2023 flsun 3d printer

Zhengzhou Chaokuo Electronic Technology Co., Ltd. – flsun3d

SR ,So fast

High speed & perfect printing • 150mm/s high speed printing • Different handheld capacitive screen • High quality printing effect

FLSUN Q5

Precise & easy to operate • With TMC2208 silent drive • Touch screen with multiple languages and new user UI • With 32-bit motherboard

FLSUN QQ-S PRO

Stable & all-metal structure • With Power-off repeadedly • Supports Auto-leveling • With Lattice Platform Hot Bed

FLSUN V400 in stock

from $849.00

Super Racer (SR) So fast

from $469.00

Flsun Speeder Pad

from $149.00

Flsun Q5

from $199.00

Sold Out

Flsun QQ-S pro

from $289. 00

FLSUN

$999.99

Flsun Speeder Pad

$699.99

V400 Pad Electronic Display , highly integrated 3D printing device based on Klipper

$299.00

V400 Delta 3D Printer 400mm/s High Speed Printing FDM 3D Printer with Filament Sensor and Proximity Extruder Delta 3D Printer 1.75 PLA DIY 3D Printers Printing Size Φ300x410mm

$1,999.00

Our mission is to "put the personalized production capacity to everyone's desktop".

3D Printers

Materials

Accessories

FLSUN

3D Printers

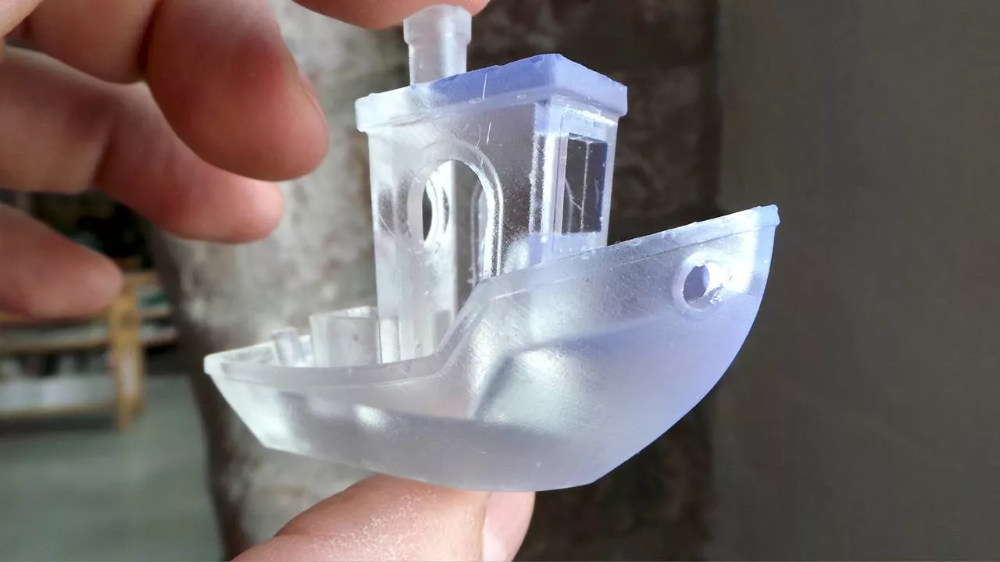

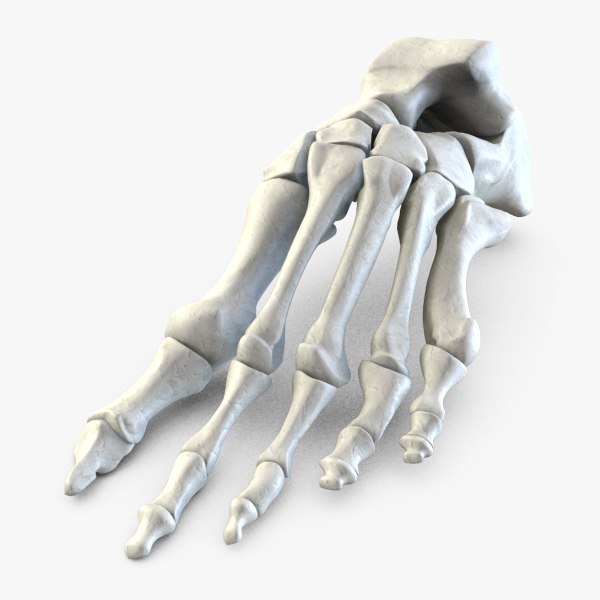

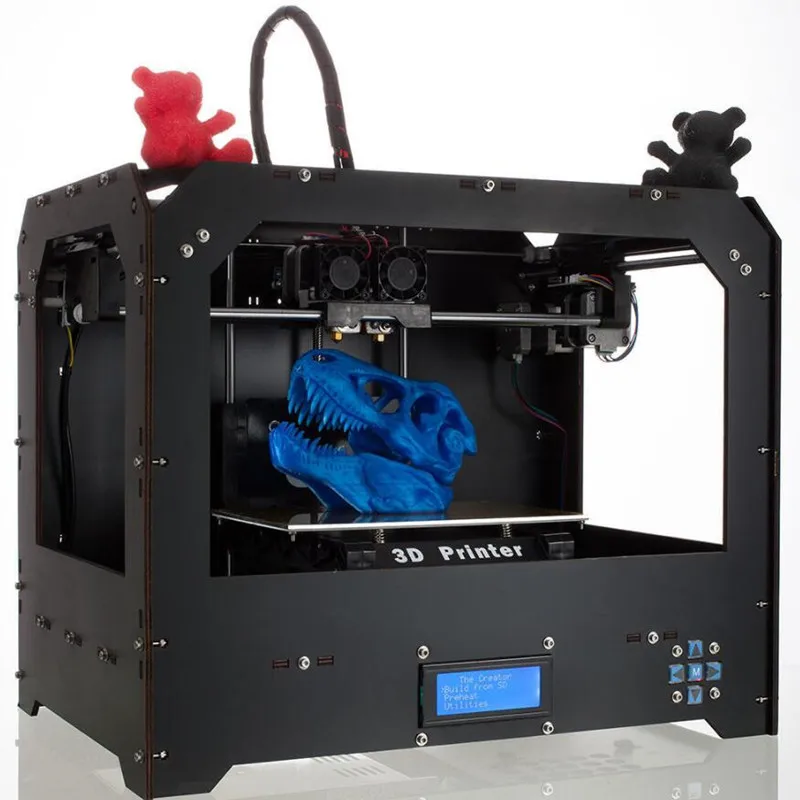

3D printer application fields:Medical applications, industrialproduction,Architectural design, lighting production Scientific research technology, personal DIY

Shop Now

★★★★★

Very friendly seller! I was impressed with the fast delivery and perfect packaging.And it's very easy and simple to assemble, plug and play. Since this product has a good mechanical structure, you can expect fast printing and perfect quality printing. I am so happy that I can now purchase this product at a good price. I would like to strongly recommend this product and the seller.

Author name

Los Angeles, CA

★★★★★The machine is excellent, prints PLA out of the box at 120mm/s and the acceleration is very fast. Linear rails are excellent and are the kind that has the hole to lubricate them. Also belt tensioning is built in with a knob. Join the facebook group to get the best out of it

Giulio

Italy

★★★★★I wished I had purchased an FLsun printer first...I have 2 other traditional 3d printers...I always have to tinker with them. I first got the QQ S Pro...flawless printing ( any fails were due to operator error ) Now I've got the Speed Racer, this unit has all of the reliability of it's cousin but is much faster.

I have been slicing HOURS off of prints, yet quality is high! Example:. 34 hours estimated by slicer...act [...]

Larry G

US

★★★★★it’s a good machine, 60mm/s stock easy and gives very nice quality parts. Out of the box it’s extremely precise also in line width! If you’re experienced and you can stretch the budget I would recommend the SuperRacer, it just needs the extrusion multiplier calibration and retraction for each filament.

Giulio

Italy

★★★★★Add customer reviews and testimonials to showcase your store’s happy customers.

Author name

Los Angeles, CA

FLsun Super Racer Review (2023)

The FLsun Super Race is a Delta 3D printer that prints almost three times faster than the popular FDM 3D printers. But apart from faster printing speeds, what else does the printer offer? Should you buy it? Read on to find out.

Apart from the widespread Cartesian 3D printers, e.g, the popular Ender 3 v2 or the Anycubic Vyper, the other type of printers you can buy are Core XY 3D printers or Delta 3D printers. The latter are exotic and are also considered complicated. Delta 3D printers are also difficult to repair and the maximum size of the printed parts is limited due to the design and the resulting round print bed.

But are all these allegations true? We’ll find out in our FLsun Super Racer review below.

AVAILABLE ON AMAZON

Before the Flsun Superracer, we had tested another Delta 3D printer, the Monoprice Mini Delta V2. The Monoprice printer stood out for its plug & play capability, good results and a reasonable price. The Flsun Super Racer has some work to do given that it’s nearly twice the cost of the Mini Delta.

In this Guide

The FLsun Super Racer is well packaged. The printer is made of high-quality metal frame and is shipped with lots of practical accessories in the box.

For such a highly complex mechanism, the printer has an amazingly simple structure. For example, attaching the print head is simply a matter of clipping it in – that’s it! An attachable level sensor measures the print bed. After the print bed has been measured, you can insert filament and you’re ready to print. The easy operation makes this printer suitable for beginners and experienced makers alike.

The Flsun Super Racer uses Cura slicer. In the slicer, the print speed is preset to 120 mm/s. If you have some experience with 3D printing, such a high printing number may make you uncomfortable. Generally, we know that if you want clean print results, the print speed should be between 35 and 60 mm/s.

Still, the high print speed was worth a try. And indeed, the quality of prints that the Flsun Super Racer produces at 120 mm/s amazed us.

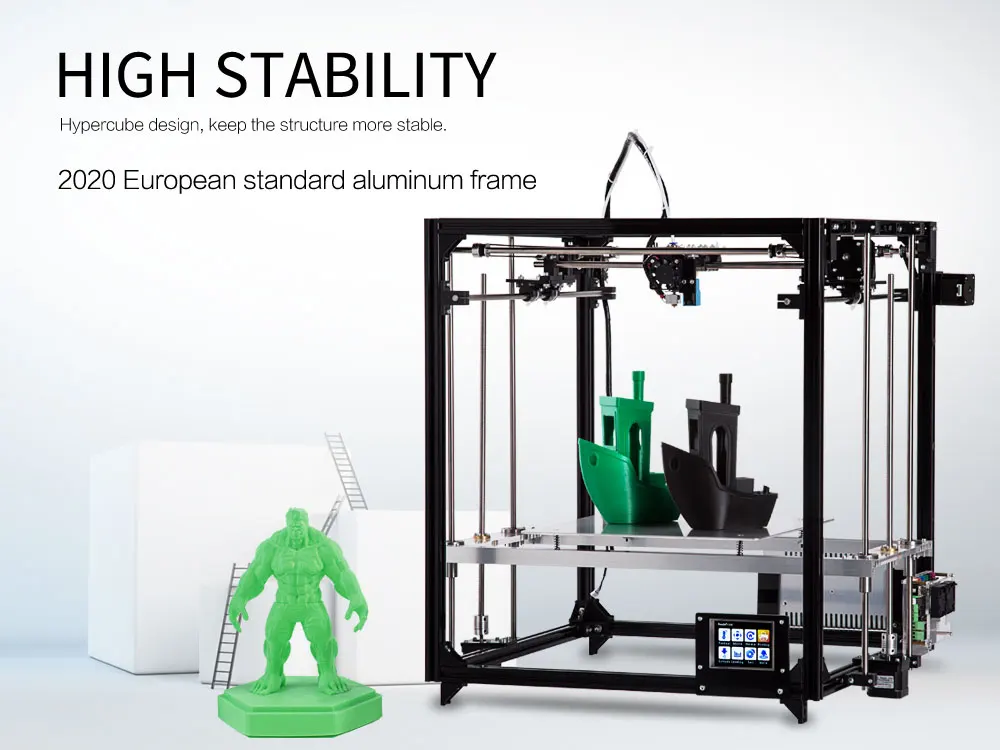

Construction

Assembling a Delta 3D printer is a little bit complicated that with printers of the classic Cartesian structure. The Flsun Super Racer kit consists of a lower and upper platform, and three guide rails. The rails, motors and print head are already pre-assembled. There are also three double connecting rods made of carbon.

The Flsun Super Racer kit consists of a lower and upper platform, and three guide rails. The rails, motors and print head are already pre-assembled. There are also three double connecting rods made of carbon.

To assemble the 3D printer, you have to fix the guide rails to the upper frame with four screws each. After that, attach the lower frame and repeat the procedure.

Now that the chassis is in place, you can start assembling the print head. Simply clamp it into the double guide rods made of carbon tubes. The rods are tensioned with springs and have opposite joint sockets at the end, which you simply clip into the joint heads of the print head and guide rail. The precisely pre-greased joint sockets were particularly pleasing.

So, simply clamp the first double guide rod, and hold the print head on the second and third. Next, connect the construct with the articulated heads on the motor linear rails. That’s it. The construction of the most complicated part of the delta printer system is done. We thought this would be more difficult since it’s usually complicated with other printers.

We thought this would be more difficult since it’s usually complicated with other printers.

The next steps are to attach the extruder to the top and connect the cable ends from the top chassis to the printhead. Thanks to different color markings, this works easily and understandably. A cable socket initially remains unused for the calibration unit.

The white Bowden hose is stretched between the extruder and the print head, and the Flsun Super Racer is ready for use.

Calibration

After switching on the printer, you first need to calibrate it before starting to print. For this, you’ll need the small attachment supplied. Clip the attachment onto the print head from below and connect the cable to the free white end of the cable. After that, it’s time to start the auto leveling.

The software will ask whether the sensor is also clipped on. After confirming this, the Flsun Super Racer automatically measures its pressure bed. Don’t forget to remove the sensor afterwards.

Don’t forget to remove the sensor afterwards.

Software

The software of the Flsun Super Racer is controlled through an intuitive color touch screen. The touchscreen is connected through a coiled cable, and can be held further down or up the strut of the printer using a magnetic holder.

The display is clearly laid out and all the necessary settings are available. The maximum printing speed of the FLsun is 200%.

The touchscreen control unit is magnetically attached and connected with a coiled cable.The Flsun Super Racer has quiet TMC stepper drivers, which is clearly evident in operation. In general, the Super Racer is a quiet printer. In normal operation, the loudest noise is from the extruder when it performs the retraction in the event of pressure jumps – i.e. before lifting the print head from the component, it quickly pulls the filament back a little so that it does not pull threads when moving.

Hardware

The complete housing including the guide rods for the motors is made of metal. Everything is solid and precisely manufactured. The running rails work flawlessly.

The print bed consists of a hardened glass plate coated with carborundum. These plates are the current standard. The bed has a big advantage: the dotted surface with different textures creates tension when the printed part cools down. After cooling, the prints can be easily detached from the print bed.

FLSun Super Racer: StructureThe filament processing system consists of a print head that is connected to a dual gear extruder through a Bowden tube. The print head has double component cooling and the brackets for the articulated heads are cast in one piece.

Print Quality

The print speed is breathtaking for the quality of prints that the FLsun Racer produces. We printed the USB holder and the Kalifa at a speed of 120mm/s. We used the magicPLA DEEP SPACE filament from 3D Jake and got a very clean result.

We used the magicPLA DEEP SPACE filament from 3D Jake and got a very clean result.

There is only one small drawback, which we’ve also seen with many other 3D printers: the tips become unclean due to the waste heat from the hot nozzle.

After that, we wanted to test the Super Racer print quality at higher speeds. Can we print the Pantheon at 200mm/s and the Zip Tie Holder at 300mm/s?

At 300 mm/s even, the the Flsun Super Racer starts becoming noisy, but the pressure became very good.

FLSun Super Racer: Print resultsThe only real disadvantage of the Flsun Super Racer is the spinning, which makes it pull strings. We first noticed strong spinning with the cable tie holder. To solve this, we increased the retract speed in the slicer settings in Cura. This made things get much better. However, we could still see wafer-thin threads.

You can melt the threads using a Bunsen burner. I think this issue happens because the retract speed just isn’t high enough to compensate for the rapid pressure movements. Also, the long path of the filament from the extruder to the nozzle via the Bowden hose could be leading to this problem. This distorts the fast retract times. Ultimately, it’s a matter of fine-tuning the pressure and retract speed.

Also, the long path of the filament from the extruder to the nozzle via the Bowden hose could be leading to this problem. This distorts the fast retract times. Ultimately, it’s a matter of fine-tuning the pressure and retract speed.

Conclusion

The Flsun Super Racer is an extremely fast and quiet 3D printer under $500 with a decent medium-sized build space. If you want even more luxury, you should wait for the Flsun V400 High Speed, which has a direct drive extruder and an installation space of 300 x 400 mm.

If you have a lot of models to print, you will definitely be satisfied with the Flsun Superracer. This is especially if the prints will fit the 260 mm print bed area in diameter is sufficient.

If you are looking for a cheaper printer, you have to make compromises in terms of speed. We recommend checking these 3D printers under $400 or these 3D printers under $300.

AVAILABLE ON AMAZON

top 10 rating according to KP

A 3D printer opens up incredible opportunities for a person. The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

Hal co-founded 3dsystems, a leader in industrial 3D printers. However, this material is not dedicated to these large machines. 3D printing is becoming more and more part of everyday life. Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

Top 10 rating according to KP

1. Creality3D Ender 3

Creality3D Ender 3. Photo: market-yandex.ruOur rating opens with a model from the world's largest manufacturer of 3D printers. The Ender 3 features an elegant and thoughtful design, excellent print quality and a wide build area. Manufacturers have provided a good arrangement of wires that do not get confused during operation. The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

The main characteristics

| Print technology | FDM/FFF/PJP | ||

| for the house/DIY | |||

| PLA, Wood | |||

| Workspace width | 220 mm | ||

| Workspace height | 250 mm | ||

| The depth of the workspace | 220 mm | ||

| Features | Heated table, displays, active cooling, nozzle change, USB, Micro SD | ||

| Press speed | 180 mm 900 mm | Number of extruders | 1 |

Pros and cons

Possibility of using various types of plastic, high quality of parts, reliable design

A small display that displays only basic information

2.

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru The model from the Chinese developer FlashForge took the second position in our rating. The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle.

Pros and cons

Webcam and Wi-Fi receiver allows you to monitor the work, unusual design, simplicity from anywhere in the world in the setup, the presence of a filament sensor

Despite the rather wide functionality, this model is hardly suitable for an experienced printer or a small production due to the small area of the working space, high price

3.

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display.

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. The main characteristics

| Print technology | FDM/FFF/PJP | |||

| for the house/DIY, Essential level | ||||

| Open Cam | Open Camera | Open Cam | ABS, PLA, Wood, HIPS | |

| Workspace width | 255 mm | |||

| Workspace height | 210 mm | |||

| Working space | 210 mm | |||

| Features | Heated table, display, active cooling, nozzle adjustment, temperature control | |||

| Wi-Fi | Wi-Fi, SD Wi-Fi, SD 9001||||

| Print speed (extruder speed) | 150mm/s | |||

| Number of extruders | 1 | |||

| Printing accuracy | X, Y 0. 01 mm 01 mm | |||

| Positioning accuracy | Z 0.002 mm |

Pros and cons

Short power cord, inaccuracies in the Russian-language menu, weak airflow system.

4. Anet N4

Anet N4. Photo: market-yandex.ruThe budget model from the Chinese manufacturer Anet N4 is equipped with all the necessary functions for a small domestic production. The base of the device is made of cast aluminum alloy. The weight of the gadget does not exceed 9kg. A transparent tinted hood protects the work surface from external sources of ultraviolet radiation. It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Key Features

| Print Technology | LCD | |

| Application | Home/DIY Professional | 30 mm/h |

Pros and cons

Ability to use photopolymer resins from any manufacturer, high polymer curing speed

Small work surface, slightly inferior to competitors in some parameters

Photon Scu0bic0 Anycu0bic08 5. S. Photo: market-yandex.ru

S. Photo: market-yandex.ru In the middle of our rating is the Anycubic Photon S model. It is equipped with an advanced optical system and a large working camera. The device has a matrix light source that provides a uniform luminous flux over the entire plane of the desktop. This allows a very high curing speed of the layers to be achieved. In addition, the printer has an original function that allows you to simultaneously print eight identical models. According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

Plus and disadvantages of

9000 Small worktop6. ELEGOO Mars Pro

ELEGOO Mars Pro. Photo: market-yandex. ru

ru This model is significantly different from its predecessor Elegoo Mars. Thanks to the advanced Z-axis mechanics and directional UV light from the diode array, it is suitable not only for hobbies, but also for fields of activity such as dentistry and jewelry. In addition, the developers moved the USB connector to the front of the device. Now there is no need to constantly rotate the gadget in the process. The weight of the device is only 7.5 kg, which makes it very convenient for transportation. A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process.

The main characteristics

| Print technology | LCD |

| Field | for the home/diy, for medicine |

| Print speed: (layer build-up) | 22. 5 mm/h 5 mm/h |

| Print precision | X, Y 0.047 mm |

| Positioning accuracy | Z 0.125 mm |

| The wavelength of light source | 405 Nm |

PLASS AND MINCOUS COURENTIONAL CENTURE, LIGHT price, good UV light 9000 9000 9000 7. Two Trees Bluer

Two Trees Bluer. Photo: market-yandex.ru This is one of the most popular home models of 3D printers. It is ideal for getting acquainted with technology, various experiments, training and prototyping. Distinctive features of Two Trees Bluer are: "quiet" drivers, which are the engine of the device, a heated table, two-way airflow and a thread break sensor. The mechanics of the printer is quite simple, and at the same time very effective. The open type case will be very convenient when cleaning the work surface. The firmware of the device provides the functions of auto-calibration and automatic resumption of printing in case the power was accidentally turned off.

Pros and cons

Low price, easy and convenient to use

Lack of protection for the work surface, poor quality of spare parts

8. Wanhao Duplicator i3 Mini

Duplicator Mini i3. Photo: market-yandex.ruMiniature 3D printer does not look like other devices. However, this feature does not affect its technical characteristics. The plastic spool is located on the right side of the bracket. Wanhao branded coating is pasted over the table. There is no platform heating, so it is recommended to use PLA plastic for printing. The manufacturer clearly states in the manual that the printer is designed to work only with PLA material and nothing else. The body of the gadget is made of sheet steel. The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer.

The main characteristics

| Print technology | FDM/FFF/PJP |

| educational, for house | PLA |

| Working space width | 120 mm |

| Working space height | 100 mm |

| The depth of the working space | 135 mm |

| Features | displays, active cooling, speed control, temperature control | USB, SD card |

| ) | 70 mm/s |

| Number of extruders | 1 |

| Printing precision | X, Y 0. 012 mm 012 mm |

| Positioning accuracy | Z 0.004 mm |

Pros and disadvantages

Good price

Lack of heating and protecting the working surface, high probability of problems with a working coil

9.

Artillery Genius. Photo: market-yandex.ruThe base of the device consists of an aluminum case, in which all the electronics are hidden. An aluminum portal is also attached to it. The latter is also a guide for the moving parts of the printer. At the top of the portal is a plastic jumper to which the spool holder and filament sensor are attached. As for the control screen, its functionality is seriously curtailed. However, it is sufficient for simple tasks, but it is impossible to configure the printer.

The main characteristics

| Press technology | FDM/FFF/PJP |

| Educational, for the house/DIY, Industrial, Professional Medium | for printingABS, Flex, Nylon, PLA, PETG, SBS, CopperFILL, DuraForm TPU |

| Working width | 220 mm |

| The height of the workspace | 250 mm |

| DEMPLE DIFFICULATION | 220 mm |

| Features | The heated table, Active speed, Contact control, Contactive |

| USB, micro-SD | |

| Print speed (extruder speed) | 150 mm/s, |

| Number of extruders | 1 |

Pros and cons

Spacious work surface, robust housing

Little functionality for a rather high price, lack of work surface protection, few functions on the control screen.

10. Tianfour Sparkmaker

Tianfour Sparkmaker. Photo: market-yandex.ruThis model is ideal for beginners, as it does not require additional settings at all before starting work. Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm.

How to choose a 3D printer

Choosing a 3D printer is not such a difficult task as it might seem at first glance. Despite the relentless interest in 3D printing and the incredible number of devices on the market, the basic requirements for models remain unchanged. Komsomolskaya Pravda turned to Svyatoslav Vulf, a blogger and host of a YouTube channel about modern technologies and experiments, for help in this matter. He regularly monitors new products on the 3D technology market and tests them at home.

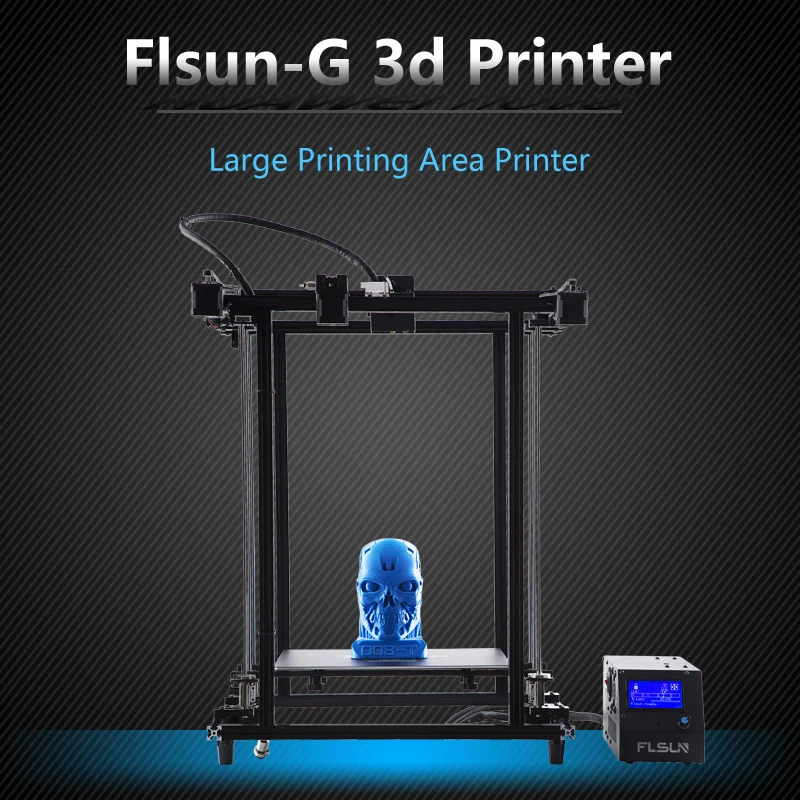

Product size

Initially, you should decide what size of products you expect to receive in the end. The required area of the working surface depends on this. Note that the price of the device also depends on the size of the latter. For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

Technology

Today, there are several technologies for printing on a 3D printer. They differ significantly from each other. Let's consider some of them.

SLA-technology — works on the basis of a liquid photopolymer, which under the influence of laser light changes its physical properties and hardens. It allows you to create figurines with the highest precision of microforms.

DLP technology is an alternative SLA method. However, instead of laser systems, LED projectors are used here, which significantly reduce the cost of 3D printers. When using this technology, the future prototype is formed layer by layer.

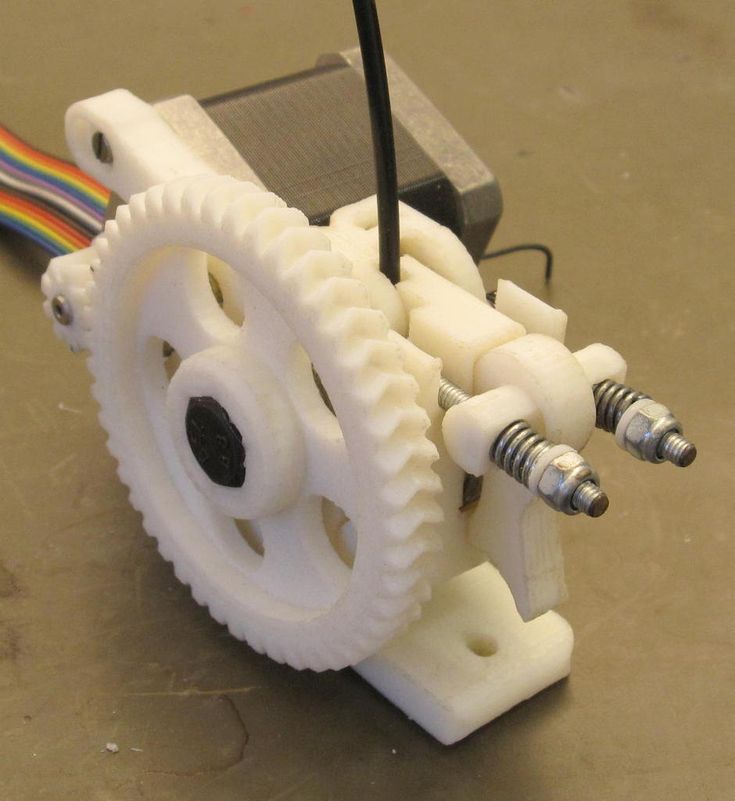

The FDM method is ideal when prototypes are required that will be actively used and not just sitting on a shelf. Here, high-strength industrial plastics will be used for production. Please note that there are other technologies, but they are very similar to the above.

Material

Before buying a printer, you should also pay attention to what materials it works with, as they have significant differences from each other. For example, ABS can take many different polymeric forms. This is a very durable plastic. It is easily sanded and processed. PLA plastic is considered more environmentally friendly. It is made from agricultural products - corn, potatoes, beets and others. In its original form, it is transparent and can be colored. PLA is just as strong but tougher than ABS. The ductility and heat resistance of SBS make it the material of choice in engineering and mechanical applications.

Noise level and drivers

An important factor when choosing a 3D printer are drivers - device engines (not to be confused with software). They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

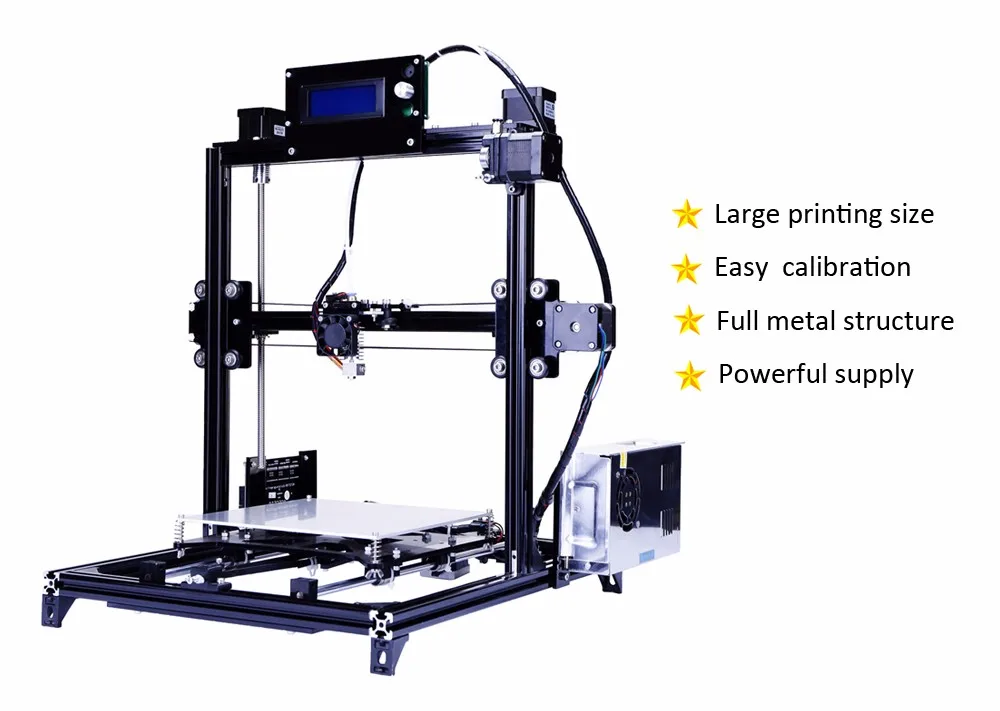

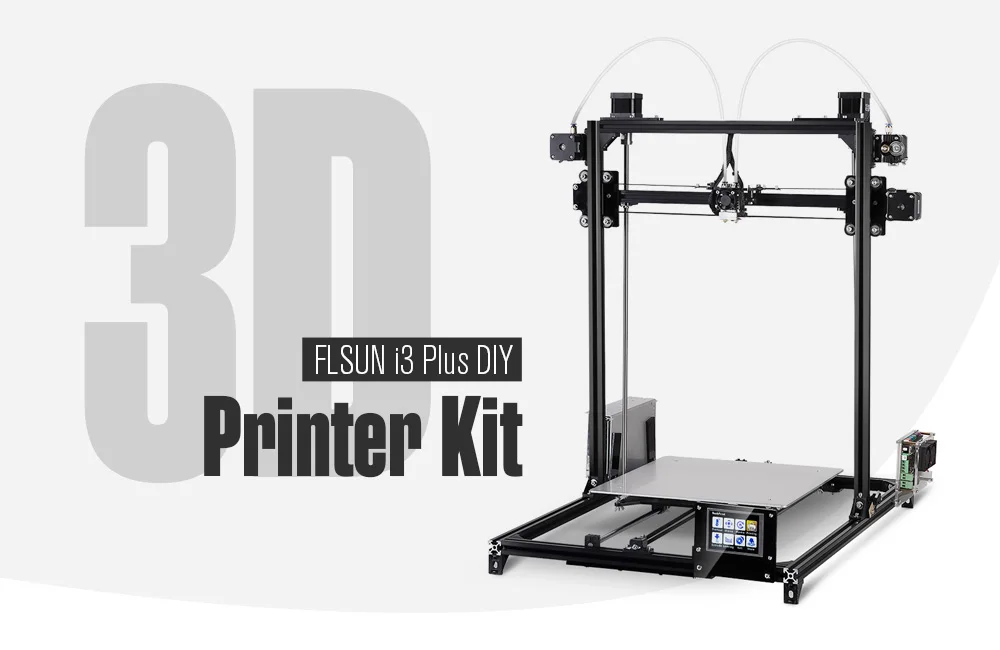

Self-assembly

Some manufacturers prepare the model completely before sale. The buyer can only get the printer out of the box and connect the power. However, there are some models that require self-assembly. Be sure to consider this factor before purchasing. If you are purchasing such a device for the first time, then it will not be easy for you to assemble it.

4 3D printing trends in 2023

Analytics and business

Experts recommend

Author: Viktor Naumov

Author: Viktor Naumov

Year after year, the adoption of additive manufacturing reaches new heights. What can we expect from 2023? Materialize, a leader in the global 3D printing market, offered its forecast based on four key trends that will drive the industry over the next twelve months:

-

the rise of smart, distributed manufacturing;

-

focus on cost reduction;

-

transition from automation of individual processes to complex automation of the workflow;

-

data security and integrity becomes a priority.

By addressing these issues, companies will be able to bring 3D printing to the level of mass production and accelerate the adoption of additive technologies.

Over the past three decades, 3D printing has established itself as a versatile and flexible tool in the manufacturing arsenal. Being a relatively new technology, it has spent most of this time somewhat isolated from the traditional manufacturing process. But in recent years, the wall between classic manufacturing and 3D printing has begun to disappear. We are starting to see these two separate worlds coming together, and the implications are enormous.

In 2023, the above trends will be the key to overcome the barriers that are still associated with the introduction of technology into industrial production. Addressing these issues will help companies scale up 3D printing to mass production and accelerate the adoption of 3D printing.

Fried Vankran, CEO of Materialize

© Materialize

1.

The rise of smart, distributed manufacturing

The rise of smart, distributed manufacturing Traditionally, production has always been concentrated in one place - usually a factory in another country. This system worked well until it stopped working. Over the past few years, we have seen how the COVID-19 crisis has paralyzed production and disrupted supply chains. We have witnessed an increase in geopolitical tensions and environmental concerns. All this taken together forced manufacturing companies to reconsider their model of centralized production. And with the help of smart digital technologies like 3D printing, manufacturers can move to multiple, smaller sites closer to customers.

Find the right 3D printer for you

However, many of the recent implementations owe their success to quick decision making in the face of scarce funds, such as reaching out to local 3D printing service providers to produce essential medical devices during the coronavirus pandemic. It can be said that 3D printing has been used as a temporary replacement. But, fortunately, such decisions have sparked new conversations about the future of production.

But, fortunately, such decisions have sparked new conversations about the future of production.

Now we see that many companies are ready to take a more strategic approach. These companies need to carefully consider which applications will deliver the most value in terms of supply chain efficiency or environmental sustainability. And this requires a change in thinking, moving from short-term solutions to the use of additive technologies as a stable method for the production of certified final parts.

A good example is CNH, an agricultural machinery company. During the pandemic, CNH was 3D-printing a vital part that could not be obtained due to COVID-related logistical constraints. The experience has proved useful, and the company is now looking at 3D printing as part of its strategy to manage supply chains in a more cost-effective way.

3D printing at CNH © cnhindustrial.com

Thus, the potential is real even in such a highly regulated field as medicine. We are seeing hospitals increasingly turning to 3D printing to create medical models and personalized implants in situ, close to patients.

We are seeing hospitals increasingly turning to 3D printing to create medical models and personalized implants in situ, close to patients.

We can say that this is the medical equivalent of a decentralized model of industrial production. Ultimately, we have smart, distributed manufacturing enabled by 3D printing that, when approached strategically, can be a recipe for success rather than an ad hoc response to problems.

Hanne Gielys, Innovation Manager, Mindware

2. Focus on cost reduction

The history of 3D printing is a history of added value. Additive manufacturing allows for design optimization, delivering performance, weight savings, time savings and supply chain savings that traditional manufacturing methods cannot achieve. In many cases, these benefits create opportunities for cost savings that affect overall manufacturing costs, from design to delivery.

Manufacturers planning to scale additive manufacturing to thousands or even millions of parts must ensure that the 3D printing process is efficient, reliable, and repeatable across multiple manufacturing sites.

Peter Lace, Executive Chairman, Materialize

A recent survey showed that the ability to reduce overall manufacturing costs is cited as the most important benefit of 3D printing. But this does not necessarily mean that the additive process itself is cost effective. Rising material and energy prices have only further increased costs.

The cost of 3D printed parts is determined by several factors, including the materials needed, the lead time per part, and the type of printer. There are two really important ways to reduce these costs. The first is more efficient work to increase production capacity. Software plays a big role in this, allowing you to optimize your designs. We can also customize the printing process to make it more efficient and repeatable. The second way is to use tools and improve quality. And you have to pay for quality.

© Materialize

If we take a certified production in the medical or aviation industry, we will see that up to 70 percent of the cost of production is accounted for by quality control. 3D printing continues to transform factory floors as companies increasingly turn to the technology for large-scale production. But to accelerate this adoption, our industry will have to work harder to bring down the cost of 3D printing.

3D printing continues to transform factory floors as companies increasingly turn to the technology for large-scale production. But to accelerate this adoption, our industry will have to work harder to bring down the cost of 3D printing.

Brian Crutchfield, Vice President and General Manager, North America

3. Transition from single process automation to integrated workflow automation

3D printing is a digital manufacturing technology, but it still requires a lot of human intervention. And such skilled workers are becoming increasingly difficult to find. According to a recent study by Materialize, finding the right people with the right knowledge and experience is a major challenge for companies that already use or are considering using 3D printers.

At the same time, scaling industrial additive manufacturing to thousands or millions requires repeatability and stability of the printing process. These two issues have increased the need for automation in recent years. The software allowed us to automate various steps in the 3D printing process, from preparing and editing files to creating supports, optimizing object placement in the build chamber, and even post-processing.

The software allowed us to automate various steps in the 3D printing process, from preparing and editing files to creating supports, optimizing object placement in the build chamber, and even post-processing.

But these are all separate processes. In 3D printing, they follow each other, merging into a complex digital manufacturing process. The promise of large-scale industrial 3D printing requires us to automate not only each individual process, but also the workflows between them. And this is what we call end-to-end workflow automation.

© Materialize

We see the same thing in the medical industry, where complex process automation is needed to cope with the surge in custom 3D solutions. The good news is that opportunities to meet this need are growing with the creation of software platforms that allow manufacturers to customize their own unique 3D printing process.

Isabelle Rombaugh, Director of Global Sales and Business Development Medical

4.

Data security and integrity becomes a priority

Data security and integrity becomes a priority We have already talked about such an important trend as distributed production. Smart digital technologies, including 3D printing, are making it possible to move production to several smaller sites closer to customers. This is a clear sign that the factory of the future will not have a single, central location. This new digital distributed manufacturing environment revolves around one key asset - data, and this data must be protected so that an unscrupulous supplier cannot steal the design and print the product on their own 3D printer.

Of course, data security is important in any kind of manufacturing, be it traditional or smart. In both cases, companies share their unique designs with contractors and suppliers, and they want to know that their design data will remain secure. But in the case of 3D printing, that's not all. Manufacturers planning to scale additive manufacturing to thousands or even millions of parts must optimize and fine-tune their unique printing process to ensure it is efficient, reliable and repeatable across multiple manufacturing sites.