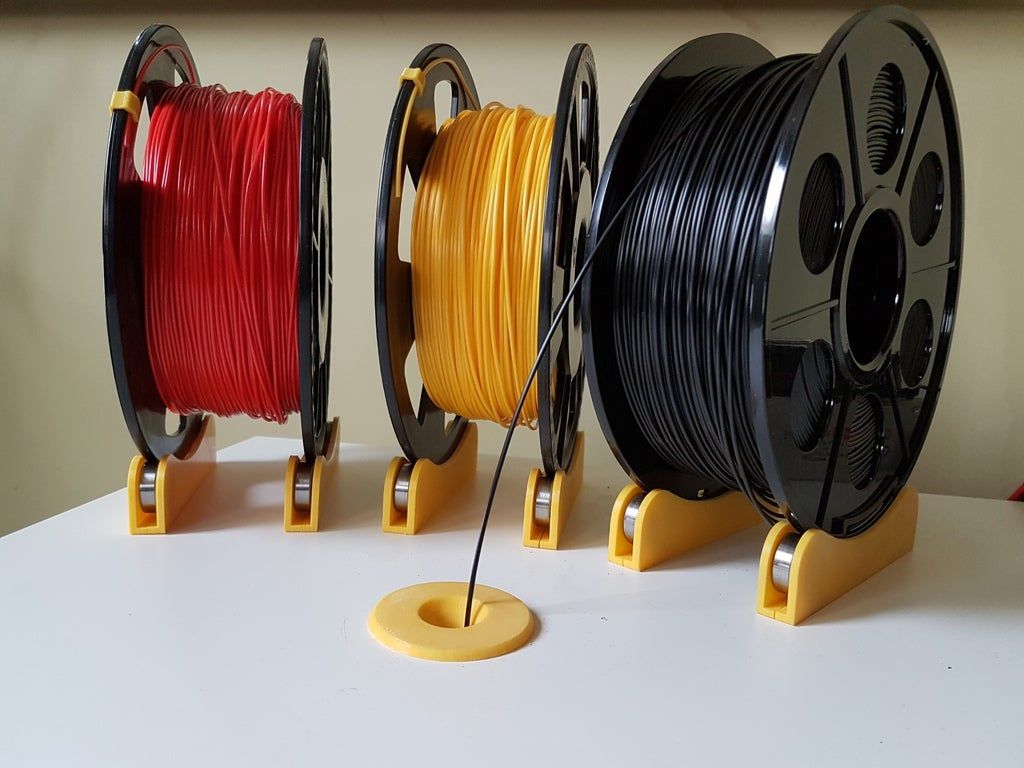

3D printer plastic spools

3D Printer Filament Material Spools

Variety of Filament Brands, Colors, & Material Types Available

View As

You probably never knew there were so many components, accessories, and parts to your 3D printer. But it is the 3D printer filament that is the lynchpin that provides the 3D printer with a way to create and provide those almost magical 3D products. The magic behind the Filament-Based 3D printer lies in the type of filament it uses.

The filament is helping to drive 3D technology through plastic filaments that are fed through a spool nozzle. The nozzle holds a liquified material that is then drawn down to a platform. Once the material is on the platform, it hardens.

This allows the nozzle to move the material to whatever location it needs to be in, allowing the model to be 3D constructed layer by layer. There are various and relevant parts to every 3D printer, and each filament serves a specific purpose. It’s crucial to find a place where you can order what you need and, more importantly, have your questions answered.

It is excellent when you can build up a long term supplier partnership with a vendor for your 3D printer’s growth and development needs. Read the Buyer's Guide below and discover more about the types, materials, applications, and filaments your 3D printer needs and the best place to find them.

3D Printer FilamentWhen you break it down, every 3D filament printer uses a filament made out of thermoplastic feedstock. It is the thermoplastic feedback that’s used for fusing deposition modeling purposes provided by 3D printers. The two standard diameters of filaments are 1.75 and 2.85 or 3mm.

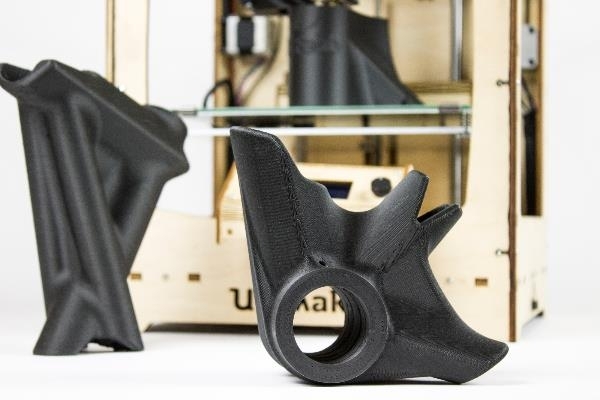

To be able to perform 3D scanned printing, you should start with the best and most effective 3D printer filament. The challenge is in the beginning when you need to determine which type of 3D printer fits your needs the best as each one can be put to use and help grow an industrial company or even provide fulfilling a personal purpose. Multifunctional 3D printers are used in multiple professional fields, from medicine to reverse engineering.

The 3D printer is a revolutionary technology that can pick up thousands of data points to recreate a 3D scanned object. Being able to create a 3D image, product, and anything in-between brings the future to you today. That's why it's so important to start at the beginning and take it step-by-step until you have the 3D printer you want and the right 3D printer filament you need.

Two 3D Printer Filament Types3D printer filament types, while having two standard diameters, also have various other attributes you need to know. Every filament type seems to come with a new color and acronym, which makes it even more confusing to determining which one you need. Two acronyms are helpful to know when learning printer filament types are FFF and FDM.

FFF is a plastic fused filament fabrication, and FDM is used in fused deposition modeling. To make things even more confusing sometimes is the two acronyms are used interchangeably. The acronym confusion began when FDM became a 3D printer trademark. That meant every other company that came up with the same type and variety of filament had to use a different acronym; hence the FFF acronym was born.

That meant every other company that came up with the same type and variety of filament had to use a different acronym; hence the FFF acronym was born.

The most common 3D printer filaments are the ones everyone seems to want, and that is the acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA). The ABS and PLA are the most common printer filament because they are the ones used in the most basic 3D printers, which makes them the most versatile and popular. The good news is the ABS and PLA are also the most reasonably priced.

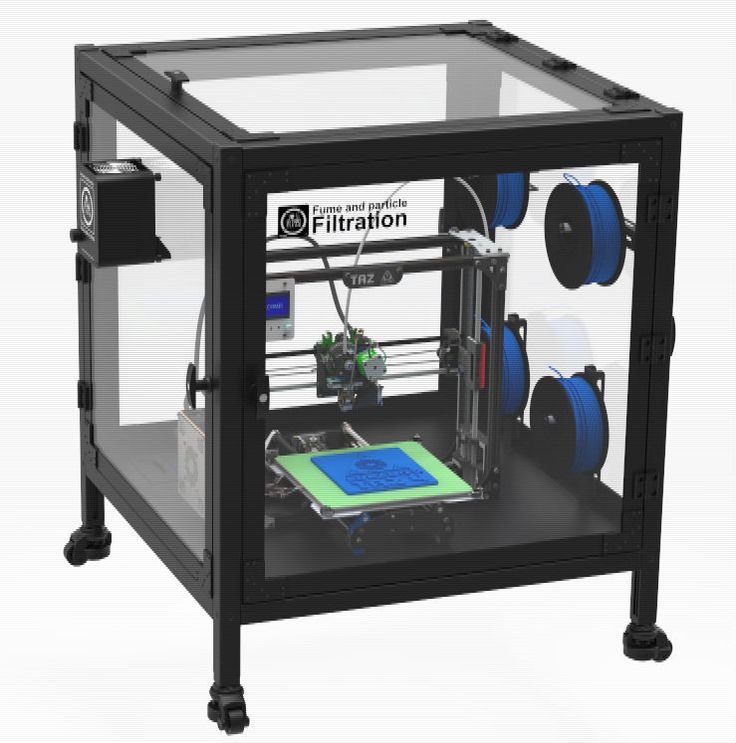

ABS is durable and non-toxic, but when you're printing, you notice an unpleasant odor, so open a window or be in a large and well-ventilated room. The ABS also tends to curl a little bit when you're printing, so it's good to be close by your 3D printer when it’s creating. The PLA is a biodegradable substance, but it tends jam sometimes, so you want to be around when your 3D printer is printing using the PLA filaments.

You now know the most common types of 3D printer filament, but here are some other types of filaments. They include:

- PET Filament - this is a 100% recyclable stable plastic that usually has no color if in its raw state

- Nylon Filament - very flexible and light and is well-suited for tool, machine parts, containers, etc. when using a 3D printer

- IGlide Filament - great to use when 3D printing custom bearings and wear-resistant parts

- DREMEL PLA Filament - anyone wanting to replicate high detail parts

- CREALITY PLA Filament - works well on flat or angled surfaces and most often used for educational prototypes or architecture models

The only person who knows which 3D printer and 3D printer filament will meet your needs best is you. It’s important you know upfront what criteria you want the technology to provide so you can then determine the best printer and filaments that will provide what you need. The worst thing that can happen if you spend a lot of money on both printer, filaments, and accessories and find none provide what you need from them.

The worst thing that can happen if you spend a lot of money on both printer, filaments, and accessories and find none provide what you need from them.

The guide above gives you an excellent place to start regarding the different names, applications, and materials you can use with various filaments. However, you still need to understand your 3D printer's capabilities before you choose any one of them.

Your Next 3D Filament StepWhen you want to know more about your 3D printer's capabilities or 3D printer filament, you need to reach out to Cable Ties and More. Cable Ties and More has answers to your questions and provides you with the best printer filament products. Reach out to Cable Ties and More just one time, and your experience will be so beneficial for your 3D printer needs you'll never go anywhere else.

3D Printing - Filaments, Reels and 3D Printing Tools

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Greg plastic spool options

Svold

Loading

06/13/2018

14563

3D modeling

Subscribe to the author

Subscribe

I do not want

9000 34

Article refers to printers:

Flyingbear P905 Good day.

When buying Greg plastic for my 3D printer, the question arose about suitable spools on which it would be convenient to put plastic coils (which are more profitable to order than with a spool), as well as good stability during prolonged use.

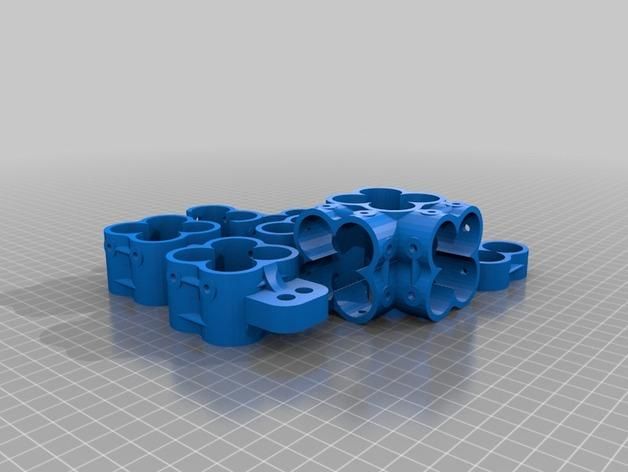

On the resources I have seen a lot of options that were either very heavy or vice versa quite fragile when used. As a result, after a little thought, I decided to combine the idea of a threaded connection (so that the coil was made of 2 halves, trying to use up as little plastic as possible) and the shape of a standard plastic coil, adding a little pathos to the theme of the plastic manufacturer's logo. As a result, we got this model (link to the coil):

Some time after I posted it, I began to remake the coil, taking into account the criticism that I received in my address and made a simple drawing of the walls (to reduce printing time), added stiffeners to the walls. The result turned out to be a coil that is practically not inferior in strength to the standard factory one (link to the coil):

The result turned out to be a coil that is practically not inferior in strength to the standard factory one (link to the coil):

About a week later I decided to redo the coil again based on the requests of people who came to me. As a result, the mounting hole was increased to 40 mm, and the plastic consumption was also reduced without losing the strength of the coil itself (link to the coil):

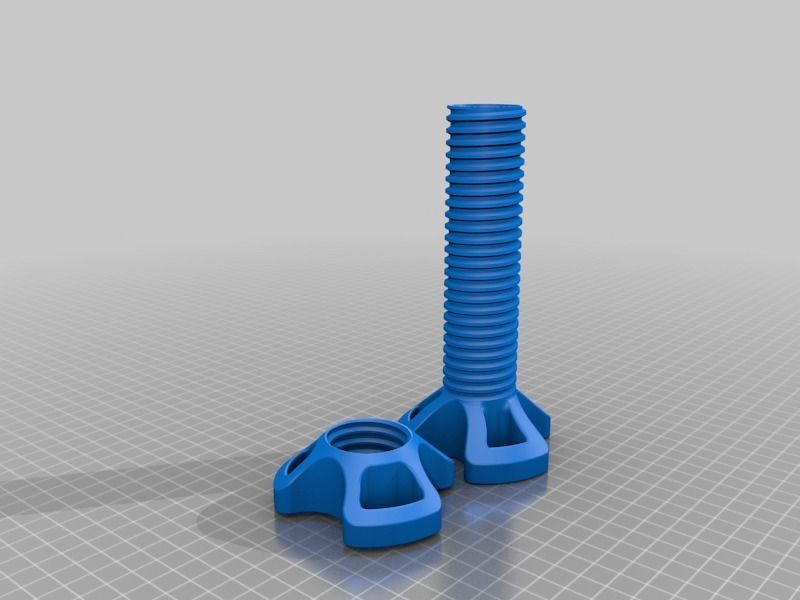

Also, based on the principle, the simpler the better, I prepared a support model for these coils, which consists of 2 parts and showed itself very well (link to coil support):

reel for 3 divisions, which is assembled like 'Lego', for plastic leftovers (link to the typesetting reel):

I hope my article is useful, I wish you all good luck and good luck.

Follow author

Follow

Don't want

34

Article comments

More interesting articles

25

Subscribe to the author

Subscribe

Don't want

In early September, we released a new version of the KOMPAS-3D Home system for amateur 3D modeling...

Read more

22

Subscribe to the author

Subscribe

Don't want

Hello everyone. The heading should not be called 3D modeling, but 3D torment, joke)) And today we have a r. ..

..

Read more

144

Subscribe to the author

Subscribe

Don't want

Hello dear friends!

I think each of us has faced such a problem...

Read more

MakerBot 3D Printer Reel Specifications

Dimensions and weight:

| Parameters\Size of reels | SMALL | LARGE | XL | XXL | 1 kg |

| Bobbin diameter | 15 cm | 25 cm | 21.59 cm | 21.59 cm | 20.32 cm |

| Bobbin Width | 4 cm | 4 cm | 8.89 cm | 17.78 cm | 7.62 cm |

| Attachment inner diameter | 5.08 cm | 5. 08 cm 08 cm | 2.54 cm | 2.54 cm | 5.08 |

| plastic diameter | 1.75mm | 1.75mm | 1.75mm | 1.75mm | 1.75mm |

| Shipping weight with reel | 0.45 kg | 1.36 kg | 2.72 kg | 4.99 kg | 1.36 kg |

| pla plastic weight | 0.22 kg | 0.9kg | 2.26 kg | 4.53 kg | 1 kg |

Compatible:

| 3D printer\Reel size | SMALL | LARGE | XL | XXL | 1 kg |

| Replicator 2/2X | + | + | + | ||

| Replicator Mini | + | ||||

| Replicator (5th generation) 5TH GENERATION MODEL | + | + | |||

| Replicator Z18 | + | + | + | + |

Temperature rating:

Solidification temperature -60-65°C

Melting point -150-160°C

Extruder temperature - 203°C

Pictures of various spools for MakerBot 3D printers:

1Kg format spool suitable for MakerBot Replicator 2/2X 3D printer and previous models.

75mm)

75mm) 75mm and 3mm)

75mm and 3mm) PRIMALLOY™ also offers excellent heat resistance as well as hardness stability within a wide temperature range.

PRIMALLOY™ also offers excellent heat resistance as well as hardness stability within a wide temperature range. 5kg (500g) Reel, White

5kg (500g) Reel, White