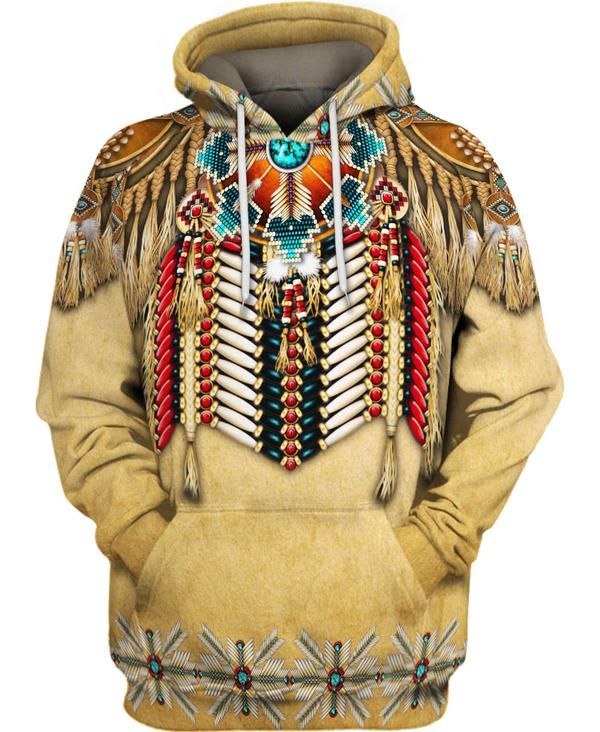

3D all over printed native american shirts

Custom Name Native American 3D Hoodie All Over Printed Native

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Click to zoom

1,918 sales |

4.from €57.60

Loading

VAT included (where applicable), plus shipping

Style

Select a style Hoodie (€57.60 - €65.11) Zip Hoodie (€67.62 - €75.13)

Please select a style

Unisex Size

Select an option S (€57.60 - €67.62) M (€57.60 - €67.62) L (€57.60 - €71.37) XL (€61.36 - €71.37) 2XL (€61. 36 - €71.37) 3XL (€65.11 - €75.13) 4XL (€65.11 - €75.13) 5XL (€65.11 - €75.13)

36 - €71.37) 3XL (€65.11 - €75.13) 4XL (€65.11 - €75.13) 5XL (€65.11 - €75.13)

Please select an option

Add your personalization

Enter the name you want on the hoodie here

256

Explore related categories & searches

Listed on Oct 27, 2022

33 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies. Tell us more about how this item violates our policies.

Tell us more about how this item violates our policies.

Oops... This page was not found!

Need help? Contact us at [email protected]

- *Best Selling

- Ornament 🎄

- *Holiday Gift

- 🎄 Christmas Gifts 🎁

- Halloween Gift

- 9/11 Patriot day

- Summer gifts 🎁

- Father's Day Gift

- Mother's Day Gift 🎁

- Independence Day 🎁

- Valentine Gift

- St Patrick's Day

- Easter Day

- Mother's Day Gift

- Father's day

- Trending

- *Products

- 3D Apparel

- Blanket

- Wall Art

- Car seat cover

- Keychain

- T-Shirt

- Hoodies

- Sweatshirt

- LongSleeve

- Phone Cases

- Tumbler

- Mug

- Pillow

- V-Neck

- Candle holder

- Photo Clip Frame

- Jobs

- Master Chef

- Barber

- DJ

- Pet Groomer

- Firefighter

- Police

- Nurse

- Trucker

- Carpenter

- Nail/spa

- Veteran

- Bus Driver

- Hobbies

- Skull

- Horse

- Wolf

- Dog

- Cat

- Hunting

- Fishing

- Jeep

- Bowling

- Darts

- Cosplay

- Astronaut - Galaxy

- Contact Us

- Track Your Order

Processed and printed in the US

Buy from 2 items to enjoy extra 10% OFF

Reliable shipping, easy returns

Back HomeYou might also like

. jdgm-verified-badge{display: none}

jdgm-verified-badge{display: none}

1533

Verified Reviews

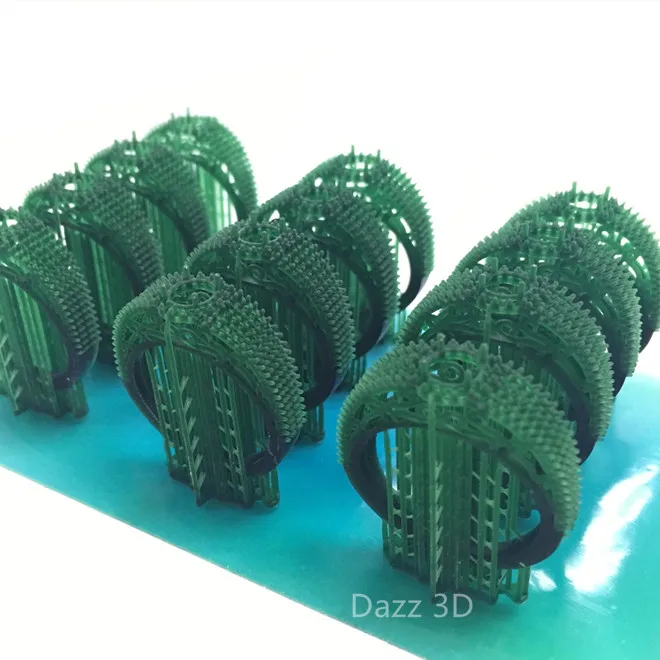

FDM clothing

I don't even remember how that thought entered my head. Perhaps the starting point was that many people draw decorative patterns on clothes with a 3D pen. And I thought, why not print the model on a 3D printer directly on the fabric?

The first question I asked myself was how to fix the fabric on the table surface?

Two options come to mind:

1. Glue the fabric onto the table.

2. Fasten flat.

When gluing fabric, you need to choose a glue that will then be easy to wash off. If it is not glued, then the fabric can be easily deformed during printing and wrinkles will appear, or the entire print will be broken. I decided to combine both methods by gluing the fabric to the table only in that part of the surface where the model will be located.

How to do it?

It is necessary to print several layers, and then lay the fabric on these layers in a straightened state, raise the nozzle and continue printing.

How I did it:

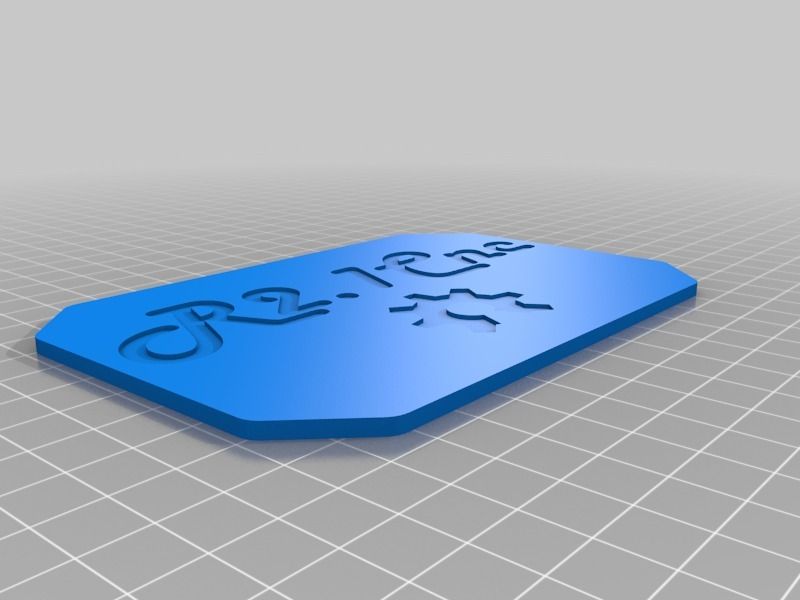

First I modeled a button and sliced this model

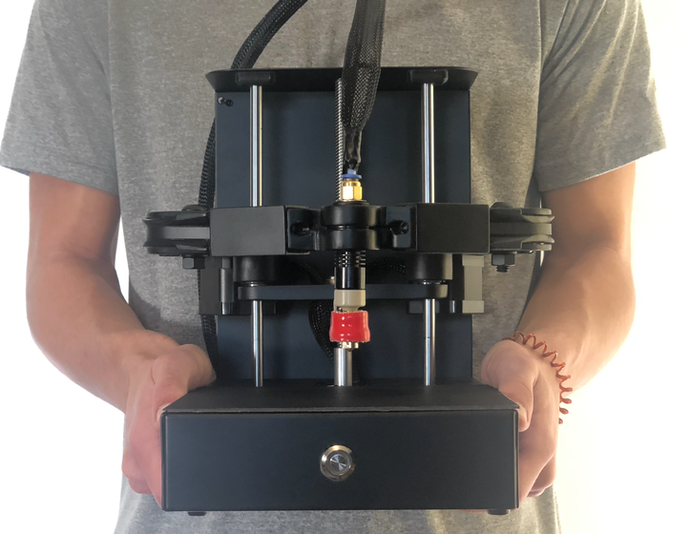

Nozzle 0.6, layer 0.2, 5 perimeters, PLA, extruder temperature 200, table - 100, model height 4 mm, speed 40 mm /sec. Diameter 25 mm.

It was decided to remove the second layer and pause instead to put the fabric on the table.

Open the G-code file prepared for printing in a text editor and delete the 2nd layer with a Z-coordinate of 0.4 mm. And instead of it we prescribe:

G1 X-30 F4800.00

G4 S20

The first line moves the extruder head along the X axis towards HOME at a speed of 80 mm / sec (My HOME prusha is X= -45, Y= -5 )

The second line pauses for 20 seconds, after which printing continues automatically. This is necessary to free your hands to hold the fabric on the table surface.

Other commands can be used, but this is enough for me personally.

At the moment when the printing stops - it is necessary to lay the fabric on the table and try to press it down a little in the place where the hot plastic lies (for this you need to warm up the table).

Naturally, the number of first and removed layers can be different.

Layers up to the fabric are needed not only to hold the material, but also serve as a kind of damper. The number of layers to be removed depends on the thickness of the fabric.

I chose a HB t-shirt for printing. Due to the structure of the fabric itself, it stretches very much, so it should not be stretched so that there are fewer wrinkles after printing.

What I did. Printed on glass, sprinkled with Coca-Cola. After printing the first layer, the extruder stepped aside and stopped. I laid down the T-shirt and tried to glue it with my fingers - it was hot and nothing stuck. He began to wait until the printing resumed, holding the fabric in a straightened state. When the extruder moved, it began to catch the fabric of the T-shirt - these few seconds were a real battle for the result. Partially, the outer contour was imprinted in one place - I continued to correct the fabric (I was terribly afraid that the cotton might char or catch fire, but this did not happen). Oh, here it is a miracle - the extruder fused the fabric into the first layer and more or less evenly began to lay the subsequent layers. Initially, part of the T-shirt was hanging from the table, and the table was moving - because of this, the fabric moved, but as soon as I laid most of the T-shirt on the table, the model was already printed in one place without displacement.

Partially, the outer contour was imprinted in one place - I continued to correct the fabric (I was terribly afraid that the cotton might char or catch fire, but this did not happen). Oh, here it is a miracle - the extruder fused the fabric into the first layer and more or less evenly began to lay the subsequent layers. Initially, part of the T-shirt was hanging from the table, and the table was moving - because of this, the fabric moved, but as soon as I laid most of the T-shirt on the table, the model was already printed in one place without displacement.

Wrinkles and extruder dirt visible on T-shirt. The edges were slightly bent, but then leveled off and the T-shirt held up until the end of printing.

Here is the print result:

Here you can see a few stripes of the outer perimeter that have shifted. In the future, they managed to be torn off, although traces remained.

What happened on the reverse side:

The fabric, although held during printing, bounced off the first layer without much effort:

The button itself on the surface is mainly stuck to the villi, so it will not be difficult to detach it, which I do did not. But closer to the center, where there was a lot of melt, the plastic also penetrated into the fabric, as you can see in the previous photo, where there are pieces of plastic remaining between the fibers.

But closer to the center, where there was a lot of melt, the plastic also penetrated into the fabric, as you can see in the previous photo, where there are pieces of plastic remaining between the fibers.

Well, the photo in the expanded form:

And from the side:

As a result, I want to note that the print was 'successful' on the first attempt. With jambs, but it worked out. If you select materials and plastic, I am sure that you can achieve good results. And the application can be anything - these are 3D logos or signs on clothes, embossed figures, protective coatings, fasteners, etc.

I hope this post has inspired someone to new achievements in the field of 3D printing.

P.S.: I decided to tear off the button - it was glued tightly in the place where a diamond-shaped groove is visible on the reverse side.

The Masters Movement, IP Litigation and Law Reform

October 2019

Author: KTU), Brisbane, Australia

3D printing is a branch of technology based on the principle of additive manufacturing (as opposed to the principle of subtractive manufacturing that underlies the traditional manufacturing industry). 3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

Currently, the development of 3D printing is in a transitional phase. The consumer "3D printing revolution", which aimed to have a 3D printer in every home, has failed. MakerBot, a pioneer in 3D printing, is having trouble with its changing approach to intellectual property (IP) issues, disrupting its ties to the open source software community, and the user audience turned away from it. As former MakerBot CEO Bre Pettis said in an interview, "The open source community has kicked us out of their paradise." As a result, MakerBot was acquired by Stratasys, a leader in the 3D printing industry, which restructured and repurposed it.

Some other key players also went bankrupt. In particular, TechShop, a membership-funded and open-to-all network of studio-workshops for home craftsmen, went bankrupt. Maker Media, which publishes Make magazine and hosts craft festivals in the United States, has gone under external control. Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC.

Industrial 3D printing continues to grow

While personal 3D printing has not developed as expected, there has been growth in a number of other forms and categories of 3D printing. Along with robotics and big data, 3D printing has become one of the promising technologies in the manufacturing industry. Companies specializing in information technology and design are working to improve the way 3D printing is used. Significant investments, especially from transport companies, have been attracted by the technology of 3D printing of metal products. In addition, there have been large-scale experiments related to the application of 3D printing in the healthcare sector, including 3D printing in dentistry, 3D printing in medicine, and bioprinting.

As technology improves and develops, there have been several cases of lawsuits being filed in the courts, as well as certain political developments regarding the regulation of the 3D printing industry. Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing.

3D printing and copyright law

A few years ago, there was a panic that the widespread use of 3D printing would lead to a wave of large-scale infringements of the rights of authors, similar to the situation that arose with the advent of the Napster file-sharing network . Although such fears have not yet materialized, there have been various conflicts related to copyright and 3D printing. For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

3D printing was also subject to the on-demand removal of content under the Digital Millennium Copyright Act (USA). Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

In addition, discussions took place on issues related to the use of technical protection measures in the context of copyright law and 3D printing. For example, the US Copyright Office has confirmed a limited technical protection exception for 3D printing stocks.

3D printing and design law

Developments in 3D printing have also raised the issue of product repair rights.

Efforts have been made in the European Union to recognize the right to repair in order to support consumer rights and develop a circular economy. In this regard, one of the important factors in achieving changes in the behavior of companies and consumers has become the European Greening Directive (Directive 2009/125/EC).

In July 2019, the United States Federal Trade Commission held a Hearing on "Can't be Repaired: A Workshop on Product Repair Restrictions. " Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

" Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

Significant and first-of-its-kind litigation has taken place in Australia regarding the right to repair under Design Law ( GM Global Technology Operations LLC v S . . - S - Auto Parts Pty Ltd [2019] FCA 97). The Australian Treasury is considering policy options regarding the practice of sharing vehicle repair information.

Australian Capital Territory (ACT) Consumer Affairs Minister Shane Rettenbury called for recognition of the right to repair from the rostrum of the Consumer Affairs Forum, which brings together ministers from both Australia and New Zealand. Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Calls for right-to-repair laws, both at the provincial and federal levels, are also being heard in Canada. As Laura Tribe, Executive Director of Open Media, noted in this regard, “We are committed to ensuring that people have the opportunity to be the real owners of the products they own.”

3D printing and trademark law

3D printing also brings uncertainty to trademark law and related legal regimes, including product substitution, identity rights, commercial use of characters, and brand identity. The legal conflict surrounding Katy Perry's trademark application for the "shark on the left" image provides some insight into some of the issues that arise in this regard.

Regarding bioprinting, Advanced Solutions Life Sciences sued Biobots Inc. In connection with the alleged violation of its trademark rights ( Advanced Solutions Life Sciences , LLC V Biobiots , 201. Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth.

Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth.

3D printing and patent law

According to the 2015 WIPO Global Intellectual Property Report "Breakthrough Innovation and Economic Growth", 3D printing patent applications are on the rise. Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry.

With the growing commercial importance of 3D printing in the manufacturing industry, there have been a significant number of litigations related to 3D printing of metal products. In July 2018, as part of the “Desktop Metal Inc.” v. Markforged, Inc. and Matiu Parangi (2018 Case No. 1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

In 2018 (after the above verdict) Desktop Metal Inc. and Markforged Inc. entered into a confidential financial agreement that settled all other litigation between them. However, in 2019 Markforged Inc. filed another lawsuit against Desktop Metal Inc. due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

3D printing and trade secrets

In addition, the first litigation regarding 3D printing and trade secret legislation took place. In 2016, Florida-based 3D printing startup Magic Leap filed a lawsuit in federal court for the Northern District of California against two of its former employees for misappropriation of trade secret information within the meaning of Trade Secret Protection Act (“ Magic Leap Inc ." v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

3D printing and open licensing

In addition to proprietary IP protections, 3D printing has a widespread practice of open licensing. Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses.

Other issues arising from the development of 3D printing

In addition to IP issues, the development of 3D printing also raises a number of other legal, ethical and regulatory issues. In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

Litigation regarding 3D printing of firearms is also ongoing in the United States. Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms.

Footnotes

* Dr. Matthew Rimmer is Head of the KTU Research Program on Intellectual Property Law and Innovation and is involved in the KTU Electronic Media Research Center, the KTU Australian Health Law Research Center and the KTU International Law Research Program and global governance.

Learn more