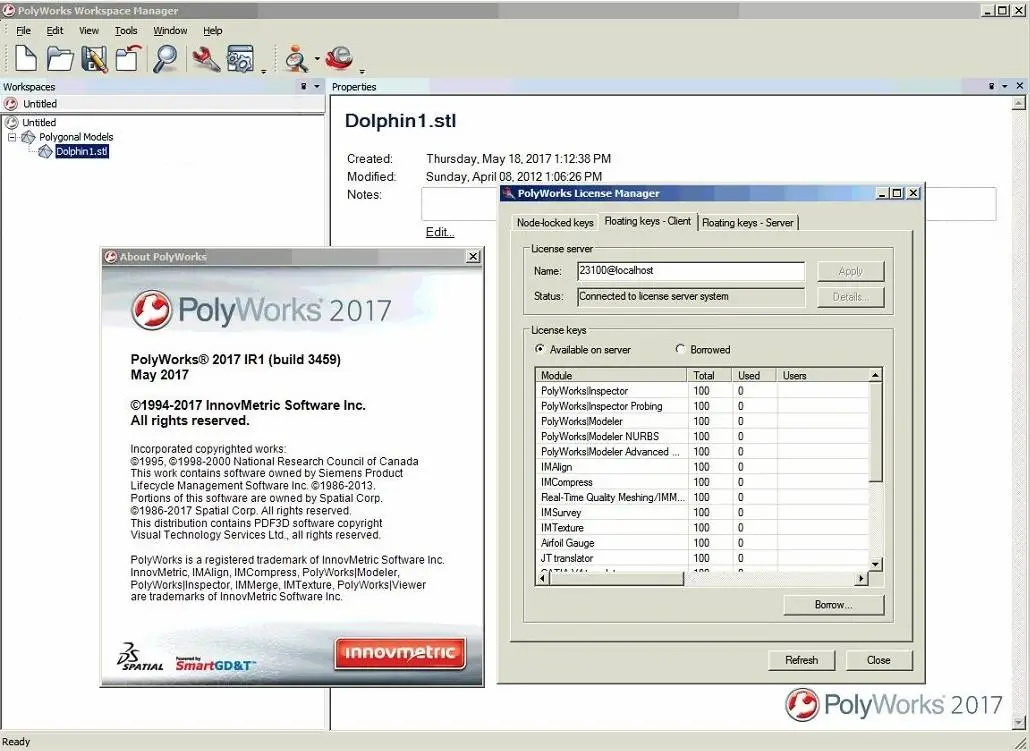

Polyworks 3d scanner

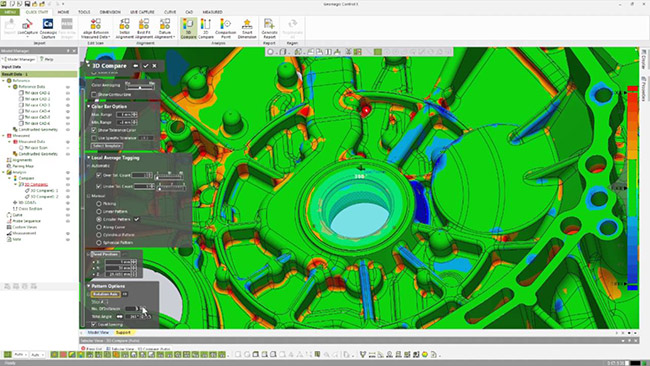

PolyWorks|Inspector™ Overview | InnovMetric Software

The 3D dimensional analysis and quality control solution to gain control of your product engineering and manufacturing process

PolyWorks|InspectorTM is a universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.

With just one software to master, dramatically reduce your operational costs by increasing measurement specialist competency, eliminating metrology silos, boosting employee mobility, and improving overall teamwork efficiency.

Interface with all 3D measurement devices thanks to a universal digitizing hub

| |

Bring all relevant data under one roof through a universal data hub

| |

Perform all inspection tasks with or without CAD data using a universal 3D metrology workflow

| |

Deploy universal inspection projects playable on any 3D measurement device

|

Complete Dimensional Analysis and Quality Control Toolbox

At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, mathematical algorithms certified by PTB, and extensive visual and audio feedback capabilities. It allows users to extract meaningful information from their measured 3D data, automate the inspection process when more than one piece is measured, and structure the presentation of measurement results to facilitate enterprisewide digital collaboration.

Complete Dimensional Analysis and Quality Control Toolbox

At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, mathematical algorithms certified by PTB, and extensive visual and audio feedback capabilities. It allows users to extract meaningful information from their measured 3D data, automate the inspection process when more than one piece is measured, and structure the presentation of measurement results to facilitate enterprisewide digital collaboration.

Surface and cross section best-fit

Best-fit measured surfaces and cross-sections to their nominal definition, with the option of constraining in rotation, translation, or within a tolerance zone.

Surface and cross section best-fit

Best-fit measured surfaces and cross-sections to their nominal definition, with the option of constraining in rotation, translation, or within a tolerance zone.

Measurement object best-fit

Construct your alignment from features, datum targets, surface points, or edge points, and use weights and axial constraints to optimize the results.

Measurement object best-fit

Construct your alignment from features, datum targets, surface points, or edge points, and use weights and axial constraints to optimize the results.

Multiple device position alignment

Align your 3D measurement device while compensating for temperature changes, and use bundle adjustment to maximize the global accuracy.

Multiple device position alignment

Align your 3D measurement device while compensating for temperature changes, and use bundle adjustment to maximize the global accuracy.

Universal data handling

Extract measured dimensions from point clouds, polygonal models, or probed points, and nominal dimensions from a CAD model or a measured part.

Deviation analysis using color maps

Obtain surface, boundary, cross-sectional, or thickness measured-to-nominal deviations, and analyze them through a color map display.

Feature-based dimensioning

Measure a feature’s diameter, position, or orientation, or distances and angles between two features, in 2D or in 3D, and configure the dimensions’ display intuitively.

Smart GD&T

Benefit from a smart GD&T engine based on the latest ASME and ISO standards, with advanced DRF, material condition, datum modifier, and tolerance zone capabilities.

Profile and Flush & Gap gauging

Evaluate advanced dimensions on fillets, design feature lines, and sheet metal part assemblies, such as radius, angle, bending, sharpness, flush, and gap.

Airfoil gauging

Extract advanced features on fan, compressor, and turbine blades to control and analyze dimensions, such as edge radius, thickness, length, width, angle, and area.

Multipiece data management

Measure multiple pieces using different 3D measurement devices, and store them in a single project folder or an online data management solution using an optimal format that minimizes disk space usage.

Multipiece data management

Measure multiple pieces using different 3D measurement devices, and store them in a single project folder using an optimal format that minimizes disk space usage.

Play Inspection tool

Use the powerful Play Inspection and Sequence Editor tools to automate measurement workflows by ordering and triggering operations.

Play Inspection tool

Use the powerful Play Inspection and Sequence Editor tools to automate measurement workflows by ordering and triggering operations.

Macro scripting

Add macro scripts to your measurement workflows to apply proprietary techniques, provide special feedback, or interconnect to other systems.

Macro scripting

Add macro scripts to your measurement workflows to apply proprietary techniques, provide special feedback, or interconnect to other systems.

Control views

Organize projects containing hundreds of dimensional and GD&T controls into small and logical groups of controls, with individual controls tied to specific alignments and coordinate systems.

First Article Inspection Reports

Quickly publish an AS9102 and PPAP-compliant First Article Inspection Report by measuring a piece from the first production run and transferring the results automatically to Excel using PolyWorks|ReportLoop™.

Statistical Process Control (SPC)

Assess the repeatability and predictability of your manufacturing processes with multipiece statistics automatically calculated for object dimensions and surface deviations.

Measurement System Analysis

Design and carry out repeatability and Gauge R&R studies and publish results in elegant, content-rich Excel templates using PolyWorks|ReportLoop™.

Market-leading Portable Metrology Platform

Renowned for the power and stability of its direct hardware interfaces, PolyWorks|Inspector offers an extensive set of guidance technologies that the world’s largest manufacturing OEMs trust to implement efficient, precise, and repeatable measurement processes for portable metrology devices.

Plug-and-play interfaces for all your portable metrology needs

Maximize the productivity of your scanning arms

Tens of thousands of portable arm operators worldwide enjoy the reliability and efficiency of our scanning and probing workflows every day.

Leverage our disruptive laser tracker innovations

We provide innovative laser-tracker-based scanning technologies that greatly accelerate the analysis and dimensional control of your large parts and tools.

Scan large structures rapidly using spherical digitizing

Minimize rework time when assembling large aerospace structures by scanning them using a spherical grid digitizer and simulating the assembly process beforehand.

Tailor measurement methods to your processes

Integrate additional measurement devices or in-house proprietary measurement techniques by creating and embedding macro scripts within your measurement objects.

Guidance technologies for repeatable 3D measurement processes

Generate high-quality surface scans

Produce great scanning results under all circumstances thanks to our unique real-time quality meshing technology that computes and displays quality metrics in real time.

Ensure sufficient scanned data for reliable feature extraction

Get real-time feedback on scanned surface, curve, and circumference coverage with guidance graphics that indicate where an operator should capture additional scans.

Implement repeatable probing workflows

Use images, text, 3D graphics, and tolerances, on your computer screen or a mixed-reality display, to deploy guided probing inspection projects that improve operator efficiency and ensure measurement repeatability on the shop floor.

Guide assembly building with real-time measurements

Accurately track part location during assembly using digital readouts simultaneously displaying real-time measured reflector positions from multiple laser trackers.

High-productivity CNC CMM Solution

PolyWorks|Inspector has reinvented the way inspection projects are set up and executed on CNC CMMs, within a flexible, user-friendly, and efficient CNC CMM operational paradigm, similar to the one we offer for portable metrology devices.

The most user-friendly offline sequencing workflow on the market

Reduce the complexity of your CMM programming tasks

We deliver shorter and easy-to-understand CNC CMM sequences, as our nominal features, dimensions, and reports are created and managed outside of the sequence editor.

Accelerate the sequencing process while staying in control

Select objects to be measured and let the sequence editor automatically find the proper tool orientations, the optimal measurement order, and collision-free measurement paths.

Fix sequencing mistakes intuitively

Our intelligent sequence editor provides immediate feedback when illogical or incorrect operations are detected, and lets you repair detected mistakes in a single click.

Avoid potential collisions automatically

We offer powerful collision analysis and avoidance technologies that detect potential tool collisions in real time and automatically modify the toolpaths to prevent them.

The most powerful online platform ever designed

Configure a CNC CMM sequence for any machine in your park

Build your measurement sequence once for a specific CNC CMM configuration, then use our conversion tool to automatically adapt it to any CNC CMM brand or type.

Protect your CNC CMM and its accessories

Avoid costly damages by detecting, in real time, potential tool collisions with parts or fixtures prior to launching a CNC measurement operation online.

Add measurement objects to a sequence effortlessly

To perform additional measurements, just create and select new measurement objects and let the sequence editor optimally insert them within your CNC CMM sequence.

Complement your CNC CMM projects with portable metrology data

Use a portable laser scanner to measure the fixtures for collision analysis purposes, or a scanning arm to measure surfaces and features that can’t be reached by the CMM.

Case Studies

Fujigiken

Fujigiken now uses PolyWorks|Inspector™ on all their measurement devices to improve the efficiency of their measurement and inspection operations.

PolyWorks|Inspector™

View case study

Saitama Kiki Co.

, Ltd.

, Ltd.Automating the measurement and inspection of drag links with PolyWorks® macros reduces operation time by 95%.

PolyWorks|Inspector™

View case study

| Single-point measuring device for portable metrology All available plug-ins for articulated arms, optically tracked probes, laser trackers, manual CMMs, and theodolites. | ● | ● | ● | ● | |

| Single-point measuring device for CNC CMMs CNC CMM plug-in with direct communication with CMM controllers, plus I++ plug-in in CNC mode. | ● | ● | |||

| Point cloud digitizer for portable metrology All available point-cloud-digitizing plug-ins and import capabilities for a wide range of native point cloud file formats for laser line scanners, fringe-projection digitizers, long-range spherical grid scanners, and more. | ● | ● | |||

| Point cloud digitizer for CNC CMMs Laser scanning tool supported within the CNC CMM plug-in. | ● | ||||

| Measurement collection for digital gauges All available measurement collection device plug-ins for digital gauges. | ● | ● | ● | ● | ● |

| Manual measurement data entry and visual checks Input of custom numerical and qualitative measurements to integrate gauge data and visual checks. | ● | ● | ● | ● | ● |

| Real-time quality meshing and offline point cloud meshing Transformation of digitized point clouds into polygonal models using real-time quality meshing for online processing while laser scanning a part, and offline meshing of point cloud data files. | ● | ● | |||

| PolyWorks|Modeler™ Light module Basic polygonal editing functionalities required to repair and adapt digitized polygonal models for downstream applications. | ● | ||||

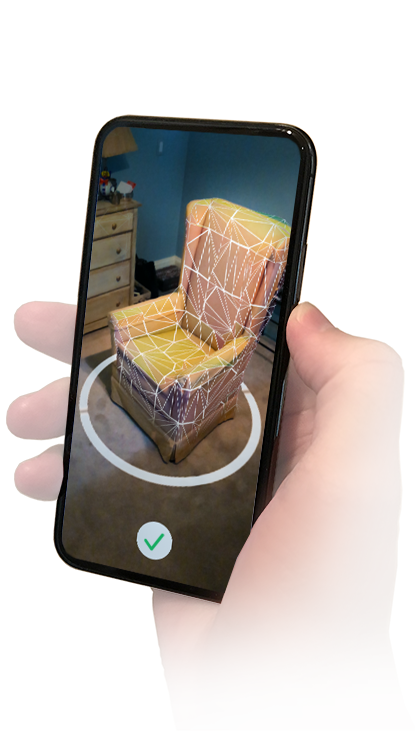

| PolyWorks|AR™ plug-in The mixed reality software solution that superimposes 3D measurement results and guidance graphics on inspected parts. | ● | ||||

| Option PolyWorks|AR™ plug-in The mixed reality software solution that superimposes 3D measurement results and guidance graphics on inspected parts. | Option | Option | |||

| IGES/STEP neutral CAD file translator IGES and STEP file import. | ● | ● | ● | ● | ● |

| Part alignment toolset Powerful set of data-to-CAD alignment techniques that include constrained surface and cross-sectional best-fits, best-fits within tolerance, as well as techniques based on features, reference targets, flush and gap gauges, and more. | ● | ● | ● | ● | ● |

| Dimensional control toolset Widest range of dimensional control tools on the market for a complete analysis of surface, boundary, and cross-sectional deviations, feature dimensions, flush and gap, profile radius, design feature line dimensions, thickness, clearance, and more. | ● | ● | ● | ● | ● |

| Smart GD&T toolset GD&T engine based on algorithms prescribed by the ASME and ISO standards, advanced Datum Reference Frame capabilities (supports datum feature patterns, composite datum features, and datum targets), material condition and datum modifiers, advanced tolerance zone capabilities (radial, slab-like, unequal bilateral, and unilateral), and more. | ● | ● | ● | ● | ● |

| Reporting toolset Control-centric reporting workflow that includes a Control Reviewer tool, control views, dynamic updateable tables and snapshots, automatic report generation, a Report Editor tool to customize report contents and layout, and export to PDF, Excel, Word, and HTML. | ● | ● | ● | ● | ● |

| Simulation mode for offline project setup Project setup without measurement hardware by simulating point cloud data and probed points, the measurement workflow, and the motion of CNC CMM components. | ● | ● | ● | ● | ● |

| Repeatable multipiece measurement workflows Multipiece project format, Play Inspection tool to automatically replay a measurement workflow, universal Sequence editor for CNC CMMs and portable metrology devices. | ● | ● | ● | ● | ● |

| Statistical Process Control toolset (SPC) SPC engine that automatically computes and updates a database of multipiece statistics for object dimensions and surface deviations. Includes trend charts, statistical color maps, and related analysis tools. | ● | ● | ● | ● | ● |

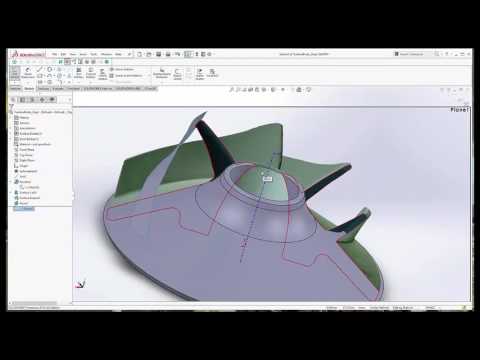

| Option Native CAD file translators Optional translators used to import CAD models and their associated Product & Manufacturing Information (PMI) produced by professional CAD solutions: CATIA V6/V5, CATIA V4, NX (UG), Creo (Pro/E), Inventor, and SolidWorks. | Option | Option | Option | Option | |

| Option Airfoil gauges Optional comprehensive dimensional analysis solution for fan, compressor, and turbine blades. | Option | Option | Option | Option | |

| One-year support/maintenance

| ● | ● | ● | ● | ● |

| Two complimentary seats to attend a Basic classroom training

| ● | ● | ● | ● |

PolyWorks for

Structured Light ScannersSkip to Main Content

Russian language

-

Industries

-

Solutions

-

Products

-

Support & Success

-

Resources

-

Company

Russian language

Tab Close Content Button

Alert

The page is not available in your preferred language.

Russian language

- Russian language

- Czech Republic

- Deutsch

- English

- Espanol

- Francais

- Italiano

- Magyar

- Nederlands

- Poland

- Portugues

- Romaneste

- Suomi

- Svenska

- Turkish

- ภาษาไทย

- 한국어

- 日本語

Select your preferred language from the list below. We will show you content in your preferred language when available, otherwise we will show English.

We will show you content in your preferred language when available, otherwise we will show English.

Preferred Language

- Bahasa Indonesia

- Czech Republic

- Dansk

- Deutsch

- English

- Espanol

- Francais

- Italiano

- Magyar

- Nederlands

- Poland

- Portugues

- Romaneste

- Suomi

- Svenska

- Turkish

- Russian language

- ภาษาไทย

- 한국어

- 日本語

To explore content available in a specific language, visit the page language directory.

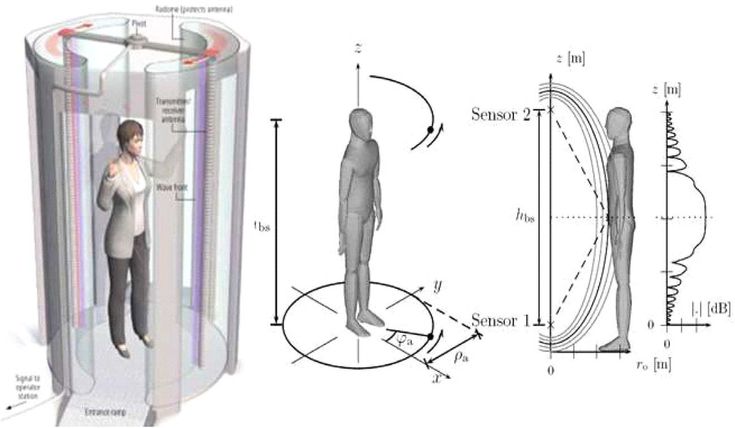

PolyWorks for Structured Light Scanners

Contact Information

Developed by InnovMetric Software Inc, Canada, the PolyWorks ® software is a third party point cloud inspection and reverse engineering solution.

Whether you're casting, milling, forming or stamping, you can rely on PolyWorks to provide a complete solution for your process. The PolyWorks software package is available as a complete package, or as a point cloud validation and reverse engineering package according to two main objectives.

SLS plug-in for PW

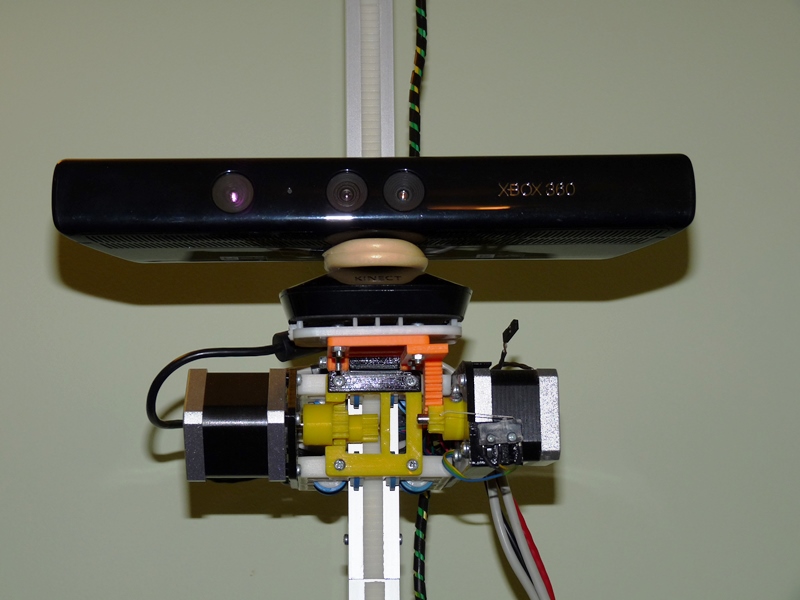

The SLS-PW plug-in provides full control of Hexagon structured light scanners from within the PolyWorks software environment. Increase the efficiency of workflows running on a single platform by reducing validation time, eliminating the need to export and import measurement data between separate programs, and minimizing the need for training.

This plug-in is based on the Hexagon Structured Light Scanning Software Development Kit (SDK), enabling the development of plug-ins for other major metrology software platforms.

PolyWorks Plug-in for Hexagon Structured Light Scanners

-

PolyWorks/InspectorTM (for point cloud inspection) allows:

- use high-density point clouds from digitizing prototypes and assemblies to quickly identify deformations and fix defects early in the manufacturing process

- improve the manufacturing process by fully controlling the first production samples received

- control the production cycle by automatically measuring tool wear and quickly detecting sharp deterioration in product quality

- check the conformity of manufactured and assembled products by randomly controlling them using automated technologies

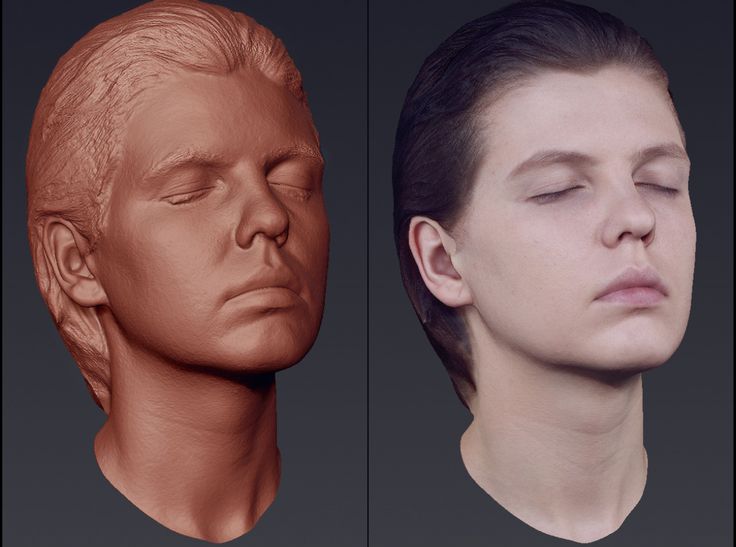

PolyWorks/ModelerTM (for reverse engineering) allows you to:

- generate manufacturable class A polygonal models

- Convert aligned point clouds to accurate polygonal models using PolyWorks 9's unique adaptive tolerance-based meshing technology0010

- Recreate accurate polygon features based on poor quality digitizing geometry data

- apply all typical CAD functions directly to polygonal models and prepare these models for various manufacturing processes such as milling, rapid prototyping, reverse engineering, verification, CFD & FEA, digital inspection, etc.

- create smooth and logical NURBS surfaces editable with conventional CAD

- Use automatic feature tracking tools to create curved meshes. Curves can also be retrieved interactively with a simple mouse click

- Limit the automatic surface creation process to predefined curves to produce more logically correct curved meshes

- Control the stiffness of NURBS mating surfaces by simulating metal sheets used to produce extra smooth, wrinkle-free surfaces

- Optimize workflows in your CAD applications by reducing the number of breakpoints and fixes, which improves the smoothness of fixes and makes it easy to create perfect curved features

StereoScan neo

Modern structured light scanner uses Smart Phase Projection technology to achieve the best results when scanning dark and. ..

..

Read more

SmartScan

This compact optical 3D scanner allows you to quickly and accurately measure complex geometries, as well as fragile and deformable parts.

Read more

PrimeScan

Entry-level structured light scanner for precision 3D scanning of industrial components in a variety of configurations.

Read more

Thank you – your preferences have been saved

To make changes please select the “Personalize Your Experience” option in the footerPersonalize your experience

Personalize your experience below. You may also click on the link in the footer, to change your preferences at any time.

Language

Select your preferred language from the list below. We will show you content in your preferred language when available, otherwise we will show English.

We will show you content in your preferred language when available, otherwise we will show English.

preferred language Please selectCzechDanishGermanEnglishSpanishFinnishFrenchHungarianIndonesianItalianJapaneseKoreanDutchPolishPortugueseRomanianRussianSwedishThaiTurkish

Your affiliation

Select your industry and divisional affiliation from the list below. We will show you content aligned to your selection(s) when available.

Industry Please selectAerospaceAgricultureAutomotiveBuildingsChemical industryConsumer productsDefenceEducation and researchElectronicsEnergy and power generationEngineering servicesForestryGeneral manufacturingGovernmentHealthcare and life sciencesHeavy construction for infrastructureHeavy machinery and equipmentMapping and geospatial contentMarine positioningMiningOil and gas industryOtherPublic safetyShipbuildingSurveyingTransportationUtilities and communications

Primary division Please selectAgricultureAsset Lifecycle IntelligenceAutonomy & PositioningGeosystemsManufacturing IntelligenceSafety, Infrastructure & GeoXalt Solutions

© Hexagon AB

PolyWorks|Inspector™ - What's New 2022 | InnovMetric Software

Efficiently take control measurements on multiple parts without CAD data

Guide figure measurement and automate figure extraction when nominal figure components are missing:

- Probe figures on the first part, then automatically guide the first part's measured figure components when measuring subsequent parts

- scan the first part; use some interactive tool to create measured primitives from point cloud data; then convert all measured figure components into measurement guides to guide figure scanning and automate extraction of measured figure components on subsequent parts

- Embed the CAD model later in the process if desired, create nominal figure components and GD&T controls, and have PolyWorks|Inspector automatically propagate those changes to all parts being inspected

Accelerated Retrieval of Shapes from a Lot of Large Deviation Parts

Use PolyWorks|Inspector2022 measurement guide technology to automate and accelerate the extraction of measured shape components on large and similar deviation parts:

- use figure extraction groups or manual selection to reliably extract measured figure components on the first part with large deviation, and then convert those measured figure components to measurement guides

- Quickly extract measured figure components from subsequent highly deviated parts using measurement guides as geometry references

Create Smart First Item Inspection Reports in Excel

Quickly publish an AS9102 and PPAP compliant First Part Inspection Report by measuring a part from the first production run in PolyWorks|Inspector2022 and automatically transfer the results to the provided FAIR template in Microsoft Excel.

Use the new one-stop data center for your digital processes

Digitally interoperate your CAD modeling, model-based definition and 3D measurement solutions:

- Import all types of GD&T controls from native CAD and QIFMBD files to digitally interact with product definition processes

- Measure the dimensional control of a scanned or probed object with a more accurate device such as a digital probe and enter the measured value into the object for reporting purposes

Experience ease of use

BTake advantage of improvements that improve user productivity and make the software easier to learn:

- enter your search term in the Options dialog box to quickly find the option you need

- Dynamically adjust color scale limits in the 3D scene to speed up the analysis of color maps of your data

CNC CMM stylus optimization for Renishaw Ph30 stylus head

Convert collision-free 3-axis CNC CMM probing sequences to optimal five-axis probing sequences by seamlessly integrating five-axis motion and touch probe probing.

Increase your stylus operator's productivity by deploying mixed reality display technology

Get visual guidance and feedback before your eyes with a menu offering common stylus tools:

- Probe correctly every time by following the guide geometry and instructions by measurement superimposed on the measured part

- evaluate the result by visualizing measured points, measurement results and digital readings in real time

- Enable standard stylus functions with our intuitive user interface

/cdn.vox-cdn.com/uploads/chorus_asset/file/12803133/IMG_4902.1419979924.jpg)