Play doh 3d printer

Play Doh best STL files for 3D printing・Cults

CHRISTMAS ROLLER - NATIVITY SCENE - PASTRY - PLAYDOUGH - COOKIE DOUGH -

Free

CHRISTMAS TEXT - PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER

€0.50

Play Doh or Cookie Cutters

€4.61

Christmas Manger Cookie and Fondant Cutter with Embosser

€1.84

Fuck You Justin Trudeau Stamps for Clay, Play-Doh, Cakes etc.

€0.86

Christmas Nutcracker Cookie and Fondant Cutter with Embosser

€1.84

Christmas Santa Claus Cookie and Fondant Cutter with Embosser

€1.84

Christmas Mrs. Claus Cookie and Fondant Cutter with Embosser

€1. 84

Christmas Elf Cookie and Fondant Cutter with Embosser

€1.84

Christmas Snowman Cookie and Fondant Cutter with Embosser

€1.84

Christmas Bell Cookie and Fondant Cutter with Embosser

€1.84

Halloween Zombie Cookie and Fondant Cutter with Embosser

€1.84

Halloween Scary Movie Cookie and Fondant Cutter with Embosser

€1.84

Halloween Skeleton Cookie and Fondant Cutter with Embosser

€1.84

Halloween Scarecrow Cookie and Fondant Cutter with Embosser

€1.84

Halloween Dead day 2 Cookie and Fondant Cutter with Embosser

€1.84

Halloween Dead day 1 Cookie and Fondant Cutter with Embosser

€1. 84

84

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - REINDEERS AND TREES (“"XMASCULTS"”)

Free

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - REINDEER

€1.50

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - GINGERBREAD MAN

€1.50

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - SNOWMAN

€1.50

PASTRY - PLAYDOUGH - COOKIE DOUGH - ROLLER - SPHRERICAL - EDUCATIONAL

€1

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - 5 point star

€1

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - CHRISTMAS TREE

€1

PASTRY - PLAYDOUGH - COOKIE DOUGH - SPIDER AN SPIDER WEB - ROLLER

€1. 50

50

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - SNOWFLAKE

€1.50

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - REINDEER

€1.50

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - CHRISTMAS STOCKING

€0.80

PASTRY - PLAYDOUGH - COOKIE DOUGH - CHRISTMAS ROLLER - BETHLEHEM STAR

€0.90

Summer Flowers - Cutter set

€2.56

Transportation - Cutter set

€2.56

Musical Notes - Cutter set

€2.56

Planets - Cutter set

€2.56

Frog Life Cycle - Cutter set

€2.56

Human Prenatal Development - Cutter set

€2. 56

56

12 Hunting Themed Stamps for Clay, Play-Doh, Cakes, etc..

€0.86

BEE AND HONEYCOMB DEBOSSED ROLLER FOR PLAYDOUGH/ PLAYDOH/ CLAY/ COOKIE DOUGH

€1.50

Animal footprint stamps for clay - playdoh - Educational

€1.49

ANIMAL FACES - Playdoh - Clay - playdough - stamps for pre-schoolers

€1.49

Elephant Symbol Play-Doh Cutter, 3d Ready Print!

€3.69

HouseV2 Symbol Play-Doh Cutter, 3d Ready Print!

€3.69

House Symbol Play-Doh Cutter, 3d Ready Print!

€3.69

Heart Symbol Play-Doh Cutter, 3d Ready Print!

€3.69

Minions Stuart Cookie and Fondant Cutter with Embosser

€1. 84

84

Minions Bob Cookie and Fondant Cutter with Embosser

€1.84

Minions Kevin Cookie and Fondant Cutter with Embosser

€1.84

Press for plasticine, children's plasticine, Play Doh

€1.65

Mixed Berry Cookie Cutter Set

€0.83

3D Print with Play-Doh or Clay for a Day

0Shares

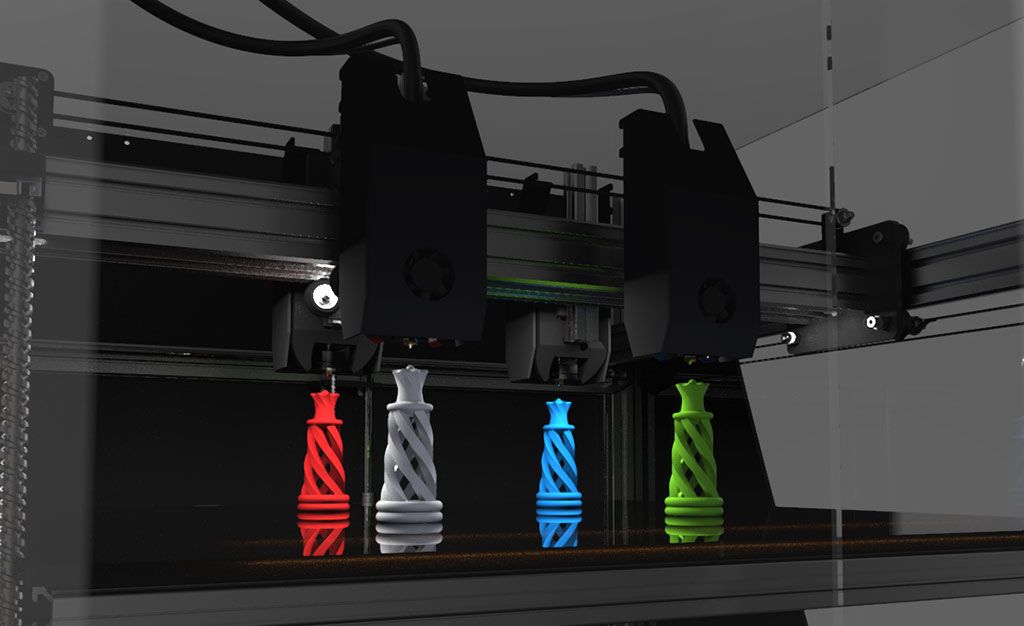

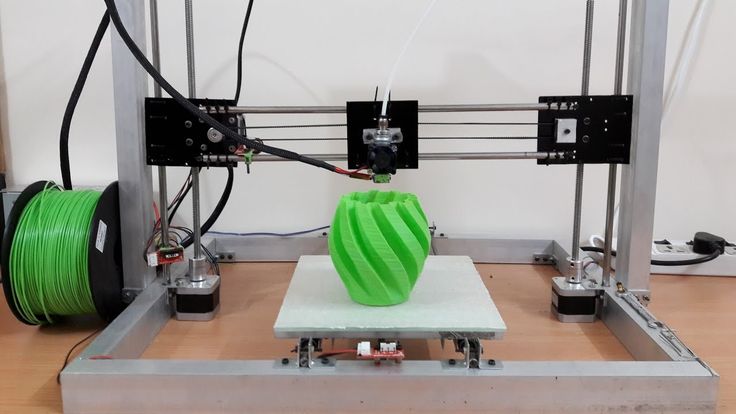

There’s a supremely cool new extruder with accompanying materials just released by the folks at Hyrel 3D. They’ve done what Play-Doh wished it would have thought of years ago by making a 3D printer print malleable materials.

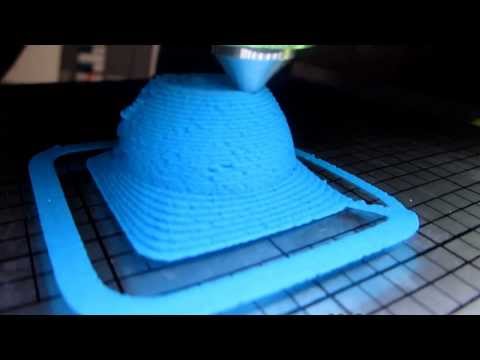

By virtue of Hyrel’s easy to swap extruder set-up, you can now swap in their new extruder, the EMO1, which is capable of printing clay, play-doh, silicone and plasticine. The print head is loaded by the brute force approach of shoving the material into the nozzle until it’s full, as you can see in the video below:

The print head is loaded by the brute force approach of shoving the material into the nozzle until it’s full, as you can see in the video below:

Hyrel started up as a project funded on kickstarter back in November 2012. After netting over three times their $50k goal, the collection of CAD designers, engineers and software developers, was able to start producing their series of Hyrel 3D printers. The printers are unique in that they’re pre-assembled, offer multiple heads, a built-in CPU and have extruder heads that are easy to swap out, depending on the task at hand.

I asked the members of the Hyrel team if the extruder will work with something like my Bukobot and got the following response from Dan:

Our HYREL EMO1 was built to be interchangeable and hot-swappable with the HYREL 3D Printer. While we would love to be able to support other 3D printers, we cannot at this time.

Further, the ability to interchange the extruder heads and the ability to hot-swap these heads is under a patent pending status. The interchangeable, hot-swap ability allows the user to swap the extruder heads themselves and the CANBUS we had integrated into the electronics allows for automatic switching between a typical ABS / PLA filament extruder head, to being able to use multiple other materials and tools, all on the same HYREL platform.

Lucky Hyrel owners will, however, be able to print all sorts of smooshy and smooth objects and I bet that Aardman Animations, famed studio responsible for Wallace and Gromit and Pirates! An Adventure with Scientists, will want one for their next film because plasticine is the same stuff used in claymation (though they haven’t used it since 1997, after switching over to the plasticine-like Newplast). And, interestingly enough, the material has other uses. See the interesting tidbit I found on Wikipedia below:

Athletics officials in high-level long jump and triple jump competitions use plasticine to help determine if the competitors are making legal jumps. A 10 centimeter strip of plasticine is placed beyond the take-off line. If an athlete leaves a mark in the plasticine, it is considered proof that the jump was a foul and the attempt is not measured.

A 10 centimeter strip of plasticine is placed beyond the take-off line. If an athlete leaves a mark in the plasticine, it is considered proof that the jump was a foul and the attempt is not measured.

Michael Molitch-Hou

Michael Molitch-Hou previously served as Editor-in-Chief of 3D Printing Industry, he is now the Editor of Engineering . com's 3D printing section. He has covered additive manufacturing technology day in and day out since 2012 and has hundreds of article to his credit. He is the founder of The Reality Institute.

90,000 use of a 3D printer for the manufacture of cosplay elements, examples of use07.10.2021

Content

-

- Advantage 3D prints for the manufacture of costume elements 9000

- Making master models

- Rating of the best cosplay printers

- FDM printers

- Photopolymer printers

- Totals

Probably everyone wanted to feel at least for a while in the shoes of their favorite hero. Or briefly be in a fantasy world. Cosplay allows, at least for a while, to plunge into a fictional world with its own laws.

Or briefly be in a fantasy world. Cosplay allows, at least for a while, to plunge into a fictional world with its own laws.

Cosplay should not be confused with role-playing, because cosplay does not imply the development of the character or history of the character. It focuses on the detailed reproduction of the image of the character to the smallest detail. nine0003

Some people think that cosplay is limited only to curvy girls in skimpy outfits, but this is far from the case. The skill of some cosplayers is amazing. They manage to single-handedly create amazing things with precision and detail that many workshops cannot reproduce.

Terminator suit from Warhammer 40k

A good cosplay is not only an external correspondence to the appearance of the selected character, it is the ability to convey the character and other features of the character (for example, characteristic movements, facial expressions, etc. ). At photo shoots, with the help of Photoshop, they try to add the atmosphere of the world to better convey the nuances of the character. nine0003

). At photo shoots, with the help of Photoshop, they try to add the atmosphere of the world to better convey the nuances of the character. nine0003

It is believed that the term Cosplay was coined by Japanese journalist Nobuyuki Takahashi. The word itself is a combination of the initial letters of the word costume (costume) and play (play).

Warhammer 40k universe photo shoot

The advantage of 3D printing for costume elements

Previously, a cosplay costume was literally made from improvised materials. Each, to the best of his skills, available tools and ingenuity, used various, mainly construction, materials to assemble the costume - isolon, glue gun, tourist rugs, etc. nine0003

Now available special materials for the manufacture of parts. The most popular of them is Eva foam.

Eva

Eva is a very convenient material for making a variety of armor. The biggest advantage over other materials is thermoplasticity. When heated, eva easily bends, and after cooling, it keeps its shape. On sale you can find eva foam of various hardness and thickness.

When heated, eva easily bends, and after cooling, it keeps its shape. On sale you can find eva foam of various hardness and thickness.

nine0043

Making armor from eva

But there are certain nuances - for the correct cutting of eva, patterns are needed (there are special patterns or patterns for pepakura are redone). When cutting, it is necessary to take into account the location of the edges and make the cut not straight, but at an angle. Sections, after gluing, must be further processed with sandpaper. The surface of eva is porous, so it is advisable to treat the surface with latex before painting to obtain a smooth surface. For painting and putty, it is desirable to use elastic materials, because eva still remains a little flexible. nine0003

Pepakura

Papercraft - this is the name of patterns (reamers) for the manufacture of various elements from paper.

Not only cosplayers are addicted to papercraft, for some it is enough to glue a paper model for a collection.

Usually pepakura is used as an inexpensive and easy way to make massive armor when there is no way to get eva foam.

First, the paper model is glued together. Paper is usually chosen with a high density to minimize the risk of deformation of the model during further work. nine0003

Finished paper model

After gluing, the model must be strengthened. For this, fiberglass and epoxy resin are usually used. When impregnating a paper model, it is very important to ensure that the geometry of the model does not "lead". Usually epoxy and fiberglass are applied in several layers. Before applying a new layer, it is necessary to wait for the polymerization of the old one, usually it takes 24 hours.

The resulting model is strong, but too angular. Models in papercraft are high-poly and it is necessary to manually smooth out the angularity with putty and sandpaper. After painstakingly removing the surface of the model, it can be painted. nine0003

nine0003

Left paper model, right after strengthening, processing and painting

Models made by this method are very heavy due to epoxy and putty. And the manufacture of one product takes a lot of time, but this method remains popular because of its availability and low cost. Epoxy can be found in any building market, and fiberglass is easily interchangeable with other materials.

Modeling and casting

This method is suitable when you need to quickly produce many identical parts. A master model is made (for example, from plasticine) and a mold is removed from it using special silicone, into which epoxy, special two-component plastics or polyurethanes can then be poured, depending on what characteristics you need to get in the finished product.

Two-component plastic purity print with metallic powder

To color the finished casting, you can knead the dye into liquid plastic or rub the mold with special powders.

It makes sense to make silicone molds if you need to make many identical elements, it is not advisable to remove the silicone mold for one casting. Silicone is still not cheap and not everywhere you can buy it. In addition, it is necessary to have some skills in silicone and plastic/resin casting in order to minimize the amount of air bubbles and get a quality casting. nine0003

Handy materials

And of course, masters know how to use the most unexpected things for cosplay. For example, PVC pipes are often used to make frames for fantasy weapons. Izolon for making feathers for wings, etc.

Acrylic folding knife

Using PVC pipes as a sword frame

3D printing

Using a 3D printer to make a complete costume may not always be advisable due to the high cost. But in the manufacture of elements with complex geometry, small elements or high detail, it can greatly facilitate the task and save a lot of time. A 3D printer becomes indispensable for printing engineering, moving elements. This is very convenient when a seat for all wiring and electronics is immediately included in the model and you don’t have to puzzle over where to place everything after assembly. nine0003

A 3D printer becomes indispensable for printing engineering, moving elements. This is very convenient when a seat for all wiring and electronics is immediately included in the model and you don’t have to puzzle over where to place everything after assembly. nine0003

But 3D printing also has its drawbacks. When fabricated on an FDM printer, models must be further processed to obtain a smooth surface. If you print on a photopolymer printer, then the cost of the finished product will be quite high. Large elements of the costume will have to be printed in parts and then glued together.

Cosplay 3D printer application examples

Whole costume printing

A 3D printer is becoming an indispensable tool for manufacturing geometrically complex suits or, for example, functional elements of armor. nine0003

Iron Man Armor.

Emily Yarid has been modeling, building and refining Iron Man armor since 2013. She initially took it up out of boredom, deciding to upgrade the costume she had.

In the Tony Stark suit, the reactor glows, the helmet automatically closes and opens. On the back there are functional "wings" that open and close.

One of Emily's ready-made costumes

The girl uses a 3D printer to make armor elements. After printing, she processes and paints the details herself.

Printed Armor

Tony Stark Mask

HALO

A user with the nickname mosquitobandito collects full-fledged armor from the HALO universe. nine0003

Armor 3D model

Armor is almost entirely 3D printed. There are a lot of issues that need to be addressed when modeling to keep the armor as mobile as it is in the game.

Shoe cover

Pre-assembly of the upper part of the armor before gluing and processing. nine0047

The armor part is pre-cut into several parts and printed in parts on an FDM printer. After printing, be sure to check how the parts fit together, as the plastic may shrink unevenly.

After printing, be sure to check how the parts fit together, as the plastic may shrink unevenly.

Treated and painted hand protection

Costume print

Making a full-fledged costume using 3D printing is not always justified. Simple shapes are much faster and cheaper to make from other materials such as eva. nine0003

But complex parts such as helmets, weapons, armor elements are much more accurate if they are made using 3D printing.

Steam Punk Star Wars Helmet

Hand making all the patterns would take much longer, and it is important to make all the patterns symmetrical. This is a very painstaking work that requires a lot of patience, perseverance and experience. nine0003

Iron Man Steampunk Helmet

Composite weapon

Some elements seem quite simple to manufacture, but it can be very difficult, even with a template, to make symmetrical and smooth bends.

Wolverine Collectible Helmet

Master model making

Sometimes the material with the desired properties is found only among foundry resins and plastics. But to remove the form, you still need a master model.

Epoxy sword casting

It was necessary to make a transparent sword. Epoxy resin is well suited for manufacturing. The master model (except for the rose) was printed on a 3D printer.

Prepared master model nine0003

The sword was printed in half - it is much easier to get a high-quality casting without bubbles. The halves of the sword are still the same and can be glued together. After printing, the surface of the master model was brought to perfect smoothness and primed.

Formwork is being prepared from improvised materials for pouring silicone molds

Preparation of the master model for filling with silicone

A slightly tinted epoxy resin is poured into the resulting mold to give an icy blue tint. After casting, 2 halves can be glued together with the same epoxy. nine0003

After casting, 2 halves can be glued together with the same epoxy. nine0003

The result is a stunning sword, as if carved from ice. Such an effect would be difficult to achieve using other materials.

Finished casting

Finished Epoxy Sword

Rating of the best cosplay printers

FDM printers

FDM technology for making cosplay has its pros and cons. nine0003

Pros:

-

Large build area. Some printer models can print an entire full-size helmet.

-

Inexpensive consumables. The cost of a plastic thread (filament) is still much cheaper than consumables for other technologies.

-

A wide selection of different materials. You can find a filament for any task - from engineering to decorative. nine0003

Minuses:

Creality3D Ender 6 (build kit)

Creality3D Ender 6

Characteristics:

Print technology: FDM/FFF

Working area size: 250x250x400mm

Number of extruders: 1

Closed Camera: Yes

Heated table: Yes nine0003

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

Inexpensive printer for a beginner who knows how to handle tools. Supplied as an assembly kit. A large build area will allow you to print large parts in their entirety, and the version with a closed body can print with any, even engineering, plastics.

Supplied as an assembly kit. A large build area will allow you to print large parts in their entirety, and the version with a closed body can print with any, even engineering, plastics.

FlyingBear Ghost 5 3D printer (assembly kit)

nine0043

Flying Bear Ghost 5

Characteristics:

Print technology: FDM/FFF

Working area size: 255x210x200 mm

Number of extruders: 1

Closed chamber: No (but there is an option to purchase)

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others nine0003

A very popular device due to its affordable price. It is sold as a kit kit (for self-assembly), but thanks to the detailed instructions and a huge number of video guides, assembly should not be a problem.

The huge fan base of FlyingBear Ghost 5 makes it easy to find ready-made upgrades and add-ons for the printer. This device is perfect for those who like to experiment and learn something new.

This device is perfect for those who like to experiment and learn something new.

Wanhao Duplicator 6 Plus

Characteristics:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: 260 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others nine0003

Wanhao Duplicator 6 Plus is a reliable workhorse for those who do not want to delve into all the nuances of a 3D printer. Available in 2 versions - with a closed case and not. It is better to immediately purchase a printer with a closed housing so that there are no problems with printing engineering plastics such as ABS, Nylon, etc.

Raise3D Pro2

Raise3D Pro2

Characteristics: nine0003

Print technology: FDM/FFF

Working area size: 305x305x300 mm - when printing with the 1st extruder;

280x305x300 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others nine0003

This is already a serious device with a large print area and 2 extruders for printing complex models. Raise3D Pro2 can be a great help in a small workshop for making decorations and cosplay.

Photopolymer printers

Photopolymer printing is not yet so common for making large items due to expensive consumables, but Western cosplayers have already appreciated the advantages of photopolymer printers for printing small items. nine0003

Pros:

-

The ideal surface of the finished model.

-

Amazing detail that is impossible to get on FDM printers.

-

Large selection of resins. You can get an optically transparent model.

Minuses:

Anycubic Photon Mono

nine0043

Anycubic Photon Mono

Characteristics:

LCD display resolution: 2560x1620 (2K)

XY Positioning Accuracy: 0. 051mm

051mm

UV wavelength: 405 nm

Working area size: 130x80x165 mm

Layer thickness: 0.01-0.15mm

Affordable photopolymer machine with a small print area. Suitable for making small items. nine0003

Phrozen Sonic Mighty 4K

Phrozen Sonic Mighty 4K

Characteristics:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

The Phrozen Sonic Mighty 4K is a professional 3D printer with a large print area and a 4k monochrome sensor. This allows you to quickly receive finished products with amazing accuracy. nine0003

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Characteristics:

LCD resolution: 15" 8K Mono LCD

XY Positioning Accuracy: 43 µm

UV wavelength: 405 nm

Working area size: 330 x 185 x 400 mm

Layer thickness: 0. 01-0.3mm

01-0.3mm

A professional 3D printer with a huge (by the standards of photopolymer printers) printable area. Perfectly fit into the workshop for the manufacture of various props. nine0003

Totals

Making cosplay requires a creative approach and solving various problems. After all, it is not at all easy to transfer into reality what is implemented in a film or game using computer graphics.

3D printing, due to its flexibility and versatility, can speed up and simplify the production of various costume elements. A 3D printer can help you get better quality stuff, even for beginners.

For workshops, a 3D printer can become an indispensable assistant in the manufacture of complex, movable costumes with movable elements. A big plus can be the ability to make an almost exact copy of any costume or its element at any time. nine0003

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | nine0554 Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

#Application

Expert in additive technologies and 3D printing with over 5 years of experience.

Share

all materials

Top 20 Inexpensive 3D Printers (from $199 to $1000)

3DPrintStory Reviews Top 20 Inexpensive 3D Printers ($199 to $1000)

Just 10 years ago, a 3D printer cost over $100,000. Today, you can easily find a cheap 3D printer for under $200. It's amazing. nine0003

Naturally, the lower the price, the more restrictions. Some of the printers on our list will not have a heated bed and the workspace will be small. Naturally, the quality of most of the models presented below cannot compete with more expensive counterparts.

But with a little patience and diligence, it is quite possible to achieve high-quality 3D printing on a printer that costs half the price of a flagship smartphone. And it's really cool!

And it's really cool!

Important note : All 3D printers in this top are supplied assembled by the manufacturer. If you have free time and want to spend less money, you can buy DIY kits and assemble the 3D printer yourself according to the instructions.

List of the best cheap 3D printers in the price range from $ 200 to $ 1000

| 3D printer | Material for 3D printing | | 0555 459 |

|---|---|---|---|

| Flashforge Finder | Pla | 140 x 140 x 140 PLA | 150 x 150 x 150 | 499 |

| XYZprinting da Vinci Jr. Mix 2.0 | PLA | 150 x 150 x 150 | 599 |

| Printrbot Simple | PLA | 150 x 150 x 150 | 599 |

| UP mini 2 | PLA, ABS | 120 x 120 x 120 | 599 |

| Monoprice Maker Select Ultimate | PLA, ABS, exotic | 200 x 2004 9043 | 699 | ROBO C2 | PLA 9055 1270558 |

| Dremel Idea Builder | PLA | 230 x 150 x 140 | 899 |

| Printrbot Simple Pro | PLA | 200 x 150 x 200 | 999 |

| Prusa i3 MK2 | Pla, ABS, exotic | 250 x 210 x 20043 | |

In the article we consider inexpensive 3Ds based etc.

nine0003

If you want to buy them, even if you live in large cities such as Kyiv, Moscow, St. Petersburg, Minsk, it may turn out that these models will not be in the online stores of your city, or they may be with a decent mark-up relative to the cost that indicated in the article.

Since most of them are European / American, it is possible that they will not be in stores at all.

Therefore, before making a choice, I recommend looking directly at eBay, Amazon, Aliexpress, etc. - many sellers on these planforms deliver to the CIS countries within 1-4 weeks on average. nine0003

It is especially worth monitoring these platforms during the discount period - Black Friday or Chinese New Year (Aliexpress or Gearbest) - prices on such days can be 2 or more times lower than usual and it is worth waiting a few weeks.

Monoprice MP Select Mini ($199)

Probably the best 3D printer on our list. Why? Because the Monoprice MP Select Mini is an impressive development with a thoughtful, compact design at a very low price. This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB. nine0003

This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB. nine0003

The heated bed and the wide temperature range of the extruder are especially pleasing, because for such a small price you get the opportunity to print in different materials: from ABS B to PLA or exotic materials like conductive PLA plastic, wood, metal-based composites and PVA.

For those who are worried about the lack of a guarantee - for such a price it is possible without it. This model is upgradeable. For example, you can install a new nozzle, change the table and add WiFi connectivity. nine0003

Small working space - 120 x 120 x 120 mm. Over time, this will definitely not be enough for you.

Specifications of cheap 3D printer Monoprice MP Select Mini

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes; nine0010

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes;

- Connection: SD card, USB.

Back to 3D printer list

M3D Micro Retail ($249)

The M3D Micro 3D printer hit the market thanks to Kickstarter. This model was presented with an incredible price of $349.

The working space of the M3D Micro is 109 x 113 x 166 mm. There are several body color options. The company has implemented "Micro Motion Technology" - a set of innovative solutions - thanks to which you get excellent quality 3D printing at a small price. nine0003

Today, this inexpensive 3D printer already costs even less than the price announced on Kickstarter. You can buy it for $249 with a 12 month warranty. By the way, it is already possible to pre-order the next "pro" version.

Specifications of cheap 3D printer M3D Micro Retail

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 116 x 109 x 113 mm;

- Minimum layer height: 50 microns; nine0010

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- XY accuracy: 15 microns;

- Open source: no;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to 3D printer list

XYZprinting da Vinci Mini ($289)

Da Vinci Mini is a successful attempt to make a 3D printer user-friendly. This model has only one button and 5 multi-colored indicators that reflect the current status of 3D printing. In addition, this affordable 3D printer is WiFi capable so you can control it over a network in your home, office or lab.

Unfortunately, you can only use the manufacturer's own 3D materials. On average, they cost 20% more than usual. However, the company also argues that the materials used (PLA) will be 100% non-toxic. nine0003

Specifications of cheap 3D printer XYZprinting da Vinci Mini

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes; nine0010

- Connection: USB, WiFi.

Back to 3D printer list

Monoprice Maker Select V2($299)

The next cheap 3D printer with a good reputation is the Monoprice Maker Select V2.

This model is an analogue of the Wanhao Duplicator i3, which, in turn, borrowed the design from the Prusa i3. But this does not affect the quality, as the Monoprice Maker Select V2 is easy to use and gives excellent 3D printing results.

Monoprice Maker Select V2 design feature is that the power supply and control panel are placed outside the 3D printer. The working space of this model is 200 x 200 x 180 mm. And this is really a good indicator for the money. nine0003

Specifications of cheap 3D printer Monoprice Maker Select V2

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm; nine0010

75 mm; nine0010 - 3D printer control panel: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

New Matter MOD-t ($299)

New Matter is a young start-up that offers a 3D printer MOD-t - An interesting design with a minimalistic design. This cheap 3D printer is WiFi enabled so you can manage print settings and print from your computer, tablet or smartphone. The working space is 150 x 150 x 125 mm. Thanks to the case, the noise during its operation is reduced. But the most interesting and attractive thing about MOD-t is the price. Only $299. In general, this is an interesting, high-quality model.

Specifications of cheap 3D printer New Matter MOD-t

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 100 x 125 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm; nine0010

75 mm; nine0010 - Control panel on 3D printer: no;

- Connection: USB, WiFi.

Back to the list of 3D printers

Printrbot Play ($399)

The Printbot Play is a very popular budget 3D printer that is often used in education. This inexpensive, reliable model, which is almost entirely made of metal.

The working space is 100 x 100 x 130 mm. Printbot Play has an extruder manufactured by the company itself - Alu Extruder v2. The body is made of powder coated steel and aluminium. SD slot provided. nine0003

You can upgrade the basic design of the Printrbot Play with a heated stand or increase the Y-axis stroke.

Wanhao Duplicator i3 Plus ($459)

The Wanhao Duplicator i3 Plus is an upgraded version of the popular Wanhao Duplicator i3 (which in turn is based on the Prusa i3).

The main features of this cheap 3D printer are a large working space of 200 x 200 x 180 mm, a steel frame, electronics integrated into the design itself (previously it was taken out separately), a slot for a full-size SD card and a touchscreen display for control. nine0003

Wanhao Duplicator i3 Plus Cheap 3D Printer Specifications

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm; nine0010

- 3D printer control panel: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Flashforge Finder ($499)

FlashForge Finder is one of the newest 3D printers on our list. This affordable 3D printer offers an average working space of 140 x 140 x 140mm.

This Finder features a transparent sidewall design so you can view the 3D printing process from any angle. A color display is installed, it is possible to transfer data via WiFi network. The printer comes with some supplies and a USB flash drive, so you can start 3D printing almost immediately. nine0003

Specifications of cheap 3D printer FlashForge Finder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 140 x 140 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- XY accuracy: 11 microns;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm; nine0010

75 mm; nine0010 - 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D printer list

XYZprinting da Vinci Jr. 1.0 Pro ($499)

What's so special about the da Vinci Jr. 1.0 pro? This is a new model from XYZPrinting, which includes many advanced features, such as support for printing materials from other manufacturers and increased speed of 3D printing.

Also features an auto-calibration mechanism, a closed chamber with a unique cooling system, and a 0.3mm nozzle option for high-quality printing of fine model details. All in all, this is a great 3D printer with a lot of useful features and at a low price. nine0003

Specifications for cheap 3D printer da Vinci Jr. 1.0 Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes; nine0010

- Connection: USB, SD card.

Back to 3D printer list

XYZprinting da Vinci Jr. Mix 2.0 ($599)

XYZprinting provides a wide range of low cost 3D printers. And paying attention to each model is quite difficult, although many of them are very interesting.

XYZprinting da Vinci Jr. Mix 2.0 stands out because it can print with two different materials and mix them to create multi-colored models. This dual-color 3D printing technology is rare in this price range ($500 to $1,000), so if you're interested in experimenting with multicolor printing, XYZprinting da Vinci Jr. Mix 2.0 is a great choice. nine0003

However, there is a drawback. This 3D printer is not compatible with materials from other manufacturers, so you will have to buy special materials from XYZprinting (as we mentioned above, they cost 20% more, but are not toxic).

Specifications of cheap 3D printer XYZprinting da Vinci Jr.

Mix 2.0

Mix 2.0 - Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 200 microns; nine0010

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes;

- Connection: USB, SD card, WiFi.

Printrbot Simple ($599)

Printrbot Simple is the flagship of the Printbot empire. This model has a great open design with a solid aluminum frame and a working space of 150 x 150 x 150mm. This inexpensive 3D printer comes fully assembled at a very good price. As you need and want to experiment, you can add a heated table and expand the workspace in the horizontal plane. nine0003

Specifications of cheap 3D printer Printrbot Simple

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 80 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional; nine0010

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to the list of 3D printers

UP mini 2 ($599)

The UP mini 2 is a low cost 3D printer that packs in impressive design and functionality. For starters, it has a touch screen panel and the ability to connect via WiFi.

But the most interesting is further. Implemented power failure protection system. 3D printing will continue after the emergency stop. Built-in HEPA air filtration system. Automatic detection of the height of the extruder nozzle. A separate, closed container for the material, thanks to which it does not deteriorate under the influence of moisture from the environment. nine0003

Great 3D printer for a small price. The only thing that upsets me a little is the small working space - 120 x 120 x 120 mm.

Specifications of cheap 3D printer UP mini 2

- Printer type: FDM;

- 3D printing materials: PLA, ABS;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 150 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D Printer List

Monoprice Maker Select Ultimate ($699)

The Monoprice Maker Select Ultimate is an extraordinary beast that combines elements from two leaders in the world of 3D printing - Zortax and Ultimaker. The Monoprice Maker has an aluminum perforated printing table, which was offered in the Zortax M200 (thanks to this table, the grip of the base of the model with the table is much better), and the software part is almost identical to Ultimaker 2 (very user-friendly interface and functionality). nine0003

This model uses a "Bowden extruder", that is, the feed blocks and nozzle are separated, unlike direct feed. This improves reliability and reduces the likelihood of 3D printing errors (although, most likely, it was necessary to sacrifice printing speed, as the weight of the printing unit increases). Given the cost, this is a good model, the analogues of which are much more expensive.

Specifications of cheap 3D printer UP mini 2

- Printer type: FDM; nine0010

- 3D printing materials: PLA, ABS, exotic;

- Working space: 200 x 200 x 175 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes;

- Connection: USB, SD card.

Back to 3D printer list

Robo C2 ($799)

The Robo C2 is a small 3D printer with tons of connectivity options. Using a specialized application, you can monitor the status of 3D printing from your smartphone or tablet. It can be connected to a Chromebook. Thanks to the built-in slicing program, you do not need to install additional printing software.

Probably the most impressive is the integration with Amazon Alexa. Users can stop, cancel and check the status of 3D printing in real time using voice commands. nine0003

nine0003

What does this inexpensive 3D printer offer? Working space 127 x 127 x 150 mm. The 3D printing speed is 300 mm/s and the resolution is 20 microns. There is a built-in 3.5'' color touch screen, a system for monitoring the amount of remaining material for printing, automatic calibration and a removable self-aligning print platform. The only drawback is that the table is not heated, so you have to use PLA plastic.

Specifications of cheap 3D printer Robo C2

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 127 x 127 x 150 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D printer list

Wanhao Duplicator 4S ($829)

The Duplicator 4S has 2 extruders. It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

One of the features of this model is a high-precision material feed wheel, which ensures the same filament feed speed. The Duplicator 4S is equipped with a 0.4mm precision nozzle. nine0003

Specifications of cheap 3D printer Duplicator 4S

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40 mm/s;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 0.4 mm;

- 3D printer control panel: yes;

- Connection: USB, SD card.

Polar 3D Printer This causes the table to rotate and the print head to move up, down, right, and left. nine0003

Polar 3D Printer This causes the table to rotate and the print head to move up, down, right, and left. nine0003 Thanks to the polar coordinate system, this 3D printer is powered by two stepper motors, so it consumes less power. In addition, it turned out to realize a larger size of the working area: 203 (table diameter) x 152 (Z coordinate) mm.

Rated $899, but there are special discounts for educational institutions. The discounted price is only $599.

Specifications of cheap 3D printer Polar 3D

- Printer type: FDM;

- Materials for 3D printing: PLA;

- Working space: 203 (table diameter) x 152 (Z-coordinate) mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 400 microns;

- Number of extruders: 1;

- 3D printing speed: 40 mm/s;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: no; nine0010

- Connection: USB, WiFi, SD card.

Back to 3D printer list

FlashForge Creator Pro ($899)

You've probably heard of this 3D printer. FlashForge Creator Pro is very similar to Makerbot Replicator 2X. This inexpensive 3D printer has 2 extruders, it has a steel closed body.

Other features include a table sizing system, and a guide screw that makes the guide system more stable and durable. The design is nothing special, but this model has earned positive reviews from the 3D community due to its reliability, versatility and ease of use. nine0003

Specifications of cheap 3D printer FlashForge Creator Pro

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40-100 mm/s;

- Open Source: design and software; nine0010

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes;

- Connection: USB, SD card.

Back to 3D Printer List

Dremel Idea Builder ($899)

The Idea Builder is plug and play. This 3D printer is designed by Dremel. It has a color touch screen display. Sufficiently large working space - 230 x 150 x 140 mm. Unfortunately, the table is not heated. On the other hand, since only PLA plastics can be used, this model is great for classrooms and teaching labs. nine0003

Specifications of cheap Dremel Idea Builder 3D printer

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 230 x 150 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes; nine0010

- Connection: USB, SD card.

Back to the list of 3D printers

Printrbot Simple Pro ($999)

The Printrbot Simple Pro is a major upgrade from the original Simple. Same open design, no body. Like its predecessor, the Printrbot Simple Pro is compact and portable. All-metal construction for excellent vibration damping and shock resistance.

The main differences are the built-in color touch screen, the ability to connect via WiFi and the free cloud service (optional), which greatly improves the 3D printing process. Simple Pro has a 32-bit processor, which ensures smooth and fast movements. And at the same time, this model is included in our top 20 cheap 3D printers, since its cost is $999.

Specifications of cheap 3D printer Printrbot Simple Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 200 x 150 x 200 mm;

- Minimum layer height: 50 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional;

- Nozzle diameter: 1.

75 mm; nine0010

75 mm; nine0010 - 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D printer list

Prusa i3 Mk2 ($999)

This is one of the best 3D printers you can buy in this price range. All nodes are open-source licensed and part of the Rep-Rap project, so there are many copies around ... but all replicas are worse than the original.

The Prusa i3 Mk2 is equipped with a heated table that has technology to compensate for temperature differences in the center and corners. There is an automatic calibration system. And of course, amazing documentation. This is an extremely versatile 3D printer that you will 100% appreciate when you start printing with unusual materials such as PLA, PET, HIPS, Flex PP or Ninjaflex, etc. nine0003

The Prusa i3 Mk2 is a 3D printer that is constantly being developed and supported by the manufacturer. Its developer Josef Prusa regularly adds new features, software and design improvements (for example, the ability to color 3D print).

Learn more