Photosensitive resin 3d printing

Stereolithography (SLA) 3D Printing Guide

Stereolithography (SLA) 3D printing is the most common resin 3D printing process that has become vastly popular for its ability to produce high-accuracy, isotropic, and watertight prototypes and end-use parts in a range of advanced materials with fine features and smooth surface finish.

In this comprehensive guide, learn how SLA 3D printers work, why thousands of professionals use this process today, and how SLA printers can benefit your work.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

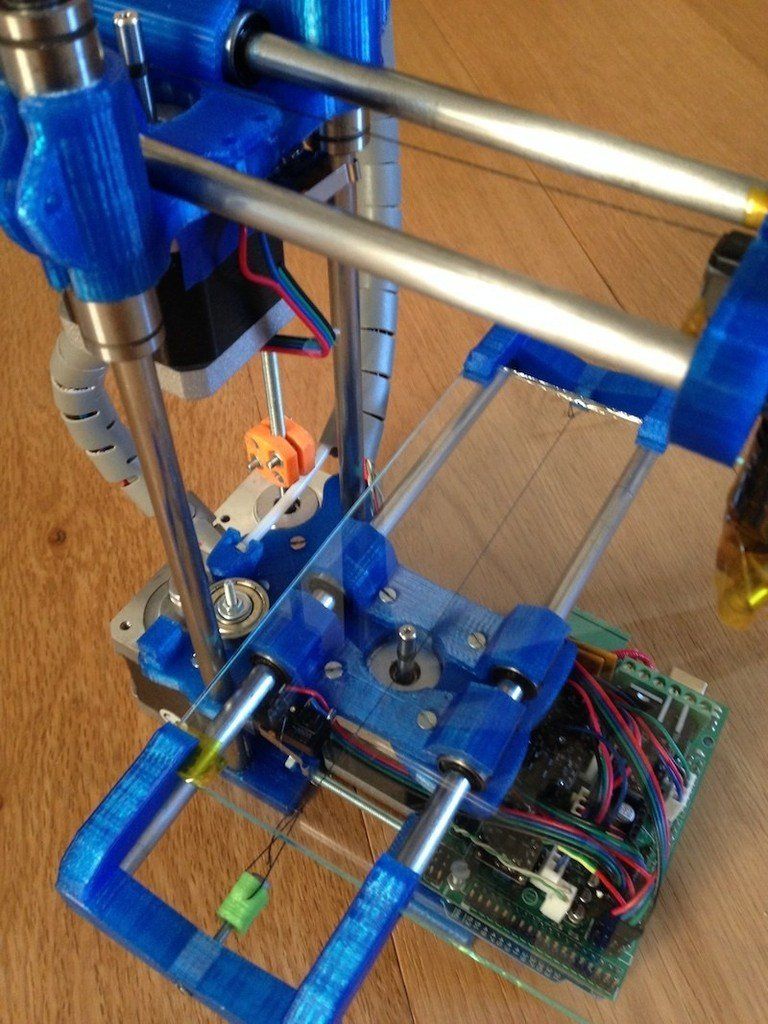

Stereolithography belongs to a family of additive manufacturing technologies known as vat photopolymerization, commonly known as resin 3D printing. These machines are all built around the same principle, using a light source—a laser or projector—to cure liquid resin into hardened plastic. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank.

Watch how stereolithography (SLA) 3D printing works.

SLA 3D printers use light-reactive thermoset materials called “resin.” When SLA resins are exposed to certain wavelengths of light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

A graphic representation of the basic mechanics of stereolithography (SLA) 3D printing.

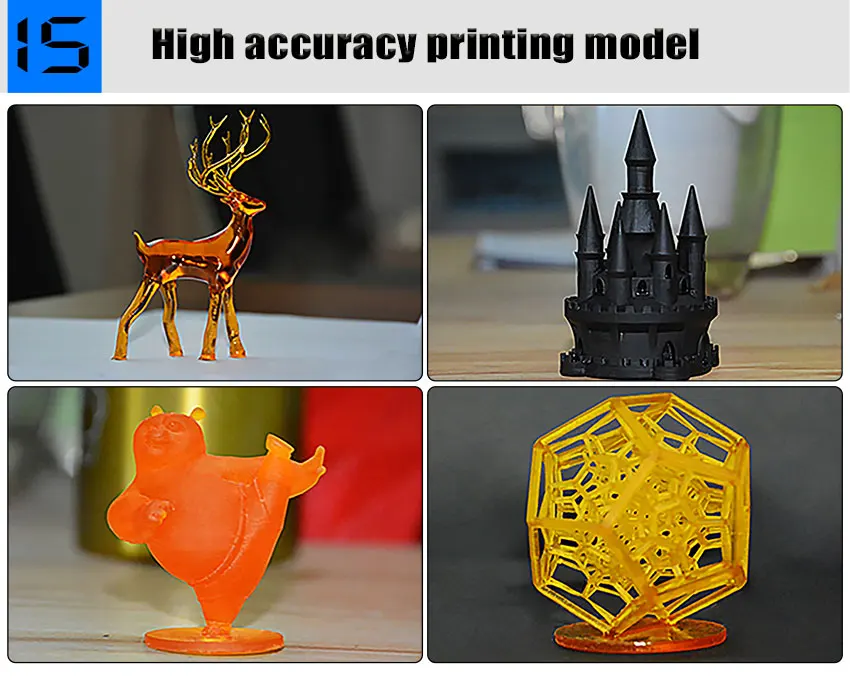

SLA parts have the highest resolution and accuracy, the sharpest details, and the smoothest surface finishes of all 3D printing technologies, but the main benefit of the stereolithography lies in its versatility.

Material manufacturers have created innovative SLA resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Advancements in 3D printing continue to change the way businesses approach prototyping and production. As the technology becomes more accessible and affordable and hardware and materials advance to match market opportunities and demands, designers, engineers, and beyond are integrating 3D printing into workflows across development cycles. Across industries, 3D printing is helping professionals cut outsourcing costs, iterate faster, optimize production processes, and even unlock entirely new business models.

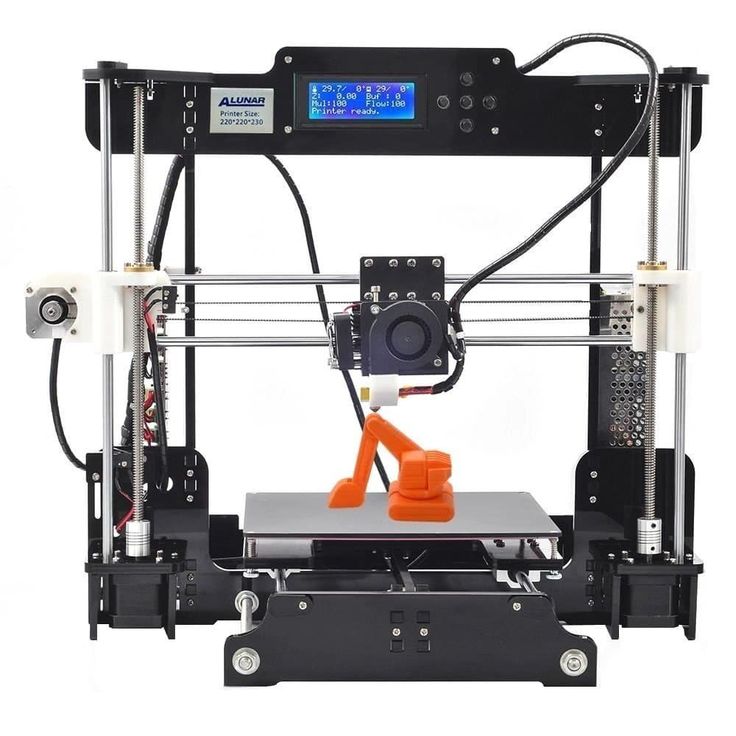

Stereolithography 3D printing in particular has undergone significant changes. Traditionally, SLA 3D printers have been monolithic and cost-prohibitive, requiring skilled technicians and costly service contracts. Today, small format desktop printers produce industrial-quality output, at substantially more affordable price points and with unmatched versatility.

Compare stereolithography 3D printing to two other common technologies for producing plastic parts: fused deposition modeling (FDM) and selective laser sintering (SLS).

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

See how to go from design to 3D print with the Form 3+ SLA 3D printer. This 5-minute video covers the basics of how to use the Form 3, from the software and materials to printing and post-processing.

Use any CAD software or 3D scan data to design your model, and export it in a 3D printable file format (STL or OBJ). Each SLA printer includes software to specify printing settings and slice the digital model into layers for printing. Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection.

More advanced users may consider specifically designing for SLA, or taking steps like hollowing parts to conserve material.

After a quick confirmation of the correct setup, the printing process begins and the machine can run unattended until the print is complete. In printers with a cartridge system, the material is automatically refilled by the machine.

In printers with a cartridge system, the material is automatically refilled by the machine.

An online Dashboard from Formlabs allows you to remotely manage printers, materials, and teams.

Once the printing is completed, parts require rinsing in isopropyl alcohol (IPA) to remove any uncured resin from their surface. After rinsed parts dry, some materials require post-curing, a process which helps parts to reach their highest possible strength and stability. Finally, remove supports from the parts and sand the remaining support marks for a clean finish. SLA parts can be easily machined, primed, painted, and assembled for specific applications or finishes.

Post-curing is particularly important for functional resins for engineering, and mandatory for some dentistry and jewelry materials and applications.

Webinar

In this webinar, Matt Lewis and Ricky Hopper walk you through an overview of the improved SLA line, and give a hands on demo of the new products.

Watch the Webinar Now

Engineers, designers, manufacturers, and more choose SLA 3D printing for its fine features, smooth surface finish, ultimate part precision and accuracy, and mechanical attributes like isotropy, watertightness, and material versatility.

Because 3D printing creates parts one layer at a time, completed prints may have variations in strength based on orientation of the part relative to the printing process, with different properties in X, Y, and Z axes.

Extrusion-based 3D printing processes like fused deposition modeling (FDM) are known for being anisotropic due to layer-to-layer differences created by the print process. This anisotropy limits the usefulness of FDM for certain applications, or requires more adjustments on the part geometry side to compensate for it.

Read our in-depth guide about FDM vs. SLA 3D printers to learn how they compare in terms of print quality, materials, applications, workflow, speed, costs, and more.

In contrast, SLA resin 3D printers create highly isotropic parts. Achieving part isotropy is based on a number of factors that can be tightly controlled by integrating material chemistry with the print process. During printing, resin components form covalent bonds, but layer to layer, the part remains in a semi-reacted “green state.”

While in the green state, the resin retains polymerizable groups that can form bonds across layers, imparting isotropy and watertightness to the part upon final cure. On the molecular level, there is no difference between X, Y, or Z planes. This results in parts with predictable mechanical performance critical for applications like jigs and fixtures, end-use parts, and functional prototyping.

SLA printed parts are highly isotropic compared to those produced with fused deposition modeling (FDM).

Because they are isotropic, SLA printed parts like this jig from Pankl Racing Systems can withstand the variety of directional forces they undergo during high stress manufacturing operations.

SLA printed objects are continuous, whether producing geometries with solid features or internal channels. This watertightness is important for engineering and manufacturing applications where air or fluid flow must be controlled and predictable. Engineers and designers use the watertightness of SLA printers to solve air and fluid flow challenges for automotive uses, biomedical research, and to validate part designs for consumer products like kitchen appliances.

OXO relies on the watertightness of SLA printing to create robust functional prototypes for products with air or fluid flow, like this coffee maker.

Industries from dental to manufacturing depend on SLA 3D printing to repeatedly create accurate, precise components. For a print process to produce accurate and precise parts, multiple factors must be tightly controlled.

Compared to machined accuracy, SLA 3D printing is somewhere between standard machining and fine machining. SLA has the highest tolerance of commercially available 3D printing technologies. Learn more about understanding tolerance, accuracy, and precision in 3D printing.

Learn more about understanding tolerance, accuracy, and precision in 3D printing.

The combination of the heated resin tank and the closed build environment provides almost identical conditions for each print. Better accuracy is also a function of lower printing temperature compared to thermoplastic-based technologies that melt the raw material. Because stereolithography uses light instead of heat, the printing process takes place at close to room temperature, and printed parts don't suffer from thermal expansion and contraction artifacts.

An example from the dental industry comparing a scanned component with the original CAD geometry, demonstrating the ability to maintain tight tolerances across an SLA printed part.

Low Force Stereolithography (LFS) 3D printing houses the optics inside a Light Processing Unit (LPU) that moves in the X direction. One galvanometer positions the laser beam in the Y direction, then directs it along across a fold mirror and parabolic mirror to deliver a beam that is always perpendicular to the build plane, so it is always moving in a straight line to provide even greater precision and accuracy, and allows for uniformity as hardware scales up to larger sizes, like Formlabs larger format SLA printer Form 3L. The LPU also uses a spatial filter to create a crisp, clean laser spot for greater precision.

The LPU also uses a spatial filter to create a crisp, clean laser spot for greater precision.

The characteristics of individual materials are also important for ensuring a reliable, repeatable print process.

Formlabs Rigid Resin has a high green modulus, or modulus before post-curing, which means it’s possible to print very thin parts with precision and a lower chance of failure.

SLA printers are considered the gold standard for smooth surface finish, with appearances comparable to traditional manufacturing methods like machining, injection molding, and extrusion.

This surface quality is ideal for applications that require a flawless finish and also helps reduce post-processing time, since parts can easily be sanded, polished, and painted. For example, leading companies like Gillette use SLA 3D printing to create end-use consumer products, like 3D printed razor handles in their Razor Maker platform.

Leading companies like Gillette use SLA 3D printing to create end-use consumer products, like the 3D printed razor handles in their Razor Maker platform.

Z-axis layer height is commonly used to define the resolution of a 3D printer. This can be adjusted in between 25 and 300 microns on Formlabs SLA 3D printers, with a trade-off between speed and quality.

In comparison, FDM and SLS printers typically print Z-axis layers at 100 to 300 microns. However, a part printed at 100 microns on an FDM or SLS printer looks different from a part printed at 100 microns on an SLA printer. SLA prints have a smoother surface finish right out of the printer, because the outermost perimeter walls are straight, and the newly printed layer interacts with the previous layer, smoothing out the staircase effect. FDM prints tend to have clearly visible layers, whereas SLS has a grainy surface from the sintered powder.

The smallest possible detail is also much finer on SLA, given 85 micron laser spot size on the Form 3+, in comparison with 350 microns on industrial SLS printers, and 250–800 micron nozzles on FDM machines.

While FDM 3D printed parts tend to have visible layer lines and might show inaccuracies around complex features, parts printed on SLA machines have sharp edges, a smooth surface finish, and minimal visible layer lines.

SLA resins have the benefit of a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance. Material range from industry-specific, like dentures, to those that closely match final materials for prototyping, formulated to withstand extensive testing and perform under stress.

Rigid 10K Resin is a highly glass-filled material for industrial parts that need to withstand significant load without bending, including applications like injection molding.

In some cases, its this combination of versatility and functionality that leads to companies to initially bring resin 3D printing in-house. After finding one application solved by a specific functional material, it’s usually not long before more possibilities are uncovered, and the printer becomes a tool for leveraging the diverse capabilities of various materials.

For example, hundreds of engineers in the Design and Prototyping Group at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) rely on open access to a fleet of 12 SLA 3D printers and a variety of engineering materials to support highly diverse research projects with industrial partners like Boeing, Rolls-Royce, BAE Systems, and Airbus. The team used High Temp Resin to 3D print washers, brackets, and a sensor mounting system that needed to withstand the elevated, and leveraged Durable Resin to create intricate custom springy components for a pick and place robot that automates composites manufacturing.

Engineers at the AMRC use a fleet of 12 SLA 3D printers and a variety of engineering materials to print custom parts for diverse research projects, like brackets for a pick and place robot (top), and mounts for sensors in a high-temperature environment (bottom).

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

SLA 3D printing accelerates innovation and supports businesses across a wide range of industries, including engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, audiology, and more.

Rapid prototyping with 3D printing empowers engineers and product designers to turn ideas into realistic proofs of concept, advance these concepts to high-fidelity prototypes that look and work like final products, and guide products through a series of validation stages toward mass production.

Learn More

Manufacturers automate production processes and streamline workflows by prototyping tooling and directly 3D printing custom tools, molds, and manufacturing aids at far lower costs and lead times than with traditional manufacturing. This reduces manufacturing costs and defects, increases quality, speeds up assembly, and maximizes labor effectiveness.

Learn More

Digital dentistry reduces the risks and uncertainties introduced by human factors, providing higher consistency, accuracy, and precision at every stage of the workflow to improve patient care. 3D printers can produce a range of high-quality custom products and appliances at low unit costs with superior fit and repeatable results.

3D printers can produce a range of high-quality custom products and appliances at low unit costs with superior fit and repeatable results.

Learn More

Affordable, professional-grade desktop 3D printing helps doctors deliver treatments and devices customized to better serve each unique individual, opening the door to high-impact medical applications while saving organizations significant time and costs from the lab to the operating room.

Learn More

3D printers are multifunctional tools for immersive learning and advanced research. They can encourage creativity and expose students to professional-level technology while supporting STEAM curricula across science, engineering, art, and design.

Learn More

High definition physical models are widely used in sculpting, character modeling, and prop making. 3D printed parts have starred in stop-motion films, video games, bespoke costumes, and even special effects for blockbuster movies.

Learn More

Jewelry professionals use CAD and 3D printing to rapidly prototype designs, fit clients, and produce large batches of ready-to-cast pieces. Digital tools allow for the creation of consistent, sharply detailed pieces without the tediousness and variability of wax carving.

Learn More

Hearing specialists and ear mold labs use digital workflows and 3D printing to manufacture higher quality custom ear products more consistently, and at higher volumes for applications like behind-the-ear hearing aids, hearing protection, and custom earplugs and earbuds.

Learn More

Many companies start using 3D printing via outsourcing to service bureaus or labs. Outsourcing production can be a great solution when teams require 3D printing only occasionally, or for one-offs that require unique material properties or applications. Service bureaus can also provide advice on various materials and offer value-added services such as design or advanced finishing.

The main downsides of outsourcing are cost and lead time. Often, outsourcing is a gateway to bringing production in-house as needs ramp up. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing also rapidly becomes expensive.

Because of the rise of affordable industrial-quality 3D printing, today, more and more companies choose to bring 3D printing in-house right away, vertically integrating into existing shops or labs, or in the workspaces of engineers, designers, and others who could benefit from translating digital designs into physical parts or who are involved in small batch production.

Small format, desktop SLA 3D printers are great when you need parts quickly. Depending on the number of parts and printing volume, investment into a small format 3D printer can break even within months. Plus, with small format machines, it’s possible to pay for just as much capacity as a business needs and scale production by adding extra units as demand grows. Using multiple 3D printers also creates the flexibility to print parts in different materials simultaneously. Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Plus, with small format machines, it’s possible to pay for just as much capacity as a business needs and scale production by adding extra units as demand grows. Using multiple 3D printers also creates the flexibility to print parts in different materials simultaneously. Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Fast turnaround time is a huge advantage to owning a desktop 3D printer. When working with a printing bureau, lead times, communication, and shipping all create delays. With a desktop 3D printer like the Form 3+, parts are in-hand within hours, allowing designers and engineers to print multiple parts in one day, helping to iterate faster and drastically reduce product development time and quickly test mechanisms and assemblies avoid costly tool changes.

Owning a desktop 3D printer results in significant savings over 3D printing service bureaus and traditional machining, as these alternatives rapidly becomes expensive with growing demand and production.

For example, to fulfill tight production deadlines, a process engineer and team at Pankl Racing Systems introduced SLA 3D printing to produce custom jigs and other low-volume parts directly for their manufacturing line. While in-house SLA was initially met with skepticism, it turned out to be an ideal substitute to machining a variety of tools. In one case, it reduced lead time for jigs by 90 percent—from two to three weeks to less than a day—and decreased costs by 80-90 percent.

| Cost | Lead Time | |

|---|---|---|

| In-House SLA 3D Printing | $9–$28 | 5–9 hours |

| CNC Machining | $45–$340 | 2–3 weeks |

| Outsourced 3D Printing | $51–$137 | 1–3 weeks |

Pankl Racing Systems significantly reduced lead times and costs by 3D printing custom jigs in-house.

With small format machines, it’s possible to pay for just as much capacity as a business needs and scale production by adding extra units as demand grows. Using multiple 3D printers also creates the flexibility to print parts in different materials simultaneously.

The Design and Prototyping Group at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) runs an open-access additive manufacturing station with a fleet of 12 Form 2 stereolithography (SLA) 3D printers for hundreds of engineers working on diverse projects across the site.

Formlabs offers two high precision SLA 3D printing systems, a growing library of specialized materials, intuitive print preparation and management software, and professional services—all in one package.

To continue exploring SLA 3D printing, start with feeling the quality of SLA for yourself: Request a free sample 3D printed part in your choice of material to be mailed straight to your door.

Request a Free Sample Part

Buy 3D Printer Resin Online

Shop by category.

Standard

Tough

Flexible

Castable

Dental

Colourants

Cleaning

Resin: 132 products

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

3DJAKE Isopropyl Alcohol 1 liter- Isopropyl Alcohol 99.9%

- Very effective

- Good cleaning properties

-

Anycubic Wash & Cure 2. 0

0 - 2 in 1 solution

- Easy handling

- 360 ° treatment

-

3DJAKE Color Mix Resin Basic 500 g, 1.000 g- Pixel accurate 3D printing (4K compatible)

- Hardly noticeable smell

- Excellent material properties

-

3DJAKE ecoResin Light Grey 500 g, 1.000 g- Budget-friendly

- Low odour

- Fast curing

-

Liqcreate Castable Wax 250 g, 1. 000 g

000 g- High precision

- Wax-based

- Clean and ash-free burnout

-

Phrozen Aqua Resin Grey 4K 1.000 g- Low shrinkage

- High resolution

- Low viscosity and odour

-

Liqcreate Premium Flex 250 g, 1.000 g- High elongation

- Soft-touch

- Easy to print

-

3DJAKE ecoResin Jet Black 500 g, 1. 000 g

000 g- Budget-friendly

- Low odour

- Fast curing

-

Elegoo Mercury Plus 2.0- Cleaning and curing

- Intelligent curing control

- 360° treatment

-

Phrozen Aqua Resin Blue 1.000 g- Low shrinkage

- Low viscosity and odour

- Fast printing

-

3DJAKE Resin Filter Set 1 set- Easy cleaning

- Separates resin from particles

- Easy to use

-

Phrozen Aqua Resin Ivory 4K 1. 000 g

000 g- Low shrinkage

- High resolution

- Low viscosity and odour

-

Liqcreate Premium Model 250 g, 1.000 g- Opaque resin

- Matt colour

- For all open source LCD & DLP 3D printers

-

Liqcreate Flexible-X 250 g, 1.000 g- High elasticity

- Good tear resistance

- Especially suitable for industrial parts

-

3DJAKE Resin Standard Black 500 g, 1. 000 g

000 g- For LCD / MSLA printers

- Easy to use

- Good adhesion

-

3DJAKE Resin Standard Dark Grey 500 g, 1.000 g- For LCD / MSLA printers

- Easy to use

- Good adhesion

-

3DJAKE Resin Cleaner 500 ml, 1.000 ml, 5.000 ml, 10.000 ml- Low odour

- Ease of use

- Suitable for ultrasonic cleaners

-

Liqcreate Strong - X 250 g, 1. 000 g

000 g- High Strength

- High Rigidity

- High Temperature Resistance

-

Liqcreate Composite-X 375 g, 1.500 g- High rigidity and flexural strength

- Excellent chemical resistance

- Ideal for both industrial and private use

-

Phrozen ABS-like Resin - Grey 1.000 g- ABS-like

- High resolution

- High hardness

-

Anycubic Wash & Cure Plus- For larger resin prints

- 2-in-1 solution

- Powerful cleaning device

-

3DJAKE Resin Colorant Transparent Red 12,50 g, 25 g- Transparent and opaque colours

- Beautiful colouring

- High quality

-

Phrozen Aqua Resin Grey 8K 1. 000 g

000 g- 3D models in high resolution

- Shore D85

- Fast and precise printing

-

Phrozen Water-Washable Resin - Black 1.000 g- Washable with water

- Robust

- Universally applicable

All prices incl. VAT.

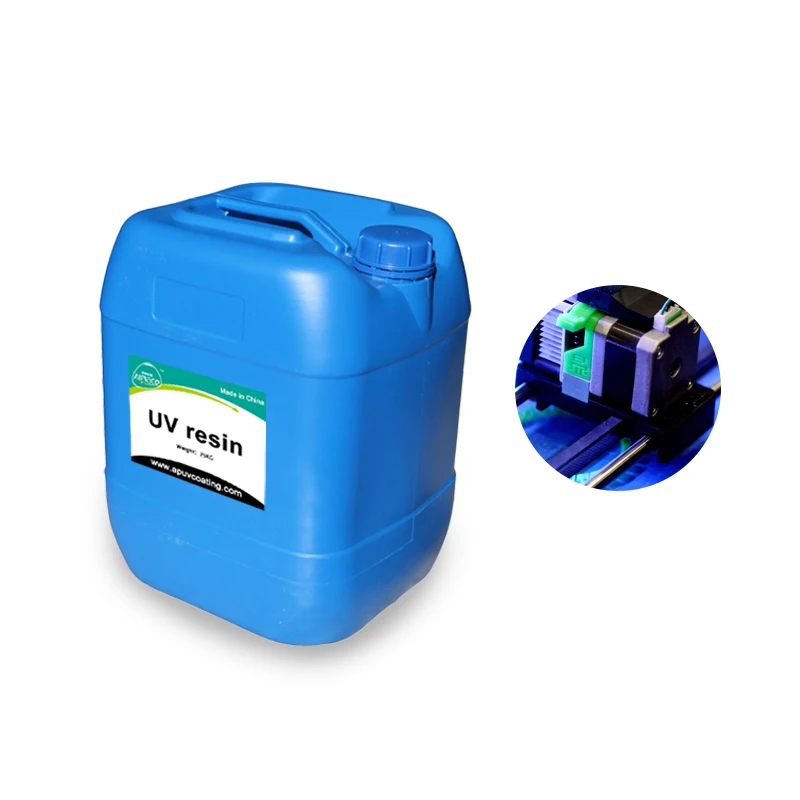

405nm photosensitive resin suitable for SLA, DLP, LCD 3D printers.

405 nm photosensitive resin suitable for SLA, DLP, LCD 3D printers.- products

- 3d printer uv resin

- transparent resin

- transparent 3d printing high transparency uv resin

Description

0024

1. Difference in material characteristics

Difference in material characteristics

PLA plastic is short for polylactic acid polymer material, usually extracted from cornstarch, a green and degradable material. PLA is commonly used as a linear material, PLA melts when heated to a certain temperature and re-solidifies when the temperature is lowered. PLA 3D printing molding also makes use of its melting and cooling characteristics.

Photosensitive resin, also known as UV resin, is a liquid composed of a polymeric monomer and a prepolymer to which a light initiator has been added. At a certain wavelength of ultraviolet radiation, a polymerization reaction is immediately induced until complete curing.

2. the difference between the forming principle of

PLA used the so-called FDM molding process, the full name of this process is called "hot melt casting technology", it is linear material into the machine through the machine feeding system of the extrusion die, extrusion die by heating the material until melted and then through certain material from the extrusion die, the pressure will melt the extrusion. At the same time, the computer controls the extrusion head to go beyond the track on the work table, so that the material is deposited layer by layer on the work table.

At the same time, the computer controls the extrusion head to go beyond the track on the work table, so that the material is deposited layer by layer on the work table.

Photosensitive resin molding process is called SLA, the full name is "light-curing stereo modeling technology", the molding process is liquid photosensitive resin impregnated with the desktop, then through the UV irradiation level, immediately by exposure to the curing part, after the formation of the layer , workbench fall height, workbench soaking liquid level, ultraviolet light for the next layer of radiation curing, so layer-by-layer molding curing.

The molding principle of the resin is a light-curing technology, at high temperatures it loses its strength and becomes soft. PLA materials use FDM equipment and melt together at high temperature, so the strength of PLA is much higher than that of resin, and resin products will be a little brittle.

Other important differences?

SLA for photosensitive resin molding requires more optics and material science. Relatively speaking, the technical threshold is relatively high. There are fewer equipment manufacturers, but their numbers are relatively high, ranging from 300,000 to millions of pieces of industrial equipment. The FDM equipment formed by PLA is mainly related to the movement and control aspects of the mechanisms, and the technical threshold is relatively low, which also leads to many manufacturers entering the market, which can be said to be uneven. The cost of equipment and materials is relatively low, the stability of operation is low, and the print quality is also relatively ordinary. Photosensitive resin molding processes are commonly used in the corporate market, while PLA printing is commonly used for personal and educational use.

Relatively speaking, the technical threshold is relatively high. There are fewer equipment manufacturers, but their numbers are relatively high, ranging from 300,000 to millions of pieces of industrial equipment. The FDM equipment formed by PLA is mainly related to the movement and control aspects of the mechanisms, and the technical threshold is relatively low, which also leads to many manufacturers entering the market, which can be said to be uneven. The cost of equipment and materials is relatively low, the stability of operation is low, and the print quality is also relatively ordinary. Photosensitive resin molding processes are commonly used in the corporate market, while PLA printing is commonly used for personal and educational use.

PLA printing is designed to melt the line material and then extrude and fold it, and the extruded hole diameter is only 0.2 to 0.5mm. Usually, if we want to print a 1kg PLA model, we need to run the machine for three days and three nights in a row to complete it. If something goes wrong, you have to start from scratch. Using photosensitive resins, the machine could ideally produce several kilograms per day.

If something goes wrong, you have to start from scratch. Using photosensitive resins, the machine could ideally produce several kilograms per day.

Photosensitive resin molding and PLA printing are molded, step by step for this type of pile molding method, the model of PLA star regions prone to larger defects, the molding process of photosensitive resin in the molding process of the liquid itself on the loose parts of the model was better support effect, therefore, the model will not have dangling parts, there are obvious flaws. In addition, PLA printing generally accumulates a height of 0.2mm or higher for each layer, while photosensitive resin solidifies with a thickness of 0.1 or 0.05mm for each layer, which directly reflects the effect of the model that the stepped grain of the PLA print model will be thicker, not too smooth; smooth.

send inquiry to us

email*

firstname*

phone

Content*

Related Product

Chat with us

How safe are 3D printing resins?

Filament Deposition Modeling (FDM) material extrusion is the most popular polymer 3D printing method, but resins are becoming more and more important to consumers. Resin technologies such as stereolithography (SLA) were previously only used in dental laboratories, engineering departments and manufacturing plants due to the high cost of the equipment. Now that machines have become more affordable, more and more ordinary users are using SLA technology, which calls into question their safety.

Resin technologies such as stereolithography (SLA) were previously only used in dental laboratories, engineering departments and manufacturing plants due to the high cost of the equipment. Now that machines have become more affordable, more and more ordinary users are using SLA technology, which calls into question their safety.

Unlike FDM devices, resin printers use photosensitive liquids to print, curing materials with ultraviolet light. Liquid polymers pose a greater potential health risk than raw materials in fiber form. The toxicity of the resource may put off some users, but printing with resin can be safe if the right algorithm is followed.

What are the Potential Risks of Resins

The word "toxicity" is troubling, but according to definitions developed by occupational health and safety professionals, any substance that, under certain conditions, can cause harm or disease, is "toxic". According to this formulation, many substances around us are potentially dangerous, including perfumes and mattress filling. But are there any particular risks when using liquid resins for 3D printing?

But are there any particular risks when using liquid resins for 3D printing?

The main concern with photopolymer resins is that they can cause skin irritation on contact. In some cases, contact of the substance with unprotected skin results in burns and blisters, which may require medical attention. If the materials come into contact with the eyes, they will cause irreparable damage.

Many resins are sensitizers, which means that prolonged exposure sometimes causes a mild allergic reaction. The chemicals that make up most resins are irritants that provoke the appearance of dermatitis - inflammation of the skin due to rejection of foreign elements. The skin quickly absorbs such chemicals, so prolonged contact with the composition or exposure to a large dose can lead to more serious consequences.

Another problem with resin 3D printing is air pollution. The material releases fumes, potentially reducing indoor air quality (IQA). Poor IQA scores can lead to headaches, fatigue, or more serious reactions such as breathing problems. These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

Long-term effects from working with liquid polymer are rare but significant:

• If the vapors are inhaled for a long time, chronic diseases of the respiratory system may appear.

• Some of the VOCs emitted by resins are suspected to be carcinogens, so they are likely to cause cancer after prolonged exposure.

• Constant physical contact can lead to severe allergies.

Standards and manufacturer's instructions

On the other hand, most resins on the market do not pose a significant hazard. Companies that produce such materials must comply with government standards and additional recommendations ISO 9001. Regulations ensure that chemicals produced by businesses are minimally harmful. However, some hazardous elements, such as asphalt fumes and synthetic mineral fibers used in fiberglass, are still widely used and over half a million workers are exposed to them.

Manufacturers usually provide Material Safety Data Sheets (MSDS) that list any potential health concerns. For example, corneal burns from overexposure to the eyes, or nausea and vomiting if swallowed. All these documents are provided in order to provide users with maximum safety when using consumables.

Some compounds may be more dangerous than others for certain people. If a person does not know if they are allergic to any materials, they should act as if they are and handle the product with care.

Safety Steps

Several government agencies have conducted research into the safety of epoxy 3D printing. They all showed that long-term emissions from printing are mostly negligible, although risks exist if proper precautions are not taken. Since studies have found traces of hazardous substances when working with resin formulations, safety regulations must be observed.

3D printing resins are not as scary as they seem, but they still need to be handled with care.