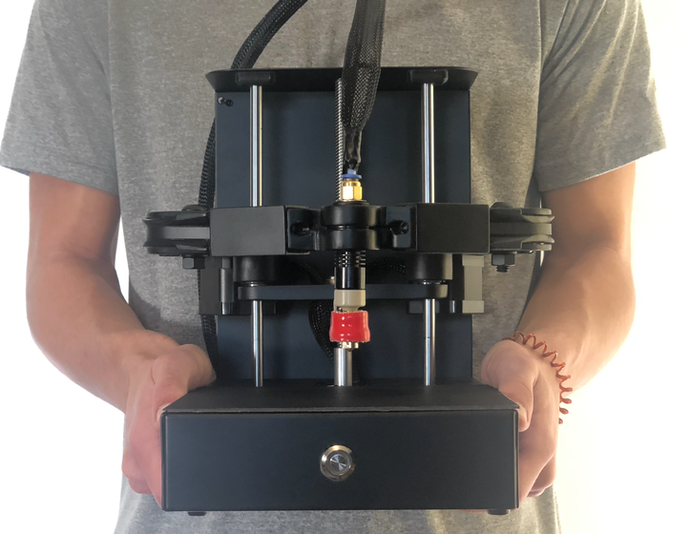

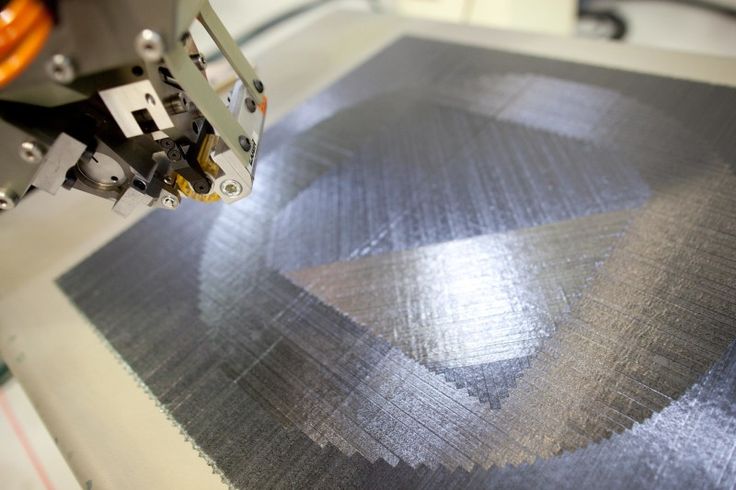

Mark one carbon fiber 3d printer

Onyx One Desktop 3D Printer

The FFF desktop 3D printer for tough, high quality Onyx parts.

Request a Quote

A bulletproof desktop 3D printer designed by engineers for engineers — the Onyx One prints accurate, beautiful, manufacturing-grade parts.

An FFF Printer for Engineers & Designers

The Onyx One brings professional-grade reliability, part quality, and accuracy to a desktop FFF form factor. Hit print and get a quality part out every time.

Built to Last

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

Precise, Beautiful

Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber filled nylon material.

Specs

Precision-built so you can 3D print precise parts.

Physical Dimensions

| Width | 584 mm |

| Depth | 330 mm |

| Height | 355 mm |

| Weight | 15 kg / 34 lbs |

Build Volume

| Width | 320 mm |

| Depth | 132 mm |

| Height | 154 mm |

Printer primary Specs

- Printing Process

- Fused Filament Fabrication (FFF)

- Z Layer Resolution

- 100 μm - 200 μm

- Printing Media

- Composite Base Filaments

- Internal Part Geometry

- Closed Cell Infill, Triangular Default

- Print Bed

- Precision Ground Composite

Materials

Compatible Materials

System Details

About the Onyx OneThe Onyx One is an advanced FFF desktop 3D printer – built to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Onyx One to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

Download Datasheet

Materials

Print with Onyx — the most versatile FFF material on the market.

Intuitive, powerful, FFF 3D printing software for your desktop machine.

Software

3D Printing Software Meets Production Management

Design your part, upload it into our browser-based software, and hit print. It's that simple.

Try It Yourself

Process

Simple FFF Process. Robust Parts.

Request a Quote

4

Talk to an expert Request a demo Try the softwareIndustrial Additive Manufacturing Platform | Markforged

The Digital Forge Platform

Our smart platform makes it easy to solve tough manufacturing problems.

Precision machines that consistently improve.

See all printers

Metals. Continuous fiber. Composites. All at your command.

See all materials

Software that dovetails into your workflow.

Learn more

Turnkey Simplicity

The Digital Forge is purpose-built to integrate quickly and seamlessly into your manufacturing ecosystem.

Robust Parts

Print repeatable, production-quality parts using materials curated for durability and strength.

Perpetual ROI

See returns in weeks, not years. Keep increasing your bottom line with consistently improving machines and streamlined operations.

Unlocked Potential

Transform your supply chain, unleash workforce creativity, and create a culture of innovation.

News & Insights

Resources

-

News & Events

Markforged to Expand into Mass Production of End-Use Metal Parts Through Digital Metal Acquisition

-

Learn Blog

AM Forward Program: Everything You Need To Know

Everything you need to know about the federal Additive Manufacturing Forward program launched in May 2022.

-

Learn Blog Customer Success Stories

Vestas

Vestas is a global leader in wind energy using Markforged’s Digital Forge additive manufacturing platform in support of its direct digital manufacturing (DDM) program to free up manufacturing processes from relying on outside suppliers and provide a knowledge base for collaboration.

-

News & Events

Markforged Expands Software Offering with Acquisition of Teton Simulation Software

-

Learn Blog

Introduction to Eiger™ Fleet

Eiger Fleet, a cloud-based software solution, is designed to accelerate the adoption of and streamline additive manufacturing operations at scale.

It offers increased operational efficiency and visibility, enterprise-level access management, and simplified workflows.

It offers increased operational efficiency and visibility, enterprise-level access management, and simplified workflows. -

Learn Blog

What are the Benefits of Adopting Metal 3D Printing? Business Side and Technical Benefits

Metal 3D printing correctly can greatly improve business efficiency and agility — whether through eliminating the need for detail drawings and machine programming, or drastically shortening lead times that bog down product development processes. Learn about the full range of business and technical benefits.

We work with

Talk to an expert Request a demo Try the softwareLet’s get started.

New MarkForged 3D printer prints carbon fiber

Looking for a way to quickly make replica car parts? Gregory Mark invented a 3D printer that uses lightweight and durable carbon fiber to print.

Gregory Mark, co-owner of Aeromotions, created wing printing technology to drive a racing car. They need to be light but strong, so carbon fiber is a good material to use. This material is suitable for the manufacture of other parts of racing cars. But using it to create spare parts is not so easy. Until now, the only approach has been to use CNC machines, which work according to rather complex schemes. But even this approach did not exclude manual fine-tuning.

Mark drew attention to 3D printing, which seemed to him promising for solving this problem. But none of the printers available on the market could create carbon fiber parts. And other materials were not suitable for these purposes. So Mark had to come up with his own solution: the MarkForged Mark One, the world's first 3D printer to use carbon fiber as a raw material.

But none of the printers available on the market could create carbon fiber parts. And other materials were not suitable for these purposes. So Mark had to come up with his own solution: the MarkForged Mark One, the world's first 3D printer to use carbon fiber as a raw material.

He presented a working prototype at SolidWorks World 2014 in San Diego. The Mark One printer can create parts from carbon fiber, fiberglass, nylon, and some other thermoplastic polymers.

According to the developer, the idea is taken as a basis that it is possible to create parts by successively stacking fibers one on top of the other. This allows you to gradually form the composite part.

The MarkForged printer is astonishingly simple. With an anodized aluminum body and a transparent print table, it looks like a Mac among 3D printers. The Mark One uses kinematic linkage to level the stage, so the user does not have to check if the machine is level after each printed part. In addition, it is very compact and easily fits on a regular table.

But first of all, the inventor points out that Mark One can create parts that are 20 times stiffer and 5 times stronger than using ABS. In addition, it has a higher strength to weight ratio than CNC machined aluminum parts. For example, the wing of a racing car is formed from a nylon shell and a carbon fiber filling laid in a honeycomb pattern. Mark believes that his device will be used by all those people who have previously had to make parts from aluminum, due to its strength and lightness. In addition to racing cars, this technology may be in demand in the manufacture of prostheses.

The Mark One is intended to be used for non-commercial purposes only. Mark believes the $5,000 price point makes carbon fiber 3D printing affordable for a wide range of consumers. He says that this material is known to almost everyone, but few have ever used it. Therefore, the developer tried to make the price affordable for many. Those who wish can evaluate the possibilities of this technology for creating various parts, devices, tools and prostheses.

It should be noted that the emergence of a printer capable of using carbon fiber for 3D printing is a huge step for this segment. Until now, the choice of materials has been limited to a narrow set of polymers, and this has not allowed the wide use of this technology. The developer notes that MarkForged can also help at the prototyping stage in the manufacture of aluminum and carbon fiber parts. With it, you can create more accurate models.

The MarkForged Mark One will be available for pre-order in February. On the company's website, you can subscribe to the newsletter and do not miss this moment. Delivery of finished products will begin in the second half of 2014.

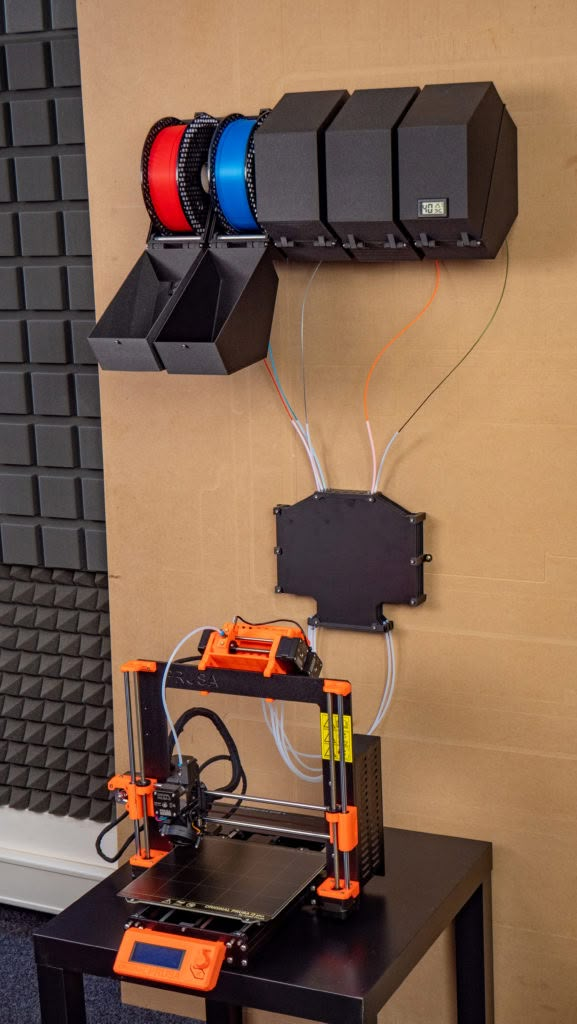

Markforged Mark Two 3D Printer Used equipment

- Description

- Detailed information

- About this seller

Selling Markforged Mark Two continuous carbon fiber 3D printer for idle. The printer is ideal for rapid prototyping of carbon nylon and continuous carbon fiber structural parts and fixtures (320x132x154mm working area). The device is in perfect condition, the total print run is less than 500 hours, the printer comes with:

The printer is ideal for rapid prototyping of carbon nylon and continuous carbon fiber structural parts and fixtures (320x132x154mm working area). The device is in perfect condition, the total print run is less than 500 hours, the printer comes with:

5 bobbins Onyx Black (carbon-filled nylon)

3 coils 150cc cm of continuous carbon wire, one of which is partially used on the machine

Kevlar, HST glass fiber, glass fiber and carbon fiber spools (partially used) 50 cc

Replacement nozzle kit, fiber and thread

All original accessories

Original box included

This description can be translated automatically. Please contact us for more information. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

| ------------------- | |

| L x W x H | 330. 0 x 584.0 x 355.0 0 x 584.0 x 355.0 |

| Weight | 16kg |

| Operating hours | 468 hours |

| Switching hours | |

| Condition | in excellent condition |

| CE marked | --------- |

| Status | inspection possibility |

| Client type | End user |

| Active since | 2022 |

| Offers online | 0 |

| Last activity | October 10, 2022 |

Description

Selling Markforged Mark Two continuous carbon fiber 3D printer for idle. The printer is ideal for rapid prototyping of carbon nylon and continuous carbon fiber structural parts and fixtures (320x132x154mm working area). The device is in perfect condition, the total print run is less than 500 hours, the printer comes with:

The printer is ideal for rapid prototyping of carbon nylon and continuous carbon fiber structural parts and fixtures (320x132x154mm working area). The device is in perfect condition, the total print run is less than 500 hours, the printer comes with:

5 bobbins Onyx Black (carbon-filled nylon)

3 coils 150cc cm of continuous carbon wire, one of which is partially used on the machine

Kevlar, HST glass fiber, glass fiber and carbon fiber spools (partially used) 50 cc

Replacement nozzle kit, fiber and thread

All original accessories

Original box included

This description can be translated automatically. Please contact us for more information. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

Details

| ------------------- | |

| L x W x H | 330. |