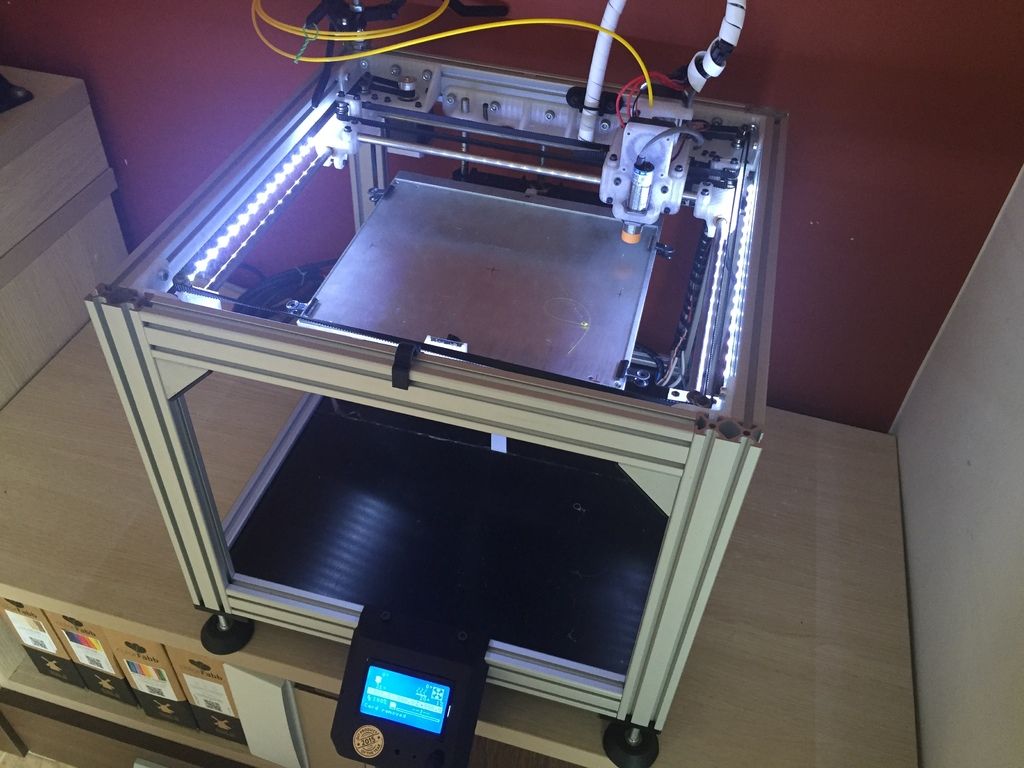

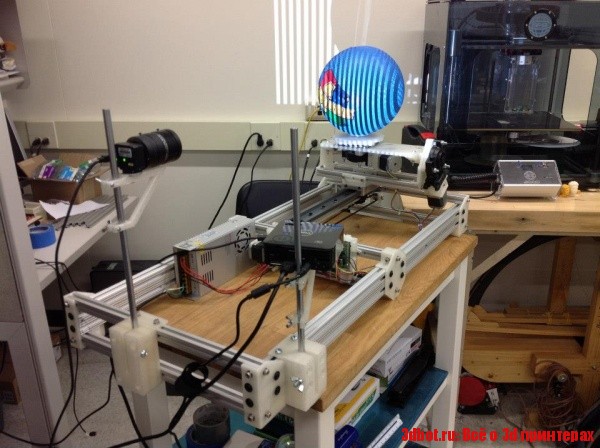

Perceptron 3d scanner

Perceptron Completes Merger with Atlas Copco

Plymouth, Mich., December 21, 2020 — Perceptron, Inc. (NASDAQ: PRCP), a leading global provider of 3D automated metrology solutions and coordinate measuring machines, today announced receiving all regulatory approvals and the successful closing of the previously announced Agreement and Plan of Merger with Atlas Copco, a world-leading provider of sustainable productivity solutions headquartered in Stockholm, Sweden.

As a result of the merger, Perceptron has become a wholly owned subsidiary of Atlas Copco. Under the terms of the merger agreement, Perceptron shareholders receive $7.00 per share in cash for each share of common stock held. Following the closing, Perceptron’s common stock will no longer be publicly traded and will be delisted from the Nasdaq Global Market.

“We are pleased to have completed the merger with Atlas Copco, maximizing value for our shareholders, providing our customers with access to a broader array of technology and products, and offering our employees exciting new growth opportunities,” stated Jay Freeland, Chairman, and Interim CEO of Perceptron. “The path forward for our combined organizations is bright and the team is well-prepared for a seamless transition.”

XMS Capital Partners, LLC acted as financial advisor and Dykema Gossett PLLC acted as legal counsel to Perceptron on this transaction.

About Perceptron®

Perceptron (NASDAQ: PRCP) develops, produces, and sells a comprehensive range of automated industrial metrology products and solutions to manufacturing organizations for dimensional gauging, dimensional inspection, and 3D scanning. Products include 3D machine vision solutions, robot guidance, coordinate measuring machines, laser scanning, and advanced analysis software. Global automotive and other manufacturing companies rely on Perceptron’s metrology solutions to assist in managing their complex manufacturing processes to improve quality, shorten product launch times, and reduce costs. Headquartered in Plymouth, Michigan, Perceptron has subsidiary operations in Brazil, China, Czech Republic, France, Germany, India, Italy, Japan, Slovakia, Spain, and the United Kingdom. For more information, please visit www.perceptron.com.

For more information, please visit www.perceptron.com.

Safe Harbor Statement

Certain statements in this press release may be “forward-looking statements” within the meaning of the Securities Exchange Act of 1934, including our expectations regarding our fiscal year 2021 and future results, operating data, new order bookings, revenue, expenses, net income, and backlog levels, trends affecting our future revenue levels, the rate of new orders, and our ability to fund our fiscal year 2021 and future cash flow requirements. We may also make forward-looking statements in our press releases or other public or shareholder communications. Whenever possible, we have identified these forward-looking statements by words such as “target,” “will,” “should,” “could,” “believes,” “expects,” “anticipates,” “estimates,” “prospects,” “outlook,” “guidance” or similar expressions. We claim the protection of the safe harbor for forward-looking statements contained in the Private Securities Litigation Reform Act of 1995 for all of our forward-looking statements. While we believe that our forward-looking statements are reasonable, you should not place undue reliance on any such forward-looking statements, which speak only as of the date made. Because these forward-looking statements are based on estimates and assumptions that are subject to significant business, economic and competitive uncertainties, many of which are beyond our control or are subject to change, actual results could be materially different. Factors that might cause such a difference include, without limitation, the risks and uncertainties discussed from time to time in our periodic reports filed with the Securities and Exchange Commission (the “SEC”), including those listed in “Item 1A. Risk Factors” of our Annual Report on Form 10-K for our fiscal 2020. Except as required by applicable law, we do not undertake, and expressly disclaim, any obligation to publicly update or alter our statements whether as a result of new information, events or circumstances occurring after the date of this report or otherwise.

While we believe that our forward-looking statements are reasonable, you should not place undue reliance on any such forward-looking statements, which speak only as of the date made. Because these forward-looking statements are based on estimates and assumptions that are subject to significant business, economic and competitive uncertainties, many of which are beyond our control or are subject to change, actual results could be materially different. Factors that might cause such a difference include, without limitation, the risks and uncertainties discussed from time to time in our periodic reports filed with the Securities and Exchange Commission (the “SEC”), including those listed in “Item 1A. Risk Factors” of our Annual Report on Form 10-K for our fiscal 2020. Except as required by applicable law, we do not undertake, and expressly disclaim, any obligation to publicly update or alter our statements whether as a result of new information, events or circumstances occurring after the date of this report or otherwise.

Technology for Automated Solutions - Sensors and Software

One Point of Contact

Solution Provider

We design, manufacture, and deliver all the components for your automated solution; including the sensor, software, mounting hardware, installation labor, and support.

Sensors

Our non-contact sensors use a high-resolution camera and various laser colors to achieve reliable measurement on bare and painted metal, chrome, translucent materials, carbon fiber, and other materials at full production speed. With its IP67 rating (dust-tight, immune to temporary water immersion), the rugged sensor housing offers protection against the adverse conditions of an industrial production line, such as weld splatter, dirt, oil, etc. All sensors are calibrated and rectified at Perceptron’s manufacturing facility and ship ready to measure.

New to the sensing family is the AccuSite™ Optical Tracking option for robotic measurement. AccuSite turns the robot into a simple mover and eliminates all temperature and mechanical drift influence from the measurement results. Available on one or multiple robots, AccuSite is the ideal option when you need CMM level accuracy on the plant floor.

Available on one or multiple robots, AccuSite is the ideal option when you need CMM level accuracy on the plant floor.

Industry Leading Software

Vector software is the backbone of Perceptron’s automated measurement solutions. Common to AutoGauge, AutoGuide, and AutoFit, Vector provides consistent measurement techniques and a complete suite of user-centric software solutions across all applications. Vector takes the sensor scan data, runs a pre-determined algorithm, and displays the results to the operator within seconds. Multiple notification methods are available to alert the operator if a measurement falls outside the set limits. All measurement results are also stored in a database for future data analysis.

The following software add-ons are also available to reduce setup time or perform advanced data analysis.

Automated Path Generation

Our Automated Path Generation (APG) module is a virtual setup of your measurement system that performs the robot programming, collision avoidance, and teaches the measurement plan for you. Ideal for off-line setup and on-site changes. You define the rules, constraints, goals, measurement plan, and APG will do the rest.

Ideal for off-line setup and on-site changes. You define the rules, constraints, goals, measurement plan, and APG will do the rest.

Watch our APG webinar on-demand here (45-minutes)

Argus

Argus is designed for anyone responsible for achieving and maintaining a stable process. It is constantly reviewing the data and looking for suspicious patterns. Once a potential problem is identified, Argus’ visualization tools display 3D multi-dimensional variation in a CAD environment, significantly decreasing the effort required to interpret complex process problems. Argus turns your production data into actionable information.

Our Team Makes a Difference

Perceptron has installation and support locations in 12 countries to offer global solutions, supported locally. Our knowledgeable team of project engineers, project managers, and customer support representatives are available to maximize your return on investment when you select Perceptron.

Our commitment to you does not end with a successful system install. By tailoring our educational and training programs to meet your specific needs, Perceptron can help you take advantage of the most powerful process control tools in the industry.

By tailoring our educational and training programs to meet your specific needs, Perceptron can help you take advantage of the most powerful process control tools in the industry.

neural network trained to change the angle of any video / Sudo Null IT News DRoman0v

Selectel Blog Working with 3D Graphics *Image Processing *Machine Learning *

Translation

Original author: Chen Gao, Ayush Saraf, Johannes Kopf, Jia-Bin Huang

In films or YouTube videos, we watch what is happening from one point, we are not able to move around the stage or shift the angle of view. But the situation seems to be changing. For example, researchers from Virginia Tech and Facebook have developed a new video processing algorithm. Thanks to it, you can arbitrarily change the viewing angle of a ready-made video stream. What is noteworthy is that the algorithm uses frames that were obtained when shooting with one camera, combining several video streams from different cameras is not required.

What is noteworthy is that the algorithm uses frames that were obtained when shooting with one camera, combining several video streams from different cameras is not required.

The new algorithm is based on the NeRF (Neural Radiance Fields for Unconstrained) neural network. This network, which appeared last year, is able to turn photos into three-dimensional animation. However, to achieve the effect of movement in the video, the project had to be significantly improved.

What exactly can NeRF do?

NeRF is trained on a large number of images of the same object from different angles. Initially, she was taught to recreate three-dimensional pictures of famous architectural landmarks and other objects. Not all images folded and read perfectly, so it was necessary to expand the initial capabilities.

By itself, the neural network is able to create a 3D image at different angles from many images. It can also isolate 2D models. These images are converted from volumetric to planar by pixel-by-pixel transfer. How exactly?

It can also isolate 2D models. These images are converted from volumetric to planar by pixel-by-pixel transfer. How exactly?

When the desired angle of view is selected, the algorithm begins to pass rays through the 3D scene and create a 2D image pixel by pixel, using the density and color data of each pixel along the entire path of the ray. To get the whole frame, the process is started several times until the required number of pixels is collected from the rays calculated from different directions. This makes it possible to generate 2D images from any angle. In general, an interesting and original approach to solving such a non-trivial problem.

Video stream with effect

To achieve a similar effect for a video stream, similar steps are required. But there is an important nuance - in the video there is only one angle for each individual frame. To cope with the task, the researchers decided to train two different models in parallel. As a result, we got 2 algorithms at once: for the static and dynamic parts of the scene.

As for the static model, it is arranged according to the same principle as NeRF. There is only one difference - all moving objects were immediately removed from the frame.

With a dynamic model, everything is much more interesting. There was not enough staff to process it. Then the neural network was taught to predict frames for a volume stream. More precisely frames to each specific time t. These moments are conventionally called t-1 and t+1. The essence of a 3D flow is reduced to an optical flow, only in this case it is built for volumetric objects.

The scientists also managed to get rid of interference and ensure frame consistency. As a result, the new neural network recreates a fairly slender video sequence from different angles. The video provided by the developers shows an effect similar to what many of us remember from The Matrix. In cinema, it is called Bullet time, when the viewer is immersed inside the image.

Total votes 55: ↑46 and ↓9 +37

Views12K

Comments ten

In contact with Telegram

Denis @DRoman0v

Engineer

Comments Comments 10

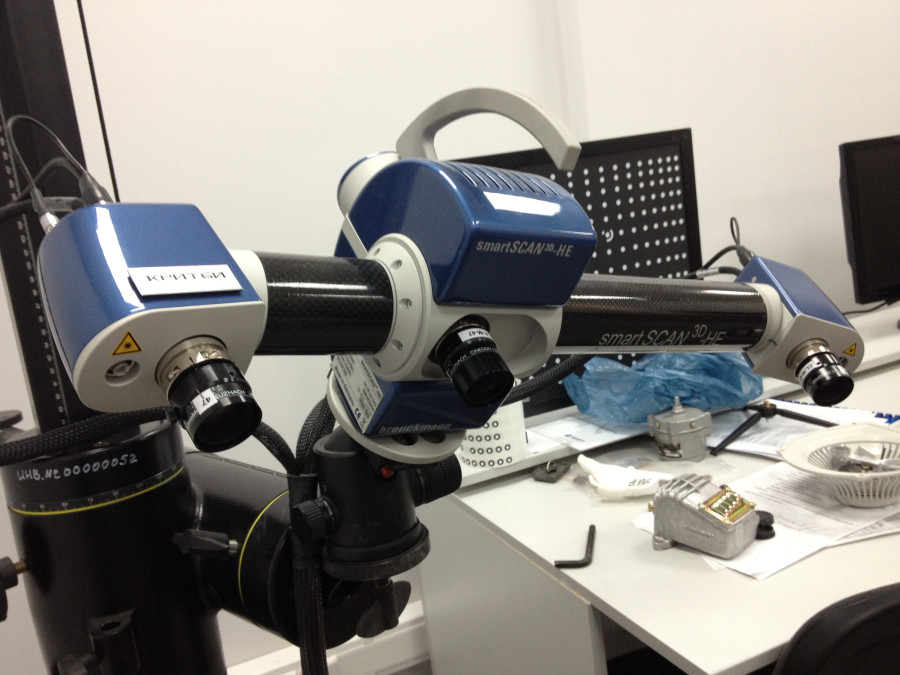

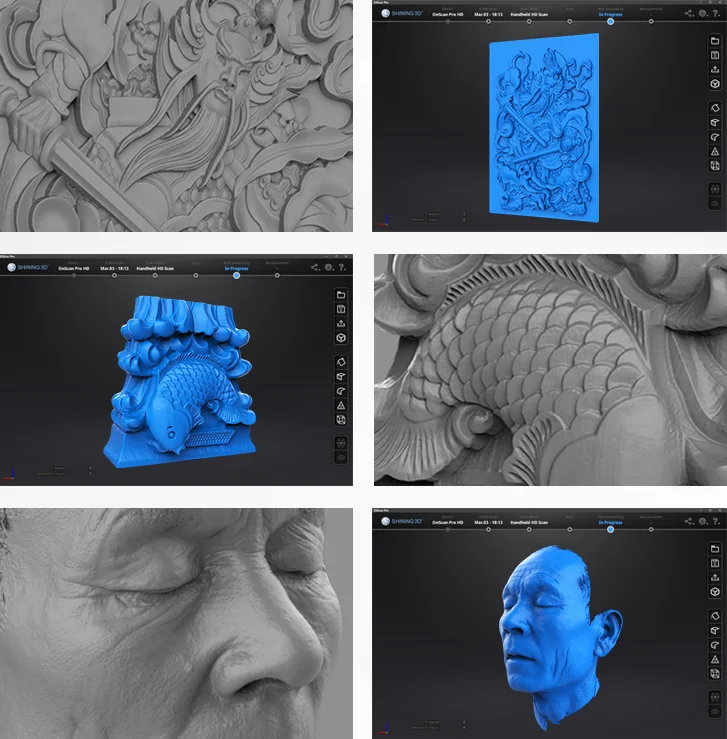

Industrial 3D Scanner Market Share, Growing Demand and Growth Forecast of Key Global Competitors to 2028

Global Industrial 3D Scanner Market Report takes a very detailed look at the current ### global market and industry situation. All relevant data or information such as market terminology, concepts, segmentation, key players and other important insights are included in the study. Company profiles, executive descriptions and other relevant data are also presented. In order to make the Global 3D Scanner market report more informative and valuable for business, the experts of these reports have provided a number of insights. The study includes a SWOT analysis that helps businesses understand their strengths, weaknesses, opportunities and threats in a complex market.

Exclusive Offer: 30% Flat Discount for a Limited Time

Get the full PDF sample report: (including full table of contents, list of tables and figures, chart) @

https://marketintelligencedata.com/ reports/5871093/global-industrial-3d-scanner-market-research-report-2022/inquiry?https://edk.news?Mode=Rukaiyya

Comprehensive analysis of global industrial 3D scanner business agglomerates mainly focuses on research results and operating conclusions focused on the main components of the report's readers, including the global Industrial 3D Scanner market participants, investors and business owners seeking highly relevant research results that reflect the intended development ability with the greatest accuracy. A typical focus in researching the global Industrial 3D Scanner market is to build a forecast and provide the client with a market assessment and growth forecasts based on a complete data archive. The aim of the research is to collect and build a high quality, authentic and credible market share analysis that covers almost all areas of the global Industrial 3D Scanner industry.

Leading players in the Industrial 3D Scanner market include:

Leica Geosystems (hexagon)

Trimble.

Faro Technologies.

GOM MBH

Nikon Metrology

Topcon

Perceptron

Basic Software

3D Digital.

Carl Zeiss optotechnik

Creeaform (Ametek)

3D systems

Z f gmbh

Maptek.

Hi Target.

Shanghai digital production

Beijing Tenyun

Radiance 3d.

Stereo3d technologies

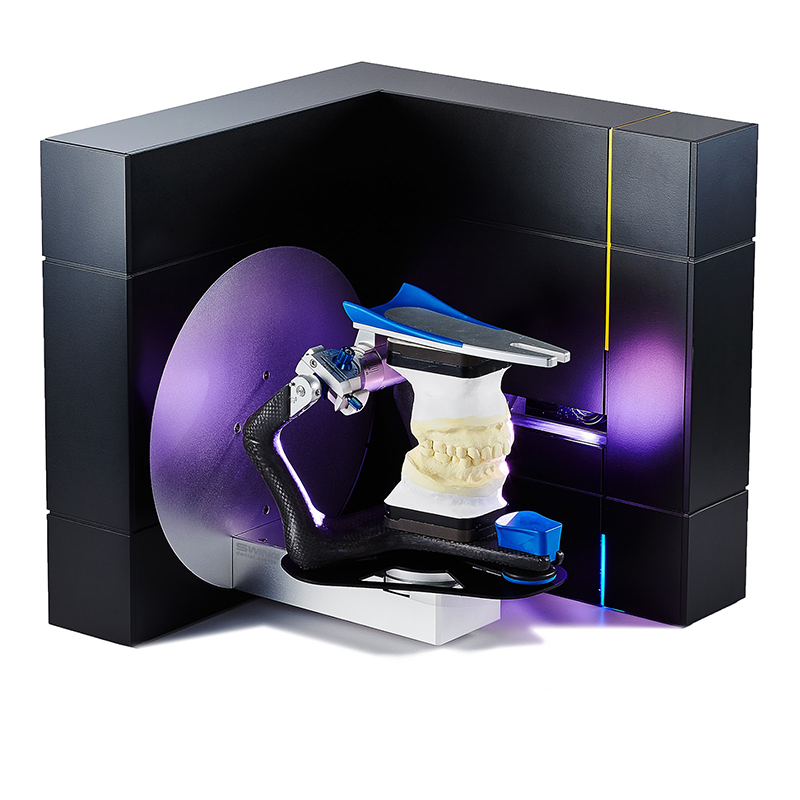

The industrial 3D scanner is divided into types of goods:

Car

Aerosmic

Heavy industry

Oil GAZ

9000,0006 :

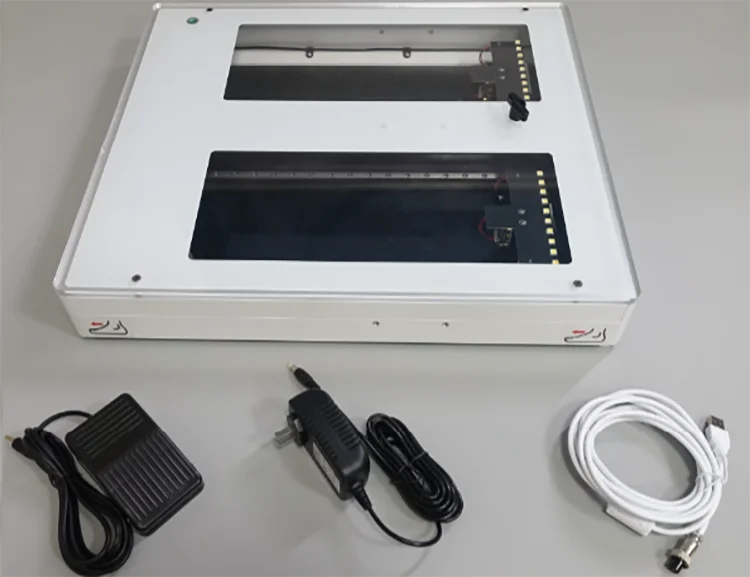

Stationary 3D scanners

Portable 3D scanners

View full report with full table of contents here @

https://marketintelligencedata.com/reports/587-recanrial-marketsreports-industry -2022?https://edk.news?Mode=Rukaiyya

In addition, the study monitors recovery-oriented activities of both private and public organizations and promotes a robust back-up plan for the efficient operation of the commercial elements of the global Industrial 3D Scanner market. The study takes a detailed look at the major companies, indicating their strategic efforts, market presence, share and status. The study provides accurate positioning of certain key players based on spatial presence, organization's overall portfolio, revenue, and recent M&A, collaborations, and partnerships that contribute to the growth prospects of the global Industrial 3D Scanner market during the market assessment period.

The study takes a detailed look at the major companies, indicating their strategic efforts, market presence, share and status. The study provides accurate positioning of certain key players based on spatial presence, organization's overall portfolio, revenue, and recent M&A, collaborations, and partnerships that contribute to the growth prospects of the global Industrial 3D Scanner market during the market assessment period.

Regional Analysis of the Industrial 3D Scanner Market:

The Industrial 3D Scanner market research report details the current market trends, development plans, and several research methodologies. It illustrates the key factors that directly manipulate the market, such as manufacturing strategies, development platforms, and product portfolio. According to our researchers, even minor changes in product profiles can lead to serious violations of the aforementioned factors.

➛ North America (USA, Canada and Mexico)

➛ Europe (Germany, France, Great Britain, Russia and Italy)

➛ Asian-Tikhoocian region (China, Imprint

➛ South America (Brazil, Argentina, Colombia, etc. )

)

➛ Middle East and Africa (Saudi Arabia, Egypt and UAE) South Africa)

What information does the Industrial 3D Scanner Market report offer readers?

➜ Fragmentation Industrial 3D scanner based on product type, end use and region

➜ Comprehensive assessment of upstream raw materials, downstream demand and existing market conditions

➜ Collaboration, R&D projects, acquisitions and product launch of each ### # player

➜ Details on the various regulations imposed by governments on consumption Industrial 3D Scanner

➜ The impact of modern technologies such as big data and analytics, artificial intelligence and social media platforms on Industrial 3D Scanner

segmentation

Chapter 2: Market competition of manufacturers

Chapter 3: Production by region

Chapter 4: Consumption by region

Chapter 5: Production by type, revenue and market share by type

Chapter 6. Consumption by application, market share (%) and growth rate by application

Consumption by application, market share (%) and growth rate by application

Chapter 7 : identification and comprehensive analysis of manufacturers

Chapter 8: Cost analysis, personnel analysis, regional production costs.

Chapter 9: Production chain, sourcing approach and downstream customers

Chapter 10: Analysis of the promotion strategy, distributors/merchants

Chapter 11: Analysis of market results

Chapter 12: market forecasts

Chapter 13: Industrial 3DSCKANERS OF MARCECTIONAL STATIONS, CONCLUSIONALS, Appendix , methodology and information support.

Continue...

Finally, the researchers have shed data from the global precision analysis Industrial 3D Scanner. In addition, it measures the long patterns and platforms supporting the growth of the market. The analysis report further evaluates the degree of struggle. The market has been comprehensively studied through an operational SWOT analysis and Porter's 5x scan. This further helps in managing the risks and difficulties of the company. In addition, it includes a significant analysis of sales methods.

The analysis report further evaluates the degree of struggle. The market has been comprehensively studied through an operational SWOT analysis and Porter's 5x scan. This further helps in managing the risks and difficulties of the company. In addition, it includes a significant analysis of sales methods.

We will contact you within 24 hours to help you find the study reports and advanced customization you need.

Thank you for your interest in a market research publication Industrial 3D Scanner; you can also get individual sections by chapter or region/country versions of reports such as Germany, France, China, Latin America, Gulf States, North America, Europe, or Asia.

ABOUT US:

Market Intelligence Data is a global leader in the research industry, offering clients contextual and data-driven research services. The organization supports clients in creating business plans and achieving long-term success in their respective markets.

Learn more