Structo 3d printer price

About Us - Structo 3D

The Structo journey began in 2012 in a small room at National University of Singapore (NUS) where a group of engineers were attempting to build an "inkless printer"; a machine that used laser to burn black marks onto paper and thus print without using ink or toner. It worked only half the time (and caught fire the other half), so the group shifted their focus to 3D printing instead. The engineers developed the first prototype of their Mask Stereolithography (MSLA) technology to demonstrate lightning-fast print speeds and scalability, and soon thereafter secured investment and officially founded Structo.

Over the next few years, the business has grown to become a household brand in the dental and orthodontics industry with customers spanning 6 continents. With our expertise in hardware, material sciences and automation systems, we have revolutionized the field of digital dentistry.

And we’re just getting started.

Soon we'll be taking our technology and know-how to other industries that need mass customisation of products.

A People-First Culture

As a startup, Structo has succeeded without a massive war chest because the founders have been able to build a great team & culture where people are constantly achieving above average performance levels (if not really high performance levels).

How have we managed to sustain this?

Trust

Once you're on board, we trust you to give everything your best shot, learn from your mistakes and try to improve 1% every day We promote work-life flexibility, as it's hard to find balance when you love what you do!

Empowerment

We think you'll be joining us because you want to build great technology and be part of building a great organization. The quickest way to do both is by giving you that freedom to do both. We don't have the time or money to micromanage you, we need you to come in and own it.

Coaching

While we don't micromanage, we are here to coach. We don't take a one shoe fits all approach. Everyone is a little different, and everyone needs a different amount of time, attention and feedback.

Everyone is a little different, and everyone needs a different amount of time, attention and feedback.

Leadership

We try to make it easy for you. No convoluted message, no counterintuitive KPIs. The leaders in the organization try to keep things simple, so that everyone can stay focused on what they love doing.

Transparency

No hidden agendas, no politics just bluntness. That might not be for everyone, but at least everyone will know what's happening.

Development

We want great people to stay and grow with us, simple. So we work towards helping our people develop to ensure they keep growing.

Focus

It's hard to make progress when you're trying to do too much at the same time. At Structo we help you focus on what's important, so that you can stack up the wins and keep moving to the next awesome project to work on.

Interested in joining us?

SEE OUR OPENINGS

Focus On: 2022 Orthodontic 3D Printer Options

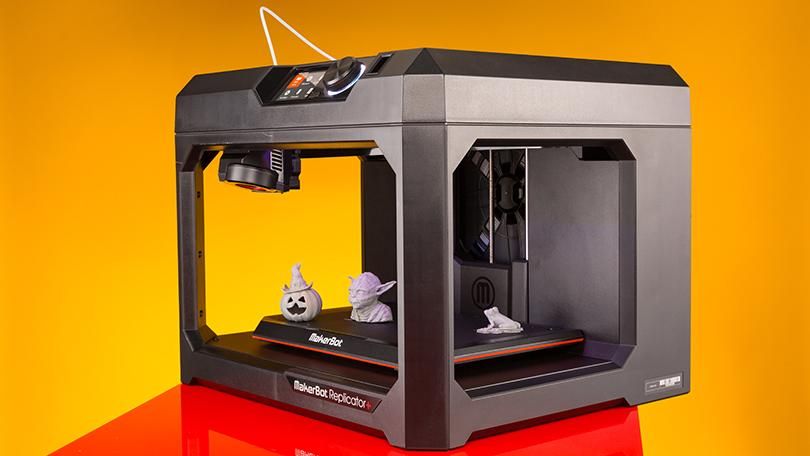

The addition of a 3D printer to your orthodontic practice can take your digital workflow to the next level. Here are six 3D printers currently on the market.

Here are six 3D printers currently on the market.

Multi-materials printing capabilities, a large-capacity print tray, all in a small footprint, the J5 DentJet, from Stratasys, is designed to reduce costs, maximize efficiency, and create more dental parts with less handling—all with the precision, accuracy, and quality you can expect from PolyJet technology. Load one tray and walk away.

For more information, visit stratasys.com.

DentaFormStructo DentaForm is a high throughput clear aligner models 3D printer. Powered by Structo’s proprietary Mask Stereolithography (MSLA) technology, the DentaForm is able to print up to 10 clear aligner models every 22 minutes. That’s enough to handle an entire aligner case over lunch.

For more information, visit structo3d.com.

Einstein Desktop 3D Printer

The Einstein Desktop 3D Printer from 365 Printing is super-fast, printing up to 8 models in just 12 minutes. The 365 Printing team of orthodontic experts gets you up and running quickly for the fastest return on investment, with access to industry-leading service and support and professional onsite installation, training, and support. The high quality Einstein Desktop 3D printer delivers industrial-quality prints starting at $8,999.

The 365 Printing team of orthodontic experts gets you up and running quickly for the fastest return on investment, with access to industry-leading service and support and professional onsite installation, training, and support. The high quality Einstein Desktop 3D printer delivers industrial-quality prints starting at $8,999.

For more information, visit 365printing.com.

JUELL 3D-3 Production Printer

With precision optics and components, the JUELL 3D-3 production printer, from Park Dental Research, delivers in speed, accuracy, durability, and price. The JUELL 3D Flash OC software offers a state-of-the-art operating system, while the Made in USA production printer is designed to withstand heavy use while providing precise models, guides, and trays.

For more information, visit parkdentalresearch.com.

UNIZ Slash 2 Plus Desktop 3D Printer

Offered by Great Lakes Dental Technologies, the UNIZ Slash 2 Plus Desktop 3D Printer delivers a 3D printing experience that is faster, more precise, and more reliable than any other device in its class. Ideal for a variety of in-office dental applications, UNIZ Slash 2 features LCD stereolithography technology, super high speed (up to 250 mm/hr), enhanced light uniformity, and multiple resin options.

Ideal for a variety of in-office dental applications, UNIZ Slash 2 features LCD stereolithography technology, super high speed (up to 250 mm/hr), enhanced light uniformity, and multiple resin options.

For more information, visit greatlakesdentaltech.com.

Form 3B+

The Form 3B+, from Formlabs, is an advanced desktop 3D printer developed for dental professionals. Its patented Low Force Stereolithography technology delivers speed, reliability, quality, and ease of use for orthodontic applications. The Form 3B+ offers peace of mind, with a fully validated workflow for your 3D print applications and easy IOS integration, with Scan to Smile chairside workflow for seamless integration in your digital eco -system.

For more information, visit dental.formlabs.com.

Structo Introduces New Dental 3D Printer

News

Singapore company Structo presented the latest DentaForm stereolithographic 3D printer, positioned as “the fastest dental 3D printer in the world.

”

” Structo's 3D printers use a fairly new and less common technology of masked LCD stereolithography (MSLA). The principle of operation is similar to DLP printers, but instead of digital projectors, LED arrays with liquid crystal masks are used. nine0003

“Users familiar with the high speed masked LCD stereolithography on OrthoForm 3D printers were interested in the possibility of higher resolution for printing high-precision models. Today, we are excited to bring such a solution to the market in the form of the DentaForm 3D printer,” commented Dhruv Sahgal, head of business development and sales at Structo.

The new product was shown today at the Singapore Orthodontic Association (AOSC) exhibition. The DentaForm 3D printer is designed to print high-precision templates for trying on crowns and bridges. The pixel size is 50 microns with a layer thickness of 25, 50 or 100 microns, and the size of the working area reaches 200x150x100 mm. The device is capable of printing up to 30 master models at one time in about an hour and a half. nine0003

The device is capable of printing up to 30 master models at one time in about an hour and a half. nine0003

“We are revolutionizing digital dentistry by breaking the speed barriers of existing 3D printers. Structo DentaForm opens up a whole range of new possibilities in the field of dentistry with our high-speed mask LCD stereolithography technology,” said Hub van Esbroek, co-founder of Structo. Additional information is available on the manufacturer's website.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected]. nine0027

Follow author

Follow

Don't want

3

Article comments

More interesting articles

8

Subscribe to the author

Subscribe

Don't want

What do plastic fish eat? Plastic, of course. British student Eleanor McIntosh won...

British student Eleanor McIntosh won...

Read more

five

Subscribe to the author

Subscribe

Don't want

Researchers have developed an artificial analogue of the pancreas - a device for delivering pancreas...

Read more

46

Subscribe to the author

Subscribe

Don't want

American startup Iro3D shipped the first 3D printers for printing metal products using the village method...

Read more

Read blogs

Installing 3D printers - Robotec

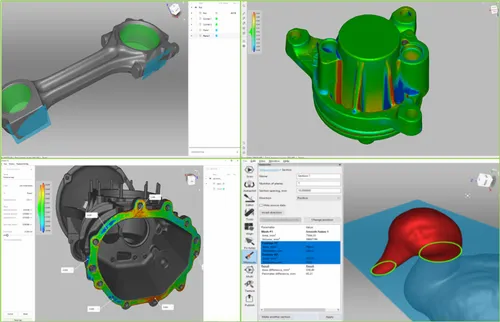

What is 3D printing?

3D printing or additive manufacturing is the creation 3D object from a digital model.

The process itself is fundamentally different from traditional production, here the material is successively layered and this does not require additional tools and shapes with certain geometry, and most importantly the material required smaller quantity. nine0003

nine0003

3D printing is a booming technology. New 3D printers are released every year, which can have a significant impact on the industry. Robotec keeps track of all new products, our experts will select the equipment, calculate the cost and time payback. Already today "Robotec" is ready to offer you equipment from the world's best manufacturers SLM Solutions, SPEE3D, Shining3D, Rapidshape, Structo. nine0041

Geometric complexity at no extra cost

3D printing makes it easy to produce complex shapes, many of which could not have been made any other way. The geometric complexity of the part does not lead to an increase in cost.

Very low start-up costs

Because 3D printing requires no special tools, there is virtually no start-up cost. The cost of a 3D printed part only depends on the amount of material used, the time it took the device to print it, and the post-processing, if any. nine0003

nine0003

Quick and easy product changes

All you need to do to create a new part is modify the 3D digital model. Each item can be customized to suit the specific needs of the user without affecting production costs.

Inexpensive prototyping with very fast turnaround

3D printer prototyping is possible at a speed no other manufacturing technology can compete with. Products that would take 8+ months to develop can now be ready in as little as 8-10 weeks. nine0003

Large range of (specialized) materials

Plastics, metals and composites. 3D printed parts today can have high heat resistance, high strength or stiffness, and even be biocompatible.

Still have questions?

Applications

3D printing includes various types of technology and a variety of materials for printing, so it is used in almost all industries.