3D printing human figures

FAQ | Shapify

General

1. Why Artec Shapify Booth?

Artec Shapify Booth features a fully automated process for creating 3D files. Use it to set up an innovative, lucrative and scalable business.

2. What is special about your software?

It’s the only software on the market that can process full body 3D scans automatically and quickly. Just compare the Shapify’s 15 minutes of automated cloud computing to create a 3D printable file with at least 2 hours of highly skilled work spent by a 3D modeller on every file made using photogrammetry or any other scanning solution.

3. I’ve heard of photogrammetry scanning solutions, but how does Shapify Booth work?

Unlike photogrammetry the Shapify Booth uses real 3D scanners. This is what has allowed us to create software which automatically creates printable 3D files.

4. What do I need to do to operate the Booth?

I. Front office

1. Meet the customer, check he or she is wearing appropriate clothes for scanning, recommend removing shiny clothes, jewelry, black shoes and glasses. Explain the process and ask the customer to hold still for 12 seconds while being scanned. Type the customer's name (or e-mail) into the system.

2. The customer stands in the booth. You click on the "Start" button and make sure the customer doesn't move during scanning.

3. After scanning, wait with the customer until the preview picture is ready. (About 5 minutes). Meanwhile discuss delivery options with the customer.

4. Make sure the preview is good and that the customer likes it.

5. Store the customer's name (e-mail), chosen delivery address, size of figurine and number. (This can also be done during step 3)

6. Charge the customer.

7. The printable 3D file will be available to order or download on your Shapify.me online account within 15 minutes.

II. Back office, via the booth operator’s online account at www.shapify.me

1. Log in to your personal account at Shapify. me. If you want to print the figurine yourself, just select the model and press the “download” button.

me. If you want to print the figurine yourself, just select the model and press the “download” button.

2. If you want to order printing with Artec, please make sure your printing account has enough credit.

2. Go to Gallery, select the required model(s), enter the delivery address, number and size of figurine(s).

3. Click on the "order" button.

Please see the video for a visual explanation

5. If I install a Shapify Booth, will it carry your brand or mine?

The branding on the booth itself cannot be modified apart from in exceptional circumstances. However, if you decide to use an exterior pod or structure for the booth, you can create your own design or use the Shapify design. In both cases, the design should be harmonized with us for technical and marketing purposes.

6. Is the Shapify Booth portable?

Yes. Shapify Booth it is the most portable and easy to deploy automated 3D scanning solution on the market. However, the booth should be assembled and calibrated by an authorized maintenance partner; this is about 4-5 hours’ work for a two man job.

However, the booth should be assembled and calibrated by an authorized maintenance partner; this is about 4-5 hours’ work for a two man job.

7. So there are 3000 3D model files included in the Optimal business model. But what if I just need to re-scan a customer?

We don’t count scans, we count the processed 3D files you choose to print or download. You can scan your customer as many times as necessary, this will be free of charge.

8. What’s in the box? What is included in the price of the booth?

– Hardware, delivered to your address

The whole scanning system - the scanning with 4 hi-res rotating scanners, lighting, and the computer to manage the process.

The first installation by our certified Maintenance Partner

- Software

There are 3 levels of software:

1. The software installed on the Booth PC for managing scanning and modelling a quick (1 min) preview so your customer can decide whether to accept the quality of the scan

2. Cloud software to process your hi-res model (3-5 min) and upload it to your personal account on the Shapify.Me web site.

Cloud software to process your hi-res model (3-5 min) and upload it to your personal account on the Shapify.Me web site.

3. The Shapify website software and interface to help you to store and manage your scans, download your files, order prints, check your scanning and printing accounts and schedules (within certain business-models)

- Warranty

1 year full warranty

With the “Optimal” business model you will also get 3000 automatically processed 3D files.

9. If I use the “optimal” model, how will I know how many files I have “spent” and what will happen afterwards?

You will have a special counter on your personal account at Shapify.me. You will always know how many files you still have left. When you have used them all, you will be able to top up your account on the website by paying $20 per extra scan.

10. Does the booth have to be connected to the internet? Can’t the file be created locally, on the booth computer?

Yes, the booth has to be connected to the internet since all the calculations are done in the cloud.

11. My client’s data will be transferred to the cloud. Is that safe?

A lot of information, from the photos on your iphone to your credit card details, is sent to and processed in the cloud. All data on the Shapify website and in the Shapify cloud is encrypted and safe.

12. Can Shapify Booth scan a couple or 3 persons together?

Yes, it can. Just remember that the more people are scanned together, the more difficult a job it is for the software, since everyone makes some slight movements even if they trying to keep totally still, and if there are several people in the booth, the volume of movements will be higher. So achieving a perfect scan of multiple people will be a little more difficult - although we have plenty of success stories!

13. What is the approximate processing time for one full body scan?

You (and your customer) will see the finished preview in about 5 minutes. Based on that, the customer can decide whether they like the scan and wish to purchase the printed 3D shapie. The hi-res fully processed file should be available in about 15 minutes on your personal account on the Shapify.me website

The hi-res fully processed file should be available in about 15 minutes on your personal account on the Shapify.me website

14. What scanners are used inside the booth?

This is the Artec L2, an enhanced version of Artec Eva, but with a wider view field and longer working distance.

15. Will we get trained to use the software and the hardware

Of course!

16. What are the installation requirements?

You’ll need a space of at least 3.3m x 3.3m, ceiling height at least 2.8 m. For electricity you should have 220V and 2500W. We recommend a fast Internet connection of 8-10M. Don’t forget you should also have a Windows laptop or a desktop to run the Shapify software. It doesn’t need to be powerful, though, all the heavy work is done in the cloud and on the Booth PC.

17. Where I can see the Booth in action?

Take a look at our map here and also keep an eye on our news.

18. Are the prices on your website in USD?

Printing

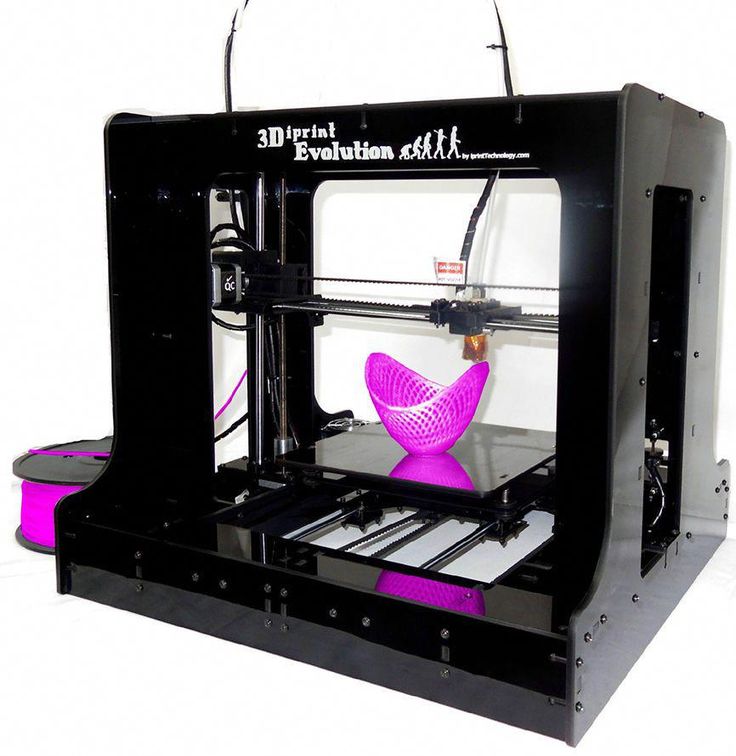

1. The Shapify Booth creates a ready-to-print 3D file. How do I turn it into a 3D printed figurine?

The Shapify Booth creates a ready-to-print 3D file. How do I turn it into a 3D printed figurine?

There are 2 options:

1. You can find your own local printing partner.

2. You own a 3D printer yourself and print the figurines on your own premises.

2. Can I order 3D prints directly from Artec 3D?

Artec 3D doesn’t offer 3D printing services.

3. What 3D file format do you support?

Our files are in .obj format (plus texture in .png) which can be easily transformed into any 3D format you need (like .ply or .stl) with free software (e.g. Meshlab).

4. What material can the figurines be printed in?

Once you have downloaded the file, you can print it out using any material you like – gypsum-based polymer, metal, plastic or even chocolate.

3D scan customers and make mini 3D figures with Artec Eva.

A present everyone will love!

What is Artec Eva

Artec Eva is the industry standard handheld 3D scanner used for capturing the human body. It was even used to make a 3D presidential portrait of Barak Obama! Using white light 3D scanning technology, it ensures safe, fast and accurate data capture. You can use this lightweight 3D scanner to make a digital portrait of adults and children, with each 3D scanning session taking around 5 minutes.

It was even used to make a 3D presidential portrait of Barak Obama! Using white light 3D scanning technology, it ensures safe, fast and accurate data capture. You can use this lightweight 3D scanner to make a digital portrait of adults and children, with each 3D scanning session taking around 5 minutes.

Start a successful 3D body scanning business

3D printed figures are a unique, fun and creative way to create fantastic memories of unforgettable moments such as birthdays, weddings, graduation, pregnancy and many others. A great and innovative gift idea, these mini figures will always be in high demand, and making them is simpler than you think. The smart combination of Artec Eva and a lightweight, portable battery pack gives you the freedom to scan absolutely anyone and everywhere. Take your 3D scanning kit to special events and capture the magic moments wherever they may happen. Creating the perfect gift has never been easier.

Click on the images below to see

shapies made by the Artec Eva

Artec Eva:

Tech specs

Another camera Camera one 30 Led Flash Texture camera twoLightweight

Only 0. 85kg

85kg

Scanning time

5 minutes

3D printable model

from 30 minutes

Polygons

Up to 1M

Throughput

Up to 30 customers

per day

Bussiness model. What you need to get started:

Artec Eva 3D scanner

$19 800

Artec Studio 11 Professional

3D scanning and processing software

1 lifetime license of AS11 version

$1 450

Artec Studio Professional

3D scanning and processing software

1-year subscription, guaranteeing you to always

be equipped with the very latest version of Artec Studio

$600

Artec Eva:

How it works

Capture a person

or couple with the Artec Eva 3D scanner and Artec Studio 3D software

Process the 3D model

using Artec Studio

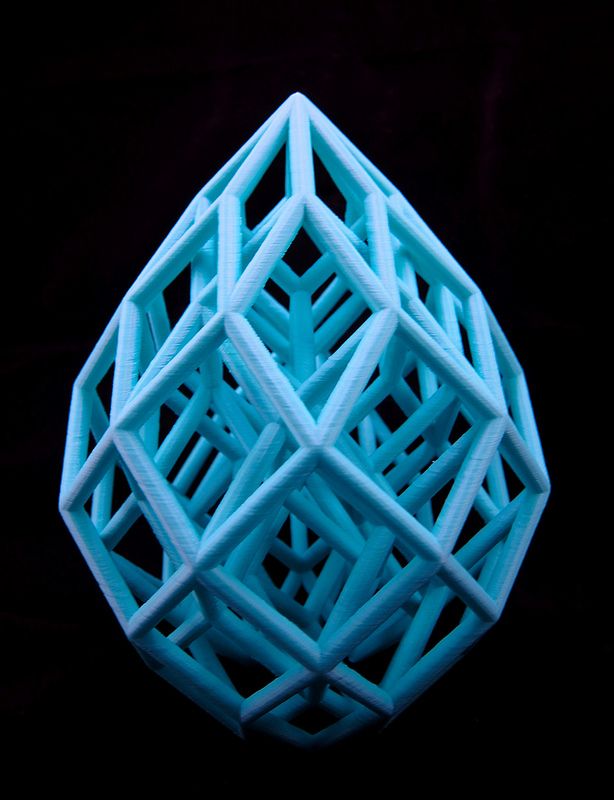

The mini 3D figure

is printed out on a 3D printer

Compatible computer

Tech requirements

Processor: Intel I5 or I7

Memory: 12 GB

Video cards: NVIDIA, AMD, or Intel

OS: Windows 7, 8, 10 – x64

Free disk space: 300 MB for installation

More on tech requirements

Want to learn more about the industry standard Artec Eva 3D scanner?

Fill out the short form below or email us at sales@artec-group. com and we will contact you as soon as we can with further information

com and we will contact you as soon as we can with further information

Name

Phone

Already making 3D figures with your Eva?

Let us know at [email protected] and we will add your business

to our scanning point map for everyone to see!

Find out more about Artec Eva on www.artec3d.com

3d printing of a person - 3d printing of figures of people on a 3d printer in Moscow

Masterpieces of fine art always amaze with filigree and liveliness of human images. It would seem that copying the human image will forever remain beyond the capabilities of ordinary people. But, nevertheless, time moves inexorably forward, sweeping away restrictions and providing opportunities.

Possibilities and advantages of the masterpiece technology

Every person on the planet is unique, therefore, any copy of a person, whether it be a statuette, a model or a portrait on paper, will also have a uniqueness. 3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

And, let it sound a little cynical, but 3D printing of a person opens up incredible opportunities in various areas of our lives. Just imagine, the creation of sculptural copies of a person takes months, and sometimes years. The cost of such a sculpture is often simply beyond the reach of an ordinary person. And the chances of becoming a model of a talented sculptor are negligible.

On the other hand, getting your own exact copy a few centimeters in size is now not at all difficult and not expensive. Moreover, a real boom in the popularity of 3D printing is brewing in the world, which will soon create a significant alternative to photo printing and video chronicles. And it's not just about private ambitions and fun!

Spheres of demand for 3D printing technology of people

3D printing of figurines is already widespread today in:

● advertising;

● decoration of wedding celebrations;

● souvenir industry;

● prototyping of industrial and commercial facilities;

● design;

● medicine.

The noble mission of innovative technology

Moreover, the circle of people professionally interested in the service in order to develop their business is constantly growing. In addition to the persistent interest in technology, its profitability and spectacularity, 3D printing of people also serves noble purposes, for example:

● allows blind people to tactilely get acquainted with the external images of their relatives and friends, communication with which is limited to virtual space;

● allows future parents to admire their baby in the womb, not only with the help of ultrasound pictures. 3D printing of a baby figurine built thanks to innovations will allow you to get to know him visually even before he is born;

● Printing figurines on a 3D printer helps people with mental trauma and disorders to adapt to a certain social environment;

● in psychology and educational disciplines, three-dimensional models of people are involved in methods of working with children.

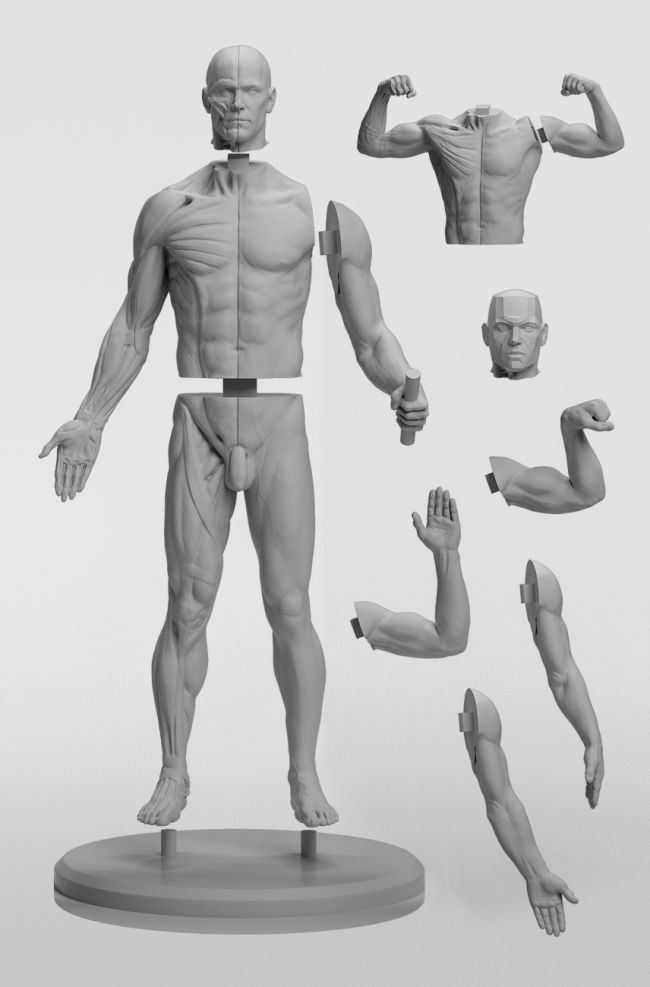

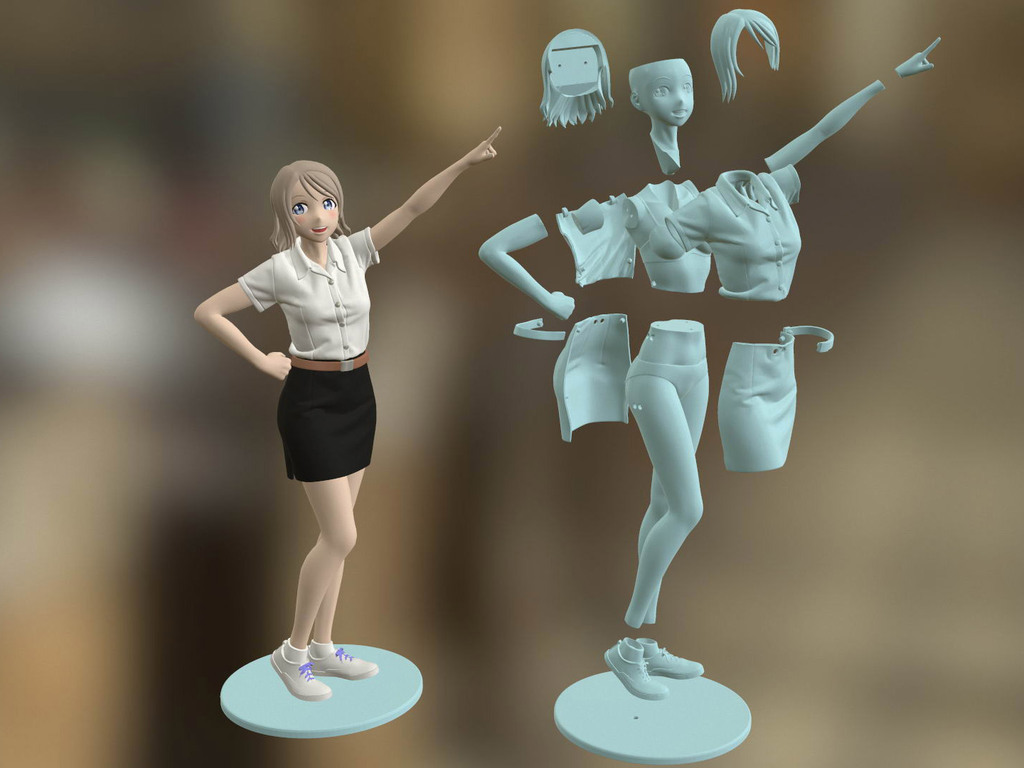

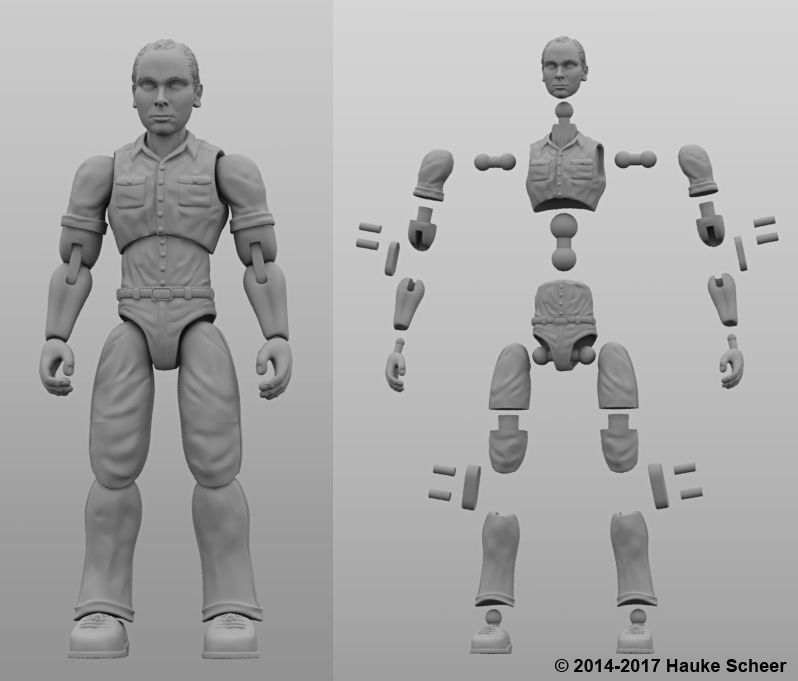

Steps for creating 3D copies of a person

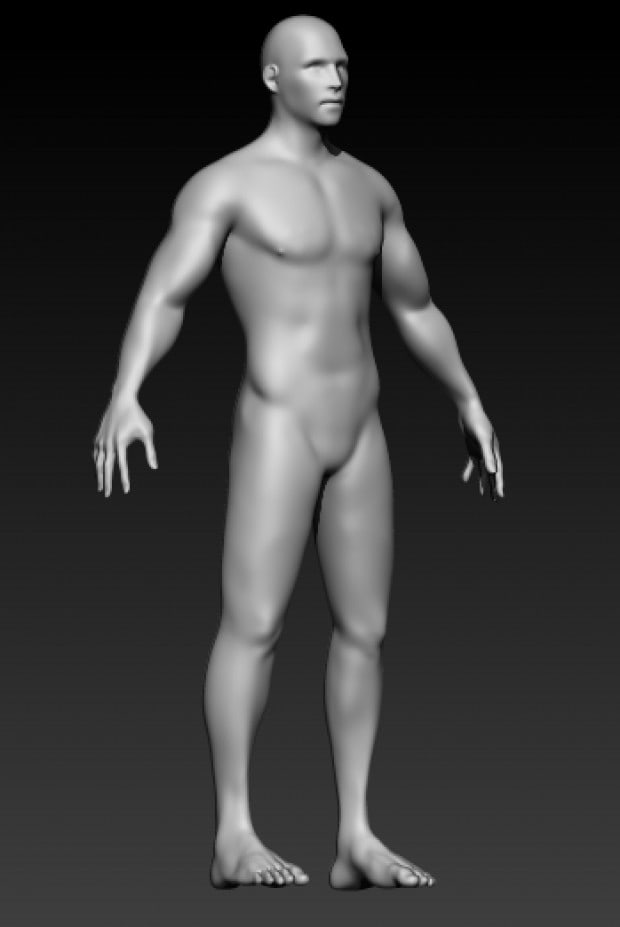

High-quality and high-quality 3D printing of people actually requires several preparatory steps.

● In the first, a full-length 3D scan of a person is performed

● In the second, a copy of the 3D model is carefully processed

● In the third, the figure is scaled down and printed.

The technology also includes a number of post-press processing measures. Figures may require surface grinding, painting or tinting, freeing them from auxiliary elements - clamps, additional details, coating with protective varnishes, finishing agents.

Consumables and features of technological processes

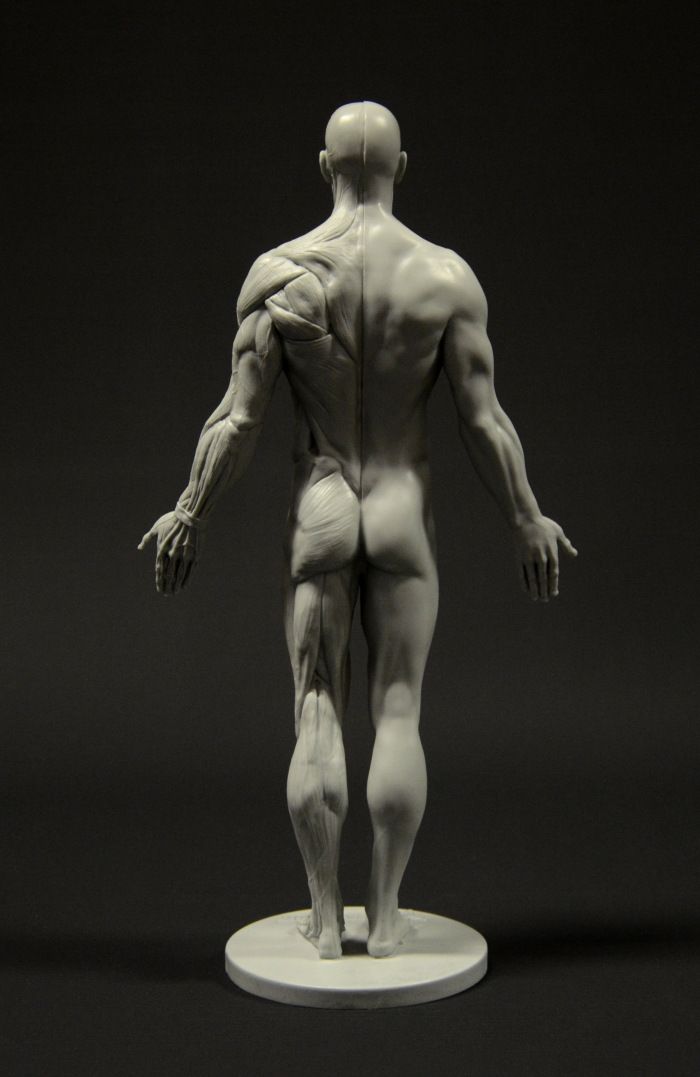

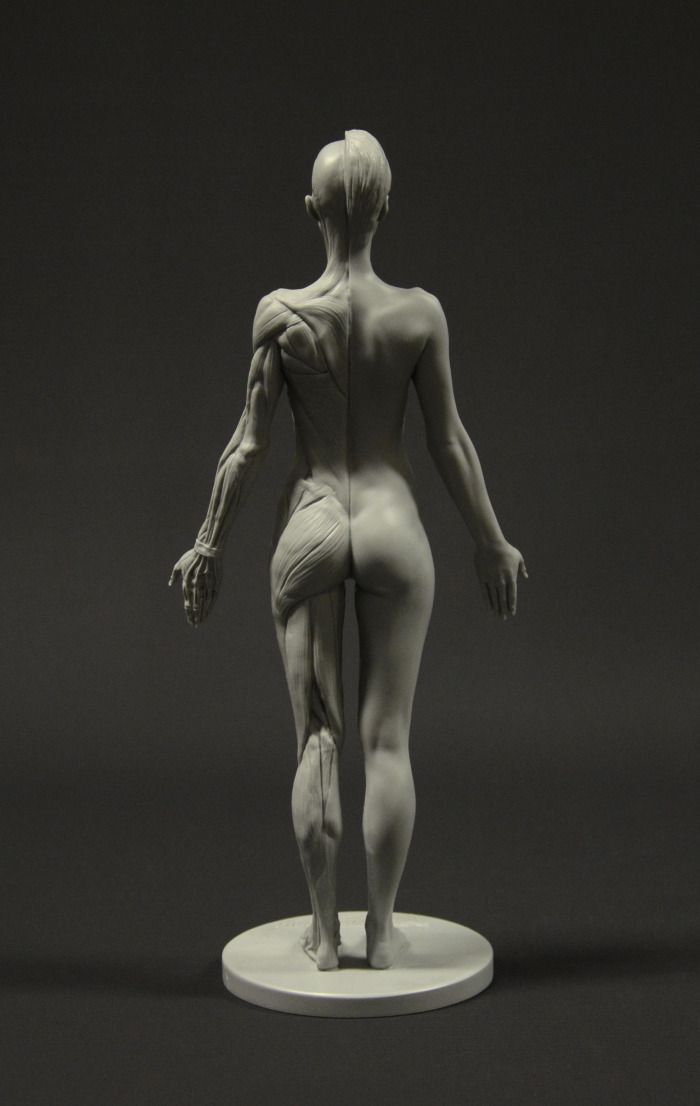

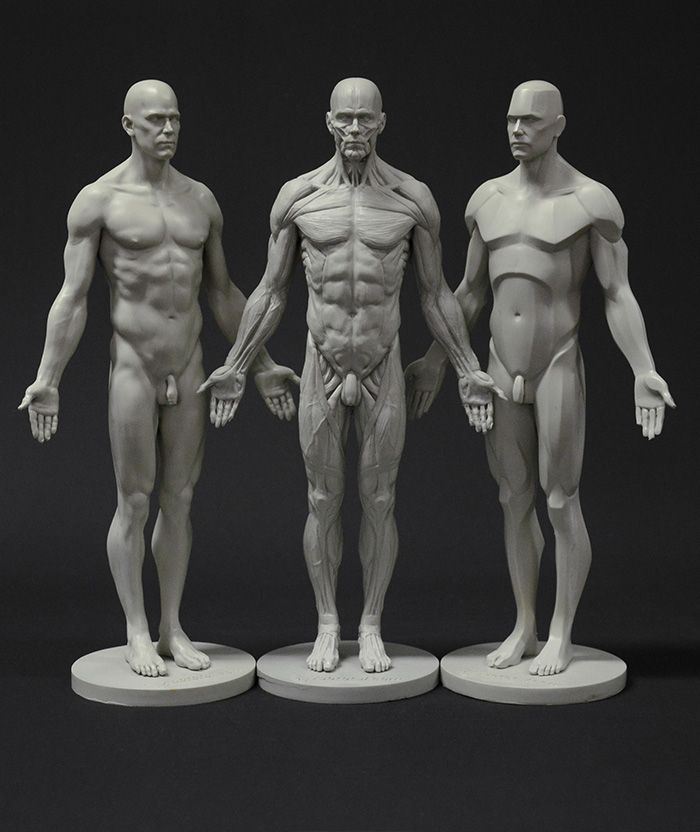

Various materials are used for 3D printing of human figures and

even different equipment, technically and technologically different from each other. So, the result can be presented in plastic, gypsum, polymer mixtures. It can be single color or multicolor. Realistic or only in general terms reminiscent of the original.

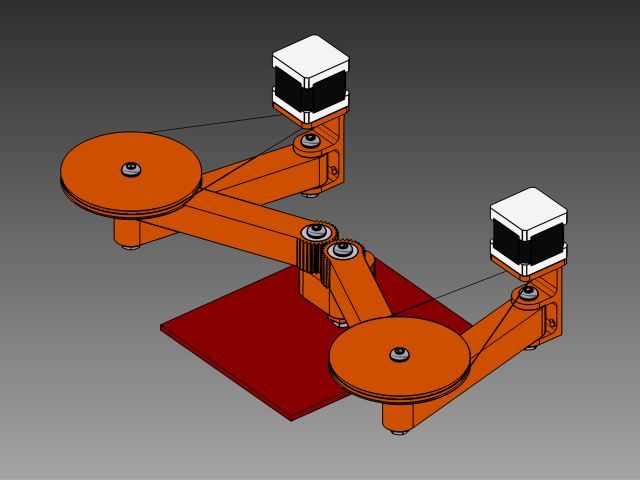

Human 3D printing technologies are also different. The most popular and frequently used are two:

● layer-by-layer reconstruction of the model on an inkjet 3D printer;

● laser baking, stereolithography on a laser printer.

For the best and most accurate reproduction of the image of a person, it is advisable to use the method of layer-by-layer gluing of a cellulose-starch mixture.

The use of 3D printed human figures in the advertising industry

Of course, the advertising industry has traditionally been at the forefront of bringing innovation to its service. 3D printing of human figures has become the basis of several high-profile advertising campaigns in Spain, Germany, and the UK, during which passers-by on the streets and visitors to shopping centers were asked to quickly create their own miniature on a 3D printer.

But the scope of advertising use of this technology is much wider:

● Figures of real company employees in company uniforms can make up a static installation.

● May be part of a believable animated advertisement.

● Given as a souvenir, they will be a powerful motivation for a common cause and common success.

● 3D printing of human figures in addition to the presentation of 3D models of industrial, construction, social facilities can bring liveliness and dynamics to the presentation of projects.

● Using a 3D printer, you can create not only mini copies of real people, but also transform familiar replicated images of famous sculptures. For example, dress the Venus de Milo in the costume of a stewardess of the advertised airline, and use a mini copy of Rodin's sculpture in an advertisement for ladies' accessories.

The position of 3D copies of a person in souvenir production

A treasure trove of invaluable prospects 3D printer and human printing will bring to souvenir production. With the help of technology, you can make:

● popular interior figurines;

● intricate paperweights;

● gift personalized figurines;

● wedding souvenirs of the bride and groom;

● commemorative figurines of anniversaries and heroes of the occasion.

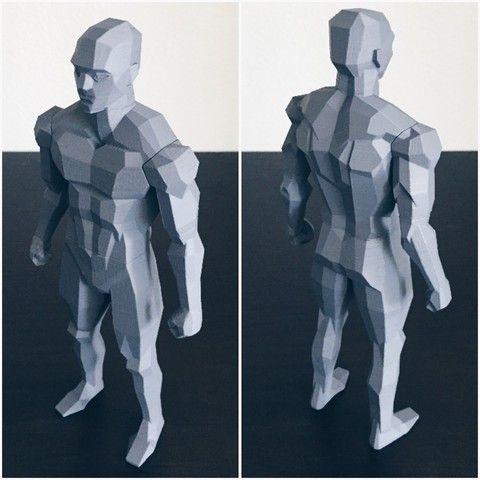

Variants of representation of the image in a three-dimensional miniature

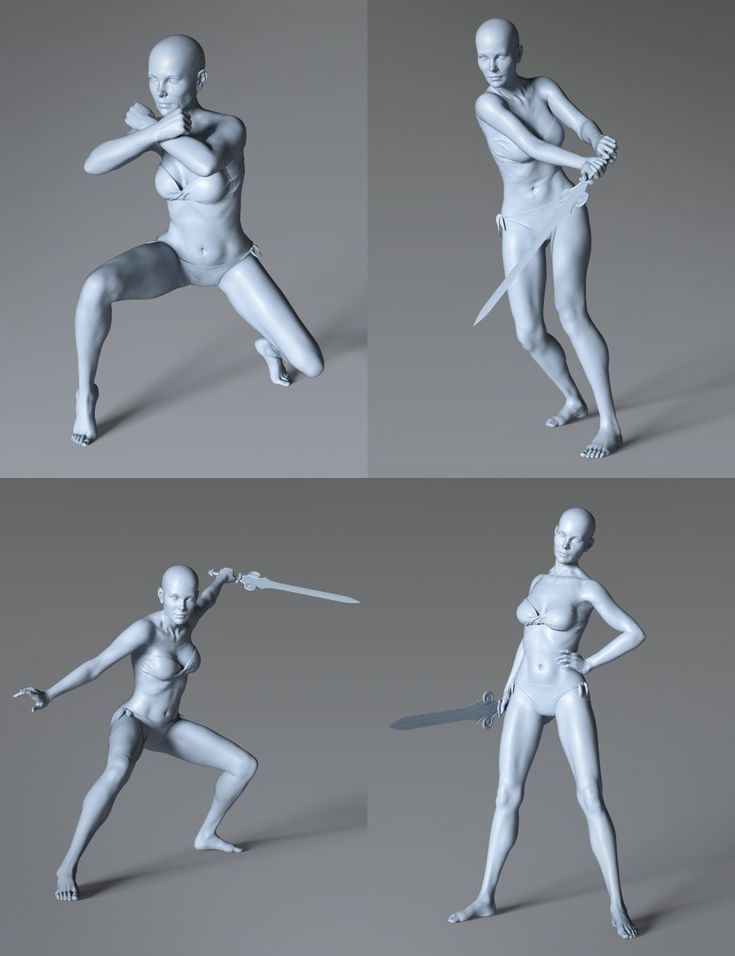

When creating souvenir miniatures of people, you can most often find three directions for recreating the image:

● realistic or ordinary, the one that can be found in an amateur photo or in life;

● staged, when models are presented in fantasy, stylized images, for example, superheroes or characters from famous fairy tales, movies, literary works, comics;

● wedding, couple real or fictional image.

Bride and groom figurines - this is just the beginning!

The industry of wedding paraphernalia, in addition to commemorative figurines of the newlyweds, can use 3D printing of figurines to create original decorations for invitations, decorating a wedding cake, a festive table, use mini-copies as props for an original wedding photo shoot and video shooting of a romantic love-story.

Online services and their features

It is worth saying a few words about online 3D scanning services. This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

Actually, the results of scanning and allow you to remotely provide services of three-dimensional modeling of a person. The more diligently the scan is made, the more similarity will be between the model and the figurine. By the way, the service of 3D printing of people can be provided not only on the basis of a scan of a real person, but also on the basis of photographs taken from different angles.

How to obtain the necessary sources for 3D printing

To recreate the image in a 3D model, try to get pictures from eight angles in a circle, where the angle step will be 45 degrees. This information will be useful to those who plan to organize a surprise related to the secret production of a mini-copy of a person on a 3D printer. And even if a spontaneous photo session provides less information about the image than a scan, the result will still be recognizable.

Our company is ready to offer all interested people 3D human printing services, as well as business cooperation in this area. Our technical equipment allows us to implement not only our own, but also third-party projects, providing a successful launching pad for your business to take off. We will be glad to assist you in creating a three-dimensional human copy and mutually beneficial cooperation.

Organ printing: how 3D bioprinting technologies have advanced and what hinders their development

Rusbase

November 12, 2019

The artificial creation of human skin, tissues and internal organs may sound like science fiction, but most of it is happening right now. In research centers and hospitals around the world, advances in 3D printing and bioprinting are providing new opportunities for human treatment and scientific research. In the coming decades, bioprinting could be the next major milestone in healthcare and personalized medicine.

Let's talk about bioprinting technology, the latest advances in the industry and the limitations that professionals face.

How a 3D printer works

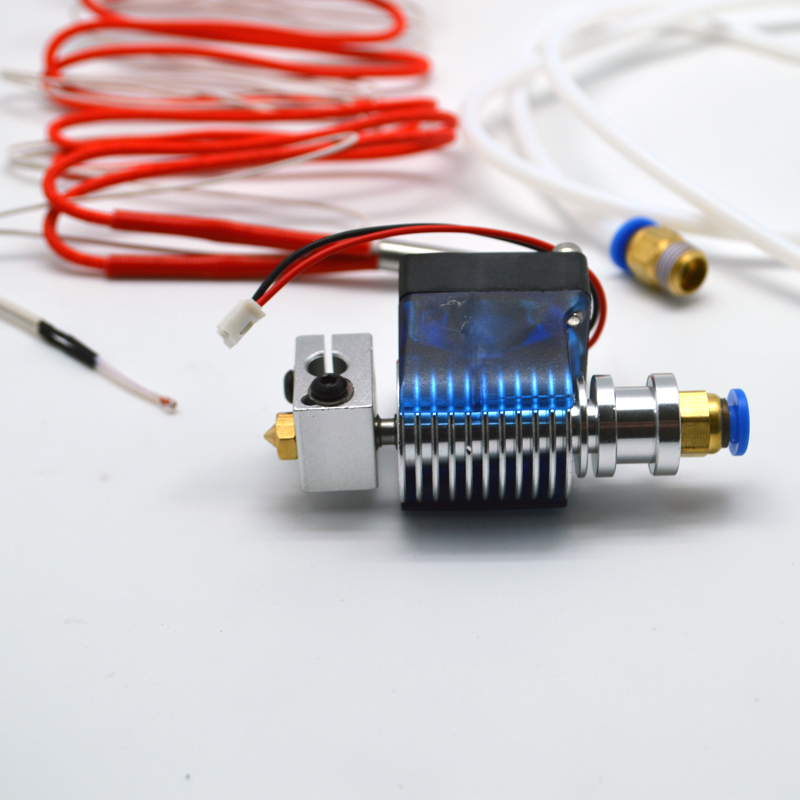

Traditional printers, like the one you have at home or office, work in two dimensions. They can print text or images on a flat surface (usually paper) using the x (horizontal) and y (vertical) dimensions. 3D printers add another dimension - depth (z). During the printing process, the printer heads can move up and down, left and right, back and forth, but instead of delivering ink to paper, they distribute various materials - polymers, metal, ceramics and even chocolate - until the "print" of a holistic, voluminous object , layer by layer in a process known as "additive manufacturing".

To create a 3D object, you need a blueprint for it, a digital file created with modeling software. After its creation, the computer-generated model is sent to the printer. Your chosen material is loaded into the machine and ready to be heated to easily flow out of the printer nozzle. As the printer reads the plan, its head moves, depositing successive layers of the selected material to create the final product.

As the printer reads the plan, its head moves, depositing successive layers of the selected material to create the final product.

As each layer is printed, it is solidified either by cooling or by mixing two different solutions delivered by the printer head. The new layers precisely lay down on the previous ones to make a stable, cohesive element. In this way, you can create almost any shape, including a moving one.

3D printing allows you to create objects with geometric structures that would be difficult or impossible to make in other ways. A wide range of products are already being created using 3D printers, including jewelry, clothing, toys, and high-end industrial products. Even a 10-year-old Moscow schoolboy has learned how to work with a 3D printer: he prints 3D figures to order and sells them through Instagram.

How a bioprinter works

Bioprinters work in much the same way as 3D printers, with one key difference - they deposit layers of biomaterial, which can include living cells, to create complex structures such as blood vessels or skin tissue.

Living cells? Where do they get them? Every tissue in the body is made up of different types of cells. The required cells (kidney, skin, and so on) are taken from the patient and then cultured until there are enough of them to create "bio-ink" that is loaded into the printer. This is not always possible, therefore, for some tissues, stem cells are taken that are capable of becoming any cell in the body (organism), or, for example, porcine collagen protein, seaweed and others.

Chitosan, a polysaccharide obtained from the external skeleton of mollusks (eg shrimp) or by fermenting fungi, is often used in bioprinting. This material has high biocompatibility and antibacterial properties. Its disadvantage is the low rate of gelation. Another popular material is a polysaccharide isolated from seaweed called agarose. Its advantages are high stability and the possibility of non-toxic cross-linking during research. However, this biomaterial does not decompose and has poor cell adhesion (the ability of cells to stick together with each other and with other substrates).

Collagen, a primary structural protein found in the skin and other connective tissues, has a high biological significance. It is the most abundant protein in mammals and a major component of connective tissue. Its disadvantages for bioprinting include the property of acid solubility. More information about biomaterials can be found here.

Based on computer designs and models, often scans and MRIs taken directly from the patient, the printer heads place the cells exactly where they are needed and within a few hours an organic object is built from a large number of very thin layers.

Organovo bioprinter creates tissues that mimic the structure and composition of various human organs

Source: Pbs.org

Scaffolding for ear or nose replacements at the Wake Forest University laboratory in Winston-Salem, North Carolina

Source: CBS News

Computer displays an image of a "scaffold" for the human ear, created in the laboratory of Wake Forest University in Winston-Salem, North Carolina

Source: CBS News

Usually more than just cells are needed, so most bioprinters also supply some sort of organic or synthetic "glue" - a soluble gel or collagen scaffold to which cells can attach and grow. This helps them form and stabilize in the correct shape. Surprisingly, some cells can take the correct position on their own without any "scaffolding". How do they know where to go? How do embryonic cells develop in the uterus, or does adult tissue move to repair damage? Same here.

This helps them form and stabilize in the correct shape. Surprisingly, some cells can take the correct position on their own without any "scaffolding". How do they know where to go? How do embryonic cells develop in the uterus, or does adult tissue move to repair damage? Same here.

Universities, researchers and private companies around the world are involved in the development of bioprinting technologies. Let's take a look at some of the amazing things they are working on.

Bioprinting in Russia

3D Bioprinting Solutions is a biotechnology research laboratory founded by medical company INVITRO. The activity of the laboratory is the development and production of bioprinters and materials in the field of three-dimensional bioprinting and scientific research. August 23, 20193D Bioprinting Solutions laboratory sent a new batch of cuvettes to the ISS to continue experiments on bioprinting in space, which began in 2018. This was reported in the press center of the laboratory. This time it is planned to use organic and inorganic components to assemble bone tissue on the world's first space bioprinter Organ.Aut.

Symposium "Biofabrication in Space"

Source: Zdrav.Expert

Organ.Aut magnetic bioprinter

Source: Zdrav.Expert

The astronauts will also grow protein crystals and experiment with printing biofilms of bacteria to study their behavior in zero gravity. Russian scientists expect to receive unique scientific data that can be applied in the development of new drugs.

Scientific director of 3D Bioprinting Solutions and leading researcher of the Institute of Regenerative Medicine, Candidate of Medical Sciences Vladimir Mironov, in his speech at the Department of Anatomy of Sechenov University on September 2, noted: “Living cells, tissues and human organs will be synthesized already in the current century. To do this, morphological sciences, such as microscopic anatomy and histology, must be digitized or digitalized, that is, digitized and made available for computer programs of robotic bioprinters, since without digital models it is impossible to print human tissues and organs. ”

Bioprinting in the world

Every year, millions of people around the world need a bone transplant. Modern bone grafts often use cement-based synthetic material in combination with the patient's own bone. However, the use of these materials has a number of limitations - some transplants caused rejection and inflammatory processes in patients. Reproduction of the natural bone-cartilage "interface" has also been problematic.

However, a team at Swansea University in 2014 developed a bioprinting technology that allows the creation of an artificial bone prosthesis in the exact shape of the desired bone, using a biocompatible material that is both durable and regenerative. At the same time, scientists from the University of Nottingham in England were working on similar studies.

It takes about two hours to print a small bone. Therefore, surgeons can do it right in the operating room. This part of the bone is then covered with adult stem cells that can develop into almost any other type of cell. This is combined with bio-ink from the printer, a combination of polylactic acid (which provides mechanical strength to bone) and alginate, a gel-like substance that serves as a shock-absorbing material for cells. The end product is then implanted into the body, where it will completely disappear within about three months and be replaced by new bone.

This is combined with bio-ink from the printer, a combination of polylactic acid (which provides mechanical strength to bone) and alginate, a gel-like substance that serves as a shock-absorbing material for cells. The end product is then implanted into the body, where it will completely disappear within about three months and be replaced by new bone.

Researchers hope that in the future, bioprinted bones can be created with sufficient reliability to support complex spinal reconstruction, and that the bone material will be further improved to increase its compatibility with cartilage cells.

Source: ETH Zurich

Successful 3D printing of human cartilage may soon completely replace artificial implants for people in need of reconstructive surgery. Back in 2015, scientists in Zurich developed technology that would allow hospitals to print a full-size human nose implant in less than 20 minutes. They believe that any cartilage implant can be made using their technique.

Researcher Matti Kesti described the technology as follows:

“

“A serious car accident can cause the driver or passenger to suffer complex nose injuries. The nose can be restored by creating a 3D model on a computer. At the same time, a biopsy of the patient is performed and cartilage cells are removed from the victim's body, such as from a knee, a finger, an ear, or fragments of a broken nose. The cells are spawned in the laboratory and mixed with the biopolymer. From this suspension, a model of nasal cartilage is created using a bioprinter, which is implanted into the patient during surgery. In the process, the biopolymer is used simply as a mold. It is subsequently broken down by the body's own cartilage cells. And in a couple of months it will be impossible to distinguish between the graft and the person’s own nasal cartilage.”

Matti Kesti

Since the implant was grown from the body's own cells, the risk of rejection will be much lower than for an implant made of, say, silicone. An additional advantage is that the bioimplant grows with the patient, which is especially important for children and young people.

An additional advantage is that the bioimplant grows with the patient, which is especially important for children and young people.

If a person is severely burned, healthy skin can be taken from another part of the body and used to cover the affected area. Sometimes intact skin is missing.

Researchers at Wake Forest School of Medicine have successfully designed, built and tested a printer that can print skin cells directly onto a burn wound. The scanner very accurately determines the size and depth of damage. This information is sent to a printer and skin is printed to cover the wound. Unlike traditional skin grafts, it only takes a patch of skin one-tenth the size of a burn to grow enough cells to print. While this technology is still in the experimental stage, the researchers hope that it will be widely available within the next five years.

As already mentioned, 3D printers print products in layers, and since the skin is a multi-layered organ with different types of cells, it is well suited for this type of technology. However, researchers still have a lot of problems to solve, in particular, how to prevent damage to cells from the heat generated by the printer. And of course, like most parts of the human body, the skin is more complex than it first appears—there are nerve endings, blood vessels, and a host of other aspects to consider.

However, researchers still have a lot of problems to solve, in particular, how to prevent damage to cells from the heat generated by the printer. And of course, like most parts of the human body, the skin is more complex than it first appears—there are nerve endings, blood vessels, and a host of other aspects to consider.

Blood vessels

Biomechanical engineer Monica Moya holding a Petri dish with printed alginate-based biotubes. Biotubes can act as temporary blood vessels similar to blood vessels that help create a patch of living tissue.

Source: embodi3D

With tens of thousands of miles of veins, arteries and capillaries in the human body, researchers are working to replace them if they ever wear out. The creation of viable blood vessels is also essential for the proper functioning of all other potential bioprinted body parts.

Biomechanical Engineer Monica Moya of Livermore National Laboratory. Lawrence uses bioprinting to create blood vessels. The materials created by her bioprinters are engineered to allow small blood vessels to develop on their own.

Lawrence uses bioprinting to create blood vessels. The materials created by her bioprinters are engineered to allow small blood vessels to develop on their own.

This development takes time, so vials of cells and other biomaterials are printed to help deliver vital nutrients to the printed environment. After a while, self-assembled capillaries connect with bioprinted tubes and begin to deliver nutrients to cells on their own, mimicking the work of these structures in the human body.

Internal organs

Many researchers hope that in 20 years the lists of patients waiting for organ transplants will become a thing of the past. They envision a world where any organ can be printed and transplanted in just a few hours, without rejection or complications, because these organs will be created from body cells according to the individual characteristics of each patient. Currently, bioprinting of fully functional complex internal organs is not possible, but research is ongoing (and not without success).

Bladder

For example, the bladder is already printed. In 2013, at Wake Forest University in the US, researchers successfully took cells from a patient's original, poorly functioning bladder, cultured them, and added additional nutrients. The 3D shape of the patient's bladder was then printed and the cultured cells soaked through it. The form was placed in an incubator and, when it reached the desired condition, it was transplanted into the patient's body. The mold will eventually collapse, leaving only the organic material. The same team successfully created viable urethras.

Physicians and scientists at the Wake Forest Institute for Regenerative Medicine (WFIRM) were the first in the world to create laboratory-grown organs and tissues that were successfully transplanted into humans. Right now they are working on growing tissues and organs for more than 30 different areas of the body, from the kidneys and trachea to cartilage and lungs. They also aim to accelerate the availability of these treatments to patients.

They also aim to accelerate the availability of these treatments to patients.

Scientists in Australia are doing similar research as well. They used human stem cells to grow a kidney organ that contains all the necessary cell types for a kidney. Such cells can serve as a valuable initial source for bioprinting more complex kidney structures.

MD, Professor of Urology, Professor of the Institute of Regenerative Medicine Anthony Atala shows a kidney created by a bioprinter. A modified desktop inkjet printer sprays cells instead of ink. The cells were cultured from the patient and the structural template for the kidney was obtained from the MRI (so it is the correct size and shape).

Using this technology, back in 2001, Atala printed and successfully transplanted a bladder into a young man, Jake.

Source: TedEd

Heart

Heart cells, laboratory-grown organelles. Source

Surprisingly, it is the human heart that can become one of the easiest organs to print, since, in fact, it is a pump with tubes. Of course, everything is not so simple, but many researchers believe that humanity will learn to print hearts before kidneys or liver.

Of course, everything is not so simple, but many researchers believe that humanity will learn to print hearts before kidneys or liver.

Researchers at the Wake Forest Institute for Regenerative Medicine in April 2015 created "organoids" - 3D printed fully functional, beating heart cells.

In April 2019, Israeli scientists printed the world's first 3D heart. It is still very small, the size of a cherry, but it is able to perform its functions. The 3D heart with blood vessels uses personalized "ink" of collagen, a protein that supports cell structures, and other biological molecules.

A Tel Aviv University researcher holds the world's first 3D printed heart on April 15, 2019.

Source: Haaretz

“This is the first time anyone anywhere has successfully designed and printed an entire heart with cells, blood vessels, ventricles and chambers,” said Tel Aviv University scientist Professor Tal Dvir.

So far, scientists have been able to print tissue from cartilage and the aortic valve, for example, but the challenge has been to create tissue with vascularity—the blood vessels, including capillaries, without which organs cannot survive, let alone function.

The Tel Aviv scientists started with human adipose tissue and separated the cellular and non-cellular components. They then reprogrammed the cells to become undifferentiated stem cells, which could then become cardiac or endothelial. Endothelium - a single layer of flat cells lining the inner surface of the heart cavities, blood and lymphatic vessels. Endothelial cells perform many functions of the vascular system, such as controlling blood pressure, regulating the components of blood clotting, and the formation of new blood vessels.

Non-cellular materials, including a large amount of proteins, were processed into a "personalized hydrogel" that served as "printing ink".

It will be years before this technology can create organs for efficient transplantation. However, the achievements of scientists in Tel Aviv are a huge milestone along the way.

Medical research and pharmacology

One of the key potential uses for bioprinted living materials is in the field of medical testing and drug research. Bioprinted tissues have several cell types with different densities and key architectural features. This allows researchers to study the impact of various diseases on the body, the stages of disease progression and possible treatments in the natural microenvironment.

Bioprinted tissues have several cell types with different densities and key architectural features. This allows researchers to study the impact of various diseases on the body, the stages of disease progression and possible treatments in the natural microenvironment.

One of the most impressive developments in recent years is the development of a desktop brain at the ARC Center of Excellence in 2016. The researchers were able to use a 3D printer to create a 3D printed six-layer structure that includes nerve cells that mimic the structure of brain tissue.

This opens up huge potential benefits for researchers, pharmaceuticals and private companies, because it will allow them to test new products and drugs on tissue that accurately reflects the responses of human brain tissue, as opposed to animal samples, which may cause a completely different response. The desktop brain can also be used to further investigate diseases such as schizophrenia or Alzheimer's.

We are far from printing the brain, but the ability to arrange cells to form neural networks is a significant step forward. By allowing researchers to work with human tissue in real time, testing processes can be greatly accelerated and results can be more realistic and accurate. It will also reduce the need to use laboratory animals for medical tests and potentially dangerous human testing.

By allowing researchers to work with human tissue in real time, testing processes can be greatly accelerated and results can be more realistic and accurate. It will also reduce the need to use laboratory animals for medical tests and potentially dangerous human testing.

Medical simulators and data registries

Source: Simbionix

Around 3,000 medical simulators are currently in use around the world to help doctors practice complex procedures. Virtual blood vessels, 3D printed organs... and no animal suffers!

The American company 3D Systems created an industry segment called VSP (Virtual Surgical Planning). This approach to personalized surgery combines expertise in medical imaging, surgical simulation and 3D printing. Surgeons using the Simbionix medical simulator for the first time often report feeling physical pain while empathizing with their virtual patient - the experience is so realistic. Organs and tissues look completely real. When stitching an organ, the surgeon sees on the screen a needle that enters the tissue, and pulls the thread. If the doctor does something wrong, the virtual blood vessels break and the organ begins to bleed. These simulators were developed by the Israeli company Symbionix, which was acquired by 3D Systems in 2014.

When stitching an organ, the surgeon sees on the screen a needle that enters the tissue, and pulls the thread. If the doctor does something wrong, the virtual blood vessels break and the organ begins to bleed. These simulators were developed by the Israeli company Symbionix, which was acquired by 3D Systems in 2014.

On September 3, 2019, the Radiology Society of North America (RSNA) and the American College of Radiology (ACR) announced the launch of a new 3D Medical Printing Clinical Data Registry to collect data on treatment outcomes using 3D printing at the point of care. This information will be a powerful tool to assess and improve patient care in real time, drive ongoing research and development, and inform patients and healthcare professionals about the best course of care.

“

“The creation of a joint RSNA-ACR 3D printing registry is essential to the advancement of clinical 3D printing. The registry will collect data to support the appropriate use of this technology and its implications for clinical decision making. ”

”

William Widock, Professor of Radiology at the University of Michigan and Chairman of the RSNA 3D Printing Special Interest Group (SIG)

According to RSNA, the information in the registry will allow for the necessary analysis to demonstrate the clinical value of 3D printing. Due to the wide variety of clinical indications, different technologies for creating physical models from medical images, and the complexity of the models, it is problematic to choose the optimal treatment method. The registry will help solve this problem.

Bioprinting software

Bioprinter and bioprinting software manufacturer Allevi introduced Allevi Bioprint Pro software on September 5, 2019. Built-in model generation and integrated slicing will allow you to focus more on experimenting, rather than setting up the printer. The program runs entirely in the cloud, which means you can create your biostructures, define materials, and track prints right from a web browser on any computer.

According to the development team, the new bioprinter with the above software is powerful and easy to use and represents another piece of the puzzle on the way to 3D printed organs.

At the same time, CELLINK, the first bio-ink company, announced the launch of a new product to become the most flexible bio-printing platform on the market. The BIO X6 bioprinter, which has no analogues at the moment, has the ability to combine more bioprinting materials, cells and tools.

Why is this taking so long?

Complex body structure

The human body and its various components are much more complex than a plastic toy. The human organ has a complex network of cells, tissues, nerves, and structures that must be arranged in specific ways to function properly. From placing thousands of tiny capillaries in the liver to actually getting a printed heart that "beats" and contracts in the human body, there is still a lot of research and testing.

Legal regulation

In addition, bioprinting technologies, like all new medical treatments, must pass safety tests and due process of regulation before they become available.

Special software and hardware

It also takes time to develop special software and hardware. These programs can be written only with the appropriate data (medical, clinical, statistical, mathematical, and so on), which someone must first collect, analyze, systematize and digitize.

Working through all of these steps requires the integration of technologies from various fields, including engineering, biomaterials science, cell biology, physics, mathematics, and medicine. So we need to be a little more patient.

The main thing is to know that those who work in the field, doctors and engineers, programmers and scientists are making progress every day both in bioprinting technology itself and in understanding how it can be used and improved. Although we are not quite there yet, there is no doubt that medicine will be very different in 10-20 years, thanks also to bioprinting.

In brief

Bioprinting is an extension of traditional 3D printing.