Wcu 3d printing

What’s New | 3DU

Hurray normalcy!

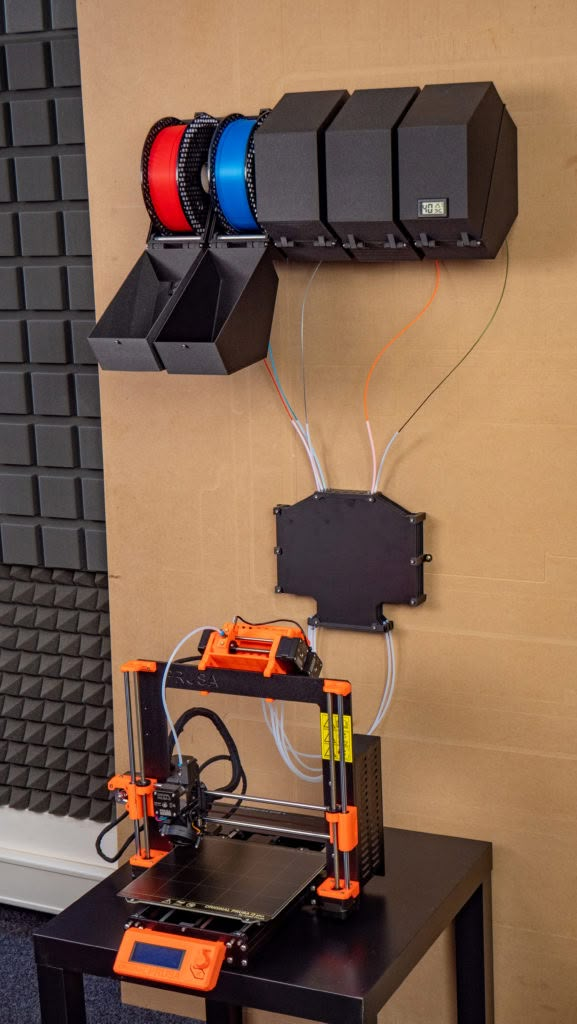

As we being to transition back to a more normal workflow, we are back printing more than ever. Now with four FDM 3D printers, as well as two new Elegoo Saturn SLA Resin printers, the 3DU is ready to print your next 3D print creation come true! Want to submit a job? Select the “Start Here” button on the home page or come speak with us at the Technology Commons service desk and we’ll be happy to assist you!

Dremel 3D45, MakergearM2, and Elegoo Saturn

As the world of 3D printing continues to grow, so does the selection of 3D Printers available to use. In an effort to improve the quality of our printers, we now have two Dremel 3D45’s at our disposal. The 3D45 offers many exciting upgrades that our previous models did not have. This includes a closeable casing while printing to reduce noise, remote-based printing services, a removable glass bed for easy print access and cleaning, as well as other neat features. We’re excited to have the Dremel 3D45’s at our disposal and would love to print you something on them!

If you have a file you’d like to submit to be printed, make sure to email visit the home page of our site and select the “Start Here” button to get your submission to us!

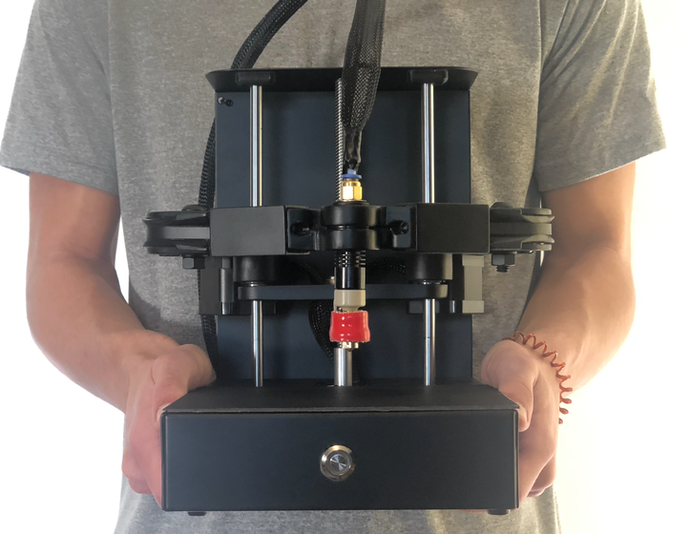

Alongside the new Dremel printers, we also now provide two Makergear M2’s that are ready to create your very next print!

The M2’s provide another great option for any PLA based print and are extremely user-friendly. For more information on using either printer, feel free to come visit our 3DU area on the ground floor of the Technology Commons.

Both the MakergearM2 and the Dremel are quality PLA printers and both are ready to be used right now! Come take a look and see which one could work for you.

If you have a file you’d like to submit to be printed, make sure to email visit the home page of our site and select the “Start Here” button to get your submission to us!

Last and certainly not least, we have added the Elegoo Saturn to our 3D printing lineup. This resin printer is the highest level of detail printer we have ever gotten to use at the technology commons.

This resin printer is the highest level of detail printer we have ever gotten to use at the technology commons.

Whether you’re looking to print a new mini for your next DND session, or perhaps a highly detailed print that normal FDM printers just can’t quite get right, the Elegoo Saturn is just the choice for you! When submitting your print to us, just tell us you’d like to print in resin and we’ll have your print in the highest detail possible!

Check out this video by Meghan O’Sullivan exploring some of the different uses of the 3DU on the Campus!

The 3DU has recently had the opportunity to partner with Hugh Jack and the Coulter Faculty Commons to bring 3D Modelling to faculty and staff of WCU. Dr. Hugh Jack, department head of Engineering and Technology, offered a two-session course in 3D Design through the Coulter Faculty Commons. The course was held in the 3DU and gave faculty and staff the opportunity to learn how to setup and print items on a 3D Printer, and how to use design software to create 3D printable items.

Dr. Hugh Jack, department head of Engineering and Technology, offered a two-session course in 3D Design through the Coulter Faculty Commons. The course was held in the 3DU and gave faculty and staff the opportunity to learn how to setup and print items on a 3D Printer, and how to use design software to create 3D printable items.

Session One of the course explained the basics of Cura, a 3D Slicing software, and how to setup and operate a Lulzbot mini 3D Printer. Participants had the experience of downloading, slicing, and printing a 3d model in the Technology Commons 3DU Makerspace. Session two focused on the basics of 3D Design using Google Sketchup. In this course, students learned how to design and prepare a model for 3D printing, as well as the basics of how to check the integrity of design for 3D Printing.

Western Carolina University - Rapid Center uses 3D printers to make face shields for faculty, staff

WCU Stories July 31, 2020

By Bill Studenc

After spending much of the spring and summer using the 3D printing technology in Western Carolina University’s Rapid Center to help develop personal protective equipment for use by health care workers in their battle with COVID-19, faculty, students and staff in the College of Engineering and Technology have turned their attention to helping employees return safely to campus this fall.

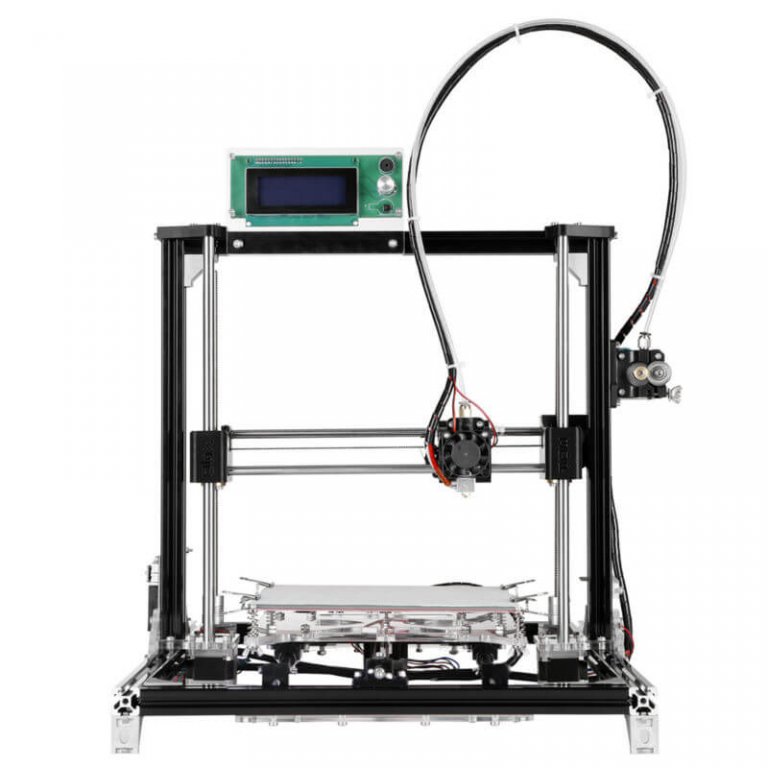

Under the supervision of Patrick Gardner, director of the Rapid Center, and Monty Graham, the center’s engineering project coordinator, several students checked out 3D printers over the summer and used them from home to help produce face shields for the medical community. By midsummer, those efforts had resulted in the delivery of approximately 3,000 shields to health care workers across Western North Carolina through WCU’s Center for Community Engagement and Learning.

Agencies receiving shields from WCU included Blue Ridge Health, Harris Regional Hospital, Haywood Regional Hospital, Cherokee Hospital, Appalachian Mountain Community Health, Vecinos, Jackson County Health Department, Swain County Health Department, WNC Eye Associates Surgery Center, Brookdale Senior Living Centers, Western Carolina Medical Society, Mercy Urgent Care, Bryson City Urgent Care, Madison County Health Department, Macon County Health Department, Asheville Buncombe Community Christian Ministries and WNC Community Health Services.

At that point, Gardner thought he was finished making face shields – until Interim Provost Richard Starnes placed an order for 1,400 shields for use by faculty and staff this fall. Gardner quickly assembled a team to get that order filled and delivered.

May graduate Anthony “A.J.” Mongold, now seeking his master’s degree in technology at WCU and one of the original students 3D printing visors from his apartment, prepared the Maker Space in the Belk Building for mass production of 3D-printed visors and performed most of the maintenance to keep machines operating.

Senior Parker Arrington, an engineering intern in the center, took over the 3D printing operation and operated a laser cutter to make the plastic shields. In the background, Rapid Center engineers Brett Banther and Shawn Lyvers delivered visors they were 3D printing at home. The 1,400 face shields were produced and delivered by Monday, July 27.

The 1,400 face shields were produced and delivered by Monday, July 27.

“It was rewarding to know the work we performed over the summer was helpful to health care workers and first responders across Western North Carolina, and it is equally rewarding to know that we are playing a role in ensuring a safe return to work for our faculty and staff colleagues,” Gardner said. “The Rapid Center was made for this type of assistance – look at a customer’s need, and develop a solution that helps them move forward with their innovation.”

College of Engineering and TechnologyFaculty and Staff

Share

90,000 residential complex from 3D printer: Lakhtacenter-Livejournal-

Lakhta Center-On Skyscraper and not only ( Lakhtacenter ) Wrote,

The city of Eindhoven (Netherlands) is going to build the world's first residential complex of five 3D printed concrete houses.

The Milestone project will be located practically in the forest, the houses will be sustainably and energy-efficient, comfortable and with modern layouts. Construction is subject to all the usual rules and regulations. The first one-story house will be printed this year, and the housewarming will be next. The remaining four houses are multi-storey. They will be built sequentially, each time improving the technology and applying the lessons learned in the previous stages.

The design is based on chaotic blocks in a green landscape. The irregular and somewhat even futuristic shape in the form of rounded boulders appeared due to the key feature of 3D printing: the ability to build and print any shape.

Residential printed complex will be located in the vicinity of the city of Eindhoven, in the town of Bosrijk, which is developing as a "sculpture garden". There are high-quality and ambitious architectural projects placed like sculptures in a continuous landscape.

By the way, Bosrijk is the first place in Eindhoven that is not connected to the gas network.

The first house - one-storey and with a wooden roof, 3 rooms, area 95 m2. The house will be ready for occupancy in mid-2019.

The long time between the design and implementation of the first house is due to the novelty of the project and unusual construction technologies. Further it will be faster and easier.

Designed by Houben & Van Mierlo Architecten and Eindhoven University of Technology.

Multi-storey buildings will have printed concrete floors and a printed concrete roof. The foundations are ordinary, based on the traditional technology of pouring concrete.

Elements of the first house will be printed by a concrete printer at the Eindhoven University of Technology workshop. In the future, the process will gradually be transferred directly to the construction site of the house. The last house will be fully realized on site, including printing works.

In the future, the process will gradually be transferred directly to the construction site of the house. The last house will be fully realized on site, including printing works.

Concrete 3D printing is almost any form of construction, precision in design and execution, any color and concrete properties. Easy implementation of the customer's wishes for each specific house.

Requires less concrete than conventional construction. Consequently, cement consumption and CO2 emissions from cement production are reduced.

The Eindhoven University of Technology in the Netherlands and the Dutch construction company BAM Infra carried out a joint project in 2017 to print a concrete bridge for cyclists. The 8-meter bridge was printed in sections using 800 layers of reinforced concrete. The bridge can withstand loads up to two tons. Service life 30 years.

The Netherlands also created the world's first 3D printed metal bridge over a canal in Amsterdam. The bridge span is 12.5 meters long and 6.23 meters wide. It took 4.5 tons of steel wire and half a year to create it.

The bridge span is 12.5 meters long and 6.23 meters wide. It took 4.5 tons of steel wire and half a year to create it.

And now - the next experiment in the field of 3D printing in the Netherlands - the residential complex Project Milestone.

These 3D houses are being printed in Dubai, UAE and Beijing, China.

Houses will probably no longer be rectangular…

Printed house by CLS Architetti and Arup, Milano

The attitude towards concrete houses is not unambiguous. Are these printed concrete buildings really good for the 21st century? After all, concrete and steel were the main elements in the architecture of the last century.

Source: houbenvanmierlo.nl, 3dprintedhouse.nl

Tags: 3d, architecture, concrete, printed house, printed bridge, modern technology, building technology

Subscribe

-

Desert infrastructure. City of the Future Neom to Spend Half a Trillion Dollars

Neom, the city of the future in Saudi Arabia, has just signed a contract with Bechtel, one of the world's largest construction companies.

Photo by…

Photo by… -

Zaha Hadid's bureau will build a metro station in Moscow

Three years later, a metro station designed by Zaha Hadid Architects will open in Moscow. The famous British bureau won the design competition.…

-

Toronto will get a "pencil tower". Super-slim skyscraper by Herzog & de Meuron

Swiss Herzog & de Meuron are going to build a super-slim skyscraper in downtown Toronto. The tower will house housing and shops. Photo by…

Photo

Hint0022 Personal diaries

Subscribe to the author

Subscribe

Don't want

3

Greetings!

Most of you - probably heard about (now - part of the series!) Movie

Avengers: Age of Ultron'2015 ( Avengers: Age of Ultron'2015 ).

One of the characters - interested me, and - as you and I will see together - not only me.

I bring to your attention a very interesting,

and seemingly quite simple

exoskeleton design methodology - for cosplay, and - not only ;-) .

Hardware:

3D printer,

laser cutting machine,

welding machine,

pneumatic tools,

hydraulic drives

...

etc.

Soft:

Fusion-360

Pepacura Designer 4.0

...

etc. etc.

There are titles, and as usual, I recommend watching without translation.

Look:https://youtu.be/5C30pwpGkRo

Building Avengers Infinity War HULKBUSTER with Colin Furze #1 | XRobots

James Bruton, Published: Apr 19 2018

Regards

Ski.

P.S.'Bonus' videos, and - possible 'backstory' of the issue involved:

https://youtu.

be/kSuaykdvl4I Making the Hulkbuster Part 1-Legs, Huge Hydraulic Legs

colinfurze, Posted 19Apr. 2018

How can it move, previous prototype'2016:

https://youtu.be/lEq0GQl4oLs XRobots - Iron Man Hulkbuster Cosplay Part 59, Final Suit Demo at DEFCON V

James Bruton, Published: Oct 24 2016

Hulkbuster cosplay - in 2015:

https://youtu.be/Q4LuWXf5Tlw Hulkbuster Cosplay at NYCC 2015 by Extreme Costumes

Dre Shinwho, Published: Oct 12 2015

[]

Follow the author

Subscribe

Don't want

3

More interesting articles

cadshef

Loading

10/16/2022

940

12 Sel

Loading

24.10.2022

1055

four

Subscribe to the author

Subscribe

Don't want

I bought new items from Anycubic Kobra Go and Anycubic Kobra Neo.

Learn more