Stretchy 3d printer filament

Ultimate Materials Guide - 3D Printing Flexible Filament

Overview

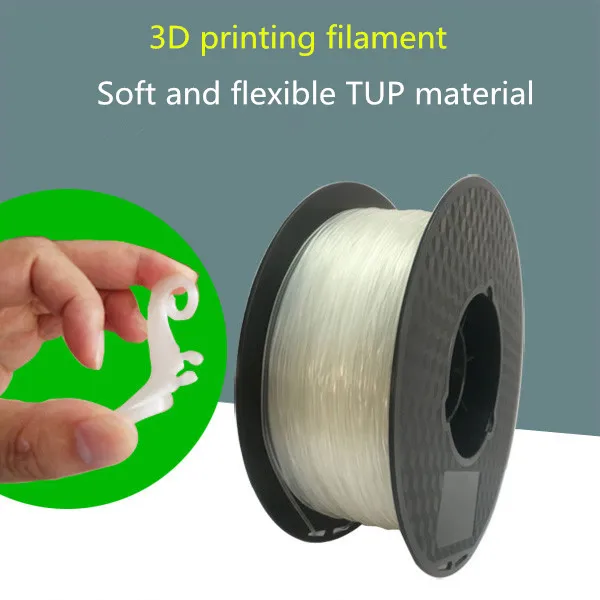

Flexible filaments are made of Thermoplastic Elastomers (TPE) which are a blend of hard plastic and rubber. As the name suggests, this material is elastic in nature allowing the plastic to be stretched and flexed easily. There are several types of TPE, with Thermoplastic polyurethane (TPU) being the most commonly used among 3D printing filaments. In many cases, these terms are used interchangeably, along with popular brand names such as Ninjaflex. The degree of elasticity in the plastic depends on the type of TPE and the chemical formulation used by the manufacturer. For example, some filaments can be partially flexible like a car tire but others can be elastic and fully flexible like a rubber band. This guide will cover tips to help you with both of these variations of flexible filaments.

- Flexible and soft

- Excellent vibration dampening

- Long shelf life

- Good impact resistance

- Difficult to print

- Poor bridging characteristics

- Possibility of blobs and stringing

- May not work well on Bowden extruders

Hardware Requirements

Before 3D printing with flexible filaments, make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 45-60 °C

Heated Bed Optional

Enclosure Not Required

Build Surface

PEI

Painter’s Tape

Extruder

Temperature: 225-245 °C

Direct Drive Extruder Recommended

Cooling

Part Cooling Fan Required

Best Practices

Flexible filaments come with many unique challenges that you want to be aware of. These tips will help you reduce the chances of common 3D printing issues such as clogging, kinking, and stringing.

Use Direct Drive Extruders

While some partially flexible filaments work fine with Bowden Extruders, most fully flexible filaments require a Direct Drive extruder for best results. The distance between the drive gear and the melt zone of the hot-end needs to be as short as possible to efficiently feed the filament into the nozzle. Additionally, the pathway through which the filament travels into the melt zone should have tight tolerances to prevent the filament from kinking or coiling inside. For these reasons, it is typically much easier to print flexible filaments with a Direct Drive extruder versus a Bowden extruder. If you are unsure about your 3D printer’s capabilities, you may want to check with the manufacturer to see if the extruder has been approved for use with flexible filaments.

For these reasons, it is typically much easier to print flexible filaments with a Direct Drive extruder versus a Bowden extruder. If you are unsure about your 3D printer’s capabilities, you may want to check with the manufacturer to see if the extruder has been approved for use with flexible filaments.

Use Slow and Consistent Feed Rates

Flexible filaments typically print best using a slow and consistent feed rate. Because the material is elastic, it can be very difficult to control sudden changes in the print speed. Higher print speeds can cause the filament to compress and will most likely result in a jam. Slow and steady is the best approach. Simplify3D provides all of your feed rate settings on the Speeds tab of your process settings so that you can easily configure these values. Finding the optimal print speed for your material can take several attempts based on trial and error. We have seen that speeds of 1200 mm/min (20 mm/s) can be a good starting point for most materials.

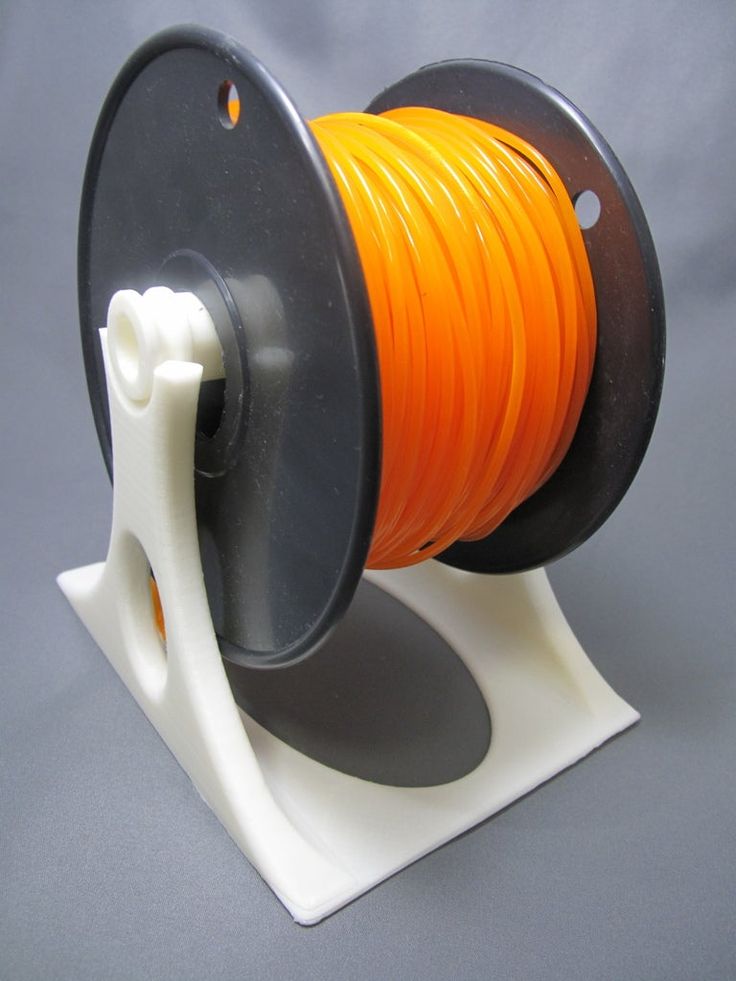

Reduce Resistance from the Filament Spool

A few tweaks to your material spool can also make a big difference with flexible materials. Typically, your extruder will pull the filament into the nozzle, forcing the filament spool mounted on your printer to unwind a bit of plastic in the process. However, because flexible materials are elastic, this will stretch the filament out as it is being pulled in and can actually result in under-extrusion. Try mounting the spool above your printer so that the filament unwinds in a downward direction which can reduce the resistance. It can also be incredibly helpful to mount the spool’s hub on a bearing to allow the spool to spin as freely as possible.

Tune Your Retraction Settings

The elastic nature of flexible filament makes it sensitive to quick movements such as retractions. In order to successfully print the filament, you will need to optimize your retraction settings to reduce these movements. While you are first starting with this material, we would recommend disabling retraction completely. You can make this change in Simplify3D on the Extruders tab of your process settings. With retraction disabled, you can focus on finding the perfect speed and extrusion rates that allow you to reliably print your models. After you are more confident in these settings, you may wish to add a very small amount of retraction with a slower retraction speed to help with any potential oozing from the hot-end. Simplify3D also includes a unique option called Coasting, which will automatically help lower the pressure in the nozzle when you approach the end of a segment, which can significantly reduce blobs and stringing with these materials. If you want more information about other options that can help reduce hairs and stringing on your prints, we have an entire section on our Print Quality Guide dedicated to that issue: How to Reduce Stringing and Oozing.

You can make this change in Simplify3D on the Extruders tab of your process settings. With retraction disabled, you can focus on finding the perfect speed and extrusion rates that allow you to reliably print your models. After you are more confident in these settings, you may wish to add a very small amount of retraction with a slower retraction speed to help with any potential oozing from the hot-end. Simplify3D also includes a unique option called Coasting, which will automatically help lower the pressure in the nozzle when you approach the end of a segment, which can significantly reduce blobs and stringing with these materials. If you want more information about other options that can help reduce hairs and stringing on your prints, we have an entire section on our Print Quality Guide dedicated to that issue: How to Reduce Stringing and Oozing.

Optimize Your Travel Movements

Retractions can be particularly troublesome for flexible materials, so it is typically best to minimize the number of retractions required for your print. Simplify3D has a great feature that was built specifically for this situation. Instead of moving in a straight line from point A to B, the software will actually choose a completely new path when moving between these points, with the goal of staying within the interior of your object so that there won’t be any oozing or stringing. With this unique feature enabled, you can greatly reduce the amount of retractions required for your print and significantly improve your print quality. To use this feature, click on the Advanced tab of your process settings, and enable the “Avoid crossing outline for travel movement” option.

Simplify3D has a great feature that was built specifically for this situation. Instead of moving in a straight line from point A to B, the software will actually choose a completely new path when moving between these points, with the goal of staying within the interior of your object so that there won’t be any oozing or stringing. With this unique feature enabled, you can greatly reduce the amount of retractions required for your print and significantly improve your print quality. To use this feature, click on the Advanced tab of your process settings, and enable the “Avoid crossing outline for travel movement” option.

Pro-Tips

- Optimize the feed rate by printing at lower layer heights in the 0.1mm – 0.2mm range. The lower layer height requires less plastic, so it allows your extruder to use a lower feed-rate, relieving the burden on the filament.

- Try to avoid using rafts with flexible materials, as the base layers of the raft have higher extrusion rates which may create issues.

- If you are designing a flexible part that needs to fit on top of another object, try using a negative tolerance between the parts so that the flexible part will need to stretch to fit over the other object snugly.

Get Started with Flexible Filaments

Now that you’re ready to start printing with flexible materials, we have a few tips to help you get started. View some typical applications below, try out a few of our sample projects, or choose a popular filament brand to purchase for your next project.

Common Applications

- Vibration dampening

- Grip Sleeves

- Phone cases

Sample Projects

- RC Car Tire

- Phone case

- Bike Handle

Popular Brands

- NinjaTek Ninjaflex, Armadillo, Cheetah

- Polymaker PolyFlex

- eSun TPE

- Sainsmart Flexible TPU

Which 3D Printing Filament is Most Flexible? Best to Buy – 3D Printerly

When it comes to 3D printing filaments, there are types that are a lot more flexible than others. If you are looking for some of the best flexible filaments for your 3D prints, you are in the right place.

If you are looking for some of the best flexible filaments for your 3D prints, you are in the right place.

The most flexible 3D printing filament is TPU because it has very stretchy and bendable characteristics that most other filaments don’t have.

Keep on reading through this article for more answers about flexible filament, as well as a list of some of the best ones you can get for yourself.

What Type of 3D Printer Filament is Flexible?

The type of 3D printer filament that is flexible is called TPU or Thermoplastic Polyurethane which is a mixture of rubber and hard plastic. Flexible filaments are composed of Thermoplastic Elastomers (TPEs), and there are a filaments under this category.

As its name implies, this type of 3D printer filaments is elastic in nature which gives the filament some chemical and mechanical properties so that they can be blended or stretched more than normal filaments.

There are many types of TPEs but TPU is considered the best and most used flexible filament in the 3D printing industry.

The degree of flexibility and elasticity of a filament is determined by many factors where the chemical composition and type of Thermoplastics Elastomers used in the manufacturing process are the most prominent.

There are some flexible filaments that have elasticity like a car’s tire whereas some can be flexible like a soft rubber band. The measurement of flexibility is done by Shore Hardness Ratings, the lower being more flexible.

You’ll commonly see values like 95A for harder rubber or 85A for softer rubber.

Is TPU Filament Flexible?

TPU is a unique 3D printing material and its flexibility is the most prominent factor of this filament. This is the first 3D printing filament that comes into mind when designing a model that needs flexibility.

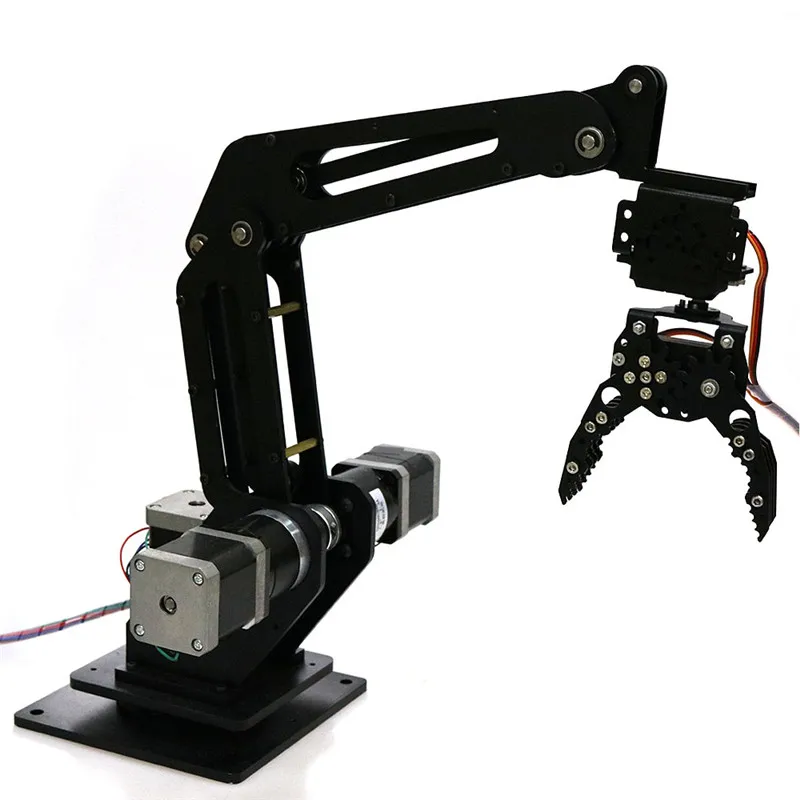

TPU has the ability to print strong parts that are flexible as well, commonly used in several industries like robotics, remote controlled objects and

TPU filament has the property of maintaining a careful balance between rigidity and flexibility, this factor makes it one of the best and easiest flexible filaments to work with.

One of many users stated that it is an excellent and flexible 3D printing filament that produces good results. The final model will be flexible enough that it can be stretched a long way before it breaks down.

It is not really squishy but is flexible enough that you can print rubber washers and gaskets.

Another buyer said in his Amazon review that he has printed isolating bushes for his CoreXY motors and since then, TPU has become his go-to flexible filament.

Is PLA Filament Flexible?

Standard PLA filament is not flexible and is actually known for being a very rigid material. PLA doesn’t bend very much and if it has absorbed moisture, it is a lot more likely to snap when enough pressure is put on it. There are flexible PLA filaments used for 3D printing that look and work like soft rubber.

There are flexible PLA filaments used for 3D printing that look and work like soft rubber.

Such type of flexible filament is an ideal choice to print 3D models that can bend and need elasticity to fit their aimed environment.

Mobile covers, springs, stoppers, belts, tires, kids toys, machine parts, and things like these can be printed efficiently with PLA flexible filament.

Flexible PLA filament works best at a 3D printing temperature of about 225 Degrees Celsius and should be printed at a speed slower than the printing speed used while printing normal PLA.

One of the best and widely used PLA flexible filaments can be purchased from MatterHackers’ official website.

Is ABS Filament Flexible?

ABS is not as flexible as TPU, but it is more flexible than PLA filament. You wouldn’t use ABS as a flexible filament, but it can bend more and has a little more give than PLA. PLA is a lot more likely to snap rather than bend compared to ABS.

Is Nylon Filament Flexible?

Nylon is a strong, durable, and versatile 3D printing material but if it is thin, it can be flexible as well. If there is very high inter-layer adhesion, the nylon can be used to print super strong industrial parts to bear a lot of weight and stress.

If there is very high inter-layer adhesion, the nylon can be used to print super strong industrial parts to bear a lot of weight and stress.

Because of its strong properties combined with flexibility, this is considered one of the best 3D printing materials because it becomes tough to break and has much better shatter resistance.

People say that it is fairly flexible, and the parts printed with this filament feel like a common flex material. It shows signs of flexibility only if it is printed thin otherwise it may not bend and may even break as well.

One user said in a review that he printed a living hinge with nylon filament and it is far better than the one he printed with ABS. An ABS hinge shows crack signs and stress marks but with a nylon hinge, it was not the issue of concern.

Best Flexible Filament for 3D Printing

Although there are plenty of flexible or squishy 3D printing filaments in the market, some are better than others. Below are the top 3 best flexible filaments for 3D printing that can be used flawlessly to get efficient results.

Sainsmart TPU

Due to its balance between rigidity and flexibility, Sainsmart TPU has gained much popularity in the 3D printing community.

This filament comes with a shore hardness of 95A and has good bed adhesion properties. These factors make it easy for users to print models with Sainsmart TPU filament even on basic level 3D printers such as Creality Ender 3.

If you are looking for a flexible 3D printing filament, the Sainsmart TPU will never disappoint you whether you are printing drone parts, phone cases, small toys, or any other model.

- Filament Diameter: 1.75mm

- Extruder/Printing Temperature: 200 – 2200C

- Bed Temperature: 40 – 600C

- Dimensional Accuracy: +/- 0.05mm

- Smooth extrusion makes it capable of achieving high dimensional accuracy and consistency

- Better Layer Adhesion

One of the buyers said in his review that there is no definite way to tell you how flexible it is, but I can say that it is one of the most flexible materials I have ever used.

It has elasticity but not as good as a rubber band. If pulled, it will stretch a little and then return. If you keep on pulling the filament or bed too hard, it may deform as well.

Your print settings and model design will also determine its flexibility, a hollow part will have more flexibility as compared to a complete solid model.

You can find a spool of Sainsmart TPU on Amazon.

NinjaTech NinjaFlex TPU

NinjaTech’s NinjaFlex 3D printing filament leads the 3D printing flexible filaments’ industry with its high flexibility and durability compared to non-polyurethane material.

This 3D printing filament is specially extracted from the thermoplastic polyurethane which is commonly known as TPU. This has a low tack and easy to feed texture making the 3D printing process easy for the users.

The filament is a strong and flexible material ideal for all types of direct-drive extruders. Some of the best applications include printing seals, baskets, leveling feet, plugs, protective applications, etc.

- Shore Hardness: 85A

- Extruder Temperature: 225 to 2350C

- Bed Temperature: 400C

- Extremely flexible

- Filament Diameter: 1.75mm

One of the buyers said in his review that the NinjaFlex filament is amazingly flexible and he can print models on his Printrbot Play without any hassle.

Talking about the print settings, he tends to print this filament a bit slower at a print speed of 20mm/s, with an extrusion multiplier of about 125%.

This helps him to get a solid first layer and a print with improved quality. Boasted extrusion multiplier is necessary because the filament is flexible and can be stretched or compressed, this is the reason that flexible filament comes out of the nozzle with a little less flow.

Get yourself a roll of NinjaTek NinjaFlex 0.5KG TPU Filament from Amazon.

Polymaker PolyFlex TPU 90

This flexible 3D printing filament is manufactured by Covestro’s Addigy Family. It is also a Polyurethane Thermoplastic filament especially designed to provide an good level of flexibility without compromising on printing speed.

It is also a Polyurethane Thermoplastic filament especially designed to provide an good level of flexibility without compromising on printing speed.

This 3D printing filament has gained much popularity as it has the ability to resist UV rays and sunlight to a great extent.

Although this 3D printing filament is a bit expensive but is worth buying. A well-known YouTuber said in his video that this filament offers good strength, flexibility, and printability.

- Shore Hardness: 90A

- Extruder Temperature: 210 – 2300C

- Bed Temperature: 25 – 600C

- Printing Speed: 20 – 40 mm/s

- Available Colors: Orange, Blue Yellow, Red, White, and Black

The filament is flexible but not very stretchy. It does have elastic or stretchy properties but after you have printed a few layers of your model, it will not stretch as much but still have good flexibility.

One of the many users stated in his Amazon feedback that he had an assumption that printing with flexible material would be a difficult job, but this filament is giving him the best results because of the above-mentioned factors.

A user who has an Ender 3 Pro with a simple direct drive extruder conversion stated that the filament is quite bendable but cannot be stretched very far.

The filament does ooze more than the PLA filament but minimizing the movement over empty space brings much better results, but turning on your Combing settings.

Get the Polymaker PolyFlex TPU filament from Amazon.

All you need to know about TPU for 3D printing

You are here

Home

So-called thermoplastic polyurethane (TPU) is a type of elastomer that is highly flexible and durable when processed. Its properties are due to the presence of alternating sequences of hard and soft segments, that is, by varying the proportion of these segments, we can change the hardness and flexibility of the material. It also affects the transparency of the final parts, the softness to the touch or the adhesion of the parts. In general, we can say that TPU is a very diverse polymer that provides a very interesting set of part characteristics. In addition, this makes it possible to apply it to create 3D printed flexible models. But what should we consider when using TPU?

In addition, this makes it possible to apply it to create 3D printed flexible models. But what should we consider when using TPU?

In the additive manufacturing industry, this material opens up many opportunities for different markets such as footwear, elastic soles, or the automotive industry for tires and shock absorbers. TPU is ideal for end-use parts, functional prototypes, concept models and custom components. This type of material is widely used to make mobile phone cases, for example, as it protects the device from bumps and cracks. Let's now look at the outstanding properties of this flexible material.

Due to its flexibility, TPU can be used to make phone cases.

Features of TPU in 3D printing

In terms of properties, we need to know that these polymers have many advantages, such as high resistance to impact, wear, abrasion and cuts. In addition, they have a fairly high adhesion to the layer, which provides excellent mechanical uniformity of the manufactured parts, making them isotropic. However, this type of material has certain limitations that we must take into account. TPU does not adapt well to hot conditions. This factor is remarkable in that, despite the wide operating range, it does not withstand high temperatures. In addition, print settings should differ depending on the technology used.

However, this type of material has certain limitations that we must take into account. TPU does not adapt well to hot conditions. This factor is remarkable in that, despite the wide operating range, it does not withstand high temperatures. In addition, print settings should differ depending on the technology used.

When printing parts with TPU using FDM, we suggest applying a thin layer of adhesive to the print bed to facilitate adhesion of the material. It is also recommended that the extrusion nozzle reach a temperature between 210 and 235°C to melt the filament (although this will vary by manufacturer). These are general tips, however, the success of a TPU will depend on each 3D printer's configuration and proper calibration; therefore it is recommended to perform small tests with this material before starting more complex prints.

Good layer adhesion results in excellent mechanical homogeneity.

In terms of stereolithography, TPU is not recommended for small, thin-walled models or models simulating high elongation materials. When setting up a model, it is recommended that the models have their final shape and be oriented close to the production platform, but not more than 20º. Thinner and taller parts will be more difficult to print, although additional supports can always be used for optimal results.

When setting up a model, it is recommended that the models have their final shape and be oriented close to the production platform, but not more than 20º. Thinner and taller parts will be more difficult to print, although additional supports can always be used for optimal results.

Which companies provide these materials?

In today's additive manufacturing market, we can find major players offering TPU for flexible parts. The giant Ultimaker has a filament called TUP 95A that is compatible with its Ultimaker S5, Ultimaker 3 and Ultimaker 2+ 3D printers. According to the company, the material can withstand up to 580% elongation at break; this thread is available in 4 different colors. Another big company is Formlabs, which introduced its so-called "elastic resin" for SLA technology last year. This resin has a hardness of 50 Shore A, in addition to high elongation and energy return. The elasticity and durability of this material allows it to be used in several cycles. In addition, the technology allows you to reduce costs and delivery times by printing directly on soft parts.

In addition, the technology allows you to reduce costs and delivery times by printing directly on soft parts.

Source: Formlabs

There are other companies that mainly develop these materials, such as Recreus, which offers a variety of 3D printing filaments. In particular, her famous thread FilaFlex.

Source

Tags:

thermoplastic polyurethane (TPU), additive manufacturing, 3D printed flexible modeling, 3D printing filament, Recreus, FilaFlex filament, Ultimaker, TUP 9 filament5A, Formlabs, "Elastic Resin" for SLA Technology

Other materials:

- Researchers determine the impact of powder processing on 316L

- Scientists ITMO University Scientists as part of megagram work under the University of Toronto

- Advantages of Materialise Magics when creating supports for 3D printing

- Vladimir Cheverikin: We register the patents of our own .

- How we taught the 3D printer to print with metal casting wax

Attention!

We accept news, articles or press releases

with links and images. [email protected]

Printing review of Zenit 3D printer with plastic FLEX

Good afternoon everyone!

With you 3Dtool and this article we continue the series devoted to complex and interesting 3D printing - engineering, as well as composite and special plastics. We will describe our experience with these filaments, share our impressions and reveal some secrets.

In our today's article, we will talk about the often forgotten and postponed, due to the complexity of printing, the elastic type of filament. We propose to consider in the review our favorite elastic thread - Flex from Esun. In addition to excellent availability, the filament is always in sufficient quantity in our warehouse.

If you carefully read our previous article about nylon, for the exhibition '3D-Expo', held October 12 - 13 in Moscow, at the Sokolnikov Expo Center, we printed a radio-controlled buggy model, which of course needed wheels. After printing the wheels conceived by the developer, the idea came to print something more interesting than the classic structure of an inflatable tire and a base disc. Someone remembered the 'US Pentagon Cellular Tires' and away we go...

A bit of background... Back in 2008, in the US state of Wisconsin, 'Resilient Technologies' technology company introduced new types of car tires to the American military industry. The innovation of these wheeled shoes was that they did not require air inflation and were completely puncture resistant. Moreover, this was achieved, not due to 'self-tightening materials', as one might think, but thanks to the 'honeycomb structure' very well known to 3D printers, where the rigidity of the wheel and tire is regulated by 'filling' the internal space, while the product itself is a kind of radial spring made of rubber.

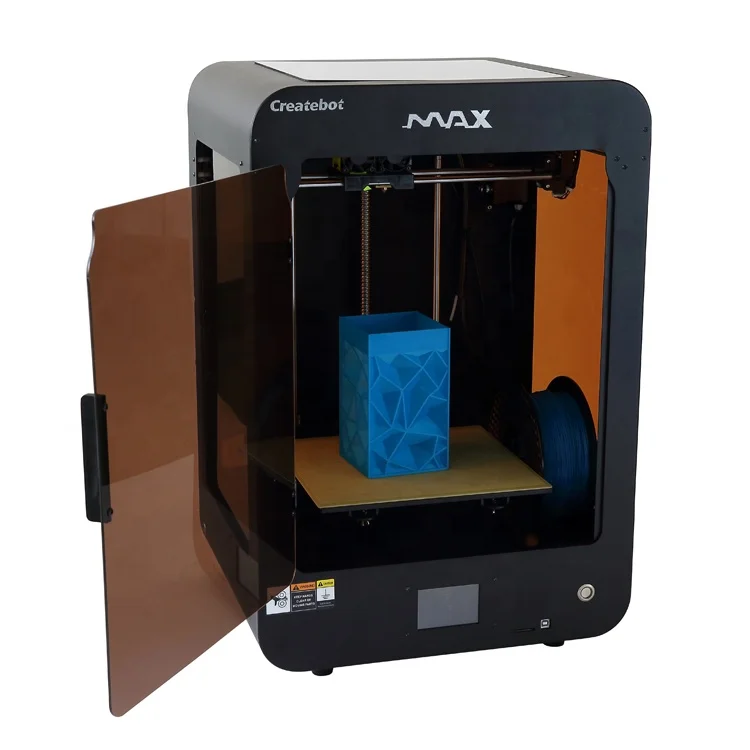

So. The task is marked, the material is selected, (we chose bright red Flex as a general advice, for the best wow effect) time to choose what we will print on? Our bench two-headed Zenit Duo just happened to be at hand, and although its second head will not be used at the moment, it suits our tasks perfectly. As many of you know, flexible filaments require a special design of the print unit's pull mechanism. It is advisable to use Direct - extruders (Bowden extruders for Flex printing are much worse). In order to prevent the plastic from being jammed by the pull gears, the extruder's take-up tube should have a wide 'neck' that fits close to the feed wheel, as well as the top of the feed tube should ensure contact with minimal gaps.

Let's start by preparing the model. Going to the well-known site - a library of 3D models, we are looking for the desired tire. Quite quickly we find, as it turned out there are not so many of them. Ours is called 'airless tire' by user 'STANTHEMAN91'. A simple modelka wave will fit in the role of an experimental cat. Next, you need to turn it into g-code. We will use not the newest, but from that it has not lost its relevance at all CUra 3.2.1 for which we already have a profile for a single-headed zenith (it can be taken from the link at the end of the article, or downloaded from the official Zenit website settings for the older 15.04 version and independently modify them for the current 'Chicken')

A simple modelka wave will fit in the role of an experimental cat. Next, you need to turn it into g-code. We will use not the newest, but from that it has not lost its relevance at all CUra 3.2.1 for which we already have a profile for a single-headed zenith (it can be taken from the link at the end of the article, or downloaded from the official Zenit website settings for the older 15.04 version and independently modify them for the current 'Chicken')

We will assemble the profile for flex printing based on the parameters of ABS plastic. It is only necessary to increase the temperature of the table, relative to the standard one, as well as change the parameters of the plastic feed coefficient and the layer thickness (quality). First, let's set the temperature settings. Extruder - 235/240 degrees depending on the color of the filament, practice has shown that different colors of FLEX are extruded at the zeniths slightly differently, most likely this is due to the diameter of the nozzle and the dyes that make up the filament itself. By the way, if someone has come across something similar in their practice, we will be happy to read about your experience in the comments.

Initially, the table temperature was set at a threshold of 105 degrees, in order to warm up the material for sure. However, during the printing process, we found out that it is optimal to use 90-95 degrees for this flex. The main thing is to apply enough adhesive and properly calibrate the platform. Feed ratio 0.92 or 92%. Less - we will get under-extrusion, more - 'snot' at the entry points to the perimeter. We leave the retraction. The structure of the printing block and the physical properties of the filament allow this.

G-code ready, go to printer. After installing the sd-card, we put the printer on warm-up and take out our favorite probe for calibrating the table from the bins. In our case, this is a set of ordinary automotive probes for calibrating cylinder head valves of any gasoline engines. In any other case, plain paper 'snowflake' 80g/m2 will do. Its thickness is about 100 microns and depending on how tightly it is clamped between the nozzle and the table, you can choose a suitable gap.

Its thickness is about 100 microns and depending on how tightly it is clamped between the nozzle and the table, you can choose a suitable gap.

Having set 3 calibration points to the desired height, we turned the screws another half a turn to press the first layer against the glass more tightly. Next, apply the adhesive. This is the 'Kores' PVA glue, well known to us from the Ultran article. Which, as it turned out, can be used not only for the 'cosmic' Ultran, it is also suitable for more mundane filaments.

We start the printing process, controlling the application of the first layer. If all settings are correct, the thread will lie flat over the entire print area of the model and will not lift up from the table at retraction points. By the way, it is better to turn off the blower in the slicer for good, or turn up the speed on the printer itself. Zenith control allows you to change most of the important settings 'on the fly'. The print speed is also not very high, because. material stretches. We printed perimeters at 40 mm/sec. this will be enough.

material stretches. We printed perimeters at 40 mm/sec. this will be enough.

After approximately 3 hours of printing, the product can be removed from the table. On examination, the material is quite soft, but hard enough to withstand a model radio-controlled buggy with full electronics. I wonder how she will behave in a combat test? But it is still far from it. First you need to print the hub to the correct bore, make 3 more copies of the tire and install it all on the chassis.. Wow. There is still a lot of work to be done, but we will write about everything about this in the next issues. What do you think it is better to print a new hub and disc from? We are waiting for your suggestions in the comments!

Catalog of 3D printers - https://3dtool.ru/category/3d-printery/ Plastic for 3D printing - https://3dtool.ru/category/rasxodnye-materialy/ Previous article in the cycle - https://3dtool.ru/stati/obzor-plastika-dlya-3d-printera-nylon-ili-esun-epa/ Zenit 3D printers- https://3dtool.