Sindoh 3d printer review

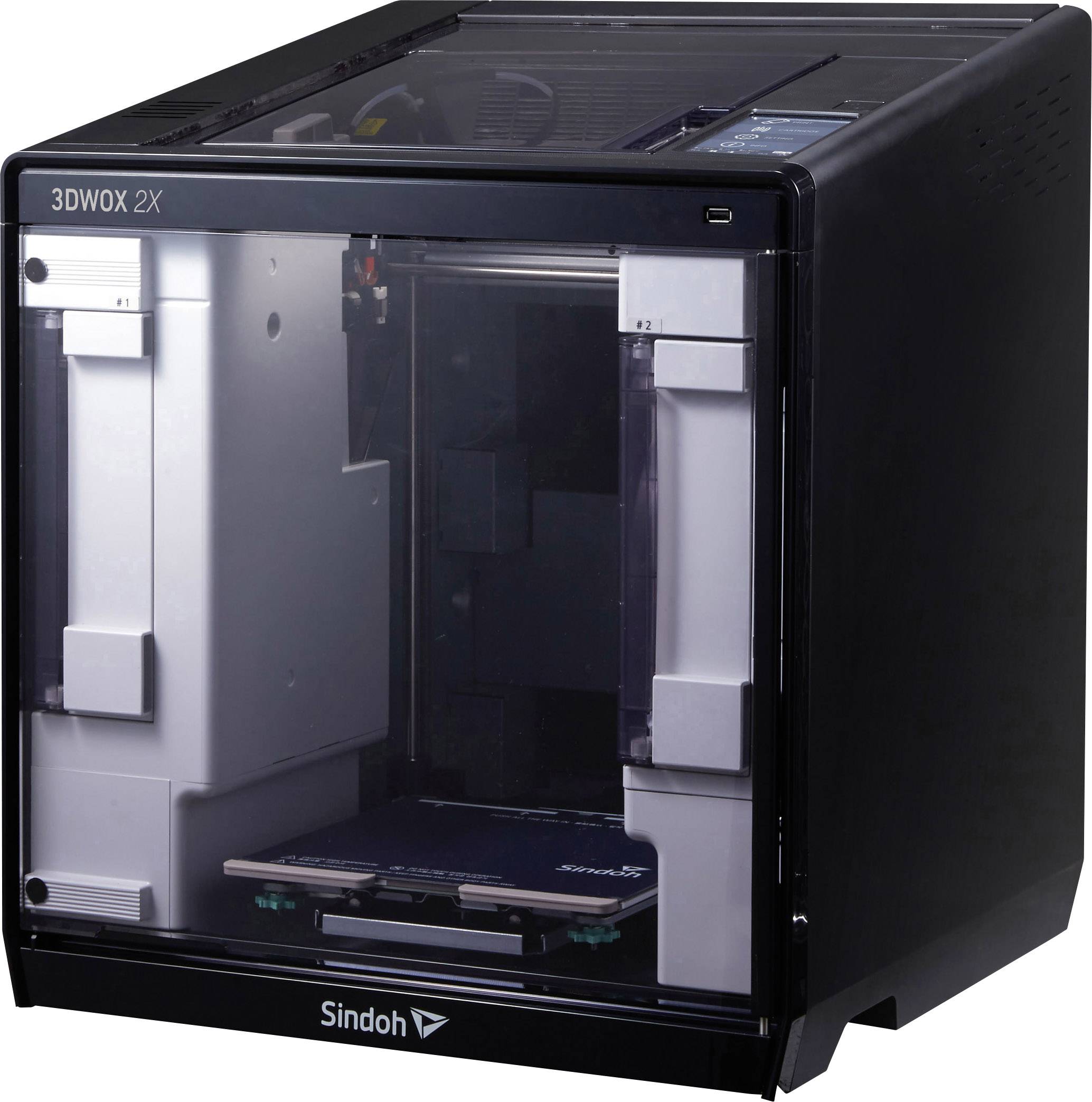

REVIEW: The Sindoh 3DWOX 2X, an accurate, user-friendly dual extrusion 3D printer

Our engineering team has put together a hands-on review of the Sindoh 3DWOX 2X 3D printer.

As the latest addition to its desktop range, the 3DWOX 2X from South Korean manufacturer Sindoh, responsible for the 3DWOX1, DP200 or DP201, is an Independent Dual Extrusion (IDEX) FFF 3D printer.

With over two years on the market, the company has branded the 3DWOX 2X as an easily-usable machine aimed both beginners and expert users. The 3D printer holds a maximum build size of 228x200x300mm, a heated bed up to 110°C, as well as a vocal guidance feature for trouble-shooting.

The following is an extensive review conducted by the 3D Printing Industry engineering team to evaluate the key claims of the 3DWOX 2X. The claims are as follows:

– Quality and accuracy

– Multi-material prints

– Ease of use / very user-friendly

– Wide range of materials

– Quiet operation

3DWOX 2X hardware: Print heads and cartridge

Unlike its predecessor, the 3DWOX1, the 3DWOX 2X is a dual extruder 3D printer. This allows for 2 different materials to be used in the same 3D printed model. The nozzles work interdependently, optimizing the production of the model, to create the multicolor, multi-material models. As a result, the weight of the print heads are reduced. Moreover, this system requires an accurate calibration which can be time consuming.

The print heads have a bowden extrusion system which puts the stepper motor supplying the filament away from the print heads. Furthermore, the filament is driven through a PTFE tube to the nozzle in the print head. This enables an increased print speed as well as precision as the heavy motor is not on the head – solidifying the claim of quality and accuracy.

Nevertheless, the drawback of this configuration is that it often reduces the quality of flexible filament prints as tolerances between the extruder gears can be too loose to be pushed toward the nozzle in the PTFE tube. In spite of this, the 3DWOX 2X handled the flexible filament well on TPU tests.

In spite of this, the 3DWOX 2X handled the flexible filament well on TPU tests.

The 3DWOX 2X is equipped with a cartridge system for each loaded spool. This keeps the spool in the machine in a dry controlled area as the cartridge is closed off. Additionally, each spool has its own RFID chip which sends information such as the filament type, and the quantity used, to the printer. Third party filaments can also be used in the open materials mode.

Dual print heads in the 3DWOX 2X.Slicer and print setup

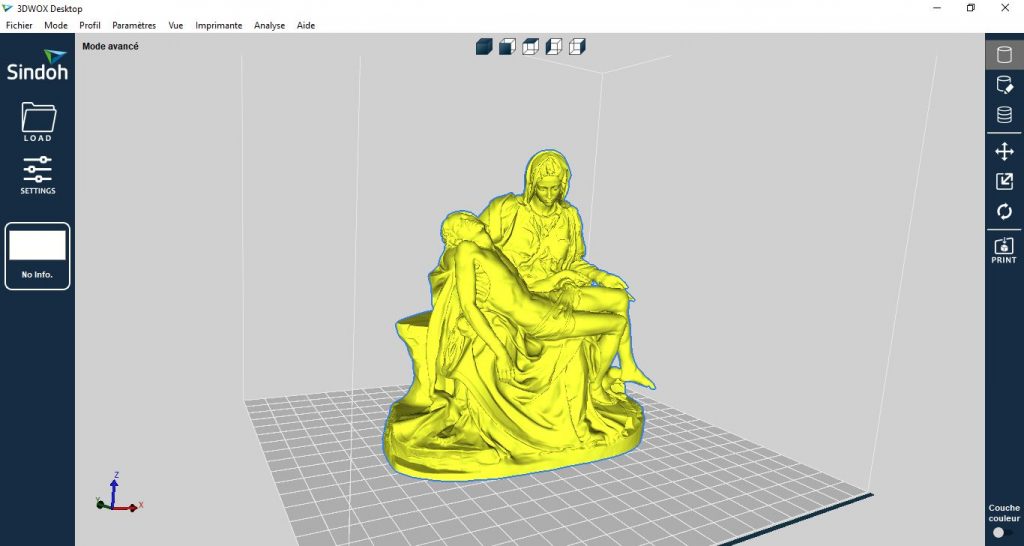

The 3DWOX 2X is compatible with several slicing softwares. For the purposes of this review, the 3DWOX Desktop Slicer was used due to its straightforward interface. The buttons on the right hand side of the screen allow users to reposition the model by moving it, rotating it, or scaling it. Two modes are available in this software, easy mode and advanced mode.

The engineering team found that the advanced mode is more suitable for those wanting to dive deeper into the parameters as it unlocks additional settings such as temperature control, retraction settings, print speeds for walls, infill, first layers, and outer contours.

Additionally, the ‘layer color’ option enables multi-color or multi-material models. Overall, the slicer was deemed to be very easy to use and the color/material distribution to the nozzles to be rather intuitive.

The Sindoh Slicer user interface.When setting up the 3DWOX 2X, the team loaded and unloaded the filament with ease thanks to the cartridge. The printer also automatically heats the nozzle and extrudes the filament to ensure the nozzle is primed and ready.

Print bed calibration, which is a semi-automatic process, took the team 5 minutes while XY calibration for the dual extruder system took 10 minutes as this step must be repeated a few times. Wi-Fi connection to the printer took no more than 2 minutes to complete. A USB drive can also be inserted directly into the 2X.

Single extruder print tests

Using Sindoh’s white PLA, several single extruder tests were conducted. The tests included a model of the 3D Benchy, a well-known benchmarking model. The 3D printed Benchy produced on the 3DWOX 2X showed good quality overall as the layers are not too visible. There were only a few strings visible between gaps as well as some artifacts which can be easily removed by hand.

The 3D printed Benchy produced on the 3DWOX 2X showed good quality overall as the layers are not too visible. There were only a few strings visible between gaps as well as some artifacts which can be easily removed by hand.

To test repeatability, 3 parts were all printed 5 times. As the reference dimensions are known from the original 3D model, the engineers were able to determine the discrepancy between measured dimensions and original dimensions, and the dispersion between them. The parts are printed in groups of 3 (1 square, 1 polygon, 1 tube).

Repeatability test on the 3DWOX 2XTo illustrate differences between the 3D printed models during the repeatability tests, the average or mean of the objects were calculated. The mean of differences is the mean of the differences between the measurements and the reference. It can be said that the difference between reference and measure under 0.1 deems the 3D printer as accurate. From the tested parts, the 3DWOX 2X was seen to be consistent and precise. It should also be noted that the printer operated rather quietly.

It should also be noted that the printer operated rather quietly.

| Hole φ | Height | Width | Length | |

| Reference | 12 | 10.000 | 15 | 15 |

| Print 1 | 11.83 | 10.100 | 15.02 | 15.02 |

| Print 2 | 11.99 | 10.080 | 15.01 | 15.04 |

| Print 3 | 11.95 | 10.010 | 15.05 | 14.95 |

| Print 4 | 11.88 | 10.070 | 15.01 | 15.09 |

| Print 5 | 11.99 | 10.110 | 15.05 | 14.99 |

| Mean of differences | 0.07 | 0.07 | 0. 03 03 | 0.04 |

| Mean of real values | 11.93 | 10.07 | 15.03 | 15.02 |

| Standard deviation (σ) | 0.07 | 0.04 | 0.02 | 0. 05 05 |

| Mean + 3 x σ | 12.14 | 10.19 | 15.09 | 15.18 |

| Mean – 3 x σ | 11.72 | 9.96 | 14.97 | 14.86 |

The table above shows the square model measurements and calculations from the repeatability tests.

Overhang tests were performed to determine the maximum overhang angle possible without supports. The model used is composed of 6 walls printed in an increasing overhang configuration. The first overhang angle is 40°. The following ones are shifted by 5°until 65°.The overhangs under 45° were well printed, however, those above were not as smooth. The surface of the last overhang was inferior, according to the team, as they deemed the overhang limit to be 60°.

The first overhang angle is 40°. The following ones are shifted by 5°until 65°.The overhangs under 45° were well printed, however, those above were not as smooth. The surface of the last overhang was inferior, according to the team, as they deemed the overhang limit to be 60°.

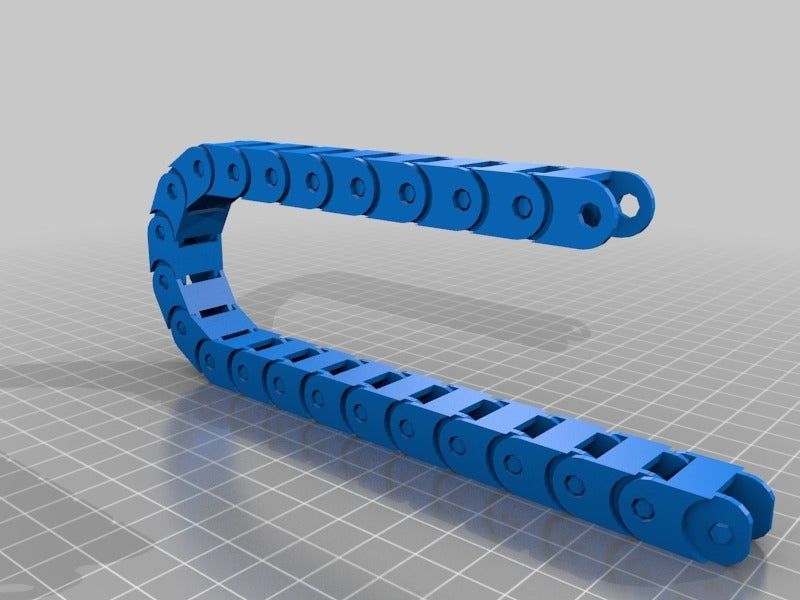

Bridging tests ranging from 5mm to 60mm were printed to evaluate the cooling ability of the printer. The team gathered that the quality remained up until the 15mm length bridge. A tower test successfully hit the 300mm height limit on the printer, while a circular trajectory test, evaluating the printer’s ability to print parts with circular sections, was generally satisfactory.

Retraction and small part tests were also conducted on the 3DWOX 2X. From the spiked model, retraction was proven to be very good as there was no stringing between the spikes. Following this, small nut and bolt models no more than 28mm were produced.They were shown to have good detail with no defects. The parts were then easily screwed together.

The parts were then easily screwed together.

Dual extrusion and real application tests

To understand the capabilities of the interdependent nozzle system, multicolor models including a two-tone 3D Benchy, vase, digger and figurine were printed using blue and white PLA. The first trial of the Benchy was not successful due to a small discrepancy between the white and blue layers and the calibration. Nonetheless, after recalibration, the second trial was able to reduce the visibility of the shift between the layers.

Image of the first (right) and second model of the two-tone Benchy.The multicolored vase model was printed to determine if the seam between two colored areas were well executed. The overall quality of each zone was good and the surface was smooth. However, the seam between the two colors left some gaps in some areas, meaning the vase was not watertight.

2X 3D printed two tone vases.

A 3D Benchy and moving crane were also printed simultaneously to test the quality of the models. Both prints were considered to be printed accurately, particularly due to the successfully produced joints and the minimal gaps between parts, allowing for easy movement on the articulated digger model.

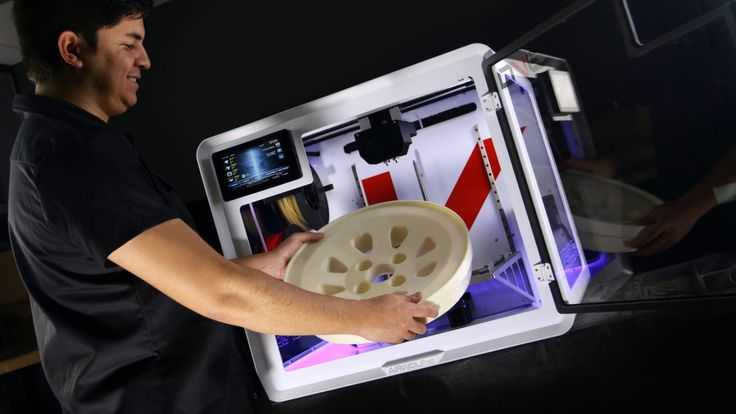

The 3D printed benchy and diggerTPU and PVA supports

Moving on to TPU, the team aimed to test the printer’s ability to process flexible filaments. At a nozzle temperature of 240°C and bed temperature of 70°C, the team printed a smooth phone case with absolutely no stringing. This was a pleasant surprise, as printing flexible filament on a bowden configuration is not often an easy process.

The 3D printed TPU phone case.The 3DWOX 2X’s ability to print models with PVA support was also tested. High detail models with lots of overhangs were produced using PLA. The final model was well printed showing no shift between the supports and the printed parts. The team found that the supports easily dissolved in warm water resulting in clean prints. The dual nozzles are very accurate when it comes to differentiating support layers from parts of the model, this can be observed in the image below depicting the accuracy on the small openings.

The dual nozzles are very accurate when it comes to differentiating support layers from parts of the model, this can be observed in the image below depicting the accuracy on the small openings.

A straightforward, competent 3D printer

From our extensive review, the team found the Sindoh 3DWOX 2X 3D printer to be a reliable, user-friendly, system capable of manufacturing large and small models with very few defects. Its dual extrusion system also enables multi-colour parts or PVA supported parts, great for detailed models and useable parts.

Nonetheless, it was noted that the 3DWOX 2X could improve with a more precise method for XY calibration. Moreover, after having done the calibration 2 or 3 times, the print heads are still not always perfectly calibrated. A “mirror” mode would also increase the system’s capabilities given its IDEX system. It is to be noted that some filament combinations are not possible. For example PLA loaded in the first print head and TPU in the second one. In addition, the size of the workspace is small when compared to the 3D printer’s overall footprint.

In addition, the size of the workspace is small when compared to the 3D printer’s overall footprint.

The Sindoh 3DWOX 2X is a very competent machine that allow users to print with confidence. The cartridge system improves the accessibility of materials as various filaments, including third party filaments, can be handled. An office environment would be suitable for this 3D printer due to its quiet operation and its vocal guidance also facilitates the use of the machine for early users.

The 3DWOX 2X is available from authorized resellers around the globe.

For in-depth reviews and other news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the 3DWOX 2X 3D printer. All photos by 3D Printing Industry.

Sindoh 3DWOX 1 Review - 3D Printing

Editors rating:

Not too long ago, Sindoh released their latest plug-and-play 3D printer. They named it ‘3DWOX 1’ and we can safely state that it is even better than Sindoh’s very successful DP200.

They named it ‘3DWOX 1’ and we can safely state that it is even better than Sindoh’s very successful DP200.

We were lucky enough to get our hands on the 3DWOX 1 and put it to the test. In this review you will read everything about the pros and cons of this machine.

Overview (TL;DR)

- Open filament system: can print 3rd party filaments

- From unboxing to printing in an hour

- Flexible (magnetic) print surface for easy part removal

- Automatic filament loading

- Assisted bed leveling

- Easy to use and well designed interface

- Great for printing ABS due to closed print chamber and flex build plate.

| Reliability | 5 out of 5 |

| User friendliness | 5 out of 5 |

| Print quality | 5 out of 5 |

| Print consistency | 5 out of 5 |

| Range of materials | 4 out of 5 |

| Support / helpdesk | 3 out of 5 |

| Slicer software | 4 out of 5 |

| Availability replacement parts | 3 out of 5 |

Unboxing & setup

Just like its predecessors, the 3DWOX 1 is a plug-and-play machine. From unboxing to printing will only take you an hour, and that’s for inexperienced user. Because we worked with the DP200 before, it only took us a few minutes to level the bed, load the filament and start a test print (which is preloaded on the device itself).

From unboxing to printing will only take you an hour, and that’s for inexperienced user. Because we worked with the DP200 before, it only took us a few minutes to level the bed, load the filament and start a test print (which is preloaded on the device itself).

What’s in the box

- 3DWOX 1 3D printer

- Refillable Cartridge Case

- Power cable

- Flexible, magnetic build plate cover

- USB stick

- USB cable

- Spatula

- Nozzle cleaning tool

- Spare PTFE tube

About 3DWOX 1

User Interface

The UI is clear and well thought-out. Where necessary, explanatory elements are enhanced with animated illustrations.

Control, connectivity, monitoring and notifications

First of, the touch screen is big and responsive, exactly what you expect from a high quality touch screen. You can start a print via USB drive, an app, or directly from the slicing software to the printer via your network. The built-in camera enables you to monitor a print from a distance. You can simply install the 3DWOX mobile app on your phone or tablet and monitor the progress of your print from a distance. Additionally you can setup an email notification for when your print is ready.

The built-in camera enables you to monitor a print from a distance. You can simply install the 3DWOX mobile app on your phone or tablet and monitor the progress of your print from a distance. Additionally you can setup an email notification for when your print is ready.

3rd party materials

In contrary to its predecessors, you can now use filament from any third party supplier as long as it is a material this printer can handle. It can’t handle flexible / soft materials and materials that have a melting temp above 482 °F / 250 °C.

Sindoh does recommend that you use the ‘manufacturer’s recommendation list for using non-Sindoh filament’ which can be found on their website.

Problem solving

We didn’t run into any big problems while testing the 3DWOX 1 but when you do, there are several ways of problem solving.

Built-in quick guides

The thing that stands out are the built-in quick guides that you can view via the interface. There are several quick guides that tackle the most important elements of the printer, e.g: bed leveling, filament loading, nozzle cleaning et cetera.

There are several quick guides that tackle the most important elements of the printer, e.g: bed leveling, filament loading, nozzle cleaning et cetera.

Print Preparation

The flexible and removable print bed makes it very easy and safe to remove an object when it’s done. Switching and loading filament is automatic when using Sindoh cartridges. You can queue print jobs via the 3DWOX software which is also your slicer. The slicer has some good and some bad elements. The built-in mesh error fixing is great but it lacks certain advanced settings, for instance settings to improve bridge quality.

Online support

While auto loading Sindoh filament via a cartridge is very easy, it took us some time to figure out how to switch to open filament mode. At first we weren’t aware about the built-in quick guides so we Googled and ended up on Sindoh’s YouTube channel.

Additionally you can take a look at the online FAQ, but to be fair, you can’t find that much information about the 3DWOX 1 there. When you can’t find what you are looking for you can always reach out to Sindoh via email.

When you can’t find what you are looking for you can always reach out to Sindoh via email.

ABS Test print

The closed print chamber, removable / flexible heated bed and excellent slicing software make the 3DWOX 1 perfect for printing ABS.

Our test case was this modular mounting system on Thingiverse made by Thingiverse user Ryan Huang.

For a functional print you want to use a material that is both strong and durable. Therefor we chose ABS.

The parts were printed with default slicer settings (200 Microns layer height) (though some parts were printed with a higher infill percentage to create stronger parts). We were impressed with the level of detail, see the knobs for instance.

We never print ABS on a 3D printer with an open structure. ABS is very sensitive for temperature changes. Even the slightest breeze can make an object warp or crack. We didn’t experience any warping or cracking during our tests.

The only con is that sometimes the raft gets too stuck to the object and is difficult to remove.

Perfect 3D printer for the classroom and office

The 3DWOX 1 is safe to use, easy to use and quiet.

Low operating sound

The 3DWOX 1 is a quiet printer. The operating sound lies just below 40 DB which makes it suitable for the classroom and office.

Print queue

The print queue feature is very handy when you share the device with a group. You can queue objects via the app or directly from the slicer.

Filament runout detection

The filament sensor keeps track of the amount of filament that’s left on the spool. It pauses the print when you’re out so you can safely switch to a fresh spool. It also warns you when starting a print in case the estimated filament amount is more than what’s left on the spool.

Flexible print bed

The flexible print bed makes it easy and safe to remove a part. When you bend the bed just a tad bit, the print pops right off.

Built-in HEPA filter

The built-in HEPA filter absorbs over 91% of all particles released by 3D printing. With the HEPA filter installed in this printer, the 3DWOX 1 is a good fit for both at home & in the classroom usage as a desktop 3D printer.

With the HEPA filter installed in this printer, the 3DWOX 1 is a good fit for both at home & in the classroom usage as a desktop 3D printer.

Sindoh 3DWOX 1 pros

- Truly plug-and-play

- Great print quality

- Easy to use

- Safe to use

Sindoh 3DWOX 1 cons

- Rafts can get too stuck

- Slicing software misses some elements

- Unable to print flexible / soft material

Conclusion

We’re impressed that Sindoh once again met our expectations. They have delivered a versatile 3D printer that can meet the demands of beginners and also experienced users. The 3DWOX 1 takes away most of the hassle you can encounter with 3D printing. From preparing prints to monitoring prints, from solving problems to swapping filament, they’ve made it as easy as can be.

Review of Sindoh 3D printers with print examples

Good afternoon!

In this review, we will introduce the readers of the 3dtoday portal to the Sindoh line of 3d printers (South Korea).

Sindoh printers are an affordable solution for those who value comfort and convenience when using technology.

The equipment uses plastic filament extrusion technology (FDM / FFF), the most popular polymers on the market are available for printing - PLA, ABS, ASA, PETG, TPU, PVA, HIPS and others. nine0003

Sindoh has many years of experience in the office equipment market, founded in 1960. Today Sindoh is an international corporation with regional offices in China, Japan, Europe and America.

Sindoh experts carry out all stages of production in-house, from research and development to production. The company's production factories are located in three regions - South Korea, China and Vietnam. The total staff is about 4000 people. nine0003

Sindoh is known worldwide for its MFP printers. Today, the manufacturer's portfolio consists not only of copiers, but also of professional 3D equipment, software and consumables.

The 3D division was founded in 2013 and the first printer (DP200) was introduced 3 years later. Today Sindoh offers the following FDM printer models:

Today Sindoh offers the following FDM printer models:

• 3DWOX 1

• 3DWOX 2X

• 3DWOX 7X

• fabWeaver A530

Sindoh's main task was to design 3D printers that would make 3D printing easy and affordable not only for professionals, but also for those who are starting their acquaintance with additive manufacturing technologies. Below we will talk about the features of printers that provide users with comfortable work.

Automatic plastic loading

Original manufacturer's plastics supplied with cartridges. The spool of material is located inside the cartridge, which in turn is loaded into a special section of the printer. The device itself pulls the thread through the supply tube to the print unit, eliminating the need for the user to do this manually.

Also on the cartridge is a smart chip that transmits basic information about the plastic to the display of the device - type, color, material residue.

At the same time, all Sindoh printers have an "open" architecture - there is no strict binding to the original filaments, it is also possible to use Russian polymers. nine0003

nine0003

Flexible Print Bed with Heated

Experienced FDM 3D printer users know how common the problem is to fix the first layer of the product on the desktop.

The Sindoh Printer Platform ensures strong adhesion of the part without the need for auxiliary agents - glue, spray, varnish, etc.

The build platform is flexible so that the print is quickly and easily removed when the print is complete. All that is required of the operator is to regularly wipe the printer table with isopropyl alcohol. nine0003

Intuitive user interface

Each Sindoh printer has a full-color touch screen on the body that controls the main functions - loading and unloading plastic, calibrating the working platform, connecting to a Wi-Fi network, etc.

Also, the printers are equipped with a voice assistant that will report on the current status and tell you how to solve problems that have arisen in the process.

Automatic Platform Calibration

Sindoh printers independently determine the current position of the desktop and suggest what actions need to be taken to align it. The user simply needs to turn the adjustment screws under the platform the number of steps shown on the display.

The user simply needs to turn the adjustment screws under the platform the number of steps shown on the display.

Remote monitoring and control

There is a webcam inside the working chamber of the printers, which transmits video of the work to the manufacturer's proprietary application. The application can be installed on a PC, smartphone or tablet. nine0003

The operator can not only remotely monitor the print, but also start, pause or cancel the job.

Quiet and safe workflow

Sindoh 3D printers are virtually silent, ranging from 40db to 55db depending on the model.

The machines are equipped with charcoal filters that protect the environment from harmful fumes produced during the melting of the plastic.

Thus, printers can be placed in a typical office or classroom without compromising the environment and people in the room. nine0003

3DWOX 1

Junior printer in the manufacturer's line. The 3D printer is equipped with a single extruder and is suitable for printing products that do not differ in complex geometry.

Key features:

• Working area - 210*200*195 mm

• Number of extruders - 1

• Extruder heating temperature - 250°C

• Platform heating temperature - 110°C

• Layer thickness – 0.05 – 0.4 mm

3DWOX 2X

3D printer with two independent extruders. Two printing units allow you to grow products of complex geometric shapes using support material. A two-color 3D printing option is also available.

Main features:

• Working area - 228*200*300 mm

• Number of extruders - 2 independent

• Extruder heating temperature - 250°C

• Platform heating temperature - 110°C

Layer thickness – 0.05 – 0.4 mm

3DWOX 7X

Large area 3D printer. The device is suitable for printing medium-sized products and small-scale production of final plastic products.

Main features:

• Working area – 380*390*450 mm

• Number of extruders – 2 independent

• Extruder heating temperature - 250°C

• Platform heating temperature - 110°C

Layer thickness - 0. 05 - 0.4 mm

05 - 0.4 mm

fabWeaver A530 Senior 3D printer in the Sindoh line. The working chamber of the printer is equipped with an active heating function, providing the best print quality with engineering polymers. nine0003

An optional smart workstation is supplied with the printer, which can accommodate up to 4 plastic cartridges. Switching between cartridges, in case of running out of material in one of them, occurs automatically, which ensures uninterrupted operation of the printer.

Key features:

• Working area – 310*310*310 mm

• Number of extruders - 2 independent

• Extruder heating temperature - 290°C nine0003

• Platform heating temperature - 110°C

• Chamber heating temperature - 75°C

• Layer thickness – 0.05 – 0.4 mm

Our engineers use Sindoh 3D printers to print large format copier components. 3D printing allows us to get the right spare parts in a short time and at minimal cost. Below are products made from ABS plastic on Sindoh printers.

Salt shaker test print

The Upper Panel A0 Presser

Bunker for Toner

9000

Our company is the official SINDOH in the Russian Federation. We supply 3D printers throughout the country, provide training on how to work with equipment, and provide warranty and post-warranty service. nine0003

We invite you to our showroom in Moscow for a personal acquaintance with Sindoh equipment and its capabilities!

Our contacts:

Address - Moscow, st. Startovaya, 13 bld. -3d.ru

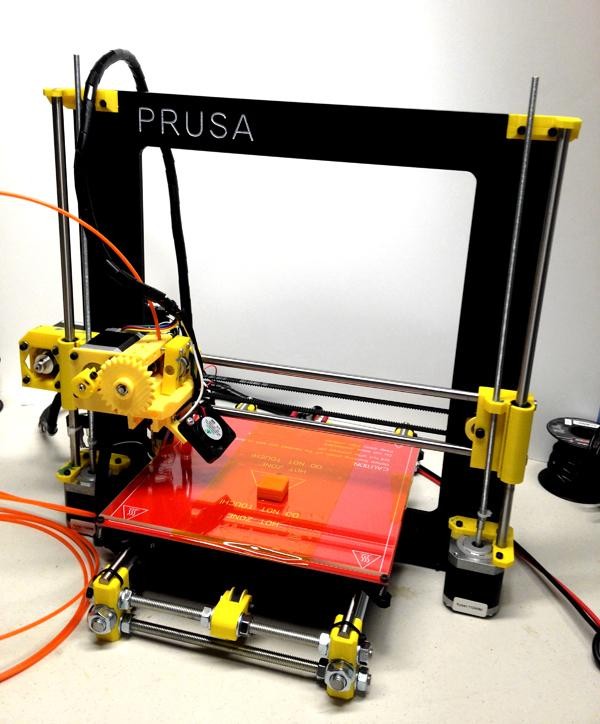

The best 3D printers for kids

This article will help you choose the best 3D printer for your child. The criterion that was used to determine these 3D printers is the age of the children. The printers discussed below will provide you with the opportunity to introduce your children to 3D printing and perhaps further interest them in engineering or a similar field. nine0003

nine0003

Introducing children to 3D printers from an early age gives them hands-on experience in making models to scale. Your kids will love creating their models and watching them take shape right before their eyes.

Below are only the best 3D printers based on both objective and subjective criteria, the final choice is up to you, but we will provide you with as much useful information as possible.

Is your child ready for a 3D printer? nine0226

If you have already mastered the technology of 3D printing, you have probably noticed that this is no longer something from the future. It's already here. 3D printing is useful for everyday use, from smartphones to cars, jewelry to medicine and more.

Kids need to be early on about 3D printing technology. And with the 3D printers below, your kids will not only learn the theory, but also get hands-on physical experience in 3D printing.

Price should not influence your decision when buying a 3D printer for a child. Instead, think about the benefits your kids will have in terms of hands-on experience using it. nine0003

Instead, think about the benefits your kids will have in terms of hands-on experience using it. nine0003

3D printer develops creative thinking

With 3D printing, you can get a small physical 3D model of plastic or other material in just a couple of hours. This technology not only speeds up simulation, but also significantly reduces the tedious development cycle of product development, design, production, testing, and product improvement.

For children who want to make a career as an engineer, a 3D printer will definitely help in their development. A 3D printer will give your child a hands-on physical experience of making their own products. This is what engineers live for. nine0003

Coming up with a design and having it in your hands in a few hours is a very exciting process. It can also be a good way to show your kids that engineering is fun.

The future of manufacturing is 3D printing

The adoption of new technologies in schools is relatively slow. This is usually due to the fact that schools do not receive sufficient funding and must follow the existing curriculum. Do not be surprised to learn that schools are still teaching children what they taught more than 10 years ago. nine0003

This is usually due to the fact that schools do not receive sufficient funding and must follow the existing curriculum. Do not be surprised to learn that schools are still teaching children what they taught more than 10 years ago. nine0003

If your children are lucky, they may be taught metalwork or woodwork anywhere from elementary to high school. Even though they are learning these skills, it is very unlikely that they will touch a 3D printer. If the institution has a 3D printer, it may not be the latest model.

3D printers have changed a lot in the last 10 years. Today, printers have become much more affordable, and the choice and competition are quite high.

XYZPrinting Da Vinci miniMaker 3D printer

First Impressions of the XYZprinting DaVinci miniMaker

The XYZprinting DaVinci miniMaker is sure to please. Not only that, the bright appearance of this 3D printer will also impress your child. Instead of seeing a boring gray box, the first impression will be like a new toy.

The similar Da Vinci Mini is more orange and will cost about $30 more. However, it does have Wi-Fi.

The build quality of the DaVinci miniMaker is excellent. It is a rugged and reliable 3D printer with compact dimensions (15.75 x 13.23 x 14.25 inches). nine0003

Specification XYZprinting DaVinci miniMaker

Age group: 14+ (8+ with adult supervision). An adult will need to unpack it, set it up, remove the pre-assembled parts, and clean the 3D printer after each use.

- Price range: Budget

- Material type: PLA (non-toxic)

- Resolution: 1mm - 0.4mm

- Workspace: 9 x 5.9 x 5.9 inches

DaVinciMaker minimaker software nine0254

MiniMaker does not use the industry standard G-code. Instead, it uses the included XYZware software. This is the limiting factor for young hungry minds. However, the 3D printer is guaranteed to work immediately after purchase.

The XYZware software is a fairly simple program. However, there are problems in terms of feedback. For example, there will be no expected error warnings, etc.

However, there are problems in terms of feedback. For example, there will be no expected error warnings, etc.

XYZ MiniMaker Kids 3D printer displays useful information. For example, there is information about how much material the 3D model will use and how long it will take to print. Children usually lose patience when they have to wait a long time. So it's great that this 3D printer gives an estimated production time. nine0003

The program does a great job of automatically preparing your 3D models for production. Unfortunately, there are limitations in terms of adding support materials in case of complex 3D models, so that the child will not be able to master this area of 3D printing.

XYZprinting DaVinci miniMaker setup and print quality

DaVinci miniMaker is easy to set up. All you have to do is plug in the USB cable and power cable, install the printhead, feed in the 3D printing material, and you're done. Calibration is not required. nine0003

This 3D printer comes with setup instructions that are a little vague at times. However, you won't have any problems setting it up, even if you're seeing a 3D printer for the first time.

However, you won't have any problems setting it up, even if you're seeing a 3D printer for the first time.

XYZprinting DaVinci miniMaker 3D printing process

There are several models in the XYZ program that can be used for 3D proofing. If you need more models, I suggest you check out Thingiverse. Or, for example, you can download Pokemon characters and print their models. nine0003

The level of detail you get with DaVinci miniMaker 3D printing is commendable given how cheap this device is.

MiniMaker runs quietly. That's impressive considering it's an open design model.

Disadvantages of XYZprinting DaVinci miniMaker

The biggest disadvantage of the miniMaker 3D printer is that it can only use the exclusive XYZ filament. The problem is that filament is more expensive than conventional brands available on the market. The manufacturer of this 3D printer probably doesn't want entry-level users to put the wrong filament in the printer. Therefore, only one type of media is used in printers. Inside this 3D printer there is a chip that checks the markers on the material. By checking, he can find out how much material was used up. Therefore, if you insert a different brand of media, the printer will indicate that there is no media and therefore it simply will not work. The only way to get this 3D printer to use a different material is probably to change the main board. So keep that in mind when you're shopping for this 3D printer. nine0003

Inside this 3D printer there is a chip that checks the markers on the material. By checking, he can find out how much material was used up. Therefore, if you insert a different brand of media, the printer will indicate that there is no media and therefore it simply will not work. The only way to get this 3D printer to use a different material is probably to change the main board. So keep that in mind when you're shopping for this 3D printer. nine0003

However, the inability to use other manufacturers' filaments should not deter you from buying a DaVinci miniMaker, as the filament spool can last quite a while. In addition, the 3D print quality of this printer is exceptionally high.

XYZprinting Conclusions DaVinci miniMaker

The XYZ miniMaker is a great 3D printer for young children and non-technical parents. Finished 3D models are very highly detailed and of excellent quality. nine0003

However, the simplicity of this printer can be a disadvantage because your children can outgrow it quite quickly, especially when they reach their teens. In addition, this 3D printer will not be able to 3D print more complex models.

In addition, this 3D printer will not be able to 3D print more complex models.

If you are interested in a 3D printer, you can check out an alternative review of the DaVinci miniMaker, in which it is considered not in the context of a device for children, but as a full-fledged 3D printer.

3D printer Monoprice Select Mini

First Impressions of the Monoprice Select Mini

The Monoprice Select Mini V2 is a very durable 3D printer. The steel construction of this printer is quite simple, but it looks reliable and there can be absolutely no complaints about it.

Important parts of the 3D printer are well sealed to avoid damage or injury during use. This 3D printer gives the impression that it should be operated by a white-coated lab technician.

Enthusiastic teens will love this 3D printer with a full color display. Although the display is not touch-sensitive, there is a thin control wheel next to it on a fancy polished steel plate. nine0003

nine0003

The great news is that you can use PLA plastic from any manufacturer to print on this 3D printer.

Specifications Monoprice Select Mini

- Age Group: 14+

- Price Range: Budget

- Material Type: ABS, PLA, XT Copolyester, PET, TPU, TPC, FPE, PVA, HIPS, Jelly, Foam, Felty

- Resolution: 1 mm

- Working space: 7 x 4.7 x 4.7 inches

Monoprice Select Mini 9 software0254

Monoprice recommends using Simplify3D, Replicator-G, Repetier or Cura software. All of these slicers are 3D printer compatible. Cura is the recommended software for Monoprice. One of the benefits of using third party software is that they have advanced settings and more options for preparing a 3D model. All of the programs listed above are also used with professional 3D printers.

Monoprice Select Mini 9 setup and print quality0254

Monoprice Select Mini V2 does not come with installation instructions. However, you can download instructions from the Monoprice website.

This 3D printer comes with some default settings. However, it is worth figuring out and tweaking these settings.

The material feed to the printer is not very well implemented and can cause problems, but in general these are tolerable little things that you will encounter in most 3D printers.

3D printing process on Monoprice Select Mini

The Monoprice 3D printer is quite loud compared to other 3D printers in this review. Moreover, it has the ability to use an SD card.

My 3D test model printed quickly and without problems. The quality of the model was excellent. However, test model settings can be optimized. The speed of 3D printing was also low, since the resolution in the Z coordinate was set to high. But this is the expected price that you have to pay for high-quality 3D printing. These shortcomings are corrected by the correct settings in the slicing program, as well as on any other 3D printer, so it's hard to say that this is a shortcoming. And the many options for print settings on the Select Mini will let your child (and probably you) learn even more about the 3D printing process. nine0003

And the many options for print settings on the Select Mini will let your child (and probably you) learn even more about the 3D printing process. nine0003

Disadvantages of Monoprice Select Mini

Although Monoprice claims that you can use ABS plastic for 3D printing, you are bound to run into problems using this material. This is because ABS requires a table temperature of 220°F while Monoprice's maximum table temperature is around 140°F. If you want to use ABS to build your models, consider buying another printer. However, before thinking about using ABS plastic in principle, read the information about its toxicity and only then make a decision. Especially considering that a child will use this 3D printer. At the same time, it is worth noting that the quality of your PLA plastic products will be good, so this disadvantage should not play a decisive role in your choice of a 3D printer for a child. nine0003

Monoprice Select Mini Conclusions

Basically, if you're looking for the ultimate 3D printer for teenagers, the Monoprice Select Mini V2 is the perfect buy at an affordable price.

The disadvantages of this 3D printer can be overlooked, especially if you just want to buy your kids their very first 3D printer.

If you are interested in a 3D printer, you can check out an alternative review of the Monoprice Select Mini, which does not consider it in the context of a device for children, but as a full-fledged 3D printer. nine0003

Flashforge Finder 3D Printer

FlashForge Finder First Impressions

Unlike the other 3D printers for kids in this review, the FlashForge Finder 3D printer is more suitable for home 3D printing or an ordinary apartment environment. This model matches perfectly with all your other gadgets.

The front of the machine has a nice, clear, full color touchscreen display. In general, the 3D printer looks bright and at the same time concise and fits perfectly into a discreet but thoughtful interior. nine0003

FlashForge Finder Specifications

- Age Group: 11+

- Price Range: Budget

- Material Type: PLA

- Resolution: 0.

8 - 0.4mm

8 - 0.4mm - Working Space: 5 x 5.5 inch

FlashForge Finder Software

FlashForge Finder uses FlashPrint software to slice 3D models. The software allows you to fully automate the slicing, the support generator for complex 3D models works well. In manual options, you can change the temperature and speed of 3D printing for kids who want to take their part design to the next level. Standard features such as the amount of material used are also included in the software. nine0003

When you use the manual setting, you will notice that the FlashPrint software is more advanced than the XYZware that comes with DaVinci miniMaker. The software also has several advanced options, such as 2D to 3D, which allow you to create an approximate 3D model from a 2D image. For example, you can use the settings to turn a face into a 3D model and print it out.

FlashForge Finder 3D Printing Process

FlashForge Finder comes with a USB stick containing a user manual. When you turn on your 3D printer for the first time, the touch screen will guide you through the initial print bed calibration. You will see instructions on how to fasten the adjusting nuts and adjust them to the correct height. The guide is user-friendly and makes setup that would otherwise be frustrating for a novice as simple and straightforward as possible. nine0003

When you turn on your 3D printer for the first time, the touch screen will guide you through the initial print bed calibration. You will see instructions on how to fasten the adjusting nuts and adjust them to the correct height. The guide is user-friendly and makes setup that would otherwise be frustrating for a novice as simple and straightforward as possible. nine0003

Feeding material to the 3D printer again can cause problems. You will need to apply some force to pull the filament through the extruder. You will definitely not succeed the first time, but it is a solvable task.

With this 3D printer, you can easily print almost any 3D model. The printer heats up quickly and is relatively quiet.

Frustration with this 3D printer is low; very close to zero according to consumer reviews, even after a few weeks of use. nine0003

FlashForge Finder Disadvantages

Although the FlashForge Finder 3D printer can be used with a variety of PLA filaments, the onboard filament container is slightly smaller than a standard 3D printer. So if you are using other brands of PLA, keep the spool away from the printer, such as on or right above a bookshelf.

So if you are using other brands of PLA, keep the spool away from the printer, such as on or right above a bookshelf.

FlashForge Finder Conclusions

The FlashForge Finder 3D printer is a couple of years ahead of its time. Surely in a few years this 3D printer can be bought in any store, just like you do now with 2D printers. nine0003

The 3D printer is quite simple and given the manufacturer's warranty, this is the perfect option if you need to introduce your family to the world of 3D printing.

Sindoh 3DWOX DP200 3D Printer

Sindoh 3DWOX DP200 First Impressions

The Sindoh 3DWOX DP200 3D Printer looks more like home appliances than a 3D printer. The printer looks like an innovative microwave oven with a transparent front opening.

Media and print engine are inside the printer. The plastic parts inside the printer are solid to the touch, so the workmanship is clearly at a high level. nine0003

Since the material for 3D printing is inside the 3D printer itself, it is slightly larger in size than its counterparts. However, the printer's cubic shape makes it easy to install, unlike other open design 3D printers that require space to access removable covers and material.

However, the printer's cubic shape makes it easy to install, unlike other open design 3D printers that require space to access removable covers and material.

DP200 is a large printer. 8.3 x 7.9 x 7.3 is one of the largest models in the home 3D printer market. If you are looking for a large 3D printer for kids, then Sindoh 3DWOX DP200 is your best choice. nine0003

Specifications Sindoh 3DWOX DP200

- Age group: 13+

- Price range: Expensive

- Material type: ABS, PLA

- Resolution: 0.5 - 0.4 mm x 7.9 x 7.9 4 inches

Sindoh 3DWOX DP200 software

Sindoh 3DWOX DP200 comes with its own 3DWOX Desktop software for slicing 3D models. The software has two modes: advanced and simple, and also provides adequate control when preparing a file for 3D printing. nine0003

Simple mode has an intuitive interface and in most cases allows you to get reliable and high-quality 3D models.

When you get comfortable with this 3D printer, you can switch to advanced mode and start experimenting with settings to improve the preparation of files for 3D printing and the quality of your 3D models.

Setup and print quality Sindoh 3DWOX DP200

Sindoh 3DWOX DP200 is delivered already assembled. All you have to do is plug it in, add some material and calibrate the table to start printing. When you turn on the printer for the first time, the color display will guide you through the calibration process. nine0003

One advantage of the DP200 printer is that you can insert a filament cartridge into it just like you would with a regular desktop printer. The media container system that the printer uses makes changing media much easier.

Sindoh 3DWOX DP200 3D printing process

After you have sent the file to the Sindoh 3DWOX printer, press the 'Start' button to make the machine start creating your model. If you have other things to do, you can step away from the printer and continue to monitor the printing process through the printer's built-in webcam.0003

Once your 3D model is printed, it is easy to take it out of the printer thanks to the flexible table.

Disadvantages of Sindoh 3DWOX DP200

The 3D printer DP200 only works with Sindoh filaments. So your 3B models will be limited by materials and colors. The good news is that Sindoh filaments are of high quality. Moreover, they are affordable.

DP200 can print with ABS. Therefore, you should consider ventilation as the fumes are toxic to some extent. Make sure the room where your 3D models will be printed is well ventilated. nine0003

Conclusions on Sindoh 3DWOX DP200

If you don't mind spending money on a 3D printer for a child, then this printer will suit you. This machine produces high-quality 3D models, and its design is simple and concise. The installation and process of 3D printing will also not cause difficulties.

If your kids have experience with 3D printers or want to learn a little more about them, then definitely buy them this 3D printer, which can give them the joy of implementing their ideas with a minimum of time spent on 3D printer maintenance.