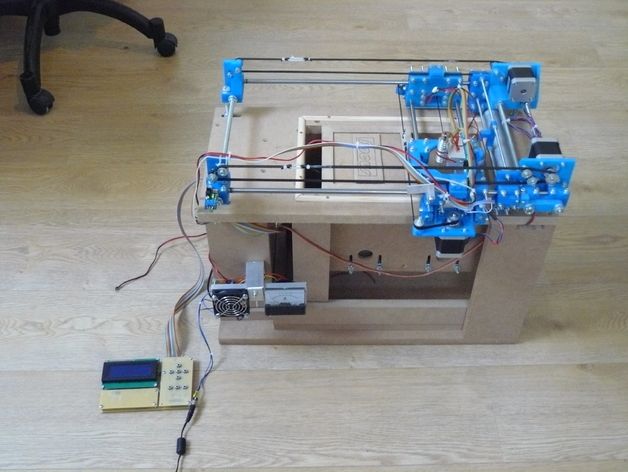

Sls plastic 3d printer

Guide to Selective Laser Sintering (SLS) 3D Printing

Selective laser sintering (SLS) 3D printing is trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts.

In this extensive guide, we’ll cover the selective laser sintering process, the different systems and materials available on the market, the workflow for using SLS printers, the various applications, and when to consider using SLS 3D printing over other additive and traditional manufacturing methods.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Selective laser sintering is an additive manufacturing (AM) technology that uses a high-power laser to sinter small particles of polymer powder into a solid structure based on a 3D model.

SLS 3D printing has been a popular choice for engineers and manufacturers for decades. Low cost per part, high productivity, and established materials make the technology ideal for a range of applications from rapid prototyping to small-batch, bridge, or custom manufacturing.

Recent advances in machinery, materials, and software have made SLS printing accessible to a wider range of businesses, enabling more and more companies to use these tools that were previously limited to a few high-tech industries.

Introducing the Formlabs Fuse Series SLS 3D printers, bringing high-performance SLS 3D printing finally within reach.

Webinar

Watch our product demo for a walkthrough of the Fuse 1+ 30W and SLS 3D printing with Formlabs experts.

Watch the Webinar

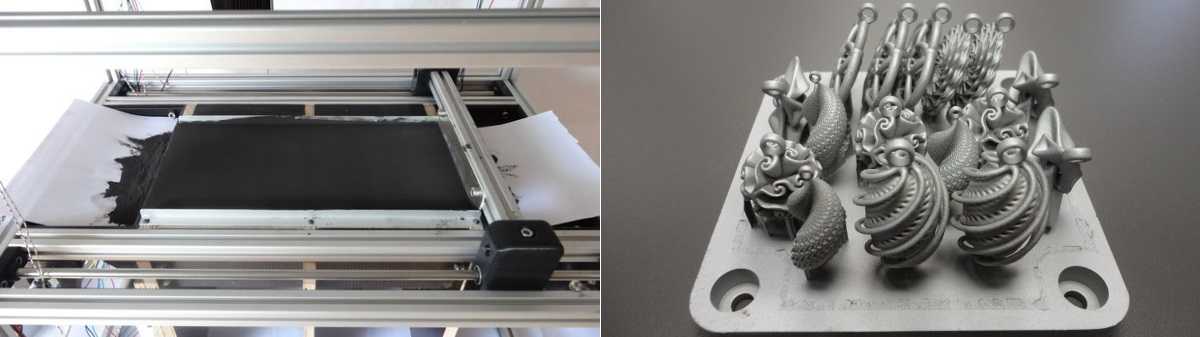

Schematic of the selective laser sintering process. SLS 3D printing uses a high-power laser to sinter small particles of polymer powder into a solid structure based on a 3D model.

-

Printing: The powder is dispersed in a thin layer on top of a platform inside of the build chamber. The printer preheats the powder to a temperature somewhat below the melting point of the raw material, which makes it easier for the laser to raise the temperature of specific regions of the powder bed as it traces the model to solidify a part. The laser scans a cross-section of the 3D model, heating the powder to just below or right at the melting point of the material. This fuses the particles together mechanically to create one solid part. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. The platform then lowers by one layer into the build chamber, typically between 50 to 200 microns, and the process repeats for each layer until parts are complete.

-

Cooling: After printing, the build chamber needs to slightly cool down inside the print enclosure and then outside the printer to ensure optimal mechanical properties and avoid warping in parts.

-

Post-processing: The finished parts need to be removed from the build chamber, separated, and cleaned of excess powder. The powder can be recycled and the printed parts can be further post-processed by media blasting or media tumbling.

For the detailed workflow, see the “The SLS 3D Printing Workflow” section below.

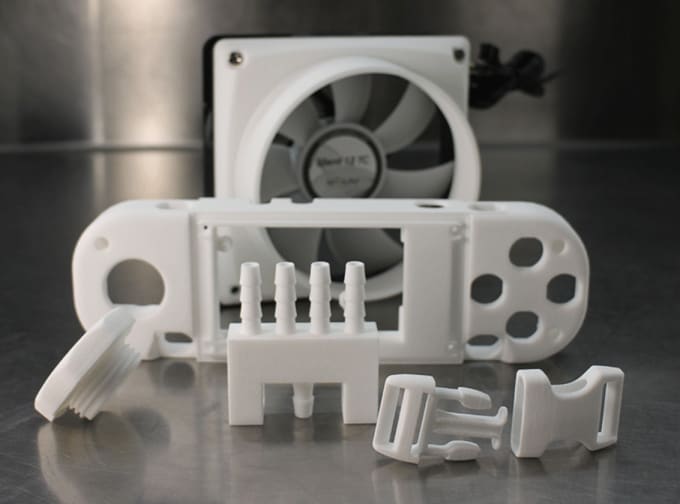

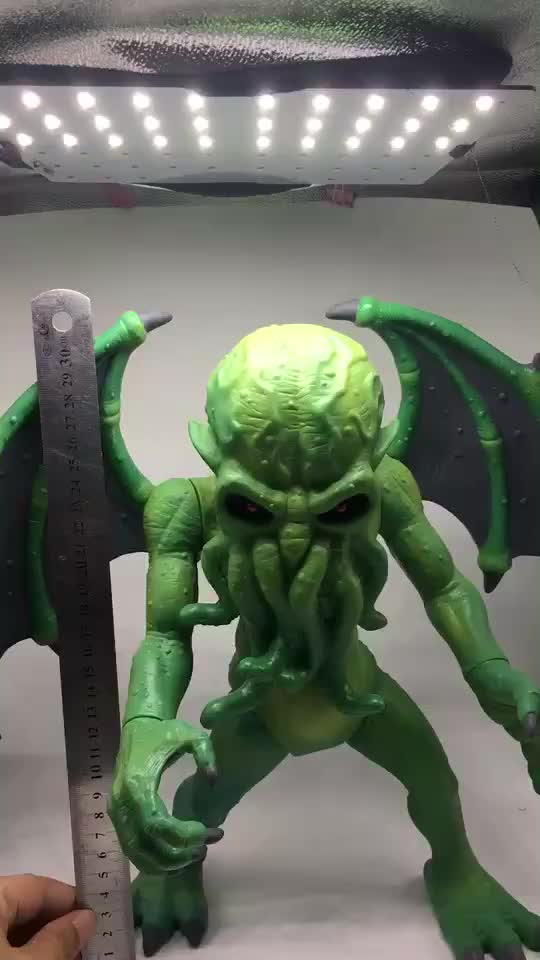

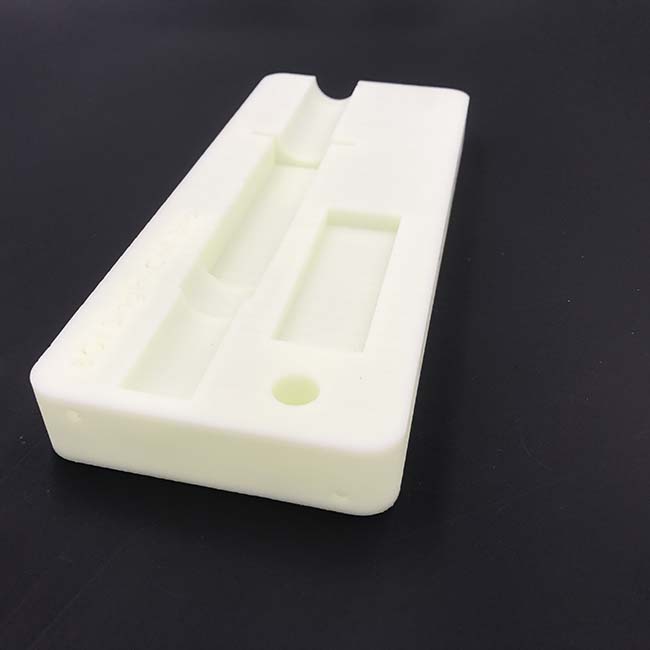

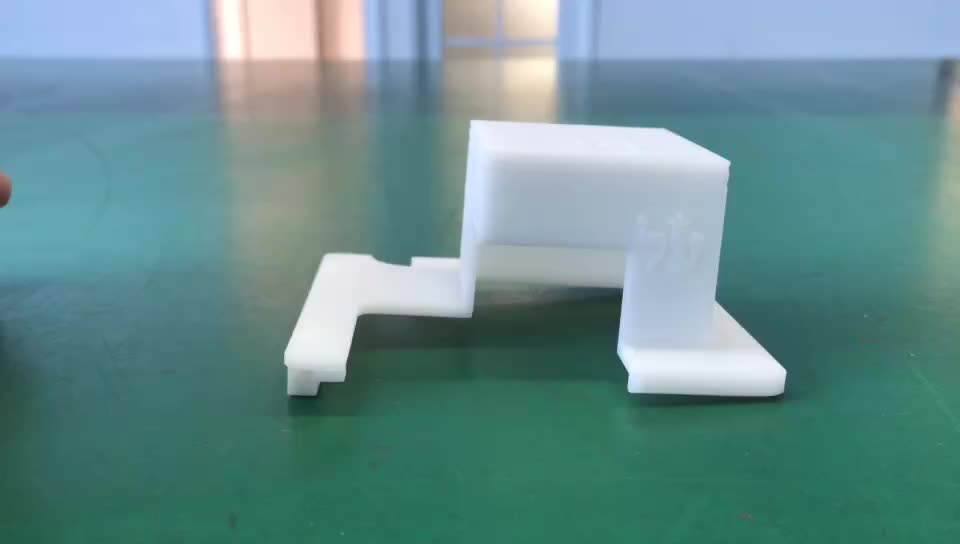

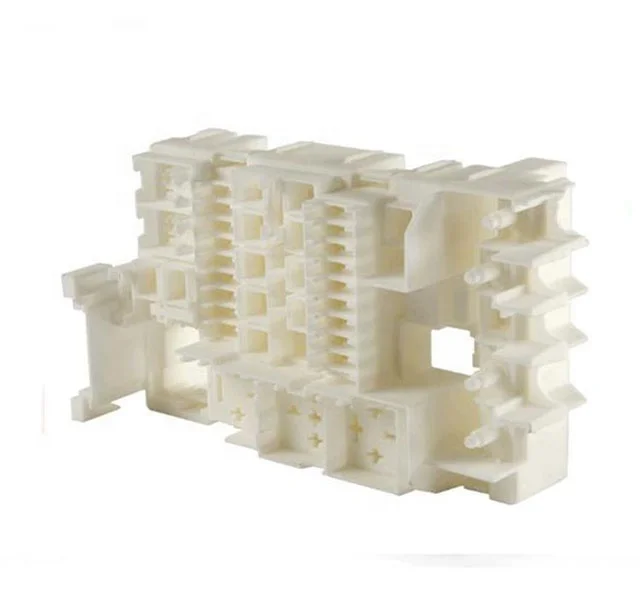

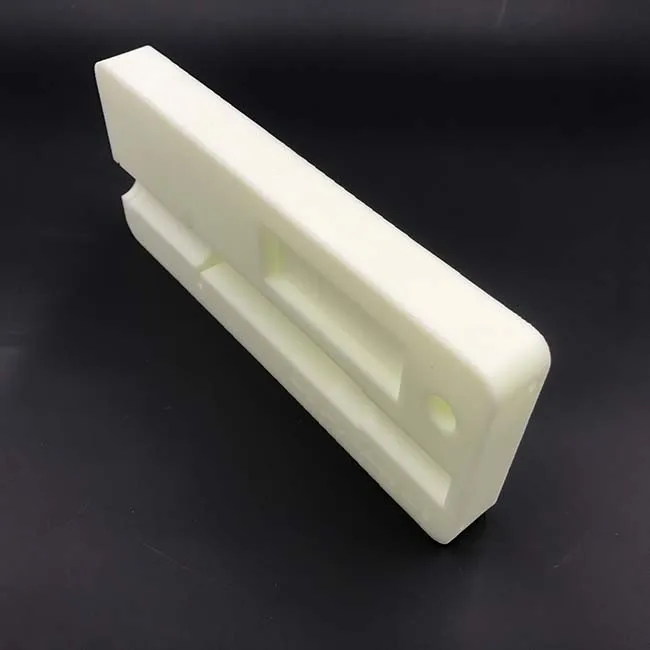

SLS parts have a slightly grainy surface finish, but almost no visible layer lines. Media blasting or media tumbling SLS parts is recommended for a smoother surface finish. This example part was printed on a Formlabs Fuse 1+ 30W benchtop industrial SLS 3D printer.

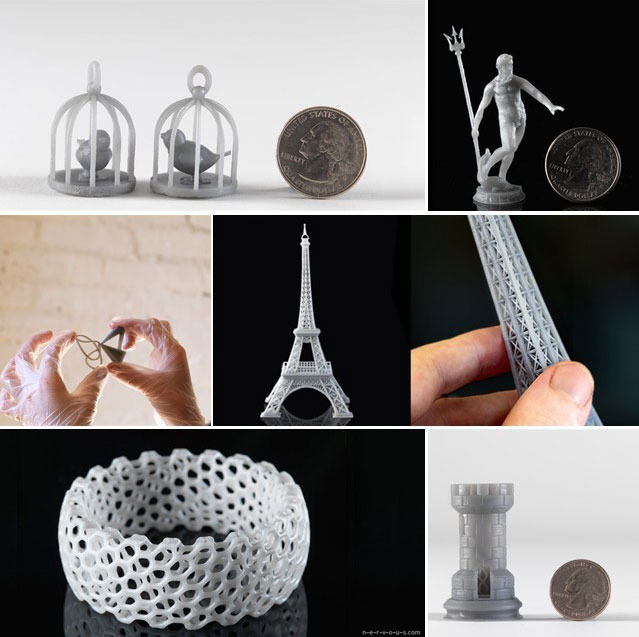

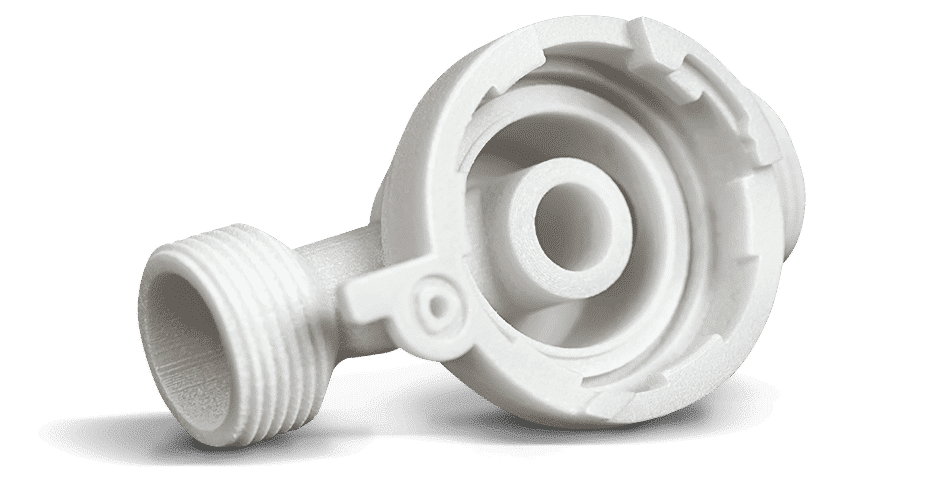

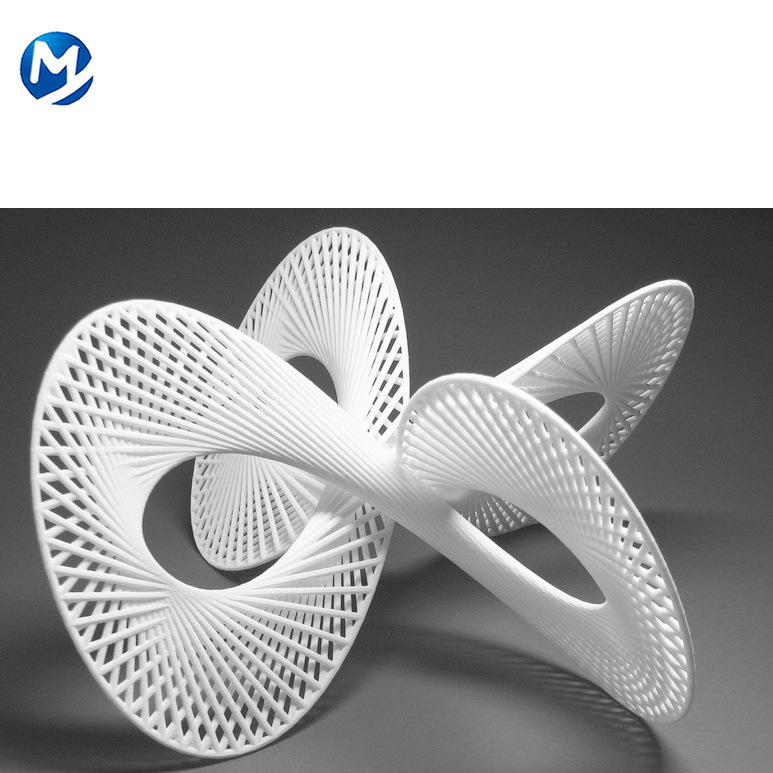

As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Parts produced with SLS 3D printing have excellent mechanical characteristics, with strength resembling injection-molded parts.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free SLS sample part printed on the Fuse 1+ 30W to your office.

Request a Free Sample Part

FDM vs SLA vs SLS: Compare selective laser sintering (SLS) 3D printing to two other common 3D printing processes for producing plastic parts: fused deposition modeling (FDM) and stereolithography (SLA).

Selective laser sintering was one of the first additive manufacturing techniques, developed in the mid-1980s by Dr. Carl Deckard and Dr. Joe Beaman at the University of Texas at Austin. Their method has since been adapted to work with a range of materials, including plastics, metals, glass, ceramics, and various composite material powders. Today, these technologies are collectively categorized as powder bed fusion—additive manufacturing processes in which thermal energy selectively fuses regions of a powder bed.

The two most common powder bed fusion 3D printing systems today are plastic-based, commonly referred to as SLS, and metal-based, known as direct metal laser sintering (DMLS) or selective laser melting (SLM). Until recently, both plastic and metal powder bed fusion systems have been prohibitively expensive and complex, limiting their use to small quantities of high-value or custom parts, such as aerospace components or medical devices.

Until recently, both plastic and metal powder bed fusion systems have been prohibitively expensive and complex, limiting their use to small quantities of high-value or custom parts, such as aerospace components or medical devices.

Innovation in the field has surged recently, and plastic-based SLS is now poised to follow other 3D printing technologies like stereolithography (SLA) and fused deposition modeling (FDM) to gain widespread adoption with accessible, compact systems.

All selective laser sintering 3D printers are built around the process described in the previous section. The main differentiators are the type of laser, the size of the build volume, and the complexity of the system. Different machines use different solutions for temperature control, powder dispensing, and layer deposition.

Selective laser sintering requires a high level of precision and tight control throughout the printing process. The temperature of the powder along with the (incomplete) parts must be controlled within 2 °C during the three stages of preheating, sintering, and storing before removal to minimize warping, stresses, and heat-induced distortion.

Selective laser sintering has been one of the most popular 3D printing technologies for professionals for decades, but its complexity, requirements, and high price have limited its use to service bureaus and large enterprises.

These machines require special HVAC and industrial power, and even the smallest industrial machines take up at least 10 m² of installation space. Setting them up takes multiple days with on-site installation and training. The complex workflow and the steep learning curve also mean that these systems require a skilled technician in-house to operate and maintain.

With a starting price of around $200,000 that goes well beyond that for complete solutions, traditional industrial SLS has been inaccessible for many businesses.

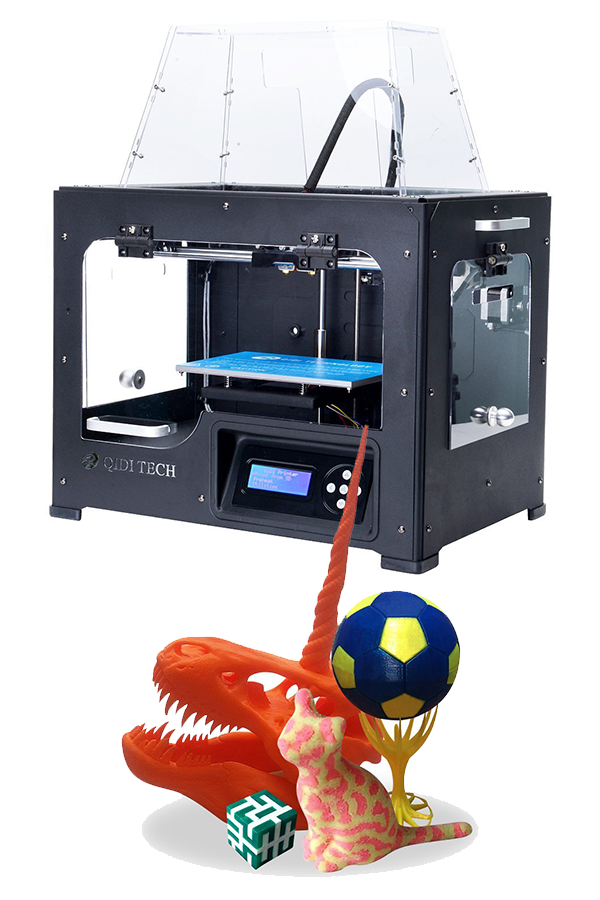

Just like with other 3D printing technologies like FDM or SLA, lower-cost, compact SLS systems have recently started to emerge on the market, but initially, these solutions came with considerable trade-offs, including lower part quality and complex, manual workflows resulting from the lack of post-processing solutions, which limited their use in industrial and production settings.

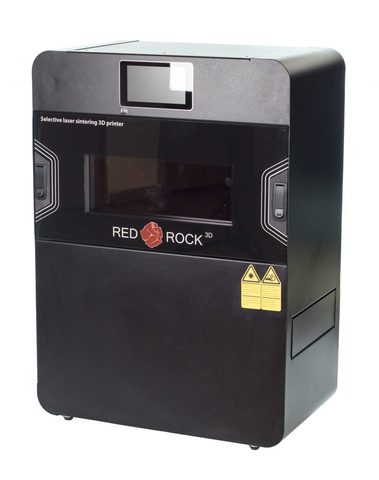

The Formlabs Fuse 1 bridged that gap and created its own category as the first benchtop industrial SLS 3D printer that offered high quality, compact footprint, and a complete, simplified workflow at a fraction of the cost of traditional industrial SLS systems. Now, the next generation Fuse 1+ 30W extends that category with a more powerful laser, improved powder handling features, and new material capabilities for industrial quality parts and high throughput.

The Fuse 1+ 30W requires no specialized infrastructure, and can easily fit into your workspace.

Fuse Series SLS 3D printers use a single laser and a smaller build chamber that requires less heating. The lower energy consumption means that they can run on standard AC power without requiring specialized infrastructure. An optional nitrogen feature for the Fuse 1+ 30W printer creates an inert gas environment, preserving the quality of the unsintered powder for a lower refresh rate (more recycled powder than new powder in consecutive builds), minimizing waste, and enabling a better surface finish on sintered parts.

Fuse Series printers also feature a patent-pending solution called Surface Armor—a semi-sintered shell that keeps the area around the parts evenly heated as they print, ensuring great surface finish, consistent mechanical properties, high reliability, and better refresh rates.

To offer a compact, contained ecosystem and end-to-end powder handling, Fuse Series printers also come with the Fuse Sift, which combines part extraction, powder recovery, storage, and mixing in a single free-standing device.

Overall, benchtop industrial SLS 3D printing with Fuse Series printers offers a slightly smaller build volume compared to the entry-level traditional SLS systems, in return for a substantially smaller footprint, simplified workflow, and lower cost.

| Fuse Series: Benchtop Industrial SLS 3D Printers | Traditional Industrial SLS 3D Printers | |

|---|---|---|

| Price | Starting at $18,500 for the Fuse 1, $28,000 for the Fuse 1+ 30W | $200,000-$500,000+ |

| Print Volume | Up to 165 x 165 x 300 mm | Up to 550 x 550 x 750 mm |

| Pros | Affordable High-quality parts High throughput Multiple material options Simplified workflow Small footprint Low maintenance | Large build volume High-quality parts High throughput Multiple material options |

| Cons | Smaller build volume | Expensive machinery Large footprint Facility requirements High maintenance Requires a dedicated operator |

The comparison is based on the Formlabs Fuse Series benchtop industrial SLS system and traditional industrial SLS systems by EOS and 3D Systems.

A drill prototype printed on the Fuse 1+ 30W (left) and on an EOS printer (right), with comparable quality but a vastly different machine price point.

White Paper

In this white paper, we evaluate the value proposition of bringing SLS 3D printers in-house, in comparison with outsourcing SLS parts from a service bureau.

Download the White Paper

The most common material for selective laser sintering is nylon, a highly capable engineering thermoplastic for both functional prototyping and end-use production. Nylon is ideal for complex assemblies and durable parts with high environmental stability.

SLS 3D printed nylon parts are strong, stiff, sturdy, and durable. The final parts are impact-resistant and can endure repeated wear and tear. Nylon is resistant to UV, light, heat, moisture, solvents, temperature, and water. 3D printed nylon parts can also be biocompatible and not sensitizing, which means that they are ready to wear and safe to use in many contexts.

Nylon is ideal for a range of functional applications, from engineering consumer products to healthcare.

Nylon is a synthetic thermoplastic polymer that belongs to the family of polyamides. It is available in multiple variants, each tailored to different applications. Nylon 12 Powder and Nylon 11 Powder are single-component powders, while Nylon 12 GF Powder is a glass-filled composite, and Nylon 11 CF Powder is a carbon fiber reinforced composite. These composite materials are developed to optimize parts for higher strength, stiffness, or flexibility. With these two-component powders, only the component with the lower glass transition point is sintered, binding both components.

- High performance prototyping

- Small batch manufacturing

- Permanent jigs, fixtures, and tooling

- General SLS parts

- Impact-resistant prototypes, jigs, and fixtures

- Thin-walled ducts and enclosures

- Snaps, clips, and hinges

- Orthotics and prosthetics*

- Robust jigs and fixtures and replacement parts

- Parts undergoing sustained loading

- Threads and sockets

- Parts subjected to high temperature

- Replacement and spare alternatives to metal parts

- Tooling, jigs, fixtures

- High-impact equipment

- Functional composite prototypes

* Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

| Materials | Nylon 12 Powder | Nylon 11 Powder | Nylon 12 GF Powder | Nylon 11 CF Powder |

|---|---|---|---|---|

| Ultimate Tensile Strength X (MPa) | 50 | 49 | 38 | 69 |

| Ultimate Tensile Strength Y (MPa) | N/A | N/A | N/A | 52 |

| Ultimate Tensile Strength Z (MPa) | N/A | N/A | N/A | 38 |

| Tensile Modulus X (MPa) | 1850 | 1600 | 2800 | 5300 |

| Elongation at Break, X/Y (%) | 11 | 40 | 4 | 9 / 15 |

| Elongation at Break, Z (%) | 6 | N/A | 3 | 5 |

| Notched Izod (J/m) | 32 | 71 | 36 | 74 |

SLS 3D printing accelerates innovation and supports businesses across a wide range of industries, including engineering, manufacturing, and healthcare.

Take control of your entire product development process, from iterating on your first concept design to manufacturing ready-to-use products:

- Rapid prototyping

- Mockups of products for in-field customer feedback

- Functional prototyping

- Rigorous functional testing of products (e.g. ductwork, brackets)

Own your supply chain and respond quickly to changing demands:

- End-use part production

- Small batch, stop-gap, and bridge manufacturing

- Mass customized consumer products

- Replacement parts, aftermarket parts, spare parts

- Long-lasting, durable manufacturing aids, jigs and fixtures (e.g clips and clamps) and tooling

- Custom automotive or motorcycle parts, marine equipment, military ‘resupply on-demand’

Manufacture ready-to-use, patient-specific medical devices in-house:

- Medical device prototyping

- Prosthetics and orthotics (i.e. limb replacements + braces)

- Surgical models + tools

- End-use parts (Nylon 12 Powder is biocompatible + compatible with sterilization*)

* Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

White Paper

This white paper showcases the cost-dynamics for real-life use cases, and presents guidelines for using SLS 3D printing, injection molding, or both.

Download the White Paper

Webinar

In this webinar, learn how affordable industrial-quality SLS 3D printers are making additive manufacturing a viable choice for end-use production and mass customization.

Watch the Webinar Now

Watch this video to see the step by step process of using the Fuse 1 selective laser sintering (SLS) 3D printer and the Fuse Sift powder recovery station.

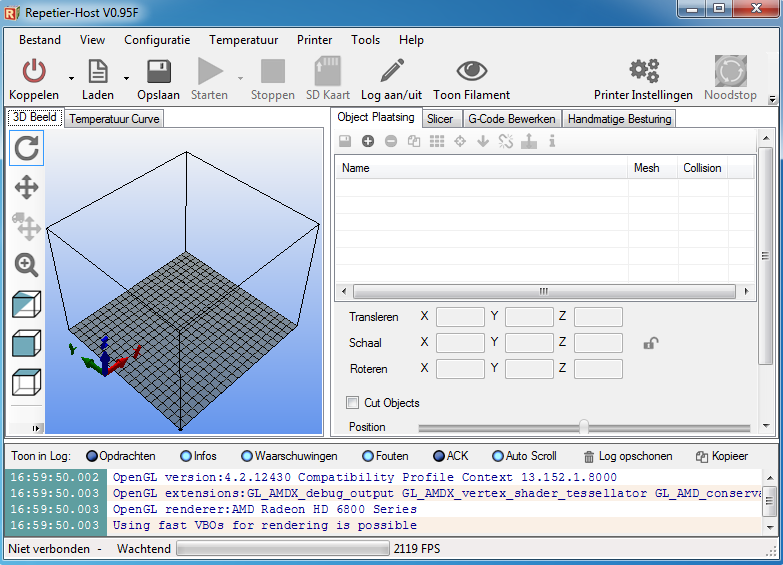

Use any CAD software or 3D scan data to design your model, and export it in a 3D printable file format (STL or OBJ). Each SLS printer includes software to specify printing settings, orient and arrange models, estimate print times, and slice the digital model into layers for printing. Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection.

Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection.

Fuse Series printers use PreForm print preparation software (free to download) that allows you to seamlessly duplicate and organize multiple parts within a 3D grid to use as much of the build space as possible for a single print. PreForm automatically suggests optimal orientation and part packing, with the ability to manually refine as needed.

The workflow for preparing the printer varies by system. Most traditional SLS systems require extensive training, tools, and physical effort to prepare and maintain.

Fuse Series printers reimagine the SLS workflow for simplicity and efficiency, with modular components to enable nonstop printing and end-to-end powder handling.

On Fuse Series printers, you can load powder easily using the powder cartridge.

Fuse Series printers use a removable build chamber so you can run another print while a previous one is still cooling.

Once all preprint checks have been completed, the machine is ready to print. SLS 3D prints can take anywhere from a few hours to multiple days depending on the size and complexity of parts, as well as the part density.

Once the print is finished, the build chamber needs to slightly cool down in the print enclosure before moving to the next step. After that, the build chamber can be removed and a new one inserted to run another print. The build chamber has to cool down before post-processing to ensure the optimal mechanical properties and avoid warping in parts. This may take up to half of the print time.

On Fuse Series printers, the touchscreen displays a live stream of the print bed during printing so you can watch each new layer take shape. This camera view is also available from your computer in PreForm so you can monitor your print without leaving your desk.

Post-processing SLS parts requires minimal time and labor compared to other 3D printing processes. It is easily scalable and yields consistent results for batches of parts thanks to the lack of support structures.

After a print job is complete, remove the finished parts from the build chamber, separate them, and clean them of excess powder. This process is typically completed manually at a cleaning station using compressed air or a media blaster.

Any excess powder remaining after part recovery is filtered to remove larger particles and can be recycled. Unfused powder degrades slightly with exposure to high temperatures, so it should be refreshed with new material for subsequent print jobs. This ability to re-use the material for subsequent jobs makes SLS one of the least wasteful manufacturing methods.

A common theme in the SLS industry is to offer separate devices for reclaiming, storing, and mixing powder. In the Fuse Series workflow, a single device, Fuse Sift, handles the extraction of parts and unsintered powder, as well as storing, dosing, and mixing of streams.

For Fuse Series printers, Fuse Sift completes the SLS printing workflow. It offers a safe and efficient system for extracting prints and recycling powder.

Fuse Sift can dispense and mix used and new powder automatically so you can reduce waste and control your powder supply.

SLS 3D printed parts are ready to use after sifting. However, there are several other post-processing steps that you might consider for selective laser sintered parts.

By default, SLS 3D prints have a grainy finish. Formlabs recommends media blasting or media tumbling SLS parts for a smoother surface finish. Parts may be spray painted, lacquered, electroplated, and coated to achieve different colors, finishes, and properties, for example, watertightness (coating) and conductivity (electroplating). Formlabs SLS parts are dark in color, so they are not ideal for dyeing.

SLS part with hydrographics from Partial Hand Solutions.

SLS parts can be electroplated for a metal-like finish.

Engineers and manufacturers choose selective laser sintering for its design freedom, high productivity and throughput, low cost per part, and proven, end-use materials.

Most additive manufacturing processes, such as stereolithography (SLA) and fused deposition modeling (FDM), require specialized support structures to fabricate designs with overhanging features.

Selective laser sintering does not require support structures because unsintered powder surrounds the parts during printing. SLS printing can produce previously impossible complex geometries, such as interlocking or moving parts, parts with interior components or channels, and other highly complex designs.

Hand splint designed with a complex pattern to reduce weight.

Engineers generally design parts with the capabilities of the final manufacturing process in mind, also known as design for manufacturing (DFM). When additive manufacturing is used for prototyping alone, it is limited to parts and designs that conventional manufacturing tools can ultimately reproduce during production.

As selective laser sintering becomes a viable rapid manufacturing method for an increasing number of end-use applications, it has the potential to unleash new possibilities for design and engineering. SLS 3D printers can produce complex geometries that are impossible or prohibitively costly to manufacture with traditional processes. SLS also empowers designers to consolidate complex assemblies that would normally require multiple parts into a single part. This helps alleviate weak joints and cuts down on assembly time.

SLS 3D printers can produce complex geometries that are impossible or prohibitively costly to manufacture with traditional processes. SLS also empowers designers to consolidate complex assemblies that would normally require multiple parts into a single part. This helps alleviate weak joints and cuts down on assembly time.

Selective laser sintering can take generative design to its full potential by enabling lightweight designs that employ complex lattice structures impossible to manufacture with traditional methods.

SLS printing is the fastest additive manufacturing technology for functional, durable prototypes and end-use parts. The lasers that fuse the powder have a much faster scanning speed and are more accurate than the layer deposition methods used in other processes like industrial FDM.

Multiple parts can be tightly arranged during printing to maximize the available build space in each machine. Operators use software to optimize each build for the highest productivity leaving only minimal clearance between parts.

SLS allows operators to pack the build chamber with as many parts it can fit and print them without supports to save time in post-processing.

The key to SLS 3D printing’s functionality and versatility is the materials. Nylon and its composites are proven, high-quality thermoplastics. Laser-sintered nylon parts have close to 100 percent density with mechanical properties comparable to parts created with conventional manufacturing methods like injection molding.

Drill assembly printed in Nylon 12 Powder. Nylon parts can be easily post-processed to achieve smooth, professional surface finishes.

SLS nylon is a great substitute for common injection molded plastics. It offers superior snap fits and mechanical joints compared to any other additive manufacturing technology. It is ideal for functional applications requiring plastic parts that will last where parts produced with other AM methods would degrade and become brittle over time.

Calculating cost per part usually requires accounting for equipment ownership, material, and labor costs:

-

Equipment ownership: The more parts a machine can produce over its lifetime, the lower the costs attributable to each individual part.

Consequently, higher productivity leads to lower equipment ownership costs on a per-part basis. Given the fast scanning speed of the laser, the nesting of parts to maximize build capacity, and simple post-processing, SLS 3D printing offers the highest productivity and throughput of all plastic additive manufacturing techniques.

Consequently, higher productivity leads to lower equipment ownership costs on a per-part basis. Given the fast scanning speed of the laser, the nesting of parts to maximize build capacity, and simple post-processing, SLS 3D printing offers the highest productivity and throughput of all plastic additive manufacturing techniques. -

Material: While most 3D printing technologies use proprietary materials, nylon is a common thermoplastic produced in large quantities for industrial purposes, making it one of the least expensive raw materials for additive manufacturing. As SLS 3D printing doesn’t require support structures and allows for printing with recycled powder, the process produces minimal waste.

-

Labor: The Achilles heel of many 3D printing solutions is labor. Most processes have complex workflows that are hard to automate, which can substantially influence the cost per part. The simple post-processing workflow of SLS printing means less labor is required and the process is easy to scale.

An SLS 3D printer represents a substantial initial investment, but it can often recoup the initial investment even faster than smaller machines. Benchtop SLS significantly reduces this barrier to entry and also the per par cost for most applications.

Outsourcing production to service bureaus is recommended when your business requires 3D printing only occasionally, but it also comes with higher costs and long lead times. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes a week or even multiple weeks to arrive.

| Cost | Lead Time | |

| Service Bureau | $118.33 | 7-10 days |

| Fuse 1+ 30W | $9.02 | 13 hours |

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Selective laser sintering enables engineers to prototype parts early in the design cycle, then use the same machine and material to produce end-use parts. SLS 3D printing does not require the same expensive and time-consuming tooling as traditional manufacturing, so prototypes of parts and assemblies can be tested and easily modified over the course of a few days. This drastically reduces product development time.

SLS 3D is ideal for creating durable, functional prototypes that are ready to undergo rigorous functional testing or to ship to customers as replacement parts or products that are ready to use.

Given its low cost per part and durable materials, SLS 3D printing is an economical way to produce complex, custom parts, or a series of small components for end products. In many cases, laser sintering is a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

Until now, industrial SLS 3D printers have been prohibitively costly for most businesses, with a single machine running over $200,000.

With the Fuse 1+ 30W, Formlabs is bringing the industrial power of selective laser sintering to the benchtop, offering high-performance materials at the lowest cost per part, with a compact footprint and simple workflow.

A new wave of independent manufacturing and prototyping starts now with the Fuse 1+ 30W.

See the Fuse 1+ 30W Benchtop Industrial SLS 3D Printer

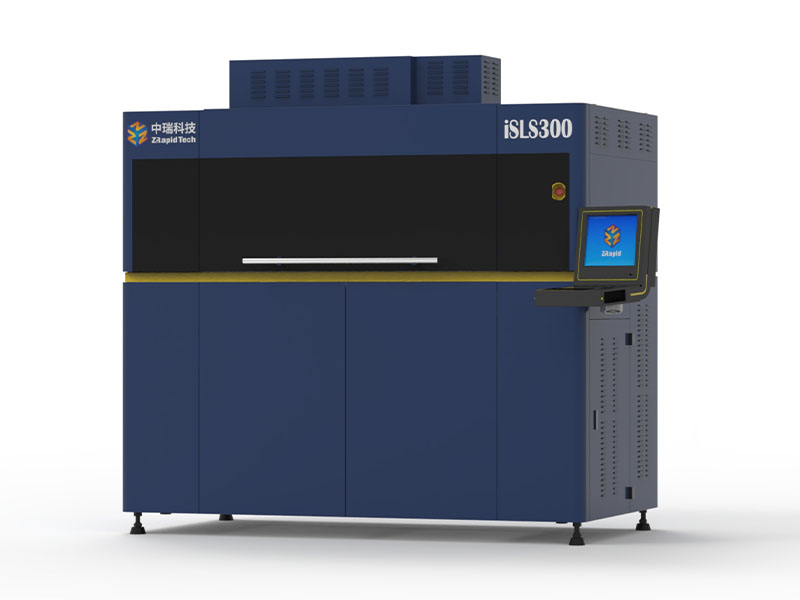

Manufacturer of compact and industrial SLS 3D printers

These industries leaders trust us

Sinterit’s compact series

Print batches of top quality SLS parts faster. Larger print volume and revolutionary fast rapid prototyping.

LEARN MORE

The SLS 3D printer for top-quality functional prototypes, research work, and to speed up the product engineering process.

The most compact SLS 3D printer to start your additive manufacturing journey.

Sinterit’s industrial series

A new industrial SLS 3D printer with the best ROI on the SLS technology market.

Priced individually

LEARN MORE

Any shape you want.

Without supports.

Without supports.Nine different materials + the ability to use third-party powders

Standard prototyping

Performance & Special Applications

Flexible

ALL MATERIALS

Build your custom solution

based on modules

Solutions

Industrial Set

Industrial performance & build volume with the best ROI on the market. An open & multi-material printer offering industrial-size build volume.

Priced individually

MORE

Performance Set

Top performance & build volume in an open, multi-material printer. Offering large build volume and industrial speed & quality.

Starts from 29.990 €

MORE

Open Set

Professional SLS quality in an open, multi-material printer. Compatible with 9 different Sinterit materials. Easily modify 32 printing parameters thanks to the open system.

Starts from 19.990 €

MORE

Entry Set

The most compact SLS 3D printer. It offers professional SLS print quality, it’s cost effective, and very easy to use.

Starts from 9.990 €

MORE

Events

Thanks to the nitrogen chamber built in to the LISA PRO, LISA X and NILS 480, you can experiment with third-party powders outside of our offer, opening up a world of flexibility.

SLS 3D printing is one of the most cost-effective means of additive manufacturing. You can reuse the unsintered powder, which acts as a supporting structure during the printing process. Some powders need to be refreshed, while others are good to go.

PRINTING COSTS

Rigo Herold

Professor Dr.-Ing., Zwickau University in Germany

It was the best choice for me to fulfill all requirements: possibility to print complex structures, price, speed, reliability.

Maurice Briggs

Director at Lazerthrust

Sinterit LISA is the most accessible means to produce precise constraint-free solutions to modern problems.

The technology does what it says on the tin and the team at Sinterit is dedicated to working with their customers to achieve their objectives.

Joshua Rosen

ECA Medical

One of the main benefits of SLS is the ability to print complex geometry in quick succession to do rapid prototyping.

SEE CASE STUDY

Peter Benthues

H. Gautzsch Firmengruppe

For a company at the beginning of an investigation, support from, and discussion with the technology experts is extremely beneficial.

The LISA is one of the few economically feasible solutions in the first stages of any AM Strategy. At lower volumes, it is a perfect solution.

SEE CASE STUDY

Lluís Llenas

Regner

The FFF and SLA parts are a good choice to get a physical impression of the designs and to assemble rough prototypes. But when it comes to producing reliable prototypes to be verified in our fatigue tests or to send functional samples to our customers for validation, SLS is the only acceptable choice.

SEE CASE STUDY

Walter Pucheanu

R&D Technician

Department of Chemical and Biological Engineering (CBI) / University of Erlangen–Nuremberg

The print quality of the Lisa PRO is impressive.

SEE CASE STUDY

Sean Higgins

Nabson Inc.

In order to keep up with our production demand, we have been operating the Lisa PRO almost 7 days a week for the past couple of months, without incident, and produced over 1500 sleeves.

SEE CASE STUDY

Case Studies

ALL CASES

We empower innovation with new possibilities based on SLS – the most powerful additive manufacturing technology.

Sinterit’s goal is to support the creativity of engineers, researchers, developers, academics, and visionaries wherever it’s needed. Our focus, every day, is on making the world more innovative and sustainable.

MORE ABOUT SINTERIT

Sinterit printers are available worldwide thanks to our distribution network. Choose the one closest to you and check out Sinterit printers in person.

DISTRIBUTORS LIST

Get SLS knowledge straight to your inbox. Keep up to date with new applications, products, and powders, while being among the first to know about new webinars, ebooks, and case studies.

Access the prestigious SLS 3D printing owners and experts club. We don’t get in touch often, but when we do you’ll know it’s worth your time.

We understand that choosing the right 3D printing technology can be a daunting task, even for professionals. That’s why we invite you to consult our advisors and ask as many questions as you need to. Our experts will help you choose the best technology for your applications, suggest the powders you will need, provide more information for specifications or tenders, or send you sample printouts demonstrating the features you’re looking for. Send a form and try to describe all your needs so we can be prepared when contacting you. Once we receive your message, we will contact you soon.

Select topic

---Price quotationTechnical questionMore product/offer detailsSample print request

First name*

Last name

E-mail

Phone number

Company name

Job title (optional)

Country

---AfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia (Plurinational State of)Bonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIran (Islamic Republic of)IraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea (Democratic People's Republic of)Korea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia (Federated States of)Moldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussiaRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUAEUKUSAUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela (Bolivarian Republic of)Viet NamVirgin Islands (British)Virgin Islands (U. S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

State

---AlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyomingDistrict of Columbia

Requested Products

Upload o file

How can we help you?

* Information about the processing of your personal data provided to Sinterit by the contact form is here. To read all our Privacy Policy please click here.

(Optional) By provision of your email address (and other data, if you wish) you agree to receive newsletter from Sinterit sp. z o.o. that may include commercial information e. g. Sinterit Lisa Pro updates, products and services offers, information about exhibitions and use-cases, as well as, from time to time, we may send you inquiries or surveys to ask you about Sinterit and our products. You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

g. Sinterit Lisa Pro updates, products and services offers, information about exhibitions and use-cases, as well as, from time to time, we may send you inquiries or surveys to ask you about Sinterit and our products. You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

Click to make an appointment and learn more about our printers

First name*

E-mail

Phone number

Company name

Country

---AfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia (Plurinational State of)Bonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIran (Islamic Republic of)IraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea (Democratic People's Republic of)Korea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia (Federated States of)Moldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussiaRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUAEUKUSAUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela (Bolivarian Republic of)Viet NamVirgin Islands (British)Virgin Islands (U. S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

State

---AlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyomingDistrict of Columbia

* Information about the processing of your personal data provided to Sinterit by the contact form is here. To read all our Privacy Policy please click here.

(Optional) By provision of your email address (and other data, if you wish) you agree to receive newsletter from Sinterit sp. z o.o. that may include commercial information e.g. Sinterit Lisa Pro updates, products and services offers, information about exhibitions and use-cases, as well as, from time to time, we may send you inquiries or surveys to ask you about Sinterit and our products. You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

Pricing

Below there are approximate costs for some example models.

Be aware that the quotation assumes that there is only one piece printed. In SLS technology, the cost per part will be much lower with a higher number of elements printed at once.

Flexible

Standard

[contact-form-7 404 "Not Found"]

Get a free sample box

The free samplebox contains two printouts made from PA12 Smooth. They are both movable designs, and each one is printed in one piece.

These are examples showing high precision and freedom of design ensured by SLS technology.

order free sample box

This product includes GeoLite2 data created by MaxMind, available from https://www.maxmind.com.

Skip to content

What is SLS 3D printing.

How does an SLS 3D printer work? Overview of additive technologies.

How does an SLS 3D printer work? Overview of additive technologies.

What is SLS?

Hello everyone, Friends! 3DTool is with you!

In this article, we will talk in detail about one of the most promising technologies 3D printing . Selective laser sintering.

Selective Laser Sintering (SLS) is an additive manufacturing process belonging to a broad family of wafer synthesis methods. In SLS, a laser selectively sinters polymer powder particles, fusing them together to create layer after layer. Granular thermoplastic polymers are used as construction material. Options for such devices can be considered in our catalog. For example, the Sintratec 3D printer.

This technology is used both for prototyping functional polymer products and for integration into small production runs, as it offers complete design freedom, high precision and produces parts with good and stable mechanical properties, unlike FDM or SLA .

Naturally, as in any other case, the possibilities of technology can be used to the full only if its key advantages and disadvantages are taken into account, so let's take a closer look at its features and principle of operation.

SLS printing process

How does SLS work?

The SLS fabrication process works as follows:

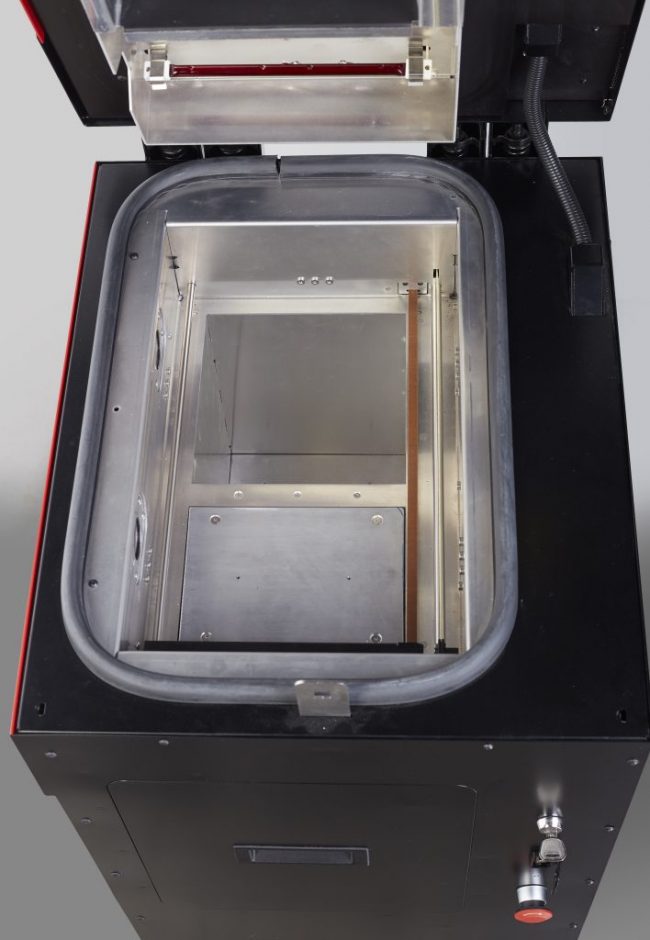

I. The powder chamber, as well as the entire printable area, is heated just below the melting temperature of the resin, after which the leveling blade distributes a thin layer of powder over the build platform.

II. The CO2 laser scans the contour of the next layer and selectively sinters (melts) the polymer powder particles. The cross section of the component is scanned ( is sintered ) completely, so the part is monolithic.

III. When the layer is completed, the work platform moves down and the blade re-coats the surface with powder.

The process is repeated until the entire part is completed.

After printing, the part is completely sealed in the non-sintered powder, so the chamber and powder must cool before being removed. Cooling down can take a significant amount of time, up to 12 hours. Then the resulting part is cleaned of powder residues with compressed air. The unsintered powder is collected for further reuse.

Schematic diagram of an SLS 3D printer.

SLS printing specifications In SLS, almost all print options are set by the printer manufacturer. The default layer height for is 100-120 µm . For example, the Sintratec 3D printer we mentioned above allows you to print a much thinner layer, the layer thickness declared by the manufacturer varies from 50 to 150 micron.

The main advantage of method SLS is that the part does not need supports . In this case, the non-sintered powder plays the role of the necessary support. For this reason, the SLS method can print geometries of any shape that are impossible to print with any other additive or subtractive manufacturing method.

When printing with this method, it is very important to use as much of the printable area as possible, especially in small-scale production. Regardless of the amount of detail in the printable area, if the overall height is the same, printing will take the same amount of time. This is because it is the recoating step that determines the total print time ( the laser scanning and sintering itself is very fast ), and the printer has to cycle through the same number of layers. Also, you need to take into account the time for refilling the hopper with powder, because the same amount is poured into the chamber, regardless of the size of the printed part.

Layer sintering

When using method SLS , the sintering strength of the layers to each other is excellent. This means that printed on SLS printer parts have almost isotropic mechanical properties.

As an example, the mechanical properties of samples printed on SLS using standard polyamide powder ( PA12 or Nylon12 ), the most commonly used material in SLS printing , are shown in the table in comparison with the properties of solid nylon:

Parts printed on SLS have superior tensile strength and modulus comparable to solid material, but are more brittle ( their elongation at break is much lower than ). This is due to the internal porosity of the resulting part.

!A typical SLS part has a porosity of about 30%!

Porosity gives parts printed on SLS a characteristic grainy surface. This porosity also means that the parts can easily absorb water and are easy to paint. At the same time, such parts require special post-processing if they are to be used in a humid environment.

At the same time, such parts require special post-processing if they are to be used in a humid environment.

Shrinkage and deformation

SLS parts are subject to shrinkage and deformation: when the newly sintered layer cools, its dimensions decrease and internal stress accumulates in it, due to which the underlying layer is pulled upwards.

Shrinkage of 3 to 3.5% is typical for SLS printing of and printer operators must take this into account during model preparation.

Large flat surfaces are most prone to deformation. This problem can be mitigated slightly by orienting the part vertically on the build platform. But still, the best way to reduce deformation is to minimize the thickness of the flat areas of the part, and add cutouts to the model where the design allows. These actions will also reduce the overall cost of the part, as less material will be used.

Finished sls-part with embedded embedded elements.

Excessive caking

Over-sintering occurs when excess heat around the contour of the part melts the unsintered powder around. This is fraught with loss of detail on small objects such as slots and holes.

Excessive sintering depends on both element size and wall thickness. For example, a slot with a width of 0.5mm or hole diameter 1mm will print successfully on a wall thickness of 2mm but will not print if the wall thickness is 4mm or more. As a general rule, slits from to 0.8mm and holes from to 2mm can be safely printed in SLS without fear of excessive caking.

Powder removal

Since printing method SLS no support required, parts with hollow sections print quickly and accurately.

Hollow sections in this case reduce the weight and cost of the part, as less material is ultimately used. But you will need to make outlet holes in the part to remove unsintered powder from the internal cavities. The general recommendation in this case is to add at least 2 outlet holes with a diameter of at least 5 mm to your part.

But you will need to make outlet holes in the part to remove unsintered powder from the internal cavities. The general recommendation in this case is to add at least 2 outlet holes with a diameter of at least 5 mm to your part.

If high rigidity is required, the parts must be printed solid. An alternative here would be to make the structure hollow, with no outlets. In this way, the powder will be compacted tightly into the part, increasing its mass and providing some additional support when mechanical loads increase, without affecting print time. Also, instead of one solid internal cavity, you can add a honeycomb structure ( similar to the infill patterns used in FDM ) to further increase the rigidity of the model. Laying out the part in this way will also help reduce warping.

Removing powder from an SLS part

General materials SLS

The most commonly used material for SLS is Polyamide 12 (PA 12) , also known as Nylon 12 . At the moment, there are more and more materials with different properties for SLS 3D printing every day, for example, elastic polymers are represented by TPE powder and its analogues. Other technical thermoplastics such as PA11 and PEEK are also available but are not as widely used.

At the moment, there are more and more materials with different properties for SLS 3D printing every day, for example, elastic polymers are represented by TPE powder and its analogues. Other technical thermoplastics such as PA11 and PEEK are also available but are not as widely used.

As an example, you can see the list of materials used in our catalog: Sintratec Powder Sls.

Polyamide powder can be supplemented with various additives ( such as carbon fibers, glass fibers or aluminum ) to improve the mechanical and thermal properties of the printed part. Materials supplemented with additives are usually more brittle and have higher anisotropy.

Post-processing

SLS produces parts with a powdery, grainy finish that is easy to paint. The appearance of SLS printed parts can be improved to a very high standard using a variety of post-processing methods such as polishing, classic painting, spray painting and varnishing. Their functionality can also be improved by applying a waterproof coating or metal coating.

Their functionality can also be improved by applying a waterproof coating or metal coating.

Advantages and limitations of SLS

Summarizing the above, the key advantages and disadvantages of the technology are given below:

- SLS parts have good, isotropic mechanical properties, making them ideal for functional parts and prototypes.

- SLS does not require support, so parts with complex geometries can be easily printed.

- SLS manufacturing capabilities are excellent for small to medium series production.

- Only industrial SLS systems are currently widely available, so lead times are longer than other 3D printing technologies such as FDM and SLA.

- SLS parts have a grainy surface and internal porosity that may require post-treatment if a smooth surface or water resistance is required.

- SLS cannot accurately print large flat surfaces and small holes as they are prone to warping and warping.

The main characteristics of SLS technology are shown in the table below:

And that's all we have! We hope the article was useful to you.

You can purchase SLS 3d printers, consumables for them, as well as any other 3d printers and CNC machines, by contacting us:

• By email: [email protected]

• By phone: 8(800)775-86-69

• Or on our website: http://3dtool.ru

Also, don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

SLS Medical 3D printers. Additive Manufacturing of Sterile and Customized Surgical Instruments

The medical industry is in a state of flux and looking for solutions to modernize current manufacturing processes. Profile specialists are interested in introducing the most efficient and innovative means of production to enterprises.

The French holding Prodways offers practicing medical professionals (surgeons, prosthetists) modern 3D printing technologies that allow them to create:

Biocompatible 3D printing materials and high-precision 3D printers from Prodways are the answer to today's demands and needs of the medical industry.

Prodways Industrial SLS 3D Printers

Prodways Technologies employees are experts in the production of industrial 3D printers and materials for the medical sector.

The company's offer includes equipment that uses the following 3D printing technologies:

- SLS - selective laser sintering of plastic powder

- DLP MOVINGLight ® digital curing photopolymer resin

Prodways printers can be used in prototyping for medical device testing, as well as in the production of customized end-use products and tools.

3D Print Ceramic Bone Substitutes

With DLP MOVINGLight ® , you can 3D print high resolution ceramics with 99% ceramic density.

The Prodways ProMaker V10 industrial ceramic 3D printer enables direct 3D printing of unique bone replacement components made from biocompatible ceramics - hydroxyapatite or calcium orthophosphate.

DLP MOVINGLight ® eliminates the machining step that is part of traditional ceramic casting technology.

Surgical Demonstration Models

Prodways SLS and DLP 3D printers provide a wide range of imaging options for training medical professionals and presentations to patients. 3D technologies allow:

- Design and grow products that illustrate a wide variety of clinical diseases and pathologies

- Create a 3D model of a patient's bone using a 3D scan and then send the 3D file to a printer for printing

Solutions offered by Prodways will make it possible to grow:

Large models with complex geometric shapes in high resolution on SLS 3D printers. The plastic powder used during the operation of the printer can be recycled and used during the subsequent production cycle, which can significantly optimize the cost of creating products.

Small parts that require high detail and precision printing to correctly identify existing pathologies using DLP MOVINGLight ® 3D printers.

Sterile and Custom Surgical Additive Manufacturing

Industrial SLS printers support printing with USP Class VI certified polyamide (PA 11-SX 1450). With this material it is possible to manufacture small and medium batches of products intended for single use in implant surgery. In this case, the products will be customized, impact-resistant and can be sterilized by means of gamma radiation.

With this material it is possible to manufacture small and medium batches of products intended for single use in implant surgery. In this case, the products will be customized, impact-resistant and can be sterilized by means of gamma radiation.

Orthopedic fast 3D printing

Prodways selective laser sintering technology allows you to create orthopedic corrective insoles that match the individual characteristics of the human foot.

Thanks to high-precision 3D scanning of the foot, it is possible to obtain a 3D model of the insole of the desired shape, with a lattice or honeycomb structure. Thus, it is possible to adjust the fit of the insole to different parts of the foot.

Depending on their type, orthopedic insoles can be printed in either PA12 or PA11 powder, both plastics are medical grade materials and are USP Class VI certified.

High Precision 3D Printing of Surgical Guides

With Prodways 3D printers it is possible to produce medical instruments of high quality and precision (tolerance levels of a few microns).