Iris 3d printer

Mcor IRIS 3D Printer Review 2022

3

See Price

Here at 3D Beginners, we cover basically any printer under the sun, and today we take a look at the rather remarkable Mcor IRIS, unique in that it steps away from traditional 3D printing techniques in favor of bringing a full-color spectrum to printing.

How does it stack up in terms of quality against additive printers? Let’s find out as we wade through the tantalizing marketing spiel to determine precisely how this ostensibly revolutionary printer stacks up.

| Printing Area | 256 mm x 169 mm x 150 mm |

| Layer Resolution | 100 Microns |

| Color Resolution | 5760 x 1440 x 508 dpi |

| Supported Filament | A4 Paper |

| Printing Technology | Selective Deposition Lamination |

Table of ContentsShow

Design & Features

When talking about 3D printers, we are tacitly referring to additive manufacturing techniques such as FDM, or if not, to other technology such as SLA. With the Mcor IRIS, the whole idea of a 3D printer as a unit designed to melt and mold plastic material, powder, or resin into a 3D model is thrown on its head.

The IRIS uses your run of the mill white office paper, the very stuff used in traditional inkjet printers. That’s right, the modern descendent of the world changing papyrus the Ancient Egyptians invented thousands of years ago.

How does it work? A stack of paper is fed into a traditional Epson printer located in the shelf unit below the IRIS one sheet at a time. The printer prints ‘’slices’’ similar to an additive counterpart but as a color outline on the borders of the soon to be model. The stack then goes through a deposition lamination process whereby each sheet is fed into the IRIS, and a multi-function head cuts a 2D profile.

From here, a nozzle on the head selectively applies a water-based adhesive that ensures the layers stick together to form the 3D model as they stack up and are pressed together by way of a heat plate to aid adhesion. The IRIS then applies a finish, or coating, that can differ based on functional needs from hardened outer layers to glossier, lacquer-like veneers. The model exits the printer as a stack of paper. The waste, excess paper is easily removed in blocks to reveal the model beneath.

The IRIS then applies a finish, or coating, that can differ based on functional needs from hardened outer layers to glossier, lacquer-like veneers. The model exits the printer as a stack of paper. The waste, excess paper is easily removed in blocks to reveal the model beneath.

The use of paper as the raw material behind the prints also means that the IRIS can print in an array and complexity of colors unheard of in 3D printing circles. By color, we mean true color as in over 1 million different hues pulled straight from the International color consortium with rich, vibrant, photo-realistic, and high definition subtleties. On the models themselves, colors are also possible in 360 degrees.

The benefits don’t stop there though as the functional cost of printing is drastically reduced compared to plastic materials. A stack of paper is markedly cheaper than multiple spools of PLA for example. Additionally, the IRIS is pretty much as environmentally friendly as 3D printers can get with fully recyclable paper waste and the ability to source paper from responsible distributors.

As for specific features and specifications, we need to start by stressing that the Mcor IRIS is through and through an industrial grade printer acting as a counterpart to the Irish company’s smaller, office-friendly, prosumer version called the ARKE.

The IRIS is no small machine measuring in at 950 mm x 700 mm x 800 mm with a total weight of 160 kg. The build volume is 256 mm x 169 mm x 150 mm with a layer resolution of 100 microns (the thickness of a piece of paper) with a color resolution of 5760 x 1440 x 508 dpi.

The Mcor IRIS uses any standard variant of A4 office paper alongside Mcor designed ink cartridges that fit into the inkjet part of the unit. The ink is designed to seep through the whole thickness of the sheet creating the colored outer layer of the finished prints.

Connectivity is assured via Ethernet. Software-wise, the IRIS uses a tandem of SliceIT and ColourIT, used for slicing models before printing and applying color respectively. The software is compatible with STL, WRL, OBJ, 3DS, FBX, DAE and PLY file types.

Printing

When eyeing up a finished print from the Mcor IRIS, we had to keep reminding ourselves that it was made of paper. The results are surprisingly solid especially when used in conjunction with a robust coating option, and the colors will charm even the most versed 3D printer. They aren’t perfect by any stretch of the imagination it must be said.

Although the color spectrum is baffling, the quality of the finished products is defined by an evident lack of detail in terms of texture on the models. In most cases, there is a distinct absence of features beyond general shapes and surfaces are flat, dull even.

The quality of the color rendering leaves something to be desired too with a slightly blurred, drab quality that is at odds with the vibrancy of plastic 3D printing, albeit in the few colors additive printing can produce. Layers are incredibly apparent throughout most models which can significantly affect the appearance of the coloring.

For the reasons above, the Mcor IRIS doesn’t stack up to the functional results of standard 3D printers where prints can be used as pre-production stress test models or serious prototyping. In our estimation, the Mcor IRIS is far better suited to artistic pursuits for sculptures, display models, ornaments and as parts of a larger art piece.

In our estimation, the Mcor IRIS is far better suited to artistic pursuits for sculptures, display models, ornaments and as parts of a larger art piece.

Alternatively, architectural firms will find the IRIS a suitable device to print 3D mock-ups of potential buildings, but as above the lack of detail means these won’t be suited to life-like renditions. The paper is quite simply not robust enough to weather the demands of a mechanical setting, pre-build testing, or as a pre-molding prototype.

Support

Mcor has seized production of the IRIS in favor of the newer ARKE and ARKEPRO, as such technical support for the IRIS is limited. The company’s website offers very little in terms of articles or tutorials and finding any support help is an arduous task in itself.

Most resellers offer a standard one-year warranty, a reasonably standard offering for these types of units.

Verdict

The Mcor IRIS has a lot going for it particularly when it comes to the full-color features and the low cost of production, but the near $50,000 price tag is a hard pill to swallow.

We weren’t disappointed with the results (the array of colors and the way they can shift effortlessly from one side of a model to the other is astounding), but instead, we felt they were at odds with the claims made by Mcor.

Beyond artistic and educational purposes, the IRIS doesn’t provide enough detail and solidity for industrial-grade uses making it a rather expensive gimmick for any serious R&D department or design studio.

Mcor is Bringing Full High Definition Color to 3D Printing with Mcor IRIS HD - 3DPrint.com

While there are several full color 3D printers on the market, and many of them are capable of producing some great models, they all tend to fall short in some important areas. Material cost is a significant drawback, especially when many powder bed 3D printers produce so much wasted material. Yes, a lot of it can be reused, but not all of it. I’ve been told by a few users that each print can waste up to 15% to 20% of the leftover powder.

While the ink jet coloring process works well, the details can often be underwhelming close up. Additionally, most color 3D printers require not only a lot of post processing, but actually require a second piece of equipment to be useful. And beyond the additional equipment cost, the process of removing excess powdered 3D printing material is time consuming and rather messy work.

Additionally, most color 3D printers require not only a lot of post processing, but actually require a second piece of equipment to be useful. And beyond the additional equipment cost, the process of removing excess powdered 3D printing material is time consuming and rather messy work.

Excess paper being removed.

The Mcor IRIS 3D printer is a bit of a different beast however. It uses the same ink jet printing technology, however it doesn’t use plastic or gypsum powder materials it uses standard copy paper. It works pretty simply, the IRIS prints a slice of the 3D model on a piece of paper while laying down an adhesive. At the same time, a cutting blade traces the outline of the model, so once the print is complete the excess paper just needs to be gently removed. That makes it significantly less expensive to use, and because all of the waste is 100% recyclable, it is also one of the greener 3D printing options on the market.

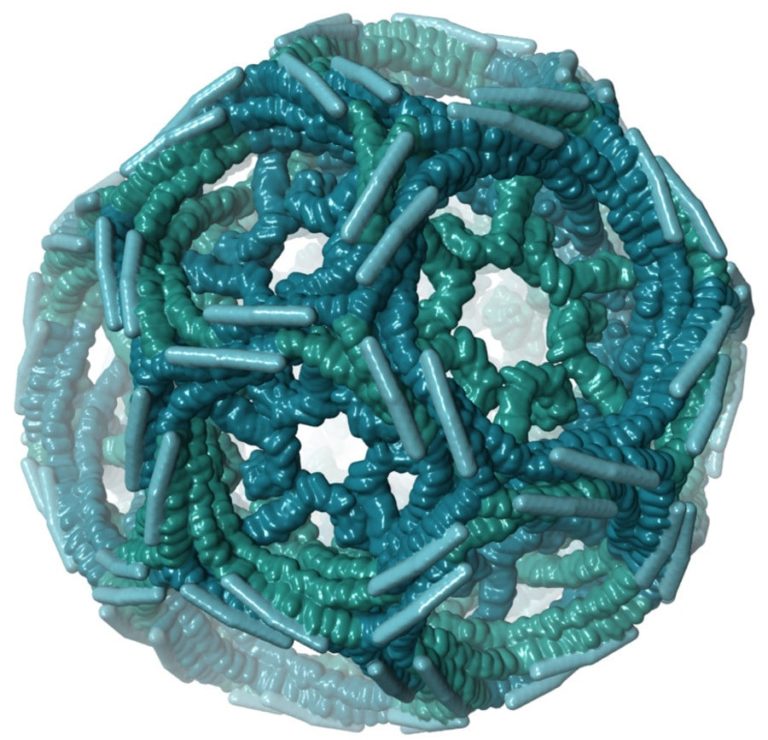

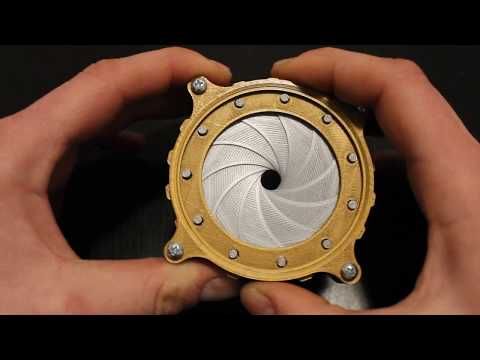

A finished color print from the original Mcore 3D printing process.

The IRIS already produces some of the best color 3D models available, and now Mcor is offering upgraded technology that turns the IRIS into an HD printer. The objects printed with IRIS HD will have even sharper small details, 360° high-definition color and a new cutting blade that lasts longer, further reduces the cost per print. Mcor will be demonstrating the new technology until Thursday at the 3D Printing conference RAPID, taking place at the Long Beach Convention Center. Mcor will be available for demonstrations in Booth 830 on the showroom floor.

The upgraded IRIS HD technology uses new printing algorithms to make the color crisper while providing better accuracy and using less ink. It is paired with the new carbide cutting tip that lasts considerably longer and will produce models with a more photorealistic appearance regardless of any text being displayed or the full geometry of the model. This can reduce the already low per print cost by an additional 20%.

“Crisply defined color and rock-bottom operating costs are critical for manufacturers, schools, service bureaus, architectural firms and others who need to 3D print a high number of realistic models.

Our SDL (Selective Deposition Lamination) paper-based 3D printing technology has always offered the industry’s highest-resolution color at the lowest operating costs. Now, with IRIS HD, we’re providing even greater access to truly photorealistic color 3D printing,” said Mcor Technologies co-founder and CEO Dr. Conor MacCormack.

The Mcore IRIS already offers the industry’s most accurate WYSIWYG (what you see is what you get) full-color 3D printing. IRIS HD prints any color, any time (ACAT) for unbeatable photorealistic color capabilities, and employs a global-standard ICC (International Color Consortium) color map. And for owners of the original IRIS 3D printer, they can easily upgrade their existing 3D printers. The new carbide cutting blade is also available for Mcor’s smaller, monochrome printer, the Mcor Matrix 300+.

Because Mcor IRIS HD uses less ink and the tip lasts longer, it delivers a 20-percent reduction in the cost to 3D print a model. Mcor’s materials already cost 10-20 percent of other 3D printing technologies, saving customers thousands of dollars and providing greater access to the technology. Mcor IRIS HD is available now for new and existing owners of Mcor 3D printers. Tell us what you think about the new HD technology on our High Definition Color 3D Printing with Mcor IRIS HD forum thread at 3DPB.com.

Mcor IRIS HD is available now for new and existing owners of Mcor 3D printers. Tell us what you think about the new HD technology on our High Definition Color 3D Printing with Mcor IRIS HD forum thread at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: full color 3d printing • iris • mcore • paper 3d printing • sdl 3d printing • selective deposition lamination

Please enable JavaScript to view the comments powered by Disqus.

3D printer Mcor IRIS

The new 3D printer from the Irish company Mcor Technologies has become another discovery in the field of cost-effective 3D printing. Mcor IRIS HD is a very special printer: like its predecessor, it uses a very atypical consumable, namely a4 office paper. The innovation of this particular model lies in the fact that, unlike its predecessor IRIS without the HD letters, this Irish miracle is able to produce a much larger color spectrum when printing, which has a very positive effect on the appearance of the final products.

Model Features

The main feature of Mcor IRIS HD, of course, is the new printing algorithm. It is thanks to him that the quality of the flowers has reached the level that you can see in the photographs. In addition, this discovery has made this ultra-economical printer even more economical.

Speaking of economy, another nice touch added to the new model is a new four-sided blade that cuts the paper during the printing process.

In total, saving Mcor IRIS HD, in comparison with its predecessor, amounted to 20%.

Materials used

As already mentioned above, the main consumable material for this 3D printer is ordinary office paper. Yes, that's right: you now have the ability to refill your 3D printer with the same fuel that you refill your old paper printer.

Software

To communicate with the computer, the printer uses a program called SliceIT. This software is compatible with all versions of Windows newer than XP. The program supports two formats: .stl and .obj. In addition, it should be said that working with a printer is very resource-intensive for any PC. So, according to the official website of the manufacturer, to work with SliceIT, the following system requirements are requested: 8 GB of RAM, 100 GB of hard disk space, 1 GB of video card memory. Also, the manufacturer recommends having two network cards with you so that one of them is allocated for the printer itself.

The program supports two formats: .stl and .obj. In addition, it should be said that working with a printer is very resource-intensive for any PC. So, according to the official website of the manufacturer, to work with SliceIT, the following system requirements are requested: 8 GB of RAM, 100 GB of hard disk space, 1 GB of video card memory. Also, the manufacturer recommends having two network cards with you so that one of them is allocated for the printer itself.

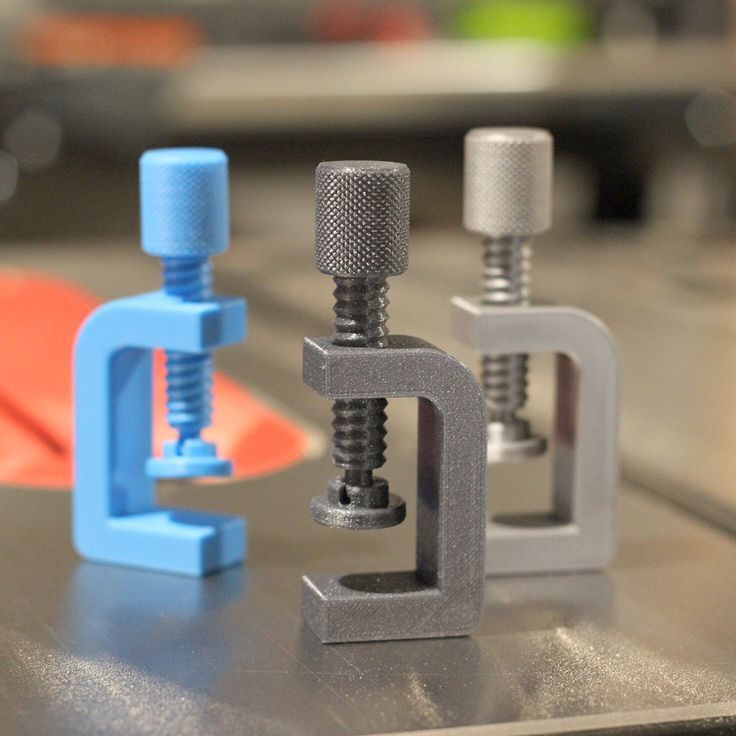

Product examples:

Main features

| Max print quality | 10 microns |

| Printable area | 256 x 169 x 150 |

| Supported materials | IRIS/MATRIX 300+ |

| Interfaces | ethernet |

| Category: | Professional |

| Max print quality: | 10 micron |

| Country of manufacture: | Ireland |

| Dimensions: | 950 x 700 x 800 mm |

| Weight: | 160 |

| Specialization: | Architecture / Education / Layout / Design / Advertising / Souvenir industry |

| Printable area: | 256 x 169 x 150 |

| Supported materials: | IRIS/MATRIX 300+ |

| X resolution: | 0. 00001 µm 00001 µm |

| Y-axis resolution: | 0.00001 |

| Z-axis resolution: | 0.01 µm. |

| Interfaces: | Ethernet |

| Supported file formats: | OBJ/STL |

| Software: | Slice IT |

Other offers:

- 3D printer Mcor IRIS

Price:

- 3D printer 3D Systems ProJet 4500

Price:

- 3D printer 3D Systems ProJet 260C (ZPrinter 250)

Price:

- 3D printer 3D Systems ProJet 360 (ZPrinter 350)

Price:

MCOR TECHNOLOGIE MCOR IRIS 3D Printer Used equipment

- Description

- Detailed information

- About this seller

MCOR IRIS color 3D printer since 2014.

Approximately 1000 operating hours.

Very good condition

This description can be translated automatically. Please contact us for more information. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

| ------------------- | |

| L x W x H | 1200.0 × 700.0 × 1770.0 |

| Weight | 350kg |

| Operating hours | 1000 hours |

| Switching hours | 3000 watch |

| Condition | good condition |

| CE mark | --------- |

| Status | included |

| Client type | End user |

| Active with | 2020 |

| Offers online | 1 |

| Last activity | July 23, 2022 |

Description

MCOR IRIS color 3D printer since 2014.