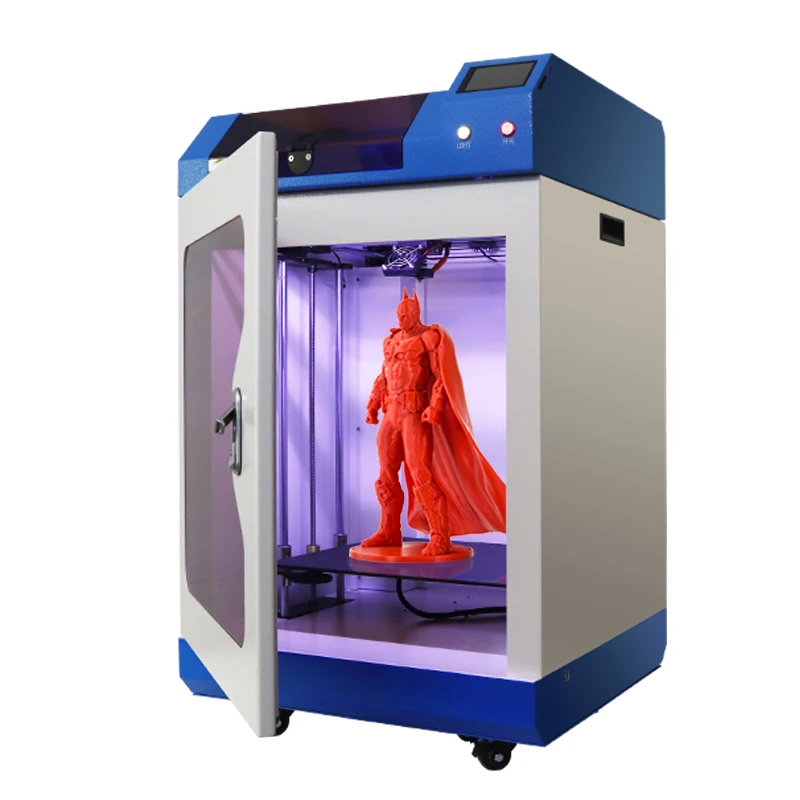

Unique 3d printers

The Weirdest and Wildest 3D Printers

Skip to main contentWhen you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

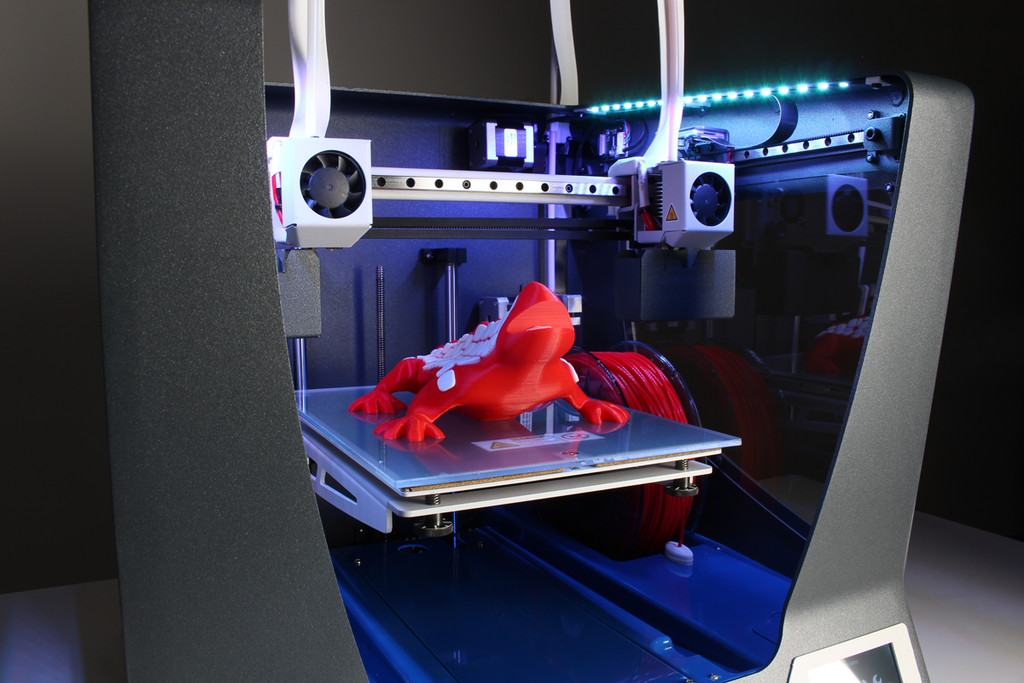

Most home 3D printers create small objects in simple plastic. But wouldn't you love to have a 3D printer that could print cookies? Or makeup? Or human organs? Here are 10 of the wildest 3D printers out there, proving that the devices can make a lot more than just doodads.

1. Mobile Fab trash-recycling 3D printer

Why you can trust Tom's Guide Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

(Image credit: Mobile Fab)One of the strongest criticisms of 3D printers is that they just print more useless plastic gewgaws. But what about a printer that can take old plastic trash and reuse it to make new objects? Once a futuristic dream, recycling 3D printers are quickly becoming a reality. But the best one so far is the Mobile Fab, a Taiwanese invention that's part bike, part plastic-cup recycler and part 3D printer.

MORE: Best 3D Printers 2014

The Mobile Fab has three parts: a machine that grinds down the plastic cups in which the popular Asian drink called bubble tea is served, a machine that takes these pieces and melts them into filament and a 3D printer that uses the filament to print objects.

The creators, who work for Taiwan-based design studio Fabraft, ride the bike around Taipei to do live demonstrations of what 3D printing can do.

2. Foodini food printer

In "Star Trek," futuristic Replicators create fully formed food. The closest thing to that here on Earth is the Foodini, a prototype 3D printer developed by Barcelona, Spain-based Natural Machines. The Foodini can print out dough, sauce, ground meat and other food materials in order to create perfectly formed pizza, chicken nuggets, ravioli and more.

In April, Natural Machines ran a Kickstarter campaign in which the Foodini was priced at $999 for a limited time and $1,300 for regular backers. The Kickstarter was unsuccessful, but the prototype works — and Natural Machines promises the commercial version is still happening.

The Kickstarter was unsuccessful, but the prototype works — and Natural Machines promises the commercial version is still happening.

3 "Made in Space" 3D Printer

(Image credit: Made in Space)Most 3D printers depend on gravity: The material drops from an extruder onto a print plate layer by layer to build objects from the ground up. But what if you wanted to 3D print something in space, where there is no gravity?

California-based engineering company Made in Space is working on a 3D printer that can print in zero gravity. And they're getting close: this August, a Made in Space prototype will be sent to the International Space Station for testing.

4. Mink cosmetics printer

Imagine if you could just print out your lipstick, eye shadow or blush, in any color or amount you desired, right from home. That's the goal of the Mink, a 3D printer designed by entrepreneur Grace Choi that launched at the Disrupt NY technology conference held in New York City this May.

Wit the Mink, people can use any photo-editing software, be it Photoshop or MS Paint, to create or select the exact color they wish. The Mink then mixes a pigment using the same basic components used in most cosmetics, and blends that pigment into makeup cream on the spot. Choi says the Mink will go on sale for less than $200 later this year.

5. 3Doodler

Most 3D printers require you to first use a computer design program to create your print object. With the 3Doodler ($99), no predesign is necessary — just pick up this 3D-printing pen and start drawing in the air.

MORE: 13 3D-Printed Halloween Costume Accessories

The pen extrudes hot, melted ABS plastic that quickly cools, forming lines in the shape in which you move the pen. It's similar to the way a regular 3D printer works: The pen is the extruder and filament cartridge, and you are the rest of the machine. Like a regular 3D printer, you start at the bottom and build upward, layering plastic on top of plastic as you build your object.

6. A whole-building 3D printer

(Image credit: Winsun New Materials)The 3D printers from China-based Winsun New Materials might not be as large as the one from Nanfang Ventilator, but they are still capable of printing near-complete buildings.

Printing in a combination of cement and glass fiber, the printer recently built parts for 10 656-square-foot (61 square meters) homes in Suzhou, China, that were then shipped to and assembled in Shanghai. A Winsun engineer told the Wall Street Journal that, although the process was efficient, unspecified local bureaucratic hurdles currently prevent the practice from becoming widespread.

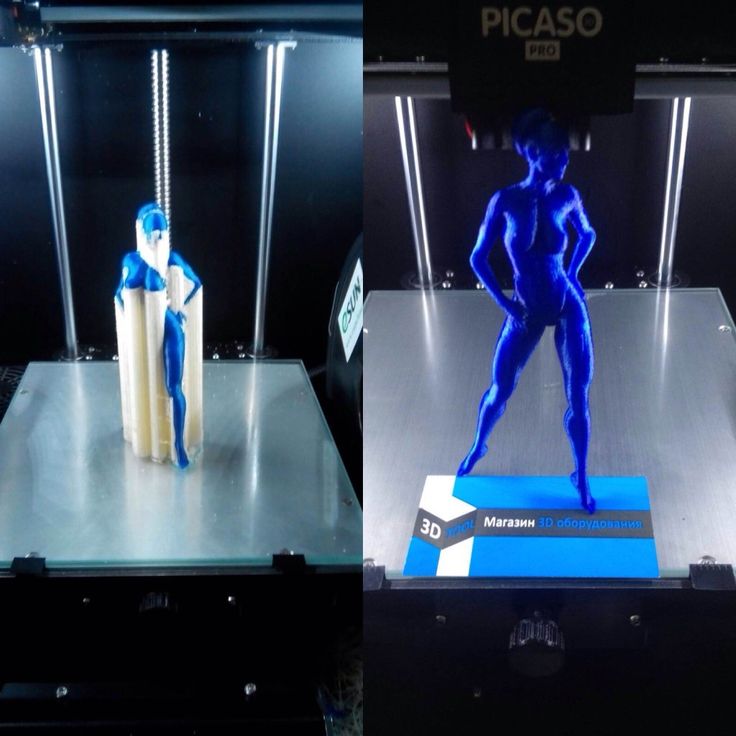

7. Human-organ printers

Need a new ear, a new lung or a new kidney? Several universities and research groups have developed various "bioprinters" that can print skin cells, organ tissue and other biological material with extreme precision, right down to the blood vessels and other fine details. They do this by laying down stem cells, which grow and differentiate into different types of cells in order to form a full organ. One of this process's main advantages is that patients' bodies are more likely to accept an organ formed of their own cells than a donor organ.

One of this process's main advantages is that patients' bodies are more likely to accept an organ formed of their own cells than a donor organ.

MORE: In Images: A 3D-Printed Liver

But the crown jewel of medical 3D printing is the ability to 3D print an entire developed, functional organ. Surgeon Anthony Atala first proposed the idea in a 2009 TED Talk, and since then, researchers at Hangzhou University in China have developed the Regenovo, a bioprinter that has successfully printed miniature, but functional, human livers and kidneys.

8. Rabbit Proto gadget printer

(Image credit: Rabbit Proto)What would it take to 3D print an electronic device — such as a cellphone — in one go? You'd need to print a circuit board, which is no easy feat. The printer would need to print a very precise pattern in multiple materials, at least one of which would have to be a conductive metal.

MORE: What Doesn't Make Sense to 3D-Print?

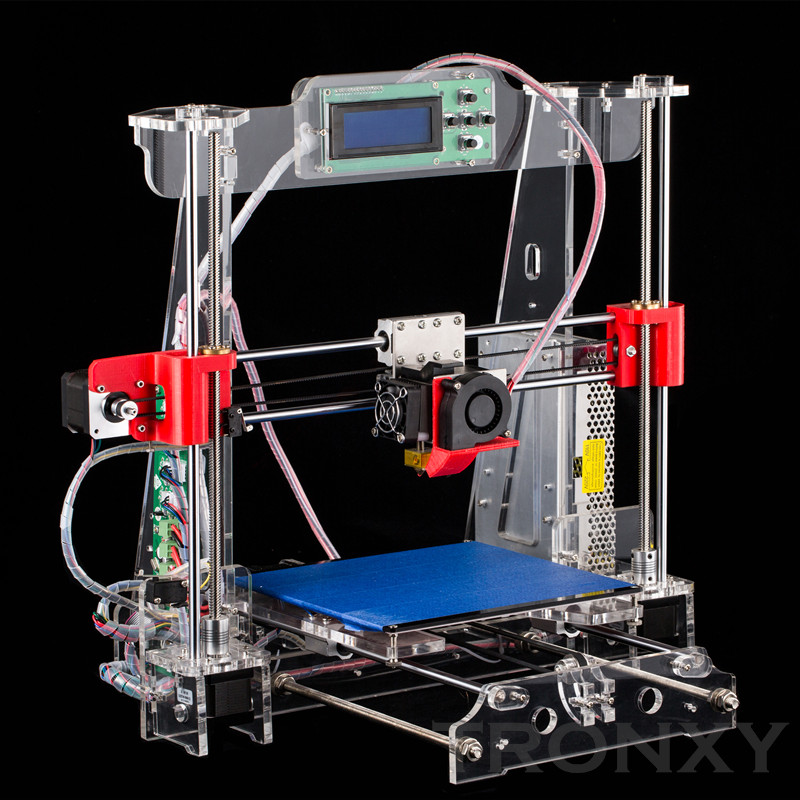

However, some 3D-printing hardware can print basic circuit boards and simple electronics. One of these is Rabbit Proto, a 3D-printer attachment that clips onto most RepRap 3D printers, creating a second extruder that lays down conductive metal alongside the main extruder that lays down plastic. This lets you print simple electronics like remote controls. It's comparatively affordable, too. One attachment is $350, sold on the company's website, but the project is open-source, so anyone with the parts and the time can build one for much less.

One of these is Rabbit Proto, a 3D-printer attachment that clips onto most RepRap 3D printers, creating a second extruder that lays down conductive metal alongside the main extruder that lays down plastic. This lets you print simple electronics like remote controls. It's comparatively affordable, too. One attachment is $350, sold on the company's website, but the project is open-source, so anyone with the parts and the time can build one for much less.

9. Chocolate 3D printer made of Legos

(Image credit: Saul, Instructables.com)3D printing in chocolate is always fantastic, but plenty of printers are now capable of this confectionary wonder. However, only one of them is made out of Legos.

With some Legos and a few simple parts, such as a funnel for the chocolate and a small heater to make it liquid, you can assemble your very own chocolate 3D printer, thanks to a user named Saul who posted the design to the online do-it-yourself website Instructables. On behalf of all humanity, Saul, we thank you.

10. World's largest 3D printer

(Image credit: Nanfang Ventilator Co. )In consumer 3D printing, the trend is to get smaller and more home-friendly. But as more industries adopt 3D-printing techniques in their manufacturing processes, printers are getting bigger, too.

In China, Nanfang Ventilator Co. is working on the world's biggest 3D printer — it measures 92 feet long, 75 feet wide and 31 feet high (28 m by 23 m by 9 m). Still nameless, it prints in metals such as carbon steel and stainless steel, and can build objects as large as 20 feet by 33 feet (6 m by 10 m). With a printer that big, Nanfang Ventilator can print parts for nuclear power plants, airplanes, ships and more.

Email [email protected] or follow her @JillScharr and Google+. Follow us@TomsGuide, on Facebook and on Google+.

- Sense Handheld 3D Scanner Review

- Make Your Barbie Battle-Ready With 3D-Printed Armor

- How 3D Printing Is Changing Etsy

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Jill Scharr is a creative writer and narrative designer in the videogame industry. She's currently Project Lead Writer at the games studio Harebrained Schemes, and has also worked at Bungie. Prior to that she worked as a Staff Writer for Tom's Guide, covering video games, online security, 3D printing and tech innovation among many subjects.

Topics

Gadgets

Tom's Guide is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

Some of the Most Surprising 3D Printing Materials Currently Available

Published on January 7, 2022 by Alexandrea P.

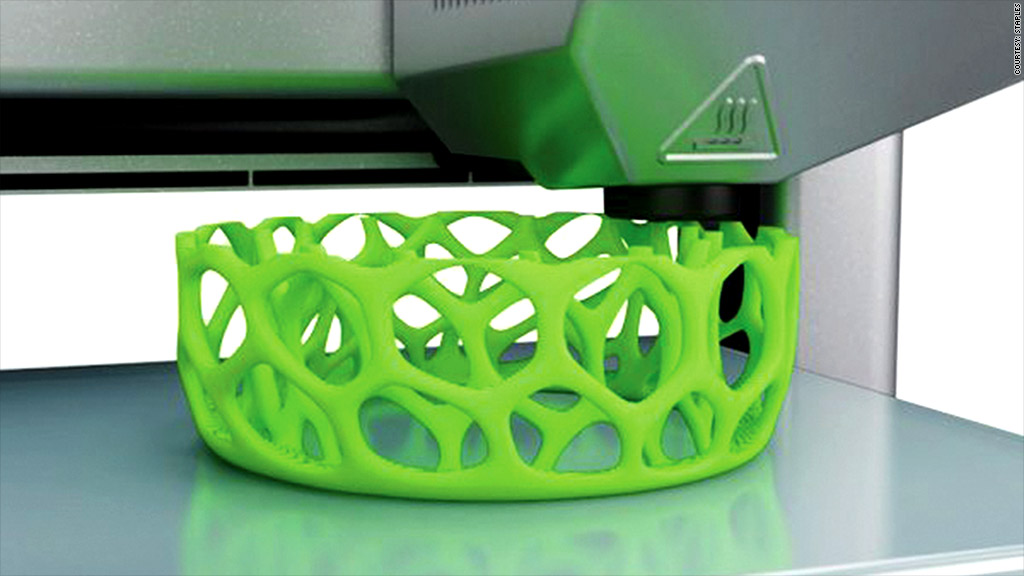

3D printing with classic materials such as plastic, metal or ceramics is widespread. In the meantime, however, there are a variety of material alternatives that are not only unusual, but also can make the 3D-printed part even more special. In our selection, we introduce you to these unusual materials. From chocolate to salt to recycled plastic waste or ash, you can now design extraordinary and unusual objects. In some cases, these materials even prove to be an excellent alternative to plastic, reducing over-consumption and the environmental impact that comes with it. Today, we’re taking a look at these surprising materials for 3D printing that you might not expect at first glance.

In our selection, we introduce you to these unusual materials. From chocolate to salt to recycled plastic waste or ash, you can now design extraordinary and unusual objects. In some cases, these materials even prove to be an excellent alternative to plastic, reducing over-consumption and the environmental impact that comes with it. Today, we’re taking a look at these surprising materials for 3D printing that you might not expect at first glance.

3D printing material from the sea

Filaments are still the most commonly used materials for 3D printing today, mainly because FDM machines are easily accessible. But did you know that some filaments are already made from shellfish and crustaceans? French company Francofil offers materials made from PLA and the shells of mussels, scallops and oysters. These shells come from recycled food service waste and are crushed to be made into filaments. The materials are manufactured in France and can be printed like conventional PLA.

Photo Credits: Francofil

Locally sourced salt

Emerging Objects is an American company that uses new technologies with innovative materials to create impressive projects. Among the most outstanding initiatives is Saltygloo, a structure made by 3D printing salt. The salt used was collected locally in San Francisco Bay. About 500,000 tons of sea salt are produced here annually due to the climatic conditions. The salt was used to additively manufacture lightweight structures on a large scale. In addition to Saltygloo, the company is known for other salt projects, such as the GEOtube tower and the construction of houses.

Among the most outstanding initiatives is Saltygloo, a structure made by 3D printing salt. The salt used was collected locally in San Francisco Bay. About 500,000 tons of sea salt are produced here annually due to the climatic conditions. The salt was used to additively manufacture lightweight structures on a large scale. In addition to Saltygloo, the company is known for other salt projects, such as the GEOtube tower and the construction of houses.

Photo Credits: Matthew Millman

Chocolate, the sweetest 3D printing material

This 3D printing material may not be as exceptional as some of the others on the list, but it is certainly among the most commonly used. The chocolate 3D printing process is similar to FDM technology, but it has different cooling properties than plastic, so the process takes longer. The popularity of this technology has increased over the years, prompting many companies to develop various projects and even chocolate 3D printers. Among the most famous is the collaboration between 3D Systems and Hershey’s, one of the largest chocolate manufacturers. We have also featured some 3D printers that can make delicious sweets, such as mycusini or Print2Taste. If you want to learn more about this technology, don’t miss the video below.

We have also featured some 3D printers that can make delicious sweets, such as mycusini or Print2Taste. If you want to learn more about this technology, don’t miss the video below.

3D printing material from ashes to remember your loved ones

The Spanish company Narbón is dedicated to introducing new technologies and innovations in the funeral sector. The 3DMemories service uses 3D printing to create original, unique and exclusive ceramic jewelry from the ashes, hair, DNA or skeletal remains of a loved one. To do this, the pattern must be processed and then combined with porcelain before the jewelry can be 3D printed. Then the enamel is applied and the piece is fixed. The service offers a range of products for men and women. Undoubtedly, 3DMemories with its range of jewelry represents an exceptional way to remember the loved one.

Photo Credits: Narbón

Wood-based filaments

Wood- or plant-based filaments have also been available on the market for some time. For example, the Dutch company ColorFabb offers several filament alternatives in this category. What began in 2014 with BambooFill was expanded in the years that followed with CorkFill and WoodFill. The wood fibers are typically mixed into a PLA/PHA base and give parts a natural, high-quality finish. Whether used to make figurines, furniture pieces or wall decorations, the filaments can be used wherever a wooden look is desirable. While ColorFabb has since discontinued its BambooFill, a similar product can be purchased in the form of Wood Bamboo from AzureFilm. According to the company, 40% recycled wood is mixed with 60% polymers for this purpose. However, to avoid problems when printing with this filament, it is recommended to reduce the printing speed. With Entwined™, the US company Fuel 3D also offers a sustainable PLA-based filament with hemp additive.

Left: ColorFabb, Right: Azure Film

A different use for linen

Another alternative to traditional filaments is a composite material made of PLA and flax from French manufacturer Nanovia. The company says that this composite material is not only a sustainable alternative to traditional filaments, but also offers the possibility of obtaining different shades of brown by applying different printing parameters. This can be achieved by simply changing the printing temperature during the manufacturing process. As far as finishing is concerned, the manufacturer recommends sealing the printed parts with a UV protection treatment so that the printed parts remain intact as long as possible.

Photo Credits: Nanovia.

3D printing with sugar

Sugar Lab was acquired by 3D Systems almost ten years ago, but spun out in 2020 and refounded as a direct-to-consumer specialty confections 3D printing company. Using the Brill 3D Culinary Studio, which was originally developed by 3D Systems and called ChefJet Pro, the company creates candy and decorations in complex shapes. The Los Angeles-based company says it is capable of producing candies in all flavors and colors. Whether it’s for birthdays, weddings or Christmas parties, The Sugar Lab offers all kinds of candy from the 3D printer. And as for quantity, the 3D printer seems to be able to produce hundreds of confections per day. While The Sugar Lab is the most well-known company using sugar as a printing material, other companies such as The Modernist Cuisine are also trying their hand at 3D printing with sugar.

The Los Angeles-based company says it is capable of producing candies in all flavors and colors. Whether it’s for birthdays, weddings or Christmas parties, The Sugar Lab offers all kinds of candy from the 3D printer. And as for quantity, the 3D printer seems to be able to produce hundreds of confections per day. While The Sugar Lab is the most well-known company using sugar as a printing material, other companies such as The Modernist Cuisine are also trying their hand at 3D printing with sugar.

3D printing with glass

Glass has been popular in numerous industries for many years and is also used in additive manufacturing. Several researchers, for example from MIT or Lawrence Livermore National Laboratory (LLNL), have developed 3D printing solutions to make glass printable. For example, the MIT team developed the G3DP2 machine, which can process 5 kg of glass per hour. With this machine, the researchers managed to create 3-meter-high glass columns at Milan Design Week. Recently, the startup Glassomer also presented its technology for 3D printing glass. The company is developing a material made of fine glass powder and plastic binder that can be processed by SLA printers.

With this machine, the researchers managed to create 3-meter-high glass columns at Milan Design Week. Recently, the startup Glassomer also presented its technology for 3D printing glass. The company is developing a material made of fine glass powder and plastic binder that can be processed by SLA printers.

Photo Credits: Glassomer

Filaments made from recycled plastic

The topic of sustainability is increasingly coming into focus in the field of additive manufacturing, which is why many companies are looking for alternatives. In recent years, several interesting products have been developed that aim to make 3D printing more sustainable by producing filaments from recycled plastic. One such project is Print The City by The New Raw, where plastics from the waste of Amsterdam and Thessaloniki residents are converted into 3D printing filament and used to print benches and other street furniture. Another initiative is the Million Waves Project, which aims to produce filament from recycled PET to 3D print prosthetic limbs for those in need. Another example is the ZUV tricycle, which was printed in Austria by EOOS using filaments made from 70 kilos of plastic waste from supermarkets in Vienna.

Another example is the ZUV tricycle, which was printed in Austria by EOOS using filaments made from 70 kilos of plastic waste from supermarkets in Vienna.

Photo Credits: The New Raw

A 3D printing material inspired by ivory

Among the multitude of materials used for 3D printing, there are some that have been developed ad hoc to meet specific requirement and solve old problems in an innovative way. One such material is Digory, which was developed by the University of Vienna in collaboration with Cubicure GmbH to meet the need for restoration of ancient monuments and objects made of ivory. It is a synthetic resin containing calcium phosphate particles and silicon oxide powder. Researchers have developed this new material with ivory-like characteristics and properties to restore objects using 3D printing or SLA technology. The similarity between the two materials is remarkable – there is hardly any difference!

The digory material on the right, is very similar to the real ivory on the left (photo credits: Vienna University of Technology)

Clay as a more sustainable 3D printing material

One unusual 3D printing material that has certainly been getting notice in recent years is clay. Technically a subsection of ceramic 3D printing, which, though difficult to print with, is known for its incredible properties, the use of clay in particular has been especially popularized through the work of Italian company WASP. For example, we recently saw that WASP and Honda have been using clay 3D printing to create more sustainable vehicles. There are many other usages as well, though many center on sustainability due to clay’s properties. This can be seen with projects like archiREEF’s terracotta tiles to restore coral in Hong Kong or 3D printed clay containers designed to reduce food waste.

Technically a subsection of ceramic 3D printing, which, though difficult to print with, is known for its incredible properties, the use of clay in particular has been especially popularized through the work of Italian company WASP. For example, we recently saw that WASP and Honda have been using clay 3D printing to create more sustainable vehicles. There are many other usages as well, though many center on sustainability due to clay’s properties. This can be seen with projects like archiREEF’s terracotta tiles to restore coral in Hong Kong or 3D printed clay containers designed to reduce food waste.

Photo Credits: Jonathan Keep

Diamond – 3D printing the hardest material on Earth

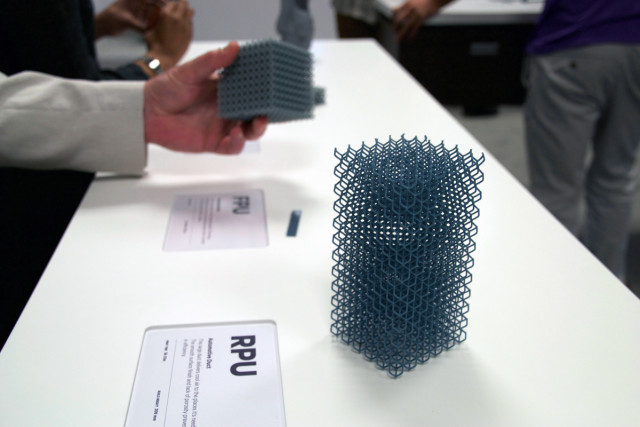

It may come as a surprise to many that it is in fact possible to 3D print one of the hardest materials on Earth, diamond. Back in 2019, Sandvik Additive Manufacturing announced that it had made the first ever 3D printed diamond composite. Though it does not sparkle, it would allow manufacturers to 3D print with this super-hard material, helping to revolutionize especially the tooling industry. Diamond has often been used in industries as far-ranged as mining and drilling to machining and medical implants especially because of its wear-resistant properties, but it is hard to machine. With this composite breakthrough, Sandvik claims that it is now possible to 3D print the material in highly complex shapes, and the company has high hopes for its applications in the near future.

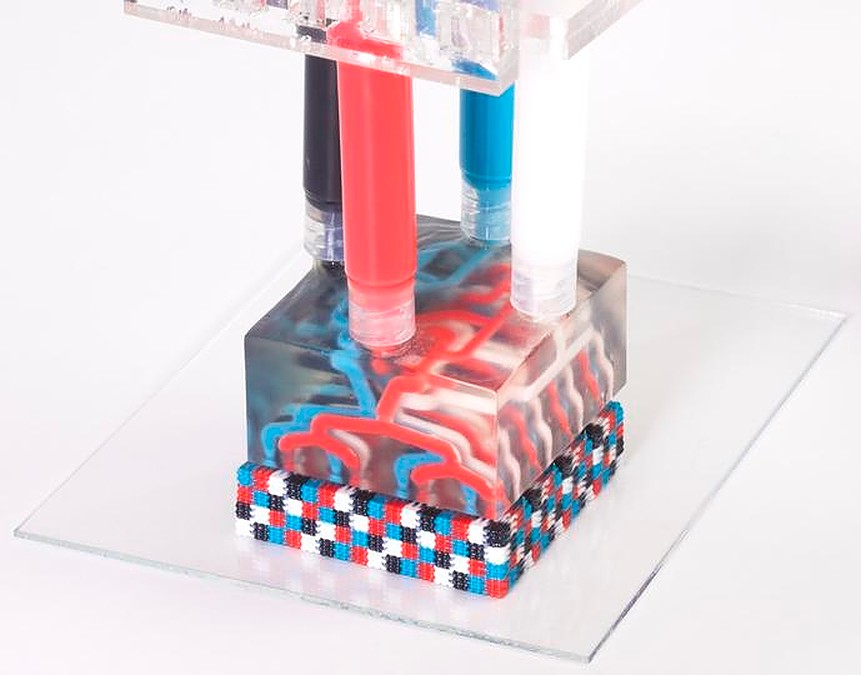

Printing with human cells

When it comes to 3D printing in the medical sector, often people’s minds turn to bioprinting. In bioprinting, cellular structures, including human ones, are made from bioinks which have been loaded with stem cells. Like in regular 3D printing, the biomaterial can then be deposited layer by layer to make things like skin, tissue, bone and even organs. Though it is still relatively in its infancy as a technology when it comes to creating viable long-term solutions, already we have seen a number of exciting projects using the technology. Notably, researchers have experimented with 3D printing organs including a heart, a kidney, a pancreas and a liver, among others. Others have also devised a way to bioprint with ceramics and bioinks to recreate bones within the human body. You can find out more information in the video below.

Notably, researchers have experimented with 3D printing organs including a heart, a kidney, a pancreas and a liver, among others. Others have also devised a way to bioprint with ceramics and bioinks to recreate bones within the human body. You can find out more information in the video below.

What do you think of our list of surprising 3D printing materials? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

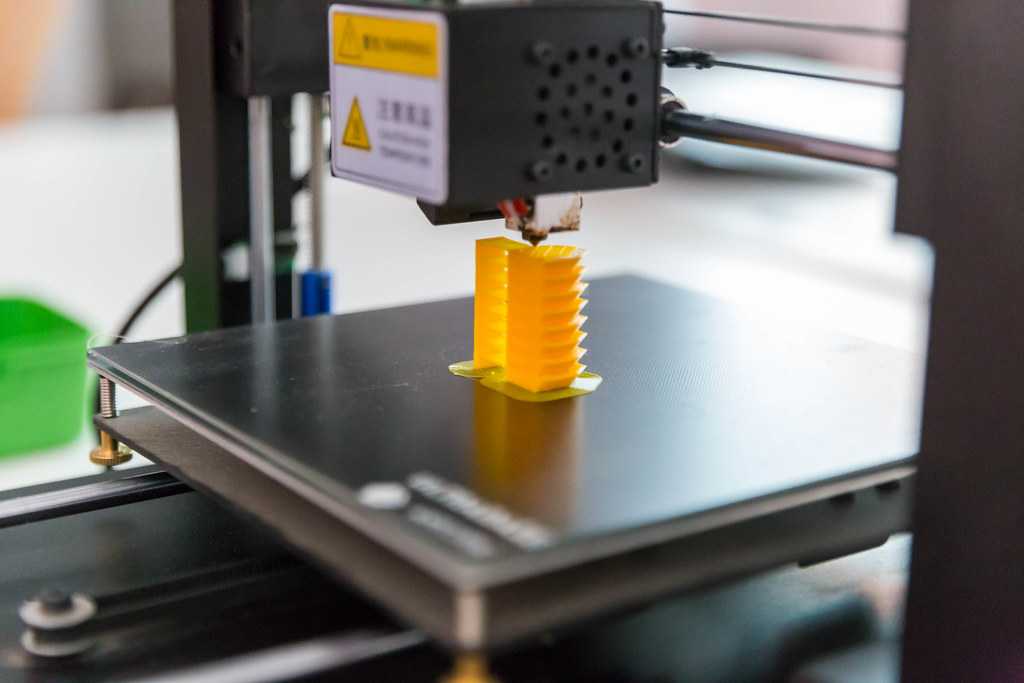

Russian scientists have created a unique 3D printer. There are some shortcomings. The reason is in the very principle of this technology. Such printers can be called slow moving, they print products in layers, applying new layers of material after the previous one has hardened.

What kind of performance are we talking about here? Therefore, in most cases, it is much easier and faster to turn the desired part from a single piece of plastic or metal than to wait for the printer to do it.

What kind of performance are we talking about here? Therefore, in most cases, it is much easier and faster to turn the desired part from a single piece of plastic or metal than to wait for the printer to do it. Russian scientists have solved this problem. They created the world's first printer that does not print 3D structures of arbitrary shape and any size in layers, but immediately produces a whole product. Let's say right away that so far we are talking only about printing from polymeric materials.

What is the essence of the unique technology developed by our specialists? Here it is necessary to recall how a dentist today makes a polymer filling. He puts a layer of a mixture of monomers on the tooth, and in order for them to turn into a polymer, he processes layer by layer with an ultraviolet lamp. This is how the tooth is gradually repaired.

- Why can't a filling be done in one pass? The fact is that ultraviolet penetrates into the material at a very short distance, - says one of the authors of the development, Kirill Khaidukov from the Federal Research Center "Crystallography and Photonics" of the Russian Academy of Sciences. - Therefore, it is necessary to apply the material in layers. For the same reason, large structures cannot be made in this way. We have replaced ultraviolet with infrared. And it has completely changed the technology.

- Therefore, it is necessary to apply the material in layers. For the same reason, large structures cannot be made in this way. We have replaced ultraviolet with infrared. And it has completely changed the technology.

It must be emphasized that infrared rays alone do not solve the problem. But the authors, using this radiation, found an unexpected and very beautiful solution. They created nanoparticles from sodium, thulium, ytterbium and fluorine, which have an amazing property. By absorbing infrared rays, they convert them into ultraviolet. The new technology works on this effect.

- The monomer blank perfectly transmits infrared radiation, it penetrates all this thickness, interacts with nanoparticles and turns into ultraviolet. But in this case, it is already evenly distributed over the entire thickness of the structure that the 3D printer prints,” Khaidukov explains. - As a result, a finished three-dimensional product is immediately obtained.

This is the first printer that does not print in layers, but immediately issues a finished product.

According to the authors, this printer can be used in three-dimensional laser drawing, micromachining of materials, in holography, electronics and data processing systems. Another area of application is biomedicine, in particular tissue engineering, which replaces damaged parts of organs and tissues using various polymeric materials.

The work was carried out at the Federal Scientific Research Center "Crystallography and Photonics" of the Russian Academy of Sciences together with scientists from the Institute of Bioorganic Chemistry named after academicians M.M. Shemyakin and Yu.A. Ovchinnikov RAS, First Moscow State Medical University named after I.M. Sechenov and Moscow Technological University. The study was supported by a grant from the Russian Science Foundation.

Rossiyskaya gazeta - Federal issue: No. 109(7572)

Share:

Nauka

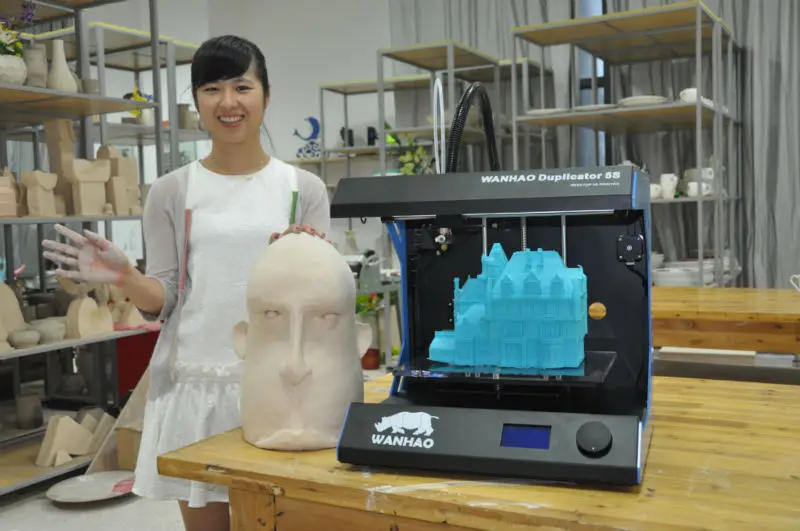

Unique objects created on innovative printers

10/11/2018

3D printing has long evolved from a completely new technology to a widely used medium for the production of various 3D projects. And although such printing is not cheap, 3D products continue to delight printer owners with such advantages as fast production cycles, time savings and high quality. Therefore, 3D printers are widely used in many areas of life to create both large-scale and small-scale projects.

And although such printing is not cheap, 3D products continue to delight printer owners with such advantages as fast production cycles, time savings and high quality. Therefore, 3D printers are widely used in many areas of life to create both large-scale and small-scale projects.

The following projects were created using modern printing and still amaze with their high quality of detail:

- Three models of the Aston Martin DB5 car were made for the filming of the famous movie "007: Skyfall" in 2012. The scale of all models was 1:3. All of them were printed for spectacular shooting of exploding cars. At the end of filming, only one model of the car remained, but it was also possible to benefit from it: it was soon put up for auction. Anyone could purchase it for ninety-nine thousand dollars. And although this price is much higher than the price of a conventional car, there were many people who wanted to purchase this model and simply interested people.

- 3D printing has not bypassed the weapon business.

The project of Cody Wilson, the American founder of the Defense Distributed network program, turned out to be more than successful. With the help of a 3D printer, he managed to create a real firearm. Wilson's pistol was made of plastic, and despite looking more like a child's toy than a dangerous weapon, Wilson managed to fire six rounds of 9mm bullets. After that, the neck of the butt of the weapon cracked, and the pistol fell into disrepair. But the very fact of creating firearms using 3D printing has amazed and inspired many people.

The project of Cody Wilson, the American founder of the Defense Distributed network program, turned out to be more than successful. With the help of a 3D printer, he managed to create a real firearm. Wilson's pistol was made of plastic, and despite looking more like a child's toy than a dangerous weapon, Wilson managed to fire six rounds of 9mm bullets. After that, the neck of the butt of the weapon cracked, and the pistol fell into disrepair. But the very fact of creating firearms using 3D printing has amazed and inspired many people. - The creation of the first violin on a 3D printer pleasantly surprised many musicians. The first violin was printed by Alex Davis. The body of the musical instrument was made of plastic, while the neck and neck were made of cardboard. Of course, such a violin is still unable to compete with the creations of Stradivari, but for amateur musicians it has become a real gift. The melody played by musicians with the help of such a violin is definitely impressive and gives hope for the subsequent development of musical instruments.

Learn more