3D food printing ppt

Top 9 3d food printing ppt THE BEST

You have a question 3d food printing ppt but have not got the exact and detailed answer you want, when you follow this article of wechoiceblogger.com, you will surely get the answer to the 3d food printing ppt question. most detailed and accurate. The results that we have listed in the top articles about asking 3d food printing ppt will definitely give you the answer you want right after.

1.3D food printing – SlideShare

Contents

- 1 1.3D food printing – SlideShare

- 2 2.3D Food printing – SlideShare

- 3 3.A 3D Food Printing Process for the New Normal Era: A Review – MDPI

- 4 4.3D Food Printing: Create food as you imagine – FoodTech Pathshala

- 5 5.A PRESENTATION ON “3D PRINTING TECHNOLOGY”. What is 3D …

- 6 6.3D Food Printing Market – SlideServe

- 7 7.3D Printing and its Application Insights in Food Industry – FutureBridge

- 8 8.3D Food Printing Presentation – [PPTX Powerpoint] – VDOCUMENT

- 9 9.

Make Ppt over introduction and history of 3D printing from the…

- Author: www.slideshare.net

- Post date: 13 yesterday

- Rating: 5(1460 reviews)

- Highest rating: 5

- Low rated: 2

- Summary:

See Details

2.3D Food printing – SlideShare

- Author: www.slideshare.net

- Post date: 19 yesterday

- Rating: 1(353 reviews)

- Highest rating: 4

- Low rated: 1

- Summary:

See Details

3.A 3D Food Printing Process for the New Normal Era: A Review – MDPI

- Author: www.mdpi.com

- Post date: 14 yesterday

- Rating: 2(1296 reviews)

- Highest rating: 4

- Low rated: 1

- Summary: Three-dimensional food printing technology can be applied to various food ranges based on the advantages of designing existing food to suit one’s taste and …

4.

3D Food Printing: Create food as you imagine – FoodTech Pathshala

3D Food Printing: Create food as you imagine – FoodTech Pathshala- Author: foodtechpathshala.com

- Post date: 1 yesterday

- Rating: 4(1662 reviews)

- Highest rating: 4

- Low rated: 1

- Summary: 3D food printing is a cutting edge technology which provides highly customized and personalized food with plenty of attractive 3-dimensional shapes.

See Details

5.A PRESENTATION ON “3D PRINTING TECHNOLOGY”. What is 3D …

- Author: slideplayer.com

- Post date: 5 yesterday

- Rating: 4(1642 reviews)

- Highest rating: 4

- Low rated: 2

- Summary: 3D printing or additive manufacturing is a process of making three dimensional solid. … Download ppt “A PRESENTATION ON “3D PRINTING TECHNOLOGY”.

See Details

6.

3D Food Printing Market – SlideServe

3D Food Printing Market – SlideServe- Author: www.slideserve.com

- Post date: 22 yesterday

- Rating: 2(1352 reviews)

- Highest rating: 4

- Low rated: 1

- Summary:

See Details

7.3D Printing and its Application Insights in Food Industry – FutureBridge

- Author: www.futurebridge.com

- Post date: 10 yesterday

- Rating: 5(1033 reviews)

- Highest rating: 5

- Low rated: 2

- Summary:

See Details

8.3D Food Printing Presentation – [PPTX Powerpoint] – VDOCUMENT

- Author: vdocument.in

- Post date: 12 yesterday

- Rating: 5(1520 reviews)

- Highest rating: 5

- Low rated: 1

- Summary: PowerPoint Presentation 3D FOOD PRINTING Knowledge and Attitudes of Millennials in the GTA Researchers: Ankita Singh, Anjali Sharma, Jason Szymanski, …

See Details

9.

Make Ppt over introduction and history of 3D printing from the…

Make Ppt over introduction and history of 3D printing from the…- Author: www.coursehero.com

- Post date: 8 yesterday

- Rating: 1(1575 reviews)

- Highest rating: 4

- Low rated: 1

- Summary: Answer to Make Ppt over introduction and history of 3D printing from the… … aviation, locomotive, food, fashion, and automotive industry.

The answers to the 3d food printing ppt question above of wechoiceblogger.com have helped you get the correct information, right? Please share this article with your friends and family to let them know more new knowledge. Wishing you a day full of joy and luck!

Top Food -3D Food Printing: Create food as you imagine

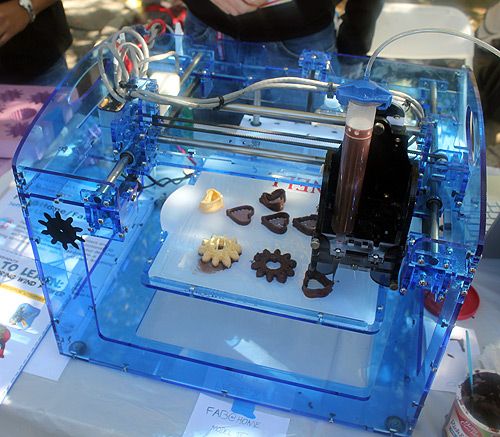

3D Printing, which is a kind of Additive Manufacturing Technology, has now

entered in the field of food processing and has also drawn attention of many researchers.

In 21st century where everything has been computerized, why should making of food continue with traditional cooking methods?

Though traditional methods have their own advantages but still they are tedious and time consuming.

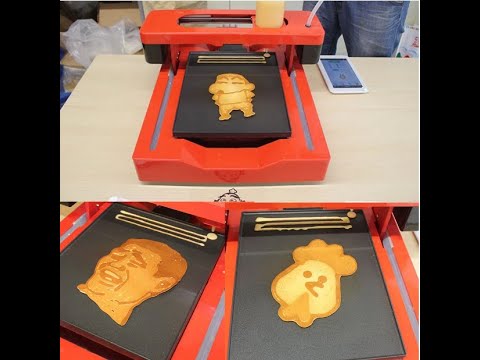

That is where 3D food printing comes in the picture to offer us highly customized and personalized food with plenty of attractive 3-dimensional shapes.

One of the major advantages of additive manufacturing over subtractive manufacturing is that it brings down the reduction in material wastage to almost zero level.

How does it work??

A 3D printer can be regarded as a robot that is instructed by a digital file of 3D graphic model.

This graphic model of an object is generally created using Computer Aided Design (CAD) software such as Auto Cad, Solid Edge, Solid Work etc.

The CAD drawing is converted to the standard tessellation language (STL) format. This STL format file is transferred to computer system that operates the 3D printer.

The same computer also has a pre-installed slicing software which is sort of specific coding. Its function is to break the 3D model into 2- dimensional layers.

The printer is instructed by the slicing software to construct these 2D layers one on the top of other until the 3D object is created.

Another important aspect of this process is feeding the right kind of material in the right form and at appropriate temperature.

It becomes very easy when you want to make something from plastic by a 3D printer.

The most common plastic used in 3D printing is ABS filaments (Acrylonitrile Butadiene Styrene) in wired form. But it becomes the most difficult when material is food stuff.

Food Formulation

Food formulation is the most complex and difficult aspect of producing edible 3D printed objects.

This is where a food technologist or a food engineer plays a vital role in making a successful 3D food product.

The formulation of food ink should be in such a way that after printing, it must gain physical stability and at the same time, it should be nutritionally rich and tasty.

One who formulates the food for 3D printing should have a precise and thorough knowledge of rheological, nutritional, and biological properties of particular food material.

Customization or personalization is one of the characterized advantages of 3D food printing. It allows us to formulate the nutritional value of the product according to the deficiency of micronutrients in a particular age group.

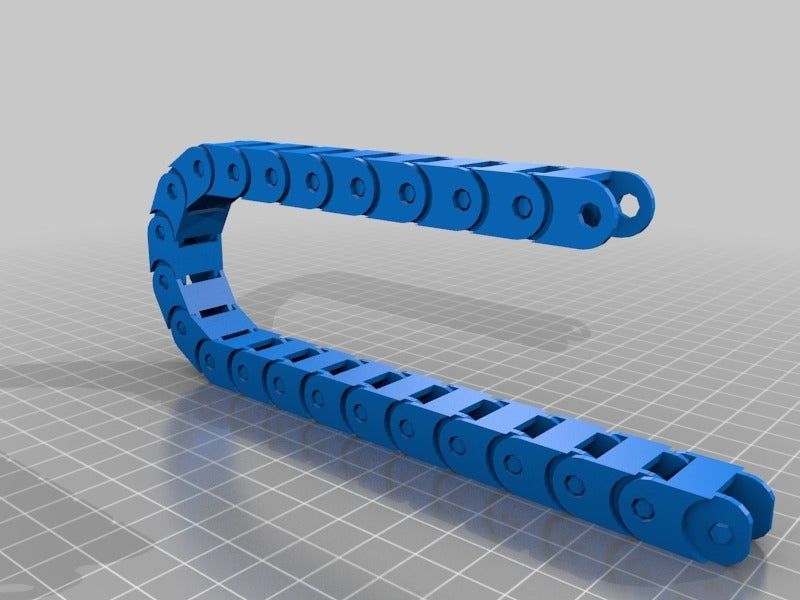

Each 3D printer is designed for a specific type of material. So when we talk about food material 3D printing, it can be classified into three categories:

- Extrusion-based Printing

- Inkjet Printing

- Binder Jetting

In extrusion-based printing, the material (solid or paste with low viscosity) is loaded into a plastic or metallic syringe. And then, it is pushed out through a micro nozzle at constant pressure.

And then, it is pushed out through a micro nozzle at constant pressure.

Application of constant pressure can be done in one of these three ways: pneumatic, piston-driven or screw-driven.

First two techniques can be used for low viscous material whereas the last one is desirable for higher viscosity material.

The 3D printer deposits the melted filament by layer, each layer on top of the others, to build the object in 3D.

When one layer is complete, the tray holding the object lowers very slightly and the extrusion process resumes, depositing a new layer of melted filament on top of the previous one.

Deposited layers are fused together as the melted plastic quickly solidifies to form a solid three-dimensional object.

This type of printing method is used for dispensing macromolecules such as hydrogel or polymer. Some of the edible hydrogel are polysaccharides, protein and lipids.

Inkjet Printing

An inkjet printer dispenses low viscosity (generally liquid) material in the form of stream of droplets falling through micro nozzle connected to thermal or piezoelectric head.

In the case of the thermal head, the print head is electrically heated to establish pulses of pressure. These pulses of pressure push the low viscous material in the form of droplets from the nozzle.

In case of piezoelectric head, the material is made to fall continuously in the droplet form by vibrating it at certain frequency.

This method is not suitable for creating complex 3D shapes because it uses only liquid materials.

Binder Jetting

In binder 3D printing, the inkjet nozzle applies a fine dry powder and a liquid glue, or binder, that come together to form each printed layer. Binder printers make two passes to form each layer.

Binder printers make two passes to form each layer.

The first pass deposits a thin coating of the powder, and the second pass uses the nozzles to apply the binder.

This method allows us to use combination of liquid and powdered materials.

Powder materials used are Sugars and starch mixtures.

And, the liquid binding agents could be corn syrup, soy sauce etc.

Reference

A Review of 3D Food Printing Technology

3D Printing of Food in food industry

3D Printed Chocolate by Cadbury Australia

In a world premiere, CADBURY DAIRY MILK launched the very first CADBURY DAIRY MILK milk chocolate 3D Printer, in celebration of World Chocolate Day on July 7, 2019.

LINK

How Hershey’s is Using 3-D Printers to Make Chocolate Kisses

3D printing technologies - online presentation

Similar presentations:

3D Printing Technologies and Trends

Additive technologies

Master class on 3D printing. Picaso 3D

Picaso 3D

3D printing technologies at the enterprise "3D Techno"

Additive manufacturing technologies

3D Printing Technologies

Additive technologies: 3D printing

Additive technology

3D printing

3D printers

3D printing technologies

The history of 3D printers

The technology

for making

three-dimensional objects with

digital data was first

developed by Charles

Hull in 1984. In 19086 he received his patent 9

invention and named this technology

Stereolithography.

T I 3D PRINTING

E

X FDM - fused deposition

H SLA - stereolithography

O SLM - selective laser

L

PAYSED

O

DLP

-

Digital

LED

g

and Printing

Slender Fronts

FDM

technology involves the creation of

three -dimensional objects for

consistent layers

,

repeating contours

.

Stereolithography

SLA - technology

additive production of models,

prototypes and finished products

from liquid photopolymer resins

.

Resin curing 9

is produced by

irradiation with ultraviolet

Selective laser melting

SLM is an additive manufacturing method

that uses

high power lasers

(typically ytterbium

fiber lasers) to create

three-dimensional physical objects

by melting metal powders.

Digital LED

printing

DLP - technology

involves

the use of

liquid plastic,

which cures

exposed to

UV light.

C for 3D

• Acryl

Printers

s

Chocolate

Other materials

K

I

H

E

M

A

T

I

K

A

Cartesian 3D printers

CoreXY and H-Bot

Delta printers

P

P

and

m

and

H

E

H

and

E

3D printers

Quick prototyping and mechanical engineering

Medicine

Architecture

Design and clothing production

Medicine

from

fast-growing

directions

3D printing

–

medicine. In 2011 there was a

In 2011 there was a

triumph

in

regenerative medicine: a printer filled with

biogel with stem cells,

"printed"

in

3

hours

a human kidney. Although

transplantation

organs

is still

far away,

scientists

are already

now

developing technologies for transplanting

3D-printed blood vessels,

Construction

Construction using 3D printing

is a serious competitor 29025 approaches. The United Arab Emirates

, Thailand, China and Russia

are already using modern

mobile printers for printing houses

directly at their location.

The printing method is the same as in other areas of application

- layer-by-layer extrusion.

Cement,

construction waste

,

former

in use

building materials,

fiberglass, etc. are used as materials.

Byt

3D printers gradually enter the manufacturing industry

food products, clothes, shoes, unique souvenirs, toys, furniture - a total of

things that people use in everyday life.

To print a wide range of household products, a person only needs a

printer and various materials for it.

3D food printer fills with ingredient cartridges and prepares the most delicious multi-ingredient dishes

according to recipes stored on a memory card.

The future: 3D printing perspectives

3D printing technology will soon enable

create

elements

for

construction of

research bases on the Moon and Mars. NASA has already

successfully tested titanium nozzles for rocket engines printed on the

3D printer.

Prospects for the exploration of the nearest planets dictate

a reduction in the cost of transporting cargo and

materials.

So,

experts of NASA

called the use of 3D printing in space the only

option

for possible planetary exploration.

Print landing pads, solid

buildings and roads on the Moon can be made from local

soil, and on Mars from basalt and regolith. More

More

Moreover, in the polar regions of Mars, water and low temperatures

will help

build

habitable

"Martian igloos" - multilayer ice

shelters from radiation and winds

P

O

C

T

R

OY 2 A

3D PRINTER

• WHICH 3D PRINTER DO I NEED?

• KINEMATICS

• SELECTION OF PARTS

• MANUFACTURE OF NECESSARY PARTS. nine0025 • PREPARATION OF ALL COMPONENTS

• ASSEMBLY OF THE BODY AND ALL MECHANICAL ASSEMBLY.

• WHICH FIRMWARE TO CHOOSE?

• CONNECTING ALL ELECTRONIC COMPONENTS

• Repeater Firmware

• DOWNLOAD AND DEBUG FIRMWARE

• REPITERHOST

• FIRST PRINT

Conclusion

Using 3D printing in everyday life

will reduce the cost of manufacturing

products;

cut

production timeline

;

develop a product of any size and shape; nine0025 exactly, without marriage, reproduce the item. Can

confidently

say

that

3D printing application provides a bright and comfortable future.

English Russian Rules

Professions of the future in agriculture. Food 3D printing engineer

Similar presentations:

Transport Process Technology

Organization of work and calculation of technical and economic indicators of the part machining section

Lifting machines. (Lecture 4.1.2)

Safe work at height

Well logging

ICE cooling system

Operation of oil and gas wells. Course of lectures in slides

Safety requirements when performing work at height

Project on technology "Rolling pin" (grade 6)

Switchgear designs. (Lecture 15)

MBOU "Zagorskaya

Secondary School

Week of Science

Professions of the future in agriculture

. 3D printing engineer

food

8b class

Modern

production technologies

physical

-

will free

labor

in

genetics,

millions

agricultural

automated

people 90.

from

heavy

Cultivation of

agricultural products will be transferred from fields to mini-farms on the roofs of

high-rise buildings. Mastering the cultivation of organisms

out of one

cells in test tubes - will solve the problem of slaughtering livestock. With the introduction of

modern technologies in agriculture, new

professions will appear: agro-cybernetic, GMO agronomist, 3D printing engineer

food products

,

operator

automated agricultural machinery

, agricultural ecologist.

3D Printing Engineer

food

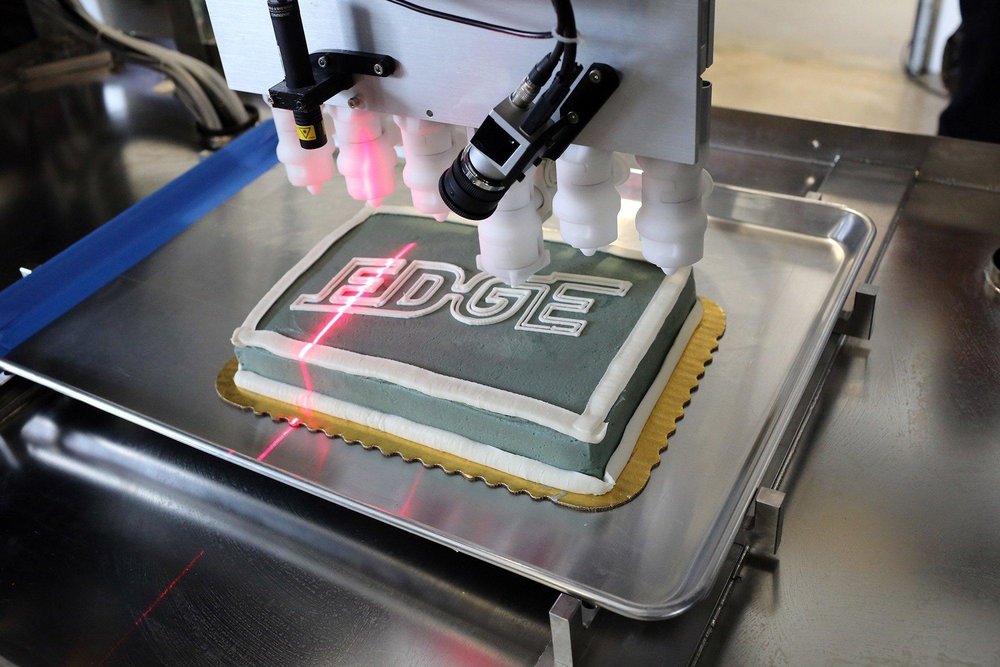

Object synthesis technologies continue to impress, especially in the field of

food production. This branch of 3D printing is considered the most unusual

and amazing. Oddly enough, today even meat can be printed using 3D printers

. The heart of the machine is a syringe, layer by layer it

lays down a viscous liquid, forming an object of a given shape. They are loaded with

paste-like or gel-like food mixtures and due to extrusion (method

of squeezing pasty materials through a hole) materials are obtained

ready meals or products.