The crane quad 3d printer

Crane Quad from M3D – Part 2 – Danal's Pub

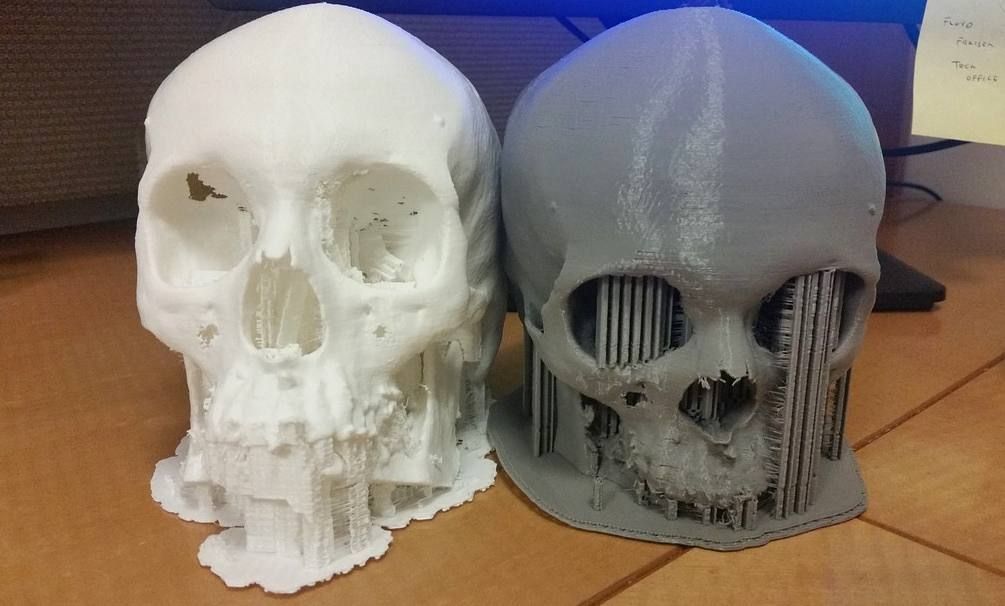

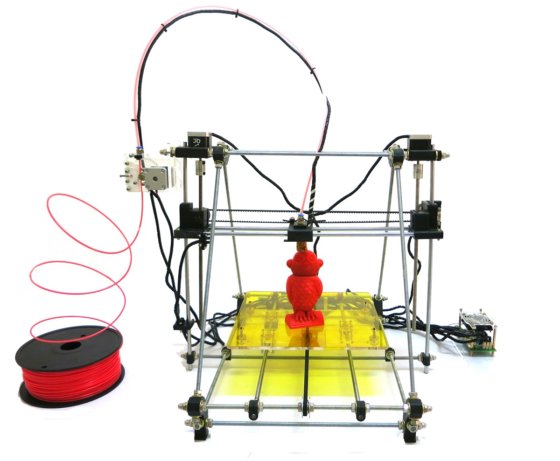

Part 1 of this review is easily summarized: Good controller, weak mechanics, all supporting a color mixing head.

Let’s talk about that head.

Ever heard of the subreddit ATBGE? Awful Taste But Great Execution? This is sort of the opposite. GCBAE. Great Concept But Awful Implementation.

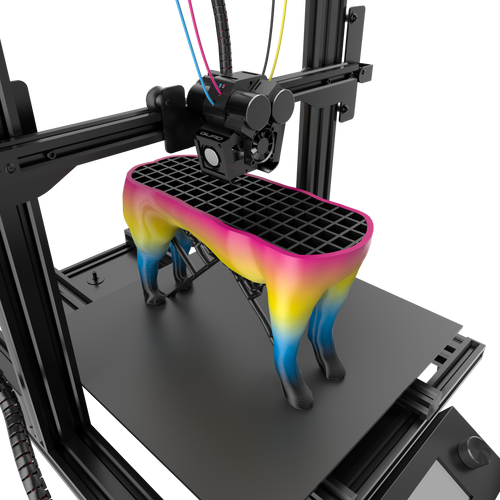

The concept behind color mixing is great, and when you get the thing loaded and working and it continues to work through one whole print, the results can be stunning. Here are a few pics from their web site:

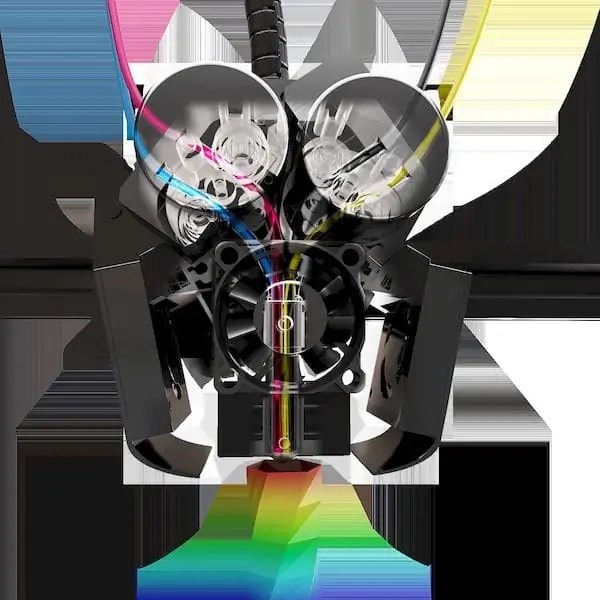

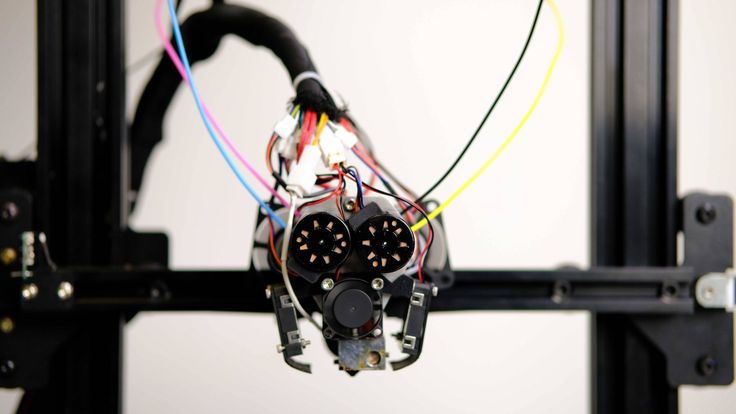

The head itself has four small geared extruder motors that drive filament into a common heat block / mixing chamber. This cutaway gives you some idea:

The nozzle fits the heatblock so well that you might think it is all one piece; in reality, the nozzle IS replaceable (with their proprietary part only).

Any mixing printhead has an interesting limit: All the inputs MUST have filament in them, or feeding filament will force melt back out that empty input. M3D publishes good instructions to help avoid this. Nonetheless, I managed to jam an input in the first few minutes of trying to load the printer.

That led to about two hours of disassembly, understanding the head, and trying to clear the block. The documentation here is severely lacking. There is some information on changing a nozzle, and I used this to get the nozzle and heat block assembly out. Clearing the block ultimately required heating that assembly, holding it in pliers, and jamming a hex tool that just happens to almost exactly fit a 1.75 hole. With four holes, there is a certain amount of “whack a mole” to get everything cleared at once. A lot of working with this eventually got all four holes where they would pass filament.

This is NOT FOR THE FAINT OF HEART. This thing is going to require advanced 3D printing skills and/or mechanical skills to get it to work at all. I came very close to damaging the white plastic insert, very close to the first print not happening at all.

With the printer now loaded and able to feed all four filaments, I started their sample print, the spiral vase. Getting layer 1 going on the manual leveled bed took a couple of tries, but nothing too serious.

Once I could see that the print was proceeding I left it to finish over the next several hours (NEVER leave a brand new printer completely alone… my phrase ‘left it’ means that I turned my attention to other things in the Bat Cave; I was always in the same room and within about 20 feet of the printer).

Result? Fairly OK-Ish for most of the print, the top 1/2 inch or so was completely de-bonded for unknown reasons. Their filament, their printer, their sample pre-sliced file.

And… the print stuck to the black print surface quite firmly. I finally chiseled it off to get the print itself free. I still have not gotten the circle of plastic, THICK circle of plastic, off the bed. Again, their filament, bed, and temperatures. This is completely unacceptable, to ruin the bed on the very first print.

Summary: Head is VERY finicky to get loaded, didn’t even make it through the sample print without jamming, and requires mad skills to unclog. Bed material grabs supplied filament so well it ruins itself.

Ick.

I’m glad I didn’t pay a lot for this thing. I’m trying to decide now how much more time to invest. I may be hard headed enough to print the fish, because my wife thinks it is cute. After that, the idea of spending all the loading/unjamming time on a regular basis… no thanks.

The Top Full Color 3D Printers on the Market

Published on December 2, 2021 by Carlota V.

When it comes to choice of a 3D printer, several criteria must be taken into account: which applications it will be used for, the desired printing speed, the final quality of the parts, the quantity to be produced, among others. For some, a particularly essential aspect is the possibility to design parts in color. It is true that color integration is rarely the number one choice, but for some users, it is key. For example when creating a visual prototype that must look like a perfume bottle, or an anatomical model where blood vessels need to be distinguished from nerves and arteries. Enter full color 3D printers.

For example when creating a visual prototype that must look like a perfume bottle, or an anatomical model where blood vessels need to be distinguished from nerves and arteries. Enter full color 3D printers.

Integrating color into additive manufacturing is currently possible, whether through machines that are capable of offering a wide range of colors, accessories to be added to the printers, or post-processing solutions that offer options for dyeing, painting, varnishing, etc. In this listing, we focus on color 3D printers, i.e. machines that can produce a multi-color part at the end of the printing process. We have sorted them by printing process: extrusion, material jetting and powder binding.

Fused Deposition Modeling

FDM technology offers several possibilities for creating coloured parts. For some color 3D printers, the presence of several extruders will allow the user to choose different filaments and combine them. Other manufacturers have developed a system that can color filaments directly inside the 3D printer: the machine releases color inks at the print head, resulting in a colored filament. Finally, there exist additional accessories available to mix different filaments together.

Finally, there exist additional accessories available to mix different filaments together.

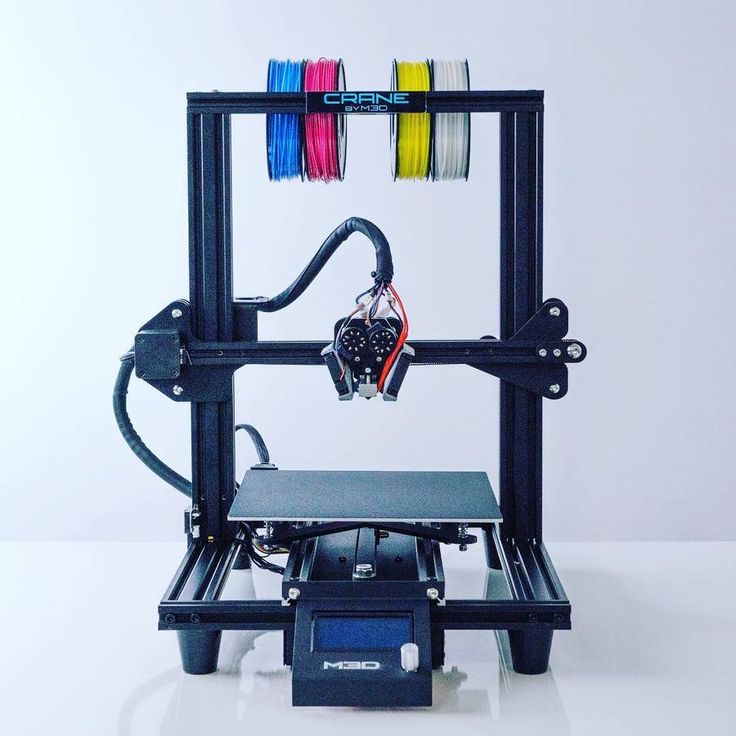

Crane Quad

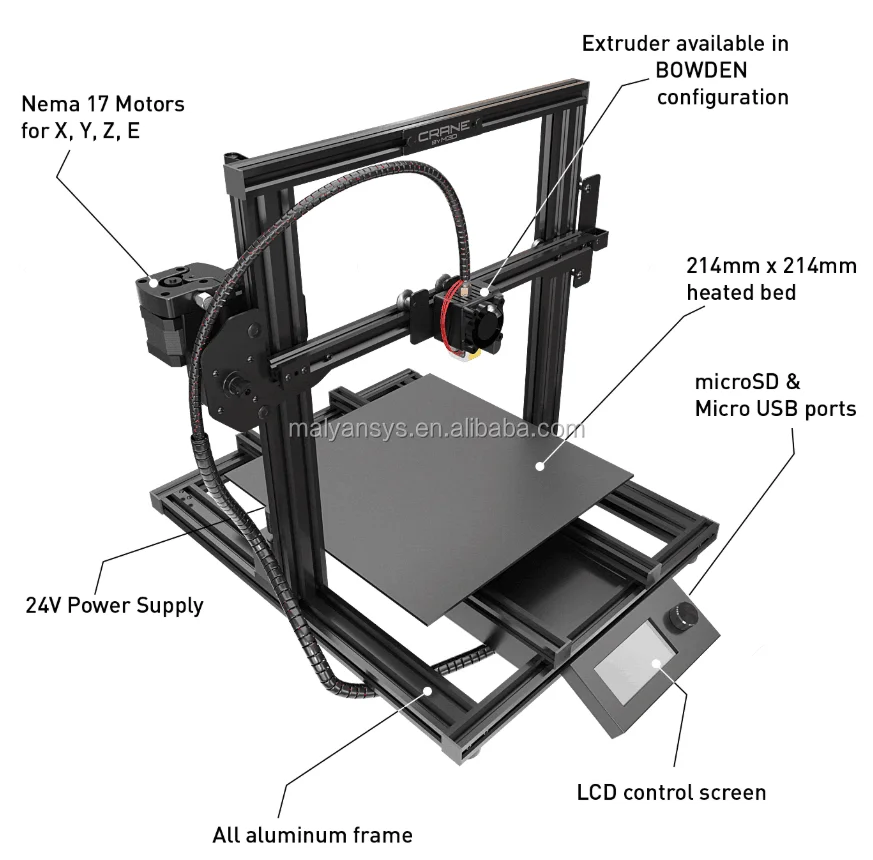

Known for launching the Micro 3D, a successful desktop 3D printer on Kickstarter in 2014, M3D continued to develop various FDM/FFF machines. Among its latest creations, the Crane Quad, a 3D printer capable of combining several filaments to create new combinations of colors or hybrid materials. In fact, the Crane Quad mixes 4 CMYK filaments to achieve more than 50,000 different colors. In addition, it offers a maximum manufacturing volume of 230 x 230 x 250 mm for a minimum layer height of 25 microns. It is marketed by M3D at a price of $999. You can find more information HERE.

da Vinci Color 3D printer and its mini

The da Vinci Color 3D printer combines FDM and Inkjet technologies, as it uses an absorbent, colorless PLA filament that can be mixed with different color inks. According to the manufacturer, CMYK ink cartridges can be used in an almost unlimited color gamut, up to 16 million shades. It has a print volume of 200 x 200 x 150 mm for a maximum print speed of 180 mm/s. In addition, XYZprinting also has a more compact version, the da Vinci Color Mini, with a smaller print volume of 130 x 130 x 130 x 130 mm. Features of this latest version include automatic calibration, wireless connectivity to connect to the printer remotely, and an optional laser engraving module for further customization of projects.

It has a print volume of 200 x 200 x 150 mm for a maximum print speed of 180 mm/s. In addition, XYZprinting also has a more compact version, the da Vinci Color Mini, with a smaller print volume of 130 x 130 x 130 x 130 mm. Features of this latest version include automatic calibration, wireless connectivity to connect to the printer remotely, and an optional laser engraving module for further customization of projects.

Element from Mosaic Manufacturing

The Element 3D printer was launched by the Canadian company Mosaïc Manufacturing. This professional machine makes it possible to achieve complex prints with different materials while obtaining realistic full-color and functional prints by combining flexible and rigid materials. It has a printing plate that reaches 120°C and a layer resolution of between 20 and 230 microns. With a maximum printing volume of 355 x 355 x 355 mm, the Element 3D printer has an all-metal gantry and a precision motion system. Other features include an internal camera for viewing the print, a touch screen control and connectivity via Wifi, LAN or USB. It is compatible with the Canva laminator, with which you can easily create, cut and manage any 3D printing project.

It is compatible with the Canva laminator, with which you can easily create, cut and manage any 3D printing project.

Palette 3

While the Palette 3 is not a 3D printer, it is probably one of the most accessible ways to design color parts. Developed by the Canadian company Mosaic Manufacturing, the machine should be connected to an extrusion 3D printer. It allows the combination of flexible and rigid materials, and users can not only create parts with complex shapes but also print in color in one go. A Pro version of the Palette 3 is also available, with advanced properties that allow users to print with technical materials and create durable, high-volume prints. Finally, the Palette 3 Pro features Splice Core Pro, a cooling system that makes filament bonding more reliable. The Palette 3 is available from €650 and the Palette 3 Pro from €850.

RoVa4D

The RoVa4D 3D printer grew out of a successful Kickstarter campaign by Canadian company ORD Solutions, which after its first Kickstarter campaign has dedicated itself to improving the capabilities of its 3D printer. This latest version supports 5 spools and a print head that allows printing with different materials and colors, from flexible materials to soluble materials. It has a printing volume of 120 x 120 x 180 mm. In order to be able to successfully achieve color printing, the machine has 5 different spools for CMYK colours (cyan, magenta, yellow, black and white), which are then mixed within the patented hotend to give the expected color as a result. The printer can currently be purchased at the manufacturer’s website for $7,500. You can find more information HERE.

This latest version supports 5 spools and a print head that allows printing with different materials and colors, from flexible materials to soluble materials. It has a printing volume of 120 x 120 x 180 mm. In order to be able to successfully achieve color printing, the machine has 5 different spools for CMYK colours (cyan, magenta, yellow, black and white), which are then mixed within the patented hotend to give the expected color as a result. The printer can currently be purchased at the manufacturer’s website for $7,500. You can find more information HERE.

XRIZE

The XRIZE is an industrial 3D printer that uses a hybrid process called Augmented Deposition to produce objects in multiple colors. This hybrid process combines extrusion-based 3D printing with a inkjet technology we know from 2D printers. While the part is created layer by layer with traditional colorless PLA, the 3D printer simultaneously releases CMYK inks (cyan, magenta, yellow, black) in the print head to add color. For example, text, images and QR codes can be printed on the part. Although the device can be described as a desktop machine, its build volume being 310 x 200 x 200 mm, the XRIZE with a price of $55,000 is less suitable for manufacturers and hobbyists but rather for industrial applications. You can find more information HERE.

For example, text, images and QR codes can be printed on the part. Although the device can be described as a desktop machine, its build volume being 310 x 200 x 200 mm, the XRIZE with a price of $55,000 is less suitable for manufacturers and hobbyists but rather for industrial applications. You can find more information HERE.

Material Jetting

3DUJ-553 and 3DUJ-2207 from Mimaki

Japan’s Mimaki, a manufacturer of traditional 2D printers, was the first to make a UV-curable, colored material jet 3D printer. Its 3DUJ-553 solution was launched in 2017 and can create parts with more than 10 million colors. It uses a UV light curing process and is intended for the professional sector. During this process, a layer of material is applied and then covered with a UV-sensitive ink that light can solidify. The process is repeated until the final part is obtained.

More recently, Mimaki developed the 3DUJ-2207, a more compact 3D printer that offers the same color printing capabilities. It is more accessible and easier to use, unlocking a larger section of the current market. The 3DUJ-2207 is particularly suited to medical professionals, researchers and teachers, but also to designers and artists.

It is more accessible and easier to use, unlocking a larger section of the current market. The 3DUJ-2207 is particularly suited to medical professionals, researchers and teachers, but also to designers and artists.

ActiveLab Digital Fabrication by Voxel8

The ActiveLab Digital Manufacturing System from Voxel8, acquired earlier this year by Kornit Digital, is another multi-material 3D printing solution using a technology based on material jetting. Its ActiveMix® technology consists of three possible elements, ActiveMix Extrusion, ActiveMix Spray and ActiveImage. The extrusion works to build 3D structures and thick films on any surface or texture with theologically tuned fluids while the spray rapidly covers large areas of a substrate with an elastomeric spray for textiles. Finally, the ActiveImage uses inkjet technology either through spray or extrusion, or both, to embed high-resolution graphics into elastomers. Users can expect full color graphics and the company points to its use especially in the creation of sporting goods, though it also has industrial and medical applications. You can find out more HERE.

You can find out more HERE.

Photo Credits: Voxel8

J55 Prime

One of the most well-known names in the world of full color 3D printers is of course Stratasys with their PolyJet technology, which has the distinction of enabling the mixing of colors, materials and even textures in one part. Though they have many different machines using Polyjet, we wanted to draw your attention to their J55 Prime which was released in 2020. This more compact solution still has the multi-material and multi-color capabilities of its larger predecessors but at a fraction of the price. It is able to print with 5 materials simultaneously meaning that users can create over 640,000 unique combinations, including Pantone Verified colors. As it has been designed for an office or studio it is also ultra-quiet, operating at the same level as a household refrigerator. Finally, it has a ProAero™ Air Extractor to capture and filter out fumes. You can find out more about the printer HERE.

ProJet CJP Series

The ProJet CJP 260Plus is 3D Systems’ most affordable and office friendly color 3D printing option. The ProJet CJP 260Plus creates photo-realistic parts in full CMY color with small feature details and the ability to use full texture/UV mapping to better evaluate the look, feel, and style of product designs. This 3D printer is based on 3D System’s ColorJet Printing technology, and has a maximum build volume of 236 x 185 x 127 mm.

The ProJet CJP 260Plus creates photo-realistic parts in full CMY color with small feature details and the ability to use full texture/UV mapping to better evaluate the look, feel, and style of product designs. This 3D printer is based on 3D System’s ColorJet Printing technology, and has a maximum build volume of 236 x 185 x 127 mm.

3D Systems manufactures an entire range of color 3D printers, including the ProJet CJP 360, CJP 260 Plus, CJP 860Pro, CJP 660Pro, and the CJP 460Plus. They vary according to their build volume, the 860Pro being the largest solution, with a build volume of 508 × 381 × 229 mm. You can find more information HERE.

Binder Jetting

ComeTrue T10

Developed by Taiwanese manufacturer ComeTrue, the ComeTrue T10 3D printer is based on a Binder Jetting technology and coloured inks (CMYK). The advantage of such a process is the possibility of printing parts without printing supports as well as its speed, the T10 is indeed able to reach a printing speed of 20mm/h. The ComeTrue T10 allows the manufacture of parts with a maximum size of 200 x 160 x 150 mm with a resolution of 1200 x 556 DPI for a minimum layer height of 0.08 mm. The ComeTrue 3D printer requires a post-processing machine to remove the finished prints (Dry Vacuum Cleaner). The ComeTrue T10 is available for a price of about 25,000€. You can find more information HERE.

The ComeTrue T10 allows the manufacture of parts with a maximum size of 200 x 160 x 150 mm with a resolution of 1200 x 556 DPI for a minimum layer height of 0.08 mm. The ComeTrue 3D printer requires a post-processing machine to remove the finished prints (Dry Vacuum Cleaner). The ComeTrue T10 is available for a price of about 25,000€. You can find more information HERE.

PartPro350 xBC from XYZprinting

Launched in 2018 by Chinese manufacturer XYZprinting, the PartPro350 xBC 3D printer uses Binder Jetting. It is compatible with standard thermoplastics, such as ABS and PLA and the machine has been designed for professionals. With a printing volume of 350 x 222 x 200 mm, the printer is, according to the manufacturer, 150% faster than machines using the same technology. Finally, the PartPro350 xBC has a removable tray so that users can easily remove parts after the printing process. According to some retailers, the price is between €25,500 and €35,000.

What did you think of our listing of full color 3D printers? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

BIQU starts accepting orders for Hurakan budget FDM 3D printers

News

capacity in the form of a quad-core single-board computer.

Hurakan relies on a 32-bit Manta M4P board built specifically for Klipper. The board with ARM STM32G0B0RE microcontroller with a clock speed of 64 MHz works in conjunction with a CB1 single-board computer with a quad-core ARM Cortex-A53 processor, clocked at 1.5 GHz and 512 MB DDR3 RAM. Silent TMC2209 drivers2 with virtually no ringing. The head also has built-in RGB illumination of the work area with almost seventeen million possible shades - purely for aesthetic reasons. Belt tension adjustment mechanisms are installed on the X and Y axes.

Belt tension adjustment mechanisms are installed on the X and Y axes.

The platform is adjusted using a "microprobe" - a miniature aluminum contact probe weighing six grams. The sensor can be purchased separately for installation on other 3D printers. The platform has zoned heating: depending on the size of the products, you can turn on the heating of the entire table (240 W) or only the central part (100 W) to save energy when 3D printing small models. nine0003

The construction area is up to 220x220x270 mm. The Bowden extruder is equipped with a filament sensor and supports polymer printing at temperatures up to 260°C. If desired, the extruder can be replaced with a high-temperature h3. These extruders, available in both air- and liquid-cooled versions, can run up to 500°C maximum, theoretically allowing even high-melting engineering thermoplastics such as PEEK to be printed, although the lack of a thermostated chamber does not play into the hands. On the other hand, h3 are already direct extruders, better suited for working with thermoplastic elastomers than stock bowden. In addition, the increased temperature of the hot end will ensure the reliability of the extrusion of glass- and carbon-filled composites. nine0003

On the other hand, h3 are already direct extruders, better suited for working with thermoplastic elastomers than stock bowden. In addition, the increased temperature of the hot end will ensure the reliability of the extrusion of glass- and carbon-filled composites. nine0003

On-board interface includes an IPS color display with HDMI connection. Alternatively, the 3D printer can be controlled via the Fluidd or Mainsail web interface with multi-machine support in the case of a farm.

BIQU Hurakan 3D Printer Specifications:

- Technology: FDM/FFF

- Number of extruders: 1

- Construction area size: 220x220x270 mm

- Layer thickness: 0.1-0.3 mm nine0038

- Nozzle diameter: 0.4 mm (standard)

- Print speed: 180 mm/s (maximum), up to 60 mm/s (recommended)

- Printing accuracy: ±0.05 mm

- Maximum hot end temperature: 260°C

- Software: Cura, Repetier-Host, Simplify 3D and other slicers

- Power consumption: up to 280 W

- Heated platform power: 100/240 W

- Maximum platform temperature: 100°C nine0038

- Filament diameter: 1.

75 mm

75 mm - Filament sensor: yes

- Adjustment: automatic

- Software: Cura, Repetier-Host, Simplify 3D and other slicers

- Dimensions: 480x470x482 mm

Pre-orders start today at a selling price of $369 with shipping starting in November of this year. Additional information is available on the BIQU official website at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

fdm biqu Clipper Hurakan

Follow author

Subscribe

Don't want

5

German company Grohe 3D prints faucets / Habr

Leonid_R

Design 3D printers

Futuristic metal faucets joined the Grohe lineup in the summer of 2019. However, you can buy them so far only in offline stores in Europe.

Source: Grohe

Grohe explains that the Atrio Icon 3D faucet component consists of 4,700 metal layers, each 0.06 millimeters thick. Faucets are printed from metal powder. After printing, the component is ground first on a milling machine and then manually. Grohe clarifies that the Atrio Icon 3D will not be mass-produced – each faucet will be made individually to order. nine0003

There are four printed faucets available in the range. The price of all four copies is decent - the mixer will cost 11,998 euros per set.

Seum added that in the final design, Grohe managed to create an ambivalent impression on the buyers. When a person looks at the Atrio Icon 3D in profile, he sees more of a crane in a traditional design.

“That's the impression you get until you look sideways and see his silhouette. From this vantage point, a person sometimes does not believe that the faucet is so thin and does not understand where the water comes from in the end,” adds Seum. nine01163D printed metal faucets are not new to the plumbing market. Back in 2016, American Standard introduced an exclusive series of its faucets, which differ from Grohe in smoother lines. American cranes manufactured by contractor DXV by order of American Standard cost decently: from 12 thousand to 20 thousand dollars - and are also made only to order.

Source: DXVIn addition to filling bathrooms, the rooms themselves are already being printed on 3D printers. A research team from Nanyang Technological University has developed a special concrete mix infused with geopolymers. During the printing process, the concrete remains watery enough to properly distribute through the 3D printer's hoses and nozzle, but is able to harden quickly enough for the machine to apply another layer on top of it shortly thereafter.

Learn more