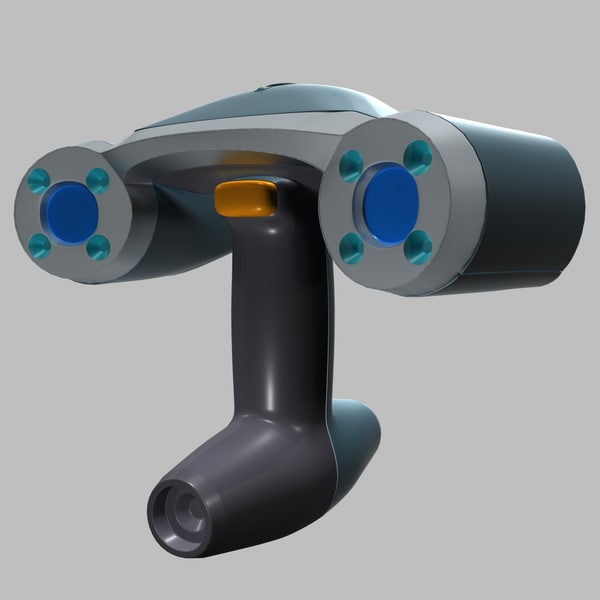

Raven 3d scanner

Raven Original Wi-Fi Wireless Scanner

Last updated date: January 6, 2022

DWYM Score

Why Trust DWYM?

DWYM is your trusted product review source. Along with our in-house experts, our team analyzes thousands of product reviews from the most trusted websites. We then create one easy-to-understand review. Learn more.

Show Contents

Contents

- Our Take

- Features

- Specifications

- From The Manufacturer

- Expert Reviews

- Overall Ranking

- Our Buying Guide

- Our Tip and Advice

We looked at the top and dug through the reviews from some of the most popular review sites. Through this analysis, we've determined the best you should buy.

Update as January 6, 2022:

Checkout The Best Scanner for a detailed review of all the top .

Overall Take

Scan documents wirelessly through WiFi or by using an ethernet cable when you go with this professional scanner. The unit uses a 7-inch LCD touchscreen display that is easy to use. There's also a built-in document editor that allows you to name your documents, crop or rotate pictures and even reorder pages.

In our analysis of 47 expert reviews, the Raven Original Wi-Fi Wireless Scanner placed 5th when we looked at the top 16 products in the category. For the full ranking, see below.

From The Manufacturer

With scan speeds up to 17 pages per minute, duplex two-sided scanning and a 50 sheet automatic document feeder, this scanner is built for any office or home setting. No cables or software installation required to start scanning to your favorite cloud destinations, email, SMB share, fax, USB flash drive, SMB network share folder and FTP. Scan quality modes support 200dpi, 300dpi, 400dpi and 600dpi.

Expert Reviews

User Summarized Score

324 user reviews

What experts liked

Like the ScanSnap iX1500, the RavenScanner can send your scanned documents to a number of locations including the cloud, but can also email or fax them directly from the scanner, and can save to a connected flash drive.

- Software How

| Full review

What experts didn't like

This scanner is a new product for 2019, so it’s difficult to gauge how it stands up to long-term use.

- Software How

| Full review

1. Canon imageFORMULA R40 Ultra Fast Automatic Scanner

Overall Score: 9.4

2. Visioneer Xerox DocuMate Image Enhancing One Touch Scanner

Overall Score: 9.3

3. Doxie Go SE Paperless Mini Scanner

Overall Score: 9.2

4. Fujitsu ScanSnap iX1500 Large LCD Touchscreen Scanner

Overall Score: 9.0

5. Raven Original Wi-Fi Wireless Scanner

Overall Score: 8.9

6. Brother DS-640 Portable Lightweight Scanner

Overall Score: 8.8

7. Epson WorkForce ES-50 USB Super Fast Scanner

Overall Score: 8. 3

3

8. Epson Perfection V550 Picture Restoring Scanner

Overall Score: 8.2

9. Canon CanoScan LiDE220 Automatic Cloud Compatible Scanner

Overall Score: 8.2

10. Epson Workforce ES-500W Multi-System Compatibility Scanner

Overall Score: 8.1

11. Canon CanoScan 9000F Document Enhancing Scanner

Overall Score: 7.9

12. Epson Perfection V600 Enlarging Energy Efficient Scanner

Overall Score: 7.8

13. Doxie Go SE Battery Powered Tiny Scanner

Overall Score: 7.7

14. Brother ADS-2000e ImageCenter Optimizing High-Speed Scanner

Overall Score: 7.6

15. Canon MX492 Compact Inkjet Scanner

Overall Score: 7.0

16. Brother DS-620 Travel USB Powered Scanner

Overall Score: 6.2

Today, the world seems to get by with far less paper, thanks to technology. Still, there are many instances where a piece of paper is the only option. When you need to turn a document or photo into an electronic file, scanners are the way to go. Even if you find you rely on it less than ever, you’ll at least occasionally need one, whether it’s at work or at home.

Still, there are many instances where a piece of paper is the only option. When you need to turn a document or photo into an electronic file, scanners are the way to go. Even if you find you rely on it less than ever, you’ll at least occasionally need one, whether it’s at work or at home.

Digitizing paper documents isn’t the only reason to have a scanner on hand. If you have printed pictures, you can scan and save them to preserve them indefinitely. You may even be able to touch up that decades-old photo of your grandmother and make up for some of the fading that happened while it was “safely preserved” in a photo album. At the very least, you’ll be able to scan and save them to a cloud-based storage service, where they can be accessible to you and your loved ones indefinitely.

Shopping for a scanner can be overwhelming, though. Most of the scanners on the market today are not only efficient and affordable, but they provide high-quality scans. Some are better than others in those areas, though, so it can help to know what your own needs are likely to be before you buy. If you foresee regularly needing to digitize stacks of documents, a scanner with a good feeder should be high on your list. If you have boxes of photos you need to save and send to the cloud, high-quality photo scanning is a must.

If you foresee regularly needing to digitize stacks of documents, a scanner with a good feeder should be high on your list. If you have boxes of photos you need to save and send to the cloud, high-quality photo scanning is a must.

Unless you’ll have a tech guru on hand to set up and troubleshoot issues with your scanner, you’ll also want one that’s easy to install and use. Some scanners do a better job of getting you online and connecting your devices. Others require extra work to get online and add additional computers. Make sure you know what you’re getting into when you pull your new scanner out of the box.

- Your first experience with your new scanner will be during setup. The Fujitsu ScanSnap iX500 provides easy installation processes, walking you through the steps to connect it to your Wi-Fi network.

- Once you’re online, you’ll also need to be able to connect to the devices in your home or office. The Fujitsu ScanSnap iX500 is compatible with Windows, Mac, Android and iOS, covering the most popular devices.

The Brother Compact Mobile Document Scanner, on the other hand, is compatible with Windows, Mac and Linux and TWAIN/WIA for PC/ICA for Mac/SANE drivers.

The Brother Compact Mobile Document Scanner, on the other hand, is compatible with Windows, Mac and Linux and TWAIN/WIA for PC/ICA for Mac/SANE drivers. - You don’t have to save your documents to a device in order to scan, though. Some scanners will let you send items directly to the cloud.

- One issue with the Fujitsu ScanSnap iX500 is that you can only connect wirelessly to one device at a time.

- If you need to edit your documents after scanning them, you’ll probably want good software for that purpose. Some scanners come with basic editing software that lets you make basic tweaks.

- If photos are your priority, stick with a model that has a scanning resolution of 4800 by 4800. You’ll get high-quality images from that. However, if you need to scan film or access 3D-scanning capabilities, you’ll need to choose from scanners that offer that functionality.

- The Fujitsu ScanSnap iX500 is designed for scanning paper documents, such as letters and memos.

It’s not as good for tackling a wide range of document types with ease.

It’s not as good for tackling a wide range of document types with ease. - Chances are you don’t have hours to waste on setting up and troubleshooting your scanner. The Fujitsu ScanSnap iX500 is easy to use with a minimal learning curve.

- Nothing comes in as handy as a document feeder when you’re dealing with a stack of paperwork. The Fujitsu ScanSnap iX500 and Raven Touchscreen Duplex Feeder Scanner have document feeders that can hold up to 50 sheets of paper at a time.

- You’ve probably experienced scanners that take a while to process each document. If you’re scanning multiple pages through a feeder, this can be especially important. The Fujitsu ScanSnap iX500 is rated at 25 pages per minute, which is faster than many competitors. You may also want to look for a scanner that features ReadyScan LED technology that cuts out that warm-up time that slows down your work.

- The good news is, scanners are more affordable than ever. You can get a great scanner at a reasonable price.

- It’s also important to consider size when you’re choosing a scanner. The Fujitsu ScanSnap iX1500 Document Scanner measures 11.50 by 6 by 6.30 inches, which means you’ll need to clear away significant space for it. The Doxie Go SE Portable Battery Scanner is only 12.25 by 2.25 by 1.75 inches, while other scanners measure 11.90 by 2.20 by 1.40 inches.

Checkout Our Other Buying Guides

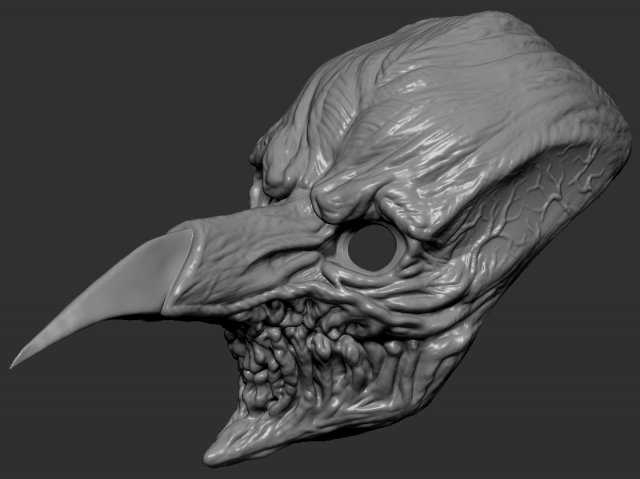

▷ raven skull 3d models 【 STLFinder 】

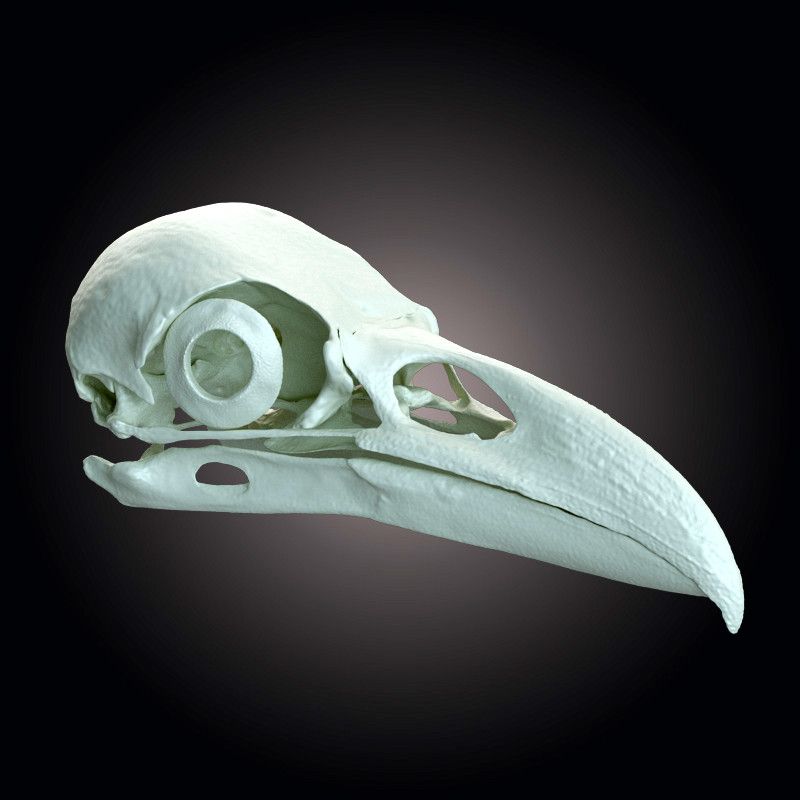

Raven skull

sketchfab

Anatomically correct model of a raven skull (Corvus corax). ...Scan from a real skull.

Raven_skull

thingiverse

This is a semi low detail raven skull modeled off pictures of a real one

Raven Skull

myminifactory

This is a raven skull based off of taxidermy images. It is not a 3D scan, I designed it in Blender to create a cleaner and easier to print model. ...It is scaled to life size at 120 mm in length.

It is not a 3D scan, I designed it in Blender to create a cleaner and easier to print model. ...It is scaled to life size at 120 mm in length.

Raven Skull

prusaprinters

This is a raven skull based off of taxidermy images. It is not a 3D scan, I designed it in Blender to create a cleaner and easier to print model. ...It is scaled to life size at 120 mm in length.</p>

Raven Skull

thingiverse

This is a replica of a raven skull based of taxidermy images. It was designed in Blender to be as close to the real thing as possible, without the holes and inconsistencies that you would get when 3D scanning it. It is scaled to life size, at 120 mm. ..

..

Raven Skull

cults3d

Raven Skull - 3D print model Files contain complete model of Raven Skull ready to be 3D printed. SCALE At 100% scale dimensions of skull are: Width approx. 26.5 mm (1.04 inches) Height approx. 25 mm (0.98 inches) Length approx. 84 mm (3.30 inches) ...

Raven Skull

myminifactory

... seen as scary because of their natural black colour and shadow like appearance. This Raven resting on two skulls will chill out any light hearted halloween party animal. https://drive.google.com/file/d/0B8IxvRA_ugDleTVMVW9WdGUxTUk/view?usp=sharing

Raven & Skull

thingiverse

Here is another archmage item. ...This time is a raven on a skull! Hope you find it useful for your sceneries! ...You can find the stl attached to this post (Non-supported version, presupported version, presupported and hollow version)

...This time is a raven on a skull! Hope you find it useful for your sceneries! ...You can find the stl attached to this post (Non-supported version, presupported version, presupported and hollow version)

Raven Skull

thingiverse

I'm am teaching myself 3d molding. ... I made this skull today. ... I hope you enjoy it.

Raven Skull

thingiverse

I printed it on an SLA printer ( Longer Orange 30 ) with support in the back of the skull. ... I never tried on FDM printer.

Raven Skull

prusaprinters

I'm teaching myself 3d modeling and I designed this skull today. ... I'm pretty happy with how it turned out so I figured I share it here.</p> <h4>Print instructions</h4><p>I used supports and a .2mm height for my print.</p>

... I'm pretty happy with how it turned out so I figured I share it here.</p> <h4>Print instructions</h4><p>I used supports and a .2mm height for my print.</p>

Raven Skull stencil

thingiverse

Raven Skull stencil

Voxel Raven Skull Statue

thingiverse

Voxel Raven Skulls Statue

Raven Skull -BC8130

thingiverse

Raven Skull - BC 8130 Corvus corax

Raven skull 3D model

cgtrader

raven skull Raven skull 3d model (smooth enable) renders in Maya 2018+ Arnold 5(scene included) textures included +textures for keyshot -mb(Maya 2018+ Arnold 5) -obj -fbx

Raven skull bicycle light

thingiverse

Bicycle light in a raven skull shape. ...Instructable is in the following link: https://www.instructables.com/id/Copper-Plated-Raven-Skull-Bicycle-Light/ Think about securing it well, mine got stolen unfortunately.

...Instructable is in the following link: https://www.instructables.com/id/Copper-Plated-Raven-Skull-Bicycle-Light/ Think about securing it well, mine got stolen unfortunately.

Filigree Raven skull

pinshape

A Filigreed raven skull. The file is the skull in two halves oriented for printing. ... This was printed at .2mm in abs

Raven Skull + Bones

sketchfab

A sculpt I did entirely on Blender. ...Quite a fun project! A raven skull and two bones just for the sake of it. ...Also, some nice lights.

Raven Skull Pendant

thingiverse

Remix of Shadowcraft_Designs Raven Skull. Used Meshmixer to attach a loop for a neclace to go through. ...

Printed beautifully in transparent on the Elegoo Mars 2 Pro.

Used Meshmixer to attach a loop for a neclace to go through. ...

Printed beautifully in transparent on the Elegoo Mars 2 Pro.

Raven skull bicycle light

prusaprinters

Instructions on assembly and optional copper plating can be found here!Original model of the raven skull itself can be found on thingiverse here.

Raven skull keyholder

thingiverse

I love this raven skull, so I modified to make a keyholder. I reccomend to print with resin, but also with FDM is good. ... Good resolution, good configurations and supports are needed.

Xayah - Raven Skull

thingiverse

This is the Raven skull on the shoulder of League of Legends hero Xayah, Made by Gero Gerhardt (gero. [email protected]) for a Cosplay. ...

More picture will follow.

[email protected]) for a Cosplay. ...

More picture will follow.

Raven Skull Mask

thingiverse

Made the Raven skull (scan?) into a mask. NOTE! You will have to scale this to fit your head. ...It fits my head scaled up to 115%, you might want to scale to 120% just to be safe.

Siamese Raven Skull

thingiverse

This is a remix from https://www.thingiverse.com/thing:2479682 Siamese Twin Raven Skulls The first print failed as I did not add enough support. ...But the second one worked just fine.

Raven Skull Earring

thingiverse

This is a remix of junior3d's Raven Skull Pendant with a ring added to attach to earring hooks. The original size of the pendant has been preserved, so you'll want to scale this down in your slicer before you print, otherwise it'll be huge. ...(For...

The original size of the pendant has been preserved, so you'll want to scale this down in your slicer before you print, otherwise it'll be huge. ...(For...

Raven Skull Cane Topper

thingiverse

This is a remix of the Raven Skull Cane Handle by Londonbrig0. As I was looking to make a prop, I was in search of a cane topper with a hole in the base. I loved this model so much decided to just adapt it for my particular needs. Scaled at 150% the...

Raven Skull Mask

thingiverse

Remixed from a scan of a raven skull to be a wearable mask with an articulated jaw. Source file can be downloaded here: https://www. thingiverse.com/thing:2484293

Files are sliced to fit a 300x300x400mm print bed. The model comes sliced for easier...

thingiverse.com/thing:2484293

Files are sliced to fit a 300x300x400mm print bed. The model comes sliced for easier...

Raven Skull Bottle Stop

thingiverse

Its a remix of a Raven Skull I found online (Boneheads) combined with a bottle stop I modeled in Inventor (I joined the two in Meshmixer). On my Formlabs +1 printer it took 3 and a half hours to make and used 24 ml of resin. Afterwards the print was...

Raven Skull Low Poly Remix

thingiverse

Low-Poly remix of the Raven Skull statue. ...

raven skull 3D print model

cgtrader

raven skull 90% of my 3d models have been checked: made wax and finished product in gold or silver

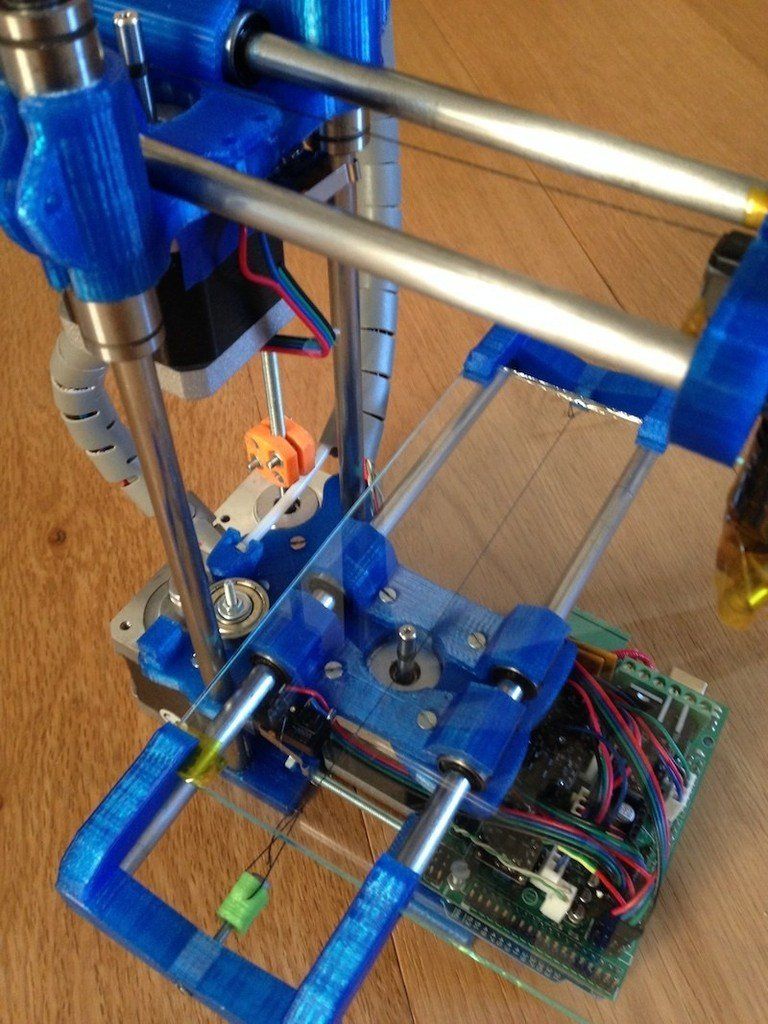

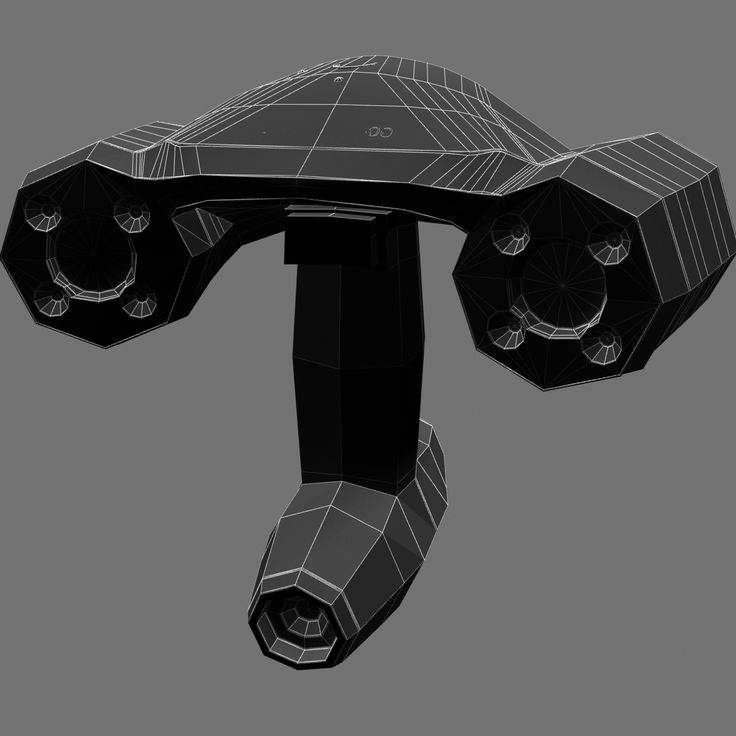

Voron printers.

Stream from VoronDesign.

Stream from VoronDesign. “The best way to be creative is plagiarism!” (c) I am, but this is not accurate.

Unfortunately, the process of plagiarism of the ideas of foreign makers in Russia is extremely hampered by the language barrier (I am now talking about even English-speaking makers, not to mention original Asia). Personally, I think that this is fundamentally wrong - if you want to make your own, find someone who made it similar and improve it! Today I want to introduce you to the work of such a creative team as VoronDesign. The guys are relatively famous in the world thanks to the beautiful designs of core-xy printers Voron 1 (on shafts) and Voron 2 (on rails, with a movable portal). These printers even have a Russian-speaking community ... But it is mostly not from Russia.

It all started with such a project as MZBOT, but now the guys from VoronDesign write about themselves that they have “common design ethos”. So the common ethos of designers. Well, ethos, and ethos, but when Volk broke away from them (later, like “Annex-Engineering”), shit flew in all directions so that it was difficult to suspect the participants of having at least some kind of ethics. But the crows really have a lot of design ethos - everything looks more beautiful than the average. A small digression - the work of Annex-Engineering with their abundance of harsh ball screws and MGN12 - MGN15 can make fans of the domestic Yo-bot with 12 rails enviously groan :-)

Well, ethos, and ethos, but when Volk broke away from them (later, like “Annex-Engineering”), shit flew in all directions so that it was difficult to suspect the participants of having at least some kind of ethics. But the crows really have a lot of design ethos - everything looks more beautiful than the average. A small digression - the work of Annex-Engineering with their abundance of harsh ball screws and MGN12 - MGN15 can make fans of the domestic Yo-bot with 12 rails enviously groan :-)

So, the advantages of VoronDesign's engineering ethos include the beauty and detail of their designs, the high quality of documentation, and the chronic unwillingness and inability to bring designs to perfection. And also a lot of not quite ordinary engineering solutions, completely uncharacteristic, for example, for domestic and Chinese printer building. And to be honest, it's not always a plus. Worth exploring though. Tormented by the desire to build something interesting, I built their Voron 1. 6 printer and began to follow their work. Well, how is Raven 1.6? The XY portal there is from 1.6, but everything else is a dense off-spec and is still being finalized. As they say - "I'm not Bill Gates, to do everything at once" (oldfags, who remember where it came from - write to ICQ). But about the cons of 1.6, both those that I saw in advance, and those that I saw only after construction, I will tell in a separate article, and here I will just go over the VoronDesign stream from March 4, where they showed a pack of their promising developments, their "promising" developments and "their" not-understand-why developments :-)

6 printer and began to follow their work. Well, how is Raven 1.6? The XY portal there is from 1.6, but everything else is a dense off-spec and is still being finalized. As they say - "I'm not Bill Gates, to do everything at once" (oldfags, who remember where it came from - write to ICQ). But about the cons of 1.6, both those that I saw in advance, and those that I saw only after construction, I will tell in a separate article, and here I will just go over the VoronDesign stream from March 4, where they showed a pack of their promising developments, their "promising" developments and "their" not-understand-why developments :-)

I must say right away that the format itself is frankly amazing in a good way - to see a crowd of makers who work more or less harmoniously on some large and common tasks is very cool and inspiring. Regardless of the results achieved.

But about what they showed... let's learn from the mistakes of others.

It all started with a show of the long-announced voron 1. 7 (now it has become 1.8). Actually, what's the catch. They promised the following key features: 1) a closed body and a slightly larger working area with the same dimensions 2) rails instead of shafts 3) direct extruder 4) replacement of the z limit switch with an FSR (pressure resistor) to a regular button. 5) New motherboard - SKR + 2209with a ready-made config (for the lazy, it used to be possible to run this banal CoreXY like 2 fingers even on an 8-bit arduino). Strictly speaking, everything that they promised was already a year and a half like no one needs. For good, it was necessary to bring to mind 1.5 with its ability to put a chimera, in extreme cases, bring to mind 1.6 (since 1.5 was canceled), but the Ravens are interested like this. And now about the ambiguity of this whole process from its very beginning. 1 and 2) actually 1.6 on rails was a long time ago in the form of Franken-voron mod (https://github.com/FrankenVoron/Voron-1.6-mod). Take it and do it, Lord, there you have rails and a closed building.

7 (now it has become 1.8). Actually, what's the catch. They promised the following key features: 1) a closed body and a slightly larger working area with the same dimensions 2) rails instead of shafts 3) direct extruder 4) replacement of the z limit switch with an FSR (pressure resistor) to a regular button. 5) New motherboard - SKR + 2209with a ready-made config (for the lazy, it used to be possible to run this banal CoreXY like 2 fingers even on an 8-bit arduino). Strictly speaking, everything that they promised was already a year and a half like no one needs. For good, it was necessary to bring to mind 1.5 with its ability to put a chimera, in extreme cases, bring to mind 1.6 (since 1.5 was canceled), but the Ravens are interested like this. And now about the ambiguity of this whole process from its very beginning. 1 and 2) actually 1.6 on rails was a long time ago in the form of Franken-voron mod (https://github.com/FrankenVoron/Voron-1.6-mod). Take it and do it, Lord, there you have rails and a closed building. True, 3 rails were needed there, and in 1.8 the Ravens managed to use as many as 4 rails on the XY axis. Straight up upgrade!

True, 3 rails were needed there, and in 1.8 the Ravens managed to use as many as 4 rails on the XY axis. Straight up upgrade!

3) direct extruder for 1.6, as well as for 1.7, is not a problem at all ... since 1.6 is absolutely compatible with 2.2 nozzles. If you want, put their own Afterburner, if you want, put mods with BMG on top, if you want, put newfangled Nimble with nema8. Those. there was no need to release another revision for the sake of adding existing mods at all. Only from the latest series of requests for 1.6 with direct.

One

Two

4) The Z-limiter, as it was idiotic, not allowing the continuation of interrupted printing, remained the same. Now it's just a little easier to implement it. 5) It would be better if, instead of replacing the MP, they wrote a good and understandable manual for installing the clipper on at least something. 6) The illumination of the working area is gorgeous in its uselessness. The fact is that the “ears” of the chic and beautiful head of the Raven block the flow of light from side lighting. This lighting is better than nothing, but still bad. Although it might even be worse than nothing. And, by the way, the button to turn off the backlight is not visible. And this is the most important thing from an engineering point of view, because LEDs installed the way they have often hit strangers in the eye. And this is just what is visible right at first sight - and after all, when designing, it was possible to make another 100-500 mistakes, with the same tensioners or engines (for a year now, they have not been able to do this engineering correctly on Vorona 2). Well, here they have everything new - everything is compatible with version 2.4 In general, as Ax said: “I ask for one thing - do not hire idiots for this business.” Apparently they didn't watch a great movie. Therefore, they did what had already been done before them and did not do it in the best way. Then there was a funny piece number 2, where they discussed the problems of the Raven 2.2 and 2.4, especially in matters of portal ends (tensioners and engines).

This lighting is better than nothing, but still bad. Although it might even be worse than nothing. And, by the way, the button to turn off the backlight is not visible. And this is the most important thing from an engineering point of view, because LEDs installed the way they have often hit strangers in the eye. And this is just what is visible right at first sight - and after all, when designing, it was possible to make another 100-500 mistakes, with the same tensioners or engines (for a year now, they have not been able to do this engineering correctly on Vorona 2). Well, here they have everything new - everything is compatible with version 2.4 In general, as Ax said: “I ask for one thing - do not hire idiots for this business.” Apparently they didn't watch a great movie. Therefore, they did what had already been done before them and did not do it in the best way. Then there was a funny piece number 2, where they discussed the problems of the Raven 2.2 and 2.4, especially in matters of portal ends (tensioners and engines).

The fact is that the original design of the Raven 2.0-2.2 in this place is terrible and there are about 5 modifications of this node, in the form of mods. Including from the people cursed in the crow chat who-must-not-be named. For some reason, the designers did not want to take a good mod (as always) and they designed another shushpanzer, calling it 2.4. So that it is not compatible with good mods from "he who must not be named." They say that 2.4 will be tested. It looks like it's on people. Oh well. Why they don't like their moderators so much and quite good, working mods for their designs, I honestly don't understand. As a result, we have unfinished 2.2 and will be 2.4. Apparently I'm far from their ethos. And then they introduced what it was all about - Voron 0. A new tiny printer on 5 rails and nema14. Insane typing speeds (like up to 120mm/s or something), add support for Mosquito and Dragon in addition to V6 hotends (hotends, by the way, are also promised for 1. 8 and 2.4). There is exactly one thing that is not clear in the problem. What did not suit their old 1.5 and 1.6? In the mini versions, they gave out exactly the same insane speeds, with a much cheaper BOM. In general, a lot of work has been done ... but in vain. Here, for example, mini 1.6. Well, like, do you need all this exoticism, if possible on 8 shafts? In general - who is interested, the links are available, join, study. A separate pleasure is the designs of Annex-Engineering. Well, once again - the guys are really great fellows, in general, if you dig their work, you can peep a lot of interesting things from the point of view of how to do it beautifully and well. But the last year has led them into an unprecedented satire on themselves, it is not so much interesting to watch as it is fun.

8 and 2.4). There is exactly one thing that is not clear in the problem. What did not suit their old 1.5 and 1.6? In the mini versions, they gave out exactly the same insane speeds, with a much cheaper BOM. In general, a lot of work has been done ... but in vain. Here, for example, mini 1.6. Well, like, do you need all this exoticism, if possible on 8 shafts? In general - who is interested, the links are available, join, study. A separate pleasure is the designs of Annex-Engineering. Well, once again - the guys are really great fellows, in general, if you dig their work, you can peep a lot of interesting things from the point of view of how to do it beautifully and well. But the last year has led them into an unprecedented satire on themselves, it is not so much interesting to watch as it is fun.

Who in Kazakhstan is implementing 3D printing technologies in various business areas — Forbes Kazakhstan

Photo: Andrey Lunin

Entrepreneurs started in 2014 with a desire to make money on 3D printing of personalized figurines. At that time in Russia it was very fashionable among media personalities to print their loved ones (their scanned 3D copies) on a printer and decorate interiors, cakes with figurines, give them to friends, relatives, colleagues. Mere mortals began to repeat behind the stars.

At that time in Russia it was very fashionable among media personalities to print their loved ones (their scanned 3D copies) on a printer and decorate interiors, cakes with figurines, give them to friends, relatives, colleagues. Mere mortals began to repeat behind the stars.

"Small" business: from buttons to PET preforms

For more than 10 years, a company from the South Kazakhstan region KAZPLAST has been... →

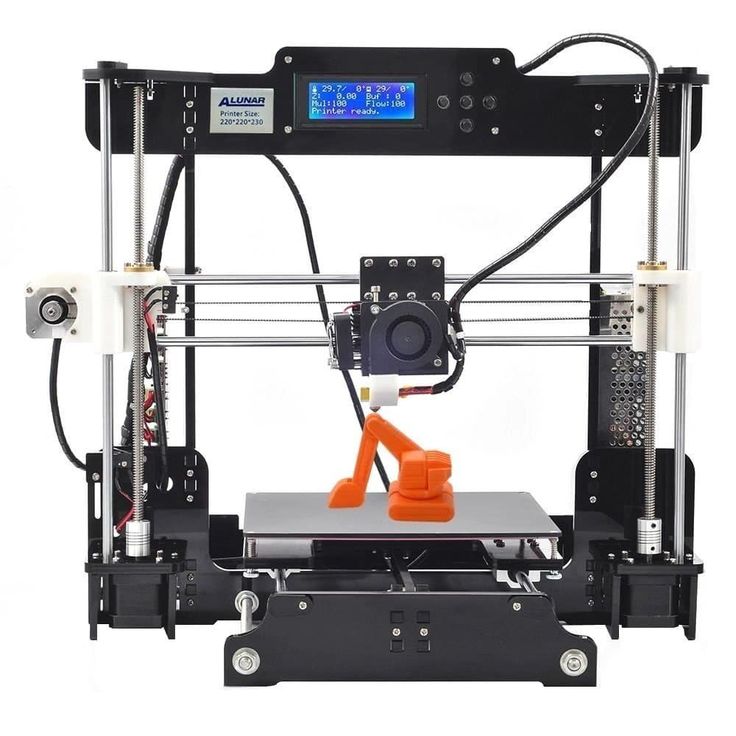

"It should go with us", - decided Denis Pogorelov , commercial director of 3D PM, and Oleg Lobakh , technical director of the company. We found an investor who invested $250,000 in the project, bought 3D printers, a 3D scanner, a computer equipment park, made a website, opened accounts on social networks and began to invite everyone to print their 3D figurines. The founders even put this message into the name of the LLP: PM means print media - loosely translated “printing figures of media personalities”.

And people went - in groups, families, couples and alone. They stood on a turntable, they were scanned by a 3D scanner, a 3D model was created on a computer, and then they were printed. A 20-cm figure costs 76 thousand tenge ( 56 thousand costs printing, 20 thousand - scanning).

- In 2014, we were the only company in the post-Soviet space that offered the full range of 3D services - from scanning to printing. Others either scanned and modeled and outsourced printing, or only printed and outsourced previous processes, - says Pogorelov.

- We even have a corresponding slogan: “Here an idea takes shape”, – Lobach notes. - People can come to us with sketches, and we already create a 3D model on a computer, offer material for printing (composites, plastic, etc.), decide how to print it if it is a prefabricated structure, because we need to take into account its strength during further operation and other points.![]()

Following the lovers of their own 3D copies, those who are connected with industry and medicine began to come to the company - clients with whom they just wanted to work. One of these customers was the Scientific and Practical Center for the Development of Social Rehabilitation. The staff of the center set the task of making comfortable knee sockets for people who have lost limbs. 3D technologies turned out to be the best solution for this. With the help of a scanner, a computer program and a printer, a stump sleeve is made, the internal relief of which repeats all the anatomical features of the injury. This makes it possible to use the prosthesis as comfortably as possible. (Other technologies don't allow for custom-fit prostheses.)

Kenes Rakishev invested in a unique Kazakh gadget

Amazon has already shown interest →

- Vice-President of another partner company, the Republican Prosthetic and Orthopedic Center, disabled. We made a stump sleeve for him and are now conducting various experiments - we are looking for solutions so that the prosthesis can be put on and taken off quickly, and be comfortable. At first, he decided to test everything on himself, and then to implement the developments in his center. The Scientific and Practical Center has already put these solutions on stream, for this they bought a 3D printer for themselves, they are going to buy a scanner and hire a specialist in 3D technologies, and then create such production facilities in all regions, - says Lobach.

At first, he decided to test everything on himself, and then to implement the developments in his center. The Scientific and Practical Center has already put these solutions on stream, for this they bought a 3D printer for themselves, they are going to buy a scanner and hire a specialist in 3D technologies, and then create such production facilities in all regions, - says Lobach.

In 2017, 3D PM, together with a developer from another Kazakh company MBionics, created the first domestic bionic prosthesis that allows a person to control an artificial hand. Maulen Bekturganov from MBionics came with an electronic filling for the prosthesis. The filling had to be “packed” into a functional, comfortable prosthesis. Moreover, the teenager for whom the prosthesis was created asked to make it in the form of the hand of one of the heroes of his favorite computer game - Deus Ex: Human Revolution. And everything worked out! A few minutes after trying on, the guy learned to make a few gestures.

An amazing case was with the manufacture of prostheses for the Abyssinian raven from the Almaty Zoo: the bird had frostbite on its paws and could not move on them.

Even the Rosnano company became interested in the development of 3D PM, which spent three years poring over the creation of comfortable prosthetic sleeves, but could not achieve the results that the guys achieved in a year of work. However, they refused to cooperate with the Russians, considering that it was better to move in this direction on their own.

Last year, 3D PM focused even more seriously on the medical field. For example, for one of the leading cardiac surgeons in Kazakhstan, the company creates cardio simulators (“artificial heart”). On them, young surgeons can "fill their hand" and already prepared to start real operations.

Photo: Andrey Lunin

Denis Pogorelov and Oleg Lobakh

- Part of the skull is cut out for stroke; The operation to close the hole is called cranioplasty. To perform cranioplasty, we create a surgical template using 3D modeling, then print it on a gypsum polymer printer, and a part of the skull is cast from biocement, which is implanted. That is, the doctor adjusts the plate to the hole not during the operation, on the person - this is done ahead of time. Thus, we and our partner company Limard National Technology have already participated in 22 operations. There are no analogues to our joint developments, , says Lobach.

To perform cranioplasty, we create a surgical template using 3D modeling, then print it on a gypsum polymer printer, and a part of the skull is cast from biocement, which is implanted. That is, the doctor adjusts the plate to the hole not during the operation, on the person - this is done ahead of time. Thus, we and our partner company Limard National Technology have already participated in 22 operations. There are no analogues to our joint developments, , says Lobach.

Domestic skull implant costs around 1 million tenge. Western - from 12 to 20 thousand euros , Russian - $ 4-5 thousand The low cost in the company is explained by the smooth running of all processes - from the moment of scanning to printing the template.

Kazakhstan manufacturer successfully sells soap in China

The leaders of the Kazakh soap factory spoke about the nuances of doing business in China... →

If all over the world, for example, dentists are already actively using 3D printing, then Kazakh ones for some reason sluggishly react to these technologies. Industry representatives are also only looking at the possibilities of 3D printing. So far, only jewelers have caught the wave (they print prototypes on which jewelry is cast) and companies that need to make prototypes (manufacturers of souvenirs, event agencies). 3D PM, for example, was approached by Danon to make prototypes of various yoghurt containers.

Industry representatives are also only looking at the possibilities of 3D printing. So far, only jewelers have caught the wave (they print prototypes on which jewelry is cast) and companies that need to make prototypes (manufacturers of souvenirs, event agencies). 3D PM, for example, was approached by Danon to make prototypes of various yoghurt containers.

The commercial director of Elektromanganets LLP from Tekeli turned out to be savvy in this regard. He began to travel around the quarries and take orders for casting spare parts, for example, for excavator buckets.

- Bucket parts keep breaking. Buying them abroad is long and expensive. And this is what he came up with: he brings broken parts to us, we scan them, make 3D models (no one will give drawings), send them to his enterprise. There they make prototypes out of plywood on capushki (computer numerically controlled machines. - Ed.), and then they cast them and sell them. The largest item that was brought to us weighed 180 kilograms, says Lobach. - To do this in the usual way, you need to use a turner, miller, grind on the machine. Then cast the mold, check. If it doesn't fit, do it again. And this takes time, materials, human resources.

- To do this in the usual way, you need to use a turner, miller, grind on the machine. Then cast the mold, check. If it doesn't fit, do it again. And this takes time, materials, human resources.

But the case of Energomanganese is rather an exception. Typically, businesses do not understand where 3D modeling and printing can be applied. Therefore, Pogorelov and Lobakh see the introduction of these technologies at enterprises in Kazakhstan as their mission.

- We can advise on exactly how to use 3D printing in a particular business, at what stage to integrate it into production. Help to select and order 3D printers and other equipment from our Russian, Chinese or American partners, deliver consumables, train staff to scan, model, print. That is, we offer turnkey solutions, - explains Pogorelov.

How to promote your own franchise in Kazakhstan

In 2005, a businessman from Uralsk Denis Seregin opened a pizzeria in his hometown ... →

Consumables 3D PM purchases from abroad.

- A kilogram of plastic costs 5 thousand tenge. From it, you can print, for example, 500 objects weighing 2 grams. The cost of each is within 6 thousand tenge ( 5 thousand - modeling, 1 thousand - printing). So consider, - Lobach offers to calculate the marginality of their business. But the company does not have mass production, so until the end of 2017, 3D PM did not see a profit: it appeared when the printers began to actively cooperate with doctors.

Entrepreneurs say that in Kazakhstan it is possible and necessary to establish the production of consumables for 3D printing. But over the invention of a domestic 3D printer, in their opinion, it’s not worth “sweating”, we are hopelessly behind in this matter: a patent for the first such printer was issued in the 80s of the last century, and every year these technologies go by leaps and bounds into future. However, there is a need to create 3D printers for specific tasks, for example, for printing human organs from biomaterials. In order to have time to jump at least into this car, 3D technologies need to be taught in schools right now. But most educational institutions, where 3D PM approached with an offer to sell high-quality printers for only 360 thousand tenge, did not show enthusiasm. The apparatus was acquired by only one school with a specialization in physics and mathematics.

In order to have time to jump at least into this car, 3D technologies need to be taught in schools right now. But most educational institutions, where 3D PM approached with an offer to sell high-quality printers for only 360 thousand tenge, did not show enthusiasm. The apparatus was acquired by only one school with a specialization in physics and mathematics.

- At the lesson, the boy designed a quadcopter, printed out the details, assembled and launched. After that, the teacher told us: “Thank you, with your help we climbed into the sky,” , the entrepreneurs recall.

Among the interesting orders, they name the work on a bill acceptor for an ATM. The assembly consists of dozens of gears, which we managed to model and print for a reasonable price. If it didn’t work out, the bank would have to order a bill acceptor in Mexico, and this is long and expensive. They made a small plastic part for Aston Martin, prototypes of a nozzle for a jet aircraft and a stele for Nazarbayev University.