How does a 3d printer make food

Food 3D printing Guide - how does it work and what can be done today

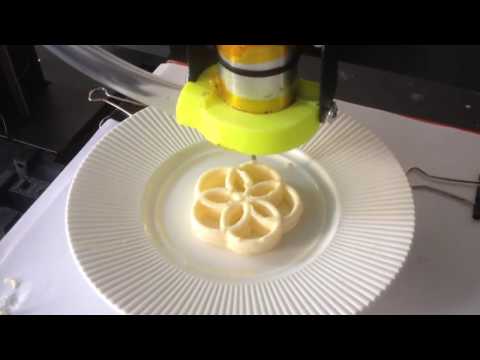

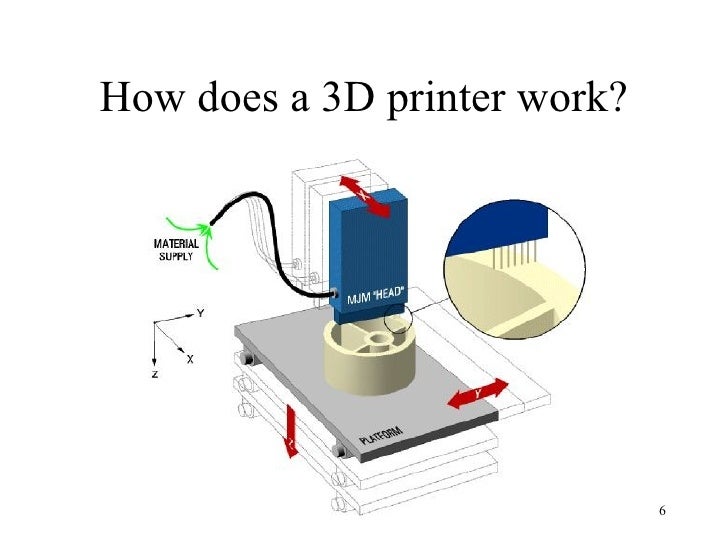

How does a food 3D printer work?The concept is the same as traditional 3D printing: a food 3D printer heats up edible ingredients before 3D printing them on the build plate, layer by layer. Another option, similar to SLS 3D printing, is to use ingredients in the form of a dry powder that is then solidified by the food 3D printer.

Discover our selection of the best food 3D printers to 3D print food or chocolate at home.

3D printing of sweet desserts

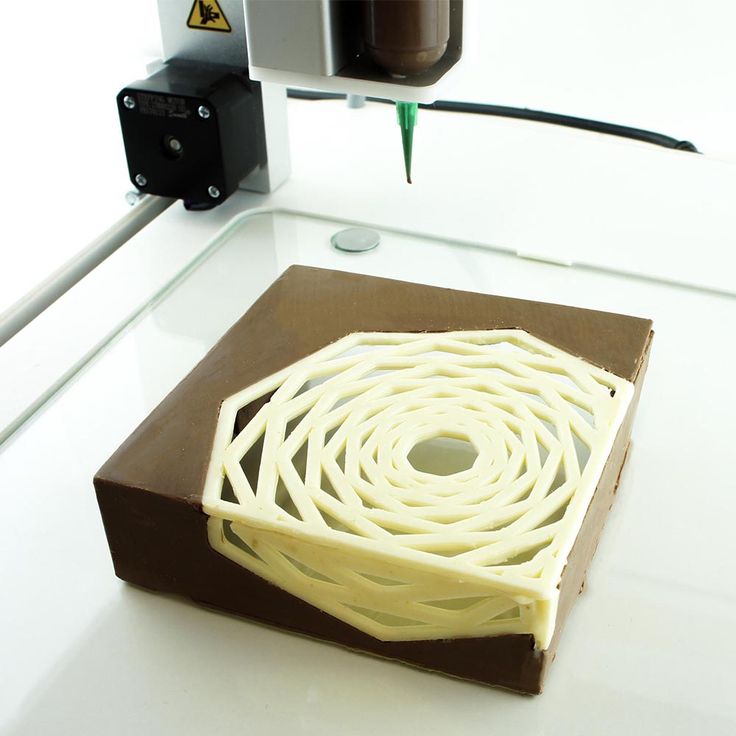

3D printing chocolateBecause of its natural physical properties, chocolate suits 3D printing perfectly. It melts at the temperature of the human body and solidifies as soon as it cools down. It is therefore easy to create customized chocolate desserts without changing the chocolate’s original taste.

Choc Edge has already released two versions of its 3D printer to make all types of chocolate designs. The 3Drag printer uses FDM technology. It is possible to 3D print almost any chocolate design that the user creates.

3D printing with sugarSugar is a malleable material that can take many forms and colors, and it is also compatible with 3D printing. Some research groups such as The CandyFab Project or the Sugar Lab from 3D Systems have developed 3D printers specialized in the printing of sugar and candies with creative 3D shapes, as shown in photos on their websites.

Sugar candy 3D printed with a Chefjet 3D printer from 3D Systems.Food 3D printing: a marketing tool

Custom 3D printed biscuitsFood 3D printing provides the opportunity to satisfy customers to see their own customized cookies created before their eyes.

This is how Oreo chose to exhibit 3D printers during the SXSW 2014 festival, allowing customers to choose the color of their Oreos’ cream.

Oreo at the SXSW festival with 3D printed cream.3D print edibles that look like you

With the best 3D scanners it is possible to create a 3D model of your own head, and to 3D print it with edible food. Some manufacturers provide the opportunity to eat pancakes or waffles with the shape of your face.

A 3D printed “face pancake” by the design company Kinneir Dufort.For one of their marketing campaigns, mayonnaise manufacturer Hellmann’s even offered customers the possibility to 3D print their face on burger buns.

Create your own product line3D printing enables the consumer to participate in the creation of a new range of products. Barilla, for example, organized a contest in 2014 to reward the best 3D model design for a new Barilla pasta.

In two months, designers sent out 216 pasta proposals from 20 different countries, and the winning design was sold by Barilla as a new product!

Barilla new pasta design by Loris Tupin, French designer at the Barilla contest.

3D printing for the food industry

100% 3D printed mealsFoodini 3D printers sold by Natural Machines and Bocusini, which successfully ran a Kickstarter crowdfunding campaign, are among the most successful 3D food printers.

These two 3D printers allowed for the very first fully 3D printed meals. These are made of successive layers, in the same way that pizzas are prepared.

The dough is cooked during 3D printing, while the tomato sauce (made of powder), water, and oil are added, followed by a layer of protein.

3D printing meatFurther pushing the boundaries of 3D printing, some scientists want to use biomaterials and animal stem cells to create 3D printed meat.

Scientists behind this approach point out the huge amount of resources needed for meat production through livestock and highlight food 3D printing as a solution to the growing needs of the world’s growing population.

Steak chips by Modern Meadow.

Brooklyn-based Modern Meadow has already successfully 3D printed steak chips made from synthetic animal protein. The company has attracted the attention of New York’s wealthiest investors, including the Rockefellers. They are now even 3D printing vegan leather.

3

D printing organic foodChloé Rutzerveld, a Dutch culinary designer, managed to 3D print a structure made of a succession of layers of dough, made of edible soil.

Organic 3D printed food by Dutch designer Chloé Rutzerveld.Mushrooms seeds, spores, and yeast are then added after a few days to offer an innovative and eco-friendly snack.

Food 3D printing in space

The strength of 3D printing is that they enable the production of a wide variety of products with reduced amounts of raw material.

Based on this simple principle, engineers see 3D printing as the ideal technology to feed astronauts on long space missions. Edibles can even last for 30 years in special plastic bags.

3D printed food for seniors:

The ‘Performance’ projectThis initiative plans to make food for the elderly with a 3D printer. Some companies such as Gel Manche already offer products with a different texture, called “smooth food”. This technology restores the product to its original form, but its texture is soft and can be swallowed very easily by people with chewing or swallowing difficulties.

Gel Manche’s 3D printed food menu.How 3D Printing Food Works

How 3D-printed food could change the way we cook and eat

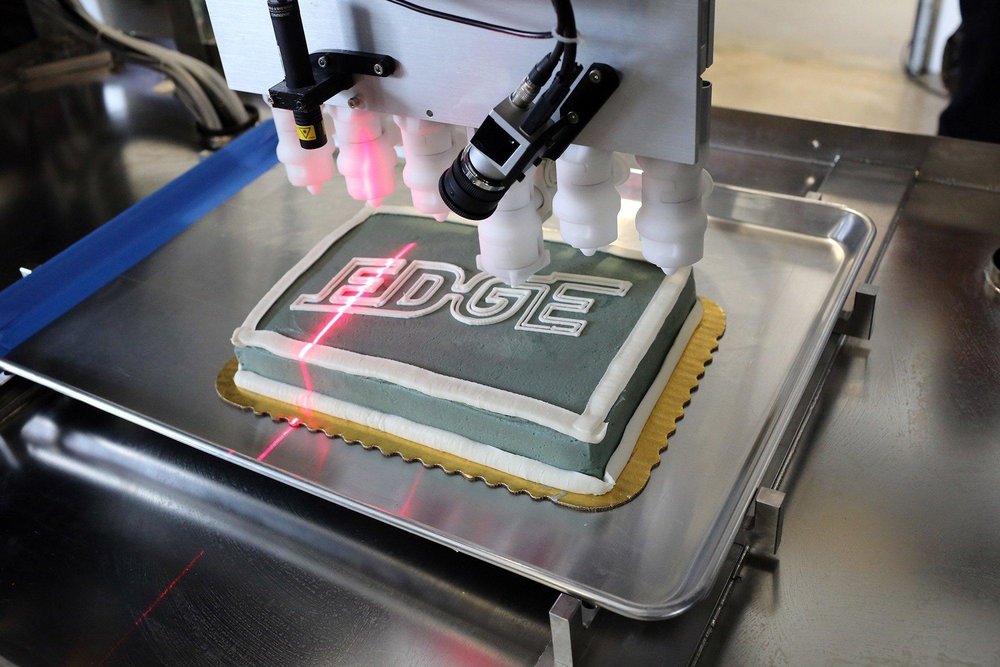

Since the 1980s, steady progress has been made in 3D printing materials, from thermoplastics to metals and now even food. Complicated cake decorations and intricate chocolates take advantage of the complex geometries possible with additive manufacturing (AM) processes. Thanks to multi-nozzle printers, it is possible to print everything from beet, spinach and carrot salad towers to pizzas. How much more appealing might children find soup laced with 3D-printed dumplings shaped like cat paws?

How much more appealing might children find soup laced with 3D-printed dumplings shaped like cat paws?

How to 3D print food

In the world of additive manufacturing, 3D printers extrude thermoplastic and even titanium filaments. When 3D-printed food is extruded, it is deposited by a nozzle guided by an STL file derived from CAD data. The digital information directs the nozzle to deposit “build material” one layer at a time. The extrusion process in a 3D-binding printer requires food of even consistency and proper viscosity for two key reasons: First, it must emerge smoothly from the nozzle. Second, it must maintain its shape upon deposition.

At first thought, the idea of sitting down to a meal of blended, extruded food is uninspiring until one realizes that extruded food is already both commonplace and tasty. pasta, sausages, breadsticks and certain breakfast cereals are all produced via extrusion. The path to tasty extruded food of consistent quality is already well established.

Direct 3D printing of food via extrusion

So exactly how does 3D-printed extruded food make a contribution to gastronomy and the culinary arts?

Chocolate is one of the tastiest of edibles that can be extruded through a heated nozzle to create intricate and creative designs direct from CAD data. The design freedom and customization that 3D printing offers in the food industry is unprecedented.

Traditionally, chocolate creations are produced by pouring liquid chocolate into molds. However, there are two inherent limitations to this process. First, molds are cost-effective for quantity production rather than limited runs. Second, design intricacy is limited by what can be successfully pulled from the mold.

Since no mold is required, it is far easier to maintain the geometry of 3D-printed chocolates from production to consumption. It is also possible to calibrate chocolate’s viscosity so it will maintain geometry as it is laid down on the print bed, layer after layer. AM processes allow for the creation of truly intricate, one-of-a-kind chocolate products. It is even possible for consumers to customize an edible item at a computer and then see their design materialize.

AM processes allow for the creation of truly intricate, one-of-a-kind chocolate products. It is even possible for consumers to customize an edible item at a computer and then see their design materialize.

Belgian chocolate is world-renowned for its quality. Now, a factory in Belgium called Miam (“yum” in French) is using four specialty 3D printers to create ready-to-eat delectable edibles from milk chocolate, dark chocolate or white chocolate. A nearby brewery commissioned The Miam Factory to 3D print chocolate beer bottles that served as memorable awards following an Easter egg hunt.

It is also easy to see how smooth, fluid products like cream cheese and mashed potatoes are amenable to the 3D-printing process. Extrusion systems with multiple nozzles allow for more complex entrees. For example, a multi-nozzle print head can automate pizza-making by depositing dough, sauce and cheese. The same process is possible for extruding different cake batters to create elaborate baked goods.

Mold Printing Food

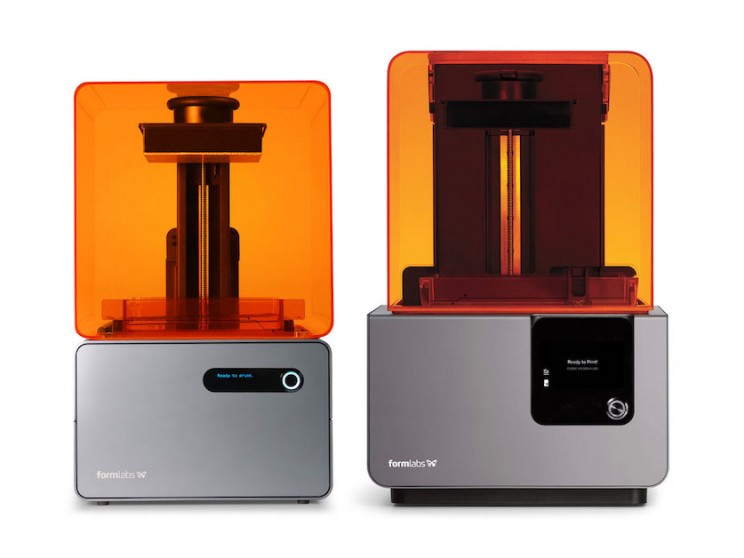

Some foods that begin as liquids cannot be extruded. Flavored gelatin is one example of a food that benefits from using another approach to 3D-printed food. For example, stereolithography (SLA) may take data directly from CAD software to create molds that are then used in food production.

3D-printed molds made of food-safe silicone are also used with chocolate and cake batter. For example, a Ukrainian pastry chef uses 3D printing to fabricate unique spherical cake molds.

Is 3D-Printed Food Safe?

However it is produced, food for human consumption must meet stringent federal requirements designed to ensure safety. When the Food Safety and Modernization Act became law in 2011, those regulations became more stringent than ever. The FSMA, the most sweeping food safety legislation in seven decades, meshes well with the potential for safe 3D-printed food. Eventually, FSMA regulations regarding food safety may amplify the demand for 3D-printed food. What's more, a custom nutrition process may help those with serious food allergies since it is possible to replicate 3D-printed food with such precision.

What's more, a custom nutrition process may help those with serious food allergies since it is possible to replicate 3D-printed food with such precision.

Is Anyone Eating 3D-Printed Food?

Is anyone eating 3D-printed food? The answer is a resounding yes! Novelty items earlier produced by consumer printers have paved the way for professional printers to produce food in restaurants and commercial kitchens.

At one gourmet restaurant in the United Kingdom, everyone is eating 3D-printed food because that is all that is served. The enterprising entrepreneurs at London’s Food Ink decided to push additive manufacturing to its logical extreme. Everything is 3D printed, including the utensils, plates, tables and chairs. At Miramar, a gourmet restaurant in Spain, food printers take on more mundane tasks, freeing chefs to better focus on their creative cuisine.

There is also a practical side to 3D-printed food. “SmoothFood” is already being served at more than 1,000 German nursing homes. Extruded food meets the needs of older residents who have difficulty chewing and swallowing. Various foods, including pork, chicken, potatoes, pasta and peas, are first cooked and then pureed before they are extruded and printed into recognizable shapes. 3D printing allows for food presentations that are visually appealing and therefore appetizing. With the infusion of $4 million from the European Union (EU), 14 companies in five countries are collaborating to expand the reach of SmoothFood.

Extruded food meets the needs of older residents who have difficulty chewing and swallowing. Various foods, including pork, chicken, potatoes, pasta and peas, are first cooked and then pureed before they are extruded and printed into recognizable shapes. 3D printing allows for food presentations that are visually appealing and therefore appetizing. With the infusion of $4 million from the European Union (EU), 14 companies in five countries are collaborating to expand the reach of SmoothFood.

3D-printed food offers both terrestrial and extraterrestrial appeal. If you think the idea of 3D-printed food is “out of this world,” so does NASA. In 2013, it awarded a Small Business Innovation Research (SBIR) Phase I contract to a Texas company so it could explore the potential for printing food on deep space missions. Astronauts would use a modest-sized 3D printer to transform space-saving bulk foods into tasty entrees.

The future of 3D-printed food

In the future, 3D-printed food may help feed the world’s population in a simultaneously sustainable and nutritious manner. For example, researchers at the Netherlands Organization for Applied Scientific Research in Germany print food using a type of algae rich in protein and antioxidants. Expanding protein sources for a growing global population helps ensure ingredient availability.

For example, researchers at the Netherlands Organization for Applied Scientific Research in Germany print food using a type of algae rich in protein and antioxidants. Expanding protein sources for a growing global population helps ensure ingredient availability.

3D food printing

3D food printing

Who needs it and why?

Today, progress is progressing by leaps and bounds: robots are being invented, medicines for previously incurable diseases, people's lives are getting easier every year more and more. One of the young inventions with broad development prospects is 3D printing. Machine parts that are difficult to make by hand, prostheses and even food are printed

In March, the world was delighted by the news of a breakthrough in the field of cooking: in Sweden (in hospitals and nursing homes) they began to prepare food using 3D printing for those who can no longer chew food on their own. For such people who have difficulty chewing and swallowing food, there used to be only one way out - to switch to a "children's" diet, mashed potatoes, cereals, and so on. But if, for example, you want normal food, you still need to grind it. And in the end, no matter how tasty it is, aesthetically it will still be disgusting.

But if, for example, you want normal food, you still need to grind it. And in the end, no matter how tasty it is, aesthetically it will still be disgusting.

“When you have trouble swallowing, you have to settle for food that isn't particularly appetizing. The idea is to make special dishes more attractive by recreating the original shape of the product. That is, the food will look, for example, like a chicken leg, but the consistency will resemble a cream pudding, ”explains Richard Asplund, head of the municipal catering department of the Halmstad district.

The program is currently being implemented on an experimental basis. The project involves researchers from Lund University and the University of Kristianstad, the equipment is offered by Cellink, and 3D printing services are provided by the service bureau Addema.

Residents of nursing homes in Halmstad and Helsingborg will serve as the jury for the pilot project.

So, it's worth understanding how 3D printing appeared, how printing devices work and what prospects await this technology in the future.

How did it all start?

History

1948

1948

The history of 3D printers dates back to 1948, when the American engineer Charles Hull developed a technology for layer-by-layer growth of physical three-dimensional objects. She got the name Stereolithography (stereolithography).

1985

1985

Mikhailo Feigen proposed to form three-dimensional models in layers from film, polyester, plastic, paper, fastening the layers together using a heated roller.

1986

1986

Carl Descartes came up with the idea of sintering powder material (powder polymers, metals, casting wax, nylon) layer by layer with a laser beam.

1987

1987

The world saw the first 3D printer in history.

True, at that time the apparatus was called a "installation for stereolithography".

In 1987, the Israeli company Cubital developed a layered sealing technology. However, it requires the use of expensive, toxic, and fairly rare polymers.

However, it requires the use of expensive, toxic, and fairly rare polymers.

1988

1988

Scott Crump described the FDM method.

Printers using this technology print objects with a molten thread of a substance (plastic, metal, etc.), which was later used to print food.

1995

1995

Until 1995, 3D printing was used only in industry, until MIT students Jim Bredt and Tim Anderson introduced the technology of layer-by-layer synthesis into the body of a conventional desktop printer.

Early

2000s

Early

2000s

3D Systems also launched its first "home" 3D printer. After that, these devices began to actively penetrate into everyday life.

How does it work?

Technology analysis

The first food from a 3D printer was obtained several years ago using the Fab@Home printer. The heart of the machine is a syringe that works on the same principle as inkjet printers. Layer by layer, he lays down a viscous liquid, forming an object of a given shape.

Layer by layer, he lays down a viscous liquid, forming an object of a given shape.

The university made the drawings of this printer publicly available, to the delight of many enthusiasts. People began their own experiments with epoxies and silicones. At the same time, gourmets appeared who began to put cheeses, glazes, etc. into the printer. It can use anything that is forced through the head of the syringe.

Instead of repeating already existing organic objects, it is much more important to learn how to create new products with individualized nutritional value.

Let's say a person needs more calcium or omega-3 fatty acids in their diet, why not print out the appropriate foods for them. Van Bomel's team is addressing just such a problem, it is they who are developing food printing technology for people with impaired chewing and swallowing functions. Printed products can use cheaper protein sources. It is more convenient, and besides, the cost of such products will be less. But a significant obstacle is the slow speed of 3D printing from edible components, after each layer is applied, one or another time is required for it to solidify.

But a significant obstacle is the slow speed of 3D printing from edible components, after each layer is applied, one or another time is required for it to solidify.

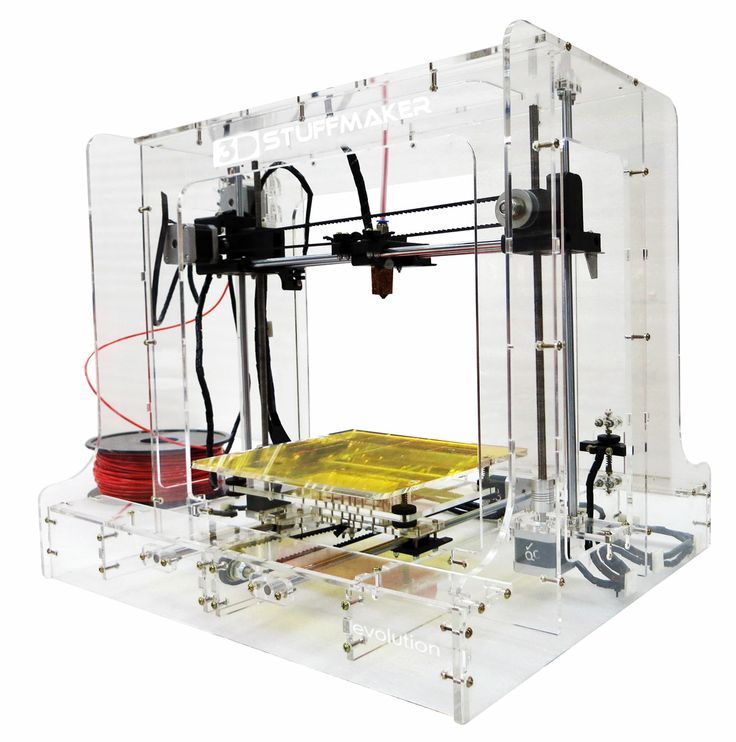

What are printers?

Great variety of food printers

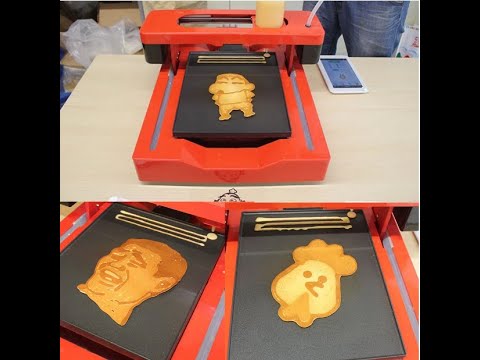

- Pancakebot. Structurally, it is similar to any food 3D printer, but it only prints pancakes of any given shape and immediately fries them;

- Choc Creator 2.0 Plus, Chocola3D, etc. - specialized printers for printing chocolate;

The above examples were taken from the sales site, that is, these printers can already be bought, they have entered the general sales market. But there are also more complex devices that exist almost in a single copy.

- Foodini by Natural Machines is the answer to the eternal question of healthy eating. Foodini users can cook with fresh ingredients, create a variety of pastas, and place them in reusable capsules, which are then printed in any 3D shape;

- Food printer for NASA from SMRC. Using raw ingredients packaged in capsules, SMRC's food printer can combine different individual ingredients to print a wider variety of foods;

Using raw ingredients packaged in capsules, SMRC's food printer can combine different individual ingredients to print a wider variety of foods;

Future prospects

What's in store for this relatively new but rapidly evolving technology? Will it develop in highly specialized areas or will it go to a wide market, or will it succeed everywhere?

3D food printing is not justified these days. But in space it can be a real salvation. Michel Terfansky of the University of Southern California explored this concept in his thesis project. He learned about the occasional annoyance of astronauts on the International Space Station with poor diets. With the help of 3D printers, friends and family could send recipes to Earth messengers. 3D printers will help save space and rid the ship of warehouses of meat and vegetables. Terfansky believes that this technology will make people happier.

Also, 3D printed food can be used to create foods with a specific nutritional value and texture for the elderly that are easy to chew and swallow.

Other uses include home cooking and personalized candy and sweets.

One way or another, 3D printing will one day, if not completely replace the product market, then at least displace a significant part of it. It will become more convenient, less expensive, more environmentally friendly. It will give more opportunities and more problems associated, for example, with device maintenance. Whether this is good or bad is your food for thought.

Text: Koryakina Anastasia, Krylova Lyubov, 2nd year student of the Faculty of Journalism, Lomonosov Moscow State University

Photo: site https://make-3d.ru/wp-content/uploads/2019/04/CELLINK -BIO-X-Main-1-768x538.png, site http://3dplemya.ru/images/site/food-1.jpg, site https://3dpechataem.ru/wp-content/uploads/2019/03 /28cc36f26ab511cbf51a69f8057e1e26-1.jpg, site http://priyoid.com/wp-content/uploads/2014/11/Foodini-3d-printer-1024x682.png, site https://3d-daily.ru/wp-content /uploads/2014/12/foodini-interview_2.jpg, site https://3dfly. com.ua/sites/default/files/u8/culinary-09-3d_printed_sugar_cubes_coffee-1024x554.jpg, site https://www.pvsm.ru/images/2015/01/26/3D-Systems-na-perednem-krae-trehmernoi-pechati.jpg, site http://3d_print.jofo .me/data/userfiles/5015/images/998976-image09.png, site https://vsevesti24.ru/wp-content/uploads/2018/02/food_main.jpg, site https://s.giftopix.com /uploads/sp92oqt9ko4dupn6c9ma6t65c4/15347021235b79b22b84dc11.32528796.jpeg, site https://www.ricorsiscuola.it/wp-content/uploads/2018/05/ricorso-riforma-professionali-a-66-tic-concorso-scuola-docenti. jpg.

com.ua/sites/default/files/u8/culinary-09-3d_printed_sugar_cubes_coffee-1024x554.jpg, site https://www.pvsm.ru/images/2015/01/26/3D-Systems-na-perednem-krae-trehmernoi-pechati.jpg, site http://3d_print.jofo .me/data/userfiles/5015/images/998976-image09.png, site https://vsevesti24.ru/wp-content/uploads/2018/02/food_main.jpg, site https://s.giftopix.com /uploads/sp92oqt9ko4dupn6c9ma6t65c4/15347021235b79b22b84dc11.32528796.jpeg, site https://www.ricorsiscuola.it/wp-content/uploads/2018/05/ricorso-riforma-professionali-a-66-tic-concorso-scuola-docenti. jpg.

Sources: website http://www.3dpulse.ru/news/eda/v-shvetsii-v-domah-prestarelyh-budut-podavat-3d-pechatnuyu-edu-pozhilym-lyudyam/, website https://www. rutvet.ru/in-istoriya-sozdaniya-3d-printerov-i-ih-princip-raboty-8253.html, site https://yandex.ru/turbo?text=https%3A%2F%2Fkakdelateto.ru%2Fpechat -edyi-na-3d-printere-vozmozhno-li-eto%2F, site https://mplast.by/encyklopedia/3d-printer/, site https://top3dshop.ru/blog/review-food-3d. html, site https://m.my3dpoint.ru/blog/novosti/3d-pechat-edy/.

html, site https://m.my3dpoint.ru/blog/novosti/3d-pechat-edy/.

characteristics, pros and cons of each model

07.04.2021

Content

-

- What is a food 3D printer

- Field of use

- used raw materials

types of food 3D-pri-priori - What is a food 3D printer

- Top 10 Best Food Printers: A List of the Most Current Models

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus 3D Food Printer with Cooling Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- 8. Mmuse – Chocolate 3D Printer PancakeBOT5 Printer F5

- 10. ZMorph VX

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking.

Here are the top best 3D food printers in different price categories for people who are fond of cooking.

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer.

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with glaze

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes;

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

Confectionery drawing is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. Wafer paper is made from rice flour and does not have a particular taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used.

Shock transfer paper is completely transparent and suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used.

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database. The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges;

-

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies.

Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

Such printers print an image on pre-prepared paper: rice, wafer or shock transfer; -

Food plotters transfer the image not to paper, but directly to the finished product. For example, a plotter is used to transfer an image directly onto a cake.

There are several types of food 3D printers:

-

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe;

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products.

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Choc Edge |

Available on credit. To checkout, add the product to the cart and follow the instructions Go

| Manufacturer | Wiiboox |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Choc Edge |

Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market. The top is based on ratings and customer reviews.

The top is based on ratings and customer reviews.

1. PancakeBot 2.0

PancakeBot 2.0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

-

Ease of operation;

-

A wide range of proposed projects;

-

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment.

Pros:

-

Versatility: the ability to print not only sweet dishes, but also side dishes;

-

Attractive appearance;

-

High build quality;

-

Convenient control by touch panel.

Cons:

-

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate.

Pros of :

-

Attractive appearance;

-

Uninterrupted work;

-

Durability;

-

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Food 3D printer Choc Creator V2.0 Plus with cold chamber

Food 3D printer Choc Creator V2.0 Plus with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs.

Pros of :

-

Availability of a cooling system for finished products;

-

High printing precision;

-

Long service life;

-

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

-

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients.

Pros:

Cons:

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients.

Pros:

-

The ability to create unique flavors;

-

Neat and bright printing;

-

Aesthetic appearance of the device.

Cons:

-

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

-

Practicality;

-

High build quality;

-

Attractive appearance;

-

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision.

Pros:

-

Ease of operation;

-

High build quality;

-

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling.

Pros:

Cons:

-

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing:

-

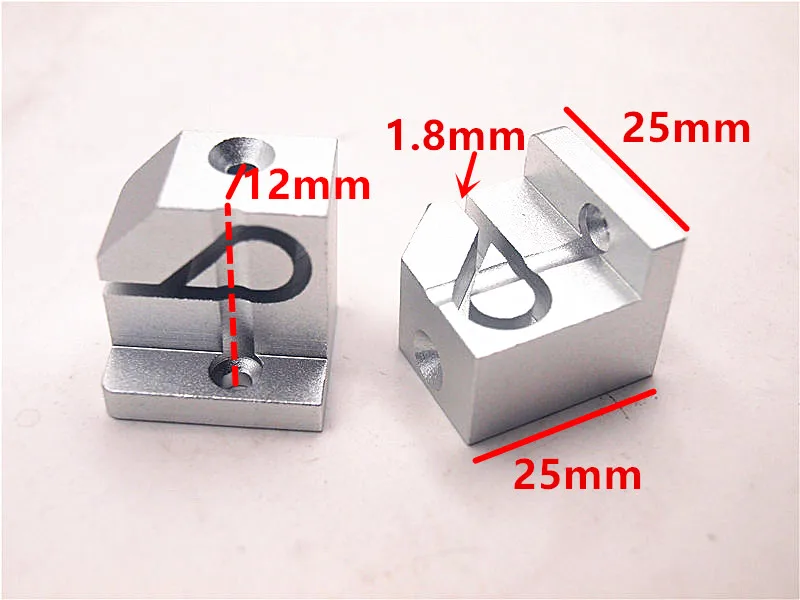

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

-

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

-

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

-

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Learn more