Uconn 3d printing club

home - 3D Printing Club

3D Printing Club

Search...Who We Are:

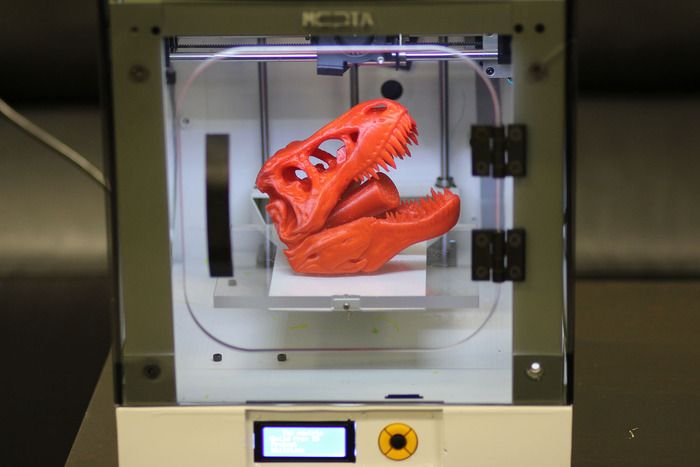

3D Printing Club is a student run group with an interest in expanding our knowledge and other students knowledge in 3D printing. We have a variety of ways students can get involved, whether its printing personal projects, printing for class assignments and capstone, or even becoming a lab tech and getting hands on experience with all 13 printers in the lab.

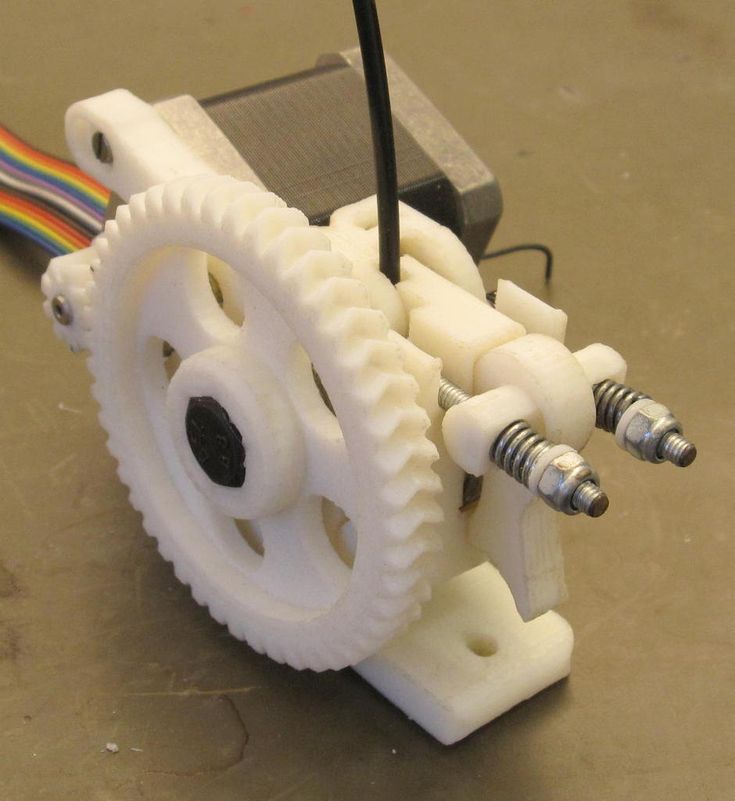

A 3D printed mechanical hand made in our lab a few years ago.

The MENU

Using the MENU, on the top of the screen, you can navigate to the different tabs that give you all the information you need to know about the club.

The “Where we are located” tab will of course direct you to our on campus lab. It tells you what building and room we are and what hours we are opened to the public.

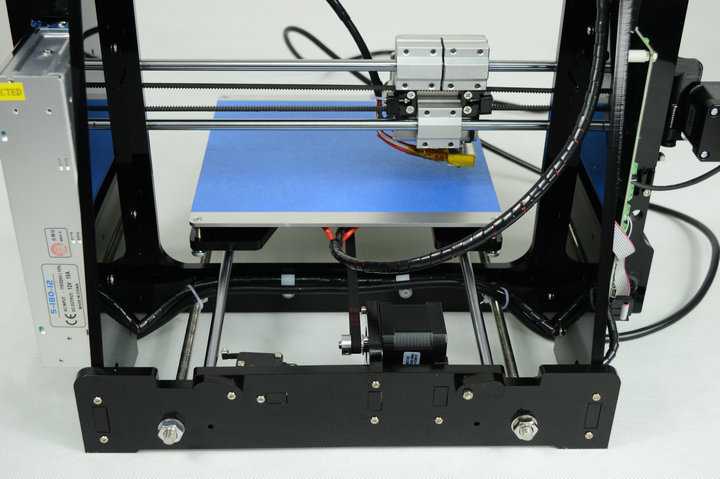

The “Our Printers” tab tells you what printers we have in the lab, including the nozzle sizes on each one. This is helpful for when you slice an item for a specific printer.

The “Submission Form” tab is a direct link to our submission form for the semester. This form is crucial for those who are active members because it is how you submit sliced objects for us to set up and print for you.

The “Lab Tech Info” tab consists of all the information you need to know if you want to be a lab tech. Lab techs are able to be hands on with the printers, so if you want to work directly with 3d printers, becoming a lab tech is the way to go.

The “Lab Tech Calendar” tab is a direct link to the schedule when lab techs are in the lab. This is convenient for members to stop by if they have questions or need help with something 3d printing related. We are always happy to help. If you have questions feel free to stop by during these times

How to Get Involved?

The “Lab Tech Calendar” tab will allow you to view our schedule of who is in lab. If you are interested in getting involved, bring $10 of club dues to our lab. This will get you 300g of printing filament to print with throughout the semester. The dues are used to give you filament and to help us get the money needed to keep machines maintained. This is why we have a no refunds policy.

This will get you 300g of printing filament to print with throughout the semester. The dues are used to give you filament and to help us get the money needed to keep machines maintained. This is why we have a no refunds policy.

We welcome all levels of knowledge to the lab. We are also happy to help with any questions or demonstrations with any 3D printing related techniques, during our lab tech hours. If you are interested in expanding your horizon in additive manufacturing, 3D Printing Club is a great place to start.

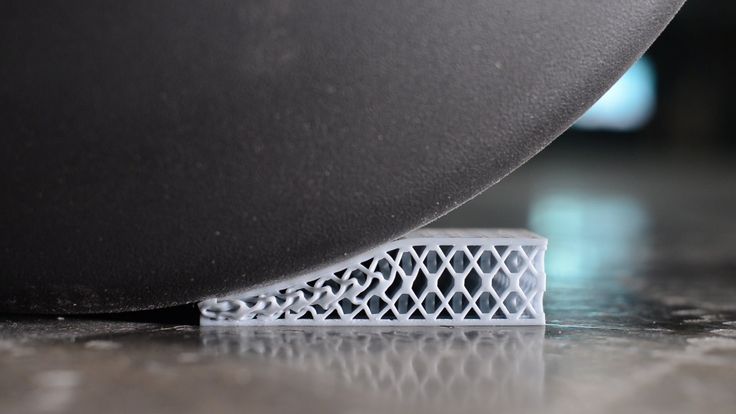

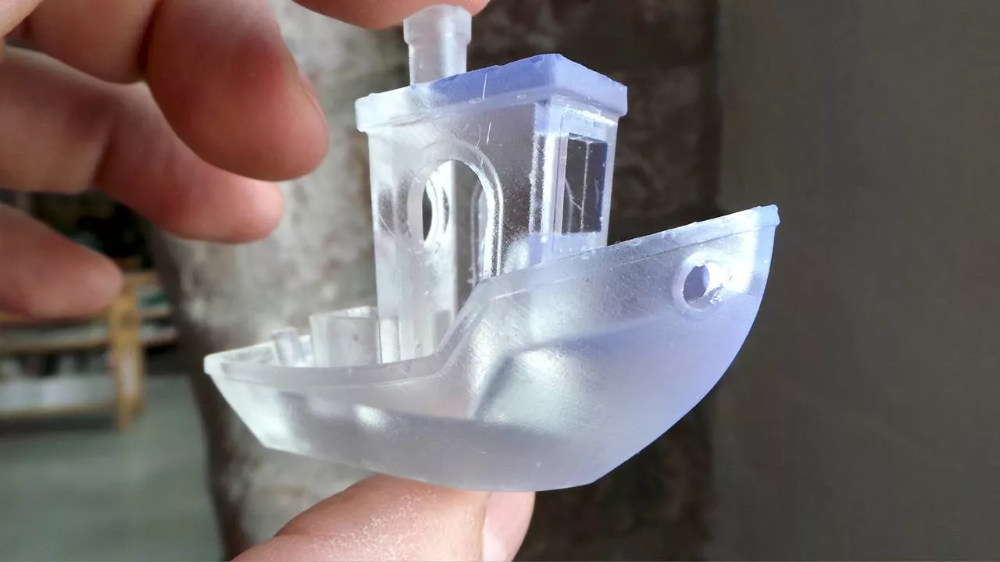

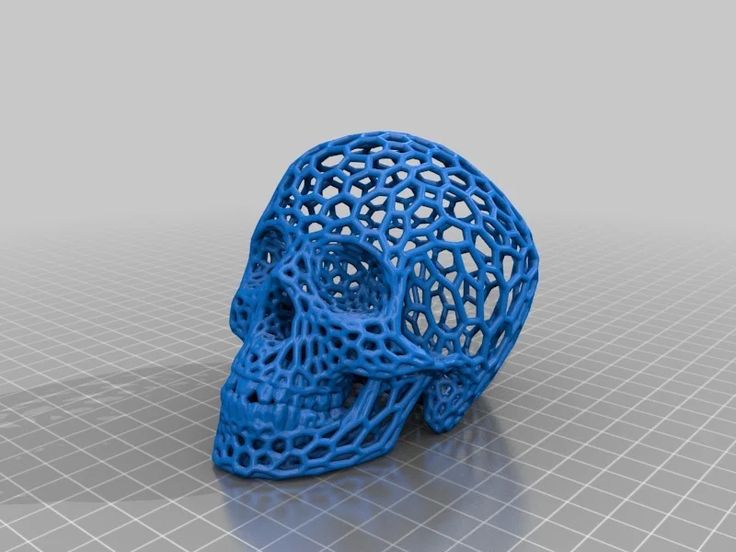

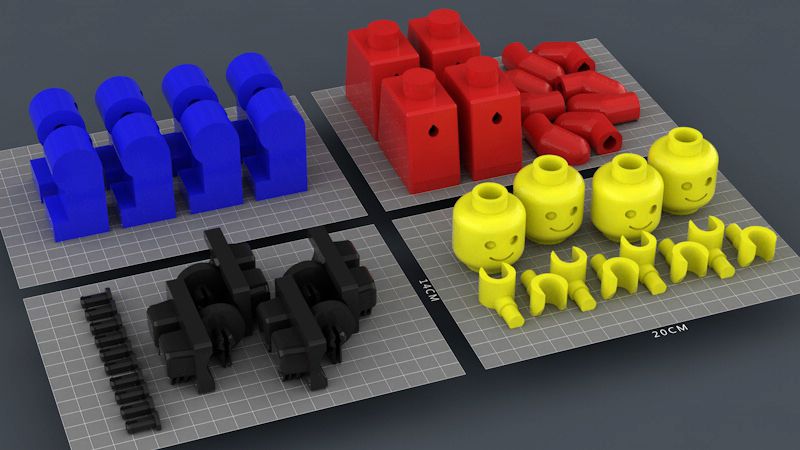

Example prints on display at our table during the Engineering Expo last year.

Social Media:

We have multiple sources of social media where you can see what we do and what local 3D printing projects are taking place. Find us on Facebook and Instagram. If you have any questions and/or can’t make it to our lab tech hours, feel free to reach out to us through email [email protected] .

- Advisor: Bashir Khoda, Ph.

D

D - Contact:

- Find us on Facebook or email [email protected]

▷ uconn 3d models 【 STLFinder 】

UCONN

thingiverse

Customized version of http://www.thingiverse.com/thing:374631 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=374631 Instructions Using the following options:...

Uconn Huskies Keychain

thingiverse

Uconn Huskies Keychain with the husky on the top and UCONN on the back

Uconn Huskies Keychain

prusaprinters

Uconn Huskies Keychain with the husky on the top and UCONN on the back Category: Keychains

UConn Iphone 4S Case

thingiverse

Customized version of http://www. thingiverse.com/thing:58001 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=58001

thingiverse.com/thing:58001 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=58001

UConn Jonathan the Husky Statue

thingiverse

The statue of Jonathan the Husky outside of Gampel Pavilion at the University of Connecticut in Storrs, CT. ... HuskyRockDone3.STL has no supports HuskyRockDone2.STL has supports generated in MeshMixer ...

UConn 3D Printing Club Geometry challenge

grabcad

I just randomly made this on SolidWorks

My Customized Simple Key Tag

thingiverse

. .. of http://www.thingiverse.com/thing:1175570 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=1175570 Instructions Using the following options: Width = 20 Length = 60 Text_Size = 1 Line2 = Line1 = Uconn Thickness = 2

.. of http://www.thingiverse.com/thing:1175570 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=1175570 Instructions Using the following options: Width = 20 Length = 60 Text_Size = 1 Line2 = Line1 = Uconn Thickness = 2

My Customized Simple Key Tag

thingiverse

... of http://www.thingiverse.com/thing:1175570 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=1175570 Instructions Using the following options: Length = 60 Line2 = Line1 = UCONN Text_Size = 1 Thickness = 2 Width = 20

bob

thingiverse

... of http://www.thingiverse.com/thing:1175570 Created with Customizer! . ..http://www.thingiverse.com/apps/customizer/run?thing_id=1175570 Instructions Using the following options: Length = 60 Width = 20 Thickness = 2 Text_Size = 1.4 Line2 = Line1 = UCONN

..http://www.thingiverse.com/apps/customizer/run?thing_id=1175570 Instructions Using the following options: Length = 60 Width = 20 Thickness = 2 Text_Size = 1.4 Line2 = Line1 = UCONN

bob1

thingiverse

... of http://www.thingiverse.com/thing:1175570 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=1175570 Instructions Using the following options: Text_Size = 1 Length = 60 Line2 = Line1 = UCONN Width = 20 Thickness = 2

My Customized Bookshelf Keychain

thingiverse

Customized version of http://www.thingiverse.com/thing:676537 Created with Customizer! ...http://www.thingiverse. com/apps/customizer/run?thing_id=676537 Instructions Using the following options: text_style = 1 text = UCONN keychain_loop = Yes

com/apps/customizer/run?thing_id=676537 Instructions Using the following options: text_style = 1 text = UCONN keychain_loop = Yes

UCONNring

thingiverse

... with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=40704 Instructions Using the following options: font_spacing = 0 Font = write/Letters.dxf font_size = 14 ring_thickness = 1.6 ring_width = 6 message = UCONN ring_size = 18.14

Mask Frame "CEG Extreme" and Small n95 fitter (High Filtration with Halyard H600)

thingiverse

Mazzocca, M.S., MD - Orthopedic Surgery & Bioskills Elifho Obopilwe - UConn Musculoskeletal Institute Thank You: Bruce Spiess, MD FAHA - UF Department Anesthesiolgy Michael Baldwin, MD, UConn Radiology Jason Hancock, PhD, UConn Physics Cindy. ..

..

Luggage Tags

thingiverse

Easy to customize (he's an OSU alumni, & his cousin went to UCONN). For their tags, I added their names on the back side. Designed in Solidworks, printed on an Objet30Pro in DURUS material. So far, they have survived many trips & seem to be quite...

3D printing of models of transport and equipment by the historical club at the International Exhibition Complex named after I.S. Shemanovsky

The Military Historical Club at the Yamalo-Nenets District Museum and Exhibition Complex named after I.S. Shemanovsky in Salekhard creates amazing models of military equipment and weapons of all times and teaches children to model posters.

Taking into account the increasing use of additive technologies in modeling, we could not pass by such a wonderful project and asked the Chairman of the Board of the Complex Alexander Alekseevich Zaimidorog to tell us more about the Club's projects and the use of 3D printing in it.

“Our military-historical club was created 15 years ago on the joint initiative of Sergei Efimovich Grishin, director of the Museum and Exhibition Complex. I.S. Shimanovsky, and us, a few adults, passionate about bench modeling and flight simulators, mainly the IL-2 Sturmovik. The club was created for equal communication between children and adults, joint game learning, attracting children to meaningful leisure, career guidance, joint study of history, computer technology, film screenings. It turned out to be a platform of the "father's club" type. Over the years, the club has been visited by many children (permanent and variable composition), some connected their lives with aviation, as pilots and aircraft technicians, some went to aviation and ship universities. The current head of the IT department at the museum is also an alumnus of the club.

For more than 10 years we have been holding online esports tournaments among IL-2 virtual pilots, exhibitions of modellers. Due to the remoteness of our city from transport routes, we switched to the online mode of exhibitions of bench models back in 2017. Information about this is available on our page in VKontakte at vikyamal.

Due to the remoteness of our city from transport routes, we switched to the online mode of exhibitions of bench models back in 2017. Information about this is available on our page in VKontakte at vikyamal.

On the site of the club, the Yamal “Victory Banner” movement began to make copies of the Victory Banner using stencils and paints. Among the club awards are victories in the all-Russian competition, which is held by the St. Basil the Great Foundation with the support of the Federation Council of the Russian Federation and the Russian Orthodox Church in 2017, various grant successes.

There has been a lot of debate about 3D printing in modeling since the advent of 3D printers. About the process as a whole and areas of application. Up to whether 3D printing will replace conventional modeling techniques. Until that happens, and I don't think it will. But the models, fully grown in 3D, are already on sale - figures, planes and ships.

In 2021, we received a subsidy (similar to a grant) from the Governor of the YNAO, with the support of the Presidential Grants Fund, for the GOREM-36. War".

War".

GOREM-36 - the head repair train, created in 1941, during the Great Patriotic War near the front line. He ensured the operation of railway transport and restored railway tracks, as the organization was liquidated in 1992 in the Purovsky district of the YaNAO, where he also built a railway.

The project provides for the creation of a model of the Toropets railway station as of the winter of 1942 on a scale of 1 to 35. It was this station, one of the first liberated ones, that GOREM-36 restored. When planning the work, it became clear that not everything necessary for arranging the layout is available for sale in the form of ready-made kits for bench modeling. It was for the production of such objects - rail and other facilities, figures in padded jackets - that the idea of 3D printing, its first steps in our club, appeared.

The fact is that in our club there is a Warhammer-40000 direction, for the manufacture of desktop figurines of which 3D printing is often used.

In addition, there is an idea about the second part of the exposition “GOREM-36. World". To create it, you will need to print railway equipment of the USSR, figures of railway workers on a scale of 1 to 35, and this range is definitely not produced by anyone.

An Internet search brought us to the Tsvetnoy Mir store (the official distributor of many 3D printer companies), where we purchased the Anycubic Photon Ultra.

In the photo: head of the IT department Evgeny Morozov prints sleepers on a 3D printer

Currently, two trial figurines from those available in the public domain have been printed. Unfortunately, now the purchase of suitable Warhammer figures is difficult due to the fact that the payment systems have not worked since February 2022. Therefore, models that are not yet related to the project have been printed. Rails, sleepers, arrows were also prepared for 3D printing and printed, programs for 3D scanning of objects were mastered.

The printing itself, the use of a 3D printer does not raise questions. Our former student, head of the IT department E.L. Morozov and one of the founder-mentors A.A. Forester cope with this quite well. But the development of the 3D models themselves or the scanning of objects is a difficult task for beginners, we had to involve club graduates - students of the capital's engineering universities, warhammer craftsmen.

The main advantage of 3D printing in bench modeling is the ability to accurately repeat the same parts in the right amount. But when we learn how to independently develop 3D models of the equipment we need, we will get the opportunity to create models of equipment ignored by such large companies as Zvezda, Tamiya and others.

Finally, in our hobby, there will probably not be a transition to digital. All the same, metal, plastics, and glue with files will be used. Therefore, in parallel, there is also a machine park with turning and milling equipment. To teach children is to teach the whole spectrum of engineering. But given all the benefits that 3D printing brings and its rapid development, we no longer see our work in the future without it.

To teach children is to teach the whole spectrum of engineering. But given all the benefits that 3D printing brings and its rapid development, we no longer see our work in the future without it.

Group of the Military History Club at the "Yamal-Nenets District Museum and Exhibition Complex named after I.S. Shemanovsky" on VKontakte https://vk.com/vikyamal

Software for Picaso 3D Designer

Regularly update Polygon X.

Update the printer firmware to version 5.411 (or higher) for correct operation. Designer XL PRO.

Improved work with high-poly models - increased speed of rotation and movement of models on the platform.

The "Dense support base" option has been added to the Professional job setup mode, which allows you to choose whether the first layer of support will be solid or not.

A number of improvements have been made to Series 2 networking.

Several bugs have been fixed related to saving Series 2 material profiles and highlighting surface models on the platform.

Update 4/19/22:

This update includes workspace changes for Designer Classic, Designer X, and Designer X PRO printers running firmware version 5.516 or later, as well as new features, built-in algorithm improvements, and some bug fixes. In particular, a bug related to incorrect time output when printing jobs generated in version 2.3.0 has been fixed.

Picaso X Core engine update

- Increased speed of loading and slicing high-poly models.

- Fixed some legacy bugs: Adjusted feed settings for seam hiding paths, as well as line widths for filling gaps between perimeters (now reduced chance of overextrusion when using gap filling) and the first two backing layers.

New Features

- Added 3D fill pattern "Lightning". This is the most economical and fastest template with automatic density that changes depending on the geometry of the model.

- Added "Mirror" function. It reflects the model about the selected axis.

Changes to current functionality

- Assembly and separation of models on surfaces is now performed through the context menu in the list of models. - The range of layer heights for auto-selection of parameters has been reduced (the "Detail" slider). For a 0.5 mm nozzle, a layer height of 0.4 mm is excluded, since this height does not guarantee good print quality on a wide range of materials at high speeds. However, you can still set these parameters manually. - Fixed model scaling error, in which the final dimension could be 0.01 mm larger than required, and some other application errors.

Interface Changes

- Minor changes have been made to the interface for viewing profiles in the PICASO 3D cloud base.

- When preparing a job for a long time, tips with the best 3D printing practices are now displayed.

- A full version of the program in Spanish has appeared.

Minimum system requirements:

- OS Windows 7 (or higher)

- .