D Printer | 3D Printing

By: Carman Le

March 15th, 2018

"Class, what is the Order of Operations?" My energetic class of fifth graders shouted out loud, "Please Excuse My Dear Aunt Sally!" What? Who is Aunt Sally? When students initially learn how to add, subtract, multiply, and divide, they are taught to perform those skills using two numbers and one operation. As they progress to the next levels, they begin to see numerical expressions with more than one operation and word problems that involve multiple steps. Introduce your students to the Order of Operations - and help them memorize the "PEMDAS" or "Please Excuse My Dear Aunt Sally" acronym as early as third grade. Putting this memory into practice can be more of a challenge - so we've come up with some tips and a fun lesson plan activity for your students to drive the concept home!

As they progress to the next levels, they begin to see numerical expressions with more than one operation and word problems that involve multiple steps. Introduce your students to the Order of Operations - and help them memorize the "PEMDAS" or "Please Excuse My Dear Aunt Sally" acronym as early as third grade. Putting this memory into practice can be more of a challenge - so we've come up with some tips and a fun lesson plan activity for your students to drive the concept home!

Read More

VariQuest Super Schools | Student Engagement | STEM | Academic Subject: STEM | VariQuest Tools: Trifecta 800 3D Printer | Trifecta™ 800 3D Printer | Project-based Learning

By: VariQuest Visual & Kinesthetic Learning Tools

January 18th, 2018

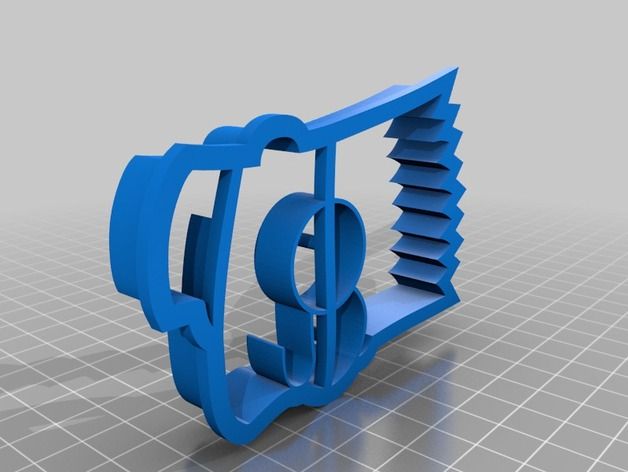

3D Printing is a relatively new concept in education curriculum - but it engages all kinds of learners, and instills real-world critical thinking and innovative problem-solving 21st century skills. Seems to be a no-brainer for an educator looking to breathe new life into a STEM curriculum. At Holly Grove Elementary School in Holly Springs, North Carolina, Ms. Jennifer Starkey, a technology teacher, has been thrilled to watch her students design, create, and learn when the VariQuest Trifecta™ 800 3D Printer brings their ideas to life - which has made her classroom the most popular in the school. With over 1,100 students in grades K-6, including some Pre-K and special education students, Ms. Starkey needed a solution to engage every learner. Starting with her 2nd, 4th, and 5th graders, who are fully immersed in the 3D printing hands-on learning tasks, the classroom has turned out some pretty amazing projects as they Ask, Imagine, Plan, Create, Improve, and Share (The Engingeering Design Cycle). It's easy to see how 3D Printing is benefiting education at Holly Grove...

Seems to be a no-brainer for an educator looking to breathe new life into a STEM curriculum. At Holly Grove Elementary School in Holly Springs, North Carolina, Ms. Jennifer Starkey, a technology teacher, has been thrilled to watch her students design, create, and learn when the VariQuest Trifecta™ 800 3D Printer brings their ideas to life - which has made her classroom the most popular in the school. With over 1,100 students in grades K-6, including some Pre-K and special education students, Ms. Starkey needed a solution to engage every learner. Starting with her 2nd, 4th, and 5th graders, who are fully immersed in the 3D printing hands-on learning tasks, the classroom has turned out some pretty amazing projects as they Ask, Imagine, Plan, Create, Improve, and Share (The Engingeering Design Cycle). It's easy to see how 3D Printing is benefiting education at Holly Grove...

Read More

Academic Subject: STEM | VariQuest Tools: Perfecta 2400 | VariQuest Tools: Cutout Maker 1800 | Featured Topics: Student Engagement | VariQuest Tools: Trifecta 800 3D Printer

By: Melissa Hughes, Ph. D.

D.

April 18th, 2017

We used to call it hands-on learning. Before high-tech classrooms, learning labs, and makerspaces, kids would build and create and make things using buttons, bottle caps, popsicle sticks, and glue. The focus was on exploration, discovery, creativity, and problem-solving. There was no clear distinction between the arts, engineering, science, and math. Kids were making things, expressing their creativity, and they were learning how things worked. The current buzzword is experiential learning, but the concept has been around for over 100 years. Dr. Maria Montessori would be thrilled to see the future of education rooted in her research. The movement of “making” brings engineering, science, technology, art and design together and overlaps those instructional principles with the natural inclinations of children the power of learning by doing.

Read More

Academic Subject: STEM | Featured Topics: Student Engagement | Academic Subject: Science | Featured Topics: Lessons and Activities | Academic Subject: Mathematics | VariQuest Tools: Trifecta 800 3D Printer | Trifecta™ 800 3D Printer

By: Heidi Glasow

March 10th, 2017

"If you build it they will come"- Field of Dreams, 1989. Dan Hurley, Director of Discovery Charter School in Inver Grove Heights, MN had the same dream in 2014, although not for a baseball diamond in his field, but rather a school to embrace a multidisciplinary curriculum with an emphasis on Science, Technology, Engineering and Mathematics (STEM). His vision was to prepare K-8 students for life-long learning, collaboration, critical thinking and problem solving. Just over one year ago his dream became a reality, and now over 200 students are engaged in an environment that values creativity, diversity, and multiculturalism. With Dan's vision a partnership also ensued with VariQuest and Trifecta™ 800 3D Printer, and STEM Fuse, a leader in K12 digital curriculum. Dan knew in order to fulfill his dream he needed to build his 'Dream Team'.

Dan Hurley, Director of Discovery Charter School in Inver Grove Heights, MN had the same dream in 2014, although not for a baseball diamond in his field, but rather a school to embrace a multidisciplinary curriculum with an emphasis on Science, Technology, Engineering and Mathematics (STEM). His vision was to prepare K-8 students for life-long learning, collaboration, critical thinking and problem solving. Just over one year ago his dream became a reality, and now over 200 students are engaged in an environment that values creativity, diversity, and multiculturalism. With Dan's vision a partnership also ensued with VariQuest and Trifecta™ 800 3D Printer, and STEM Fuse, a leader in K12 digital curriculum. Dan knew in order to fulfill his dream he needed to build his 'Dream Team'.

Read More

VariQuest Tools: Trifecta 800 3D Printer | 3D Printing | Trifecta™ 800 3D Printer

By: Geena Maharaj

September 1st, 2016

It was the best of times, it was the worst of times, it was the age of 2D art, it was the age of 3D models. Okay, maybe this story doesn't share the poetic eloquence of Dickens' silver-tongue-take on the French Revolution, but it is indeed a tale of a girl's goal being fulfilled by her grit, her moxie, and Trifecta™ 800 3D Printer.

Okay, maybe this story doesn't share the poetic eloquence of Dickens' silver-tongue-take on the French Revolution, but it is indeed a tale of a girl's goal being fulfilled by her grit, her moxie, and Trifecta™ 800 3D Printer.

Read More

STEM | VariQuest Tools: Cutout Maker 1800 | Academic Subject: Science | VariQuest Tools: Trifecta 800 3D Printer | 3D Printing | Trifecta™ 800 3D Printer | Kinesthetic Learning

By: Geena Maharaj

November 12th, 2015

I remember how fascinated I was by Morse code when I first heard about it as a young fry. I can only imagine the proverbial lightbulb (well, probably a candle at that time) that went off in Samuel Morse’s mind as he came up with the idea for nonverbally telecommunicating with others. No offense Sam, but boy, finger tapping conversations have come a long way.

I can only imagine the proverbial lightbulb (well, probably a candle at that time) that went off in Samuel Morse’s mind as he came up with the idea for nonverbally telecommunicating with others. No offense Sam, but boy, finger tapping conversations have come a long way.

Read More

Trifecta™ 800 & STEM:IT - AudioVisual Company – Audio Visual Equipment and Services

Trifecta 800 & STEM:IT

The VariQuest® Visual Learning Tools provide innovative instructional support, giving students with diverse learning capabilities the tools to succeed. The specialized instructional solutions, like Trifecta™ 800 3D Printer here, combine visual and kinesthetic learning experiences, helping to facilitate information retention, student interest, and lateral thinking. VariQuest® Tools allow for a superior interactive classroom experience for both students and educators.

USER GUIDE

TECHNICAL DATA SHEET

Trifecta

PRODUCT OVERVIEW

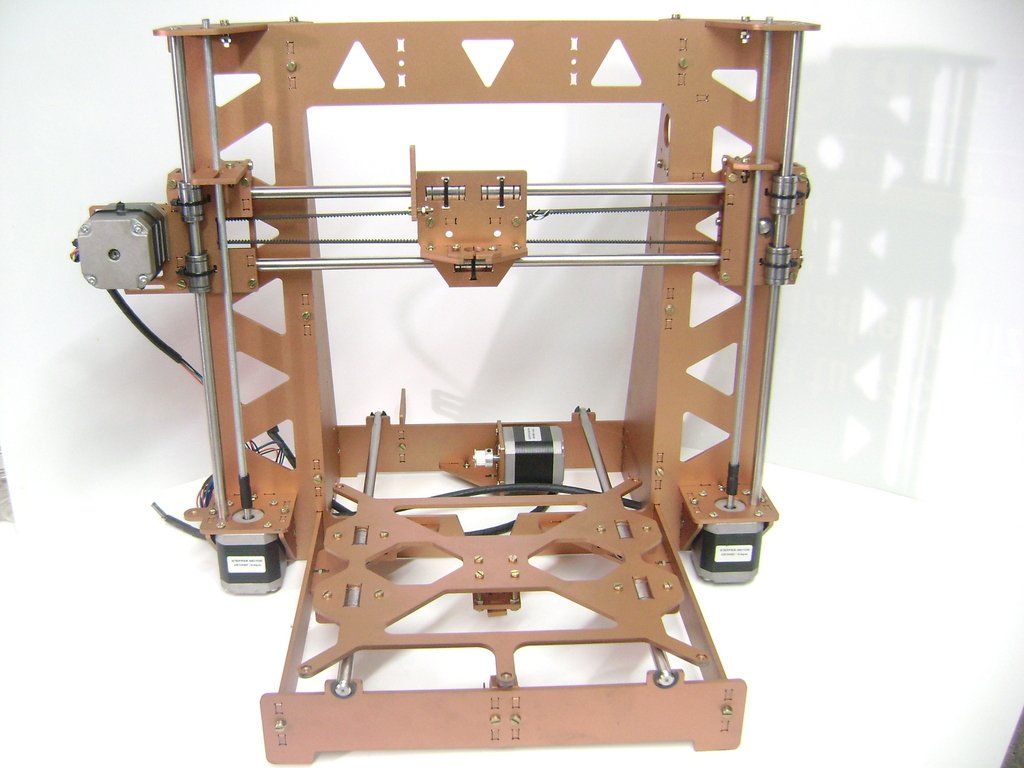

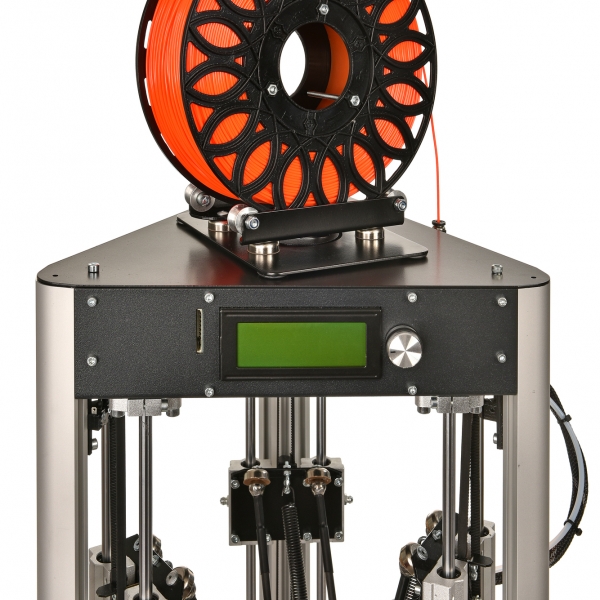

While other printers are made to appeal to a wide variety of markets, the focus of Trifecta™ 800 3D Printer is exclusively on enhancing K-12 students’ education. Curious learners will love the open design for better viewing during prints, educators will appreciate the printer’s light weight and small footprint for ease in moving from desk to desk, and environmentalists will admire the filament’s biodegradable properties.

STEM:IT

PRODUCT OVERVIEW

In the STEM:IT curriculum, educators can explore K-12 project-based lessons comprised of STEM, coding, 3D design, and interdisciplinary concepts. Lessons and challenges are aligned to national and state standards. Each lesson contains Teacher Resources that include poster templates, 3D print files, and step-by-step guides with rationales.

SCHEDULE A DEMO

Use TrifectaTM 800 & STEM:IT to:

- Differentiate instruction by providing another means of acquiring, processing, constructing content and ideas in a digital and physical capacity

- Address the needs of kinesthetic, visual, and auditory learners by walking through printing a three-dimensional object and relating it to its STEM:IT lesson

- Engage students with whole-brain experiences that combine left-brained analysis tasks with right-brained visual perception learning

- Amplify the value of makerspaces by connecting curiosity with curriculum

- Instill real-world critical thinking and innovative problem solving while incorporating 21st century skills

REQUEST SUPPLY QUOTE

VARIQUEST PRODUCTS

TOOLS THAT TRANSFORM CLASSROOMS

Perfecta® 2400STP and Perfecta® 3600STP

Perfecta 2400 STP and Perfecta 3600STP have a fully-integrated scanner and comes equipped with the VariQuest Design Center, a touch-enabled workstation storing thousands of education-based templates and graphics, making poster-designing a cinch.

Perfecta® 2400PRO

Create full-color posters and banners with the brand new Perfecta® 2400PRO, a wide-format printing system that includes the VariQuest Design Software on our touch-screen workstation, designed to work together with all VariQuest tools.

Trifecta™ 800 & STEM:IT

While other printers are made to appeal to a wide variety of markets, the focus of Trifecta™ 800 3D Printer is exclusively on enhancing K-12 students’ education.

Cutout Maker 1800

A revolutionary, digital die-cut system created specifically for schools, the Cutout Maker will help you bring lessons to life with automatically-cut letters, numbers, manipulatives, shapes and bulletin board collections.

Poster Maker 3600

Reinforce key learnings, encourage cooperative group work and promote school pride with easy-to-customize, quick-printing posters & banners made with this ink- & toner-free tool.

Design Center 2300 & Software

Created with educators, students, and parents in mind, the Design Center 2300 and VariQuest Software will help increase academic achievement, boost productivity and transform your school.

Cold Laminator 2510

Make posters, banners, and cutouts last longer with the easy-to-use VariQuest Cold Laminator 2510.

Learning Modules

Aligned to Common Core State Standards, the VariQuest Learning Modules include cross-curricular activities that incorporate the use of visuals and manipulatives...

Motiva™ 400

Reward students, teachers and staff quickly and affordably with the Motiva™ 400. Create full-color personalized award plaques, flashcards, study aids, bumper stickers, parking permits, and more with this on-the-spot recognition and fundraising tool.

Perfecta® 2400

Designed by the makers of the original Varitronics PosterPrinter™ – used by over 37,000 schools since 1988 – the VariQuest Perfecta™ 2400 System is your ideal solution for printing full-color posters.

13 BEST CONSTRUCTION 3D PRINTERS OF 2019

A 3D construction printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm.

In both cases, paste-type components such as concrete are used as the filament. The material is ejected from a special nozzle to form layers. In simpler (very) extrusion of pasta is like using a bag to dispense frosting on a cake.

The printer builds foundations and walls layer by layer. The base is literally the printer's build plate. However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm).

Benefits of building 3D printing

• Eco-friendly : 3D printed houses can be built with sustainable materials. What's more, some construction 3D printers use solar energy and emit little CO2.

• Affordable: 3D construction printers can build affordable housing, providing great relief to people in poor areas or after natural disasters.

• Scalable: 3D construction printing reduces certain construction costs. For example, the cost of 1 square meter of wall using traditional construction methods is approximately $75, while for an Apis Cor house 3D printer it is only $27.

• Efficient: Because materials are 3D printed on demand, machines produce less waste. In addition, 3D construction printers can complete the foundation of a house in less than a few days, while traditional construction methods take weeks or even months.

• Design flexibility: Curved walls and unique facades can be easily created with a 3D printer

Disadvantages of 3D construction

• Expensive initial investment: These 3D printers can sometimes cost up to a million dollars.

• Partially Built Houses : Only house frames are built. The 3D printing process is usually paused to manually install plumbing, wiring, and fittings.

• Rough Appearance : The exterior of most 3D printed houses is not as smooth as traditional houses.

• Lack of Certification: Construction sites are regulated by law and there are important safety standards that must be met, which can be difficult with 3D printing methods (different repeatability, dimensional stability, etc.).

CONSTRUCTION 3D PRINTERS: OVERVIEW

We divide construction 3D printers into three categories: house building 3D printers that you can buy, prototype concrete printers, and concrete 3D printing services.

Home 3D printers available

AMT printers

Pictured: AMT S-6044 Long and AMT S-300

), 11 x 31 x 80 (maximum)

• Material: Concrete / Clay / Gypsum

• Country: Russia

Equipment manufactured by AMT-SPETSAVIA - workshop and field portal construction 3D printers (COP-printers, Construction Objects Printing): and from small-format (for printing small architectural forms ) to large (for printing buildings up to 30 floors high). Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

BetAbram P1

• Assembly size : 1.6 x 8.2 x 2.5 m

• Material : Concrete

• Country : Slovenia

BetAbram is a small Slovenian team that has been working on building 3D printing equipment since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second iteration and is available with additional printheads: basic, "Orto" for smoother layers, and rotatable for more design options.

COBOD BOD2

• Build size : 11.98 x 45.07 x 1.53 m

• Material : Concrete

• Country : Denmark

This construction 3D printer is fast, with a speed of up to 18 meters per minute. BOD2 is modular and can be adapted to various sizes. COBOD is a 3D Printhuset company.

Constructions-3D 3D Constructor

• Assembly size : 13 x 13 x 3.8 m

• Material : Concrete

• Country : France Their 3D Constructor machine is mobile thanks to its rubber tracks and fits in a 20ft shipping container for easy transportation from one construction site to another.

CyBe Construction CyBe RC 3Dp

• Assembly size: 2.75 x 2.75 x 2.75 m

• Material: Concrete

• Country: Netherlands This easy-to-use 3D printer is capable of reaching heights of up to 2.75 meters and only requires two people to operate.

ICON Vulcan II

• Build Size : 2.6 x 8.5 x ∞ m

• Material : Concrete

• Country : United States

ICON wants to revolutionize the construction industry with its Vulcan II printer. The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

MudBots Concrete 3D Printer

• Build Size : 1.83 x 1.83 x 1.22 m (minimum)

• Material : Concrete

• Country : United States of Mudts003 Concrete 3D Printers USA. Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Stroybot2

Build Size : 10m x 15m x 6m

Material : Concrete

Country : United States

StroyBot, also known as the Rudenko 3D Printer, is a versatile mobile design printing system supplied as a build kit user. On average, he can print a 100 square meter house in 48 hours (walls only).

WASP Crane WASP “Infinity 3D Printer”

• Build Size : Ø 6. 3 x 3 m

3 x 3 m

• Material : Concrete / Earth materials

• Country : Italy

WASP Crane is an evolution of the previous WASP construction printer 12MT. This open source builder is modular and multiple Crane printers can work together on the same project, giving theoretically endless 3D printing possibilities.

Concrete printers work projects

Apis Cor 3D printer

• Assembly size : 8.5 x 1.6 x 1.5 m

• Material : Concrete

• Country : United States

Apis Cor, a 3D based construction company Francisco and claims to be able to 3D print a house in less than 24 hours. Their Apis Cor printer is similar to a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Batiprint3D 3D Printer

• Build Size : -

• Material : Concrete / Other

• Country : France

Batiprint 3D made headlines internationally when it completed the Yhnova 3D print shop in Nantes, France. Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

S-Squared ARCS VVS NEPTUNE

• Build Size : 9.1 x 4.4 x ∞

• Material : Concrete

• Country : United States

S-Squared, also known as Square3D "4D printing", which aims to provide fast, reliable, environmentally friendly and affordable housing for poor areas. ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale.

Construction printing services

Contour Crafting 3D Printing System

• Material: Material: Concrees

• Country: United States

This automatic construction system is capable of 3D -printing large buildings and high -high infrastings. Contour Crafting (also known as CC Corp) aims to improve the effectiveness of disaster relief through concrete admixture technology.

XtreeE 3D Printer

• Build Size : -

• Material : Concrete

• Country : France

XtreeE develops custom 3D printing solutions for construction, engineering and architectural design. This startup is located in France and has already completed a number of 3D construction projects.

This startup is located in France and has already completed a number of 3D construction projects.

Wax3D. From drawing to metal.

It has been a year and a half since we started selling our modeling wax composition for 3D printing of wax molds for metal casting. At first, there were many doubts, including ours, that this material was generally needed by someone. There were fears that the value of the totality of its consumer properties lies outside the range of economic feasibility. I had to experiment a lot, work with foundries across the country, communicate with both foundry workers and with the end customers of castings. In fact, we have come a long way in introducing our technology into production: from an idea that arose more than 2 years ago to working with end customers of castings on a commercial basis.

Somewhat unexpectedly for us, we are engaged not only in the production of Wax3D, but also in the printing of wax waxes on order, and at the moment, in the full cycle of work with clients. This was not our goal from the beginning, but as it turned out, you can tell someone for a long time and stubbornly and explain the prospects, but all this is empty when there are no real examples of commercial use. And what can be commercial use if no one is doing it? The result is a vicious circle. A year of speeches at various forums, exhibitions and seminars showed that the public somehow revives only by the time the photos of real waxes appear on the big screen and, most importantly, castings made from them. And it is desirable that these were not trinkets. Based on the understanding received, the decision was born: to do it yourself. For, as they say in the troops of Uncle Vasya: 'No one but us'!

This was not our goal from the beginning, but as it turned out, you can tell someone for a long time and stubbornly and explain the prospects, but all this is empty when there are no real examples of commercial use. And what can be commercial use if no one is doing it? The result is a vicious circle. A year of speeches at various forums, exhibitions and seminars showed that the public somehow revives only by the time the photos of real waxes appear on the big screen and, most importantly, castings made from them. And it is desirable that these were not trinkets. Based on the understanding received, the decision was born: to do it yourself. For, as they say in the troops of Uncle Vasya: 'No one but us'!

The path is difficult, but, as it turned out, quite commercially justified!

For about half a year now, the queue for wax printing has not been getting smaller, despite the constant growth of the printer fleet. On average, machine time for printing from Wax3D is scheduled for all machines for a period of 3 to 4 weeks.

Now, re-reading the comments to my first articles on wax printing, I can't help but smile - there was so much skepticism and doubt! However: 'The dog barks, the caravan moves on.' - a principle for all time.

This concludes the lyrical introduction. Let's move on to facts and figures.

Initially, I wanted to give detailed information in this section with numbers, formulas for calculating the cost and cost-effectiveness, but I realized that this would be beyond the scope of such an article, and no one would read it anyway. That's why I didn't waste my time or yours. Everything is short and sweet.

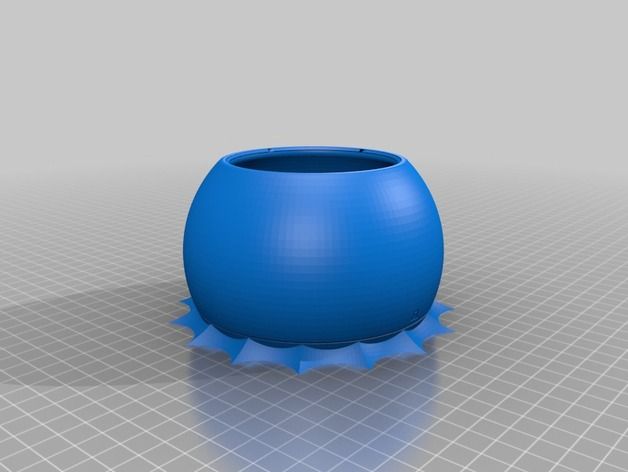

1. What products are Wax3D stencils suitable for?

For any products, the detailing of which does not exceed the capabilities of FDM 3D printing. That is, these are not jewelry, but rather the casting of rather large technical parts.

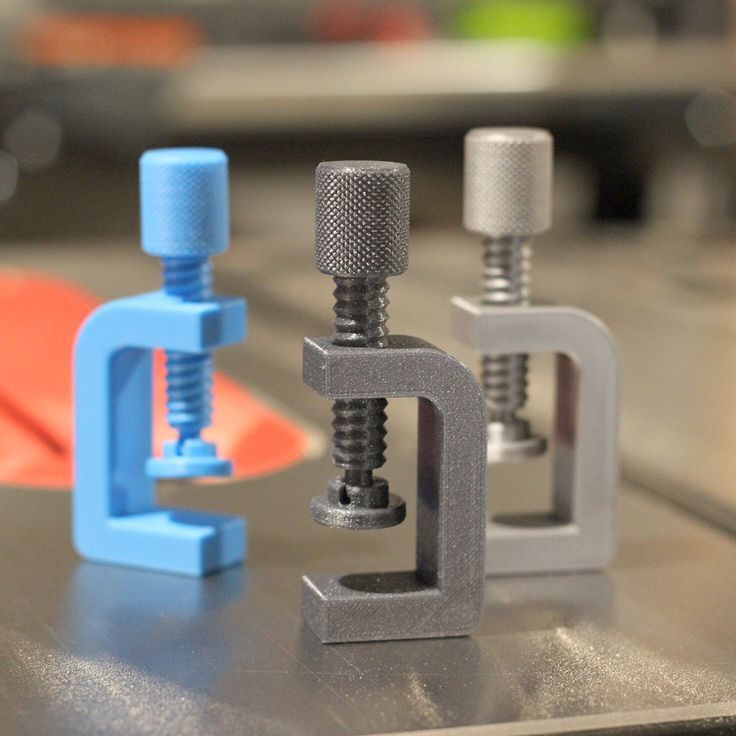

The photo shows examples of what we have been doing lately:

Meticulous quality control ))

Bronze casting on printed wax wax

2. For which runs is the technology suitable?

For which runs is the technology suitable?

From a single piece to a run of dozens of stencils. With the increase in circulation, the cost of the final product falls slightly.

Here's a simple example we've been working on:

We were commissioned to print a batch of stainless steel test casting waxes. 4-12 copies of each item were printed. The cost of one stencil ranged from 500 to 1500 rubles. That is, the average price of wax can be taken for 1000 rubles.

For a trial run, this price is more than justified, since the cost of manufacturing wax casting equipment for one wax mold in this case is on average 150.000 rubles. Subsequently, after all approvals and field tests, each product had its own wax casting equipment. This was justified, since the circulation of each casting subsequently amounted to about 5000 copies and the price of the tooling added only 3-5 rubles to the price of the final product. It is not difficult to estimate that a batch of 150 castings is on the borderline of the expediency of manufacturing tooling. For smaller batches, it is advisable to use 3D printing of Wax3D stencils.

For smaller batches, it is advisable to use 3D printing of Wax3D stencils.

Staples, staples... A whole bunch of staples!

But the staples are already made of steel. No wonder they tried!

3. Economic feasibility. To what extent is printing from Wax3D with subsequent casting more profitable than other technologies for producing metal products?

In short, the entire production cycle of a casting is on average 10-12 times cheaper than milling and 8-9 times cheaper than metal 3D printing.

Let's take as an example one of the completed orders for casting from steel CT45. The pedal assembly of an ancient mechanism that wished to remain anonymous. Printing with metal to the client was calculated in the region of 500.000 rubles. Printing the same wax + casting cost him about 60,000 rubles.

4. Is it possible to print everything from PLA, burn it and cast it?

Yes. Burn it out. Cast off! :) Once, now, our regular client asked us to print one form from PLA for him to try out for subsequent burning. Of course, we went to meet him and did everything as he asked. The next time he ordered stencils from us, he didn't even think about PLA. What happened, I asked him?

Burn it out. Cast off! :) Once, now, our regular client asked us to print one form from PLA for him to try out for subsequent burning. Of course, we went to meet him and did everything as he asked. The next time he ordered stencils from us, he didn't even think about PLA. What happened, I asked him?

In the course of burning out, the crust of the mold burst and the casting was hopelessly damaged. Its surface was far from ideal - there were caverns and non-straits. The rather high ash content is to blame for everything, but the most important thing is the increased gas formation during burning. And there is no way to defeat this flatulence without changing the technology and composition of the molding sand.

Printing from PLA costs about the same as from Wax3D, but not sure about the result. The price of a mistake is quite high. That is why for us the issue of burnable polymers is closed once and for all.

5. What is the process for working with Wax3D stencils? What needs to be changed in the casting technology in order to work with such waxes?

If the foundry is equipped with a boilerclave for melting waxes from classic model wax compositions, then nothing needs to be changed.

Sprues and sprues adhere to Wax3D wax just as well as wax models.

The shaping of the crust is just as easy and uses the same technology.

A good plus, which was appreciated by casters, is the rather high strength and flexibility of our waxes. Unlike stencils made from model waxes, our Wax3D printouts can be dropped more than once :)

6. Who are Wax3D stencils NOT suitable for?

For foundries not equipped with a boilerclave, but using open baths of hot water to melt wax models from the crust. The melting point of Wax3D is 96C +-3c. The temperature of boiling water is not enough to bring the printout into a highly fluid melt state. The required temperature for this is 120-150C, and it is easily achieved in the boilerclave.

7. Are there any tricks to printing from Wax3D?

Wax3D is a very unusual material for 3D printing. The rod is quite delicate, flexible, breaks easily, softens at temperatures above 45 ° C and melts at 96C.

Printing with this material is possible in a rather narrow temperature range: from 110 to 135c. Below these temperatures, it does not adhere well in layers; above this range, it is prone to slipping and the formation of artifacts on the surface.

The table for the first layer must be set to a temperature of 100-110c, for the remaining layers it must be turned off!

Nothing out of the ordinary? However, there are 4 most common obstacles in the way of a wax printer :)

a. Not every printer out of the box will print at temperatures below 170C. These features of the firmware can of course be fixed or bypassed. Information on how to do this is on our website in the description of the wax.

b. To paraphrase Dr. House from the TV series of the same name: 'All printers lie!' - they lie shamelessly, without embarrassment and a twinge of conscience! Maybe because they are not burdened with faith or morality, but most likely because they all have different temperature sensors that are calibrated differently, or not calibrated at all! At hot end temperatures around 100c, the spread of real indicators can reach 10-15c, but there are also unique ones. ..

..

The same, and even more so, for the table temperature. And if your printer cheerfully reports to you that the table is heated up to 100s, then its actual temperature can range from 60 to 90s.

Therefore, I will separately note that I mean precisely the degrees of Mr. Celsius, and not the parrots and 'parrot wings' of a certain spherical printer in a vacuum. A calibrated thermocouple is an essential tool for any 3D printer!

c. Some slicers, such as Polygon slicers from Picaso, for some unknown reason, do not know how to work with the printer table and change its temperature during printing. It is impossible to manually change the temperature of the table during printing on Picaso printers. I have not encountered similar difficulties on other printers. Of course, you can get around and solve all this, but how - it's better to ask Picaso3D.

#supovsorry! ))

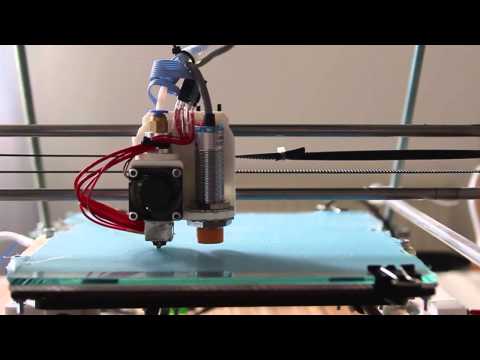

Some printer models are designed in such a way that they can only print with a very limited set of polymers. And the reason for this is most often the device of the head

And the reason for this is most often the device of the head designer printer. We recommend our customers to have a Teflon tube inside the thermal barrier, going all the way to the nozzle, as well as good cooling of the thermal barrier. If the thermal barrier does not cool well or the filament pulling mechanism itself heats up, do not expect stable printing. Here I will not poke a finger at any manufacturer - everyone knows his own heroes :) Also, a direct filament supply to the extruder is required without long Teflon tubes with several kinks. And, of course, NOT a 'bowden' serve.

Our choice of plywood workhorses with direct feed and Titan Aero print head.

Will I urge you to master this material? For you, like us, to print wax wax at a price 50 times cheaper than printing on Solidscape? The fact that the market for such a service is not saturated and is practically devoid of offers? Of course not! Why do we need competitors? Print better gnomes - they are so lacking for everyone !!! :D

All our materials and works will be available at the 3Dtoday Fest in November.