3D printer for miniatures reddit

The best 3D printer for miniatures in 2021

Looking for the best 3D printer to spice up your tabletop games? You've come to the right place. We've narrowed down a list of the best 3d printers for miniatures.

If you want the TLDR. Here's our findings:

| Top miniature 3D printers | Our verdict |

| Anycubic Photon Mono S | Budget-friendly 3D printer for miniatures |

| Creality Ender 3 | Best for terrains |

| Phrozen Sonic Mini 4k | Best in details, quality accuracy and speed |

How did we come up with this list?

We've collected a bunch of pain points and things that people like about their miniature 3D printer from these following sources.

/r/PrintedMinis subreddit

3D printing miniature facebook group

Online reviews

And our own experience as a 3D printing company

Without further ado, let's get started.

Top 3D printers for miniatures

1. Anycubic Photo Mono

Best Budget 3D Printer

Anycubic Photon Mono

The Photon Mono is the best LCD 3D printer that we've gotten our hands on. We own 8 of these machines and use it as part of our manufacturing process. It's cheap but the print quality is almost the same as the ones that we get from our Formlabs 3. If you're looking to buy your first 3D printer, we recommend going for a resin 3D printer like this one instead of buying an FDM printer.

$229.00 from Anycubic

Commisions earned

The Anycubic Photon Mono is the best budget-friendly 3D printer for D&D miniatures because it offers the best print quality at a budget price.

So what's so special about this 3D printer better that it blew away the competition?

Pros

- Ease of use

- Beginner-friendly

- High quality

- High resolution 3D prints

- Almost invisible print lines

- Very fast printing time

- One of the cheapest resin 3D printers in the market

Background info

The Anycubic Photon Mono is an LCD 3D printer. LCD 3D printers are a subset of SLA 3D printing and uses resin as it's main material. For those who don't know what SLA 3D printing is, SLA 3D printers use UV laser to selectively harden parts of resin. [1] This makes SLA 3D printers highly accurate with almost no visible layer lines.

LCD 3D printers are a subset of SLA 3D printing and uses resin as it's main material. For those who don't know what SLA 3D printing is, SLA 3D printers use UV laser to selectively harden parts of resin. [1] This makes SLA 3D printers highly accurate with almost no visible layer lines.

What makes LCD 3D printer a little different is that it uses an LCD screen to mask the UV light onto to the resin to the form the shape, layer by layer. This makes LCD 3D printers a lot faster than SLA but a bit less accurate and a bit limited in size. LCD 3D printers also way cheaper compared to SLA 3D printers.

Technical Specs

| Build volume | 130mm(L)*80mm(W)*165mm(H) |

| XY resolution | 51 microns |

| 3D printing technology | LCD-based SLA |

| Connectivity | USB |

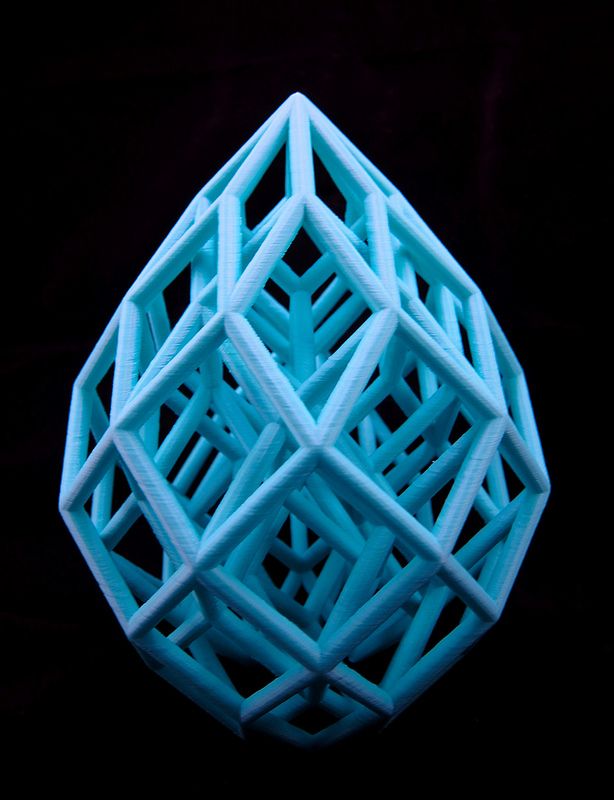

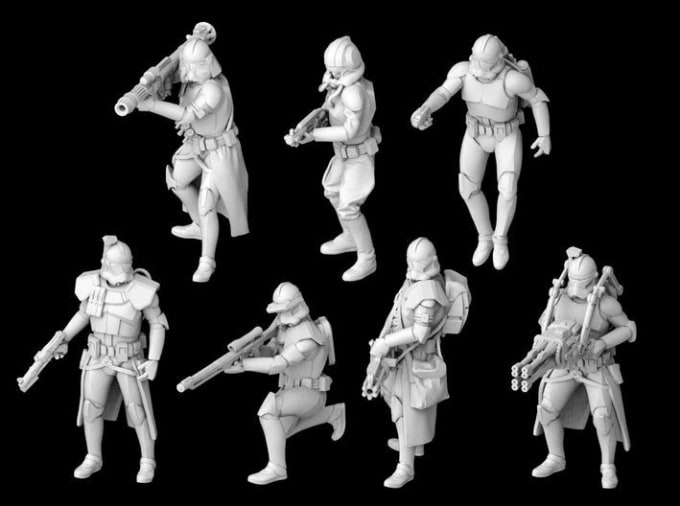

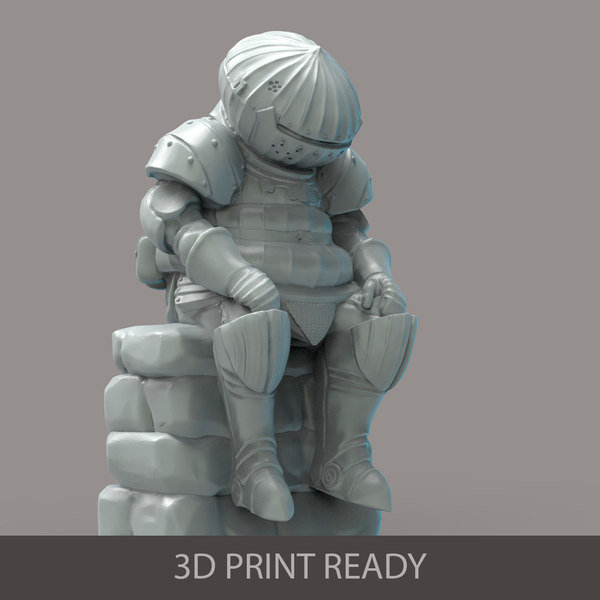

Sample 3D prints

We 3d printed these miniatures using our own Anycubic Photon Mono.

- 3d printed wallstreet bets

- On the left, printed on the Anycubic Photon Mono

How much does it cost to 3D print a miniature with the Anycubic Photon Mono?

It depends on the volume of your 3D model. Their resin costs about $40/kg. Assuming, a model volume of 1000 mm³ = 1 gram of resin. We're looking. at $0.04 per 1000 mm³ or simply $0.04/gram.

Our formula looks something like this:

Model volume (in grams) X $0.040 = Total material cost

Note however that this doesn't include any overhead cost. So if you're planning to start your own 3D printing business selling miniatures, you need to account for those as well.

Here's what each model's material cost would look like.

| Hero Forge Miniature | Ogre miniature - Thingiverse | |

| Height | 28mm | 130mm |

| Volume | 50grams | 142. 5grams 5grams |

| Material cost | $2 | $5.7 |

Is it worth it?

Hell yeah! If you want great looking miniatures for your tabletop games then you should get a 3D printer that can produce high resolution prints. The level of detail that you get from this price point is insane.

Our verdict

We own industrial SLA printers, Formlabs 3 and many more, but when it comes to 3D printing miniatures, the Anycubic Photon Mono has been our go to machine. Not only is it the right tool for the job, but it blows away all the other LCD and DLP printers on the market.

We've tested a bunch of LCD and DLP printers but we were never satisfied with them because of the amount of failed 3D prints that we get from them. As seasoned 3D printing professionals, we and we think this is the best 3d printer for miniatures especially if you're a beginner.

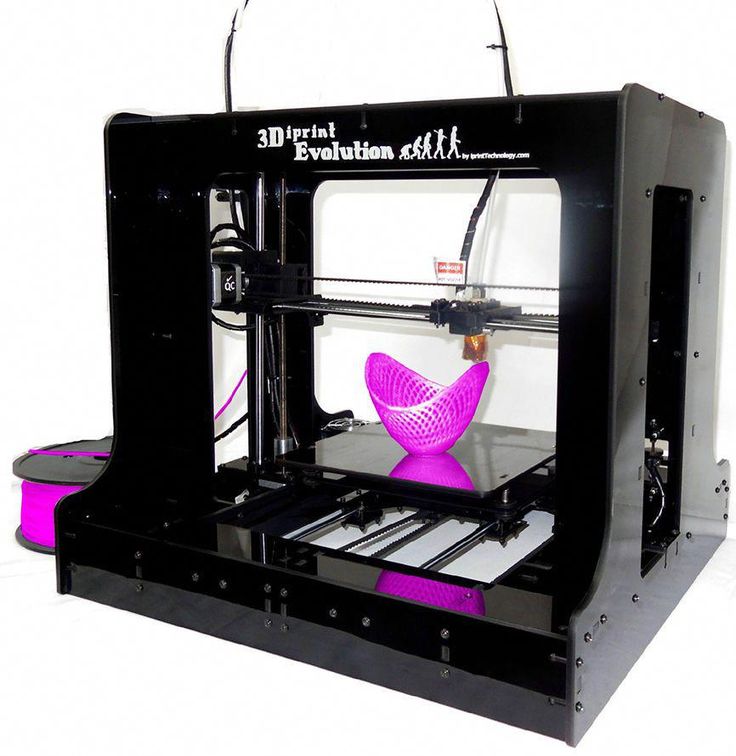

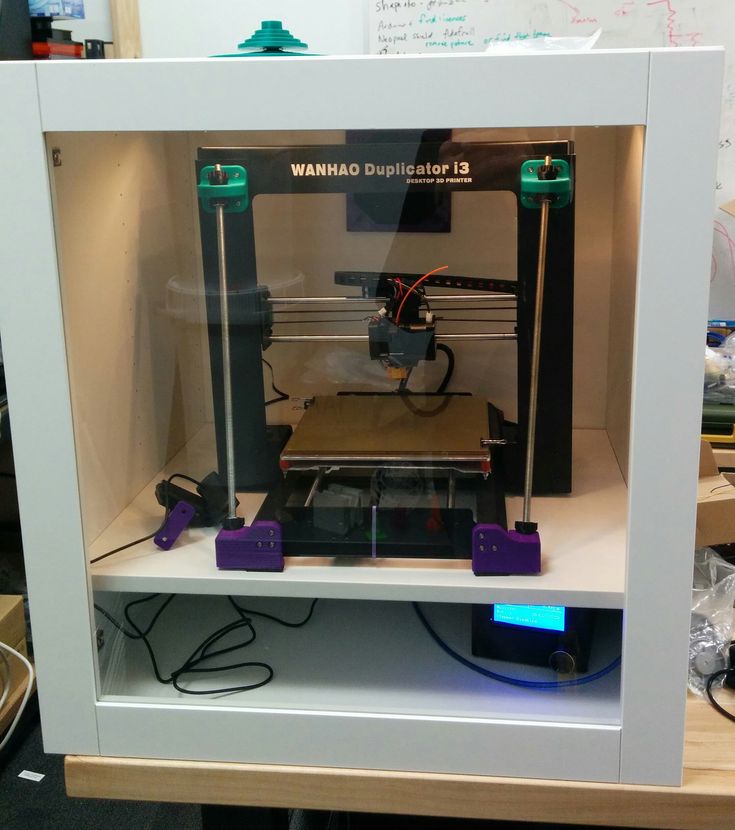

2. Creality Ender 3 v2

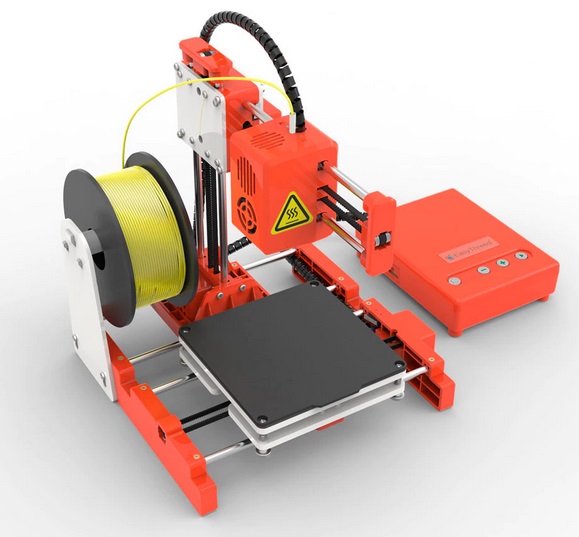

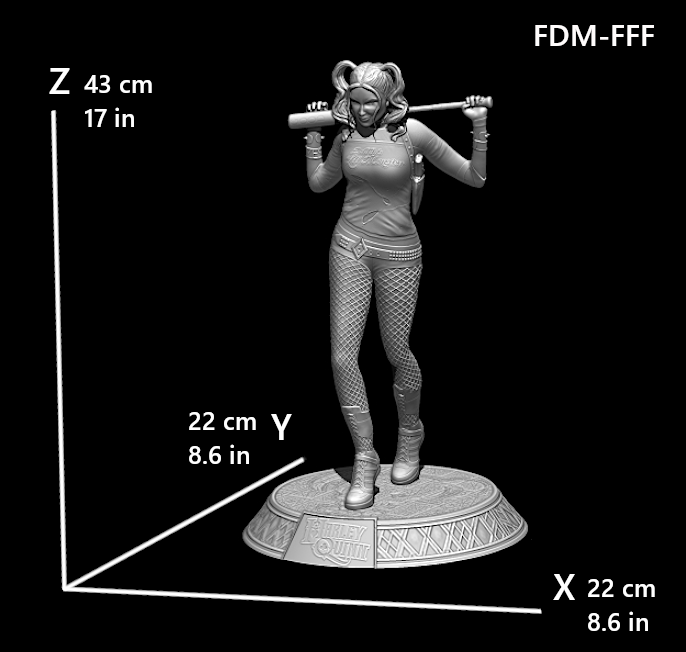

The Creality Ender 3 is one of the many FDM printers on the market.

What caught our attention is its immense popularity among the tabletop and gaming miniatures community. Every Facebook or Reddit post that we see, everyone seems to mention the Creality Ender 3.

So what makes this 3D printer so popular among the miniatures printing community?

First off, it's cheap. The Ender 3 v2 costs around $200. The material cost is also cheap compared to its resin counterpart.

The Creality Ender 3 has become the entry level 3D printer for many beginners.

We personally don't own one because we've sworn off FDM 3D printers for life. We hate cleaning FDM supports an the print quality doesn't reach our standards. It would take hours of polishing to get a smooth surface with an FDM 3D printer. And when printing larger models, FDM 3D printing has a tendency to warp. We'd rather use our industrial SLA 3D printer for that. (Slight flex).

Technical Specs

| Build volume | 192mm(L)*120mm(W)*245mm(H) |

| XY Resolution | 100 microns |

Pros

- Easy to use

- Cheap

- Large build volume

- Great for 3D printing miniature terrains

Unlike the other 3d printers listed here, the Creality Ender 3 does not use a touch screen interface. It uses a knob to navigate your 3D printer settings. Some people actually prefer this method over touch screen because its more responsive and less susceptible to glitches.

It uses a knob to navigate your 3D printer settings. Some people actually prefer this method over touch screen because its more responsive and less susceptible to glitches.

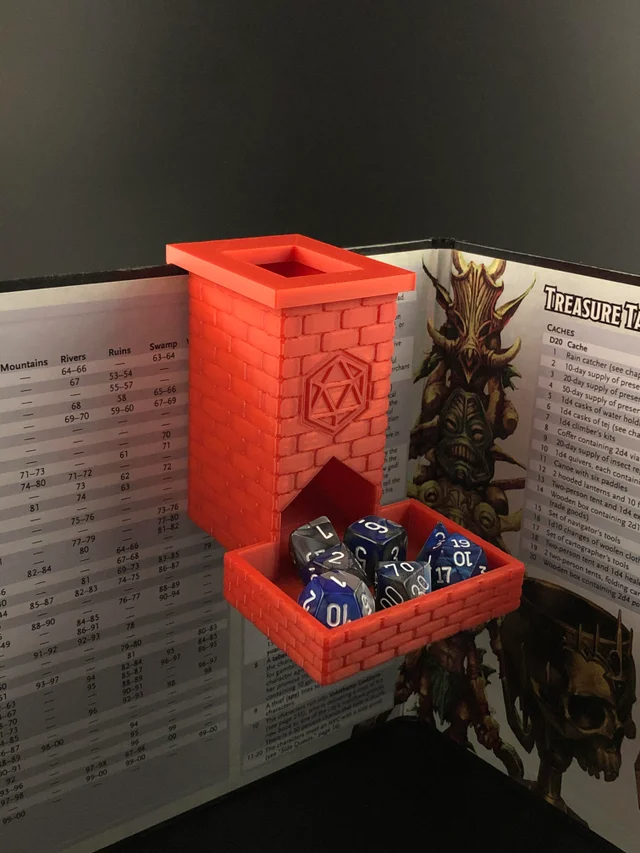

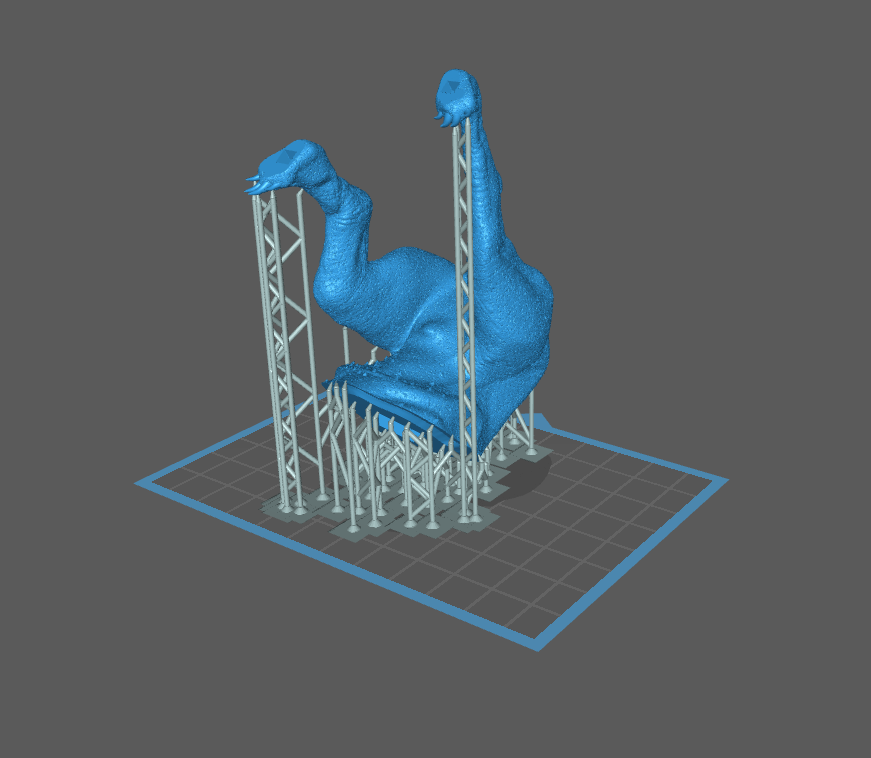

Best 3d printer for terrains

Where the Creality Ender 3 shines is on 3d printing terrains. Most of the miniature community actually owns both a resin 3D printer and FDM 3D printer. They use their FDM 3D printers to print their terrain models because it's cheaper and it has a larger build volume compared to their resin counterpart. Terrains are less complex in design and don't necessarily need a smooth surface finish so you can get away with 3D printing them in FDM.

Here's an image of a 3D printed terrain using the Creality Ender 3 courtesy of /u/Singuy888

Our verdict

If you're on a tight budget, the Creality Ender 3 might be a good option for you. The Creality Ender 3 v2 is actually more expensive than the Photon Mono S but the materials used on these machines are cheaper compared to resin printing.

For miniature printing, you might be able to get away with it but the quality is relatively bad compared to resin 3D printers that we mentioned here. If you're making a large miniature, then this would be a lot cheaper compared to its resin counter part.

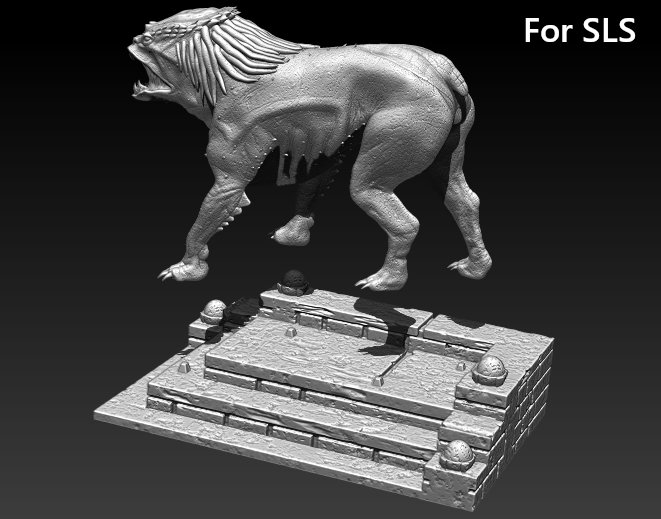

3. Phrozen Sonic Mini 4k

Best overall 3D printer for miniatures

Phrozen Sonic Mini 4k 3D Printer

The Phrozen Sonic Mini 4k produces high resolution miniatures and costs only a $100 more than the Anycubic Mono.

If you're beginner, jumping into a 4k resin printer shouldn't be an issue. And for seasoned veterans, a 4k 3D printer should be in one of your bucket lists.

$349.99 from Phrozen3D

Commisions earned

The Phrozen Sonic Mini 4k is what you should buy if you want fast printing, highly detailed prints all at a friendly price. The Sonic Mini has an XY resolution of a whopping 35 microns.

It's getting a lot of love from the tabletop miniature community because of it's price and the high resolution that you can get from it.

Here's a video of how it compares to super expensive industrial 3D printers out there.

Sample 3D prints

- courtesy of Phrozen

- courtesy of Phrozen3D

Our thoughts on professional SLA and DLP 3D printers for miniatures

Formlabs Form 3

Before we fell in love with the Anycubic Photon, Formlabs 3 was our bread and butter when it comes to 3D printing miniatures. Unlike the Anycubic, Formlabs is a full on SLA 3D printer. This makes it more accurate, but at the same time, slower to 3D print compared to LCD 3D printers.

Technical Specs

| Build volume | 14.5 × 14.5 × 18.5 cm (5.7 × 5.7 × 7.3 in) |

| XY resolution | 25 microns |

| 3D printing technology | SLA |

| Connectivity | USB/WiFi |

Sample 3D prints

Pros

- High accuracy

- Versatile, not limited to miniatures

Is the Form 3 worth it for printing miniatures?

Unless you have the money to spend, we don't think it's worth it. Both the Form 3 and Anycbuic 3D printers have almost the same build volume and the quality doesn't seem to be that far off, at least, when it comes to miniatures. And you can probably purchase 10 Anycubic Photon Mono with the price of one Formlabs 3.

Both the Form 3 and Anycbuic 3D printers have almost the same build volume and the quality doesn't seem to be that far off, at least, when it comes to miniatures. And you can probably purchase 10 Anycubic Photon Mono with the price of one Formlabs 3.

If you're planning to do more than miniature 3D printing, then maybe it is. We use our Formlabs 3 for our 3D printing service and it has been reliable for quite some time now. (We started with the Formlabs 2). But over time, we've seen less value in it. It can't 3D print large objects and it's too slow to 3D print miniatures or other regular sized 3D prints. We've come to a point where we use the Photon Mono to do most of the jobs that the Form 3 used to do.

Asiga Pro 4k

The Asiga Pro 4k cost at least $25,000. It wasn't intended for miniatures but we still gave it a try.

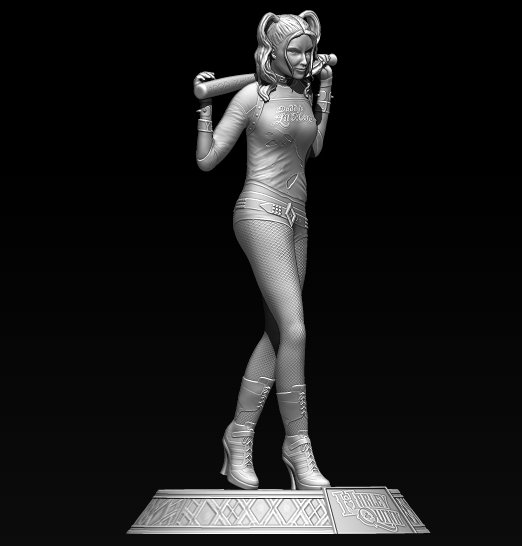

Here's a really complex tabletop miniature that we 3D printed on the Asiga Pro 4k.

We don't think the images do justice on how insane the quality is. It also only took 4 hours to print this masterpiece.

It also only took 4 hours to print this masterpiece.

Should you buy an Asiga Pro 4k for miniatures?

To be honest, it's an overkill. You're probably better off with the Phrozen Sonic Mini 4k.

We bought the Asiga Pro 4k because we need it for our industrial 3D printing services. It's fast and reliable, as we don't have the time for failed prints so for us this is worth it.

If you run a 3d printing business or if you have the money to spend, it might be a good choice for you. But you should probably get the Asiga Max X as that offers an even higher resolution at 27 microns, cheaper at $10k, but with a smaller bed size.

Our final thoughts

So what is the best 3d printer for miniatures?

The Anycubic Photon Mono is hands down the best affordable 3D printer for tabletop miniatures. It's cheap, reliable, easy to use, and it produces high quality 3D prints. For 3D printing terrain, our top choice is the Creality Ender 3. And if you want high resolution 3D prints that blows even the Anycubic out of the water, then you should go with the Phrozen Sonic Mini 4k.

And if you want high resolution 3D prints that blows even the Anycubic out of the water, then you should go with the Phrozen Sonic Mini 4k.

If you're a beginner and thinking of buying a 3D printer that fits your budget, you can't go wrong with this 3D printer. Heck, it's even cheaper than an FDM printer but with 10x the print quality.

6 Best 3D Printers For Miniatures in November 2022 (D&D & More)

The rise of video games has pushed tabletop games to the fringes, but those who enjoy these games are often die-hard fans. With custom characters and models for games becoming so pricey, many have decided that buying a 3D printer for miniatures and printing their own custom models is the way forward.

Miniatures commonly refer to games like Warhammer, Dungeons & Dragons and 28mm miniatures, but 3D printing miniatures can mean any kind of small model.

This article gives advice about the best 3D printers for miniatures for both models and terrain you can buy based on your priorities, preferences, and budget, as well as key tips for printing miniatures – and beyond the specs, the factors that actually make a difference to miniature print quality.

BUDGET PICK

Anycubic Photon M3

High quality 4K screen for low price

Larger build volume than Photon Mono 4K and Elegoo Mars 3

Available at anycubic here Amazon here

QUALITY PICK

Anycubic Mono X 6K

Higher-quality 6K LCD screen

Much larger print area for printing many miniatures in one job

Available at anycubic here amazon here

FOR TERRAIN

Creality Ender 3 V2

Lower quality than a resin printer, but ideal for terrain

Great low-cost entry-level printer

Available At Creality here Amazon here

Why 3D Print Your Own Miniatures?

Rather than being limited by the models featured in the catalogs of miniatures companies, and having to pay in excess of $10 per model, with a 3D printer you can print whatever you want, and also save up to 90% on the purchase price!

Some designers online publish their miniature files for free online (we include the best places later on), but even premium models are extremely cheap – often just a few dollars. And when you buy these, you get to keep the STL file, so you can print the model over and over again.

And when you buy these, you get to keep the STL file, so you can print the model over and over again.

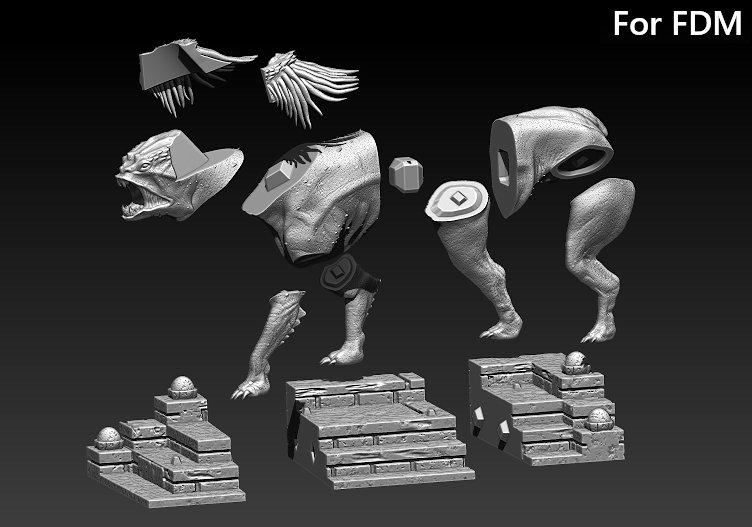

Some premium files even come with their slicer profiles pre-made so that you just need to import the file, and print.

So for deciding whether to buy or 3D print your tabletop miniatures, the main two factors are choice, and price.

The Best 3D Printers for Miniatures

| Name | Printer type | Build volume (mm) | XY Resolution | Price | Where to buy for best price? |

|---|---|---|---|---|---|

| Elegoo Mars 2 Pro | Resin | 129 x 80 x 160 | 50μm | $220 | Elegoo here |

| Anycubic Photon M3 | Resin | 163 x 103 x 180 | 40μm | $300 | Anycubic here |

| Elegoo Mars 3 | Resin | 143 x 90 x 175 | 35μm | $300 | Elegoo here |

| Anycubic Mono X 6K | Resin | 197 x 122 x 250 | 34μm | $569 | Anycubic here |

| Phrozen Sonic Mini 8K | Resin | 165 x 72 x 180 | 22μm | $699 | Phrozen here |

| Creality Ender 3 V2 | FDM | 220 x 220 x 250 | $279 | Creality Store here | |

| Ender 5 Plus | FDM | 350 x 350 x 400 | $579 | Creality Store here |

How Much Does It Cost to 3D Print Miniatures?

It costs around $1 per miniature 3D print on average, though this will vary depending on the size of the model, and the type of resin used. A 1L bottle of resin will print between 30-35 miniatures of a reasonable size, with hobbyist resins costing $20-40.

A 1L bottle of resin will print between 30-35 miniatures of a reasonable size, with hobbyist resins costing $20-40.

Remember however that you’ll use some resin on miniatures on supports, so only around two-thirds of your resin goes into the actual models.

Why Not To Use FDM For 3D Printing Miniatures (But You Should For Terrain)

While FDM 3D printers have larger print areas, and the filament is cheaper and non-toxic, you can’t get anywhere near the same level of detail. And minuscule details are the key to amazing-looking miniatures.

You’ll see the layer lines on the model, and will need a fair amount of finishing and post-processing to reach your quality standards. To put it into perspective, if you saw an FDM-printed miniature in a shop, you probably wouldn’t buy it.

But, you can print the larger, rougher parts with an FDM printer, such as terrain, backgrounds, and accessories like towers, bridges, and other cool add-ons. Often these parts will be wider than desktop LCD printers can fit, but an FDM printer like the Ender 3 should be able to print it, and if not, a larger printer like the Ender 5 Plus surely can.

Overall, we recommend buying a resin printer for miniature models, and an FDM printer for terrain and accessories. However, if you’re a complete beginner and resin printing is intimidating, then you can still print adequate quality miniatures with an FDM printer.FDM printed terrain for miniatures. Source

The Best 3D Printers For Miniatures 2022 – Reviews

We picked both FDM and resin printers depending your preferences. The first part features the best resin printers for miniatures in every price range, and then the best FDM 3D printers for miniatures we recommend are listed.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Best Resin 3D Printers For Miniatures

Elegoo Mars 2 Pro Mono — best low cost resin 3D printer for miniatures

- Price: $250 — Available at Elegoo store here / Also available on Amazon here

- Maximum print volume: 5.1″ x 3.1″ x 6.3″

An LCD 3D printer capable of fast speeds and very fine details despite the low price, the Elegoo Mars 2 Pro has fast become a mainstay in desktop 3D printing. When we tested it for our Elegoo Mars 2 Pro review, we were very impressed with the quality it delivered at such a low price.Clank 3D print we printed on the Elegoo Mars 2 Pro

When we tested it for our Elegoo Mars 2 Pro review, we were very impressed with the quality it delivered at such a low price.Clank 3D print we printed on the Elegoo Mars 2 Pro

For makers who have experience with 3D printing and are comfortable with the added complexities of resin printing, the Elegoo Mars could be your perfect 3D printer for miniatures and tabletop models. It can print smoother models with clearer, crisper finishes than FDM printers, and the resins used do not cost as much as they used to.

- We also recommend an Elegoo washing and curing station — Available on Amazon here

The 2K 6″ LCD screen gives the printer great precision for solidifying resins, with layer resolutions between 0.01-0.2mm available. It comes with CHITUBOX, the highly-praised resin 3D slicer which slices models quickly to save you time, and also includes useful features such as tools that hollow out models before you print to lower material costs, if you don’t mind slightly less durable parts.

Overall, the Elegoo Mars 2 Pro Mono is one of the best low cost resin printers around, and for creating miniatures, if you have the tech know-how, you may find resin printing meets your needs best.

Top value: If you’re happy with a 2K LCD, the Mars 2 Pro is your best option. If you have the money, opt for the Elegoo Mars 3 or Photon M3.

We were impressed with the details of the miniatures we printed with it.

Cons

Newer, higher-spec printers have since been released – however, most cost more.

Anycubic Photon M3

- Price: Check latest price at Anycubic here

- Build Volume: 163 x 103 x 180 mm

- XY Resolution: 40 microns

- Minimum Layer Height: 10 microns

The newly released Anycubic Photon M3 hits its stride in miniature making by bundling in better specs at the same price as its predecessors, the Photon Mono and Mono 4K.

These enhancements are most pronounced with a larger 163 x 103 x 180 mm build volume. This might not seem like much on paper, but means the Anycubic Photon M3 can produce much larger single models or batch print more copies of the same in one sitting than the Mono 4K, let alone the original Mono.

This might not seem like much on paper, but means the Anycubic Photon M3 can produce much larger single models or batch print more copies of the same in one sitting than the Mono 4K, let alone the original Mono.

The extra z-height lends itself well to taller models, excellent if you’re working to produce large figurines for display purposes.

The Anycubic Photon M3 and Mono 4K both use a monochrome 4K LCD, but the Photon M3’s larger 7.6” screen handles the larger build volume. In numbers, this means a slight downgrade to a 40 micron XY resolution compared to the Mono 4 K’s 35 microns, but at these low numbers, the difference is indistinguishable to the naked eye, even for veteran miniature aficionados.

We still recommend the Photon M3 over the Mono 4K for the larger build volume – at this level, a 5-micron difference is not going to make a difference, even in the most precise of miniatures.

Against the standard Mono’s 2K LCD, there’s no competition: the Anycubic Photon M3 delivers far better fine details and features on even the most complex Warhammer and D&D figures. It does so fast as well, with a solid 50 mm/h print speed, which equates to roughly 30 minutes per 28 mm model.

It does so fast as well, with a solid 50 mm/h print speed, which equates to roughly 30 minutes per 28 mm model.

Extremely affordable.

Perfect for larger miniatures – especially taller models.

Cons

Slightly lower resolution than the Mono 4K – but this is because of the larger screen and build volume on the Photon M3.

Anycubic Mono X 6K

- Price: Check latest price at Anycubic here / Amazon here

- Build Volume: 197 x 122 x 250 mm

- XY Resolution: 34 microns

- Minimum Layer Height: 10 microns

Positioned as an upgrade to the popular budget Mono X, the Anycubic Mono X 6K doesn’t reinvent the wheel as much as building upon those solid foundations and fantastic build quality.

Leading this is a jump to a 6K display, an enhanced light matrix to improve curing uniformity, and a larger 9.25″ LCD. In practice, this means a high level of print quality and a sharper 34 micron XY resolution across a larger surface.

For miniature makers, this means a noticeable jump in quality over the Mono X, especially on finer parts such as hairs, scales, horns, armor detail, and facial features.Printed on the Mono X 6K. Credit: u/MaxHereticus66

This applies to large and small figures or models thanks to the Anycubic Mono X 6K having a roomy 197 x 122 x 250 mm build volume for a resin printer. In other words, the Anycubic Mono X 6K is as suited to printing large Warhammer tanks, knights, and warhounds as classic space marine 28 mm miniatures.

We highly recommended the Mono X when it was the best-quality mid-range resin printer around, and the Mono X 6K builds on this wonderfully. However, if you want to save money, the Photon M3 is a great shout if you’re comfortable with 4K resolution, as the Mono X 6K costs double the price.

For amateur Warhammer players and those partial to the occasional Friday night D&D session, the Photon M3 remains the most cost-effective option. But, for next-level resolution, the Mono X 6K is the best out there.

The Mono X was already a top pick – now it’s upgraded.

6K LCD offers superb rendering of intricate details.

Even larger build volume for producing many miniatures at once.

Cons

Expensive compared to budget 3D printers for miniatures.

If you don’t need all 6K quality, opt for a Photon M3, Photon Mono 4K, or Elegoo Mars 3.

Phrozen Sonic Mini 8K

- Price: Check latest price at Phrozen here

- Build Volume: 165 x 72 x 180 mm

- XY Resolution: 22 microns

- Minimum Layer Height: 10 microns

Widely considered one of the best consumer-grade resin 3D printers on the market, the Phrozen Sonic Mini 8K is ideal for super high-quality miniatures, whether for tabletop gaming, display, or war gaming.

If you can stomach the price tag, the Phrozen Sonic Mini 8K is as premium as the best 3D printers for miniatures get – unless you go full industrial.

The Phrozen Sonic Mini 8K offers a best-in-class 22 micron XY resolution. It outperforms much-loved resin printers such as Elegoo Mars family and Anycubic Photon Mono X 6K and Mono 4K. In action, this type of resolution renders even the tiniest features in exquisite detail, even on small 28 mm miniatures.A 4K print on the left, and 8K on the right. Source: Geek Gaming Scenics

Now, for all its ability to create superb miniatures, the Phrozen Sonic Mini 8K does have one major drawback compared to other resin printers – a smallish build volume.

It sits at 165 x 72 x 180 mm, putting it on par with much cheaper alternatives like the Anycubic Photon Mono 4K.

This is necessarily a downside if you’re printing single large figures, but it does reduce the scope for batch printing multiples simultaneously, so if you want to produce large volumes for your business or home games, consider Phrozen’s Sonic Mighty range, the Anycubic Mono X 6K, or Elegoo Saturn S.

Overall, if you’re looking for the best quality miniatures, and aren’t too worried about a slightly smaller build volume, the Phrozen Sonic Mini 8K is largely unrivaled.

Best-in-class 22 micron XY resolution.

Perfect for small 28 mm figures with precise features and details.

Cons

Small-ish build volume for the price.

Best FDM 3D printers for miniatures

Creality Ender 3 V2 — Best 3D printer for miniature terrain

- Price: Check price at Creality Official Store here / Available on Amazon here

- Size: 220 x 220 x 250 mm

- Resolution: 100 microns

Considered one of the best cheap 3D printers around, the Ender 3 is famed for its reliability and effectiveness for the price. It comes as a 3D printer kit, but takes under an hour to assemble and it’s really easy – just 20 screws.

It’s an FDM printer, so it cannot reach the same level of precision as an Elegoo or Anycubic resin printer. However, it’s one of the best FDM 3D printers for terrain for miniatures, as it prints reliably, cheaply, and has a decent print volume of 220 x 220 x 250 mm.

If you want to avoid resin printing you can use it to print miniatures, but they won’t have the same level of precision, and you’ll need to do some sanding and general post-processing to get them closer to the level you’re happy with.

But, the Ender 3 V2 is the best printer in its price range for terrain, and PLA filament is very cheap and super easy to print with. The only issue could be if you want to print large towers or terrain that doesn’t fit within the build volume.

Best low-cost FDM kit – easy to build and print with, and it’s reliable and durable.

Very upgradable: many extruder, bed, hotend, and other upgrades available.

Cons

Not well suited to miniatures – stick to terrain, and strongly consider a resin printer instead.

Ender 5 Plus – best 3D printer for miniatures terrain

- Price: Check latest price at Creality here / Amazon here

- Build Volume: 350 x 350 x 400 mm

- Printing Accuracy: 100 microns

- Layer Thickness: 100-400 microns

If you’re leaning towards a budget FDM printer like the popular Ender 3, but its build volume doesn’t quite measure up to the size of terrain you’re planning to print, the Ender 5 Plus is a great alternative.

It supersizes the build volume to a generous 350 x 350 x 400 mm, ideal for those sprawling backdrops for your tabletop and D&D adventures that simply won’t fit on a stock Ender 3.

As low-cost consumer-grade printers go, this volume size is up there and should cover all your terrain needs. It’s particularly suited to intricate ruins, battlefields, towers, rocky outcrops, dungeons, and the like – perfect for heightening that crucial sense of immersion.

Aside from the large format, Ender 5 Plus also features some handy benefits over the Ender 3. It comes with a BLTouch automatic bed leveling probe to save time and effort, so you can concentrate on bringing to life terrain.

There are also dual z-axis lead screws to improve stability and, by extension, overall print quality. Elsewhere, it boasts a filament sensor that alerts you if the filament runs out or breaks, so you won’t waste any more time than you need on a print that won’t complete.

The Ender 5 Plus is priced over double what you’d expect to pay for the Ender 3, but if you can stretch your budget, it’s a do-it-all terrain printer that’s well worth the extra money.

Massive 350 x 350 x 400 mm build volume.

Convenience features like automatic bed leveling and filament sensor.

Ideal for large backdrops and terrain models.

Cons

More than double the price of the Ender 3 and Ender 3 V2.

Important Specs & Factors To Consider Buying a 3D Printer For Miniatures

Layer Height

Different 3D printers have different minimum layer heights, for example the Elegoo Mars 3 has a minimum layer height of 0.01mm, or 10 microns. The Creality Ender 3 V2 has a minimum layer height of 0.1mm, or 100 microns.

The smaller the layer height you choose for your models, the better the quality, and the less visible the layer lines will be.

However, the lower the layer height, the more layers you’ll have in your model, which increases the time it takes to print, and also increases the chance of a failed print.

We advise that you don’t need to go all the way down to 0.01mm on your resin 3D printer with miniatures – 0. 03-0.04mm is a good range for great quality. To put that into perspective, in a 6cm tall resin miniature print, with 0.05mm layers, that is 1200 layers to print.

03-0.04mm is a good range for great quality. To put that into perspective, in a 6cm tall resin miniature print, with 0.05mm layers, that is 1200 layers to print.

Screen Quality and Precision: Do you need a 4K, 6K, or 8K Screen? And Should You Buy a Mono 3D Printer?

The most important thing is to pick a mono 3D printer. They cure and print resin layers often 3x faster, and often last up to 4x longer, too, so they’ll save you money and hassle replacing parts continuously.

We recommend you opt for a 4K resin printer if you can afford it, as they’re not too much more expensive than 2K MSLA printers now, and you will notice an improvement in precision, especially on details like hair and beards, or hands and fingers on your models. If you have the money, go for an 8K printer – but it isn’t a necessity.

However, do not look solely at the specs when determining if a printer is high quality.

A 2K screen with a printer made from high-quality parts – such as build plate bolts and resin vat locks that can handle low layer heights and retain accuracy and aren’t prone to threading – will produce better miniature models than a shoddily built 4K printer.

Focus on buying a well-made printer made by a reputable company with a high-quality screen.

High-quality brands include Anycubic, Elegoo and Phrozen in these lower price ranges, and we highly recommend these if you’re printing miniatures at home or other precise resin models.

That being said, there are noticeable differences at each resin quality level – mostly after you’ve primed the models.

Corners will look a bit sharper, and certain facial features and muscle definitions will come out better generally – but you can still create very good models on 4K or even 2K LCD screen resin printers, you just get that extra sharpness when you go up to 6K or 8K.

How Speed and Size Works with a Resin Printer

Resin printers work differently from FDM printers. Instead of printing one part at a time as an FDM printer’s extruder traces the layer, LCD printers flash an entire layer at once, so no matter how many models are being printed within the build plate, they’ll all print in the same amount of time.

So, the only factor that determines how long a resin print job will take is the height of the tallest model.

This makes the build size of a resin printer important, as the more models you can pack into the area, the more models you can print in one job – in the same amount of time. Large 3D printers can print potentially 20+ miniatures at once – though most hobbyist printers can print around 3-4 reasonably sized miniature models.

Things to Remember When 3D Printing Resin Miniatures

Resin is toxic and irritant – never touch it directly, and if you do, wash your hands thoroughly with soap and water. Wear a mask to avoid the fumes, generally try to avoid the room when printing, and if possible put the printer near ventilation.

There is post-processing involved after printing – you’ll need to scrape the resin prints off the build plate, remove the supports (wear gloves), wash the resin off of the prints with isopropyl alcohol, dry them, and cure them in UV light. Then, optionally you can fix any imperfections, prime and paint them for your custom look. We recommend buying your brand’s wash and cure station to save you time and hassle.

Then, optionally you can fix any imperfections, prime and paint them for your custom look. We recommend buying your brand’s wash and cure station to save you time and hassle.

You will need to replace parts – the two main culprits are FEP films, and screens, which will need to be replaced over time. This puts you out of action for a while, and costs money.

Read more: is 3D printing miniatures cheaper (we calculated the exact cost for FDM and resin printing miniatures)

What makes a good 3D printer for miniatures

- Precision: measured in microns, this is key for how detailed even the smallest features of your models will be. The best resin 3D printers for miniatures often reach 35 microns, for great details. FDM printers can’t reach these same resolutions.

- Print area: since MSLA printers cure entire layers of resin at once, larger build areas mean you can print even more models in the same amount of time.

- Stable, metal frame: a heavy frame is less influenced by other variables such as the vibrations that can affect model quality, even slightly. High-quality parts are key to accurate miniatures, so pick up a printer by a reputed brand known for making well-built products.

Best Practices for FDM 3D Printing Miniatures

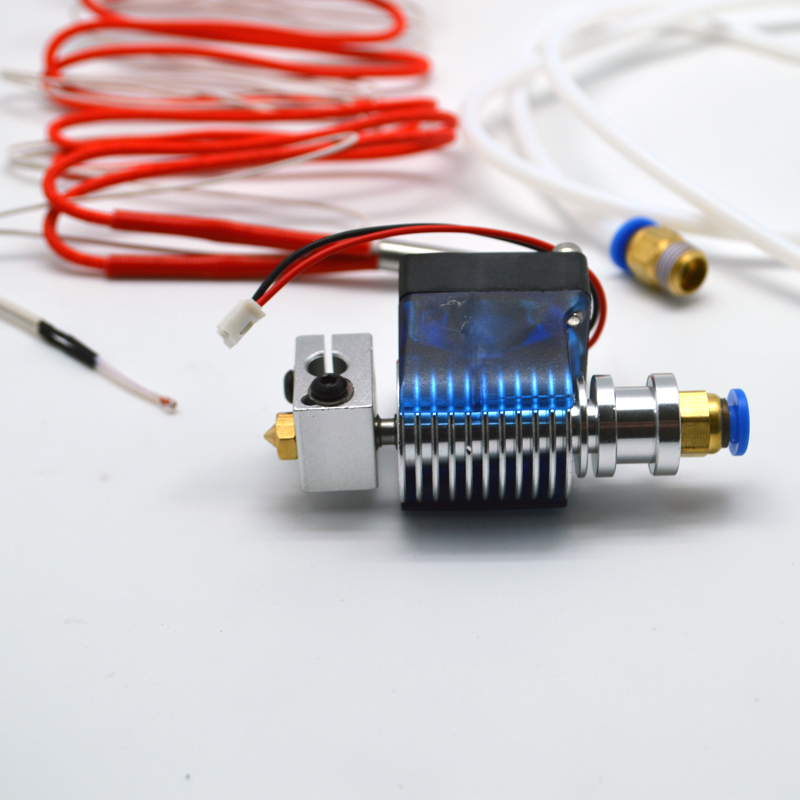

- Nozzle size: using a small nozzle makes for better precision on printers, and though they print slower, this isn’t a big problem when printing small models that do not take long anyway.

- Slow printing speed settings: if you have the fastest 3D printer around, such as a delta 3D printer, you should slow it down when printing small, precise models. You may want to reduce speed to as low as 20-30mm/s.

- Infill percentage: you may want to change this based on how strong you want your miniatures to be. If you want to save on material costs and don’t mind giving up some part strength, you can reduce infill to 10%, though some hobbyists who want solid models may go for a higher infill percentage.

- Retraction settings: optimize retraction settings to prevent oozing and stringing of filament, which can occur especially often with PLA.

- Post-processing: not directly related to your printer, but you can decide whether to paint your model, sand or polish it to enhance its finish.

Where to find files for miniature 3D prints?

Here are some sites that host free and paid files:

- MyMiniFactory

- Cults3D

- Thingiverse (all free)

- Gambody (specialized in video game/comic book models)

- Pinshape

And here are some articles where we recommend miniature-related prints:

- Dungeons and Dragons 3D print files

- Warhammer 40K 3D prints

- 3D printed figurine files

- 3D printed anime figure files

- 3D printed dice towers

- 3D printed dragon files

Post-Processing and Painting Miniature Prints

Really, a miniature isn’t truly finished without some post-processing love and attention. After all, 3D printers can only go so far when it comes to bringing out the lush detail and intricacies of a model.

After all, 3D printers can only go so far when it comes to bringing out the lush detail and intricacies of a model.

Support Removal

First, remove any support structures by either removing them by hand or using clippers, or in the case of soluble supports, immersing them in the appropriate liquid, usually water.

Cleaning and Sanding

Next, you’ll want to clean and improve the print surface to remove blemishes, blobs, marks from the supports, and other imperfections.

We recommend ordinary sandpaper or a sand sponge – they are cheap, effective, and come with grit coarseness levels for quick sanding, smoother finish, etc.

Alternatively, you can buy a small nail grinder with different attachments suited to miniature post-processing. You can also use a hobby knife, scalpel, or precision needle files for those hard-to-reach places.

Glue Parts Together (If Multiple Parts) and Fill In Holes

After cleaning up the print, glue or attach parts of the mini using a bonding agent (you can also do this after painting if you prefer), and fill in any drainage holes, seams, gaps, and cracks using a brush and a mix of resin and baby powder.

Be sure to cure the newly-applied resin mixture afterward. You can use non-cure products like the excellent Apoxie Sculpt to fill in gaps.

Priming and Painting

Next stop, we have painting. First, we’ll need to prime the minis to create a strong first layer for successive layers of paint to adhere well.

Both spray and brush paint options are viable – any old primer from your hardware store will do. If you’re looking for a brand name, we recommend Tamiya Surface Primer.

Two light coats are a good option to be on the safe side. Allow plenty of time for the primer to dry properly.

Finally, paint your miniature. Standard miniature etiquette and techniques apply here. We recommend using regular acrylic paints found at any hobby store such as Vallejo Game Color. We recommend investing in different brush sizes to cover the painting of everything from large single-color portions to small intricate details.

From there, take your time painting, and remember, practice makes perfect. Your first minis might not look perfect, but stick with it, and they start coming out great in no time.

Your first minis might not look perfect, but stick with it, and they start coming out great in no time.

Is it legal to 3D print Warhammer models?

It is legal to 3D print Warhammer figures as long as you do not try to sell them or use them for any other kind of commercial use. Patent laws prevent anyone from selling any object based on someone else’s intellectual property. If you design the model yourself however, if it isn’t identical or a total imitation of another’s copyrighted work, then you aren’t infringing on their copyright or patents.

However, keep abreast to new changes in laws that affect where creators and IP holders stand legally. For example, the 2021 Appropriations Act changed the way holders of IP and perceived infringers interact. This article is also useful for a general understanding of where you stand with 3D printing and intellectual property.

We would like to conclude this article by reminding readers to be careful, as intellectual property (IP) laws prevents the creation, download or 3D printing of trademarked characters. You can get into trouble if you print a trademarked character such as a Pokémon, with some large companies becoming increasingly studious in pursuing people breaking these laws.

You can get into trouble if you print a trademarked character such as a Pokémon, with some large companies becoming increasingly studious in pursuing people breaking these laws.

Is it worth buying a 3D printer for miniatures?

If you plan on printing large numbers of miniatures, it is definitely worth buying a 3D printer for miniatures. You can print any model you want rather than buying whatever’s available, and for a fraction of the price. You can get started for cheap by spending under $300 on an Anycubic Photon M3 or Elegoo Mars 3.

What is the best material for 3D printing miniatures?

Resins are the best material for 3D printing miniatures, as they have fine details like faces and weapons that filament won’t be able to match. Some of the best affordable resin materials are made by companies like Siraya Tech, Anycubic, and Elegoo, letting you print fantastic details on your miniatures within your budget.

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability.

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale production. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas.

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

Custom heads for LEGO men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

3D Printed Chaplain

Chaplain 3D model from Warhammer 40k

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

DC Universe Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Seal of weapons

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer.

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a rather weak .380 ACP cartridge and could withstand a maximum of ten shots.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan.

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip.

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0063

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez.

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle.

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over the classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

A big advantage over the classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts are modeling and posting models and detailed instructions for assembling traction prosthetic hands and fingers in the public domain so that any user can print and make a prosthesis at home.

Simple Traction Hand Model

Production

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased.

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Prototyping

Gas turbine prototyping.

Prototyping by traditional methods is often time consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing.

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production. After all, the production of traditional stencils with filling in molds took up to 5 weeks, and the 3D printed model is ready by the morning.

Totals

Despite the unethical side of 3D printing, there are still more positive use cases. 3D printers have become indispensable assistants in various industries - from home hobbies to serious industries. With the help of 3D printers, unique products are made that could not be obtained using other machines.

Popularization of 3D printers is a matter of time. But do not forget that 3D printing is just a tool, just like a drill or a hammer. It depends only on the user how it will be used.

Best resin 3D printers of 2022

Buying a 3D printer can be quite intimidating, especially if you don't know much about this hobby. Best polymer 3D printers cost between $200 and $2,000, so it's no coincidence choice. Before you make a purchase, you need to think about what exactly you want to use it, as it will greatly influence the choice of printer. For example, if you plan to create large miniatures or prototypes tools, you will need a printer with a large build volume. you also you need to decide what level of detail you want from the printer, as this greatly affects its value. While a 4K-capable printer in our days is quite affordable, 6K will raise the price significantly.

Build volume is a measure of how how big a product a 3D printer can produce. If you want to do something large, you will need to purchase a printer with a large (or even very large) print volume. Generally speaking, printers with large build volumes require a bit more fiddling (and can be more error prone user) than their equivalents with standard volumes.

3D printer LCD resolution will determine the level of detail of your beautiful miniatures. Printer 4K in these days is considered the standard for all but ultra-budget models, and its more than enough for most projects.

Monochrome 3D printer LCD masking is better than a printer with RGB (or color) masking LCD display. Monochrome transmits UV light better than their color alternatives, which means each layer is scanned much faster.

Ultimately, it's up to you which of the above features is more important to you. Each of the following polymer 3D printers excel in one area or another, often several.

|

| ANYCUBIC Photon Mono X | ANYCUBIC Photon Mono 4K | Elegoo Mars 3 | Prusa SL1S Speed Bundle | ANYCUBIC Photon M3 Max | Creality HALOT-ONE |

| Assembly volume, mm: | 192x120x250 | 132x80x165 | 143x89x175 | 127x80x150 | 300x298x164 | 130x82x160 |

| Resolution: | 3840×2400 (4K) | 3840×2400 (4K) | 4098×2560 (4K) | 2560×1620 (2K) | 6480×3600 (6K) | 2560×1620 (2K) |

| Print speed: | 60 mm/h | 50 mm/h | 50 mm/h | 1. | 60 mm/h | 1-4 seconds per layer |

| Printing accuracy, mm: | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Resolution along the XY axis, mm: | 0.05 | 0.035 | 0.035 | 0.049 | 0.040 | 0.050 |

| LCD, inch, monochrome: | 6. | 6.23 | 6.66 | 5.96 | 13.6 | 5 |

| MSRP, US$: | 480 | 250 | 380 | 2000 | 1300 | 200 |

ANYCUBIC Photon Mono X offers the best vital features for the price of any 3D printer consumer grade polymer-based.

Premium feature set, reasonable price, speed. But the disadvantage may be that it is not as easy to use as entry level models.

Mono X function set for head above normal. With dimensions 7. 5x4.7x9.8" Mono X build area more than enough for any thumbnail you might want build. It also offers high speed, 4K resolution and better Z-axis support than similar models.

5x4.7x9.8" Mono X build area more than enough for any thumbnail you might want build. It also offers high speed, 4K resolution and better Z-axis support than similar models.

ANYCUBIC Photon Mono 4K excellent copes with the creation of standard thumbnails quickly and easily, and it is not difficult master.

Among the advantages are the price, speed and ease of use. Cons - standard build volume and possible problems with the touch screen.

He may be smaller than his older brother, Mono X, but it still packs a punch.

Excellent 4K resolution and standard build volume make it a very good option for users, who want to make a large number of standard miniatures without much fuss. It is fairly easy to set up, even for beginners, and its compact size means he can stand at the small end of the table without attracting a lot of attention.

Elegoo Mars 3, perhaps the most a well-known 3D printer among beginners and experts.

Pros: very popular and intuitive, good resolution, slightly larger build volume. Minuses: more expensive than analogues.

Overall, Mars 3 lives up to its reputation as the easiest-to-use resin printer, and offers a robust set of features. Mars 3 is slightly better than its main competitor Mono 4K, in almost all significant categories, especially in terms of volume assemblies. However, reviews show that over time it is not as fast as the Mono 4K. However, due to its popularity on Reddit and YouTube, one can find absolutely a ridiculous amount of tutorials on how to use Mars 3 and that gives it slight edge in the beginner-friendly category.

Best high-end: original Prusa SL1S Speed Bundle.

Pros: speed, really professional level, supports simple post-processing. Cons: price, some deprecated features.

The world of resin 3D printing has hobbyists and small businesses. If you want to make serious money by selling your thumbnails or other products on stores like Etsy and you already have some resin printing experience, the Prusa S1LS Speed is a good option.

3 to 2.4 seconds per layer

3 to 2.4 seconds per layer  23

23