Positive impacts of 3d printing

What are the Advantages and Disadvantages of 3D Printing?

3D printing, also known as additive manufacturing, is becoming popular with manufacturers. The demand is growing due to some of the revolutionary benefits that it can provide. Like almost all technologies it has its own drawbacks that need considering.

This page aims to help with the selection process. We will cover each of the advantages and disadvantages of 3D printing.

This production process offers a range of advantages compared to traditional manufacturing methods. These advantages include those related to design, time and cost, amongst others.

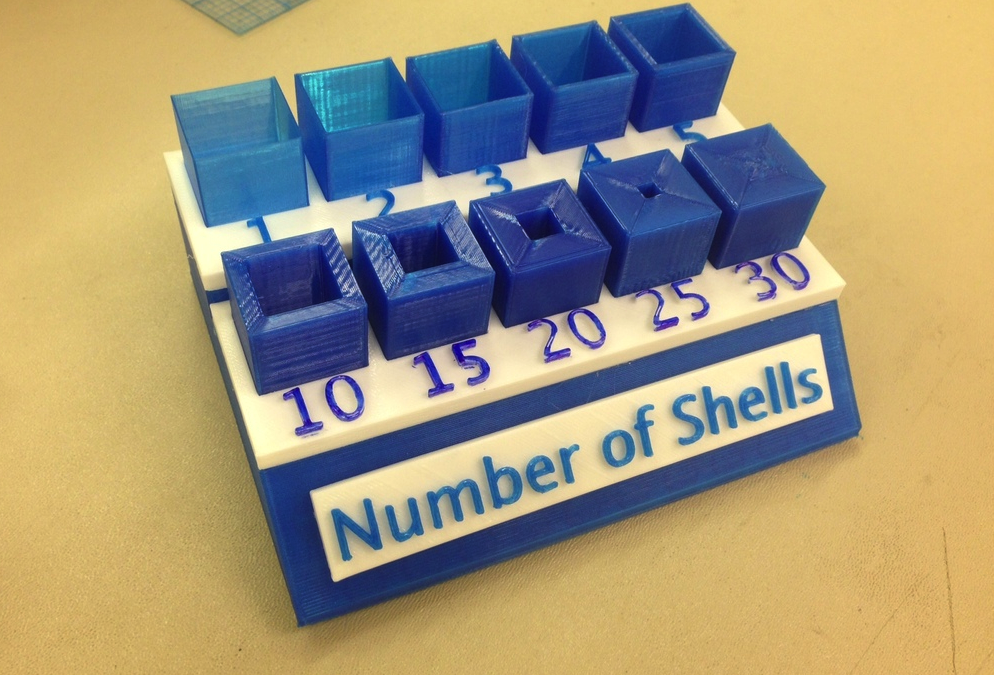

1. Flexible Design

3D printing allows for the design and print of more complex designs than traditional manufacturing processes. More traditional processes have design restrictions which no longer apply with the use of 3D printing.

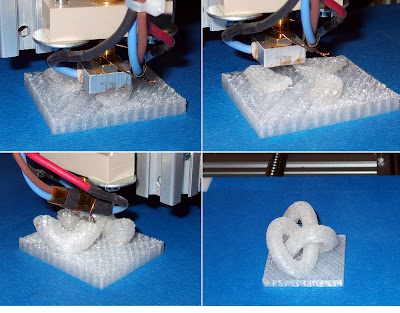

2. Rapid Prototyping

3D printing can manufacture parts within hours, which speeds up the prototyping process. This allows for each stage to complete faster. When compared to machining prototypes, 3D printing is inexpensive and quicker at creating parts as the part can be finished in hours, allowing for each design modification to be completed at a much more efficient rate.

3. Print on Demand

Print on demand is another advantage as it doesn’t need a lot of space to stock inventory, unlike traditional manufacturing processes. This saves space and costs as there is no need to print in bulk unless required.

The 3D design files are all stored in a virtual library as they are printed using a 3D model as either a CAD or STL file, this means they can be located and printed when needed. Edits to designs can be made at very low costs by editing individual files without wastage of out of date inventory and investing in tools.

4. Strong and Lightweight Parts

The main 3D printing material used is plastic, although some metals can also be used for 3D printing. However, plastics offer advantages as they are lighter than their metal equivalents. This is particularly important in industries such as automotive and aerospace where light-weighting is an issue and can deliver greater fuel efficiency.

However, plastics offer advantages as they are lighter than their metal equivalents. This is particularly important in industries such as automotive and aerospace where light-weighting is an issue and can deliver greater fuel efficiency.

Also, parts can be created from tailored materials to provide specific properties such as heat resistance, higher strength or water repellency.

5. Fast Design and Production

Depending on a part’s design and complexity, 3D printing can print objects within hours, which is much faster than moulded or machined parts. It is not only the manufacture of the part that can offer time savings through 3D printing but also the design process can be very quick by creating STL or CAD files ready to be printed.

6. Minimising Waste

The production of parts only requires the materials needed for the part itself, with little or no wastage as compared to alternative methods which are cut from large chunks of non-recyclable materials. Not only does the process save on resources but it also reduces the cost of the materials being used.

7. Cost Effective

As a single step manufacturing process, 3D printing saves time and therefore costs associated with using different machines for manufacture. 3D printers can also be set up and left to get on with the job, meaning that there is no need for operators to be present the entire time. As mentioned above, this manufacturing process can also reduce costs on materials as it only uses the amount of material required for the part itself, with little or no wastage. While 3D printing equipment can be expensive to buy, you can even avoid this cost by outsourcing your project to a 3D printing service company.

8. Ease of Access

3D printers are becoming more and more accessible with more local service providers offering outsourcing services for manufacturing work. This saves time and doesn’t require expensive transport costs compared to more traditional manufacturing processes produced abroad in countries such as China.

9. Environmentally Friendly

As this technology reduces the amount of material wastage used this process is inherently environmentally friendly. However, the environmental benefits are extended when you consider factors such as improved fuel efficiency from using lightweight 3D printed parts.

However, the environmental benefits are extended when you consider factors such as improved fuel efficiency from using lightweight 3D printed parts.

10. Advanced Healthcare

3D printing is being used in the medical sector to help save lives by printing organs for the human body such as livers, kidneys and hearts. Further advances and uses are being developed in the healthcare sector providing some of the biggest advances from using the technology.

Like with almost any other process there are also drawbacks of 3D printing technology which should be considered before opting to use this process.

1. Limited Materials

While 3D Printing can create items in a selection of plastics and metals the available selection of raw materials is not exhaustive. This is due to the fact that not all metals or plastics can be temperature controlled enough to allow 3D printing. In addition, many of these printable materials cannot be recycled and very few are food safe.

2. Restricted Build Size

3D printers currently have small print chambers which restrict the size of parts that can be printed. Anything bigger will need to be printed in separate parts and joined together after production. This can increase costs and time for larger parts due to the printer needing to print more parts before manual labour is used to join the parts together.

3. Post Processing

Although large parts require post-processing, as mentioned above, most 3D printed parts need some form of cleaning up to remove support material from the build and to smooth the surface to achieve the required finish. Post processing methods used include waterjetting, sanding, a chemical soak and rinse, air or heat drying, assembly and others. The amount of post processing required depends on factors including the size of the part being produced, the intended application and the type of 3D printing technology used for production. So, while 3D printing allows for the fast production of parts, the speed of manufacture can be slowed by post processing.

4. Large Volumes

3D printing is a static cost unlike more conventional techniques like injection moulding, where large volumes may be more cost effective to produce. While the initial investment for 3D printing may be lower than other manufacturing methods, once scaled up to produce large volumes for mass production, the cost per unit does not reduce as it would with injection moulding.

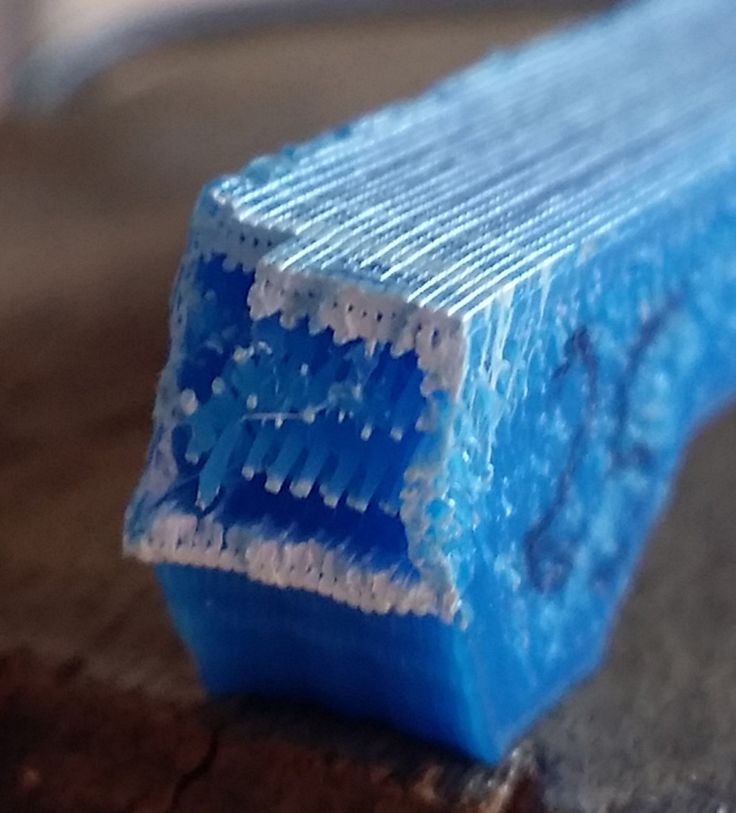

5. Part Structure

With 3D printing (also known as Additive Manufacturing) parts are produced layer-by-layer. Although these layers adhere together it also means that they can delaminate under certain stresses or orientations. This problem is more significant when producing items using fused deposition modelling (FDM), while polyjet and multijet parts also tend to be more brittle. In certain cases it may be better to use injection moulding as it creates homogenous parts that will not separate and break.

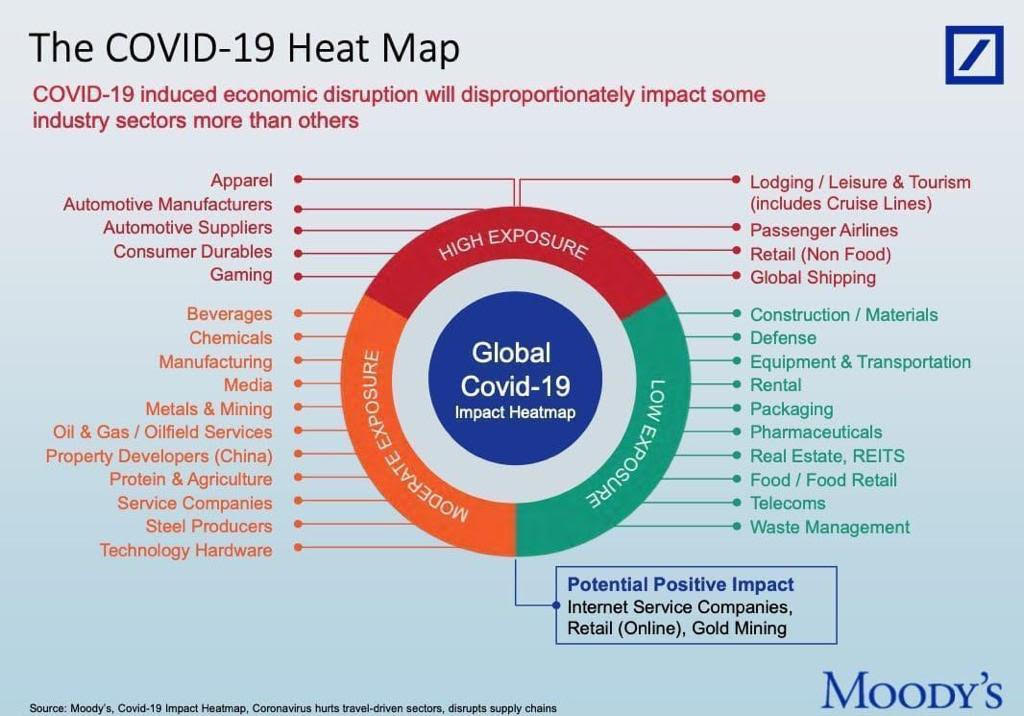

6. Reduction in Manufacturing Jobs

Another of the disadvantages of 3D technology is the potential reduction in human labour, since most of the production is automated and done by printers. However, many third world countries rely on low skill jobs to keep their economies running, and this technology could put these manufacturing jobs at risk by cutting out the need for production abroad.

However, many third world countries rely on low skill jobs to keep their economies running, and this technology could put these manufacturing jobs at risk by cutting out the need for production abroad.

7. Design Inaccuracies

Another potential problem with 3D printing is directly related to the type of machine or process used, with some printers having lower tolerances, meaning that final parts may differ from the original design. This can be fixed in post processing, but it must be considered that this will further increase the time and cost of production.

8. Copyright Issues

As 3D printing is becoming more popular and accessible there is a greater possibility for people to create fake and counterfeit products and it will almost be impossible to tell the difference. This has evident issues around copyright as well as for quality control.

Get Further Advice On 3D Printing

Need help with determining whether 3D printing is the right process for you?

Contact our team of world-leading experts with over 20 years of experience in the additive manufacturing field.

Our technology experts help to ensure our customers apply the correct technology process depending on each individual or company requirements:

Related Frequently Asked Questions (FAQs)

The Positive Effects of 3D Printing

What makes the utilization of 3D printing on a global scale so exciting is that the technology is being used in nearly every industry in extraordinary ways.

You may be surprised to discover that you may be using or looking right at 3D printed works in your daily life, without even recognizing it. Ponder the fascinating and effective reasons why 3D printing is making a great impact on the world.

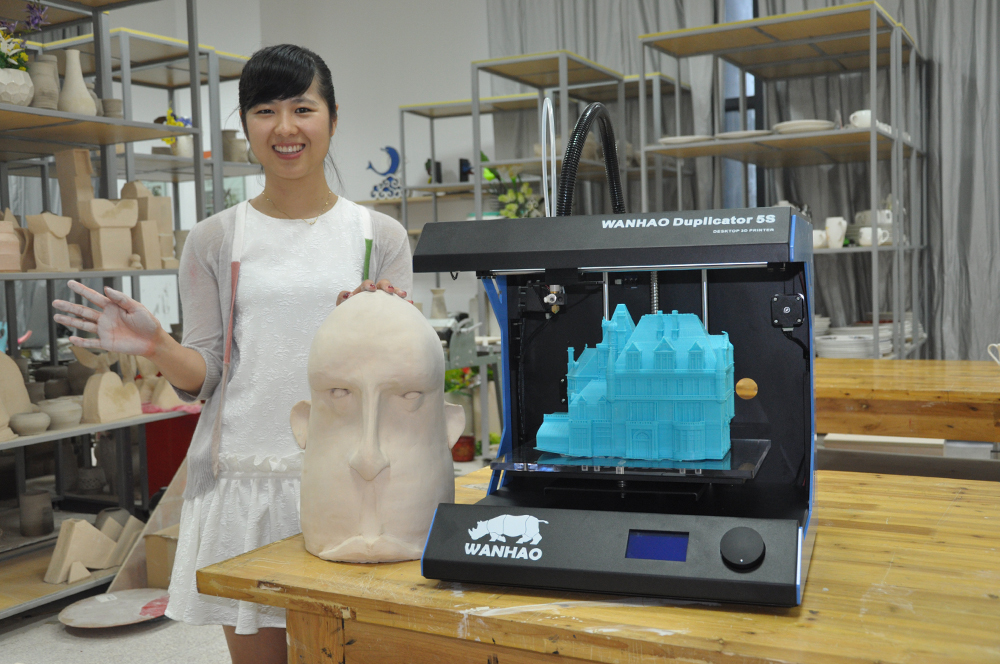

1. 3D Printing is Revolutionizing and Combining Industries

There are tons of companies across various trades that you may think are not using 3D printing technologies, but are. From finance to fashion design, many wide-reaching industries are taking the hint and integrating the possibilities of 3D printing into their businesses. Not only are slow-moving industries changing rapidly in its wake, but medical, business, education, and manufacturing powerhouses are starting to collaborate together to discover new 3D printing solutions for all.

Not only are slow-moving industries changing rapidly in its wake, but medical, business, education, and manufacturing powerhouses are starting to collaborate together to discover new 3D printing solutions for all.

2. 3D Printing is Saving Lives

Printing body organs sounds like science fiction, but it is fast becoming a reality. 3D technology has made the creation of customizable human body organs and parts possible. Doctors and medical scientists can use the technology to design and replace organs that are a compatible DNA fit for each patient. This kind of technology can save hundreds of thousands of people globally who are suffering from illness and disease and remove them from extensive organ donor waiting lists.

3. 3D Printing Reduces the Cost of Everyday Items

Additive manufacturing, also known as 3D printing, can also be used to print everyday objects for your home and work life from a variety of materials. Digital Trends shares that coasters, pen holders, showerheads, outlet protectors, wall mounts, measuring cups, candle holders, vases, and even smartphone cases are just some of the things that can be created with a 3D printer.

A few decades ago, the idea of wearing 3D printed dresses, belts, and footwear sounded like a line from a science-fiction novel. Local fashion designers and other creatives can print you the ideal outfit, tailored to your exact measurements, in a smorgasbord of materials, colors, and patterns right now.

4. Quicker Customization of Biomedical Devices is a Reality with 3D Printing

The Food and Drug Administration notes that the printing of biomedical devices allows manufacturers and designers to make changes easily to create devices matched to a patient’s anatomy. As a result, many biomedical devices like custom dental plates and prostheses can be created very quickly. In past years, it would take weeks for a dentist to send specifications to a large manufacturer and receive a patient’s custom dental designs for advanced repair or surgery.

Individuals who struggle to get a comfortable fit can now receive a simple scan of their mouth and custom dental works can be printed to scale in a single day at the same office. Finding a prosthetic that fits well and is effective for an individual was tricky, costly, and time-consuming in the past. Now, empowering amputees with the ability to receive high quality, well-fitted prostheses quickly is one of the issues that 3D printing technology solves.

Finding a prosthetic that fits well and is effective for an individual was tricky, costly, and time-consuming in the past. Now, empowering amputees with the ability to receive high quality, well-fitted prostheses quickly is one of the issues that 3D printing technology solves.

5. Rapid Prototyping and Warehousing is Simplified With 3D Printing

With the help of 3D printing, a product design can be transformed into a prototype quickly. The speed of manufacturing all sorts of products has risen exponentially, so offering an array of products without retaining all of the stock is now possible with 3D printing. This enables decentralization and helps companies to save money by printing on demand. This lessens the responsibility of manufacturers and businesses in storing vast amounts of inventory that may or may not sell. When a sale is made, then the product is printed and shipped.

6. 3D Printing Streamlines the Construction of Cars, Aircraft, and Spacecraft

In the manufacturing world, 3D printing is making a ripple impact. What used to take tons of people and a long construction process can now be completed in a fraction of the time. Geek.com states that 3D printing is now being used to create replacement parts for combat aircraft and to construct next-generation spacecraft to roam the universe. Although producing automotive parts with the 3D printing process is not new; the first 100% 3D printed car hit the road only a few years ago. Consumers can also expect the prices to decline on these items over time.

What used to take tons of people and a long construction process can now be completed in a fraction of the time. Geek.com states that 3D printing is now being used to create replacement parts for combat aircraft and to construct next-generation spacecraft to roam the universe. Although producing automotive parts with the 3D printing process is not new; the first 100% 3D printed car hit the road only a few years ago. Consumers can also expect the prices to decline on these items over time.

7. 3D Printing Can Construct Homes and Other Buildings

Did you know that buying a house made from 3D printing technology is now an option? There are industrial-level 3D printers that make printing construction materials a reality. Some scholars report a global housing crisis in the near future, but 3D printing can provide shelter and safety for all kinds of people who are at risk. When a building is destroyed or needs renovation, 3D printing technologies are able to facilitate faster reconstruction than ever before.

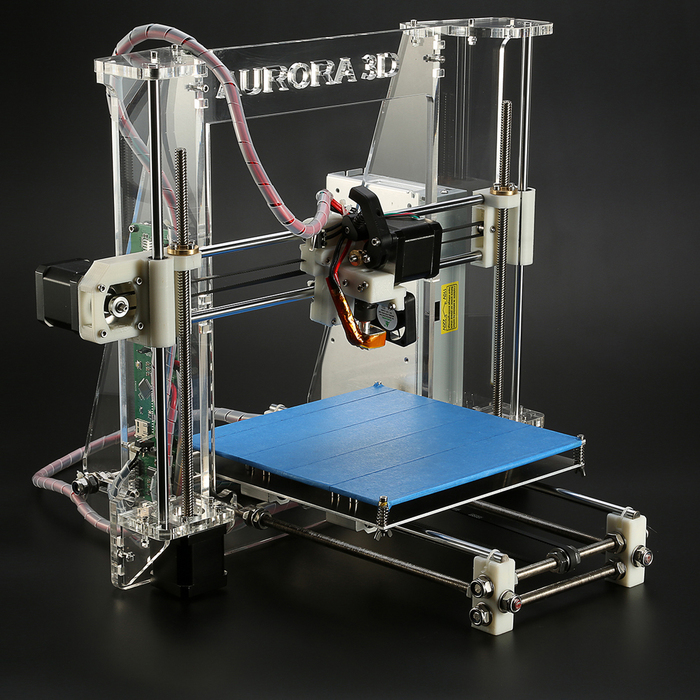

8. 3D Printing Enables the Everyday Person to Be Creative

As Moore’s Law of Exponential Growth predicts, 3D printing will only become cheaper and more accessible to significant parts of the population in the near future. Prices vary, but you can currently buy a 3D printer for as low as $200 online. Small-town entrepreneurs with access to the technology can quickly manufacture their own products and cut out the middlemen. The everyday person with an innovative, experimental edge can start designing and printing all kinds of products the same day.

The vast influence of 3D printing can no longer be ignored. Expect far more unique applications of 3D printing in the future as the exponential technology decreases in price, grows more effective, and rises in availability. As more creative individuals from every industry bring their ideas to the drawing board, we can expect more inventions and applications of 3D printing with a positive impact for all in the future.

About the Guest Blogger

Mohamed Bah handles online media relations for Mecsoft Corporations, and in his spare time, he enjoys swimming, traveling, basketball, and playing with his puppy, Leo. He also volunteers in his local community because he believes in showing kindness to everyone.

References:

– Daniels, Patrick. (14 June, 2018). 20 things you’ll never have to buy again if you own a 3D printer. Designtechnica Corporation. Retrieved from: https://www.digitaltrends.com/cool-tech/useful-3d-printed-household-items/

– Food and Drug Administration. (26 March 2018). 3D Printing of Medical Devices. Retrieved from: https://www.fda.gov/medicaldevices/productsandmedicalprocedures/3dprintingofmedicaldevices/default.htm

– Minor, Jordan. (7 May 2018). The Coolest Things to Ever Be 3D Printed. Ziff Davis, LLC, PCMag Group. Retrieved from: https://www.geek.com/tech/the-coolest-things-to-ever-be-3d-printed-1739009/

Advantages and disadvantages.

How 3D printing affects business and our lives - Trade on vc.ru

How 3D printing affects business and our lives - Trade on vc.ru What is 3D printing?

1132 views

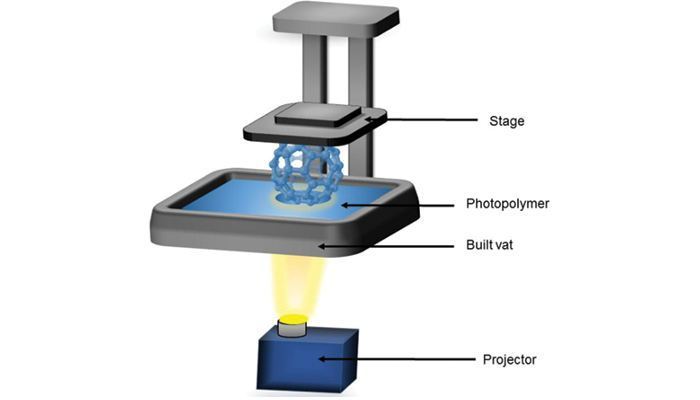

3D printing is a process in which a digital model is turned into a tangible, solid three-dimensional object, usually by applying many successive thin layers of material. 3D printing has become popular so quickly because it makes manufacturing accessible to more people than ever before. This is partly due to the price (the starting price for a basic 3D printer is around $300) and the small size of the printers compared to traditional manufacturing. nine0003

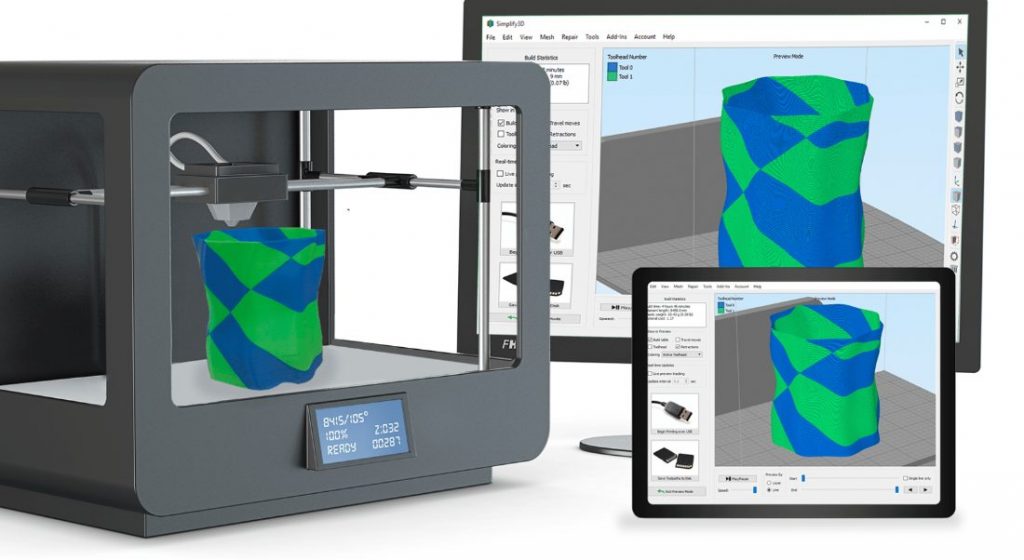

How does it work?

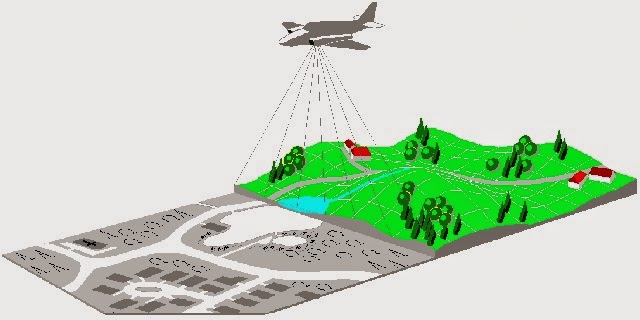

First, the virtual design of the object is done. This design will work like a blueprint for a 3D printer. Virtual design is done using computer-aided design (CAD) software, a type of software that can produce accurate drawings and technical illustrations. A virtual design can also be created using a 3D scanner, which creates a copy of an existing object by photographing it from different angles.

CAD software for creating a 3D model

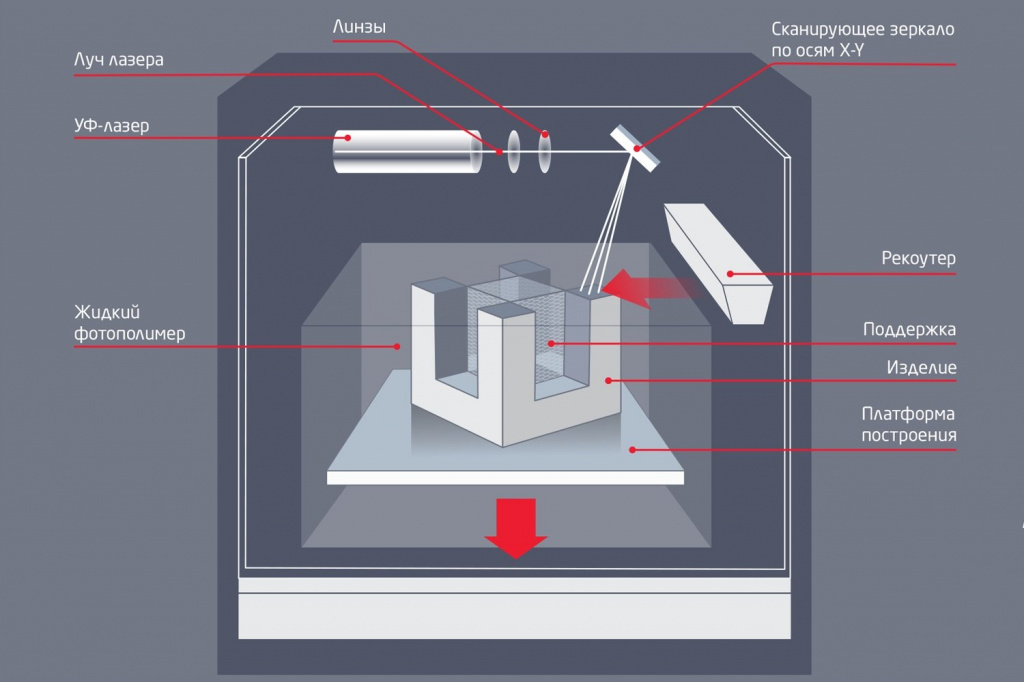

Once the virtual model has been created, it must be prepared for printing. This is done by splitting the model into many layers using a process called slicing. When slicing, the model is cut into hundreds or even thousands of thin horizontal layers using special software.

Slicing the 3D model

After the model has been cut, the slices are ready to be loaded onto the 3D printer. This is done using a USB cable or Wi-Fi connection to move the sliced model from the computer to the 3D printer. When the file is loaded onto the 3D printer, it reads each piece of the model and prints it layer by layer. nine0003

How are things printed?

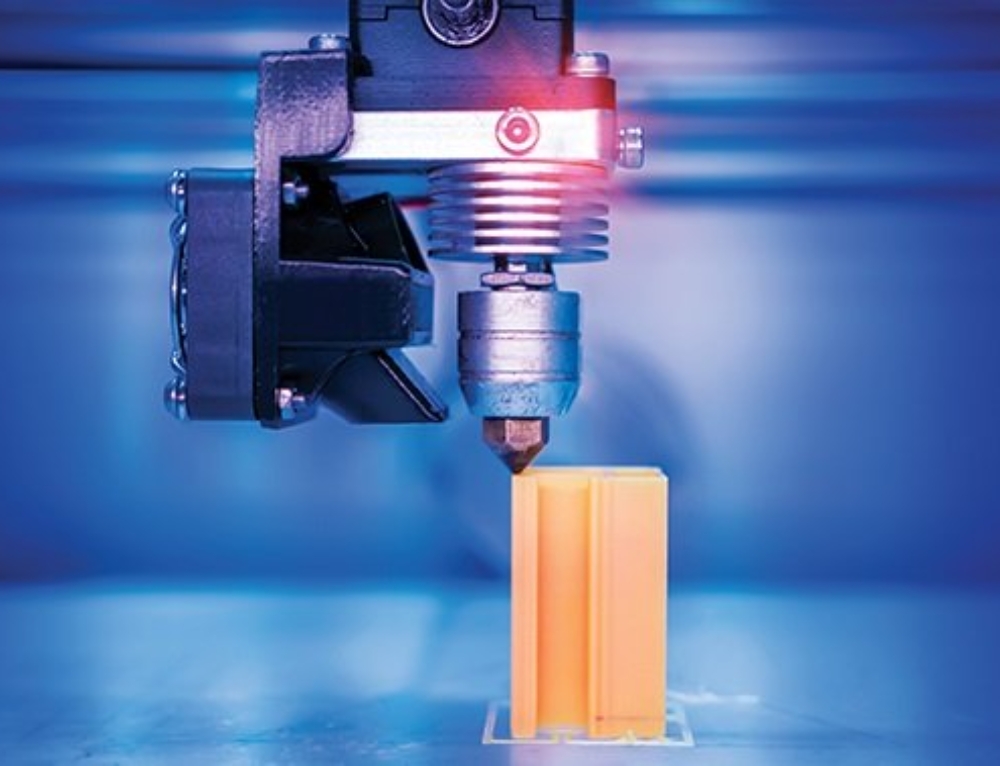

The 3D printer will begin printing layers of material in a process known as material extrusion. Depending on the type of 3D printer and the material used, there are several methods for material extrusion.

3D printer nozzle.

Most commonly, a 3D printer has a nozzle that ejects a semi-liquid material such as molten plastic, metal, or cement. The extrusion nozzle can move both horizontally and vertically as it precisely places the material following the pattern of the digital model layer by layer. nine0003

The extrusion nozzle can move both horizontally and vertically as it precisely places the material following the pattern of the digital model layer by layer. nine0003

This process is repeated until the 3D printer has reproduced each layer of the extruded digital model.

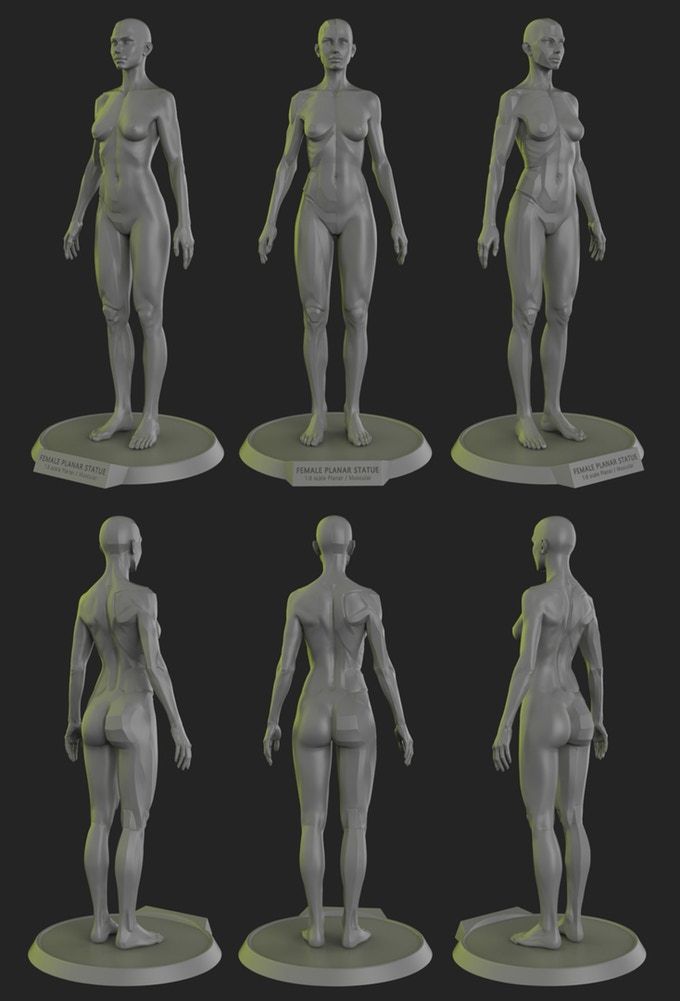

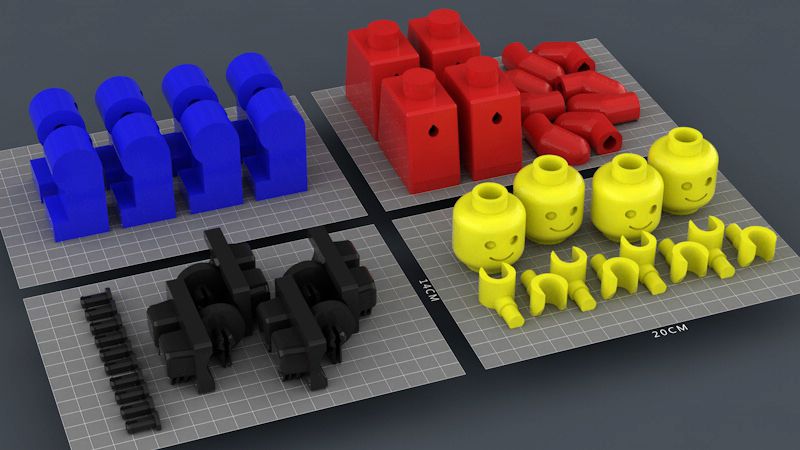

What kind of things can be done with 3D printers?

Almost anything you can imagine can be turned into a 3D printed design. 3D printers are helping designers, engineers, and even ordinary people create complex objects in ways that previous manufacturing methods were not capable of.

3D printers are being used to create toys, phone cases, tools, clothing, tables, lamps, pottery, art, and even cars. nine0003

Medicine is also finding new ways to use 3D printing to help patients. Physicians can now print 3D medical models that are so accurate that surgeons can essentially test-run a patient's 3D model before actually operating on that patient. 3D printed models are also being used to create less expensive, stronger and more suitable prostheses for people who have lost limbs.

7 benefits of 3D printing:

1. Cost optimization

Less equipment, material and labor costs.

Cost optimization is important for every business. One of the benefits is that when using 3D printing, operating costs, labor costs and material costs combined are lower than large-scale production.

Cost of the machine

The cost of operating the machine plays a very small role in the total cost of the production process. The energy required to create parts in an industrial environment can be expensive, but the ability to design and build complex parts and products in one step provides an increased level of efficiency and saves time. Thus, the cost of operating the machines is offset by the savings gained from speed. nine0003

Labor costs

The good thing about 3D printing is that labor costs are low. Compared to traditional manufacturing, where different people may be required to work on several different machines, or a production line is required to fully assemble a product. The printer will require an operator to start the mechanism and start the automated process of creating the loaded design. Consequently, labor costs are significantly lower than in traditional production. nine0003

The printer will require an operator to start the mechanism and start the automated process of creating the loaded design. Consequently, labor costs are significantly lower than in traditional production. nine0003

Material costs

The range of materials for 3D printers used for 3D printing is growing every day, and in recent years this has made it possible to optimize the final cost of the product even better.

Less transport costs

One of the biggest benefits of 3D printing is that it reduces the distance the product will have to travel. Because 3D printers can create a product from start to finish, this allows designers to design a product in one country and email it to another country to prepare for production. There is no need for prototypes to be moved from factory to factory to complete the process. This makes 3D printing an industry that can be created around the world without leaving a trace. Thus, there is a reduction in sea, air and road transport. nine0003

2. Less waste.

Less waste.

The traditional manufacturing process is basically a subtractive process in which raw materials are lost and reused over and over again, resulting in high costs and waste. The advantage of 3D printing is a unique way of creating a product with minimal waste, the so-called additive manufacturing. While more traditional methods involve waste that can be reused or recycled, it still takes time and effort to determine how and when this waste will be used. High volume 3D printers do it themselves. nine0003

Thermoplastic materials, for example, can be melted, solidified (cooled to become solid), melted again, solidified again, and so on. Thus, production "waste" can be reused.

3. Time Reduction

We live in a rapidly changing world where everything is for yesterday and this is where 3D printing can really make a difference. One of the big advantages is that parts and products can be produced much faster than using traditional methods. Complex designs can be created as a CAD model and then turned into reality in just a few hours. This embodies design ideas in a way that can be quickly tested and developed in a short amount of time. Whereas traditional methods can take weeks or months to get from design to prototype to production. nine0003

This embodies design ideas in a way that can be quickly tested and developed in a short amount of time. Whereas traditional methods can take weeks or months to get from design to prototype to production. nine0003

4. Competitive advantage

Businesses can create better, better, and more advanced products in a shorter amount of time, which provides a competitive advantage. It also allows you to develop products at an early stage, prototyping faster, which means the product will be invented, ready for production and market sooner. The ability to create a life-size prototype allows designers to think differently about the products they are developing. nine0003

The product is often left to the imagination. This increases the risk of losing information somewhere during the connection, which at some point can lead to serious problems. It is this natural value that will make it possible to speak with your partners, investors and clients in the same language. After all, you can not only talk about a product that will be produced in some time on the other side of the world, but also touch it. The probability that the produced product will not be able to satisfy the needs and agreements, will be expensive is quite high, which means it should be described as best as possible from the very beginning. One of the benefits of 3D printing is that it allows you to quickly create a concept that people can physically hold in their hands, eliminating any fear or misunderstanding. While this may only be a prototype and still open to change, it does at least give an idea of what the end result will look like, offering a more accurate representation than a description. nine0003

The probability that the produced product will not be able to satisfy the needs and agreements, will be expensive is quite high, which means it should be described as best as possible from the very beginning. One of the benefits of 3D printing is that it allows you to quickly create a concept that people can physically hold in their hands, eliminating any fear or misunderstanding. While this may only be a prototype and still open to change, it does at least give an idea of what the end result will look like, offering a more accurate representation than a description. nine0003

Test the market

Understanding whether a model will succeed requires a lot of research, especially when it comes to traditional production methods. However, prototyping with 3D printing will allow businesses to get feedback from potential buyers and investors like never before. The product can be customized and changed right up to the very last minute, which traditional production methods do not offer. This means that 3D printing offers a unique and valuable way to determine if a product has the potential to go to market and be successful at the same time. nine0003

This means that 3D printing offers a unique and valuable way to determine if a product has the potential to go to market and be successful at the same time. nine0003

5. Error reduction

When it comes to designing parts and products, designers must consider efficiency. The production of many parts and products requires a large number of steps using traditional production methods. Therefore, each step can lead to an error with the risk of restart, which will lead to problems with the overall production process. A one-step manufacturing process is more advantageous.

There are many industries that have a long and drawn out production process. Where some of the steps are to create a CAD model and then develop a prototype which may require adjustments before it is finally sent to final production. This is a process that takes a lot of time, and none of the steps can be skipped, since they all play a role in the production process. However, one of the advantages of 3D printing is that it creates a product in one step, without interaction with operators during this process. You just need to finalize the design and upload it to the printer. This eliminates dependency on a range of manufacturing processes and enhances control over the final product. nine0003

You just need to finalize the design and upload it to the printer. This eliminates dependency on a range of manufacturing processes and enhances control over the final product. nine0003

In the traditional manufacturing process, failed prototypes cost time and money. With every wrong prototype you have to go back to the drawing board and there is no guarantee that it will be right the second time around. Even small adjustments have a significant financial and time impact on the entire process. This is where 3D printing can eliminate risk, as designs can be tested by creating a production-ready prototype before proceeding to final creation. This helps build confidence in the design before investment is made and extra money is paid out to take it to the next level of mass market production. nine0003

6. Privacy

Continuous prototyping and production on our own 3D printer ensures that designs never leave the company's premises, protecting your intellectual property. No third parties can ever claim your innovations. Every innovative design is kept in-house, so you don't have to worry about privacy anymore.

Every innovative design is kept in-house, so you don't have to worry about privacy anymore.

7. Custom Made

The freedom to design is one of the great benefits of 3D printing. Because 3D printing is ideal for one-off production and the creation of individual parts in a single process, this means you can take advantage of the opportunity for customization. Therefore, many industries such as medicine and dentistry are using 3D printing and design because of the ability to create customized implants and aids. In fact, sports equipment can be created specifically for athletes, and thus individual details can be created in a way that has never been done before. nine0003

Traditional methods relied on shapes and cutting, making the tuning process very labor intensive. In contrast, customizing 3D printed products can have improved structural integrity, make complex changes, and change parts to meet specific requirements. This setup gives 3D printing endless possibilities.

Disadvantages of 3D printing:

1. Initial cost of the printer

Initial cost of the printer

You need to buy a 3D printer, and even though the return on investment will be fast and high, the initial investment must be made. nine0003

2. Post-processing

A 3D printed object in most cases requires some post-processing.

3. Print time

When it comes to producing many objects, 3D printers are slow compared to other manufacturing technologies. Aside from mass production, another disadvantage is the long print times for single prints. Depending on the size and quality of the printer, printing can take anywhere from a few hours to a few days, but if the printer fails when it's almost finished printing, you'll have to start over. However, by making sure the 3D model and print file are well designed and cut, and the printer is set up correctly, you can almost guarantee that the print will be perfect. nine0003

4. Special skills are required to work with 3D models.

Once you have purchased a printer, you must learn how to create and modify 3D models. 3D modeling is a skill that takes a lot of time and effort to fully master, a process of trial and error. But once you learn how to use the program, you can print whatever comes to your mind.

3D modeling is a skill that takes a lot of time and effort to fully master, a process of trial and error. But once you learn how to use the program, you can print whatever comes to your mind.

5. Job Loss in Manufacturing

As we mentioned in the Benefits of 3D Printing, this technology allows you to create product designs and prototypes in a matter of hours because it only takes one step. This eliminates many steps that are used in traditional manufacturing. Due to this, no large labor costs are required. Thus, the introduction of 3D printing can lead to a reduction in manufacturing jobs. For countries that rely on large numbers of low-skill jobs, job cuts in manufacturing can have a big impact on the economy. However, it is likely that robotics will have a much greater impact here. nine0003

Conclusion

For any business, their customers are the key to success, so customer satisfaction becomes an important part of their strategy. By staying ahead of the competition and giving customers what they want, industrial 3D printers have changed the way businesses deliver exactly what they need. Customer expectations have changed because they want to receive goods quickly and efficiently.

Customer expectations have changed because they want to receive goods quickly and efficiently.

The benefits of 3D printing are wide and varied. Many industries are starting to incorporate 3D printing into their processes in an attempt to capitalize on the technology in a variety of ways. This is a technology that has grown significantly in recent years and will continue to grow as it continues to improve on what it has to offer. When you consider all the advantages of 3D printing, it becomes obvious that it will soon become a technology that will overtake traditional methods. It's just a matter of time. nine0003

It is the ability to print complex shapes and interlocking parts without the need for any assembly that makes 3D printing so unique. It is possible to create small complex shapes at very low cost and in a short amount of time. The ability to design and manufacture objects of various shapes without the need for special tools provides businesses with a higher level of flexibility when it comes to manufacturing and helps reduce costs. The strength of 3D printing is that it promotes innovation and is ideal for on-demand customization. This gives businesses the ability to design and build products like never before. A process that allows the imagination to be free because there are almost no boundaries. It can bring old designs back to life for a number of industries where parts are obsolete. nine0003

The strength of 3D printing is that it promotes innovation and is ideal for on-demand customization. This gives businesses the ability to design and build products like never before. A process that allows the imagination to be free because there are almost no boundaries. It can bring old designs back to life for a number of industries where parts are obsolete. nine0003

3D printing is a rapidly growing industry with great potential for the future. We have just begun to understand how 3D printed objects can make our lives easier, more convenient, safer and healthier. And because 3D printing is advancing as fast as people can come up with new designs to print, it may not be long before we live in a world where you can 3D print your lunch, a tailored shirt, or repair parts. everyday items. all without leaving your own home. nine0003

The Fialan team will help you realize your wildest projects and ideas.

Regardless of the scale and specification - the savings in purchasing in China not only a 3D printer, but also equipment for such niches as medicine, CNC, cafes and bars, warehouse equipment and many others will cost you up to 30% cheaper compared to the domestic market.

You can learn more about profitability and get professional advice at the link: equipment for business. nine0003

Also, please call +38 (044) 290‑76‑11

The positive impact of 3D printing on our health and the environment essay example

In a couple of decades, 100 billion land animals will be needed to supply the world's population with meat, dairy products , eggs and leather goods. The continuation of the livestock population could lead to huge, perhaps unsustainable, losses on our planet.

In addition, research shows that 11 million people will have diabetes in 2025. To make matters worse, another study suggests that the number of people who will have diabetes in 2025 will double to 22 million (Boyle et al., 2001). Today, about 315 million people in the world suffer from diabetes. Many people think that diabetes is caused by eating sugar, this is a hoax. Diabetes is actually caused by eating a typical diet based on meat and animal products. nine0003

Both of the above problems can be solved with one simple change in our diet. Meat and animal products are almost indispensable in our diet, but there may or may not be another way.

Meat and animal products are almost indispensable in our diet, but there may or may not be another way.

3D printing is a revolutionary technology that is helping to create completely new approaches to design and manufacturing. Especially for implications in the geopolitical, economic, social, demographic, environmental and security sectors (Campbell, Williams, Ivanova, & Garrett, 2011). 3D food printing is currently limited by high costs, time, and volume (Lin, 2015), but 3D printers will soon become faster, cheaper, and more accessible to the general public and households. nine0003

In the future, 3D printers will be able to print just about any food imaginable, including foods we eat a lot like fruit, pasta, chocolate, and even chewing gum. In addition, food that cannot be found in nature, such as edible growth. And we will be able to print personalized food (Tran, 2016).

Looking at the amount of research that is and is still being done regarding 3D printing technology, and when we look at what is already possible with 3D food printing, I believe that 3D printing will have a big positive impact on our health and the environment, eliminating much of the agricultural sector worldwide. nine0003

nine0003

With a focus on society's food choices, there are several trends. People are becoming more conscious of their choices and believe that food can benefit both their health and the environment. To show their awareness, people are starting to pay more attention to healthy food and sustainable food.

In the past two decades, increasing environmental awareness, animal welfare and worker safety are seen as trends in human society, causing people to question modern farming practices. This is reflected in the growing demand for organic and sustainable products, which are perceived as being less harmful to the environment than conventional foods (Saba & Messina, 2003). Consumer concern for the environment appeared in the late 60s. This has led to a general distrust of society, industry and modern technology. These interested consumers can be defined as those who know that the production, distribution, use and disposal of products lead to external costs, and who evaluate such external costs negatively. These people try to minimize this negative effect by changing their eating behavior (Grunert & Juhl, 1995). One of the behavioral changes is the purchase and consumption of sustainable food. In the process of creating environmentally friendly and environmentally friendly products, the use of chemicals and pesticides is excluded. These substances are considered harmful to the environment. Unfortunately, the prices of organic and organic foods are notoriously high compared to conventional food products. This leads to the fact that buying and consuming organic products is not an option for many people. Through carbon dioxide, methane and nitrous oxide emissions, agriculture is responsible for about one-fifth of the annual increase in human-caused greenhouse gas emissions, which contributes to global warming (Grasty, 1999).

These people try to minimize this negative effect by changing their eating behavior (Grunert & Juhl, 1995). One of the behavioral changes is the purchase and consumption of sustainable food. In the process of creating environmentally friendly and environmentally friendly products, the use of chemicals and pesticides is excluded. These substances are considered harmful to the environment. Unfortunately, the prices of organic and organic foods are notoriously high compared to conventional food products. This leads to the fact that buying and consuming organic products is not an option for many people. Through carbon dioxide, methane and nitrous oxide emissions, agriculture is responsible for about one-fifth of the annual increase in human-caused greenhouse gas emissions, which contributes to global warming (Grasty, 1999).

3D printing can help solve this environmental problem by eliminating a large part of the agricultural sector (Tran, 2016). This will be done by printing products instead of using land to grow products. Instead of growing different types of food, the agricultural sector will now focus on the production of various ingredients. This change in the sector will ensure that the human footprint on our planet is very much limited, and therefore reduce climate change (Tran, 2016). nine0003

Instead of growing different types of food, the agricultural sector will now focus on the production of various ingredients. This change in the sector will ensure that the human footprint on our planet is very much limited, and therefore reduce climate change (Tran, 2016). nine0003

On the other hand, this change will also have a downside. If agricultural practices are completely changed or completely replaced, this will have a significant impact on our ecosystems (Tran, 2016).

Nutrition is the most important health impact throughout life (Kussmann & Fay, 2008). More and more people are realizing the importance of their health and are paying more and more attention to their diet. There are also many people who need a special, personalized diet. This may be due to dietary needs, allergies, or even personal taste preferences. Malnutrition is one of the main causes when it comes to unreached genetic potential, decreased physical and cognitive risk scores, and increased risk of certain diseases (Milner, 2002). Diabetes, the artist, heart disease, dementia, obesity and cancer together account for 70% of all causes of death. All these diseases are associated with lifestyle, and therefore each of them can be prevented. Speaking of these diseases, all animal products play a leading role. Diabetes expert and researcher Dr. Weir Bernard claims that diabetes is caused by a diet that accumulates fat in the blood, indicating a typical diet based on meat and animal products. In addition, Harvard conducted a study in which they looked at 9studies, finding that just 1 serving of processed meat a day increased the chance of diabetes by 51%. In addition to this, a study based on 800 studies from 10 different countries shows that there is a direct link between processed meat consumption and cancer (Andersen & Kuhn, 2016).

Diabetes, the artist, heart disease, dementia, obesity and cancer together account for 70% of all causes of death. All these diseases are associated with lifestyle, and therefore each of them can be prevented. Speaking of these diseases, all animal products play a leading role. Diabetes expert and researcher Dr. Weir Bernard claims that diabetes is caused by a diet that accumulates fat in the blood, indicating a typical diet based on meat and animal products. In addition, Harvard conducted a study in which they looked at 9studies, finding that just 1 serving of processed meat a day increased the chance of diabetes by 51%. In addition to this, a study based on 800 studies from 10 different countries shows that there is a direct link between processed meat consumption and cancer (Andersen & Kuhn, 2016).

Personalized nutrition can meet the needs and preferences of an individual's health status and body type. With our traditional food supply chain, personalized nutrition comes with additional costs. This is because products with controlled ingredients are much more difficult to manufacture. nine0003

This is because products with controlled ingredients are much more difficult to manufacture. nine0003

This is where 3D food printing can come in handy. There are already several organizations that are working on personalized 3D printed food. The first personalized meals will likely start with a simpler structure, such as bars, that will include our essential daily nutrients and vitamins (Tran, 2016). If long-term investment is made in research towards personalized nutrition, there is a possibility that in the future it will be able to provide each individual with exactly the right nutrition that he needs (Tran, 2016). More importantly, we will all have a 3D printer in our home that can receive information about us and use that data to print products appropriately (Lin, 2015). When 3D printing is ultimately designed so that we can print anything, the production of meat and animal products may be out of the question. This will result in people not eating or reducing their intake of an animal-based diet, and thus it is possible that the chances of cancer, diabetes, and cardiovascular disease will be drastically reduced. nine0003

nine0003

In conclusion, I can say that the agricultural sector is a major player in both negative climate change and our health. Both of these negative effects can be reduced by changing the diet of the population. If people reduce their consumption of meat and animals, our health and environment will change for the better.

With developments in the 3D printing industry, 3D food printing can help us reach our goal of living a healthy and sustainable life. This is of course the preferred future scenario for those who really want to live this way. Only for those who are not informed about these issues, it is unlikely that they will stand aside from meat and animal products. With the right information and the right way to spread that information, everyone can choose sustainable and healthy food by choosing 3D printed food. nine0003

Sales folder print

10/07/2020 No Comments

Printing a sales folder can be a salesperson's best friend. Printing these informative folders gives companies a reason to invite a potential client to a meeting.