Rigid 3d printer

RigidBot 3D Printer Review 2022

2.5

See Price

| Printing Area | 254 mm x 254 mm x 254 mm |

| Layer Resolution | 100 microns, 125 microns, and 254 microns |

| Supported Filament | PLA, ABS, Laywoo-D3, and Nylon |

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Extruders Diameter | 0.35 mm |

The story of the RigidBot 3D printer is as much a cautionary tale as an artifact from the heady days of the first commercially available home consumer printers.

Hot the heels of a phenomenally successful Kickstarter campaign that raised over $1 million, creator Michael Lundwall looked to offer budding makers with an affordable, quality product that was easy to use.

Marred by manufacturing issues, angered backers, and rising costs, the campaign barely managed to ship out all the promised units, culminating in Lundwall filing for bankruptcy after four years of toil and mismanagement.

Aside from the sad end to such a promising start, the RigidBot manages to remain a pioneer in today’s 3D printing landscape. So what exactly does the RigidBot offer? Let’s dive in.

Table of ContentsShow

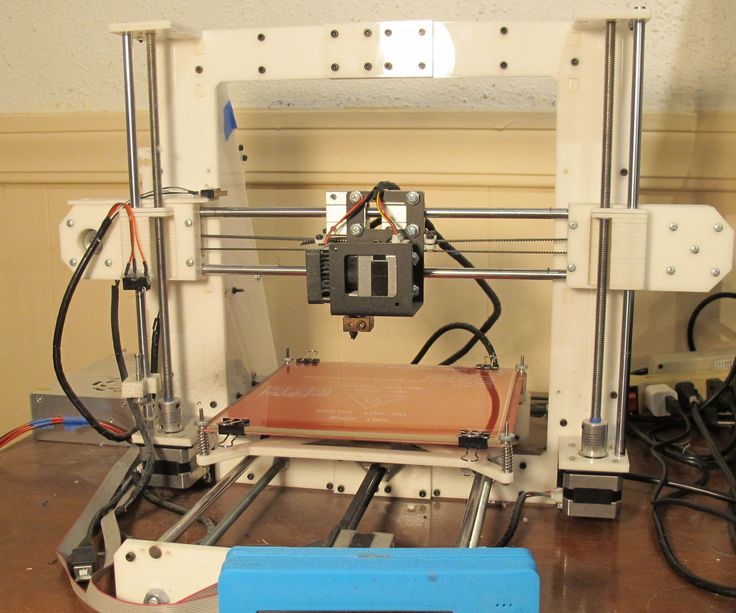

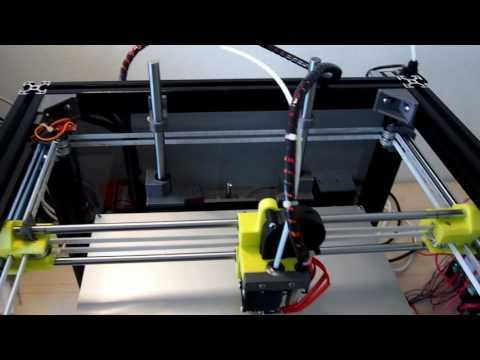

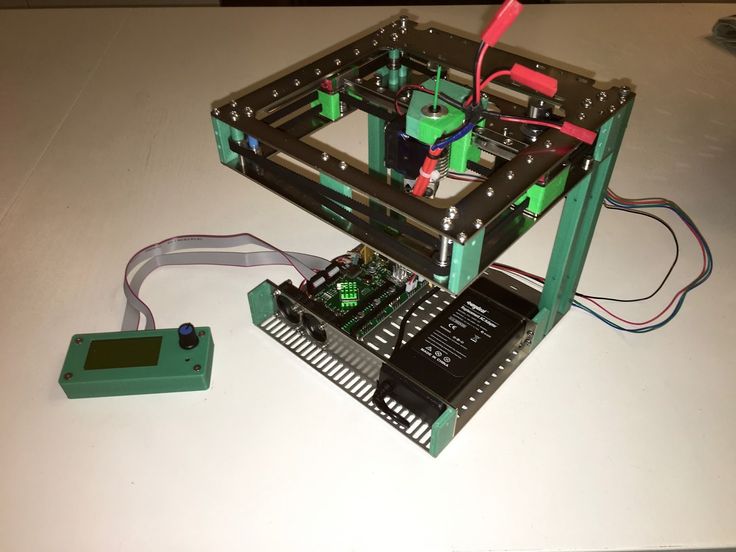

Design and Features

In keeping with its name, the RigidBot is a sturdy printer thanks in part to the robust frame made from steel frame rodes supported by injection molded corners and an acrylic build platform. The Rigidbot is among the most stable printers around and deserves praise for the simple, yet reliable build design.

In a twist on the usual setup of printers, the RigidBot is expandable through a set of injection molded plastic joints that allow the user to swap in and out steel bars of varying height to achieve their desired size on the X, Y, and Z axes. Said bars aren’t part of the shipped package, although they are readily available at any hardware store worthy of the name. The actual process is simple enough and involves unscrewing the existing rods and replacing them with the new ones.

The aesthetics of the RigidBot aren’t anything to write home about by any stretch of the imagination. The design is minimal and functional with sharp angles and minimal embellishment all in a standard black color. We understand this lack of aesthetic appeal is linked to keeping the manufacturing costs down, but this sentences the Rigidbot 3D to a workshop rather than a home office.

The lack of protective casing means the RigidBot isn’t suited for educational contexts with younger users, which is surprising given this printer was often touted as a user-friendly, educational option. We would feel uncomfortable demoing prints in front of unversed crowds likely to unwittingly touch hot parts.

The Rigidbot 3D printer sticks to the Cartesian design with the XYZ supported by linear motion bearings. The stepper motors use 1.8 step angle with 1/6 micro-stepping with the X and Y axes managed by the extruder holding rods, while the build plate moves around on the Z axis.

The Rigidbot has a good build area of 254 mm x 254 mm x 254 mm. Layer resolutions vary from 100 microns at the highest speed setting, to 254 microns on the lowest, all using a 0.35 mm nozzle diameter.

Layer resolutions vary from 100 microns at the highest speed setting, to 254 microns on the lowest, all using a 0.35 mm nozzle diameter.

The single extruder is of the direct drive variety and uses it uses Fused Filament Fabrication technology and ships with a heated bed (that can reach up to 100-degrees centigrade and displays a cluster of positioned red LED when in use) while the build plate itself is a standard aluminum build. Interestingly there’s scope for a dual extruder upgrade with the existing hardware already in place – a vestige of a Kickstarter pledge category that included dual extruders.

Filament wise, the Rigidbot uses standard fare 1.75 mm diameter filament and supports PLA, ABS, Laywoo-D3, and Nylon. It tends to work best with PLA, but we’ve had reasonable results with other materials.

The Rigidbot covers connectivity reasonably well with a USB port for untethered printing as well as a USB connection to a PC. As an open-source printer, it supports all manner of slicing software including Cura, Pronterface, and Slic3r. It can also read STL, Obj, GCode files. It’s the usual process of slicing in software, transfer to USB, plugging the flash drive into the printer, choosing the file and triggering the print.

It can also read STL, Obj, GCode files. It’s the usual process of slicing in software, transfer to USB, plugging the flash drive into the printer, choosing the file and triggering the print.

An affixed LCD control panel manages on-printer controls with five button controls to navigate, which we found to be responsive and useful listing barebones information (temperature, X, Y, Z calibration details, and instructions), but more than enough for functional use.

Assembly

The RigidBot 3D printer is shipped in both a kit and assembled format. In kit form, the package includes all the parts including any add-ons linked to stretch goals on Kickstarter. Chances are if you are buying it now, you’ll get it second hand so what comes in the box is a matter of luck. Those that received them during the campaign did, however, complain about missing hardware, so be wary that there is a risk.

The printer is packaged well with ample amounts of styrofoam for transit protection. The components and accessories are organized in trays of protective styrofoam cutouts that protect each part separately – a nice tough that suggests some logistical foresight.

Our model was of the pre-assembled variety and once out of the box required calibration work. Plug in the PSU, switch to the correct voltage and then connect the USB cable. As a tinkerer’s dream, the mechanical setup of the RigidBot isn’t straight forward. It involves tightening axes screws, limiting axes, and leveling the build plate.

The calibration is manual and involves tweaking a set of leveling screws on each of the four corners of the bed. From there, it’s a frustrating game of back and forth between the edges trying to level the bed by eye.

First timers will suffer while veterans should find it arduous, but not overly complicated. At this point, we strongly wished the RigidBot had an auto-calibration feature. Note that once the bed is leveled, it is pretty hard to dislodge and stays perfectly in place, so there’s a silver lining.

Next, you’ll need to feed the spool through the thin steel rod that is called a spool holder, but which we feel is grossly insufficient and prone to movement. Then, you’ll have to feed the filament into the top of the extruder by pushing down on the gear release switch. Feeding the filament is surprisingly simple and easy to do.

Then, you’ll have to feed the filament into the top of the extruder by pushing down on the gear release switch. Feeding the filament is surprisingly simple and easy to do.

From here, we can begin printing.

Printing

Belying its price and build, the RigidBot consistently produces quality prints even at fast speeds, although slower speeds produce better prints as is the case with any printer. We did encounter the occasional issue with layering mishaps, but these tend to be few and far between.

Overall, the RigidBot is versatile from small detailed prints to larger decorative pieces. The build area is a bit of a double-edged sword: ABS prints were prone to warping especially on the base, while PLA worked well time after time.

We also recommend using blue painter’s tape every time. Without out it removing finished prints involves more force than we were comfortable using especially for more intricate projects. There was always a sense that we could sentence 25 hours of work to the trash can with one false move.

Our biggest gripe with the RigidBot is the straight up awful and dangerous power supply unit. We won’t mash our words, it’s a fire hazard, and though we didn’t experience this first hand, the internet is littered with horror stories of these PSUs catching fire unexpectedly.

The power supply unit is a mess of cost-cutting oversights with shoddy soldering, botched circuity, and low-quality components. There’s a shot circuit disaster lurking around every corner. Besides, it’s overpowered for the printer. Invest in a replacement PSU as soon as you can.

Support

Given that the RigidBot 3D printer is no longer produced and the company behind it is now defunct, there is no official, sanctioned assistance. The RigidBot website is also offline so what used to house a host of tutorial videos and articles is now empty.

There remains, however, an active community of RigidBot enthusiasts who are more than happy to provide a helping hand to first timers, as well as advice and access to official documentation. Invent-A-Part, a company associated with the RigidBot also has a few instructional videos on YouTube about the printer, which can be helpful, and also sells replacement parts.

Invent-A-Part, a company associated with the RigidBot also has a few instructional videos on YouTube about the printer, which can be helpful, and also sells replacement parts.

When buying the RigidBot, more than likely second hand, you are taking somewhat of a risk. As such, we highly recommend picking it up for a low price to balance out the potential for a dud project and the cost of upgrades.

Verdict

Due to its age, the RigidBot is beginning to feel outdated with numerous improvements in both component technology, design, and functionality making the printer feel somewhat obsolete.

With that said, the RigidBot remains a highly customizable printer that cries out for modification. The near modular design means replacing and upgrading parts is relatively easy and encouraged.

The print quality isn’t in question: it performed well particularly if we consider the low price. The only real technical gripes were the PSU, the low-quality spool holder, the absence of parts that a selection of users experienced, and the sense that some of the hardware was manufactured with the sole aim of cutting down on manufacturing costs.

In many ways, the RigidBot is an ideal skeleton printer for a tinkerer that wants a strong starting block for an involved, mod-heavy project. The RigidBot offers the perfect foundations to build a stellar kit-style printer.

First timers might struggle with the intrinsic tinkering (and tricky leveling demands) involved in using this printer, and we can’t recommend it in that respect.

3DSourced Has Acquired Rigid.Ink - 3DSourced

We’re very pleased to announce that we have struck a deal to acquire rigid.ink, and all the excellent content that the rigid.ink team have posted over the years will now be hosted on our site.

Founded in 2014, rigid.ink was known throughout the industry for manufacturing and selling some of the highest-quality 3D printer filament around – and at a time when 3D printing was still in its infancy, and getting ahold of reliable filament was a real struggle.

More recently, rigid.ink stopped selling filament, with the founding team focusing on their 3D printing educational platform, IO3DP. Over the time they operated, they posted excellent content on different aspects of 3D printing, from their ultimate 3D printing troubleshooting guide, to how to unclog your extruder or nozzle, and much more.

Over the time they operated, they posted excellent content on different aspects of 3D printing, from their ultimate 3D printing troubleshooting guide, to how to unclog your extruder or nozzle, and much more.

We have agreed on a deal to host that excellent on our site, and to keep it updated as changes and advances occur in the industry, as part of our commitment to being the most informative 3D printing site on the web. All the content from the rigid.ink site is available within this section of our site, and you can view all the posts previously on that site below.

Rigid.Ink Content

Guides, Rigid Ink

Your 3D print not sticking to the heated bed is one of the most common issues with many 3D printers. If your adhesion is lacking, you might end up with warped print … Read more

Rigid Ink, Guides

If you want to learn more about 3D printing, whether you’re hunting for the best 3D printing book for some solid tips to get better prints, or to get full step-by-step technical training to … Read more

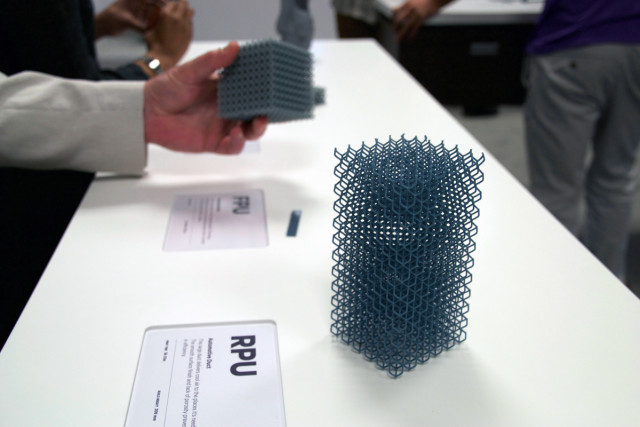

3D Printer Materials, Editors’ Picks, Guides, Rigid Ink

Being entirely water soluble, and non-toxic, this compound is used extensivly within almost every facet of modern life…

Rigid Ink, Guides

3D printing is an amazing technology whose possibilities are only just beginning to be explored by tens of thousands of enthusiasts around the world. If you’re new to 3D printing, it can … Read more

If you’re new to 3D printing, it can … Read more

Rigid Ink, Guides, Hidden Gems

3D printing is an amazing technology that can tend to be confusing at times. A lot of this confusion comes from the numerous technical terms and acronyms that have attached themselves to … Read more

Rigid Ink, 3D Printer Materials, Guides

The dreaded filament spool tangle can be a complete deal breaker to any print, and can seemingly strike at any time. If spools are used or stored incorrectly they can happen with … Read more

Rigid Ink, 3D Printer Materials, Guides

This article will clear up the confusion surrounding TPU vs TPE, how they’re best used for printing and take you through the steps to achieving best results. Ironically, flexible filaments don’t have to be hard … Read more

Rigid Ink, Guides

One of our biggest gripes about 3D printing is that your finished print invariably ends up looking, well… a bit 3D printed. Sometimes that’s fine, but other times it’s not. Here are our … Read more

Here are our … Read more

Rigid Ink, 3D Printer Materials, Guides

Clear 3D printing can be a bit of an enigma, the success of your clear prints down to a number of things. In this guide, we’ll take you through which materials can be … Read more

3D Printer Materials, Guides, Rigid Ink

What do you do when you want to print a more complicated design, one that has overhanging parts that require support or involves a lot of detail? How about a situation where … Read more

3D Printer Materials, Feature Stories, Guides, Rigid Ink

In this guide, you’ll learn why PETG filament is fast becoming a favorite. We’ll explain what PETG is, how to 3D print PETG perfectly (and some tips and tricks for the best … Read more

Rigid Ink, Guides

When browsing for your last printer, 3D printer nozzle size may well have been the last thing on your mind. It’s an often overlooked detail. Depending on what you need to print; … Read more

Rigid Ink, 3D Printer Materials

This article is going to give you all the information you need surrounding PLA 3D filament – what it is, what it’s good for, and how to print with it. PLA is … Read more

PLA is … Read more

Rigid Ink, Guides

In this guide, you’re going to learn why 3D printing is relevant to education and how to make it relevant to your students or children of any age (suitable for elementary and … Read more

Rigid Ink, 3D Printer Materials, Rankings

The availability of new, exciting 3D printing materials has increased dramatically in a few short years. Originally, you were confined to just your regular PLA and ABS filaments on any machine costing … Read more

Rigid Ink, Guides

You’ve received your free sample, or just have a small amount of filament left. But now what, what can you actually print with it? We hear you, you’ve got a busy life … Read more

Rigid Ink, Guides

We’ve all been there. You start a print job and right away things begin to go off the rails. The first layer of your print material isn’t properly adhering to the surface … Read more

Rigid Ink, 3D Printer Materials, Guides

Are you looking to expand the horizons of your 3D printing? Do you feel that your usual go-to 3D printing filaments are constricting the creativity of your designs? Maybe you simply need … Read more

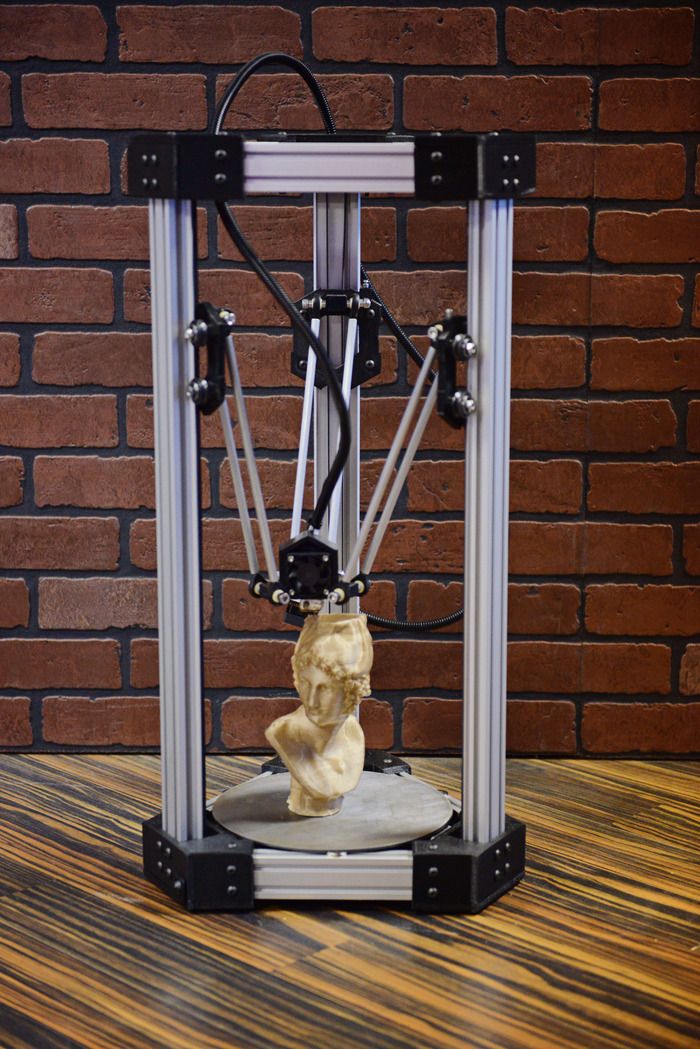

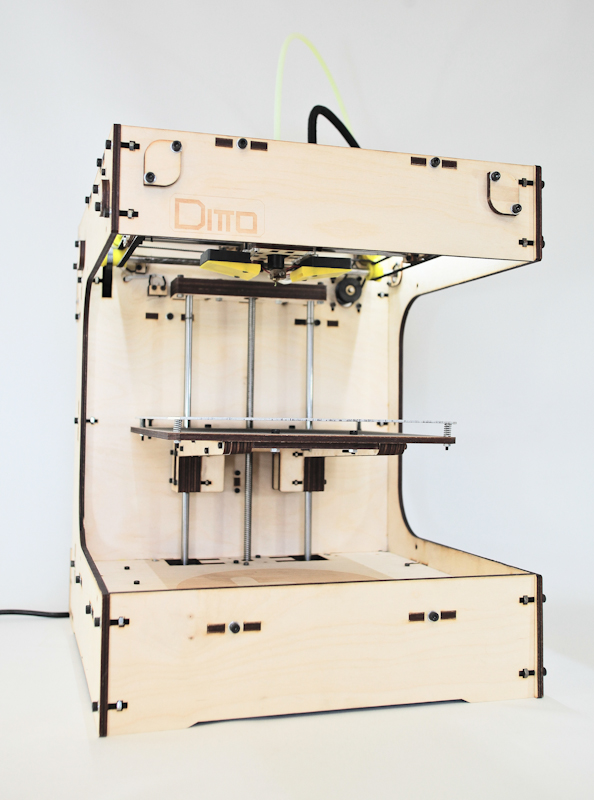

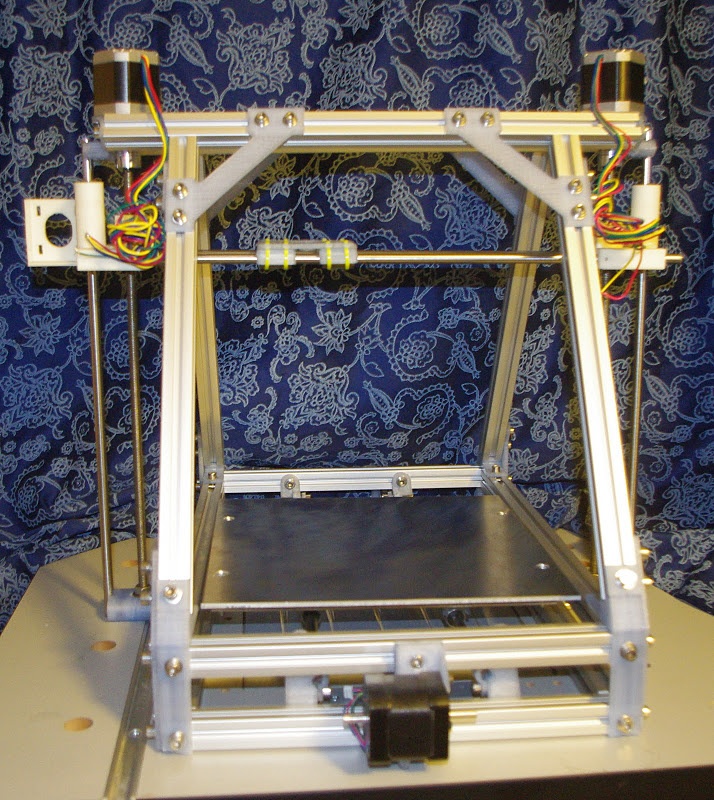

3D printer Gigant large build area 400*400*400

Description

3D printer with large 3D printable area

Large print volume is one of the main advantages of Gigant 3D printer. A significant increase in the print area is made possible by the use of a rigid metal frame.

A significant increase in the print area is made possible by the use of a rigid metal frame.

The huge print area allows you to print large objects on the Gigant 3D printer, such as a bust of a person, industrial structures, furniture elements, boxes and cases for equipment. Such a printer will be an indispensable assistant in any production.

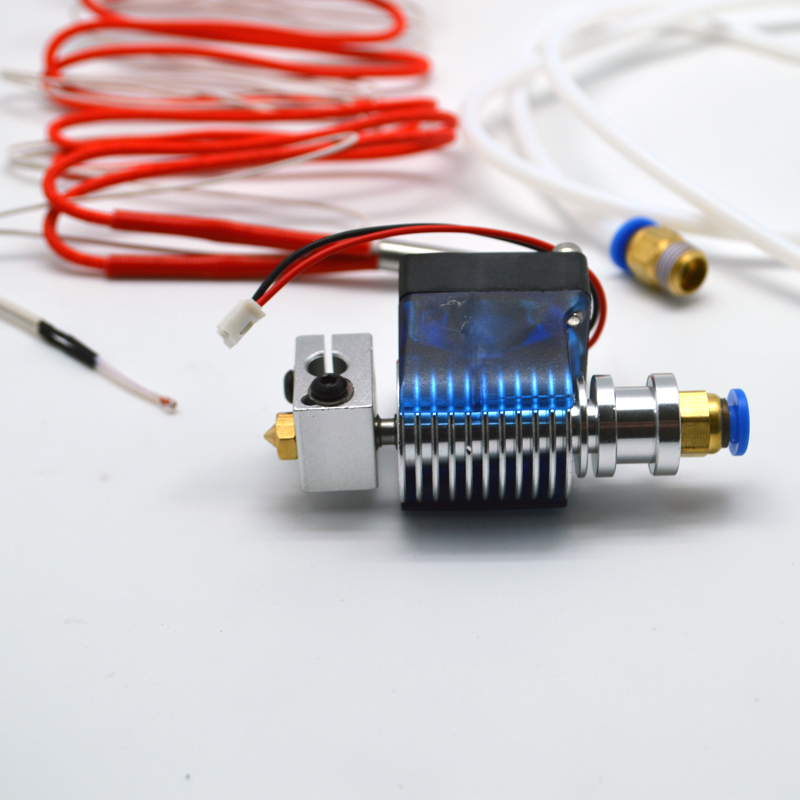

E3D extruder

The Gigant 3D printer uses the best E3D extruder because The extruder is the most important part of any 3D printer. The E3D extruder, as well as the 3D printer itself, are made in Ukraine. The Gigant 3D printer uses all known types of plastic for printing with the most common diameter of plastic filament for 3D printing.

This is one of the few 3D printers that uses Ultimaker technology and uses plastic with a filament diameter of 1.75mm. You can use for printing: ABS, PLA, PVA, HIPS, PC, PA, POM, FPE, Taulman, Laywood, Laybrick, BendLay, Flex, etc.

The optimum layer height for 3D printing is 200 microns. You can choose the layer height yourself in the 3D printer software. The printer's Z-axis accuracy (minimum layer height) is 3.75 microns.

You can choose the layer height yourself in the 3D printer software. The printer's Z-axis accuracy (minimum layer height) is 3.75 microns.

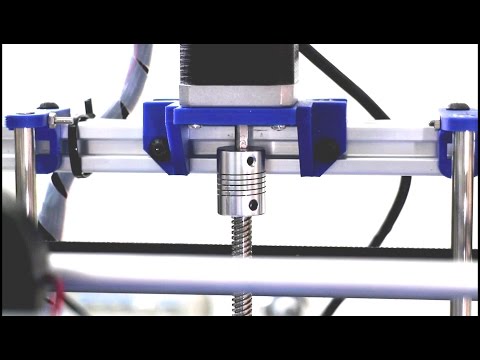

The Gigant 3D printer has a rigid and durable metal body that allows you to print ultra-precise products at high speeds. The Gigant 3D printer uses ball screws (ball screws) - the most reliable and accurate way to fasten the 3D printer platform.

Guide rails ensure precise and smooth running of all elements of the 3D printer. Due to the reliable fastening along the entire length of the rail, the rail does not deform during operation and guarantees high quality 3D printing.

Platform heating allows you to create the necessary temperature conditions for 3D printing with all types of plastic. Removable glass platform provides a perfectly flat surface and quick replacement in case of printing a new object.

The display allows you to control all 3D printing parameters and set up your 3D printer without connecting to a PC. An additional option is the ability to control the 3D printer via the Internet. A built-in camera allows you to remotely control the printing process.

An additional option is the ability to control the 3D printer via the Internet. A built-in camera allows you to remotely control the printing process.

Another advantage of this printer is its automatic calibration, which removes human intervention from the platform level calibration process.

3D printer specifications:

Gigant 3D printer

| Model | Gigant |

| Printer dimensions | 500*500*560 mm |

| Printable area | 400*400*400 mm |

| 3D printing type | FDM |

| Number of extruders | one E3D+ |

| Nozzle diameter | 0.4mm |

| Maximum nozzle temperature | 250 degrees Celsius |

| Duotone | single color |

| Plastic diameter | 1.75 mm |

| Plastic filament type | all types |

| PLA recommended temperature | 180-210 |

| ABS Recommended temperature | 220-240 |

| Print speed | 250mm/s |

| Layer height | 50-200 microns |

| layer thickness | 0. 10-0.40mm 10-0.40mm |

| Positioning accuracy | XY axis 0.0128mm, Z axis 0.00125mm |

| Body material | Steel |

| Housing type | semi-closed |

| Z-axis drive type: | Trapeze screw set |

| Linear guides | Precision Rails |

| Platform | with heating and glass cover |

| Maximum platform temperature | 120 degrees Celsius |

| LCD display | graphic display with stand-alone operation without PC |

| Ethernet, Camera, web remote control | optional |

| Software | CURA, PrintRun |

| System | Windows, Linux, Mac |

| Connection | USB, SD Card |

| Print size | STL;GCode;obj;dae;amf |

| Platform Auto Calibration | no |

| Official warranty and support | yes |

| Voltage | 200-240V 4. 0A 0A |

| 100-120V 7.0A | |

| Weight | 20kg |

| Country of manufacture | Ukraine |

Back Home

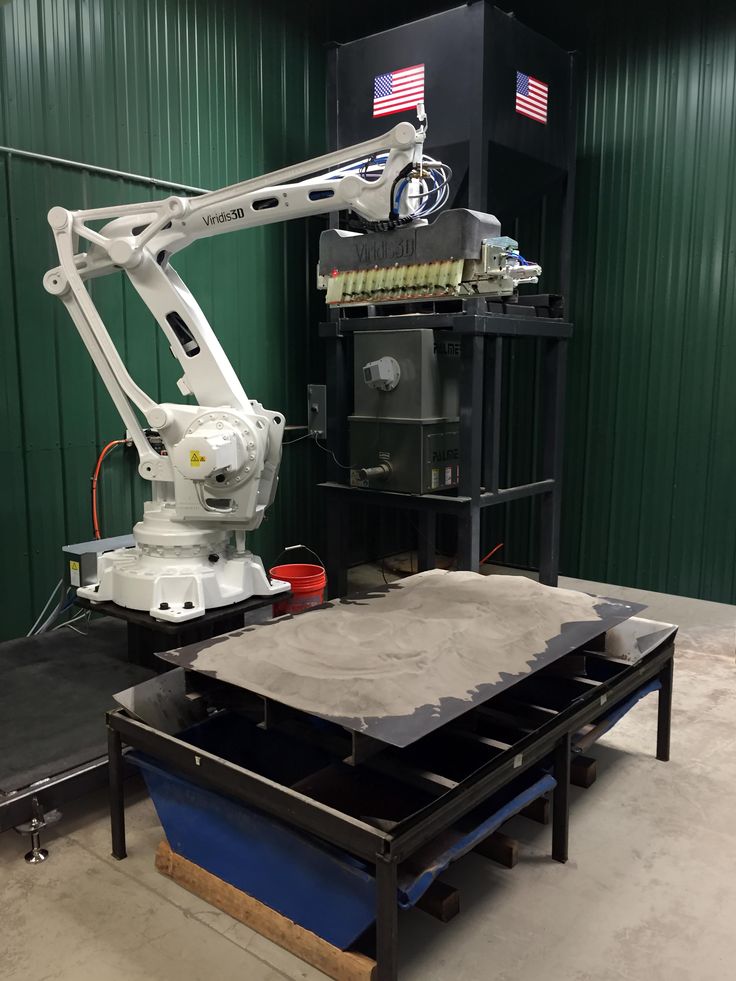

Large Area 3D Printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer Additive Machines produce high-strength thermoplastic objects for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts

3D printing of large-sized end products, components and tooling in the automotive, shipbuilding and oil and gas industries

Creation of outdoor and interior design objects and design products for construction, production of facing materials - and aircraft industry

Manufacture of large-sized stencils or burnt-out master models for metal casting and metallurgy

Creation of auxiliary fixtures, printing of templates for robotic equipment (robots, cobots, robotic arms or carts)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D printers

Discovery 3D Printer 2021

Compact 3D printing solution for large items

Learn more

Super Discovery 3D Printer Compact 9 3D printer0007

Combination of compactness and high productivity up to 2 kg/h

Learn more

Super Discovery 3D Printer Hybrid 3D Printer

Advantages of printing with granules and filaments in one device build chamber and print speeds up to 6 kg/h

More details

Super Discovery 3D Printer Workstation

2 in 1: unique combination of large format 3D printer and milling system

More details

Your unique 3D printer

Do you need to print an item larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare specifications by model

Compare 3D Printer

Solutions catalog

3D printing consumables

Do you have questions about 3D printing materials?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

- PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is flexible, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Advantages of Discovery 3D Printer Solutions

ISO 9001 certified products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling of the part after printing

Accelerate new product development with dual extrusion system

Repair and replace products faster and more economically than contractors

Ability to use a large number of third-party materials

Self-leveling platform function for automatic compensation of unevenness

Case Studies

FDM 3D Printing of Airbus Parts

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

A robust mold for autoclave molding of parts with a sealed surface and a low coefficient of thermal expansion.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Create a chair with large format 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

Printed solid statue, 1. 87 m high and 45 kg weight.

87 m high and 45 kg weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

3D printed oversized bottles for the exclusive display of Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype lid printed at 29 x 19 x 4.5 cm and weighing 146 g.

A prototype of a modular toilet has been printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed ventilation grille measuring 59 x 89 x 4. 5 cm and weighing 3500 g.

5 cm and weighing 3500 g.

3D printing of functional motorcycle part

| Industry: | Automotive |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | PACF |

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.0036

10cm x 9cm x 2.5cm supported prototype printed

3D printed square

| Industry: | Instrumentation |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | fireproof ABS |

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlayer adhesion and minimal warping.

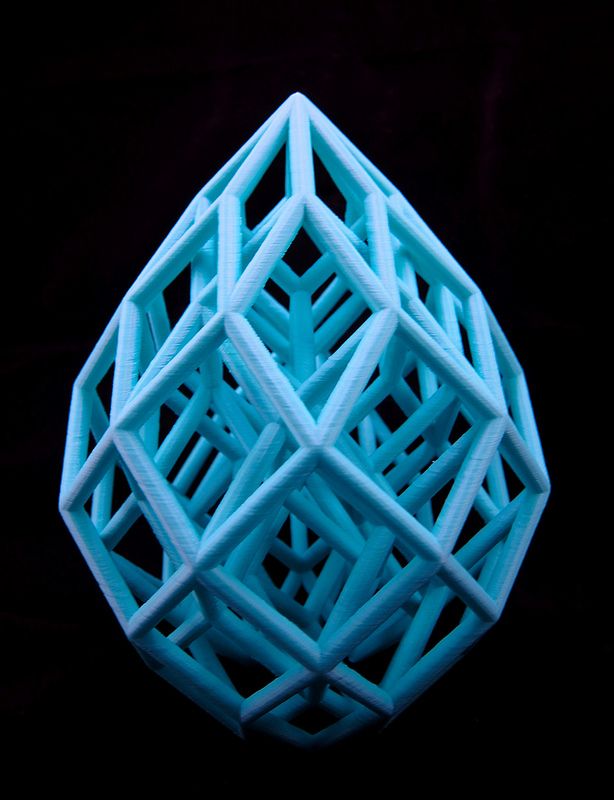

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Using an 8mm extruder, a pyramid is printed with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large, complex geometries

- How can 3D printing help you optimize production?

- Features FDM technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM technology, overview of equipment and consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

Best prices for this class of equipment

3D printer training

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology should I choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side, these modules carry out uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How can I speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process.

:quality(80)/images.vogel.de/vogelonline/bdb/1696600/1696673/original.jpg)