Dreamer flashforge 3d printer manual

FLASHFORGE DREAMER USER MANUAL Pdf Download

Table Of Contents

3-

page of 46

- Contents

- Table of Contents

- Bookmarks

Advertisement

Table of Contents

-

-

9

Chapter 1.SETTING up the DREAMER

-

25

Chapter 2. A THOROUGH LOOK at the FLASHPRINT SOFTWARE -

36

Chapter 3. MAKING YOUR FIRST PRINT -

44

Chapter 4. ADDITIONAL INFORMATION

ADDITIONAL INFORMATION

User Guide

Dreamer Desktop 3D Printer

1

Dreamer User Guide |

www.ff3dp.com

Table of Contents

Previous Page

Next Page

Table of Contents

-

-

9

Chapter 1. SETTING up the DREAMER -

25

Chapter 2. A THOROUGH LOOK at the FLASHPRINT SOFTWARE

A THOROUGH LOOK at the FLASHPRINT SOFTWARE -

36

Chapter 3. MAKING YOUR FIRST PRINT -

44

Chapter 4. ADDITIONAL INFORMATION

Related Manuals for Flashforge Dreamer

- 3D Printers Flashforge Dreamer User Manual

(69 pages)

- 3D Printers Flashforge Dreamer User Manual

(61 pages)

- 3D Printers FlashForge DREAMER User Manual

Desktop 3d printer (60 pages)

- 3D Printers Flashforge Dreamer Desktop 3D Printer User Manual

(52 pages)

- 3D Printers Flashforge DREAMER Quick Start Manual

(36 pages)

- 3D Printers Flashforge DREAMER Quick Start Manual

(14 pages)

- 3D Printers Flashforge DREAMER Quick Start Manual

(9 pages)

- 3D Printers Flashforge Finder Quick Start Manual

(11 pages)

- 3D Printers Flashforge Finder User Manual

(88 pages)

- 3D Printers Flashforge Creator Pro Quick Start Manual

(16 pages)

- 3D Printers Flashforge Creator Quick Start Manual

(22 pages)

- 3D Printers Flashforge FINDER User Manual

(66 pages)

- 3D Printers Flashforge Creator Pro User Manual

(54 pages)

- 3D Printers Flashforge Finder User Manual

(65 pages)

- 3D Printers Flashforge Guider II Assembly Instruction Manual

Replacement of high-temperature extruder kit (10 pages)

- 3D Printers Flashforge Adventurer3 Quick Start Manual

(21 pages)

Summary of Contents for Flashforge Dreamer

|

|

|||||||||||||||||||||||||||||||||||||||

What our users say about us:Peter Morgan: "Thanks for this website! With help from your instructions I’ve got my dishwasher working again. " "

Nick Jackson: "Your site’s been a massive help because the user manual didn’t come with the product. Thanks a lot."Leslie Scott: "I finally found the user's guide with you that I couldn’t find anywhere else! Totally happy!" |

||||||||||||||||||||||||||||||||||||||||

|

Take a look through our user manuals in our on-line library, with instruction manuals and service handbooks downloadable in PDF format. Our instructions database is constantly updated and supplemented with new products. Looking for instruction manuals? Ask us!

SEARCH-MANUAL.com Sitemap.xml |

||||||||||||||||||||||||||||||||||||||||

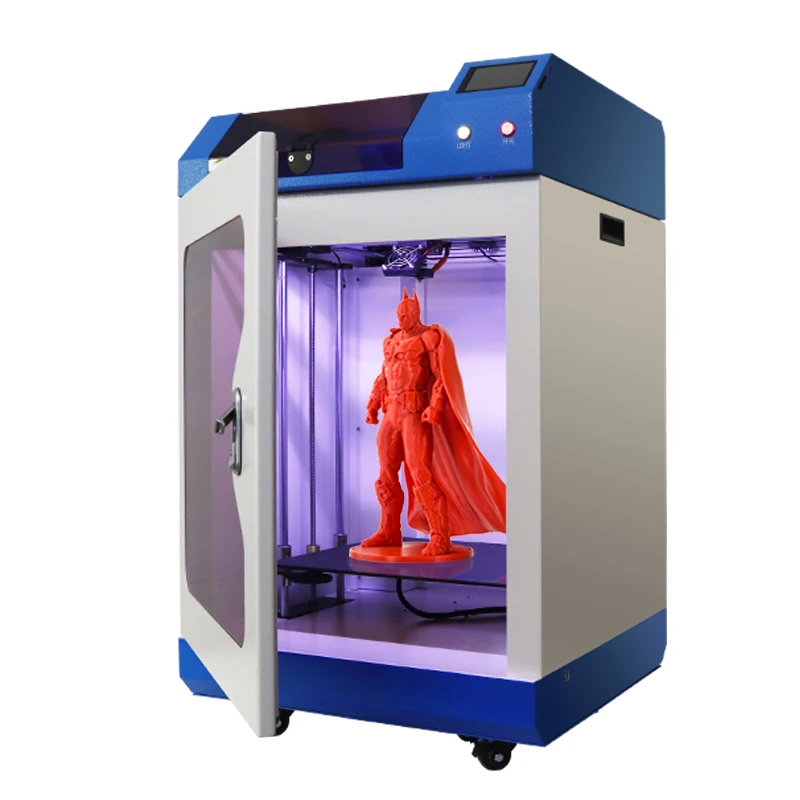

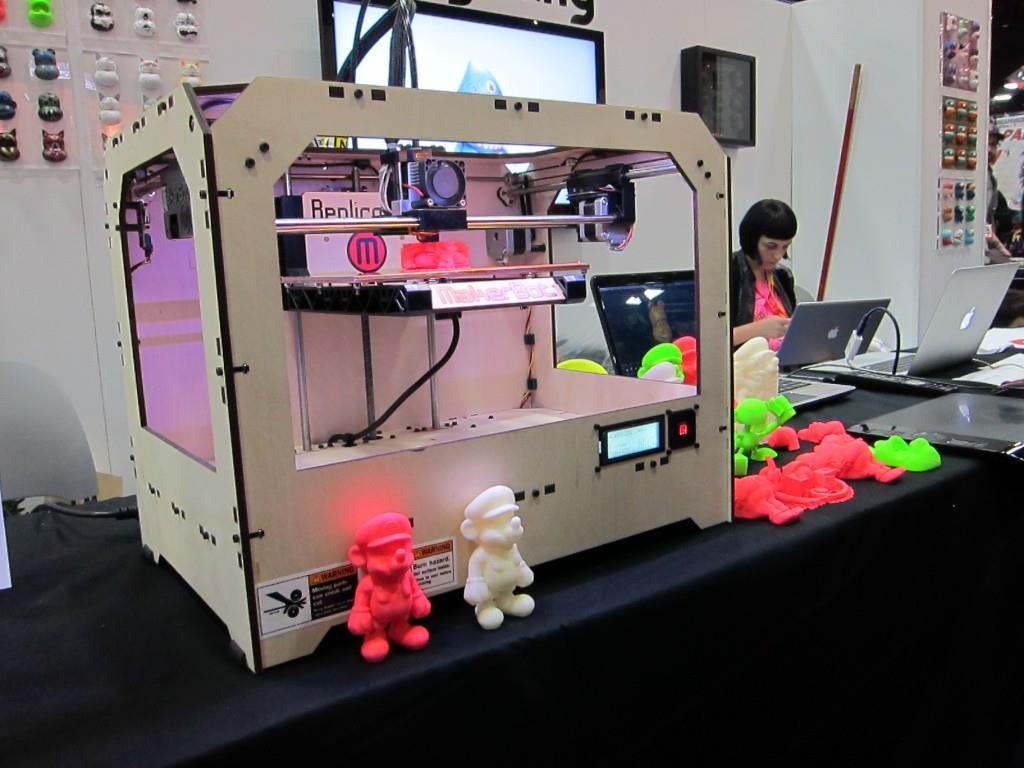

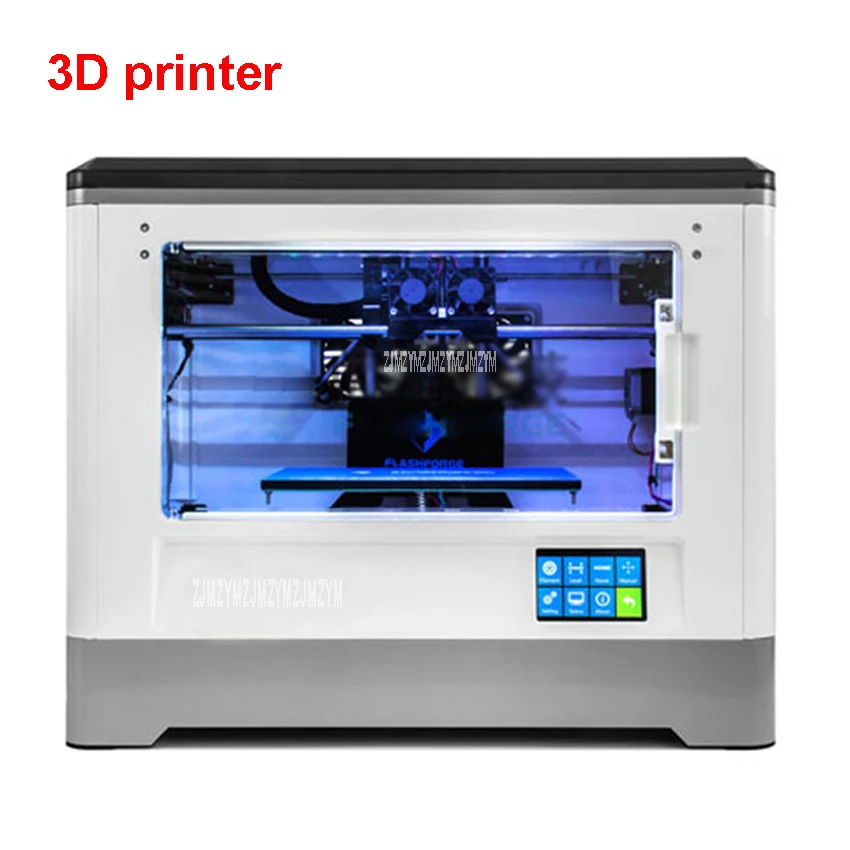

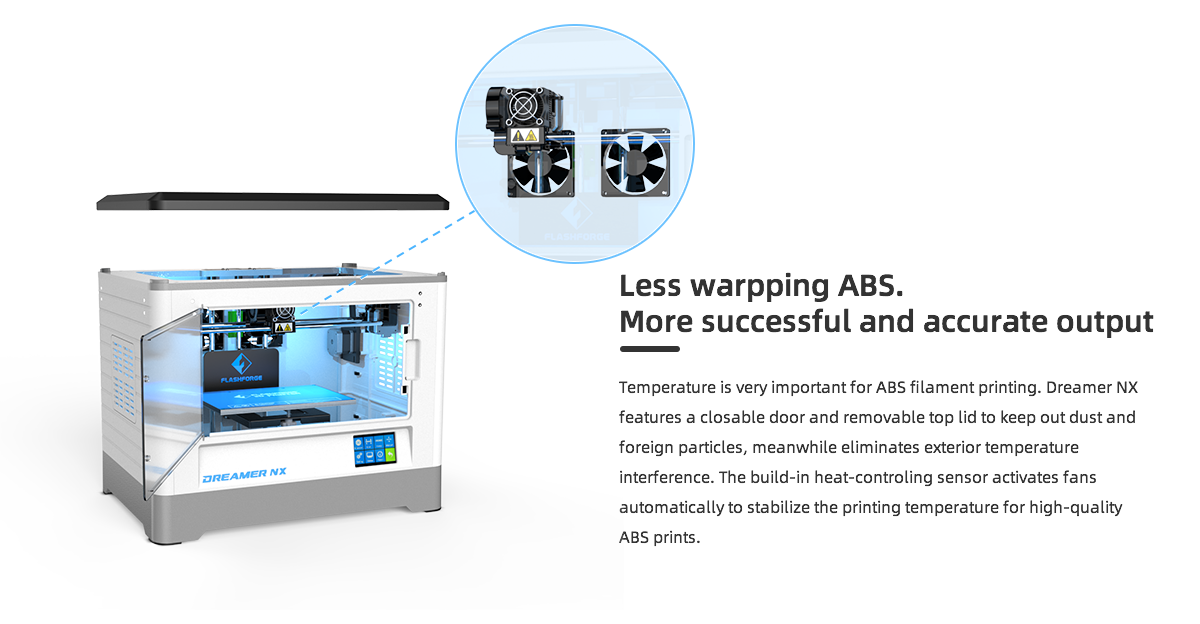

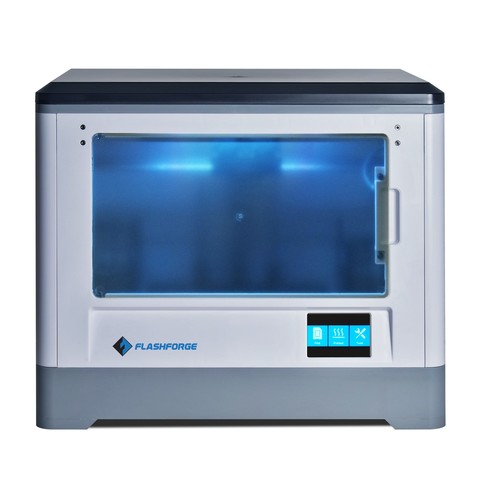

Overview of 3D printer Flashforge Dreamer

3d printing has been my passion for the last 2-3 years. I purchased a Makerbot Replicator 2 3D printer a little over a year and a half ago and have since printed everything from Christmas ornaments and necklaces to toys for my son. I eventually got used to my Replicator 2, although at first I had some difficulty setting it up, loading it, leveling the desktop, and keeping all the settings up and running. When I was asked to review a new 3d printer, I admittedly hesitated a bit with the answer.

I eventually got used to my Replicator 2, although at first I had some difficulty setting it up, loading it, leveling the desktop, and keeping all the settings up and running. When I was asked to review a new 3d printer, I admittedly hesitated a bit with the answer.

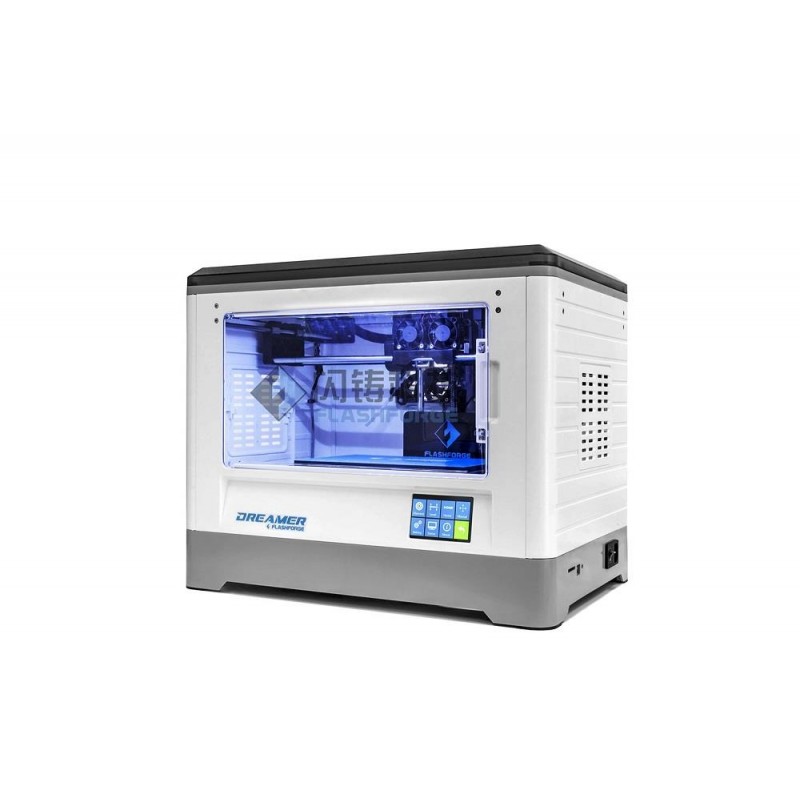

First impression

When I first unpacked the Flashforge Dreamer, I thought "they must have sent me the microwave by mistake". The new 3D printer in appearance reminded me of a small microwave oven, and even guests sometimes asked why I have a microwave in my office. It weighs about the same as the Replicator 2. It really looks good, so you're not afraid to put it in a prominent place in the house. I have seen quite a few 3d printers that are ugly on the outside. and Flashforge Dreamer is definitely not one of them, and the reason is primarily in a completely closed chamber. It looks good and seems solid enough. The only slight complaint about the appearance is the plastic surfaces of the case, which add a sense of cheapness to its appearance. But after a while, I changed my mind. The design of the case is made so that you can see most of the parts of its design that make it work.

But after a while, I changed my mind. The design of the case is made so that you can see most of the parts of its design that make it work.

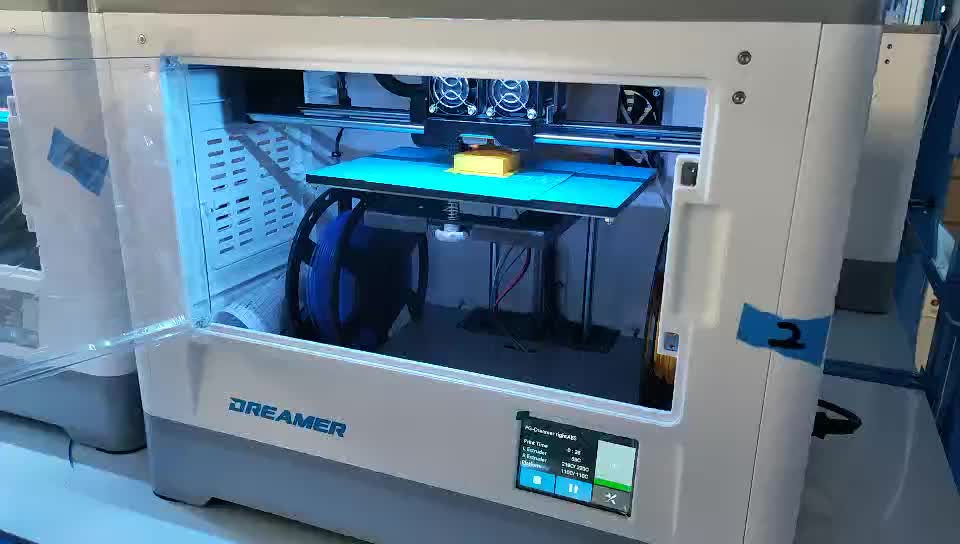

Installation

As I found out later, all 3d printers are similar, but not quite. It seemed to me that my experience with the Replicator 2 would be enough, but unfortunately this was not the case. Installation went quickly and without difficulty. I took it out of the box, secured the extruder with two screws, turned on the power, and loaded the plastic. The model I tested had two extruders and came with a spool of red PLA plastic and white ABS. Loading took place on time to spit. There were buttons for loading and unloading filament on the touch screen. I pressed the button, waited for it to warm up and loaded the plastic through the hole on top. Just 30 seconds and the printer was ready to go.

The first stupidity

Without reading the instructions, I immediately downloaded a few files and decided to print them. This was a big mistake. I forgot to level the platform before starting to print. In short, as a result, the extruder was clogged, and I had absolutely no idea how to clean it. I wrote a message to the support service and within an hour I received detailed instructions for disassembling the extruder and clearing the blockage. The whole process took me 20-25 minutes.

This was a big mistake. I forgot to level the platform before starting to print. In short, as a result, the extruder was clogged, and I had absolutely no idea how to clean it. I wrote a message to the support service and within an hour I received detailed instructions for disassembling the extruder and clearing the blockage. The whole process took me 20-25 minutes.

First print.

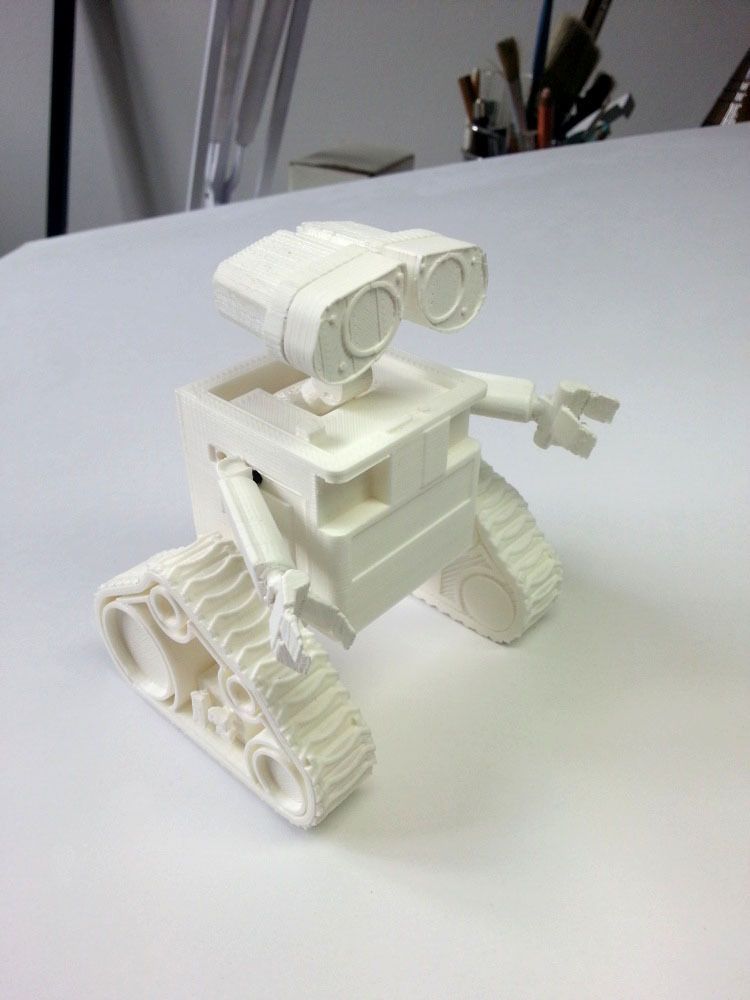

I finally set up my printer and printed a little frog. I decided to start small, just to make sure everything was in order with the settings. The result was great. The frog looked flawless even though it was printed without support. The next model was a spinning wheel toy car that was printed in one go. I tried to print it on other 3d printers, but the result was worse every time.

I expected similar results from the Flashforge Dreamer , but to my surprise the ABS printed car came out almost perfect. Spoiled the impression of a small defect on one side. But the wheels turned, and I could roll it without difficulty, just like any of my son's other cars.

But the wheels turned, and I could roll it without difficulty, just like any of my son's other cars.

Resolution and print quality.

I was surprised by the print quality. It was commensurate with the quality of my Replicator 2, and in some cases even higher than I'm used to.

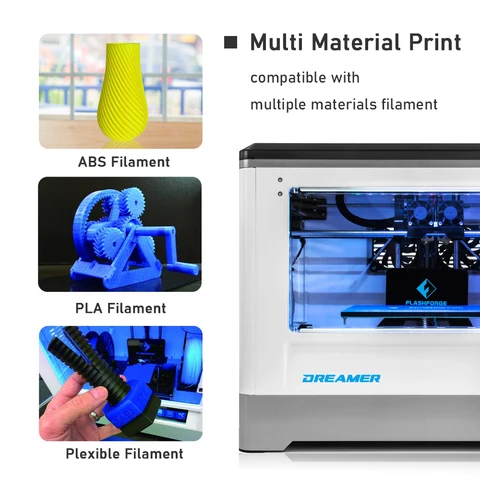

Dual Extruder

I've never used a 3d printer with two extruders before. They allow the support to be printed in a material that is different from that of the main model. It also makes it possible to print in two colors, and get more vibrant 3d objects. Colors add charm to any object, whether it's a toy car, a pretty box, or a piece of jewelry. I probably don't want to go back to a printer with a single extruder anymore.

Software.

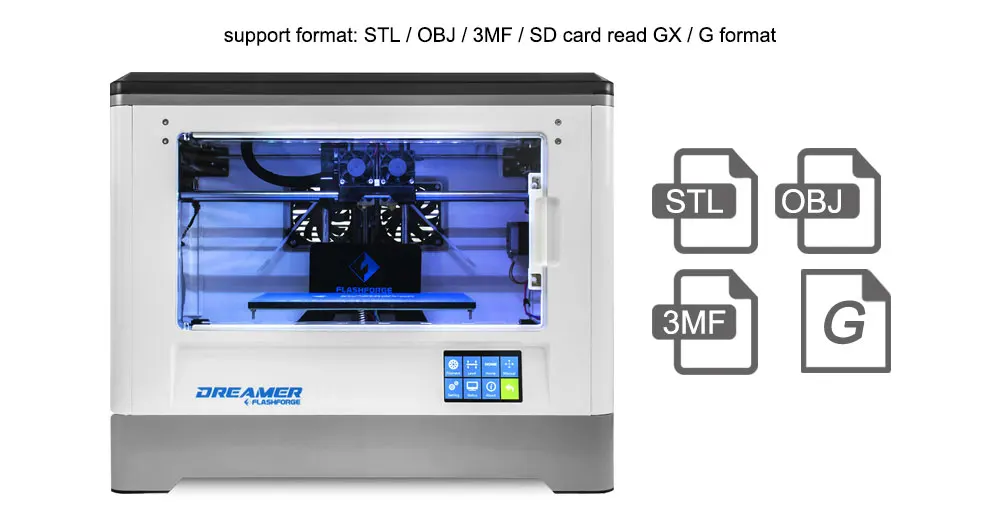

One of the most time-consuming and complex processes in 3d printing is, of course, the cutting of layers of objects, and the process of generating a gcode that is sent to the printer in order to control the printing process. The Flashforge software proved to be easy to use. I just installed it, loaded the object and hit print. I was offered several options for slicing, the choice of extruder and printing temperature. I left most of the parameters by default, since they were in the values I needed. A couple of minutes after pressing "OK", the printer began to print. This was probably the fastest print submission I have ever made. Yes, this printer gives you the choice of settings you need, and it's great for beginners and advanced users alike.

The Flashforge software proved to be easy to use. I just installed it, loaded the object and hit print. I was offered several options for slicing, the choice of extruder and printing temperature. I left most of the parameters by default, since they were in the values I needed. A couple of minutes after pressing "OK", the printer began to print. This was probably the fastest print submission I have ever made. Yes, this printer gives you the choice of settings you need, and it's great for beginners and advanced users alike.

Unsuccessful

If you still talk about the negative sides of this 3d printer, because it should be an honest review. I would like a little more volume. Of course, the 9.1” x 5.9” x 5.5” volume is sufficient for printing small objects, but I am used to the larger volume of my Replicator 2. I have not yet had to print an object that was larger than the maximum possible, but I feel that in one fine day I may need extra centimeters. The cheap appearance of the extruder, made of powder-coated steel, did not immediately convince me of the high quality of the 3d printer. But at the same time, the printer mechanism was made of high quality and executed with high accuracy, and this is what matters when printing.

But at the same time, the printer mechanism was made of high quality and executed with high accuracy, and this is what matters when printing.

Specifications

- Interfaces: Wi-Fi, USB, SD

- Positioning accuracy: 0.1 mm - 0.2 mm

- Layer thickness (resolution): 100 - 500 microns

- Print volume:

- ” x 5.5”

- Nozzle diameter: 0.4 mm

- Print speed: up to 200 mm/s

- Platform temperature: 120°C maximum

- Power: 100 – 240V, 50/60Hz Wattage:

- W

- Overall size: 19 x 16 x 13 inches / 485 x 400 x 335mm

- The size of the box: 25 x 23 x 19 months / 565 x 535 x 430mm

- Brutto weight: 32LBS

- Weight Net: 27LBS

Software 9000

- File type: STL / X.

- OS: Windows, OS x, Linux

- Software: FlashPrint

Consumables

- Materials: ABS, PLA, PVA, etc.

30082 Body colors, black, yellow, red, blue, green, transparent

30082 Body colors, black, yellow, red, blue, green, transparent - Filament diameter: 1.75 mm - 1.80 mm

Features

- 3.5” multi-touch capacitive LCD 9 extruder with built-in fan provides instant cooling of printed objects

- ARM Cortex M4 processor provides fast and stable processing performance

- 4 GB internal memory

- FlashPrint software (included)

- A aviation alloy platform provides maximum stability against deformation

- Support for printing ABS, PLA, PVA, Nylon, etc.

- 12 LEDs cover the print chamber

Conclusions 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 printer Flashforge Dreamer for those who are looking for a medium-sized device capable of printing at high resolution.

The printer is very stable, and leaving it to print for several hours in my absence, I was not at all afraid. I have spoken to many 3d printer owners and have heard many stories about how often models that were left to print turned out to be unsuccessful. I left it again with no problem.

The printer is very stable, and leaving it to print for several hours in my absence, I was not at all afraid. I have spoken to many 3d printer owners and have heard many stories about how often models that were left to print turned out to be unsuccessful. I left it again with no problem. by Whitney Hipolite

It prints ABS plastic better than any of the improved or newer printers.

Made in a stylish and comfortable design:

- metal case;

- durable one-piece top cover;

- external handles;

- front panel opens 180 degrees;

- Tilt screen and buttons 45 degrees for easy viewing.

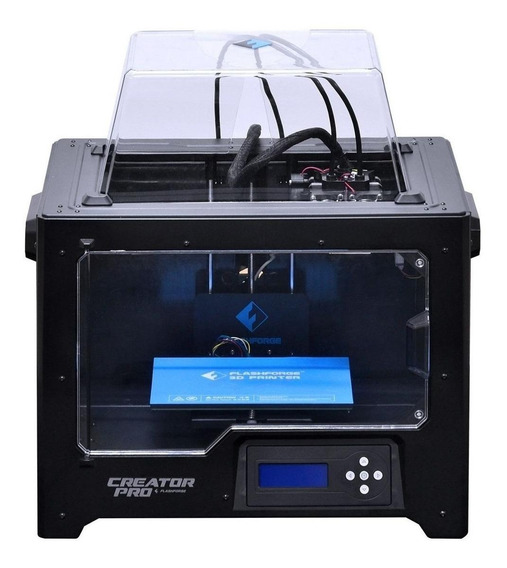

Metal support and 10mm Z-axis guide rods for improved Z-axis accuracy. FlashForge Creator Pro plates are made from the same 6.3mm aluminum alloy used in the aerospace industry. Due to the correct temperature distribution, they do not deform even after prolonged exposure to high temperatures.

Creator Pro's closed body helps stabilize temperatures for more precise, warp-free ABS printing.

| Features | |

| Trade-in | Yes |

| 10% promotion for plastic | Yes |

| Weight (without packaging) | 15 kg |

| Warranty | 12 months |

| Thread diameter | 1.75 mm |

| Nozzle diameter (mm) | 0.4 |

| Display | LCD display |

| Connection interface | USB, SD |

| Number of extruders (print heads) | 2 |

| Housing material | high strength metal with acrylic sides |

| Operating systems | Linux, Windows 8, Mac OSX, Windows 7 |

| Supported file formats | STL, gcode |

| Software | ReplicatorG |

| Manufacturer | Flash Forge |

| Capacity | 24cm3/hour |

| Construction area size | 225 x 145 x 150 mm |

| Dimensions (without packaging) | 320 x 470 x 380 mm |

| Print speed | 30-80 mm/s |

| Country of origin | China |

| Platform heating temperature | 100 C |

| Print Technology | FDM\FFF |

| Plastic type | PLA, ABS |

| Power consumption | 100-240V, 50-60Hz, 450W |

| Equipment | |

ABS plastic (0. 6 kg) 6 kg) | 1 piece |

| PLA plastic (0.6 kg) | 1 set |

| SD card | 1 piece |

| USB cable | 1 piece |

| Top removable cover | 1 piece |

| Warranty card | 1 piece |

| Spool holder | 2 pcs |

| Nozzle deflector | 1 piece |

| User manual in Russian | 1 piece |

| Site Leveling Chart | 1 piece |

| Card reader | 1 piece |

| Screw set | 1 box |

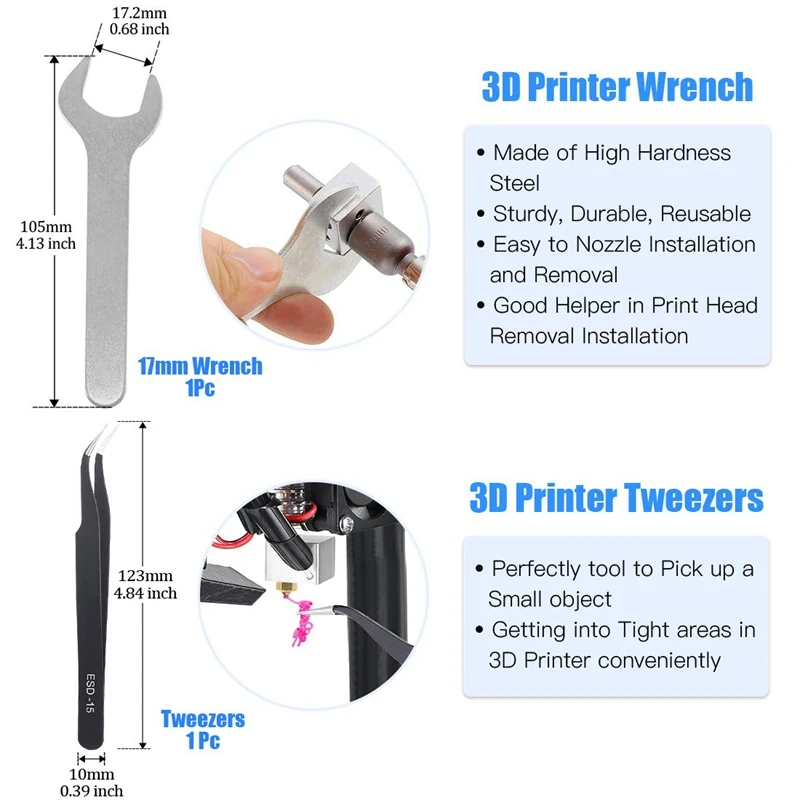

| Tool kit | 1 box |

| Knife | 1 piece |

| Screwdriver | 1 piece |

| Tweezers | 1 piece |

| Table sheet | 2 pcs |

| Mains power cord | 1 piece |

| Removable side panels | 2 pcs |

| Spatula | 1 piece |

Hi all. Today we will have a review of the updated FlashForge Creator Pro printer. We chose this printer not by chance, it has the highest rating on the 3DHUBS 3D printing enthusiasts website.

Today we will have a review of the updated FlashForge Creator Pro printer. We chose this printer not by chance, it has the highest rating on the 3DHUBS 3D printing enthusiasts website.

FlashForge is a Chinese company Zhejiang Flashforge 3D Technology Co., Ltd. Established in 2011 and today is one of the largest in China.

Technical characteristics

| Press technology | FDM |

| Press area 14 225x145x150 | |

| ДИАМЕТР СОПЛА | 0,4 |

| ВЕС БЕЗ УПАКОВКИ | 14 |

| РАЗМЕРЫ БЕЗ УПАКОВКИ | 320х467х381 |

| ЗАКРЫТЫЙ КОРПУС | да |

| ОБДУВ | Есть |

| SCREEN AVAILABLE | Yes |

| PRICE | 79 000 |

Equipment

The box is very compact.

The printer is packaged very compactly and with good quality.

The bundle is quite decent considering that the printer requires almost no assembly.

- 2 plastic spools (ABS/PLA)

-

PLA fan hood

-

Flash drive

-

USB-A to USB-B cable

-

Hexagon set

-

Replacement table cover.

-

2 spool holders.

-

Mains power cable

-

Manual in Russian and warranty card

-

Tubes for guiding the 3D filament

The 1kg plastic spool (the hole diameter of the spool is 51 mm) didn't fit on the FlashForge and MakerBot holders. For them, you will have to print the holders for the coils.

FlashForge pleased with a very high-quality and solid assembly. Externally, the printer looks very solid. There are handles on the side for easy carrying of the printer. The door does not open up, but to the side. This means that it does not have to be held when manipulating inside the printer. The closed door "snaps" on 2 small magnets, this ensures that it does not open during printing.

The door does not open up, but to the side. This means that it does not have to be held when manipulating inside the printer. The closed door "snaps" on 2 small magnets, this ensures that it does not open during printing.

The screen and buttons are at a 45 degree angle to the body. To look at the screen, you don’t have to bend over if the printer is on a pedestal at waist level. A trifle, but nice.

The cover is one-piece and rigidly attached to the top of the printer. It takes some effort to get it off.

Mechanics

Two plastic feed motors are located on the “head” of the printer. In theory, this increases the weight, and consequently the inertia. But on the other hand, this layout allows you to print with soft types of plastic without problems.

The Y motor is attached to the carriage. The X-axis motor is placed on the body. Nothing dangles anywhere and does not play. The straps are well tensioned.

Trapezoidal screw and 2 shafts mounted on the Z axis. There are convenient wide screws for calibrating the table. The table is very quickly calibrated with 3 screws.

Setting the table level is quite simple. Go to Utilities - Level Build Plate. The table rises to the highest point. The nozzle moves to the center of the table. Using a feeler gauge or paper, set the gap. Calibrating only one position of the nozzle, it seems to me, will not be enough.

By the way, the printer is calibrated “cold” (that is, without heating the table and nozzles).

It is recommended to use the Flash Print Slicer with the printer.

FlashPrint

Most recently, an updated Creator Pro has been added to FlashPrint (previously ReplicatorG was suggested). The flash drive that came with the kit contained an outdated version of the program. I recommend immediately downloading the current version from the site.

The program is partially Russified, the interface is very similar to MakerBot. Especially the left toolbar

But unlike MakerBot, there are some interesting additional features in the program.

For example, the ability to cut the model.

The cutting plane can be set with the mouse.

Or any of the axes.

The ability to place supports manually is, I think, very convenient. There are 2 types of support.

These are tubes (they are by default)

And lines

The most interesting thing, in my opinion, is the ability to convert drawings into three-dimensional bas-reliefs.

The program has quick quality settings. (low - 0.30mm standard - 0.18mm and high - 0.14mm).

By the way, when choosing PLA plastic, the best print quality appears - a layer of 0.08 mm.

To enable advanced settings, open the file - settings tab and switch from Basic Mode to Expert Mode.

Advanced settings.

Here you can already roam with the settings. Retract settings, print support speed, wall width for nozzle cleaning when printing with two types of plastic and much more.

Print tests

We evaluated the printer more from the point of view of a novice user, so the printer had 1 attempt to print the model.

For tests, we used Esun ABS, PLA, PVA, HIPS plastic. When switching from one type of plastic to another, the extruder was cleaned with Esun cleaning plastic (By the way, a good and convenient thing. It is very economical. A standard 100 gr package turned out to be quite large).

The first thing we tested was ABS, of course. On the move, it turned out such a boat. (15% infill, Standard quality).

Still, when printing ABS in a closed chamber, it is desirable to blow it. Especially on small details.

Printed tests. (filling 15%, quality High).

Big test.

Small test.

The folded corners are not the deformation of the ABS during cooling, but an attempt to tear the model off the table. FlashForge has a very "tenacious" table surface. It is simply unrealistic to tear off parts from ABS from a cooled table.

Printing in two colors.

Slight mixing of colors in places. But this is more of a slicer drawback.

Same tests printed with PLA.

Boat.

Big test.

Small test.

Two color printing.

Quite worthy. Although this is a larger printer designed for ABS plastic. For PLA, a lack of airflow is sometimes noticeable.

Printing with soluble supports.

PLA+PVA

Despite the fact that PVA is a very capricious and fluid material, FlashForge did a good job. Although I could not print a small fang on one side of the model. This most likely happened due to a lack of airflow on one side of the model.

This most likely happened due to a lack of airflow on one side of the model.

Washed model.

ABS+HIPS

Here the printer was in its element and did a great job.

Half washed skull.

It's a pity that Flash Print decided that the thin septum in the nose was a model error and removed it.

Typing speed test

The dice test was not very revealing. Although when considering the first and last cube, ripples from the inertia of the head at high speeds are visible.

Results

I really liked the printer. It has a lot of nice little things, from airflow (which is simply necessary when printing small models from ABS) to a convenient slicer. Sturdy and tidy body. And of course very high quality printing.

A minute of advertising)

Buying equipment from our company, you get 10 benefits:

1. Opportunity to use the Trade In program.

2. Guarantee - 12 months

3. Instruction in Russian

4. Technical support during the entire period of operation

5. You buy a Wanhao 3D printer from the official Wanhao distributor in Russia

6. Free shipping.

7. Free training in our office.

8. Opportunity to buy a printer on credit through TKS, OTP, Renaissance banks.

9. 10% discount on plastic forever.

10. An opportunity to get acquainted with the printer in our demo room.

Review prepared by Anna Panfilova, 3D printing specialist at Tsvetnoy Mir.

Subscribe to our groups on Facebook and VK to keep abreast of the latest events.

Review of FlashForge 3D printers

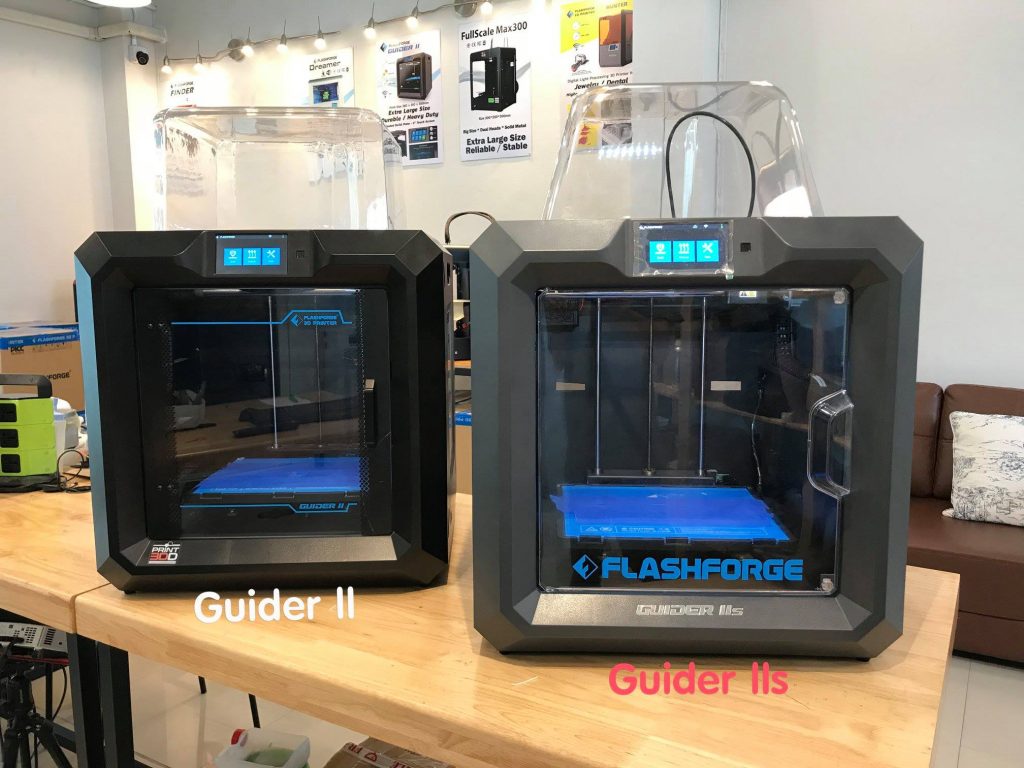

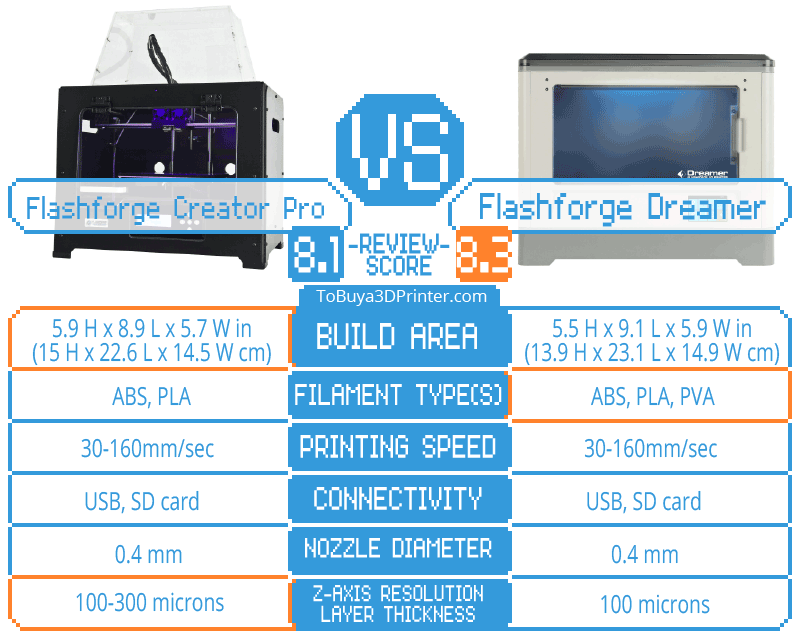

Hello everyone. Today we have prepared a review of two models of 3D printers - FlashForge Dreamer and FlashForge Creator Pro.

-

FlashForge is a Chinese company Zhejiang Flashforge 3D Technology Co., Ltd. Established in 2011 and today is one of the largest in China. Last year, the company produced 30 thousand 3D printers and ranked 4th in terms of sales of 3D printers in the world.

-

FlashForge Dreamer and FlashForge Creator Pro are top 10 printers on the 3DHUBS 3D printing enthusiast site.

3DHUBS has a lot of positive feedback from both beginners and advanced users. These printers are valued for their very good value for money.

Specifications

As you can see from the technical specifications, the printers are almost the same. Unless Dreamer is a newer and more advanced model, with a bunch of small improvements that may be useful to the user.

Appearance

There are more differences in appearance. Dreamer has become more compact compared to Creator Pro.

Plastic spools stow away inside the printer instead of hanging outside. On the one hand, this allows you to additionally dry the plastic inside the printer chamber, on the other hand, it will be problematic to shove a spool of 1 kg or more. And if you “start” the plastic from the outside, you will have to remove the cover.

FlashForge Creator Pro does not have this problem. You can hang the spools on the case or print the spool holder. The lid has a space for feeding plastic outside the chamber.

Mechanics

The kinematics of the printers is similar and made according to the most popular scheme. Nothing new here.

The head moves in the X and Y axes, the platform moves in the Z axis. The printer prints without problems not only ABS and PLA, but also more whimsical, softer types of plastic.

Or say Woodforce from Fiber Force.

By the way, the plastic turned out to be very interesting. The nozzle does not clog and smells like wood. Very easy to skin.

The most interesting thing is the Dreamer airflow. In appearance, the blower casing is only on the left nozzle. And there are no more differences from the same Flash Forge Greater Pro.

The main difference was noticeable on the first print. At the back of the printer are 2 fairly large fans. They blow air out of the chamber.

They blow air out of the chamber.

There are ventilation grilles on the sides that draw air into the printer.

It turns out that air is constantly circulating inside the camera during printing. Surprisingly, this turned out to be a great solution for PLA printing. Airflow occurs from all sides of the printed part. Even small details are excellent, without “streaks”.

Creator Pro cannot boast of such stability. In hot weather, small PLA products may lack airflow.

FlashForge Dreamer is equipped with a convenient touch screen and Wi-FI.

Slicer

It is suggested to use FlashPrint as a slicer. A fairly convenient program with a pleasant interface, also partially Russified. This can be a big plus for beginner printers.

The program has several rather useful functions. For example, the ability to cut the model.

The cut plane can be set with the mouse or along one of the axes.

The ability to place supports manually is what I so often missed in Cura. There are 2 types of support.

Tubes (they are by default)

And bollards.

But the most interesting feature, in my opinion, is the ability to convert drawings into three-dimensional bas-reliefs.

The program has quick print settings. (low - 0.30mm standard - 0.18mm and high - 0.14mm. When choosing PLA plastic, the best print quality appears is a layer of 0.08mm.). It will be convenient for beginners during the first steps.

There are also advanced settings for finer print settings. To enable advanced settings, you need to open the file tab - settings and switch from Basic Mode to Expert Mode.

Settings for retraction, support print speed, wall width for nozzle cleaning when printing with two types of plastic and much more.

Print tests

And of course the review would not be complete without print tests.

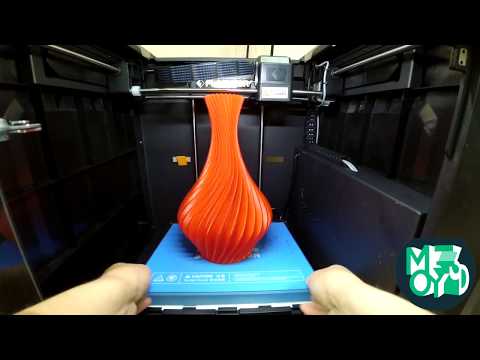

FlashForge Creator Pro

ABS from ESUN, layer 0.15.

PLA from ESUN, layer 0.15.

And the most interesting thing is printing with supports.

ABS+HIPS

PLA+PVA

FlashForge Dreamer

ABS+HIPS from ESUN, layer 0.15.

PLA+PVA

Carbon Fiber NylForce, layer thickness 0.15

PLA, Bronze Color 0.14

9000 9000FIBRA PLANT FIBR Force and blue PLA from ESUN, layer thickness 0.18

Ninjatek Soft Cheetah Post-apocalyptic duck, 0.18 layer thickness, 0% infill

0.18 layer, Flashforge Dreamer printer. Esun eCopper and eAlfill plastic.

Results

Both printers surprisingly give a very decent print result “out of the box” without any “finishing” and shamanic settings.

FLASHFORGE Creator Pro keeps up with its older brother FlashForge Dreamer in print quality. The maximum that you can find fault with is the insufficient airflow of small PLA models in the Creator Pro.

The maximum that you can find fault with is the insufficient airflow of small PLA models in the Creator Pro.

Visually, FlashForge Dreamer is, in my opinion, more of a "home" printer. Neat, compact. Plus the ability to connect via WI-FI so as not to pull extra wires. But here everyone will decide for himself whether it is worth overpaying for aesthetics and comfort or not.

Traditionally, a minute of advertising)

Buying equipment from our company, you get 10 benefits:

- Opportunity to use the Trade In program.

- Warranty - 12 months

- Manual in Russian

- Technical support throughout the entire life cycle

- You buy a 3D printer from an official distributor in Russia

- Free shipping.

- Free training in our office.

- Possibility to buy a printer on credit through TKS, OTP, Renaissance banks.

- 10% discount on plastic forever.

- An opportunity to get acquainted with the printer in our demo room.

Learn more

User manuals for the use of FlashForge 3D Printers contain basic instructions that need to be followed during installation and operation. Before starting your appliance, the instructions should be read through carefully.

User manuals for the use of FlashForge 3D Printers contain basic instructions that need to be followed during installation and operation. Before starting your appliance, the instructions should be read through carefully. ..

..  It features Fused Filament Fabrication (FFF) printing technology; a build volume of 11.0 x 9...

It features Fused Filament Fabrication (FFF) printing technology; a build volume of 11.0 x 9...  With a build volume of 5.9 x 5.9 x 5.9", the Adventurer 3 prints your 3D models in an enclosed print area with a removable heated print bed. The single extruder is detachable, utilizes stainless steel tube material, and can heat up to 392°F in approximately 50 second...

With a build volume of 5.9 x 5.9 x 5.9", the Adventurer 3 prints your 3D models in an enclosed print area with a removable heated print bed. The single extruder is detachable, utilizes stainless steel tube material, and can heat up to 392°F in approximately 50 second...  Use PLA filament to create prints in resolutions as fine as 100 microns, or in rougher 500-micron layers when a quicker, less intricate result is required. Send your prepared 3D files to the Finder via USB, Wi-Fi, or SD card, and navigate the menu via its 3.5" LCD touc...

Use PLA filament to create prints in resolutions as fine as 100 microns, or in rougher 500-micron layers when a quicker, less intricate result is required. Send your prepared 3D files to the Finder via USB, Wi-Fi, or SD card, and navigate the menu via its 3.5" LCD touc...  ..

.. I took the batteries out put them back in and nothing is working. Please advise...

I took the batteries out put them back in and nothing is working. Please advise...