3D printer bay reviews

3DPrintersBay Reviews | Read Customer Service Reviews of 3dprintersbay.com

5-star

77%

4-star

6%

3-star

3%

2-star

5%

1-star

9%

BI

Brian Ivie1

review

Ok so I didn't do my due diligence on…

Ok so I didn't do my due diligence on reviewing 3d printers bay before ordering. I then got online after I ordered my cr10 pro v2 and got scared thinking this was a scam site. I called PayPal and they told me I needed to wait 5 days before making a claim. That day I got a ups tracking # from them. The second day it was shipped from California the third day it was delivered to my home in utah. 3 days total I received a brand new in box perfect condition cr10 pro v2 exactly what I ordered way cheaper than any other site. I agree with some other reviews that this is a company that has problems just like any other. My experience was perfect take that for what it's worth.

Date of experience: March 10, 2022

Advertisement

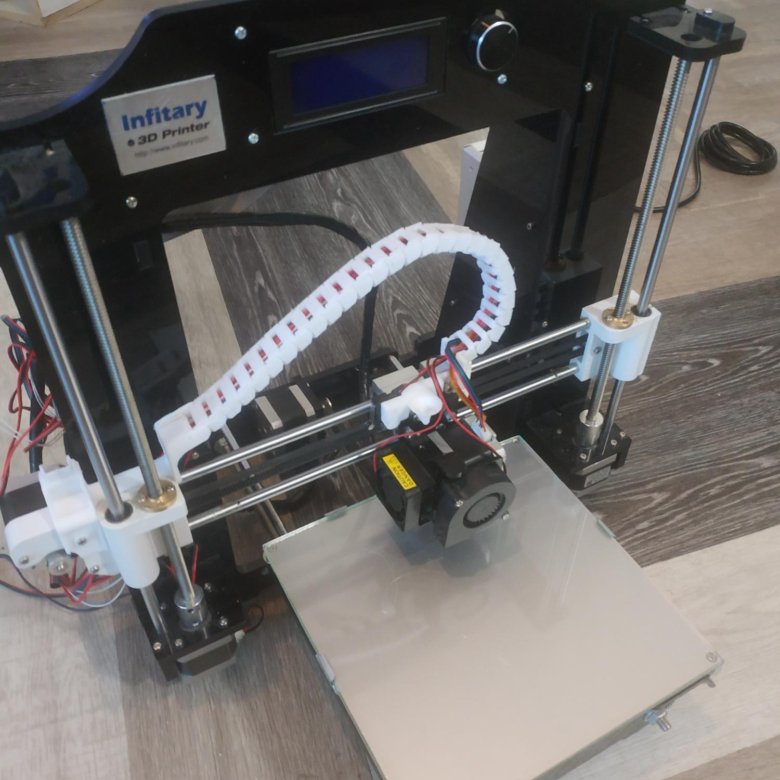

Take a look

FB

Forrest Byrd1

review

Very happy with fast delivery Sidewinder X2

I received the Artillery Sidewinder X2 a few days ago. Delivery was about 9 days, and was tracked using UPS Tracker. The printer assembly was simple; only 3 large pieces with screws already installed. Some instructions for bed leveling were not fully clear, but YouTube helped here. Prints were much faster than the Ultimaker 3, and were perfect; no strings, and smooth, using PLA+ from Micro Center. The touch screen looks good, but has had some mis-touches (maybe needs calibration). Still, I like this 3D printer. Very happy with the printer and the delivery.

Delivery was about 9 days, and was tracked using UPS Tracker. The printer assembly was simple; only 3 large pieces with screws already installed. Some instructions for bed leveling were not fully clear, but YouTube helped here. Prints were much faster than the Ultimaker 3, and were perfect; no strings, and smooth, using PLA+ from Micro Center. The touch screen looks good, but has had some mis-touches (maybe needs calibration). Still, I like this 3D printer. Very happy with the printer and the delivery.

Date of experience: February 04, 2022

SI

Sparksfli Inc.2

reviews

It came!!! Everything is perfect! Shipping because of the pandemic delayed the shipment. I am printing without any issues!

I ordered my Ender 3 v2 on New Years Eve. It has been 3 weeks, and all I get is a run around. The communication is lackluster, and the responses that I get tell me that my printer is NOT coming from a "warehouse" in the U.S.

It has been 3 weeks, and all I get is a run around. The communication is lackluster, and the responses that I get tell me that my printer is NOT coming from a "warehouse" in the U.S.

Last purchase ever from 3dprintersbay.com

1/26 Just got an email saying that they are waiting for a shipment from factory. Could be another 7 to 10 days for them to recieve, and an additional 3-5 to ship to me.

Date of experience: January 25, 2022

ND

Neptune's Dog Training and Obedience2

reviews

I bought two printers from them

I bought two printers from them, The Ender 5+, and the FLSUN QQS-Pro. Neither printer has ever worked without major maintenance. The QQS-Pro arrived with terribly damaged belts, had to be repaired, and even when repaired, never worked quite right. When I contacted PIRATEbay about it, they put me onto a FLSUN person and left the chat. That was their customer service.

When I contacted PIRATEbay about it, they put me onto a FLSUN person and left the chat. That was their customer service.

The Ender 5+ has never worked well either, and the extruder arrived in bad shape. Again, their answer is to put you onto a rep from the other company, and disappear. Two strikes is enough for me, I'm not giving them another chance. You shouldn't either.

Date of experience: December 06, 2021

Daniel Sweeney3

reviews

Great, fast service, good prices

Could have bought my printer direct from the manufacturer, price was about the same, but thought having a USA company provide it in case of any issues was a good idea.

I am very pleased that I did. There was a minor shipping issue with the manufacturer, and Andy responded to my email within the hour to set it straight. Everything arrived in pristine condition and my first several prints came out perfect. I will be continuing to use 3DprintersBay with confidence.

Everything arrived in pristine condition and my first several prints came out perfect. I will be continuing to use 3DprintersBay with confidence.

Thanks!

Date of experience: August 28, 2021

Advertisement

DG

David Gus1

review

These have to all be fake reviews

These have to all be fake reviews. Their customer service is horrible. Printer came broken it's been a month still no part. They want me to redo a ticket that's already been done with the manufacturer. They will make you deal with the manufacturer and not do anything to make it right. You will have to pay shipping to send it back. You are taking a gamble when you order from them I hope your printer doesnt have any issues. I am out to warn any and everyone. Terrible experience.

Terrible experience.

Date of experience: July 25, 2021

TI

Tim1

review

International 3D Printer Order

I ordered a Sonic Mighty 4k from 3DPrintersBay; communication from their support team was phenomenal - I was provided with accurate information regarding backordered items, as well as fantastic assistance and guidance in dealing with customs to ensure my printer arrived quickly. Highly recommend them, and will be using them for resin re-supplies in the future.

Date of experience: May 13, 2021

PS

Poison Snakescandy2

reviews

3DPrintersBay is a wonderful company!

3DPrintersBay is a wonderful company! , I ordered the Ender5 Pro 3D Printer , they had the best price online , I placed my order with free shipping and it arrived at my door in two days! , if you need a printer this is the company you want to purchase from , best price and fast shipping!! , Thank you 3DPrintersBay

Date of experience: May 22, 2021

JA

James3

reviews

I am happy with my purchase.

After a bit of research, I decided to buy the Ortur 20w laser. It was delivered in about a week. I am not very experienced with this type of equipment, but there was plenty of support and youtube videos. It does everything I need, from lettering to photo engraving. I am happy with my purchase.

Date of experience: June 07, 2021

Advertisement

Kevin Cantrell11

reviews

This company is awesome they provided…

This company is awesome they provided my products quick than initial predicted. The products from Phrozen come well packaged and very little assembly is necessary. 3DPrintersBay was great. I couldn't have asked for more they really went out for me. I appreciate everything 3DPrintersBay and Phrozen did to get me my products for a project I was working. Very grateful to them.

Very grateful to them.

Date of experience: January 26, 2021

HJ

Howard James1

review

Great company

Great company. Family run. They go above and beyond what is expected I highly recommend them. My Photon S was delivered well protected and exactly on time from California warehouse. It took about 10 minutes to get my first print going. I’ve heard a few people complain that plastic casing seem breakable. I don’t really slam my printer around. So I’m not worried. All the critical parts seem rock solid.

Date of experience: December 22, 2020

H.

H.K.KING1

review

BEST IN BUSINESS and MOST AFFORDABLE IN THE BUSINESS, BLAZING FAST SHIPPING ⚡

This is the best online store for your 3D print needs, unbeatable prices, shipping so fast, The Flash couldn't keep up!

Ordered on a Wednesday and by Friday I went out to check the mail and almost tripped over my NEW CREALITY ENDER 3 V2 on my porch!

THIS COMPANY IS AWESOME!

MUCH LOVE 💛

Date of experience: April 26, 2021

RH

Ronald Heath2

reviews

I purchased a Geeetech A20T

I purchased a Geeetech A20T. The printer arrived quickly and I was impressed with how easy it was to receive great service from 3DPrintersBay.

The printer arrived quickly and I was impressed with how easy it was to receive great service from 3DPrintersBay.

The printer was well packed and was really easy to set up. I have printed numerous things now with no problems.

If you buy one of these three color mixing printers, remember to reset after each print when using SD card, or it will choose the wrong color to start.

Date of experience: August 14, 2020

Advertisement

Rick Lohre1

review

Ordered two laser engravers and an…

Ordered two laser engravers and an accessory. Received on laser engraver and accessory. When questioned about the order and shipment, they put me in touch with the manufacturer. I doubt this is even a US based company but a front for a Chinese based company. As of two weeks later, the second laser has still not shipped!

As of two weeks later, the second laser has still not shipped!

Date of experience: December 21, 2020

QZ

Quinn Zhang1

review

Great experience

I bought a Creality 3d Printer and I had a great experience with 3DPrintersBay: (1) that's the best price I found all over the internet; (2) customer service was fast and effective; (3) shipping was fast and my printer was delivered within only 3 work days in the US; (4) my printer is now setup and running perfectly.

Date of experience: December 24, 2020

EB

Elliot Blanford1

review

Is this a real company?

Ordered a 3D printer on Black Friday from here. They had a great price and the order processed on December 1. It’s now December 30 and nothing has shipped and customer service is not responding. I want to give them the benefit of the doubt but hmmm...

They had a great price and the order processed on December 1. It’s now December 30 and nothing has shipped and customer service is not responding. I want to give them the benefit of the doubt but hmmm...

EDIT: Ok they are a real company at least. I know this because they tried to contest my review lol. Also, I finally got the gift that was ordered on black friday. It arrived January 15. Merry Christmas I guess. Good job guys I'm bumping you up to 2 stars

Date of experience: December 30, 2020

EH

E House2

reviews

They are the best in the market!

I had a wonderful experience ordering a laser from 3dPrintersbay. In less than 2 weeks it was delivered, a day earlier than expected. Such a great experience the day after it arrived I ordered a second laser.

Don’t waste time, effort or money on the other guys, 3dPrintersbay is the way to go.

Date of experience: February 27, 2021

Advertisement

EM

Erin Matthews1

review

Fast Delivery and quick email responses

After checking nearly every site that sell the 3D printer I was searching for, I found that delivery times were 3-4 weeks out. 3D Printers Bay had delivery marked at the standard 3 weeks but to my surprise, my Phrozen Sonic Mini arrived in just a little over 2 weeks. That made my faith in 3D Printers Bay justified and I have brought all of my business associates to them.

Date of experience: May 27, 2020

JG

John Govin1

review

Great customer service

I had a unique situation in buying a laser engraver. The customer service went above and beyond to ensure I could complete my purchase. They had by far a much better price than the consumer giants out there. Shipping was timely, product as advertised. Great job overall.

The customer service went above and beyond to ensure I could complete my purchase. They had by far a much better price than the consumer giants out there. Shipping was timely, product as advertised. Great job overall.

Date of experience: May 13, 2021

IX

Indrid X.1

review

Solid Experience

I ordered the printer on backorder and the printer came in much earlier than expected in great condition. I contacted them to check the status of the printer and they were incredibly helpful.

EDIT: The printer itself came with the no name power supply, not the meanwell that the "branded powersupply" in the description would suggest. Printer still works fine for me either way.

Date of experience: May 05, 2020

Take a look

Advertisement

About 3DPrintersBay

Information provided by various external sources

Buy Best 3D Printers from the Original Authentic 3D Printer Manufacturers at the Best Prices. #1 3D Printers Marketplace.

#1 3D Printers Marketplace.

Contact

Categories

- Media Company

- Online Marketplace

The Trustpilot Experience

Anyone can write a Trustpilot review. People who write reviews have ownership to edit or delete them at any time, and they’ll be displayed as long as an account is active.

Companies can ask for reviews via automatic invitations. Labeled Verified, they’re about genuine experiences.

Learn more about other kinds of reviews.

We use dedicated people and clever technology to safeguard our platform. Find out how we combat fake reviews.

Here are 8 tips for writing great reviews.

Verification can help ensure real people write reviews about real companies.

It goes against our guidelines to offer incentives for reviews. We also ensure all reviews are published without moderation.

We also ensure all reviews are published without moderation.

Take a closer look

3d Printer's Bay Marketplace Nightmare : 3Dprinting

I recently had an experience trying to purchase a 3d Printer, the Ender5, from 3D Printer's Bay Marketplace. In the process of attempting to purchase the printer, I used their contact form or anyhow tried to. The first contact attempt was for the Tuesday business day, the next for the Thursday, and then the Friday business day. I ended up in the time elapsed getting a lost cart email. I decided to use a reply to that to contact them. Several hours later, I decided to post on Trust Pilot about my experience. After that post I quickly got a response and then got another email to please take it down since they had a "SEV1 incoming email issue". I find it hard to believe that they could have a complete failure of their incoming email and yet get my incoming email.

They informed me in that same email that the issue was under investigation. How can ANY business sped four days not knowing they had a major fault with their only posted method of contact with them? So I went and updated my post that they obviously had no idea they had this kind of issue.

How can ANY business sped four days not knowing they had a major fault with their only posted method of contact with them? So I went and updated my post that they obviously had no idea they had this kind of issue.

Another email from them... taking exception to my updated post. And they also reported my Trust Pilot posting. I updated the post at that point to reflect that they did not actually know they had an issue. I got another email from them as well. Basically techno gibberish trying to claim that incoming and outgoing mail protocols are different depending on origination. Last I checked SMTP and POP3 protocols are the same everywhere.

Here is the trust pilot post in the event that they force me to take it down.

To date I have yet to even purchase a printer from this company. I have contacted them 3 times over 4 days with pre-purchase shipment questions and I have yet to get a response. HOWEVER I did get a reminder from them that I left the printer in my cart and hey go back and make the purchase please.

This level of pre-sale service is making me reconsider the advisability of purchasing anything from them at any point.

UPDATE:

The company did respond to my 4th contact attempt. However, that response came 1 hour after my initial posting here. Followed 2 hours later by a request to take this review down. In the request to take it down, they cited a SEV1 issue with their incoming (previous word added as a correction) email system. However, a SEV1 issue would have prevented them from responding to me as they would never have even gotten my incoming email.

They also knew that if there was an issue for several days(see second update). IF there was an issue of this severity, they should have posted a notice about it on their contact form page along with a notice to email them directly. This wasn't done.

After getting the response from them and the following up request to remove the this review, I did a little due diligence on this company. They are not BBB accredited. The BBB score of 3dprintersbay.com is an F. The business does not post an accurate address on their website. Additionally, when I located the address on the BBB website, I checked it on Google Maps. One way is a multi-way intersection, the other way is between two houses in a residential area in a small town.

The BBB score of 3dprintersbay.com is an F. The business does not post an accurate address on their website. Additionally, when I located the address on the BBB website, I checked it on Google Maps. One way is a multi-way intersection, the other way is between two houses in a residential area in a small town.

Reddit posters routinely complain about the communication, or total lack there of from the company.When there is an issue with a product they simply refer the one making contact to the vendor, even when the issue is a lack of reply from the vendor. This results in an empty loop of communication.

Everything I have found out about this company leads me to believe they are not to be trusted.

UPDATE TWO:

The vendor in question has reported this post because of "technical issues". Incoming Mail server issues. Yet they got the email I sent them directly.

To state for the record, I am not going to use 3dprintersbay for this purchase based on my experience so far and the research I did during the buying process.

I will correct my first update where I stated that the company knew about the issue for several days prior to contacting me. Based on the email from Andy they did not even identify that their only communication information posted on their website had been broken since sometime early Tuesday morning till after I emailed Friday. They took exception in an email to me that they did not even know to post a notice until after I contact them. This is the correction to that error on my part.

Obviously this vendor will take any approach to removing negative feedback. Reporting bad reviews. In other cases I've come across in my research offering discounts for removal of bad reviews. It has become increadingly obvious that they will take any means necessary to prevent people from voicing their negative experiences about their business.

Overview of current 3D printers for production, printing with refractory materials (PEEK, PEKK, PAEK, Ultem, etc.)

The article applies to printers:

Zortrax Endureal TotalZ Anyform 1200-PRO/PRO(2X) TotalZ Anyform 950-PRO/PRO(2X)

Today we will get acquainted with the real industrial giants - 3D printers that are used in various industries. Their main feature is the high heating temperature of the extruder, which allows printing with refractory materials. The review presents equipment from Russian manufacturers, Chinese industrial 3D printers, as well as European and American brands.

Their main feature is the high heating temperature of the extruder, which allows printing with refractory materials. The review presents equipment from Russian manufacturers, Chinese industrial 3D printers, as well as European and American brands.

Contents:

- Equipment of Russian manufacturers

- Chest SM-A284

- F2 Pro

- Total Z AnyForm PRO Series (HOT+)

- Equipment of foreign manufacturers (China)

- CreatBot F1000

- CreatBot PEEK 300

- IEMAI MAGIC-HT-MAX

- IEMAI MAGIC-HT-PRO

- Intamsys Funmat PRO 410

- Intamsys Funmat PRO 610 HT

- Equipment manufacturers from Europe and America

- Stratasys Fortus 450mc

- Stratasys F900

- 3DGence Industry F421

- 3DGence Industry F350

- 3DGence Industry F340

- Zortrax Endureal

- Which 3D printers print with thermoplastics?

- Why are refractory materials so good?

Russian equipment

Domestic manufacturers do not remain in the shadows, and develop really cool equipment that perfectly copes with printing with refractory materials.

► Casket SM-A284

Industrial FDM printer Casket SM-A284 is a development of KBSM JSC, which was intended to solve the company's own problems. This robust, reliable and stable additive plant can operate in any environment.

Spacious print chamber with build area of 300x300x300 mm and heated bed allows you to achieve high-quality results. The unit is compatible with most refractory and general purpose materials. The company continues to introduce new technologies and materials that will be available to users after trials and tests.

Casket SM-A284 has 2 high-temperature extruders (with heating up to 500⁰С). Their lightweight design ensures stability when working at high speeds.

For comfortable work, the box is equipped with a powerful ventilation system and a built-in Wi-Fi module.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer body: Closed

- Thread diameter: 1.

75 mm

75 mm - Extruder type: Bowden

- Number of print nozzles: 2 pcs.

- Independent extruders: Yes

- Number of independent extruders: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 180°C

- Print chamber temperature: 130°C

- Print area: 300x300x300 mm

- Calibration: Automatic

- Print/grow speed: 120 mm/s

- Layer thickness: 0.05 mm

- XY-axis accuracy: 0.05 mm

- Number of colors: 2 colors

- Video camera: Yes

- Supported materials: PLA, ABS, PETG, HIPS, TPU, PA, PC, PPSU, PA/CF, ASA, ESD-Safe, ULTEM, PEEK

► F2 Pro

An industrial printer with endless possibilities. FDM equipment works on the unique F2 technology, which allows you to heat the extruder to operating temperature in just 3 seconds. High accuracy of temperature maintenance (up to 0.3⁰С) allows to achieve unsurpassed quality.

F2 Pro has a large print area of 1000x600x1000 mm, which allows you to set up mass production or production of large-sized parts. The F2 Pro has everything you need in industrial printing: a heated chamber with forced air convection, quick-change extruders with a nozzle setting from 0.15 to 1 mm, and an automatic calibration platform.

The 3D printer is equipped with electronics developed by the company, but nevertheless, the operation of the printer remains intuitive.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of print nozzles: 2 pcs.

- Independent extruders: Yes

- Number of independent extruders: 2 pcs.

- Extruder temperature: 550 °C

- Table temperature: 140 - 160 °C

- Print chamber temperature: 80 - 160 °C

- Print area: 1000x600x1000 mm

- Calibration: Automatic

- Print/grow speed: 150 mm/s

- Layer thickness: 50 - 500 µm

- XY accuracy: 5 µm

- Z-axis accuracy: 2 µm

- Number of colors: 2 colors

- Nozzle: 0.

4 - 1 mm

4 - 1 mm - Supported materials: PETG, ABS, PEKK, SBS, PEI, PEEK-CF, PC, Nylon, PA and derivatives, Flex, TPE, TPU, etc., ABS-PC, PEEK, WAX3D, Ultem, PLA, HIPS, ASA, PP

► Total Z AnyForm series PRO (HOT+)

We decided to present this series of industrial 3D printers with 3 models: 1200 PRO(HOT+), 950 PRO (HOT+) and 650 PRO (HOT+), which differ only in the construction area . Total Z AnyForm PRO has several configurations, including those with a high-temperature heating module for the HOT + extruder. The HOT+ series printers have 2 independent extruders with a maximum heating temperature of up to 500⁰С, which allows you to work with materials such as ULTEM, PEEK, PPSU, PSU, PEI, as well as with the original material of TOTAL-PEEK's own production.

AnyForm 1200 PRO (HOT+) with a construction area of 1200x650x1200 mm is one of the largest FDM devices on the market. The 3D printer can easily cope with printing large-sized products or mass production.

AnyForm 950 PRO (HOT+) with a construction area of 950x650x950 mm and 650 PRO (HOT+) with 650x500x650 mm have all the advantages of the older model. They can print multiple materials at the same time, which can be fed automatically, up to 4 spools of 2.5 kg without operator intervention.

AnyForm PRO (HOT+) 3D printers are complete workstations equipped with a computer. Mobile units are easily integrated into production.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 1 pc. (option 2 pcs.)

- Extruder temperature: 500°C

- Table temperature: 200°C

- Print chamber temperature: 300°C

- Print area: 650x1200x1200 mm

- Layer thickness: 50 µm

- Full color printing: No

- Heated table: Yes

- High Temperature Printing: Yes

- Video camera: Yes

You can find the full catalog of Total Z equipment on our website.

Equipment of foreign manufacturers (China)

China's 3D equipment industry has long since stepped forward. The largest manufacturers create equipment for various industries - from medicine to heavy and defense industries. Industrial high-temperature 3D printers from Chinese companies are easily introduced into production of any scale.

► CreatBot F1000

Manufacturer's top model with the largest build area. The printable area of 1000x1000x1000 mm allows you to implement almost any project. Versatile equipment has a wide range of features for comfortable printing, as well as a camera to monitor progress and built-in Wi-Fi module. Heated oven and heated table with auto leveling function for high quality prints.

The maximum extruder temperature of 420°C allows the CreatBot F1000 to print on a variety of materials, including engineering and high-temperature plastics - Carbon Fiber, Nylon, PC and others.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 420°C

- Table temperature: 100°C

- Print chamber temperature: 60°C

- Print area: 1000x1000x1000 mm

- Calibration: Automatic

- Print/grow speed: 120 mm/s

- Layer thickness: 50 µm

- XY-axis accuracy: 0.011 mm

- Z-axis accuracy: 0.0025 mm

- Heated table: Yes

- High Temperature Printing: Yes

- Video camera: Yes

- Plastic detection: Yes

- Resume system: Yes

- Supported materials: PLA, ABS, PETG, HIPS, PVA, Carbon Fiber, Nylon, PC, TPU, PEEK, ULTEM

► CreatBot PEEK 300

A professional, high performance 3D printer built for the toughest jobs. Thanks to the extruder with a heating temperature of up to 500°C, it can work with most refractory materials. The heated chamber and working platform allow you to get the highest quality result, without delamination and deformation.

Thanks to the extruder with a heating temperature of up to 500°C, it can work with most refractory materials. The heated chamber and working platform allow you to get the highest quality result, without delamination and deformation.

The CreatBot PEEK 300 has a build area of 300x300x400mm which is ideal for making small items, mass production of small objects or printing for science and research applications.

The industrial unit is equipped with all the successful CreatBot solutions - a built-in filtering system, a convenient color touchscreen for control, high-quality cooling and others.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 200°C

- Print chamber temperature: 120°C

- Print area: 300x300x400 mm

- Print/grow speed: 150 mm/s

- Layer thickness: 40 µm

- Heated table: Yes

- High Temperature Printing: Yes

► IEMAI MAGIC-HT-MAX

The IEMAI MAGIC-HT-MAX 3D printer is designed specifically for tough environments and can handle any task. This 3D printer has everything you need for high-quality thermoplastic printing - a high temperature extruder, a heated chamber and print platform, as well as a built-in progress camera.

This 3D printer has everything you need for high-quality thermoplastic printing - a high temperature extruder, a heated chamber and print platform, as well as a built-in progress camera.

IEMAI MAGIC-HT-MAX can handle a wide range of materials. A special box for loading, storing and drying plastic before printing allows you to achieve impressive results.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 180°C

- Print chamber temperature: 150°C

- Printing area: 500x500x700 mm

- Print / grow speed: up to 150 mm/s

- Layer thickness: 0.

05 – 0.3 mm

05 – 0.3 mm - XY Accuracy: 2.5 µm

- Z-axis accuracy: 0.78 µm

- Number of colors: 2 colors

- High Temperature Printing: Yes

- Video camera: Yes

- Nozzle: 0.4 - 1 mm

- Supported materials: PEEK, CF-PEEK, PEKK, CF-PEKK, PEI 1010/9085, PPSU, PC, CF-PC, PA, CF-PA, GF-PA, ASA, ABS, CF-ABS, PETG HIPS , TPU, PLA, CF-PLA, PVA

► IEMAI MAGIC-HT-PRO

The IEMAI MAGIC-HT-PRO professional high temperature 3D printer can be placed on the table or on the floor. This fairly compact printer can be used for high-quality functional prototypes and small-scale production.

Robust metal housing and carbon filtration system make it possible to work even in small production areas. The 3D printer has impressive precision and high performance.

The printer comes with a cabinet-stand, which also serves as a compartment for storing material.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer body: Closed

- Thread diameter: 1.

75 mm

75 mm - Number of print nozzles: 2 pcs.

- Independent extruders: No

- Extruder temperature: 500°C

- Table temperature: 170°C

- Print chamber temperature: 120°C

- Printing area: 310x310x410 mm

- Print/grow speed: up to 150 mm/s

- Layer thickness: 0.05 – 0.3 mm

- XY Accuracy: 12.5 µm

- Z-axis accuracy: 1.25 µm

- Number of colors: 2 colors

- High temperature printing: Yes

- Video camera: Optional

- Nozzle: 0.4 - 1 mm

- Supported materials: PEEK, CF-PEEK, PEKK, CF-PEKK, PEI 1010/9085, PPSU, PC, CF-PC, PA, CF-PA, GF-PA, ASA, ABS, CF-ABS, PETG HIPS , TPU, PLA, CF-PLA, PVA

► Intamsys Funmat PRO 410

Intamsys Funmat PRO 410 professional high-temperature 3D printer is designed for use in various industries. A feature of the device is a closed-type build chamber, which maintains a stable temperature to improve adhesion between layers.

All-metal extruder has a heating temperature of 450°C, which allows you to work with most refractory materials. A nice bonus is the ability to work with two materials at the same time, for example, for printing with soluble supports.

For convenient data exchange, the manufacturer has equipped the Funmat PRO 410 with a built-in Wi-Fi module.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Independent extruders: No

- Extruder temperature: 450°C

- Table temperature: 160°C

- Print chamber temperature: 90°C

- Printable area: 305x305x406 mm

- Calibration: Automatic

- Print / grow speed: 30 - 300 mm/s

- Layer thickness: 50 µm

- XY-axis accuracy: 0.

016 mm

016 mm - Z-axis accuracy: 0.0016 mm

- High Temperature Printing: Yes

- Video camera: Yes

- Nozzle: 0.4 mm (0.25, 0.5, 0.6, 0.8, 1.2 mm)

- Supported materials: ABS, ABS-ESD, FLEX, HIPS, NYLON 12, NYLON 12 CF, NYLON 6, NYLON 6 CF, PC, PC-ABS, PEEK, PEEK CF, PET-G, PLA, PVA, Tough PLA , TPE, Wood-filled, Carbon-filled

► Intamsys Funmat PRO 610 HT

Intamsys Funmat PRO 610 HT is the top model in the line. The 3D printer easily solves the most complex problems of production and prototyping. The manufacturer equipped the Intamsys Funmat PRO 610 HT with an all-metal extruder with a heating temperature of 500°C, which can work with any thermoplastics, including ULTEM and PEEK.

Intamsys offers not only high-quality and reliable equipment, but also materials for printing on its 3D printers. For example, soluble support materials for PLA and engineering plastics.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 300°C

- Print chamber temperature: 300°C

- Print area: 610x508x508 mm

- Calibration: Automatic

- Print / grow speed: 30 - 300 mm/s

- Layer thickness: 50 µm

- XY-axis accuracy: 0.016 mm

- Z-axis accuracy: 0.0016 mm

- High Temperature Printing: Yes

- Video camera: Yes

- Nozzle: 0.4 mm

- Supported materials: PEEK, PEKK, PEI, PPSU, PC, Nylon, ABS, PLA, PVA, TPU, Carbonfiber Reinforcement

European and American equipment

Equipment made in the USA and Europe relies on high precision and full automation of the 3D printing process. All equipment presented in this section are high-tech devices that demonstrate maximum accuracy and repeatability of the result.

All equipment presented in this section are high-tech devices that demonstrate maximum accuracy and repeatability of the result.

► Stratasys Fortus 450mc

This additive machine, despite its rather compact size, has high accuracy and productivity. The construction chamber 406x355x406 mm allows you to start mass production, create prototypes and final parts.

The equipment works according to proven algorithms and has a built-in data protection function. Stratasys printers can be used for the defense and space industries. They are compatible with all thermoplastics and show consistently good results.

The Stratasys Fortus 450mc comes preloaded with software.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Independent extruders: Yes

- Number of independent extruders: 2 pcs.

- Print area: 406x355x406 mm

- Calibration: Automatic

- Layer thickness: 12.7 - 33 µm

- XY-axis accuracy: 0.127 mm

- Heated table: Yes

- High Temperature Printing: Yes

- Supported materials: ULTEM, Nylon 12 CF, PEI, PEKK

► Stratasys F900

The Stratasys F900 3D printer sets the standard for quality and precision in 3D printing. The large build area is perfect for printing large parts or mass-producing small parts. The printer can cover any production needs in the creation and development of products.

Integrated software allows you not to waste time converting data to the desired format, but print directly from CAD. This significantly reduces the time from development to launch into production.

Data-protected device can be used in defense, space, automotive and other industries.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Number of independent extruders: 2 pcs.

- Print area: 914x609x914 mm

- Calibration: Automatic

- Layer thickness: 12.7 - 50.8 µm

- XY-axis accuracy: 0.089 mm

- Heated table: Yes

- High Temperature Printing: Yes

- Supported materials: ABS, PC, ULTEM, Nylon 6 and Nylon 12

► 3DGence Industry F421

Polish brand 3DGence Industry F421 high-speed, reliable and productive 3D printer has excellent kinematics. Special algorithms monitor the operation of stepper motors and correct it if something goes wrong. This allows you to achieve the most accurate results even in unstable conditions on the production floor.

3DGence Industry F421 has a modular system to meet different needs. Interchangeable extruders with heating temperatures from 280°C to 500°C allow you to print on a variety of materials, including high temperature ULTEM and PEEK. A convenient system for reading information about the material allows you to automatically determine the type of plastic and its weight.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of independent extruders: 2 pcs.

- Extruder temperature: 280 - 500°C

- Table temperature: 180°C

- Print chamber temperature: 180°C

- Print area: 380x380x420 mm

- Calibration: Automatic

- Print / grow speed: up to 400 mm/s

- Layer thickness: 50 - 300 µm

- XY accuracy: 6 µm

- Z-axis accuracy: 7 µm

- Number of colors: 2 colors

- Video camera: Yes

- Nozzle: 0.

5/0.5 mm or 0.4/0.4 mm

5/0.5 mm or 0.4/0.4 mm - Supported materials: PLA, ABS, ASA, PA6/69, PC, ULTEM™ filament, PEEK

► 3DGence Industry F350

The 3D printer with the 3DGence Industry F350 Modular System can print a variety of plastics. Interchangeable extruders with different heating temperatures allow you to adapt this 3D printer to any task.

The system can print with different materials and, like the previous one, is equipped with a material recognition function. The smart assistant not only determines the weight and type of plastic, but tells you when you need to load an additional spool.

The manufacturer offers a cloud service for managing a 3D printer, which makes work as comfortable as possible.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic filament

- Printer housing: Closed

- Thread diameter: 1.

75 mm

75 mm - Extruder type: Direct

- Number of print nozzles: 2 pcs.

- Extruder temperature: 280 - 500°C

- Table temperature: 180°C

- Print chamber temperature: 130°C

- Print area: 340x340x350 mm

- Calibration: Automatic

- Layer thickness: 40 - 300 µm

- XY accuracy: 6 µm

- Z-axis accuracy: 0.7 µm

- High Temperature Printing: Yes

- Nozzle: 0.5/0.5 mm or 0.4/0.4 mm

- Supported media: PLA, ABS, ASA, PA6/69, PC, PEEK

► 3DGence Industry F340

The 3DGence Industry F340 Professional FDM Printer is a user-friendly additive machine with smart features and convenient controls. The manufacturer has equipped this model with all the latest developments that make 3D plastic printing of high quality.

Modular system with different extruders allows you to adapt to any production requirements. Printing with high temperature resins or standard plastics allows you to select and install a replacement module that is ideal for the task at hand.

Maintaining the required moisture content of the material and automatic supply of plastic make the work as comfortable as possible.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of print nozzles: 1 pc.

- Extruder temperature: 190 - 500°C

- Table temperature: 140 -160°C

- Print chamber temperature: 85°C

- Print area: 260x300x340 mm

- Calibration: Automatic

- Layer thickness: 40 µm

- High Temperature Printing: Yes

- Nozzle: 0.4 mm

- Supported materials: PLA, ABS, PET, Nylon, PP, ASA, PC, PC-ABS, PC-ESD, PEEK

► Zortrax Endureal

Another Polish manufacturer Zortrax introduces a new generation of industrial printers. High-tech equipment of this brand is chosen by many manufacturers from around the world. Zortrax produces not only 3D printers, but also its own line of materials for 3D printing, as well as software that makes working with additive technology as comfortable as possible.

High-tech equipment of this brand is chosen by many manufacturers from around the world. Zortrax produces not only 3D printers, but also its own line of materials for 3D printing, as well as software that makes working with additive technology as comfortable as possible.

Despite being easy to use, Zortrax 3D printers offer innovative solutions that take printing to the next level. The company's equipment is chosen by individual users and companies representing different industries.

TheEndureal from Zortrax is a third generation 3D printer that works effectively with a variety of plastics. To achieve the highest quality results while maintaining all the properties of the material, the manufacturer has equipped Endureal with perfect temperature control. Accurate tracking of parameters at each stage allows you to save all the properties of the material.

Filament storage in closed heated chamber, auto-annealing function after printing helps to achieve high mechanical properties of the material.

Zortrax Endureal uses LPD Plus (Layer Plastic Deposition Plus) technology. This technology is similar to FDM, but differs from it in that products are created with detachable soluble supports.

The equipment is supplied with a service and repair tool kit. This significantly reduces the cost and time for maintenance and minor troubleshooting, as well as reduces downtime.

Although Endureal is an industrial unit, it is easy to operate. Thanks to its user-friendly interface, Zortrax Endureal is easily integrated into any production.

Specifications:

- Print technology: LPD Plus

- Print material: Plastic thread

- Printer body: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of independent extruders: 2 pcs.

- Extruder temperature: 480°C

- Table temperature: 220°C

- Print chamber temperature: 200°C

- Print area: 400x300x300 mm

- Guides: XY rails, Z shafts

- Calibration: Automatic

- Layer thickness: 450 µm

- Z-axis accuracy: 200 - 250 µm

- Video camera: Yes

- Nozzle: 0.4 mm

- Materials supported: Z-PEI 9085, Z-ULTRAT Plus (single extruder), Z-PEI 1010, Z-PEI 9085, Z-ULTRAT Plus, Z-SUPPORT High-Temp (tear-off), Z-SUPPORT ATP ( for two extruders)

Which 3D printers print with thermoplastics?

Since 3D printing with refractory materials is practically not used for everyday tasks, all thermoplastic printing equipment is professional or industrial. Manufacturers create different 3D printers - from compact desktop models to industrial plants and robotic systems that can handle any print volume.

The main difference between 3D printers for printing with refractory materials from other devices is the high extrusion temperature, which is usually 400⁰С and higher. Also, equipment for working with high-temperature plastics has design features:

Also, equipment for working with high-temperature plastics has design features:

- Closed heated print chamber. Provides good adhesion between layers, allows you to evenly cool the part after printing.

- Heated work table. Helps improve first coat adhesion and print stability.

- Compartments for storing or drying plastics. There are without heating (in more budget models) and with heating. They allow you to prepare plastic for printing and keep it dry, which is especially important for hygroscopic materials.

- Air cleaning system. Powerful built-in filters reduce the amount of harmful fumes during the printing process.

Why are refractory materials so good?

When it comes to professional printing or industrial applications, special attention is paid to the quality of the material and its properties. Standard plastics such as ABS, as well as engineering polymers (Nylon, PA, PP, carbon fiber materials) perform well in the manufacture of functional prototypes, small products and even final parts in various industries. But some industries have a need for better and more reliable materials that have exceptional characteristics.

But some industries have a need for better and more reliable materials that have exceptional characteristics.

Refractory materials, and more precisely products made from them, can be used in the most severe conditions. High wear resistance, chemical and temperature resistance make it possible to successfully replace metal products, parts made of alloys and ceramics. Some experts believe that plastics based on PEI, PAEK and PSU will partially replace metal production in the near future.

High temperature plastics can be used in the manufacture of components for the aerospace, defense, automotive and mechanical industries. Due to the special properties of products made of refractory materials, they can be used in research and scientific activities.

Thank you all, the material was prepared by a team of LIDER-3D specialists, we will be glad to hear your questions in the comments.

If you are interested in equipment made of this material, please contact us at LIDER-3D to get detailed expert advice, as well as purchase this equipment on our website.

Follow us on social networks: VKontakte, Telegram, Instagram, YouTube, Ya.Zen, Twitter, Facebook to be the first to receive the most interesting materials!

Overview of high-temperature 3D printers with Formnext 2017 Today, we note the significantly increased number of 3D printers since last year for working with high-temperature engineering plastics, starting with polycarbonate and further to polyamides, Ultem, PEEK, PPSU and composites based on them.

These materials are used in the aerospace industry, the chemical industry, and medicine, where properties such as low weight, high temperature resistance, mechanical strength, chemical inertness, and biocompatibility are in demand. We wrote more about engineering filaments and their application here.

Differences between industrial 3D printers

To work with engineering plastics, the printer must have a high-temperature extruder. There are two classes of equipment here. Junior - up to 300 ° C, this is enough for modifications of ABS, polycarbonate and polyamides. Senior - above 300 ° C. For PEEK or Ultem you need about 400.

Junior - up to 300 ° C, this is enough for modifications of ABS, polycarbonate and polyamides. Senior - above 300 ° C. For PEEK or Ultem you need about 400.

Extruder is not everything. A heated platform or vacuum table is a must to keep the part in place. And printing should take place in a working chamber isolated from the outside world, maintaining a predetermined temperature. Failure to comply with the mode leads to deformation or violation of the integrity of the printed object.

So, let's look at the patterns we've seen.

Intamsys

The Chinese manufacturer offers four models of 3D printers. The basic Funmat and Funmat Pro work with common plastics, from PLA to nylon, and composites. Funmat HT and Funmat Pro HT are already capable of printing in PEEK, Ultem and PPSU.

Intamsys FUNMAT, FUNMAT HT

- Working chamber: 260 x 260 x 260 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.

4mm;

4mm; - FUNMAT: extruder up to 280°C, bed up to 150°C;

- FUNMAT HT: extruder up to 450°C, bed up to 160°C.

Compact printers with a closed working chamber, in the HT version it is equipped with heating, maximum temperature 90 °C.

Intamsys FUNMAT PRO, FUNMAT PRO HT

- Working chamber: 450 x 450 x 600 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.4mm;

- FUNMAT PRO: extruder up to 280°C, bed up to 150°C, chamber up to 60°C;

- FUNMAT PRO HT: extruder up to 450°C, bed up to 160°C, chamber up to 120°C.

Industrial printers for printing large parts with high-temperature plastics, equipped with a heated working chamber.

ROBOZE

One of the leading companies producing high-temperature 3D printers, we wrote more about it here. Offers three printers for engineering filaments. Roboze One is the basic model for common plastics - from PLA to polyamide inclusive. Roboze One +400 - with a high-temperature extruder, Roboze Argo 500 - a large installation, with a working chamber of 500 x 500 x 500 mm. Roboze printers are interesting in the rejection of drive belts and the use of a rack-and-pinion transmission to move the print head.

Roboze One is the basic model for common plastics - from PLA to polyamide inclusive. Roboze One +400 - with a high-temperature extruder, Roboze Argo 500 - a large installation, with a working chamber of 500 x 500 x 500 mm. Roboze printers are interesting in the rejection of drive belts and the use of a rack-and-pinion transmission to move the print head.

Roboze One +400

- Working chamber: 200 x 200 x 200 mm;

- extruder temperature: up to 400 °C;

- layer thickness: from 50 µm.

The printer is designed with an emphasis on reliability, all parts of the extruder are made of metal.

Roboze Argo 500

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 550 °C;

- chamber temperature: up to 180 °C.

The older Roboze model has a vacuum table to hold the part. Compartments for filament are equipped with heating. When one coil runs out, the machine automatically switches to the next one.

Compartments for filament are equipped with heating. When one coil runs out, the machine automatically switches to the next one.

VSHAPER

A Polish manufacturer whose product range includes high-temperature printers for medical applications and five-axis 3D printing machines.

VSHAPER 270 Med

- Working chamber: 270 x 270 x 200 mm;

- extruder temperature: up to 450 °C;

- layer thickness: from 50 µm.

A medical-grade printer with an anti-microbial chamber coating and a built-in UV sterilizer that sterilizes every layer as it prints. The main purpose is the printing of implants and additional equipment for surgical operations.

VSHAPER 5-Axis Machine

- Working area: cylinder 300 mm in diameter and 300 mm high;

- automatic change of hotends;

- heated working chamber;

- the ability to print one model with several materials.

The five-axis design allows complex shapes to be printed without supports. The ability to print one model with several materials with different properties allows you to create parts with complex composition, for example, with an inner core made of a stronger material, or with a coating or inserts made of flexible. For the convenience of printing with different materials, the platform is also optimized - it is divided into cells that can be set to different heating temperatures.

The printer is already available for pre-order, and shipments will begin, according to the manufacturer, from January 2019.

3DGENCE INDUSTRY F340

- Working chamber: 260 x 340 x 340 mm;

- layer thickness: from 150 microns;

- chamber temperature: up to 85 ˚C;

- extruder temperature: up to 500 ˚C.

The printer can be equipped with one of three printing modules. Standard - up to 265 ˚C, medium - up to 350 ˚C, high temperature - up to 500 ˚C. Printed modules - with two hotends, for the main and auxiliary materials. Among other interesting features, we note the preheating of the plastic and the coil mass sensor.

Standard - up to 265 ˚C, medium - up to 350 ˚C, high temperature - up to 500 ˚C. Printed modules - with two hotends, for the main and auxiliary materials. Among other interesting features, we note the preheating of the plastic and the coil mass sensor.

Apium

Apium Additive Technologies GmbH is a German manufacturer of small printers for high temperature PEEK, Ultem and PPSU filaments and composites. Apium is translated from Latin as "celery". For products, support for printing with metal-filled filaments is declared for further baking.

Apium P155

- Working chamber: 155 x 155 x 155 mm;

- extruder temperature: up to 520 °C;

- table temperature: up to 160 °C;

- layer thickness: from 100 µm.

Desktop high temperature printer with a small printable area. It is the successor to the Indmatec HPP 155. Apium also offers a slightly larger model - P220, with a print area of 200 x 160 x 160 mm.

GEWO 3D

The German manufacturer offers one high-temperature printer, with a very serious margin for the heating temperature of the printing platform and the working chamber.

GEWO HTP 260

- Working chamber: 350 x 150 x 165 mm;

- layer thickness: from 20 µm;

- extruder temperature: up to 450 °C;

- table temperature: up to 270 °C;

- chamber temperature: up to 260 °C.

Prints with all common engineering plastics, equipped with two extruders. Possibility of installation of a spindle for machining of a detail is provided.

MiniFactory Innovator 2

- Working chamber: 300 x 160 x 160 mm;

- layer thickness: from 30 µm.

Finnish dual extruder printer, the manufacturer focuses on PEEK printing. Other engineering plastics such as ABS, polycarbonate or Ultem are also supported.

Omni3D Factory 2.0

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 360 °C;

- table temperature: up to 130 °C;

- chamber temperature: up to 70 °C.

An industrial printer from Poland is equipped with two extruders and can print large parts from ABS, polycarbonate, polyamide and composites based on them.

DynamicalTools DT600

- Working chamber: 600 x 450 x 450 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 500 °C;

- table temperature: up to 150 °C.

The Spanish printer with two independent printheads, in addition to normal printing, supports printing modes for two identical or mirror parts at the same time. Works with all high temperature filaments up to PEEK, Ultem, PPSU. Equipped with systems for heating plastic and automatic change of coils.

Equipped with systems for heating plastic and automatic change of coils.

HAGE3D 140L

- Working chamber: 700 x 500 x 400 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 450 °C;

- chamber temperature: up to 85 °C.

Austrian industrial machine that supports most engineering filaments and composites. Heated working chamber, three-zone heating table.

AIM3D

The company offers a complex of equipment for the manufacture of metal objects. At the first stage, the part is printed on a 3D printer, at the second stage it is placed in an oven, where the binder plastic burns out and the metal filler is sintered.

AIM3D ExAM 255

- Working chamber: 255 x 255 x 255 mm;

- layer thickness from: 20 µm;

- table temperature: up to 120 °C.

The printer does not work with filament, but with granules. This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. You can also print with plastic pellets, which is usually cheaper than using filament.

This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. You can also print with plastic pellets, which is usually cheaper than using filament.

AIM3D ExSO 90

- workpiece diameter, up to: 90 mm;

- 6-sided heating;

- isolation and collection of fumes generated during sintering;

- temperature: up to 1350 °C.

Furnace for high-temperature sintering of parts printed on AIM3D ExAM 255 in an inert gas atmosphere.

How to purchase an industrial 3D printer

Looking for an industrial 3D printer? Top 3D Shop is the official representative of most of the manufacturers mentioned in the review, we are ready to supply equipment, commissioning, training and maintenance.

We have made a comparison table for these machines, with technical nuances - print and camera temperatures, materials used, number of extruders and estimated cost.