Pop it 3d print

Funko Pop 3d Print - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(234 relevant results)

25+ 3D Printed Fidget Toys You Can Print Today

Fidget spinners and fidget toys took over the world at their popularity peak, and they’re still very commonly sought and seen today. It’s easy to see why, there’s just something really fun about idly doing something that requires little effort or even thought that’s somehow satisfying.

3D printed fidget toys add to this satisfaction by being toys and spinners you can make and customize yourself. Sometimes they’re recognizable fidget spinners, sometimes they’re unique spins (get it?) on little desk ornaments that you can play with when you’ve got a free hand or two.

While the classic fidget spinner is the most popular, there’s a surprising variety of fidget toys out there. From spinners to cubes, and even small anxiety helpers, there are a lot to choose from.

I know I’m sick of dropping pens I wasn’t even aware I was holding and wondering what that floorboard noise is before realizing it’s my own unconsciously bouncing leg. So we’re going to look at some cool 3D printable fidget toys to keep your hands occupied and your mind at ease.

3D Printed Fidget Spinners

Beginning with the classic, despite their initial patent being granted in 1997, fidget spinners became an overnight global sensation back in 2017. Suddenly everyone had or wanted one, and they became a staple of school playgrounds and office buildings alike.

Suddenly everyone had or wanted one, and they became a staple of school playgrounds and office buildings alike.

By 3D printing your own fidget spinners, you can create your own rendition of these suddenly popular wonders, and here are a few of my favorites.

Customizable Caps

Pretty much any 3D printing project is in some way customizable, but it’s always cool when the design itself incorporates changeable shapes and parts to suit your mood or taste. While small, the changes you can make with the different caps in this design are pretty cool.

By printing the caps in different colors or adding different designs to each shape, you’ll effectively 3D print several fidget spinners in one!

Jet Engine Fan Fidget Spinner

Just like fidget spinners themselves, there’s something almost hypnotic about watching a whirring fan. Combining the two, this design is for a 3D printed fidget spinner that looks just like a jet engine fan!

The space between the fans is replicated with indents that curve inwards, giving the illusion of a working turbine. It’s a really clever design given its simplicity, and is satisfying to use too! If you like the design but want something a little closer to a standard fan, then why not check out this turbofan fidget spinner?

It’s a really clever design given its simplicity, and is satisfying to use too! If you like the design but want something a little closer to a standard fan, then why not check out this turbofan fidget spinner?

Celtic Infinity Knot

What is it about modern spins on old designs that give new life to traditional images? I don’t know, but I will tell you that I love it.

The Celtic Infinity Knot 3D printed fidget spinner is one of my favorites. Despite it being a centuries-old depiction of the trinity, its shape lends itself very well to a 3D printed fidget toy, and this design is one of the best around.

The layered design is simple but elegant, and it looks cool even as a desk ornament when not in use. Whether you recognize the Triquetra from a Celtic upbringing or just from Thor’s hammer, this is an undeniably cool fidget spinner to 3D print.

Pokéball Fidget Spinner

In 2016, around a year before the boon of fidget spinner popularity, the world was introduced to a similarly explosive fad, Pokémon Go.

Given the coincidence of these two pop culture storms, it’s not surprising that some people blended them together. This teacher realizes their students were obsessed with both, and so designed this 3D printed Pokéball fidget spinner for their class!

The iconic red and white design blends together while spinning to make a satisfyingly hypnotic view. All-in-all, it’s a great 3D printed fidget toy for any Pokémon fan!

3D Printed Fidget Cubes

Another popular variation on the 3D printed fidget toy is the fidget cube. They’re significantly younger than their spinning counterparts, only becoming commonplace in 2012, but their simple designs lend themselves well to 3D printing.

Fidget cubes also rarely rely on the inner mechanisms common to fidget spinners, so are arguably easier to print and assemble.

Like their spinning siblings, fidget cubes come in a few varieties, and so you’ll want to pick your favorite.

Original Fidget Cube

Based on the fidget cube’s debut style, this original cube is an easy fidget toy to 3D print and tinker with.

It’s easy to see why this 3D printed fidget cube is one of the most popular toy designs out there. It’s simple, it’s fun to put together, and it’s satisfying to use.

The different sides all have what you’d expect from a fidget cube, a smooth indent on which to rub your thumb, a notch-guide like a one-path maze, and a little wheel to turn.

If you, like me, often find yourself rolling a pen between your fingers or thumbing the notches in your computer mouse, then you’ll find this simple 3D printed fidget cube to be a relaxing addition to your desk.

Fidget Spinner Cube

Fidget spinners and fidget cubes are not mutually exclusive concepts, as this design for a fidget spinner cube shows.

As the name suggests, this is a 3D printed fidget cube designed to spin like a fidget spinner at the press of a button. If you’ve ever flicked some dice on a table just to watch them spin on their edges will tell you that it looks pretty cool as it forms an unmistakable diamond shape.

If you feel like getting creative, then why not tweak this design to include lights, brighter colors, or even images that can blend as it spins?

Kobayashi Fidget Cubes

Kobayashi fidget cubes are a set of interlocking parts attached by hinges that can be rotated and moved to make different shapes. They’re popular as fidget toys and make for very satisfying 3D printer projects. Think of them as plastic origami sets, that’s what I do.

A good example of these 3D printed fidget toys is this fidget star design that form different shapes depending on where you bend the hinges. They’re a fun play with without needing to pay too much attention.

For something more traditional, there’s also this Kobayashi cube design that goes from a snake to a cube and everything in between with the right movements, making an excellent fidget toy that won’t drive you crazy.

Puzzle Cubes

3D printed fidget toys don’t all need to be used idly, some are designed to be looked at and figured out while you fidget. The most famous example of this is the Rubik’s Cube, but not all puzzle cubes need to be so mentally taxing (or is that just me?)

The most famous example of this is the Rubik’s Cube, but not all puzzle cubes need to be so mentally taxing (or is that just me?)

It’s strange to think of puzzles as fidget toys, but the distinction is narrow enough to believe. Some 3D printed fidget cubes involve color coordination like this one.

There’s also this easy-print puzzle cube that operates like a 3D jigsaw. It’s simple but finicky enough to offer the kind of mild distraction you might be looking for. It can even be a good toy for young children if you print it big enough.

Similar to it is this ‘Identical Twins’ puzzle cube that makes a great 3D printed fidget toy that’s easy to make and a little trickier to put together to make a satisfyingly neat shape.

If you want something a touch more complex, I really like this double cube design that shifts and shapes similar to an old-school ‘cootie catcher’ that many of us played with as kids.

Rotating Fidget Toys

Most 3D printed fidget toys will rotate or pivot in some shape or form, but there are few sights more inherently gratifying than seeing cogs and gears work together in perfect sync.

If you’re careful with the measurements and make sure they fit just right, you can make some awesome 3D printed fidget toys with moving gears.

Epicyclic Fidget Toy

Starting with one of the coolest designs, this epicyclic fidget toy goes a little beyond the standard ‘move a lever and watch it go’ format.

The dome-like handle makes it easy to hold while you fidget away. An excellent toy for procrastinators, and fun to mess with, I recommend getting these little pieces printed and moving before you chew the end off another pencil.

Simple Gear Toy

While more of an educational trinket, this easy-to-make gear toy is no less a 3D printed fidget toy to get started.

Ideal for beginners or people who want to introduce their children to the fundamentals of mechanics, it’s a great little pocket toy to 3D print and fiddle with when you find yourself idle.

Similar to this but a touch cooler is this multi-directional gear toy that’s just as easy to print. Personally, I find it stands out because it looks like Batmobile wheels if printed in black, but that might just be me.

Personally, I find it stands out because it looks like Batmobile wheels if printed in black, but that might just be me.

Bevel Gear Toy Set

Beveled gears have always looked cool to me, so I had to mention this beveled gear toy set as a 3D printed fidget toy option that’s a little bigger than most but no less worthy of a place at your workstation.

It’s only large in its standard size, but provided you keep the ratio equal; you can scale it to be any size you want. It’s a simple concept of moving a gear around a printed circle that’s notched to match the gear’s teeth.

Elliptical Gears

Like most 3D printed fidget toys, elliptical gears are really cool to look at. With their often-oval shape and lack of central pivots, they move and turn in hypnotic ways like how you’d imagine one of DaVinci’s flying machines would look.

There are plenty of cool examples of elliptical gears as fidget toys you can 3D print. This easy shape is a good early project if you’re new to 3D printing, or you can opt for the standard egg shape like the one found here to satisfy your procrastination needs.

If you want to get fancy, then you should check out this four-way elliptical gear set that’s just like a fidget spinner you move yourself. With enough color variation and some intricate fingerwork, it makes for an awesome 3D printed fidget toy.

Fun Fidget Gear Designs

3D printed gear fidget toys don’t need to always look like they were taken from a gutted machine. Some designers have gone out of their way to make fidget toys that resemble recognizable shapes and icons.

These heart gear fidget toys are excellent examples of this. Heart ornaments are common just about anywhere, so why not make one you can fidget with? I don’t recommend giving them as Valentine’s gifts, however, as their fractured look might give the wrong impression!

If you love this design, then there’s also this micro gear heart that works well as a keyring so you can fidget on the go. Or go the other way and get yourself printing and assembling this massive version to show just how much you love to fidget!

I also love these updated gear cube designs which combine the fun of gear mechanisms with the intricacies of a puzzle cube.

As a Whovian, I can’t talk about cool fidget gear designs without mentioning my personal favorite, this geared Tardis fidget toy that resembles the good Doctor’s iconic time machine!

You may also be interested in:

- 30 easy and fun things to 3D print

- 30+ cool 3D printable toys

- 50+ coolest things to 3D print

- 3D printed RC planes

- 3D printed RC cars

- 3D printed dice files

- 3D printed dice tower files

- 3D printed fishing lures

- 3D printed wallets

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared.

However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself. The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

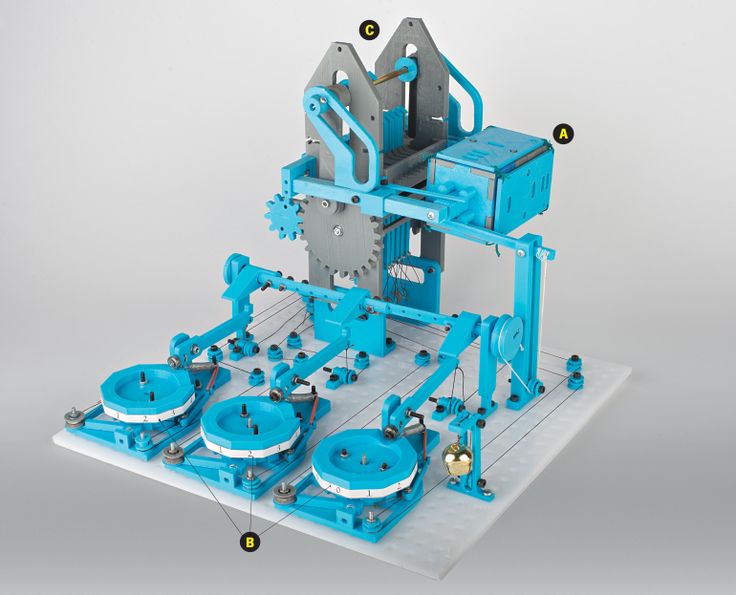

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas. At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards "green agenda " is developing, reducing CO2 emissions, building with more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element.

That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

3D printed wind tower. 3D printed wind tower. Construction 3D printing, or, as it is also called, additive construction, has just appeared, and I want to believe in its bright future. There are many prerequisites for this, but a lot still needs to be done for success. First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing could help solve the global housing shortage and bring more automation to other areas of construction.

First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing could help solve the global housing shortage and bring more automation to other areas of construction.

Alexander Kornveits

Expert in the field of additive technologies and 3D printing, head of the Tsvetnoy Mir company

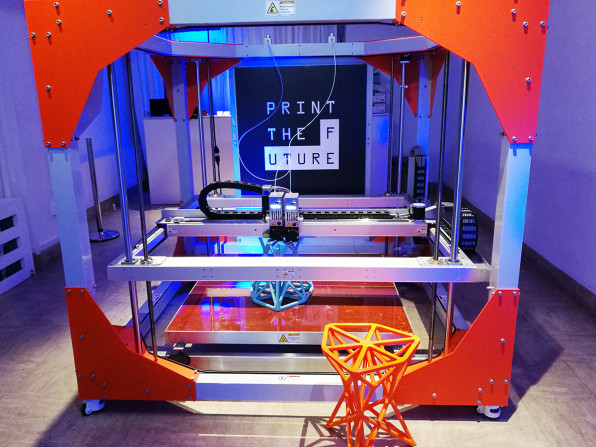

What is 3D printing and how it can be used! Interesting!

What is 3D printing

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

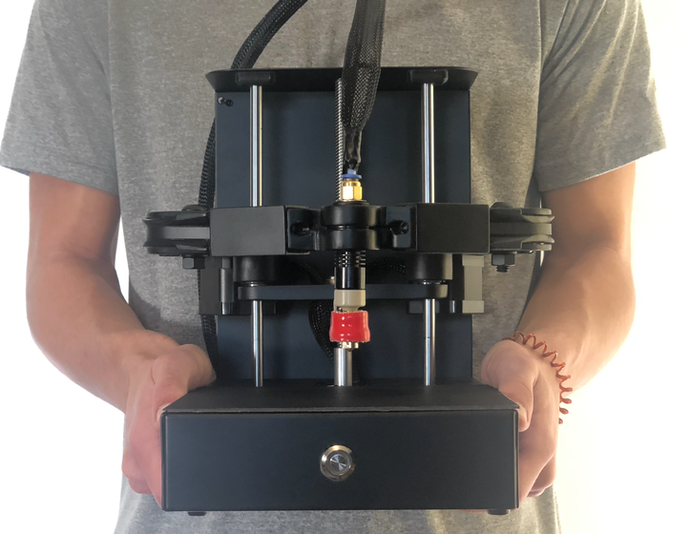

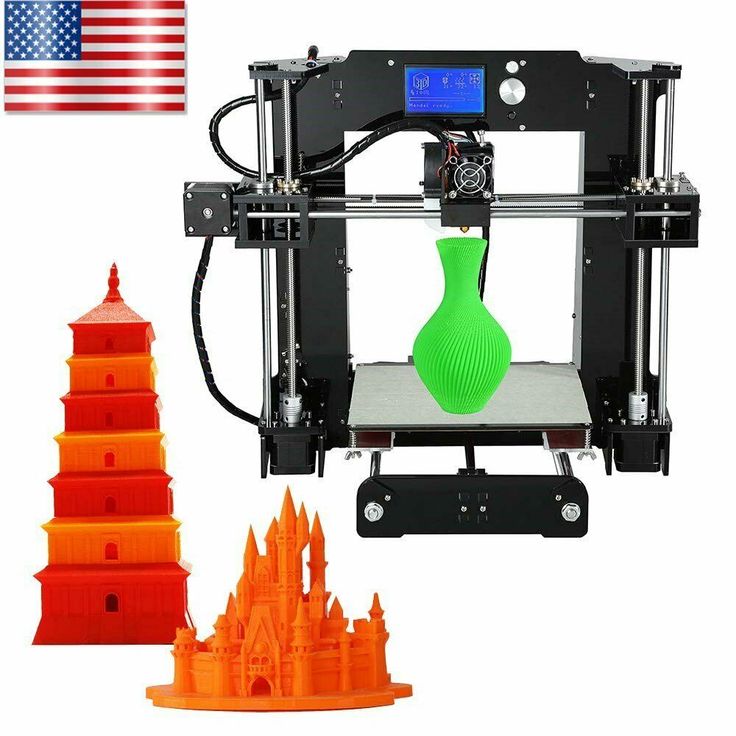

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to the 3D printer;

- The 3D model is reproduced.

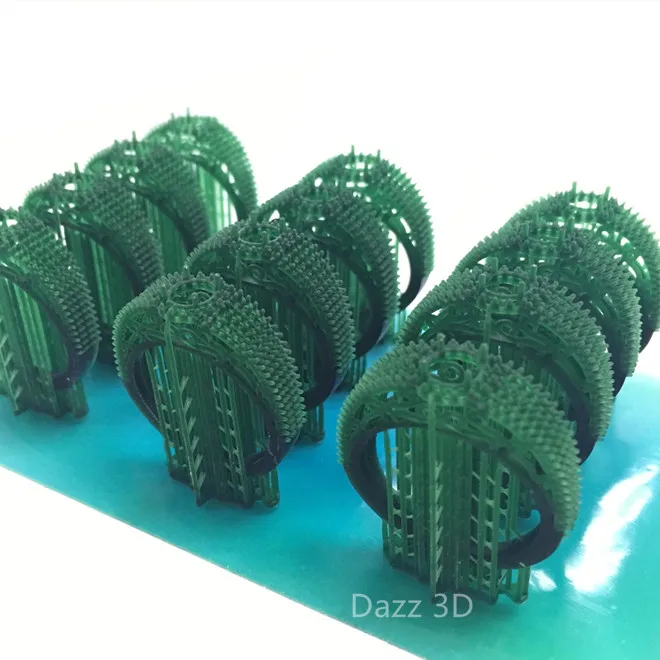

Objects are rendered gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique.

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Different 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) .

One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic;

One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic; - Laser stereolithography (SLA) . The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage;

- Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

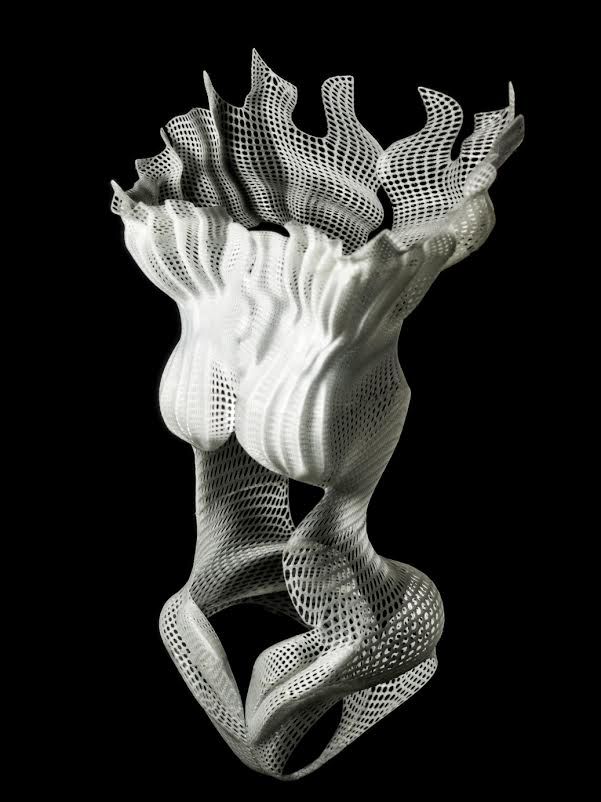

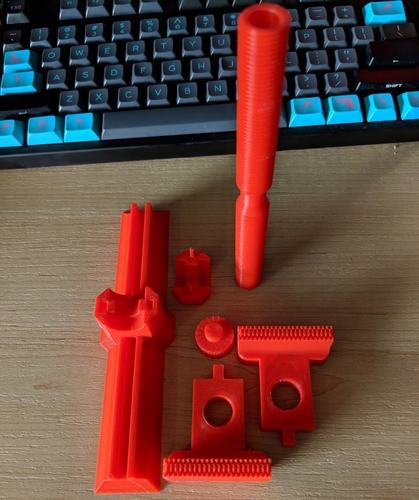

As you may have guessed, the applications of 3D printing are extremely wide. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.