Upm formi 3d printing

Large Scale Additive Manufacturing | UPM Formi

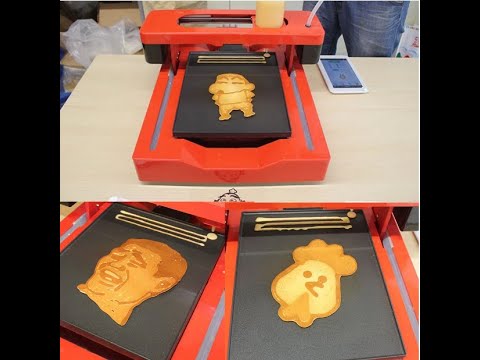

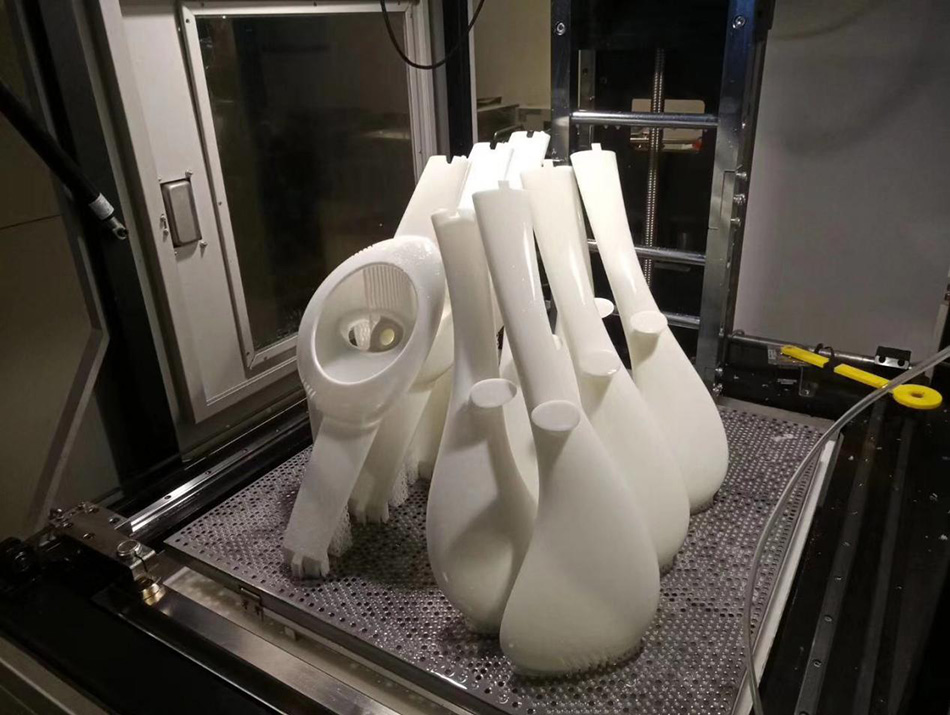

Large scale additive manufacturing (LSAM) transforms the way of producing large pieces. Granulate-based printing is 37 times faster than filament-based methods on average, enabling large constructions to be printed efficiently. UPM Formi 3D composite materials fits well to LSAM processes.

Efficient manufacturing without moulds

Natural touch

100% recyclable

New sustainable alternative

Efficient manufacturing

- Scrap rate of production is virtually 0%

- Easy to print large constructions

- Weight of the parts is reduced to minimum

- Manufacturing without moulds

- Wood like post processing

New sustainable alternative

- Biobased materials are 100% recyclable

- Biocomposite is a sustainable material: the wood fibres originate from certified forests

- Its carbon foot print is 50% less compared to traditional oil-based materials

Problem:

- Long lead times of casting moulds.

Significant amount of waste generated by CNC milling

3D printing of casting moulds enables:

- Sreamlined and simlified local mould production with minimum amout of manual work needed

- Faster lead time

- Significant mould weight reduction

- No waste / high material effiency

- Compatibility with plywood stuctures

- Efficient manufacturing without moulds

- Natural touch

- Several colour possibilities, by adding colour masterbatches during the printing process

UPM Formi 3D grades are safe and easy to print in open athmosphere.

Grade recommendation: UPM Formi 3D 20

UPM Formi 3D 20 is an excellent material for granulate-based 3D printing with large nozzles (2–8 mm) due to its dimensional stability.

- Self-supporting molten stage properties

- Improved first layer adhesion

- Shear thinning melt flow

- Fast cooling

- Extremely low shrinkage

- Cellulose fibres prevent the creation of internal stresses

- Soft to sand

- Improved paint absorption

Final prints can be further post-processed e. g. for outdoor use.

g. for outdoor use.

Photo illustrates adaptive layer height 3D printing of a perfect sphere (photo credit: Adaxis / Sculptur). See video.

Here you can find downloadable UPM Formi 3D brochures, guidelines, recommendations and technical data sheets.

Technical Data Sheets

UPM Formi 3D40 Product Data sheet »

UPM Formi 3D20/19 Product Data sheet »

Safety Data Sheets

UPM Formi 3D 40 SDS »

UPM Formi 3D 20/19 SDS »

Flyers

3D-printed furniture concepts »

3D-printed kayak from biocomposite »

Printing complex shapes »

Freedom of design for sustainable furniture manufacturing » Lower carbon footprint compared to fossil-based 3D printing material »

UPM launches a new biocomposite material for 3D Printing: naturally perfect prints both for fine detail or large scale

Press Release 16. 4.2018 11:00 EEST

4.2018 11:00 EEST

(UPM, Helsinki, 16 April 2018 at 10:00 EET) - UPM Formi 3D is a new type of biocomposite that has been specially developed for 3D printing. It brings together advanced cellulose fibre and biopolymer

technologies.

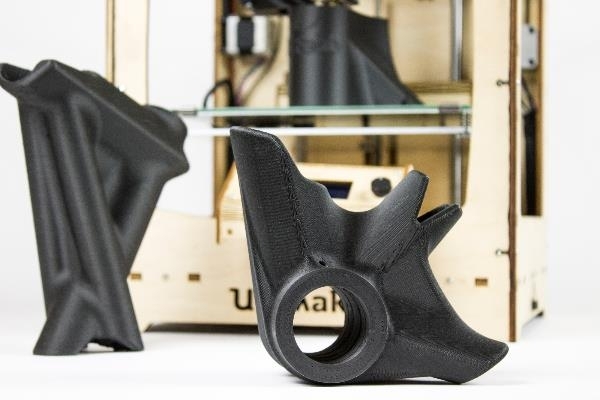

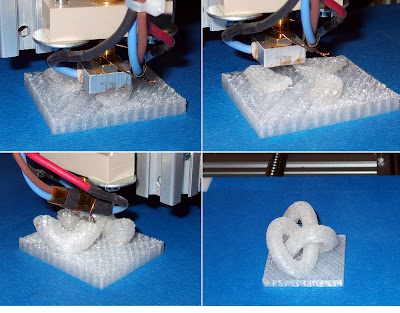

With a matte finish and a surface that feels natural to the touch, filaments for 3D printing can be produced in light colours as well as dark. The new material has been engineered to flow smoothly through small nozzles enabling fine details. At the same time, UPM Formi 3D's fast cooling and low shrinkage ensures improved dimensional stability and makes it the ideal material for large scale printing. UPM Formi 3D's self-supporting molten stage properties enable round or other complex shapes to be produced without a separate support material. Wood like post processing of prints is another benefit of the new biocomposite: fine sanding, reduced paint absorption and easy to glue with PVAC.

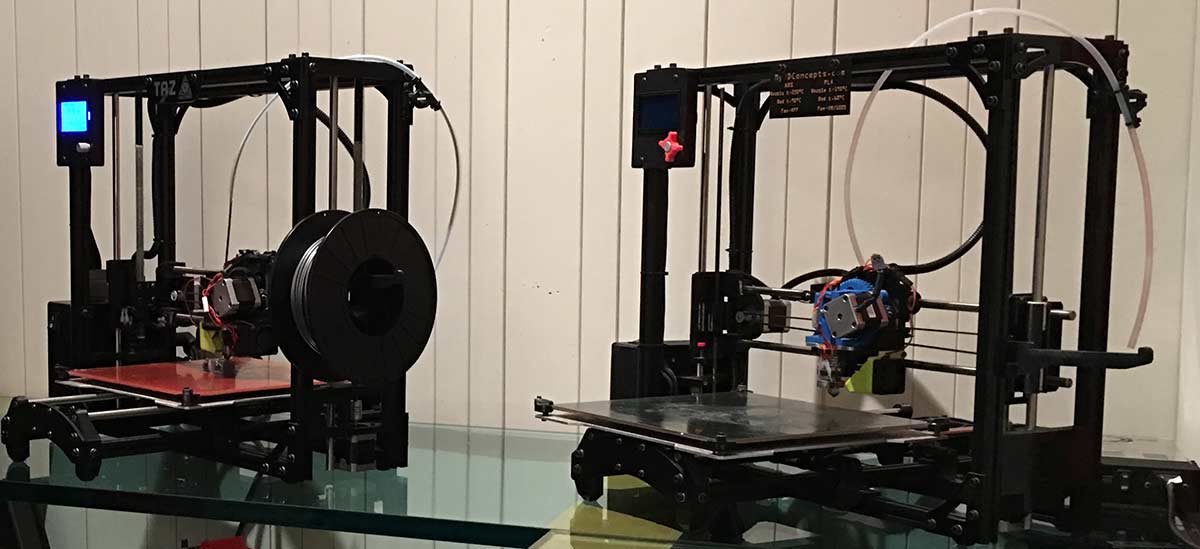

UPM Formi 3D is produced and sold in granule form to producers of filaments for 3D printing or directly for large scale printing from granules.

Typical UPM Formi 3D end use applications are prototypes, design, education and concept modules e.g. for architecture. UPM Formi grades are available with FSC® and PEFC(TM) certification.

On the 18 and 19 April 2018, UPM Formi 3D will be presented at the NORDIC 3D EXPO at the Dipoli Conference Center in Espoo in Finland. At the exhibition, UPM Biocomposites and Maker3D will be pleased to provide further information as well as material samples, filaments and demonstrate live printing.

Watch UPM Formi 3D video

For further information please contact:

Eve Saarikoski, Application Manager, 3D Printing, UPM Biocomposites: Tel: +358 408 352 395

UPM, Media Relations

Mon-Fri 9.00-16.00 EET

tel. +358 40 588 3284

[email protected]

UPM Biocomposites

UPM Biocomposites creates value from renewable and recyclable materials by combining expertise and technologies within fibre based engineered materials businesses. UPM Biocomposites consists of UPM ProFi outdoor products for construction and UPM Formi granulates for injection moulding and extrusion. UPM Biocomposites factories are located in Finland and Germany. www.upmprofi.com. www.upmformi.com

UPM Biocomposites factories are located in Finland and Germany. www.upmprofi.com. www.upmformi.com

UPM

UPM leads the forest-based bioindustry into a sustainable, innovation-driven and exciting future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Specialty Papers, UPM Paper ENA and UPM Plywood. UPM provides sustainable and safe solutions to the growing global consumer demand. Products are made of renewable and recyclable materials. The group employs around 19,100 people worldwide and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Follow UPM on Twitter | LinkedIn | Facebook | YouTube | Instagram | upmbiofore.com

Maker 3D

Maker 3D is a Finnish designing and manufacturing company for 3D printed products and services with fast delivery times. The company distributes also a range of top brands for desktop printing and is located in Helsinki. http://www.maker3d.fi/

http://www.maker3d.fi/

NORDIC3DEXPO

NORDIC3DEXPO, is an international trade fair for 3D printing and 3D technologies. The exhibition will take place from 18 to 19 April 2018 at the renewed Dipoli Conference Centre in Espoo, in conjunction with the FIRPA 20th anniversary conference. The target visitor groups are companies that use 3D printing and technologies as well as researchers, students and hobbyists in the 3D technology sector. http://3dexpo.fi/index.html

UPM demonstrates robotic applications for large-scale 3D printing in collaboration with ABB and Prenta

Press release 3/4/2019 11:00 AM EEST

At Nordic 3D at the Espoo Dipoli Convention Center, UPM is demonstrating large-scale 3D printing robotic applications in collaboration with ABB and Prenta.

Large-scale granular 3D printing opens up new possibilities for designers and manufacturers. Robotic granular printing saves time and costs for large 3D parts in a short time. Potential business areas include, for example, furniture design, molding or boat manufacturing.

Potential business areas include, for example, furniture design, molding or boat manufacturing.

- Industrial robotic printing and UPM Formi 3D biocomposite allow 3D printing with high geometric accuracy. PrentaRobo is designed for industrial production as a tool to create a new and cost-effective product, says Riku Rusanen, Executive President of Prenta Finland.

ABB Robotics has been instrumental in the development of an innovative robotic 3D printing system. ABB is a leading supplier of industrial robots and their software, hardware and complete application solutions.

- This is the first technological innovation that represents the next level of large-scale industrial 3D printing. We were able to use the extrusion head in our 6-axis IRB6700 robot to create a 3D printing system that is ideal for very precise and large-scale layer-by-layer production. External axes and motion tracking have been added to achieve an even larger working area. Users can in turn control the extrusion head and create print paths with our 3D modeling software RobotStudio, the industry's leading PC solution for offline programming, configuration and virtual commissioning,” says Pasi Kukkonen, Product Manager, ABB Oy robotics.

Development of biocomposite technology

UPM Formi 3D views have been developed specifically for 3D printing. They combine advanced cellulose fibers and biopolymer technologies.

UPM Formi 3D is produced and sold in granular form directly to granular alloy manufacturers or 3D filament manufacturers. Granular printing with an industrial robot from ABB and a biocomposite from UPM is already being used, for example, in Sweden for a collaborative 3D workspace called The Wood Region.

- Together with our partners, we open up a world of new possibilities in the field of full-scale 3D printing. Large-scale 3D printing technology is evolving rapidly and we are part of that evolution, with our biocomposite technology and wood-based feedstock offering, says Ewe Saarikoski, Application Manager, UPM Biocomposites.

The low shrinkage and self-sustaining melt flow with the ability to print up to 75 degrees on UPM Formi 3D ensures that large round or other complex shapes can be printed without deformation problems even directly onto the plywood surface.

Post-processing of printed parts like wood is another plus of the biocomposite. The print can be easily completed using traditional woodworking methods.

UPM Formi 3D views are 100% recyclable and also available with FSC® and PEFC(TM) certification.

For further information please contact :

Eve Saarikoski, Application Manager, 3D Printing, UPM Biocomposites: eve . saarikoski @ upm . COM

Photo on the topic

9,0003

UPM BioComposites

UPM Biocomposites creates value based on the renewable and survivable materials, combining the experience and technology on the basis UPM Biocomposites manufactures UPM ProFi exterior products and UPM Formi granules for injection molding and compression molding. UPM Biocomposites has factories in Finland and Germany.

www. upmprofi.com . www.upmformi.com

upmprofi.com . www.upmformi.com

UPM

UPM provides renewable and sustainable solutions and innovation for a fossil-free future. The company has six business lines: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Specialty Papers, UPM Communication Papers and UPM Plywood. The company employs 19,000 people and has an annual turnover of about 10.5 billion euros. The company's shares are listed on the NASDAQ OMX in Helsinki. UPM Biofore Company - Beyond Fossil www .upm .com

ABB

ABB (ABBN: SIX Swiss Ex) is a leading technology leader with a comprehensive offering for the digital industry. With a history of innovation spanning over 130 years, ABB is today a digital leader with four customer-focused core businesses: electrification, industrial automation, motion and robotics, and discrete automation, supported by the ABB Ability common digital platform. ABB's leading power grid business will be transferred to Hitachi in 2020. ABB operates in over 100 countries and employs 147,000 people.

ABB's leading power grid business will be transferred to Hitachi in 2020. ABB operates in over 100 countries and employs 147,000 people.

Prenta Oy

Prenta Oy is a Finnish-based industrial technology company specializing in 3D printing. Prenta focuses on large scale FGF printing and combines robotics with 3D printing. Prenta designs and manufactures FDM 3D printers and provides various 3D related services. Prenta was founded in 2014 and employs 6 people.

NORDIC3DEXPO

NORDIC3DEXPO is an international trade fair for 3D printing and 3D technologies. The exhibition runs from 3 to 4 April 2019year at the Dipoli Convention Center in Espoo. The target groups of visitors are companies that use 3D printing and technology, as well as researchers, students and hobbyists in the field of 3D technology. http ://3 dexpo . fi / index . html

UPM offers cellulose-based FDM 3D printer material

News

Follow author

Subscribe

Don't want

13

Finnish woodworking company UPM offers a new material for printing on FDM 3D printers - UPM Formi 3D biocomposite with cellulose filler.

UPM Formi 3D is a biocomposite material consisting of polylactide (PLA plastic) and cellulose. According to the developers, the novelty has improved characteristics and is better suited for FDM 3D printing than the usual composite materials filled with sawdust. The material is designed with the possibility of printing with small diameter nozzles, which will allow to obtain products with higher resolution and detail.

Fast cooling and low shrinkage facilitate large format models, while low softening flow reduces the need for support structures. After printing, UPM Formi 3D gives a matt surface that is pleasant to the touch. The material does not emit unpleasant odors, is sanded like natural wood, glued with polyvinyl acetate (PVA glue) and can be easily painted without excessive absorption. UPM Formi 3D has received international Lean Forestry certifications from the Forest Stewardship Council (FSC) and the Program for the Mutual Recognition of Forest Certification Schemes (PEFC).

Possible applications include rapid prototyping, design, education and printing of architectural models. UPM does not manufacture filaments per se, and offers a new material in the form of granules for the production of filaments by specialized companies or use in 3D printers with specialized extruders that accept granules. For example, the Dutch company Octofiber already offers UPM Formi 3D filament at a selling price of €34.12 per 750 g.

April at NORDIC 3D EXPO in Espoo, Finland. For detailed technical data, 3D printing recommendations and purchase information, please visit the manufacturer's website at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday.

Learn more