Big format 3d printer

Large Volume 3D Printers | MatterHackers

Bring your most ambitious prints to life with these large-volume 3D Printers! From the enormously large Modix 3D Printers to flexible & industrial-grade 3D printers from brands such as Raise3D, MakerGear, or BCN3D; MatterHackers has the right large-volume 3D printer to fit your needs.

Available for purchase as kits or ready to ship fully assembled, these large-volume 3D Printers will enable you to print BIG and explore product development and prototyping without the need to invest in costly, full-scale additive manufacturing systems.

Guides & Articles

What is 3D Printing?

3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

Anatomy of a 3D Printer

Get an understanding of how 3D printing works, from the inside and out. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work?"

The Top Ten Tips For Getting Started With 3D Printing

We were all noobs at one point! Here the ten best tips for getting started with 3D printing - whether it's your first time 3D printing or you need to brush up on the basics, this guide will help you out!

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

How To Calibrate Your 3D Printer's Extruder

This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints.

3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print

The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process.

How To Get The Best 3D Printed Parts By Understanding Extrusion Settings

Melting is a critical concept to 3D printing, and yet it hasn’t received a lot of in-depth attention. This article will teach you how to extrude your filament properly so it flows smoothly. Make filament jamming, delamination, and weak parts things of the past.

3D Printing Essentials: How to Succeed with Every Bed Surface Solution

Matching 3D printing filaments with the proper bed surface material is an important part of the 3D printing process. Read more to find out the best path to success.

Read more to find out the best path to success.

3D Printing Essentials: Filament Loading

Proper filament loading and unloading is a necessary part of 3D printing without trouble. Read on to learn the essential method you should be following.

3D Printing Essentials: Bed Leveling

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. Read this essential guide to see what it takes to do it right.

Quick Tips: How To Get Started With Batch 3D Printing

Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

WHY SHOULD I SELECT A LARGE-VOLUME 3D PRINTER?The number of available large-volume 3D Printers is growing every day. Whether you are just getting started with 3D Printing, consider yourself an experienced hobbyist, or are a professional looking to take that next step into the world of large-scale production there is a large-volume 3D Printer to fit your needs.

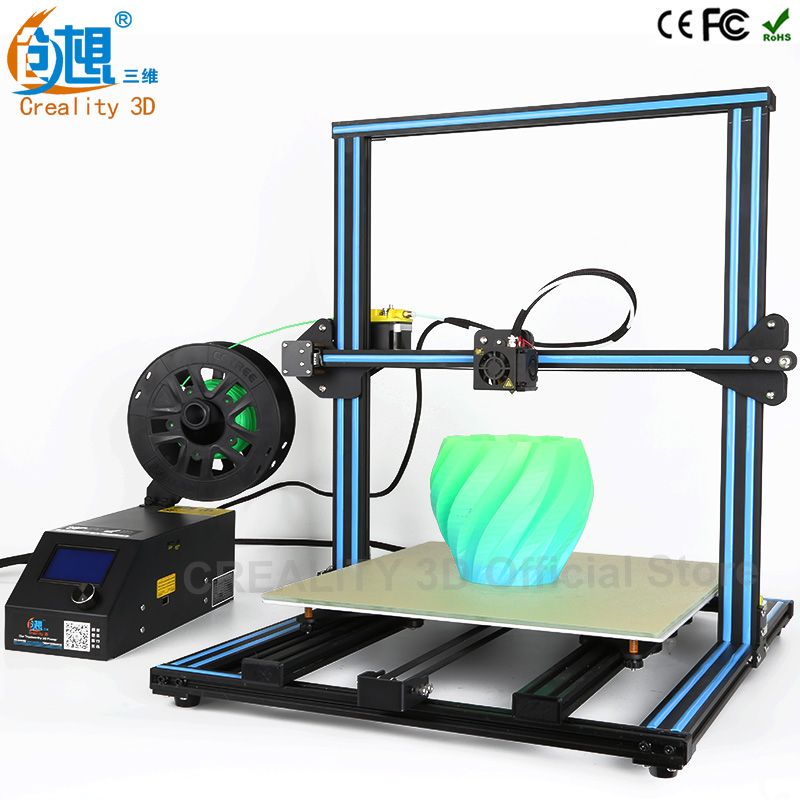

Large-volume 3D Printers can range in price from as low as $500, such as the Creality Ender 5 Plus, while some can be as expensive as $15,000, such as the absolutely massive Modix Big-180X.

There are many other additional factors to consider when discussing the costs associated with large-volume 3D printers. It's important to thoroughly take into consideration things such as the type of 3D Printer Filament Or 3D Printer Resins you are planning to print with, the type of HotEnds and Nozzles required, as well as any other accessories such as Build Surfaces & Fume Extractors.

HOW LARGE CAN I PRINT?The Modix 3D Printer line easily takes the lead when it comes to print volume. Large, highly upgradable, and available exclusively as kits these printers are exceptional options for achieving ridiculously large prints.

- Modix BIG-40: 400mm x 400mm x 800mm, starting at $5,600

- Modix BIG-60 V3: 600mm x 600mm x 660mm, starting at $4,500

- Modix BIG-120X: 1200mm x 600mm x 640mm, starting at $7,550

- Modix BIG-120Z: 600mm x 600mm x 1200mm, starting at $7,450

- Modix BIG-180X: 1800mm x 600mm x 600mm, starting at $15,150

- Modix BIG-Meter: 1010mm x 1010mm x 1010mm, starting at $13,150

Modix BIG-60 V4 3D Printer Kit

- Home

- Store

- 3D Printers

- FDM 3D Printers

- FDM 3D Printer Kits

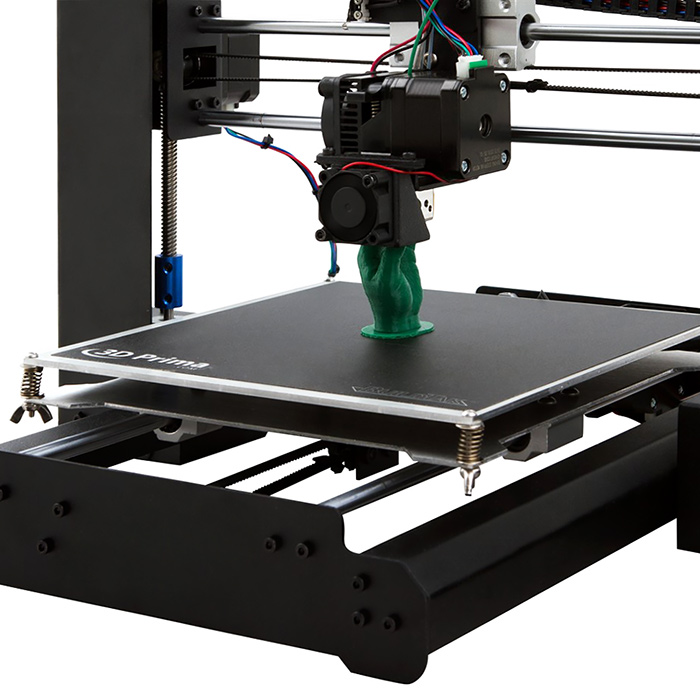

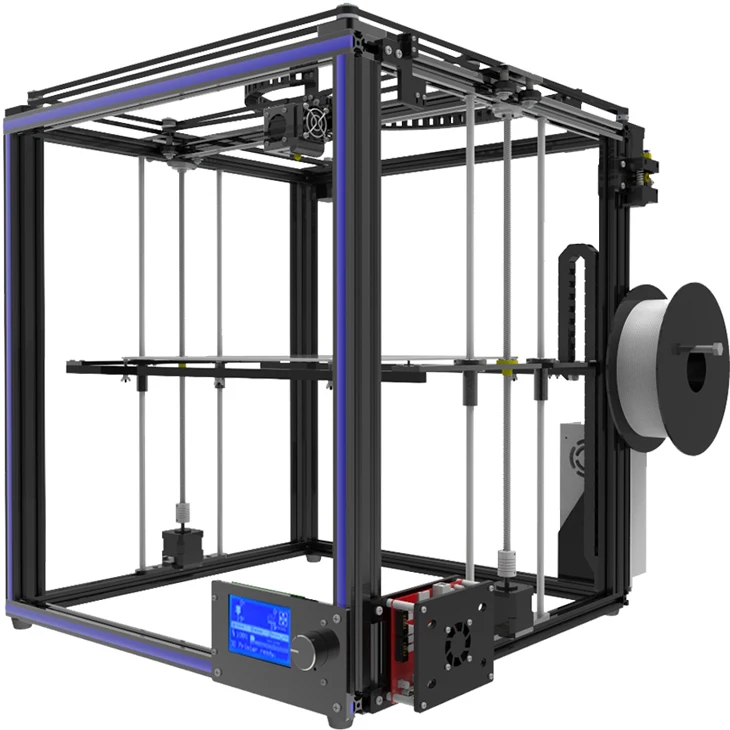

The Modix BIG-60 V4 is a giant format 3D printer with a huge build volume, dual zone MIC-6 build plate, and genuine HIWIN linear rails. It is also equipped with the new and improved Griffin print head.

It is also equipped with the new and improved Griffin print head.

- Giant format build volume

- Print with any material

- Virtually limitless build volume

Remove from wishlist Add to wishlist loading...

Available Add-ons (15)

Show More Addons

Product No. M-UAC-LF7P

| List Price: | $5,500.00 |

|---|---|

| Price: | $4,900.00 |

| Price: | $... |

| Order Now: | Processed Immediately |

A Do-It-Yourself, Giant Format, High-Quality 3D Printer

The name “BIG-60” is almost an understatement of just how large this 3D printer can create your models. Keep your designs in one piece and print full-size with confidence in the heavy-duty construction and motion system.

Here are the key features of the Modix BIG-60 V4 3D printer:

- Giant format build volume

- AC powered, 1,350 Watt, dual zone MIC-6 build plate with a smooth PEI surface

- Equipped with the New and Improved Griffin Print Head.

- Genuine HIWIN MGNW9 Linear Rails for belt-driven X and Y Axes and smooth rods for ball-screw driven Z axis.

- Upgrade as needed - plenty of options available to improve your 3D printing experience

- Automatic bed calibration

- Print with any material

- One year warranty and lifetime support by Modix

Virtually Limitless Build Volume

With a build volume that can be measured in feet, the Modix BIG-60 V4 boasts one of the largest build volumes in our catalog; save yourself the trouble of splitting your large 3D models into several smaller ones and print your designs in one piece.

- Build Volume: 600mm x 600mm x 660mm (23.6in x 23.6in x 26in)

- 3D prints hundreds of small parts at once

- Create large 3D prints for prototyping, demonstration, or manufacturing large end-use parts

Easy 3D Print Adhesion and Print Removal

Such a large build plate necessitates excellent adhesion to ensure that even the longest 3D prints stay stuck to the build plate throughout the job while releasing with ease when finished. A precision milled MIC-6 aluminum build plate covered with a premium smooth PEI sheet does just that, all while utilizing a dual-zone AC bed heater to bring just the center to temperature or the entire build plate if necessary.

- 1,350 Watt, AC powered bed heater for sustained 120°C bed temperature.

- Aluminum MIC-6, milled cast build plate for the flattest build plate.

- Smooth PEI bed sticker to ensure bed adhesion with most materials.

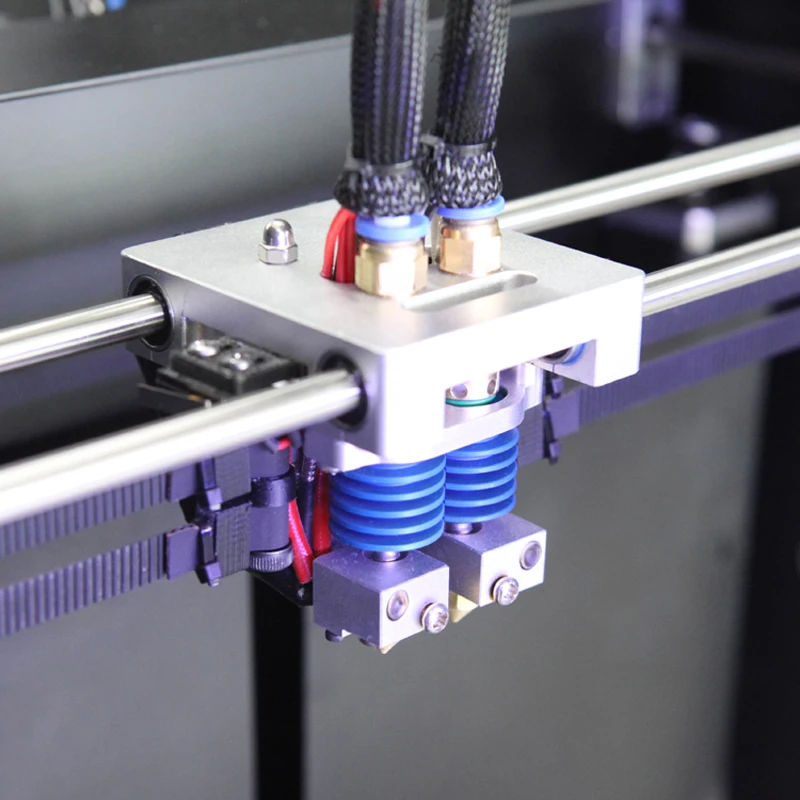

High Flow Griffin Print Head

Every Modix 3D printer kit comes with the new Modix Griffin Print-head. This offering consiststs of a custom extruder made by Bontech (based on the BMG model) and of a new hotend designed by Modix. The Bondtech extruder provides a double drive-gear system that grabs the filament from both sides. The heat block is made of nickel-coated copper, for a faster heat transfer and compatibility with higher printing temperatures, and includes other high-quality Slice Engineering components.

- Upgrade PT-1000 Temperature Sensor enables printing at temptures up to 500°C

- The new print-head design makes nozzle replacements much easier, and even allows a quick swapping of the entire filament melting subsystem.

- Rigid mounting of the heat-block allows one-handed nozzle replacement, making it even easier to test different nozzle diameters.

Precision Motion in Every Axis

A machine this size needs heavy-duty components to keep everything running smoothly. Genuine HIWIN linear rails guide the X and Y Axes while the Z axis is guided by smooth linear rods, with an optional HIWIN rail upgrade.

Genuine HIWIN linear rails guide the X and Y Axes while the Z axis is guided by smooth linear rods, with an optional HIWIN rail upgrade.

- Each HIWIN MGNW9 rail is preloaded for smooth motion.

- 9mm genuine GATES GT2 belts and 4 SFU1204 ball screws with belted gear reduction drive the 3D printer.

- Upgrade Z axis’ smooth rods with HIWIN MGNW9 linear rails.

Build the Ideal 3D Printer For You

Pick and choose components to match your individual use case and better meet your budgetary needs. Optional customization is available at the time of purchase but regularly published support guides are available through Modix’s online service portal.

- Optional enclosure kit add-on for higher-temperature materials.

- Casters to easily move your Modix BIG-60 V4 around.

- Service guides walk you through the upgrade process.

Automated and Guided Bed Calibration

When you have a 3D printer bed this large you want to make sure getting a perfect first layer is easy to achieve every time. The fully automatic BL-Touch bed leveling probe works exceptionally well at measuring any dips and bumps in the build plate (even miniscule ones) and allows the firmware to compensate for these variations.

- Genuine BL-Touch Bed Leveling Probe to measure 100 points on the bed.

- Built-in macros guide you through the leveling routine.

- Start from a level playing field using the bed adjustment macro

Unlimit Your 3D Printing Capabilities With The Open Filament System

The Modix BIG-60 V4 proudly supports open filament utilization, allowing you to purchase and use any filament that is compatible with the printer’s capabilities.

-

1.75mm only with the included Griffin Print Head.

-

Griffin Hotend components are rated for 500°C and so far were verified in the printing of up to 340°C.

-

Must require a bed temperature at or below 120°C

What Materials Can I Print with the Modix BIG-60 V4?

Whether you’re using one or two Griffin Hotends, expect excellent control of flexible filaments like PRO Series Flex or TPU while the adjustable extruder gear tensioner gives you the ability to try different settings for harder or softer materials. Here is a list of 3D printing materials compatible with the Modix BIG-60 V4:

- PLA and Tough PLA

- ABS and ASA

- PETG and CPE

- Nylon

- NylonX, NylonK, and NylonG (with a sold-separately hardened steel nozzle)

- Ultrafuse 316L and 17-4 PH

- TPU and TPE

- PVA and Soluble Supports (when used as a support material in the second extruder)

- Polycarbonate

- View all compatible materials here.

Which Modix 3D Printer is Right for Me?

As Modix 3D printers all start their lives as kits, it’s incredibly modular and easy to manufacture different variations in machine size and build volume. Features, hardware, and usability is virtually identical across different models, with the main difference being the build volume dimensions:

- Modix BIG-40: 400mm x 400mm x 800mm, starting at $5,600

- Modix BIG-60 V4: 600mm x 600mm x 660mm, starting at $4,500

- Modix BIG-120X: 1,200mm x 600mm x 640mm, starting at $7.550

- Modix BIG-120Z: 600mm x 600mm x 1,200mm, starting at $7,450

- Modix BIG-180X: 1,800mm x 600mm x 600mm, starting at $15,150

- Modix BIG-Meter: 1,010mm x 1,010mm x 1,010mm, starting at $13,150

What Comes with the Modix BIG-60 V4 Kit?

BIG-60 V4 PRINTER ASSEMBLY KIT

- See a full packing list here.

- Modix Griffin Print Head

- Modix Clog Detector

- Modix Z Crash Detector

- Modix PT-1000 High-Temperature Sensor

ACCESSORIES

- Allen Key Set

- 7mm Nozzle Wrench

- Thin Oil - 20cc

- Zip Ties (100)

Modix BIG-60 V4 Kit Technical Specifications

What are the Dimensions for the BIG-60 V4?

- Build Volume: 600mm x 600mm x 660mm / ~23in x 23in x 25in

- Assembled Dimensions (with enclosure): 906mm x 1,060mm x 1,356 mm / 35.6in x 41.7in x 53.4 inch

- Shipping Weight: 120 kg (265 lbs)

What are the Modix BIG-60 V4's printer properties?

- Technology FFF: Fused Filament Fabrication

- Assembly: Self-Assembly

- Closed print chamber: Optional add-on

- Enclosure type (Optional): Aluminum composite panels (ACP), 3mm thick.

Polycarbonate doors and top lid

Polycarbonate doors and top lid

- Feet: Articulated leveling feet included (casters optional add-on)

PRINT HEAD:

- Number of print heads: One print head is included, (optional secondary print head add-on)

- Default filament diameter: 1.75mm, can be converted to 3mm by the user

- Extruder brand & model: E3D Aero Extruder (direct drive)

- Hotend brand & model: Modix Griffin Printhead ; Secondary Griffin Printhead (Optional)

- Included nozzles (mm): 0.4mm, 0.6mm, 0.8mm for Primary hotend 0.4 for Secondary hotend

- Hotend max. temperature: 500ºc

- Extruder motors: Motech MT-1703HS168A Direct drive extruders gear reduction of 1:3

- Filament runout sensor: Dedicated sensor per extruder

MOTION:

- X & Y axis linear guides: HIWIN MGW9

- Z axis guides: Smooth Rods included.

2

2

PRINT BED:

- Bed plate: Alcoa Mic-6, 6.35mm milled cast aluminum plate

- Number of heaters: AC heater, 1,350 Watt , dual zone

- Temperature controller: Autonics TCN4 PID controller

- Maximum bed temperature: 120ºC

- Bed leveling probe: BL touch probe

- Bed leveling: Bed shape is measured by probing 100 different points.

- Bed tilt leveling: Semi-Automatic, guided by an on-screen macro

- Bed motion system: 4 x ball-nut screws. Each screw is mounted to a dedicated stepper motor with a belt gear system

ELECTRONICS:

- Electronic controller: Duet3D: Duet2 Wifi

- User interface: 7” Touch screen – PanelDue from Duet3D

- Remote control (WiFi): Upload Gcode files right from your desktop

- Direct connectivity: SD Card, USB cable

- Ethernet: Optional with Duet3D Ethernet board.

Should be purchased and replaced by customer

Should be purchased and replaced by customer

- Electronics (DC) power: Meanwell 24V/280Watt power supply powering the electronic and motion system. Universal AC input: 110-230V, 50/60 Hz

- Bed heaters (AC) power: Direct AC feed, 1370W Silicone pad heater. Two versions are available: 110V and 230V. We supply according to shipping destination. Power requirement for bed heater in North America is a dedicated 15A outlet.

- AC power cords: We supply the required AC cords for each country

What is the Software for the Modix BIG-60 V4?

- Operating System Compatibility: GNU/Linux, Mac, Windows

- Recommended Software: MatterControl, Cura, PrusaSlicer

- Firmware: RepRapFirmware

- Supported File Types: .stl

- Printable Formats: Gcode

FAQ:

- How long will it take for my purchase from MatterHackers to be shipped?

- Items purchased from MatterHackers will be shipped from the manufacturer's US-based warehouse.

There may be a lead time on orders, depending on stock availability.

There may be a lead time on orders, depending on stock availability.

- Items purchased from MatterHackers will be shipped from the manufacturer's US-based warehouse.

- Can I return a 3D printer kit if it has been opened?

- Returns will not be accepted for any opened 3D printer kit. New, unopened 3D printer kits may be returned within 30 days of purchase.

- What kind of support does MatterHackers provide for warranty replacement components?

- MatterHackers provides support for warranty replacement components. Assembly instruction, troubleshooting, and technical support are provided directly by the Modix Support team.

Large format FDM printers Discovery 3D Printer

Rapid Prototyping

Experts recommend

Key Benefits of Discovery 3D Printer | Technology and features of the 3D printing process | Applications | Equipment line | Implementation History: FDM Printing for the Navy | Results: briefly

We are already seeing real examples incredible flexibility and efficiency of additive manufacturing in the context of the global economic crisis. Experts argue that the pandemic will bring the Fourth Industrial Revolution closer, and many businesses today see digital technologies as a means of survival, and not just to increase competitiveness in the market.

Experts argue that the pandemic will bring the Fourth Industrial Revolution closer, and many businesses today see digital technologies as a means of survival, and not just to increase competitiveness in the market.

iQB Technologies continues to expand its product portfolio: in April 2020, our company became the exclusive distributor in Russia of Discovery 3D Printer industrial 3D printers from the Spanish manufacturer CNC Barcenas. For the first time, we present equipment for 3D printing of large-sized products and prototypes based on FFF/FDM technology.

CNC Barcenas is a rather young business: it is a little over ten years old. Since 2009, the company has been specializing in the production of CNC machines (milling, engraving and laser cutting), and in 2014 it expanded its capacity by starting the development, design and production of unique industrial 3D printers.

Bumper

Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 1800 x 600 x 4500 mm, weight: 12 kg

The first solution for the 3D printing market was the Discovery 3D Printer, followed by the even more innovative and large-format Super Discovery 3D Printer, based on the direct extrusion of polymer pellets. In 2019, the Super Discovery 3D Printer Workstation, an industrial 3D printing and post-processing system, was introduced. In 2021, an updated and improved modification of the Discovery 3D Printer 2021 was released, as well as the Super Discovery 3D Printer Compact and Hybrid models.

In 2019, the Super Discovery 3D Printer Workstation, an industrial 3D printing and post-processing system, was introduced. In 2021, an updated and improved modification of the Discovery 3D Printer 2021 was released, as well as the Super Discovery 3D Printer Compact and Hybrid models.

CNC Barcenas continues its pioneering work and is today one of the leaders in the European large format 3D printing market with many large scale projects to its credit.

Submit the online application and we will advise you in detail on the implementation of 3D printing in the industry!

Key benefits of Discovery 3D Printer

-

Much lower cost printers than competitors offering the same technology and quality.

-

Constant development of technologies and expansion of experience in the areas of 3D printing and machine tool building.

-

All equipment is completely designed and manufactured at CNC Barcenas facilities in Spain.

-

The ability to customize the printer for the tasks of each individual client.

-

The best drive and motor components for quality and fast printing.

-

Correction of irregularities during printing (calibration of nozzles and platform).

-

Debugging equipment up to 100% result.

-

The open material system allows a significant reduction in operating costs.

-

Internal cameras in printers that provide remote monitoring of the production process from any device.

-

Easy to operate hardware and intuitive Simplify 3D software.

Cover prototype

Equipment: Discovery 3D Printer, material: 3D850, dimensions: 29 x 19 x 4. 5 cm, weight: 146 g

5 cm, weight: 146 g

Technology and features of the 3D printing process

The FFF (Fused Filament Fabrication) technology used in Discovery 3D Printers is a complete analogue of FDM (Fused Deposition Modeling - layer-by-layer deposition modeling). This is the most accessible and popular additive technology, it is familiar to all users of home 3D printers, but it is also widely used to solve serious production problems. Its undoubted advantages include high productivity, the ability to produce large-sized products and the relatively low cost of equipment and consumables.

The disadvantages of this method are the highest degree of surface roughness among all additive technologies (the quality depends on the nozzle diameter and materials), the risk of plastic spreading and increased sensitivity to temperature changes. Note that the Super Discovery 3D Printer model equipped with a cutter will immediately correct the roughness and post-process the product right in the printer chamber.

As consumables, thermoplastics or composites are used in the form of threads wound on spools (so-called filaments), or granules. Their range is very diverse and allows you to choose the most suitable materials for the tasks to be solved in terms of physical and mechanical properties - ABS, PLA, nylon, polycarbonates, polyamides, polystyrene, polyethylene and many others.

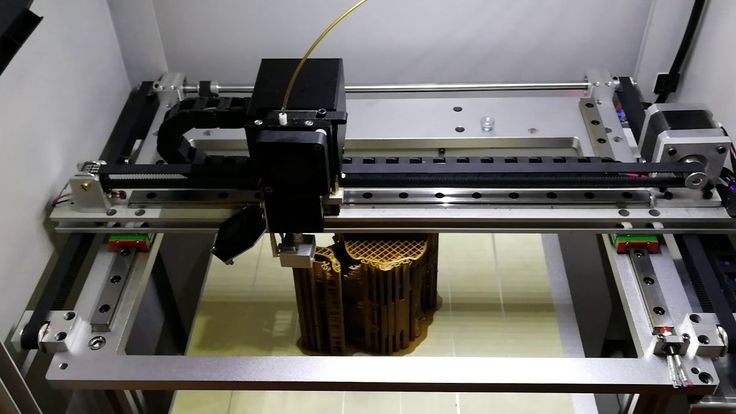

Building an object in Discovery 3D Printer

The process of creating a product using FDM/FFF technology includes the following steps:

-

Export 3D model to 3D printer software in .stl format.

-

Preparation for printing: division of the model into layers and orientation on the construction platform, if necessary, the creation of supports. The result is a G-code containing all print settings.

-

Printing process by layer-by-layer extrusion (extrusion) of molten material. The extruder (print head) moves from bottom to top along the X and Y axes, the working platform moves along the Z axis.

-

Extraction of the printed object from the 3D printer, removal of supports, post-processing.

The filament printing method is used in the junior model of the Discovery 3D Printer line. The Super Discovery 3D Printer and Super Discovery 3D Printer Workstation implement the innovative Direct Extrusion of Pellet technology. The difference from standard FDM is that the consumables are in the form of granules rather than filaments. This method makes it possible to speed up and make more economical the production of large objects.

Helicopter seat

Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 120 x 70 x 45 cm, weight: 20 kg

Statue

Equipment: Super Discovery 3D Printer, material: ABS with cellulose fiber, height: 1.87 m, weight: 45 kg

Discovery 3D Printer Applications

Every industry is different, which is why CNC Barcenas tailors the 3D printers it produces to the requirements of specific applications and projects that require rapid prototyping or rapid production of end products. Discovery 3D Printer can be successfully used in the following industries:

Discovery 3D Printer can be successfully used in the following industries:

-

automotive industry;

-

aerospace industry;

-

shipbuilding;

-

defense sector;

-

railway industry;

-

household goods and equipment;

-

furniture industry;

-

architecture;

-

the medicine;

-

education;

-

Industrial Design;

-

3D printing services.

We printed large-sized parts and saved about 70% of the costs that are usually spent on prototyping by subcontractors

Juan Galindo Perez, Prototyping Manager, BSH Spain

Equipment line

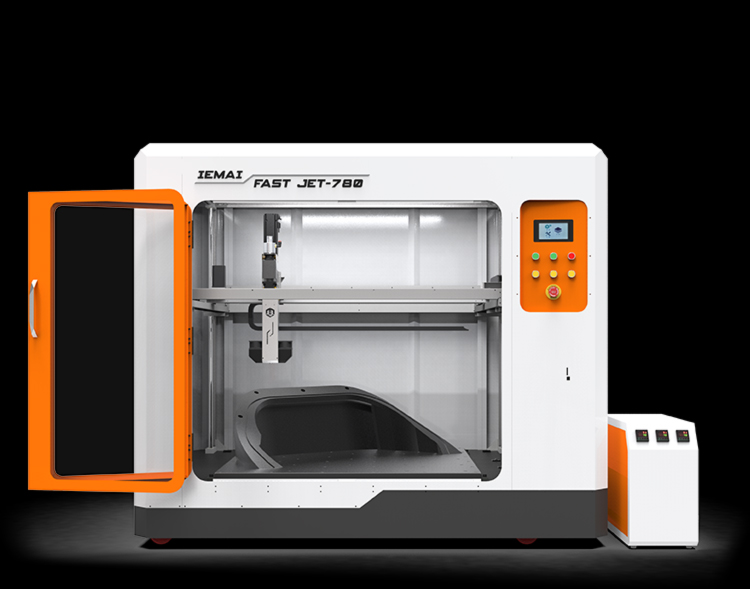

Discovery 3D Printer 2021

The industrial 3D printer based on FFF technology is designed for the production of large parts from technical plastics within the framework of complex and long-term projects. As consumables, all filaments available on the market that conform to the standard 1.75 mm format can be used. The printer is equipped with a built-in dual extrusion system that can be used to create supports and parts from different materials in different colors. Discovery 3D Printer is one of the most attractive solutions on the market in terms of price and quality, given the dimensions of the printed products.

As consumables, all filaments available on the market that conform to the standard 1.75 mm format can be used. The printer is equipped with a built-in dual extrusion system that can be used to create supports and parts from different materials in different colors. Discovery 3D Printer is one of the most attractive solutions on the market in terms of price and quality, given the dimensions of the printed products.

-

Works with ULTEM, PLA, ASA, ABS, PA, HIPS, 3D850, PETG, ABS Medical, ABS Hi and many more

-

Fully enclosed chamber and heated bed (up to 175°C) with auto leveling function that automatically compensates for minor unevenness during printing

-

Build Chamber Size (W x D x H): 1150 x 800 x 500 mm

-

Printer size: 1150 x 800 x 500 mm

-

Weight: 300 kg

-

Extruder (max. temperature): 450 °C

-

Working load: 80-140g/h

-

Print speed: up to 400 mm/s

-

Layer thickness (minimum): 0.

1mm

1mm -

Software: Simplify 3D

Super Discovery 3D Printer

The machine was designed as a one-stop solution for Industry 4.0 to produce large-format parts up to 2.5 m in size. general expenses. Individual configuration is possible for any needs of large industry.

-

Works with all thermoplastics e.g. ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and heated platform (up to 175°C) with automatic leveling function for the most demanding materials

-

Automatic supply of granules, no restrictions on the amount of material and, as a result, on the weight of the product.

-

Build Chamber Size (W x D x H): factory standard 1300 x 2500 x 1000 mm, custom configuration available

-

Printer dimensions with feed funnel and electrical cabinet: 2000 x 3590 x 3000 mm

-

Weight: 1200 kg

-

Extruder (max.

temperature): 450 °C

temperature): 450 °C -

Working load: <6kg/h

-

Print speed: up to 200 mm/s

-

Layer thickness (minimum): 0.5mm

-

Software: Simplify 3D

Super Discovery 3D Printer Compact

Compact and high performance industrial grade 3D printer for pellet extrusion printing. The machine is designed to create small and medium-sized products up to 1100 x 800 x 500 mm, and at the same time has all the advantages of the previous model Super Discovery 3D Printer, allowing you to reduce costs and increase print speed.

-

Fully enclosed chamber and heated platform (up to 150°C)

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Polymer Granule Direct Extrusion Technology

-

Build chamber size: 1100 x 800 x 500 mm (modifiable)

-

Automatic feeding of granules and no restrictions on the amount of material

-

Weight: 450 kg

-

Extruder (max.

temperature): 410 °C

temperature): 410 °C -

Working load: 2 kg/h

-

Print speed: up to 100 mm/s

-

Layer thickness (minimum): 0.5mm

-

Software: Simplify 3D

Super Discovery 3D Printer Hybrid

A combined solution that implements two additive technologies at once - the filament printing method and direct extrusion of polymer granules, which can also be used separately. The innovative 3D printer works with any thermoplastics and has a build chamber up to 1100 x 800 x 500 mm, which can be modified to suit your individual needs if desired.

-

Combined solution for printing with filaments and polymer granule extrusion technology

-

Fully enclosed chamber and heated platform (up to 150°C)

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Build chamber size: 1100 x 800 x 500 mm

-

Automatic feeding of granules and no restrictions on the amount of material

-

Weight: 300 kg

-

Extruder (max.

temperature): 410 °C

temperature): 410 °C -

Working load: granules - 2 kg/h, filaments - 80-100 g/h

-

Print speed: granules - up to 100 mm/s, filaments - up to 400 mm/s

-

Layer thickness (minimum): granules - 0.5 mm, filaments - 0.1 mm

-

Software: Simplify 3D

Super Discovery 3D Printer Workstation

The perfect combination of a large format industrial 3D printer and a milling system. The plant is designed for the production of large batches of large parts and prototypes. The principle of operation, just like that of the Super Discovery 3D Printer model, is based on the direct extrusion of granules. The special design allows the entire production process to be carried out, including post-processing, since both the extruder and the milling motor are present on the working platform. The Super Discovery 3D Printer Workstation is capable of performing large-scale post-processing jobs, as well as cutting, punching or 3D engraving on plastic, photopolymer, foam, wood and other materials.

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and heated platform (up to 175°C) with automatic leveling function for the most demanding materials

-

Automatic feeding of granules, no restrictions on the amount of material and, as a result, on the weight of the product

-

Build Chamber Size (W x D x H): factory standard 1500 x 2000 x 1000 mm, custom configuration available

-

Printer size: 2000 x 3590 x 3000 mm

-

Weight: 1500 kg

-

Extruder (max. temperature): 450 °C

-

Working load: <6kg/h

-

Speed: up to 200 mm/s

-

Layer thickness (minimum): 0.5mm

-

Milling motor: high-frequency brushless motor with air-cooled ceramic bearings, speed 4500-18000 rpm.

-

Software: Simplify 3D + CNC software

Case History: FDM Printing for the Navy

By order of the Spanish Navy, the state-owned shipbuilding company Navantia has developed and implemented the Shipyard 4. 0 strategy (“Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of Things, etc. Read more about Shipyard 4.0 in the article.

0 strategy (“Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of Things, etc. Read more about Shipyard 4.0 in the article.

CNC Barcenas has been involved in two R&D projects for additive manufacturing. The first of these is called 3DCABINS and involves the production of fully equipped ship cabins through research and selection of the most suitable materials. For example, on the Discovery 3D Printer and Super Discovery 3D Printer installations, prototypes of a modular toilet for a naval ship were made. Compared to traditional production methods, the weight of the products has been reduced by almost 50% and their cost has been significantly reduced. The second project, ADIBUQUE, uses 3D printers to manufacture complex components for the navy sector, which are installed and tested on ships under construction.

Objects printed on the Super Discovery 3D Printer for the 3DCABINS project:

- modular toilet, material: flame retardant ABS, dimensions: 2200 x 1700 x 1200 mm, weight: 250 kg

– ventilation grille, material: ABS with carbon fibre, dimensions: 59 x 89 x 4.5 cm, weight: 3500 g

Using the Discovery 3D Printer enabled Navantia to:

-

modernize the production process and increase productivity;

-

reduce production and assembly time;

-

reduce labor costs;

-

reduce the amount of work on processing and painting;

-

increase the energy efficiency of production;

-

improve product quality.

Summary: briefly

The Discovery 3D Printer is a Spanish-made range of additive machines with an excellent price/performance ratio for creating large-sized products and prototypes. The main features of the printers are large print format (up to 2.5 m), affordable FFF / FDM technology, ease of operation and unique technological solutions, such as an integrated dual extrusion system, correction of unevenness during printing, individual configuration of printers, 3D printing and post-processing in one system. All these advantages will optimize the production of enterprises in various industries - from the automotive industry and shipbuilding to medicine and household appliances. Discovery 3D Printer will suit both large industrial productions and innovative companies in the small and medium business segment.

The main features of the printers are large print format (up to 2.5 m), affordable FFF / FDM technology, ease of operation and unique technological solutions, such as an integrated dual extrusion system, correction of unevenness during printing, individual configuration of printers, 3D printing and post-processing in one system. All these advantages will optimize the production of enterprises in various industries - from the automotive industry and shipbuilding to medicine and household appliances. Discovery 3D Printer will suit both large industrial productions and innovative companies in the small and medium business segment.

Discovery 3D Printer Solutions are available to order at .

Article published on 04/23/2020, updated on 11/30/2021

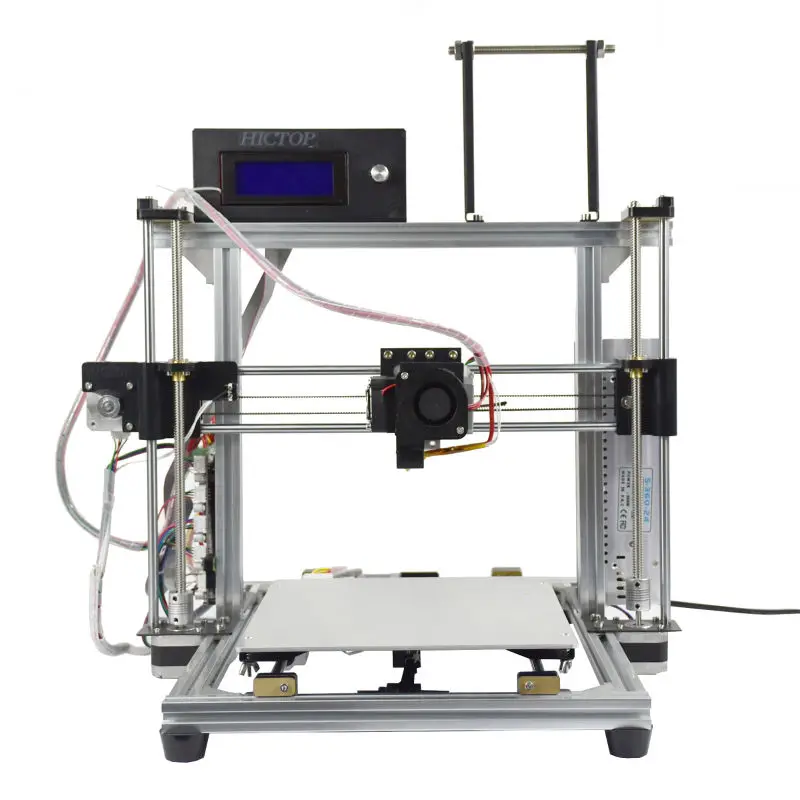

CreateBot D600 Large Professional 3D Printer

Hello everyone, the company 3Dtool is with you. Today in our review is an impressive 3D printer that takes professional 3D printing to a new level.

It proudly bears the name CreatBot D600 and comes in a fairly sturdy wooden box.

Let's start unpacking it

The printer is packaged just fine, with foam padded on all sides, all glasses sealed with packaging film to avoid scratches, and inside the moving parts are fixed with nylon ties.

CreatBot D600 , it is no coincidence that it has these numbers in the name, because the size of its working area is 600 mm x 600 mm x 600 mm and the usable volume is 216 liters.

Also, its main advantage (besides the size) is the dual print unit with two separate extruders

The size of the working area is impressive, because there are not many FDM 3D printers on the market that can compete with the D600 in this indicator. At the same time, the dual print unit can print supports using soluble materials. Such capabilities allow CreatBot D600 to create complex models of large size. That in itself is a rare combination and is highly demanded in the market of professional 3D equipment.

Housing

The printer body is all metal and its overall dimensions are 915 x 845 x 1085 mm . The weight of the printer is 125 kg , which, coupled with a rather impressive rigidity, has a beneficial effect on reducing vibration during printing.

There are many opening doors and windows on the body, providing access from any side to the printed model.

With a fully enclosed housing, the possibility of external interference in the operation of the printer is eliminated, the noise level during operation is reduced, and the temperature inside the chamber is maintained at a constant temperature so that the product does not deform during printing. Thanks to this, the printer allows you to print with high shrinkage plastics, such as ABS derivatives or nylon, without problems.

The location for installing the material spools is at the back of the housing.

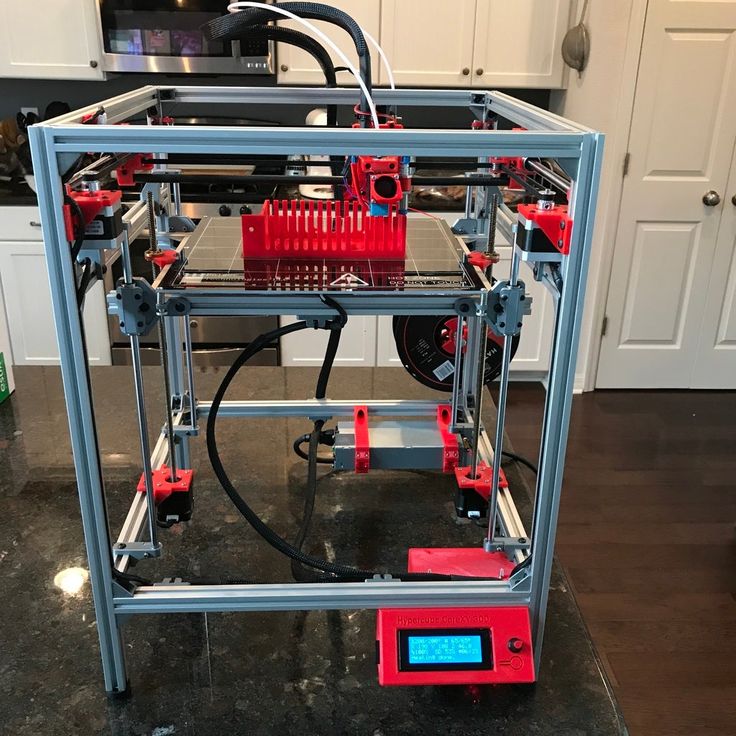

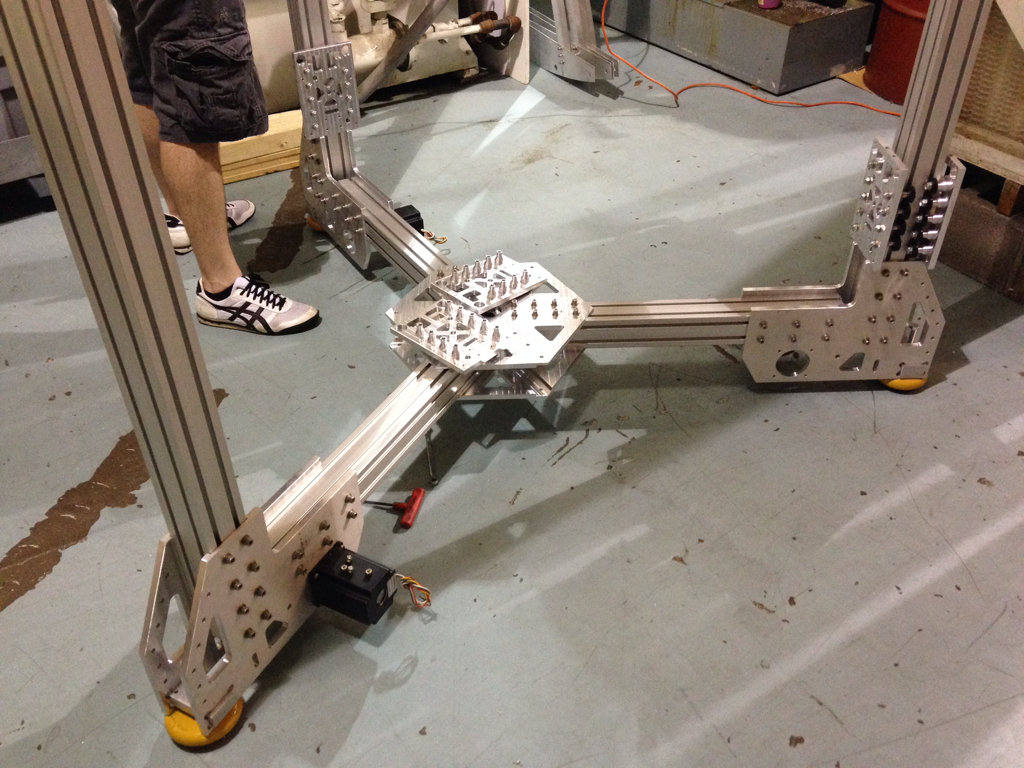

Kinematics

Designed as a single unit with a belt, rail guides provide a high degree of positioning accuracy, higher than not only their counterparts, but even some optical printers available on the mass market. The classic kinematic scheme allows you to print, albeit a little slower than analogues at H-Bot and Core-XY systems, but much more reliable due to the direct drive of the motor along the axes. By the way, along the axis Y the printing unit moves due to the movement of two belts (one per rail), but one powerful stepper motor with a through drive

Along the axis Z , the heating table is moved by two ball screws installed at the side walls. As guides for the table, there are four cold-rolled shafts with a diameter of 16 mm .

Along the X and Y axes, block rail guides with an integrated belt are installed.

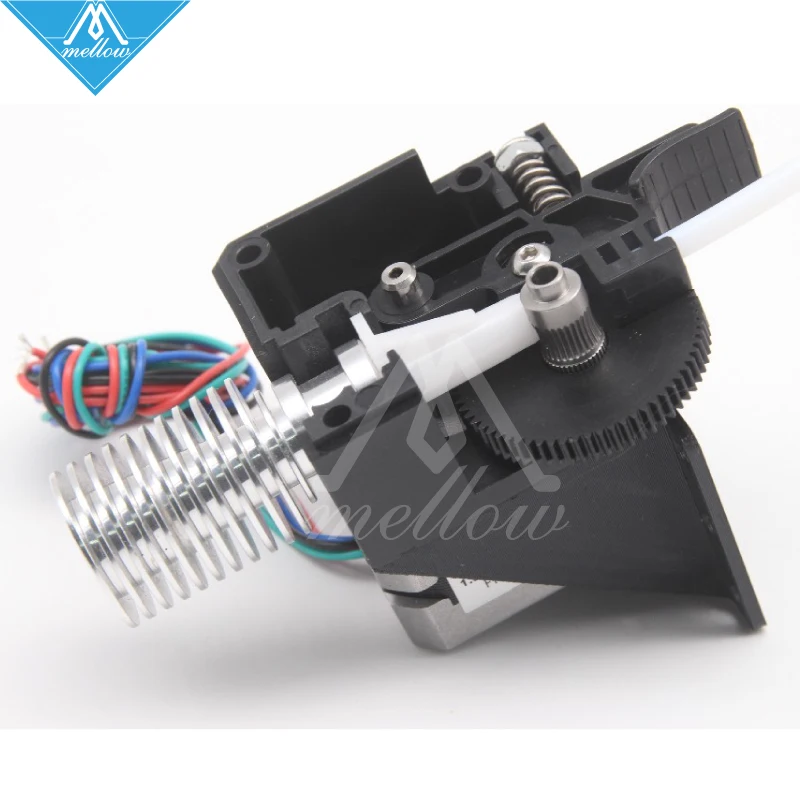

Extruder

As standard, the printer has a dual print unit with two extruders. Optionally, it is possible to install a third. The extruders are equipped with a gear ratio 1:10 .

The pull mechanism is completely metal. This allows you to confidently print with any materials, which is also provided by the nozzle heating limit, right up to 400°C . The printing unit itself is made according to the classic direct extruder scheme, has an extruder tube and heating blocks similar to the Vulcan. The cold zone (ColdEnd) is forcibly blown by two small fans, the speed of which can be adjusted.

Nozzles with a diameter of 0.4 mm are installed by default. They are interchangeable and, if necessary, you can always install other diameters suitable for your tasks (0.3, 0.5, 0.6, 0.8, 1.0 mm) .

When the power is suddenly turned off, the printer automatically remembers the current position and saves the print data, lowers the build platform and retracts the nozzle.

The platform of a heating table is made of glass ceramics. Can heat up to 100 - 110 °C . This is not as much as, for example, MarkForged printers, but allows you to use any of the most common materials for 3D printing. The adhesive on the platform is a BuildTak-like surface that securely holds even very large objects made of high shrinkage materials (eg ABS).

The calibration screws are located at the bottom of the heating table.

Control screen

For convenience, the printer is equipped with a 4.3” touch screen with an English menu. There are separate menus for preheating and movement along the axes. It is quite easy to handle. Intuitive icons allow you to quickly understand the tools and manage the printer, with almost one touch.

Interfaces

3D printer CreatBot D600 is equipped with a USB 1. 0 port. This allows you to pair with a computer and send print jobs from it directly. However, we recommend using the USB flash drive slot to the right of the display in order to take full advantage of the device's capabilities.

0 port. This allows you to pair with a computer and send print jobs from it directly. However, we recommend using the USB flash drive slot to the right of the display in order to take full advantage of the device's capabilities.

Software

The printer comes with free software CreatWare based on the popular and well-known Cura 1.5.4, which can be downloaded from the manufacturer's website.

It is very simple and easy to learn, so there should not be any problems in working with this software.

This 3D printer is designed to solve serious problems of printing large-sized models. The quality of workmanship and ease of use allow the CreatBot D600 to be used in professional 3D printing studios, various design and design offices 24/7. The build quality of the 3D printer is factory. All components of the 3D printer are made of high quality components. Significant advantages of CreatBot D600 include:

1) The ability to heat the extruder up to 400 degrees (Important for 3D printing with engineering plastics)

2) Reliable and accurate kinematics for a working area of this size.