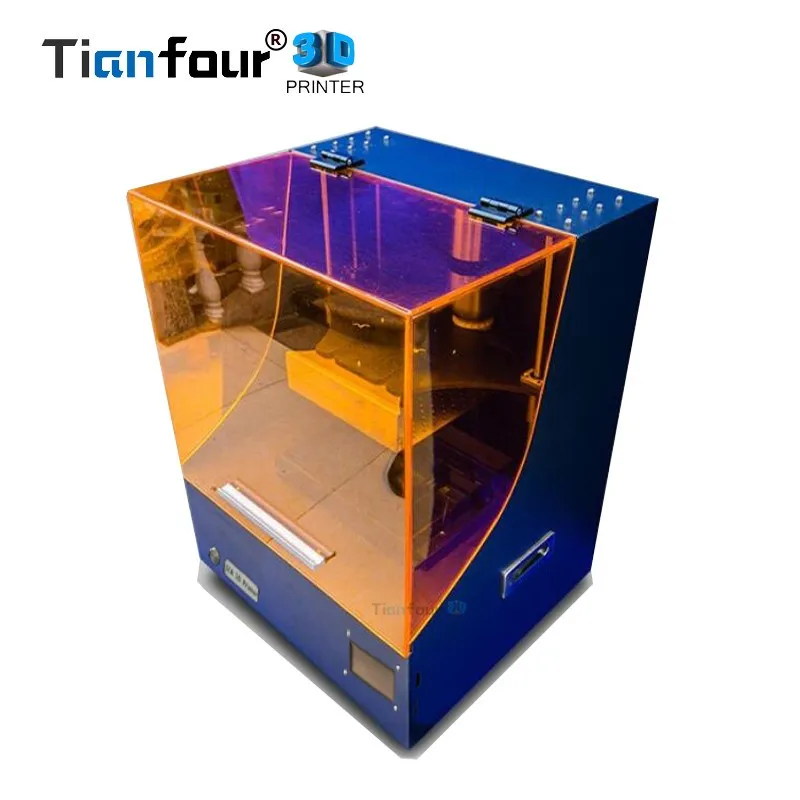

Sla lcd 3d printer

SLA vs DLP vs LCD 3D Printing: Which Is Best?

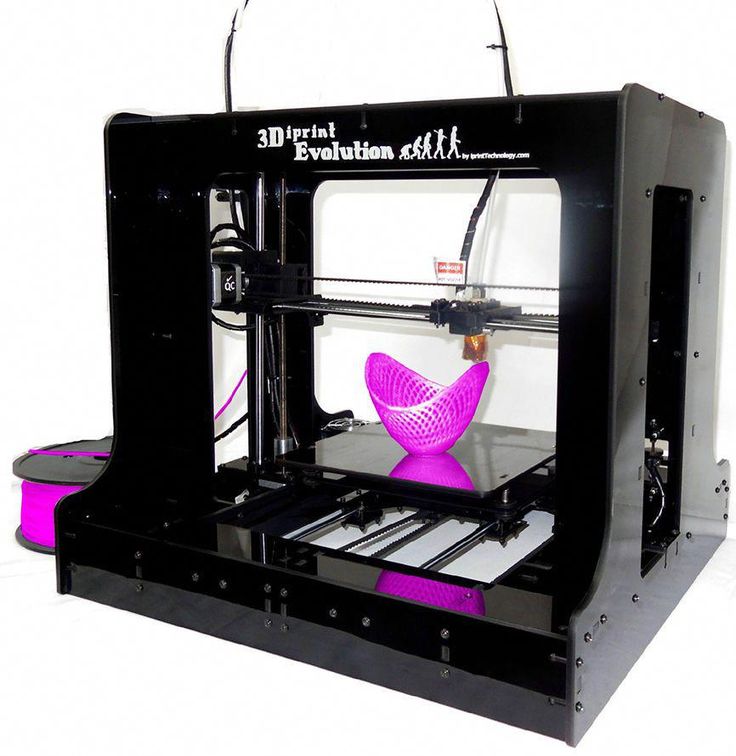

Stereolithography (SLA), Digital Light Processing (DLP), and LCD are three very similar resin 3D printing technologies. They all use photopolymer resins in a resin tank, and cure the resin to form solid 3D printer models. But there are subtle differences to consider when choosing whether to buy a DLP vs SLA 3D printer, or when considering a 3D printing service.

- Don’t forget to check out our ranking of the best resin (SLA and DLP) 3D printers

This article considers the differences between SLA, LCD and DLP. If you want any specific information about these technologies, we have written detailed guides on:

- Our complete guide to Stereolithography 3D printing.

- Our complete guide to Direct Light Processing 3D printing.

This guide is also part of our FREE 3D printing technologies EBook. You can download it here.

SLA vs DLP vs LCD 3D Printing: How they work

SLA 3D printing

Stereolithography is the oldest 3D printing technology, having been commercialized way back in the mid-1980s by 3D Systems. The invention of SLA over 30 years ago marks the inception of 3D printing, which has evolved to change millions of lives today.

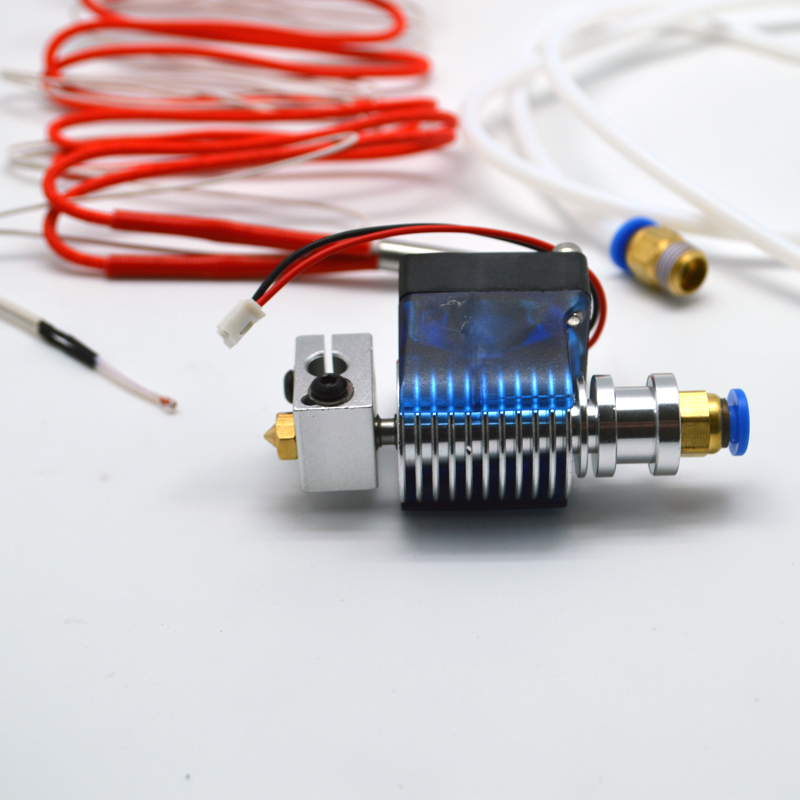

SLA uses a laser beam to selectively solidify parts of the resin, stored in a resin tank or resin vat. The laser beam is shone at the bottom of the tank, and is directed by mirrors called galvanometers to the precise area to be cured.

This continues until the layer is completely cured, before the build platform rises up by one layer, and the process repeats again and again until the part is finished.

Great SLA 3D printers include:

- Formlabs Form 3: $3,499 — Available on Dynamism Store here

- 3D Systems FabPro: $2,150 — Available on Amazon here

DLP 3D printing

Digital Light Processing was invented a couple of years later in 1987 by Larry Hornbeck of Texas Instruments — though not for the purpose of 3D printing, but for movie projection, which the technology has wide use in.

DLP 3D printing uses a projector, rather than a UV light laser as with SLA. The projector flashes light onto the entire layer of resin at once, selectively solidifying the part using thousands of minuscule mirrors called DMDs (digital micromirror devices) that direct the projection of light.

These projectors use pixels, with layers consisting of voxels, as with regular 2D or 3D cameras.The DLP 3D printing process. Credit: robotsinthesun.org.

LCD 3D printing

More recently, low cost LCD 3D printers have become popular, offering better quality than FDM 3D printers can for the same price. These resin 3D printers use LCD panels using LED lights to cure resin in a similar way to DLP 3D printers.

As with DLP, LCD 3D printing involves flashing entire layers at once to cure resin housed in the resin tank, but LCD printers don’t use mirrors. Instead, powerful LCD panels shine light via LEDs at the model, which the LCD panel blocks off in the areas that are not to be solidified.

The LCD screen only lets the light pass through areas that are to be cured into the finished part, simplifying the process and removing the need for any mirrors or galvanometers.

Great LCD printers include:

- Anycubic Photon Zero: $199 — Available on Amazon here

- Elegoo Mars: $200 — Available on Amazon here

- Elegoo Mars Pro: $277 — Available on Amazon here

Key differences between SLA, DLP and LCD 3D printing

Though SLA, DLP and LCD are largely similar — they both cure resins and operate layer by layer — there are some key differences between them.

- If you buy a DLP or SLA printer, you’ll need a 3D slicer for resin printing. Check out our ranking of the best resin 3D slicers

The biggest difference between SLA and DLP is the difference in method used to cure the resin.

DLP uses a projector, LCD 3D printing uses an LCD screen, and SLA uses a UV laser that traces the dimensions to be printed. DLP and LCD are faster than SLA as they can create entire layers at once, whereas SLA requires manually tracing the dimensions of each layer with the laser.Stereolithography printers use a UV laser rather than a projector.

DLP and LCD are faster than SLA as they can create entire layers at once, whereas SLA requires manually tracing the dimensions of each layer with the laser.Stereolithography printers use a UV laser rather than a projector.

Another lesser difference but worth noting is that DLP 3D printers usually have shallower resin tanks — the tanks which resin material is stored in during printing. If you’re big on saving money this is an advantage, as this reduces the waste of expensive unused resins.

SLA vs DLP vs LCD: Print Quality Comparison

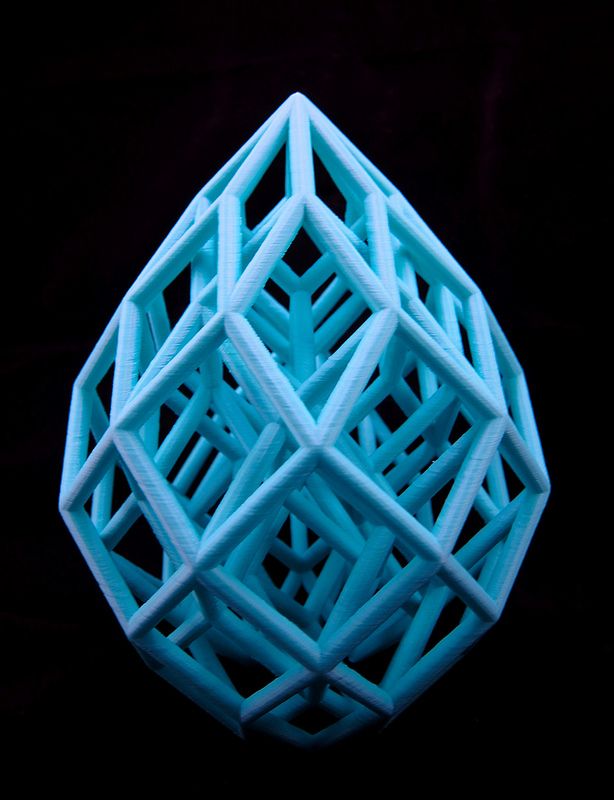

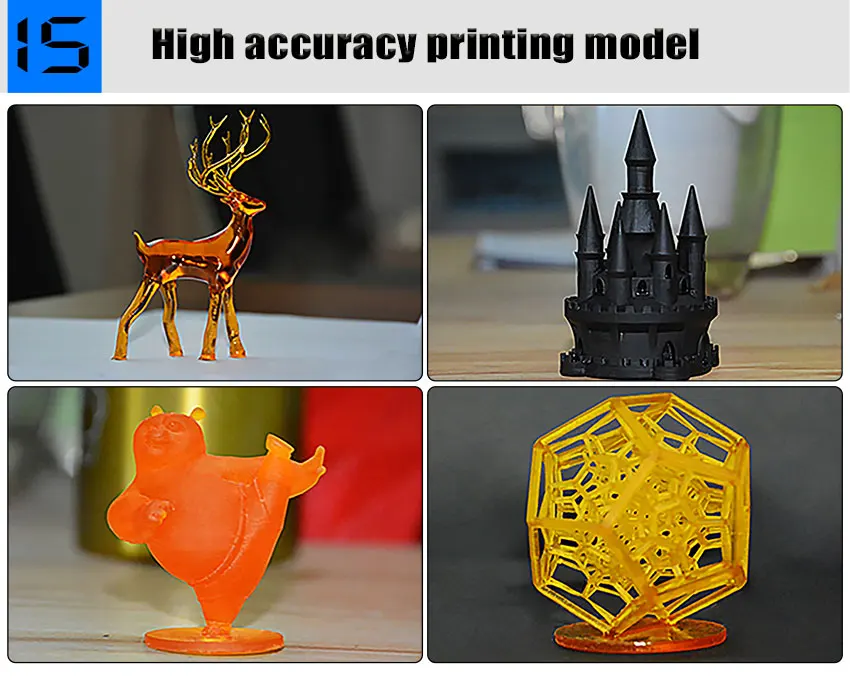

Resin 3D printing is known for being one of the most accurate and precise 3D printing technologies, and even low cost LCD printers are able to create complex geometries that technologies like Fused Deposition Modeling just cannot match.

Honestly, the print qality of an LCD 3D printer compared to a DLP or SLA 3D printer depends on the 3D printer used. An expensive SLA 3D printer will be far better than a cheap DLP 3D printer, with higher quality components used and better resolutions and precision.

- For more information on resolutions, we have a guide to high resolution 3D printers.

The technologies themselves are similar in their ability to create accurate models, it is the execution that affects quality.

A DLP vs SLA quality comparison, by EnvisionTEC. Note that EnvisionTEC specialize in DLP printers and therefore we cannot guarantee impartiality between the two technologies on their behalf.SLA vs DLP vs LCD: 3D Printer Comparison

If you’re choosing between an SLA or DLP 3D printer, what’s best for you depends largely on your printing priorities.

- View our ranking of the best resin 3D printers.

For example, if print speed is a big priority, then absolutely go with a DLP 3D printer as they are on average far quicker.

If you value reliability, go with an established brand known for solid printing such as Formlabs’ Form 3 SLA printer. Again, the technology differences are small enough that it is more based on what you as an individual require, rather than choosing between two technologies.

In the same vein, if you need a printer capable of producing jewelry molds, or models for use in dentistry, pick a printer that specializes in these areas such as an EnvisionTEC DLP printer or a Formlabs SLA printer.

If you’re looking for a cheap printer that can print passable prototypes at home and can accept slightly lower quality, go with an LCD 3D printer such as the Elegoo Mars or AnyCubic Photon S.

- Elegoo Mars: $200 — Available on Amazon here / Elegoo Mars Pro Available for $279 on Amazon here

- AnyCubic Photon S: $350 — Available on Amazon here

- Formlabs Form 3: $3,499 — Available on Dynamism Store here

Resin Comparison

Some resins may work with both DLP and SLA printers, or with DLP and LCD printers, so there is some overlap. But not always, as though some 3D printer companies allow their machines to be used with any third party resins, some restrict them to only use their branded resins.

The best resins for you ultimately depend on what you’re looking to achieve with SLA, DLP or LCD 3D printing. Basic resins exist for fun, hobbyist 3D printer projects, as well as specialized castable, dental, engineering, or 3D printed jewelry resins.

More industrial and professional quality resins will cost more, and can cost upwards of $100/liter. The most basic resins can cost far less, at around $40, but will not offer the same level of quality, even on high quality resin printers.

We recommend some high quality resins below:

- Recommended SLA 3D printer resins on Matterhackers

- Recommended DLP 3D printer resins on Matterhackers

- LCD 3D printer resins we recommend on Matterhackers

SLA vs DLP vs LCD: Print Speed

Due to SLA involving a laser passing over each area of the part to be solidified, while DLP and LCD can cure whole layers instantly, DLP and LCD are generally faster than SLA printers.

As for which is faster between DLP and LCD, again this depends on the 3D printer you purchase. More expensive resin 3D printers will likely print faster and at better quality, and a $2,500 DLP 3D printer will almost certainly print faster than a $300 LCD 3D printer.

For an extremely fast 3D printer, consider:

- Uniz Slash Plus: $1,999 — Available on Matterhackers here

We also have buyer’s guides recommending:

- The best budget resin printers

- The top rated large resin 3D printers

- DIY resin kits

Conclusion

Overall, the differences between DLP and SLA are minimal, but can be important depending on what you’re looking for in a technology or printer. These differences mean it is best to evaluate printers on a case-by-case basis rather than on the actual technology, to make sure you get what you want. Pick the best 3D printer for you, not the best technology.

SLA, DLP & LCD printing technique and compatibility of resins

3D-printing was discovered more than 30 years ago by the original founder of 3D-systems[1]. This first 3D-printer was named stereolithography apparatus and used a laser to cure a light reactive resin. During the years after the discovery, other companies like EnvisionTEC[2] came up with new methods of curing the light reactive resin, by projector, instead of a laser. The last years, companies like Wanhao[3] and Anycubic[4] made resin based 3D-printing accessible for everyone by the introduction of cheaper LCD based 3D-printers.

This first 3D-printer was named stereolithography apparatus and used a laser to cure a light reactive resin. During the years after the discovery, other companies like EnvisionTEC[2] came up with new methods of curing the light reactive resin, by projector, instead of a laser. The last years, companies like Wanhao[3] and Anycubic[4] made resin based 3D-printing accessible for everyone by the introduction of cheaper LCD based 3D-printers.

During these past years, many companies came up with their own 3D-printing technique and named it differently, although it is based on one of the three techniques listed below. Picture source: Formlabs website.[5]

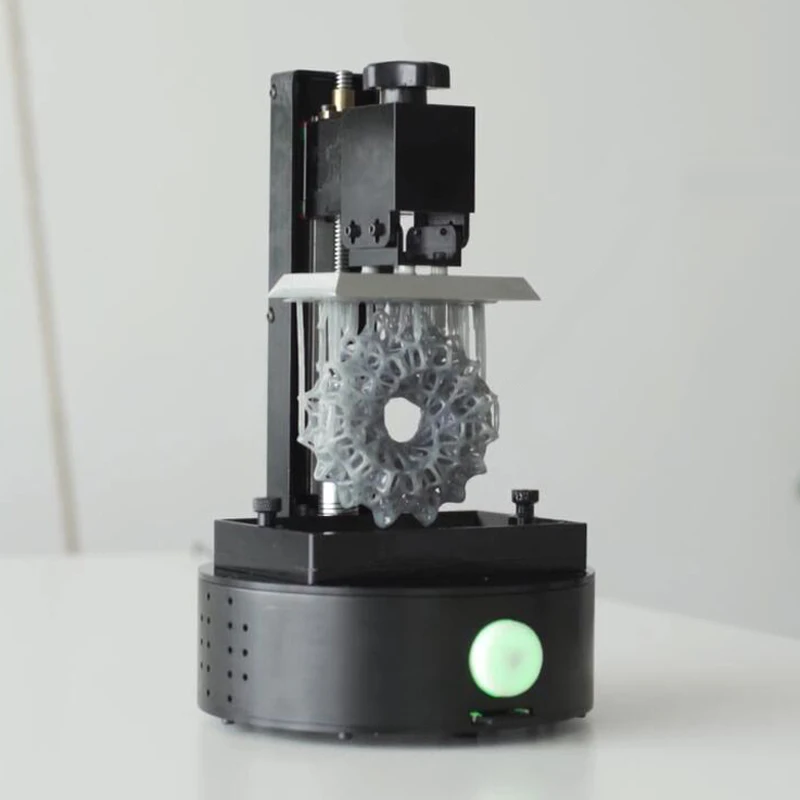

Laser SLA is based on the original invention, used by companies as 3D-systems, Formlabs, UnionTech[6] and Peopoly Moai[7]. The laser is used to selectively cure the resin, by scanning the surface. The resin cures and becomes a hard plastic at the spots where the laser ‘hits’ the resin.

DLP-SLA is a technique which uses a projector to selectively cure the resin. It is generally a faster printing technique compared to Laser SLA, due to the fact that the projector can expose the whole layer at once, where a laser has to scan to cure the resin. A few single LED’s are in the center of the DLP projector. The light from these LED’s is guided to a DMD chip, which creates the actual curing pattern. This 3D-printing technique is used by companies like EnvitionTEC, Sprintray[8], Atum3D[9], Rapidshape[10], Miicraft[11] and Kudo3D[12]

One of the latest developments in resin 3D-printing is MSLA, also called LCD based 3D-printing. This technique uses an affordable LCD screen to create the mask, eliminating expensive DMD chips that are used in DLP techniques. This technique works by an array of LED’s illuminating on the LCD. The LCD is used as a mask, which creates the curing pattern. The liquid resin turns into a rigid plastic on the spots where the light ‘hits’ the resin. Companies like Wanhao, Anycubic, Sparkmaker[13], Kudo3D, Creality[14], XYZprinting[15], Phrozen[16], and many more.

Companies like Wanhao, Anycubic, Sparkmaker[13], Kudo3D, Creality[14], XYZprinting[15], Phrozen[16], and many more.

How do SLA, DLP and LCD 3D-printers compare?

There are many differences between the three main resin based 3D-printing techniques. The table below shows the generic differences.

| Laser SLA | DLP SLA | MSLA | |

| Build Area | ++ | – | + |

| Price | – | – | ++ |

| Speed | + | ++ | – |

| Quality | ++ | ++ | + |

One of the main drawbacks of Laser SLA techniques is its price for the machines and consumables. This also applies to DLP 3D-printers. DLP printers have another technical disadvantage to keep in mind, the (affordable) DMD chips are usually 1920*1080 pixels, which limits the quality of printing when upscaling the build area. LCD based printing is a lot cheaper compared to the other techniques. These machines are more affordable and also consumables like FEP foil for your resin tray is cheaper.

LCD based printing is a lot cheaper compared to the other techniques. These machines are more affordable and also consumables like FEP foil for your resin tray is cheaper.

What most users don’t realize is that the LCD display is also count as a consumable, which should be replaced from time to time. The build area is dependant on each machine and technically it is easier to create a bigger build area, by placing a bigger LCD in the machine.

Image by All3DP: different resin 3D-printing techniques explained

Are all resins compatible with the different printing techniques?

Not all resins are compatible with the different printing techniques. It is important to read the resin manufacturers datasheets to understand if it is compatible with your 3D-printer. Laser based 3D-printers have a very powerful laser, which would need a slower curing resin to get a stable printing process. While LCD based 3D-printers have a low power LED light source, which works very well with fast curing resins. DLP 3D-printers can be configured in many different ways, making it impossible to predict curing behaviour of the resin without testing.

DLP 3D-printers can be configured in many different ways, making it impossible to predict curing behaviour of the resin without testing.

The Liqcreate resins are developed to work with most techniques. Liqcreate Strong-X, Clear Impact, Deep Blue, Stone Coal Black and Hazard Glow are developed to print on Laser- and DLP based machines, while still working on LCD 3D-printers when exposure times are increased. While the Liqcreate Premium line is developed to print fast on low-power DLP and LCD printers. Read more about the resins here:

[1] www.3d-systems.com

[2] www.envisiontec.com

[3] www.wanhao3dprinter.com

[4] www.anycubic3d.com

[5] www.formlabs.com

[6] www.uniontech4d.com

[7] www.peopoly.net

[8] www.sprintray.com

[9] www.atum3d.com

[10] www.rapidshape.de

[11] www.miicraft.com

[12] www.kudo3d.com

[13] www.sparkmaker3d.com

[14] www.creality3d.cn

[15] www.xyzprinting.com

[16] www.phrozen3dp. com

com

Content

-

- SLA

- Principle of operation

- PLASUS

- Printing

- Printers 9009 9000 9000) work

- Pros

- Cons

- Printing example

- Best DLP printers

- SLA

- LCD

- How it works

- Pros

- Cons

- Printing example

- Best LCD printers

- Scope

- Summary

Photopolymer printing is usually associated with delicate, miniature products. After all, it is photopolymer printers that come to the rescue if you need to make a small but detailed model.

Currently, photopolymer printers can work on one of three technologies - SLA, DLP or LCD. Each of the technologies has its own advantages and disadvantages.

In order not to make a mistake with the choice of model, you need to understand which technology is suitable for printing specific products. For example, for a jeweler and a dentist, the main criterion will be accuracy, and for a person who plans to print figurines for his hobby, the quality of the surface and the not very expensive cost of consumables.

For example, for a jeweler and a dentist, the main criterion will be accuracy, and for a person who plans to print figurines for his hobby, the quality of the surface and the not very expensive cost of consumables.

SLA

SLA is one of the first patented 3D printing technologies. It was patented in 1986 by Charles Hull. DLP and LCD are similar in basic principles to SLA, but appeared much later.

How it works

As a material for printing, SLA printers use photopolymer resins - light-sensitive polymers that harden under the influence of a certain spectrum of UV radiation.

A laser beam is used as a “hardener”, which is focused on the desired point with the help of mirrors. The beam sequentially “draws” a slice of the model. So gradually, layer by layer, the model is “grown” on the desktop.

How SLA technology works

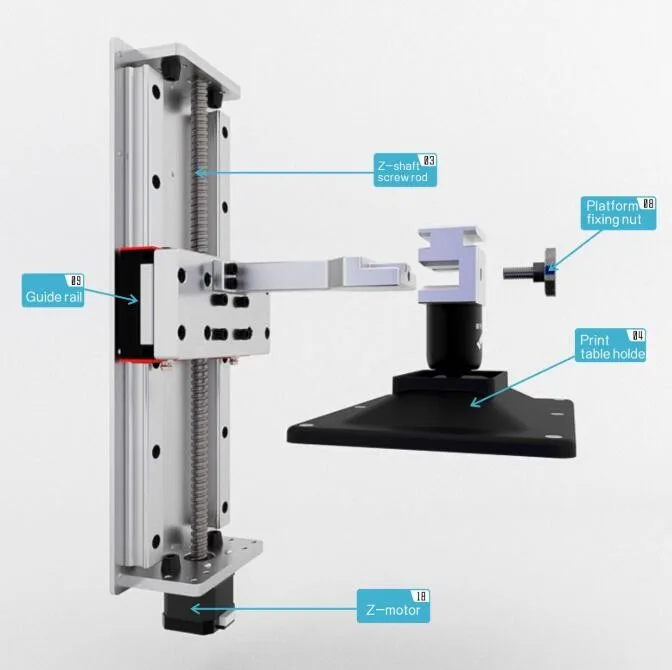

There are two options for the location of the printed table - top and bottom.

Top table

Visually it looks like an inverted FDM machine, the model is printed upside down on such a machine. The table moves during printing from the bottom up, the laser module is located at the bottom of the machine, under the polymer bath. The bottom of the bath is usually made of silicone - it transmits UV radiation well and practically nothing sticks to it.

Top position printer model

This is the most popular desktop SLA printer solution.

Table down

The laser module is located at the top of the printer above the resin bath, and the printing table, during printing, gradually lowers down, plunging into the resin.

Industrial SLA with table bottom

This arrangement is traditionally used in industrial machines with a large print area. The only inconvenience is that the bath must always be filled with a photopolymer. And when changing the type of resin, you will have to completely drain the entire photopolymer and thoroughly wash the bath.

Pros

-

Large selection of consumables. Due to the growing popularity of photopolymer printing, many specific resins have appeared - from soft flexes to photopolymers with increased strength characteristics (for example, there is a very strong, biocompatible photopolymer for making temporary dental crowns).

Cons

-

Expensive consumables.

Printing example

Cardiac muscle printed on Formlabs Form 3

SLA printed rings

Prototype Spoon

Butterfly figurine printed on Formlabs Form 3

Technical model

Snow shovel prototype. Made on Formlabs Form 3L

Top SLA printers

The leader in the production of SLA printers is Formlabs. In the Formlabs lineup, you can find both small desktop models and professional machines with a large print area.

In the Formlabs lineup, you can find both small desktop models and professional machines with a large print area.

Form 3

Formlabs Form 3

Specifications:

-

XY resolution: 25 µm

-

Laser spot size: 85 µm

-

Laser power: One 250mW laser

-

Working area size: 14.5×14.5×18.5cm

-

Layer thickness: 25 – 300 µm

This printer can be compared to a small professional machine. Despite its small dimensions, it can easily cope with the most complex models.

Formlabs Form 3L

Formlabs Form 3L Versus Form 3

-

XY resolution: 25 µm

-

Laser spot size: 85 µm

-

Laser power: One 250mW laser

-

Working area size: 33.

5×20×30cm

5×20×30cm -

Layer thickness: 25 – 300 µm

This printer allows you to print large format models or quickly produce small batches of products.

With the advent of faster and cheaper technologies, SLA printers have become less popular. They are mainly used in industries with high requirements for quality and print stability.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Formlabs |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Formlabs |

DLP

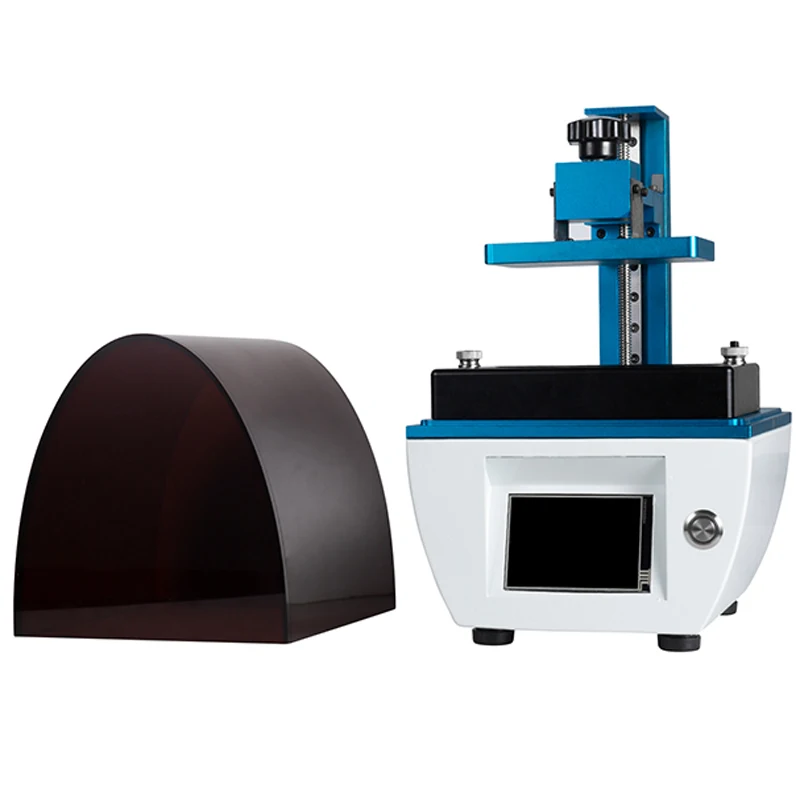

DLP technology is based on the principles of SLA, but instead of a laser, a projector is used as a source of UV radiation.

How it works

The material used is photopolymer resin, but unlike SLA, the light source is not a beam, but a DLP projector. This significantly speeded up printing, because the projector, unlike the beam, illuminates the entire layer at once.

How DLP technology works

The projector is located at the bottom of the printer, under the resin tank. The bottom of the container is usually made of a transparent, wear-resistant film. Such a film transmits UV radiation well, practically nothing sticks to it, and if it breaks, it can be easily replaced.

Pros

Cons

-

Parasitic light is possible. Exposure of the entire layer at a time can cause parasitic illumination of the resin.

-

projector resource. The projector is the heart of a DLP printer. Be sure to pay attention to the resource of the projector. For example, FlashForge Hunter claims a minimum projector life of 50,000 hours. This is a lot.

Printing example

A batch of rings printed with DLP technology

Ring patterns printed on FlashForge Hunter

Props for miniatures 28 mm

Jaw model made on FlashForge Hunter

Best DLP Printers

FlashForge Hunter

Specifications:

-

XY Resolution: 0.

0625mm

0625mm -

Print speed: 10mm/h

-

Light source: 405nm LED

-

Working area size: 120x67.5x150 mm

-

Layer thickness: 0.025-0.05mm

FlashForge is renowned for the quality of its printers. Hunter is no exception. It turned out to be a good “workhorse” capable of solving a variety of tasks.

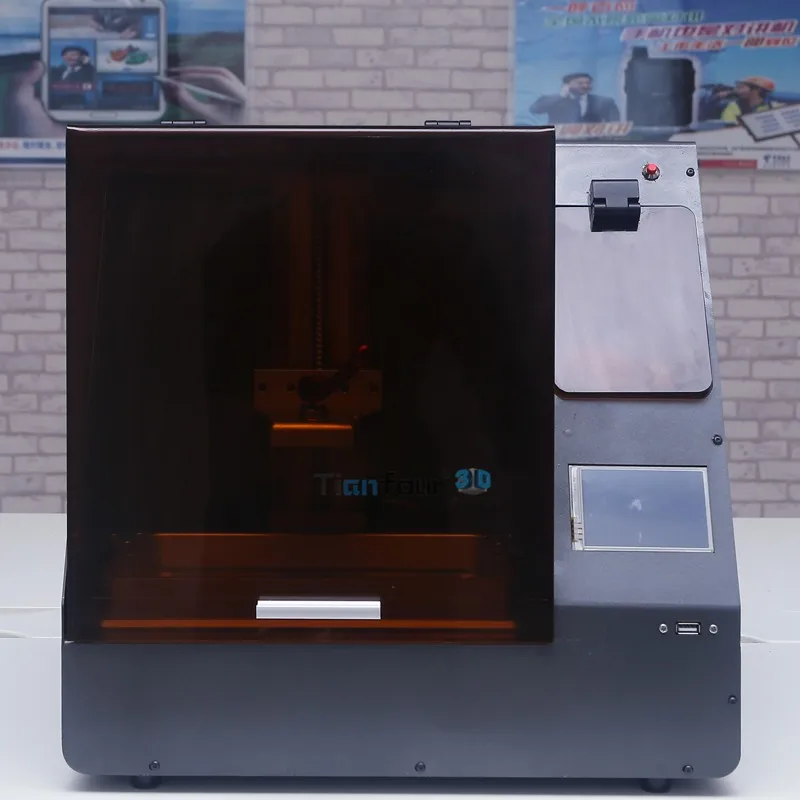

DLP technology is used less and less. It is being stubbornly replaced by more affordable 3D printers based on LCD technology.

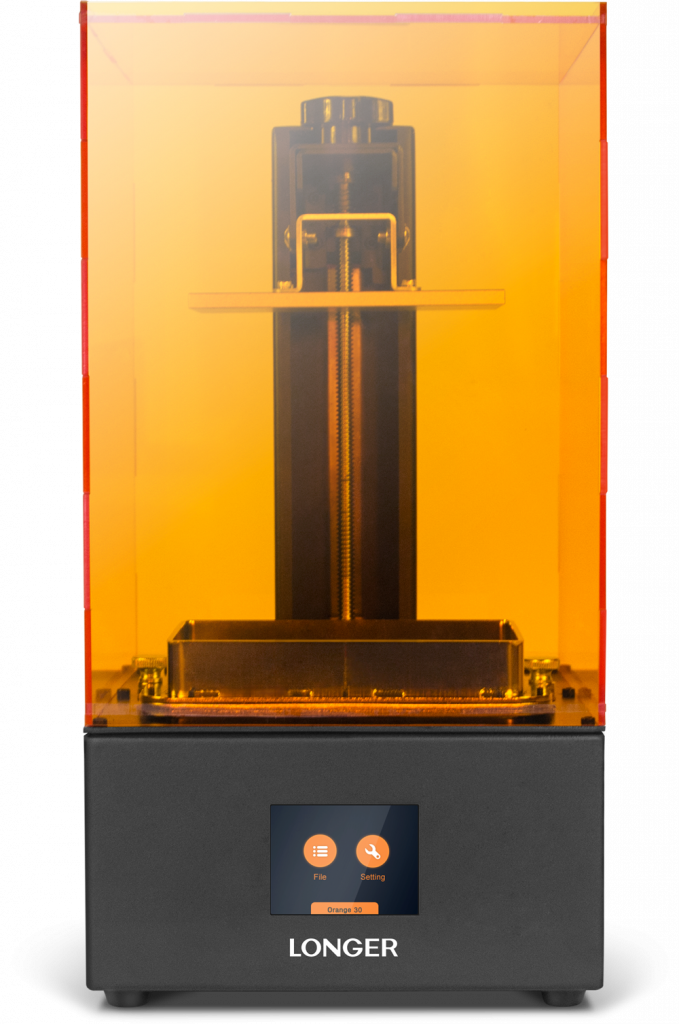

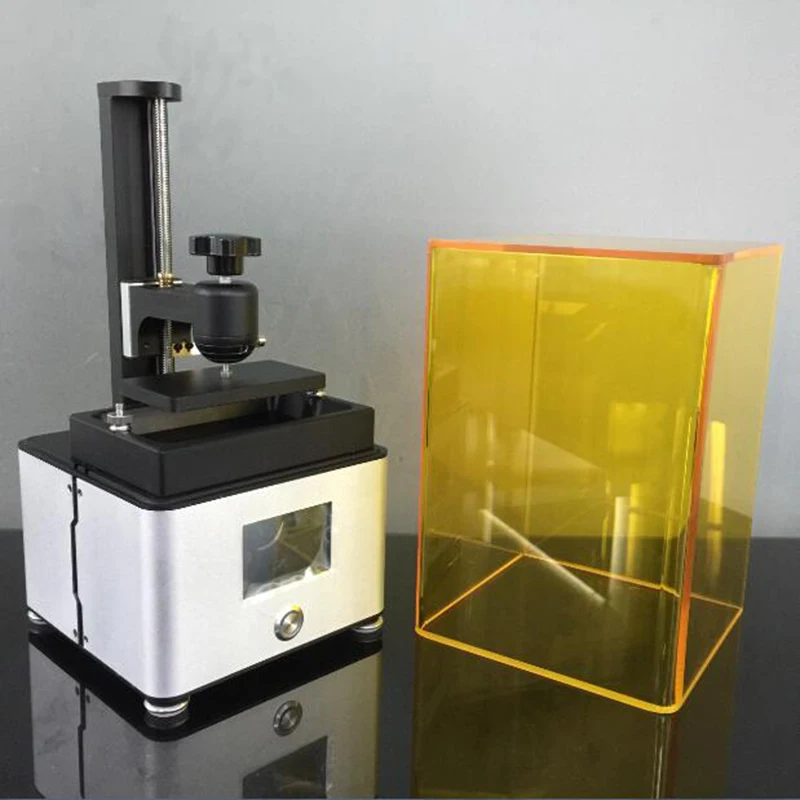

LCD

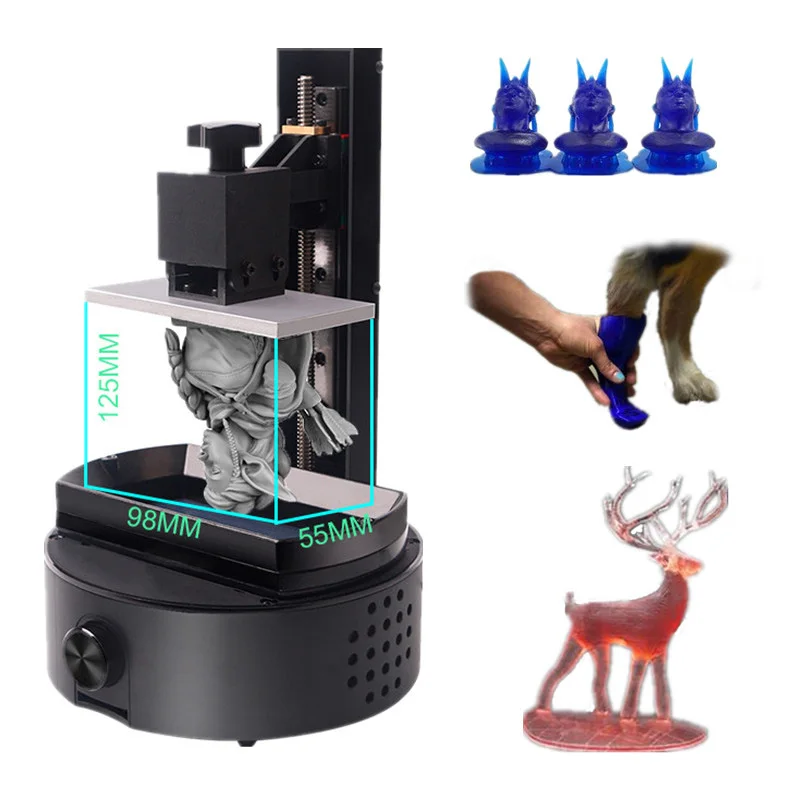

LCD technology is the youngest among photopolymer printers. Initially, LCD appeared as a more affordable analogue of DLP technology, suitable for home use.

The first LCD printers had a number of unpleasant children's sores (uneven illumination of the working area, etc.), which over time were resolved or compensated. With the development of technology, in addition to models for home use, devices have appeared that are not inferior in accuracy to DLP and can be used for production tasks.

How it works

The technology almost completely copies DLP, only LEDs are used instead of a projector. Under the bath is an LCD display (similar to the display of a smartphone or tablet), which dims in some places, allowing light to pass through only in the right places.

How LCD technology works

Since the module with the screen and LEDs is located at the bottom of the printer, the bottom of the resin tank is transparent. As with DLP, transparent film is usually used.

Pros

Cons

-

Less accurate. Budget models are good for printing miniatures or figurines, but their accuracy may not be enough for, for example, jewelry.

-

The print quality may not be the same over the entire printable area. Since an array of LEDs is used as the UV source rather than a single light source, the work area may be illuminated unevenly. This problem can be solved programmatically or physically.

Print example

Small miniature made with Anycubic Photon Mono

Troll printed on LCD machine

Model switchgear busbars made of soft polymer

Castle model made on Phrozen Sonic Mini 4K

Figurine made with Anycubic Photon Zero

Troll printed on LCD printer

Best LCD Printers

Anycubic Photon Zero

Anycubic Photon Zero

Specifications:

-

LCD display resolution: 854x480 px

-

XY Positioning Accuracy: 0.1155mm

-

UV wavelength: 405 nm

-

Working area size: 97x54x150 mm

-

Layer thickness: 0.

01-0.2mm

01-0.2mm

Budget model focused on home use. Good for home use.

Anycubic Photon Mono

Specifications:

-

LCD display resolution: 2560x1620 (2K)

-

XY Positioning Accuracy: 0.051mm

-

UV wavelength: 405 nm

-

Working area size: 130x80x165 mm

-

Layer thickness: 0.01-0.15mm

Anycubic Photon Mono is already a more serious device. Thanks to the LCD display of higher resolution, it was possible to increase the accuracy and quality of the finished models.

Phrozen Sonic Mini 4K

Phrozen Sonic Mini 4K

Specifications:

-

LCD resolution: 6.1" 4K Mono LCD

-

XY positioning accuracy: 35 microns

-

UV wavelength: 405 nm

-

Working area size: 134x75x130 mm

-

Layer thickness: 0.

01-0.30mm

01-0.30mm

Mono LCD matrix, with high resolution, allows you to print very quickly and accurately.

Wanhao GR1

Specifications:

-

LCD resolution: 6.3" 2K HD

-

XY Positioning Accuracy: 0.055mm

-

UV wavelength: 405-410nm

-

Working area size: 140x78x200 mm

-

Layer thickness: 35-100 microns

The larger working area allows you to make more models at once, and a special UV-LED matrix ensures uniform illumination.

LCD printers are successfully capturing the market by displacing more expensive DLP and SLA printers. This of course contributes to their availability and a wide variety of models.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao |

Application

Dentistry

Precision is very important in dentistry. A slight distortion of even 0.1 mm can make the painstaking work of making a crown or prosthesis useless.

A slight distortion of even 0.1 mm can make the painstaking work of making a crown or prosthesis useless.

Jaw Model

3D printed aligner

In addition to the accuracy of the printer, the material chosen also plays an important role. It is necessary to use special resins with a small percentage of shrinkage.

Jewelry production

The full potential of photopolymer printers is revealed in the jewelry industry. In addition to precision, detail and perfect surface quality are very important.

Ring made of burn-out photopolymer

From model to finished product

Previously, such products had to be very painstakingly cut by hand or made from wax on high-precision CNC machines. Now it is enough to make a digital model and, with the help of a printer and burnt resin, quickly produce the required number of products ready for casting.

Prototyping

Printing prototypes, making master models, etc.

Helmet and other photopolymer prototypes

Prototype housings

FDM technology is not suitable for everything. Sometimes you need to quickly make a model of a future product with a smooth surface, professional photopolymer printers can easily cope with this task.

Hobby

Affordable photopolymer printers have become a great help for miniature lovers. It is much easier to model and print a 28 mm action figure of your favorite hero than to make it by hand for a long time and painstakingly.

Soviet motorcyclist in 28mm scale

“Spare parts” for miniature 28mm

And large decorative figurines are more accurate compared to FDM printing. After the LCD printer, you do not have to sand the model for a long time to smooth out the layers.

bust of a girl

Modeling

For large and sketchy layouts, FDM printers can be used, but their accuracy is not enough for making small parts. Having a 3D model, you can quickly make a very accurate and detailed layout of a building or an entire block.

Model of the statue of V.I. Lenina

Printed and painted building layout

Summary

Despite all the advantages of photopolymer printers, there are small nuances that are common to all technologies.

Washing the model. After printing, the model must be washed from resin residues. The best way is an ultrasonic bath with alcohol, sometimes you can get by with a glass of isopropyl alcohol and a brush.

“Illumination” in the UV chamber. After rinsing, the model must be “additionally illuminated” in a UV chamber, otherwise the polymer will not gain the strength declared by the manufacturer.

To illuminate the model, you can use a regular UV lamp or a manicure machine. They will cost less than professional dryers, although it may take more time to “light up”. Before buying, make sure that the lamps shine in the desired UV spectrum.

strength of polymers. Despite the huge variety of resins, they are still inferior in strength to the plastic filaments used by FDM printers. The exception is some highly specialized resins.

For some, these nuances can be significant disadvantages, but despite this, photopolymer printers are used both as home printers and as work machines in various fields.

What is the difference between photopolymer 3D printing technologies

Basics of 3D

Rapid prototyping

Experts recommend

3D printers

Author: Alexey Chekhovich

Author: Alexey Chekhovich

SLA: laser stereolithography | DLP: Digital Light Processing | LCD: photopolymerization with LCD screen | The main differences between the three technologies | Print Quality Comparison | Comparison of 3D printers | Comparison of photopolymers | Print speed | Conclusion

SLA, DLP and LCD are three similar technologies for stereolithographic 3D printing, and users often have a question: which method to choose for additive manufacturing tasks?

All three technologies are based on the use of a photopolymer resin that is layer-by-layer cured during printing in a special tank of a 3D printer, in other words, on the process of photopolymerization in a bath. Let's look at the differences to consider when buying a 3D printer (SLA, DLP or LCD) or when using a 3D service.

Let's look at the differences to consider when buying a 3D printer (SLA, DLP or LCD) or when using a 3D service.

We will select a 3D printer for your production tasks! Call +7 (495) 223‑02‑06 or leave an online request for a free consultation:

Book a consultation with 3D experts

SLA: laser stereolithography

SLA (Stereolithography Apparatus) is the oldest additive technology. It was introduced in the mid-1980s by 3D Systems. The invention of SLA more than thirty years ago marked the beginning of 3D printing, which has changed millions of lives.

SLA printers use a laser. It selectively illuminates the photopolymer resin in the printer's tank. The laser beam shines on the bottom of the tank and is guided by mirror galvanometers to the precise area to be cured.

This continues until the layer is completely cured, then the build platform is raised one layer, and the process is repeated until the model is printed.

iQB Technologies experts recommend the article Affordable 3D services for business: an industrial SLA printer is being mastered in Krasnodar

DLP: Digital Light Processing

The DLP (Digital Light Processing) method was invented somewhat later - at 1987 by Larry Hornbeck of Texas Instruments, though not for additive manufacturing, but for film projection, where this technology has found wide application.

DLP printing uses a projector rather than a UV laser like SLA. The projector emits light at once on the entire layer of resin, selectively curing the part with the help of thousands of tiny mirrors, called digital micromirror devices (DMD), directing the light projection.

These projectors use pixels to create images and layers are made up of voxels, just like conventional 2D or 3D cameras.

LCD: photopolymerization with LCD screen

Recently, inexpensive LCD printers have become popular, offering better quality than FDM machines at the same price. This type of photopolymer printer uses LED-backlit liquid crystal panels to cure the resin, similar to DLP-based equipment.

This type of photopolymer printer uses LED-backlit liquid crystal panels to cure the resin, similar to DLP-based equipment.

As in the case of DLP, LCD printing consists in the simultaneous illumination of entire layers to cure the photopolymer, but without the use of mirrors. Instead, powerful LCD panels emit light onto the model using LEDs. The LCD panel blocks backlight in areas that cannot be cured.

The LCD screen only allows light to pass through the areas to be cured onto the finished part, simplifying the process and eliminating the need for any mirrors or galvanometers.

Key Differences Between SLA, DLP and LCD

Although SLA, DLP, and LCD technologies are similar in many ways—they are all based on the layer-by-layer curing of photopolymer resin—there are a few key differences between them.

The main difference between SLA and DLP/LCD is the method used for photopolymerization.

DLP uses a projector, LCD uses an LCD screen, and SLA uses a UV laser to mark the dimensions of the printed model. DLP and LCD printers are faster than SLA machines because they can create entire layers at the same time, while laser stereolithography requires manual tracking of the dimensions of each layer with a laser.

The RAYSHAPE Shape 1+ Professional DLP Printer is a compact solution ideal for a dental or manufacturing lab

There is another less significant but noteworthy difference: DLP printers usually have smaller resin tanks. If you want to save money, then this will be an advantage: the consumption of unused expensive resin will decrease.

Read the article Post-curing products in SLA printing: how to increase strength and quality in the blog

Print Quality Comparison

Resin 3D printing is known as one of the most precise additive processes, and even budget LCD printers are capable of creating complex geometries that technologies like FDM simply cannot match.

An example of LCD printing of industrial parts

The print quality of an LCD printer compared to a DLP/SLA printer depends on the specific hardware. An expensive SLA machine is expected to be much better than a budget DLP due to higher quality components and better resolution and accuracy.

The technologies themselves are similar in their ability to create accurate models, and it is execution that affects quality.

Comparison of 3D printers

Do you hesitate between SLA and DLP printers? Analyze your 3D printing priorities.

If print speed is most important to you, choose a DLP solution, in most cases it will provide significantly better performance.

If you value reliability, choose a brand known for print quality. To reiterate, the differences in technologies are not so great as to make a choice between them; choose a printer based on your individual requirements.

To reiterate, the differences in technologies are not so great as to make a choice between them; choose a printer based on your individual requirements.

Likewise, if you're making molds for jewelry or dental models, choose a 3D printer that's designed for those tasks.

Printing Dental Products with the Wiibox 280 Plus LCD Printer at 5K Resolution

If you're looking for a cheaper printer that can print usable prototypes at home and are satisfied with slightly worse print quality, get an LCD printer.

Photopolymer comparison

Some photopolymer resins are suitable for both DLP and SLA installations, as well as for DLP and LCD printers. But this is not always the case. Some equipment manufacturers provide an open material system (i.e. use any third-party photopolymers), while others restrict their use to their proprietary materials.

The choice of photopolymer depends on the goals you want to achieve with SLA, DLP, or LCD printing. There are basic resins for hobbyist projects, and there are specialized resins for 3D printing casting models, dental, engineering or jewelry.

There are basic resins for hobbyist projects, and there are specialized resins for 3D printing casting models, dental, engineering or jewelry.

Photopolymer resin in containers and products created by DLP printing

Higher-quality industrial and professional grade photopolymers cost more. Budget materials, in turn, will not provide the same level of quality in production, even on high-end printers.

When choosing a photopolymer, you need to find out the wavelength of the printer's light source. It is also indicated on the consumable. The most popular SLA/DLP/LCD printers on the market today use 405nm illumination and related resins.

Print speed

In the SLA machine, the laser passes through every part of the cured part, while DLP and LCD-based equipment can instantly cure entire layers. Thus, DLP and LCD technologies provide faster printing than SLA.

When comparing the speed of DLP and LCD printing, it depends on the 3D printer.