Nylon resin 3d printer

Everything you need to know about Nylon 3D printing

Before you get started with Nylon 3D Printing, we’ve compiled some of the basic information you’ll need to know. Read on to learn the advantages, disadvantages, history and applications of Nylon 3D printing

Nylon Filament and 3D Printed Gear

When it comes to 3D printing materials, Nylon has to be mentioned as one of the most popular materials for professional users. This can be attributed in large part to its popularity outside of 3D printing. Nylon has a wide range of applications thanks to its unique properties and the benefits of 3D printing mean that parts can be made on the fly easily and inexpensively.

That said, desktop Fused Deposition Modeling (FDM) 3D printing technology, which is one of the most widely-used types of 3D printing, can sometimes involve a lot of trial and error. Some materials are easy to print with while others have a comparatively bigger learning curve.

Through this article, we will share everything you should know about Nylon 3D printing. Nylon can be 3D printed using three different technologies, namely FDM, Selective Laser Sintering (SLS), and MultiJet Fusion (MJF). However, the scope of this article is focused around FDM 3D printing.

UNDERSTANDING NYLON AS A MATERIAL

Chemical Composition

Nylon was first synthesized by DuPont, the American chemical company, in 1935. It developed the material for commercial usage and since then Nylon has become a common feature in numerous industries.

Nylon refers to a group of plastics known as polyamides. They are mostly semi-crystalline and generally very tough materials. It is found in many variants but the most common ones are Nylon 6, Nylon 6-6, and Nylon 12. It is a thermoplastic material, i.e., it becomes soft on heating or liquid when heated beyond its melting point and hardens on cooling. This process of heating and cooling can be carried out multiple times without significantly affecting its inherent chemical or mechanical properties.

Nylons can be easily blended with numerous other plastics to form composites, enhancing their performance parameters. This is widely done in automotive industries and some common composites in 3D printing are glass-filled nylon and carbon-fiber-filled nylon. Nylon is a versatile material and is suitable for almost all types of manufacturing operations like injection molding, extrusion, and additive manufacturing (in FDM, SLS & MJF).

Some of the most popular applications of nylon material are:

➜ In the textiles industry, nylon is used in the manufacturing of fishing lines, and food packaging.

➜ In the fashion industry, nylon is used as a fabric to manufacture products like hosiery, lingerie, raincoats, windbreakers, and athletic wear used in sports.

➜ In the electronics industry, nylon is used as insulators and switch housings.

➜ In the automotive industry, nylon is used in the production of parts such as intake manifolds, door handles, and radiator grills.

In consumer products, nylon is used in sporting goods such as ski bindings and skateboard wheels.

➜ In manufacturing machinery for moving parts such as gears and rollers.

NYLON in 3D PRINTING

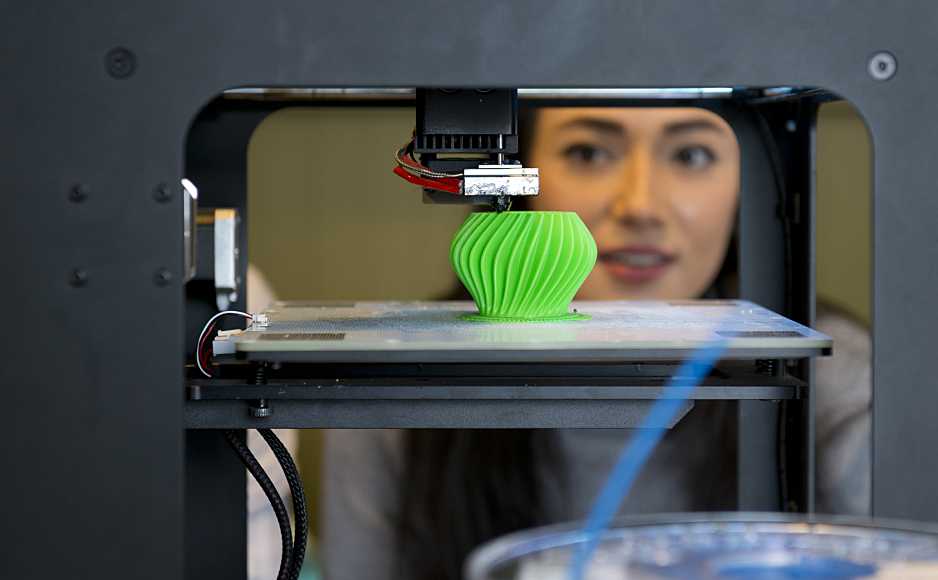

In the same way that nylon has become a go-to material in traditional manufacturing, nylon has become a popular material to use with 3D printers. 3D printing provides the added benefits of unlimited geometries, iteration and customization, and low-volume affordability.

Nylon’s flexibility and durability help in 3D printing parts with thin walls. Its low coefficient of friction with a high melting point makes it especially resistant to abrasion and enables it to be used in printing for parts such as functional interlocking gears.

Nylon exhibits mechanical properties comparable to ABS (another widely used material in traditional & additive manufacturing). ABS is defined by its strength but Nylon’s resistance to wear and fatigue makes it superior for applications requiring such properties.

Apart from the advantages, nylon has one major drawback that can often hamper its printing performance – hygroscopicity, i.e., its moisture absorption property. This property is detrimental in delivering predictable performance. But this same property helps nylon in easy post-processing with fabric dyes and spray paints thereby making it suitable for use in the printing of aesthetic (display) models.

There have been successful cases of a patient receiving a titanium pelvis implant, another getting a new titanium lower jaw. A motorcyclist patient whose face had been seriously injured in a road accident had it rebuilt with 3D printed parts.

Bioprinting allows for the 3D printing of artificial organs, helping solve organ failure issues in patients faster, important to both the patient and his/her family and to healthcare systems.

3D printed tissues have been developed for pharmaceutical testing as a cost-effective and ethical means of helping identify the side effects of drugs and validating safe dosages.

Pills can be produced, using the 3D printing process of Binder Jetting. The process allows the pills produced to be very porous, therefore enabling high dosages in a single pill that can be dissolved quickly and easily digested, useful for treating conditions such as epilepsy.

FUSED DEPOSITION MODELING (FDM) NYLON 3D PRINTING

As mentioned earlier, nylon 3D printing in FDM is a bit difficult but with the right tools it can be used to produce consistent results. We will start with some of the common challenges with nylon 3D Printing.

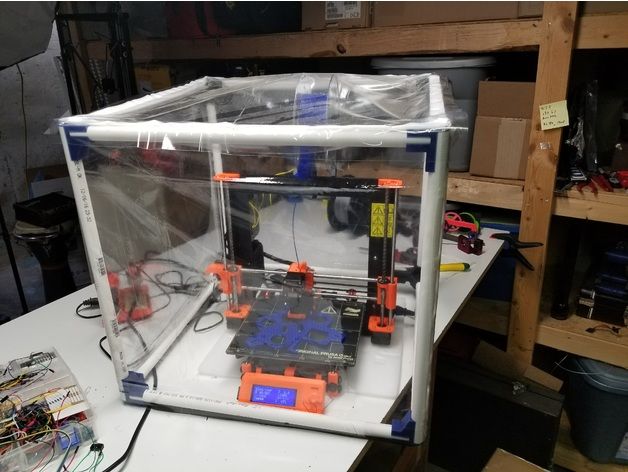

Common Challenges with Nylon 3D Printing

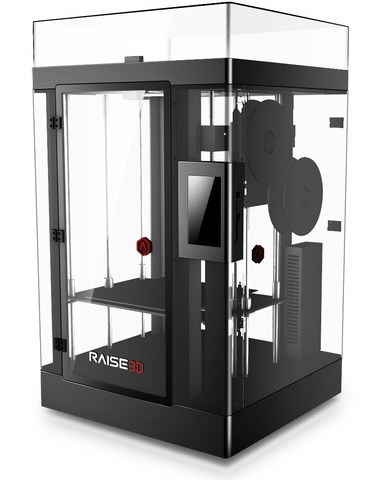

One challenge in nylon 3D printing is that nylon is highly hygroscopic. Even short-term exposure to high humidity can result in “wet” filament which, when printed, can lead to inconsistency in dimensional accuracy and part strength. Due to this property, it is critical to store the nylon filament in a dry place. Professional FDM 3D printers are enclosed so moisture can be safely avoided but for new users working with DIY or cheaper desktop printers, the material is exposed to air while printing. This makes it prone to moisture. The moisture absorbed by nylon gets heated up when it passes through the heater and the moisture forms bubbles only to burst during the heating process. This bursting leaves visible gaps in the 3D printed parts, leading to poor output.

This makes it prone to moisture. The moisture absorbed by nylon gets heated up when it passes through the heater and the moisture forms bubbles only to burst during the heating process. This bursting leaves visible gaps in the 3D printed parts, leading to poor output.

Additionally, nylon is prone to warping issues. Warping occurs when there is uneven cooling of the print and the print curls from the build plate, distorting the printed part. This can be avoided by efficient gluing of the print bed and using a heated bed to keep the bottom layer of the print mildly heated so that it sticks to the bed for the duration of the print. As an extra precaution, the cooling fans can be switched off (all slicers have options to switch off fans during printing) while printing with nylon.

It is also recommended that printing nylon is conducted in a well-ventilated area due to its chemical composition.

Solutions to Nylon 3D Printing

Luckily, there are professional 3D printers such as the MakerBot METHOD that are both affordable for businesses, and have features that enable easy and consistent 3D printing with nylon. One example of these advanced professional features is an enclosed heated build chamber, which minimizes warping and inconsistent cooling during the print, and can also be used before printing to dry the filament on the spool. Another such feature is sealed material bays, which prevents the material from contact with the surrounding environment. These two additions almost entirely solves the problems associated with nylon 3D printing and might be worth considering during purchase if nylon is a preferred 3D printing material.

One example of these advanced professional features is an enclosed heated build chamber, which minimizes warping and inconsistent cooling during the print, and can also be used before printing to dry the filament on the spool. Another such feature is sealed material bays, which prevents the material from contact with the surrounding environment. These two additions almost entirely solves the problems associated with nylon 3D printing and might be worth considering during purchase if nylon is a preferred 3D printing material.

FDM NYLON MATERIAL PROPERTIES

| PARAMETER | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 196°F | 91°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 250,000 psi | 1,700 MPa |

| Flexural Strength (ASTM D790, 15 mm/min) | 14,000 psi | 97 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 9500 psi | 66 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | >320,000 psi | >2,200 MPa |

| Strain at Yield - Elongation (%) | >10% | >10% |

| Notched Impact Strength (ASTM D256) | >3. 5 ft-lb/in 5 ft-lb/in | >187 J/m |

(Specifications for MakerBot Nylon)

ADVANTAGES

➜ Mechanical Properties

➀ High impact resistance - Durable in situations where parts are constantly banging together or being dropped.

➁ Abrasion resistant - Nylon’s low coefficient of friction allows nylon to be used in applications with moving parts that would otherwise wear on each other

➂ Flexible - In thinner geometries nylon can be flexed repeatedly without fracturing

➜ Post-Processing: Nylon is hygroscopic and this property helps it to be easily post-processed by absorbing fabric dyes and spray paints.

DISADVANTAGES

➜ Hygroscopic: Nylon is hygroscopic, i.e., it absorbs moisture from the air which can affect its print quality and ultimately the part performance.

➜ Pre-Drying: Nylon should be pre-dried to remove any moisture it has absorbed. This requires extra effort, extra equipment, and extra time. And if the drying is insufficient, then the print shows

This requires extra effort, extra equipment, and extra time. And if the drying is insufficient, then the print shows

➜ Warping: Nylon is prone to warping and thus can distort the part.

WHERE TO BUY?

Nylon material can either be bought from filament manufacturers or 3D printer manufacturers.For the MakerBot 3D METHOD, we recommend use of MakerBot Nylon as it is optimized to deliver great results.

Looking for a professional 3D printing platform that works with a variety of manufacturing-grade materials? Learn more at makerbot.com/method.

Related Posts

Phrozen Nylon-Green Tough 3D Printer Resin - 1kg

Consumables

$199.95 $149.96

Phrozen Nylon-Green resin is an excellent resin for producing prototypes and even functional parts that require both rigidity and flexibility. It is a tough resin that will suit many applications and can even be manipulated being able to return to it’s original shape and size.

In stock

Phrozen Nylon-Green Tough 3D Printer Resin - 1kg quantity

Free shipping on orders over $199 ends 1st Dec

GUARANTEED SAFE CHECKOUT- Visa Card

- MasterCard

- PayPal

SKU: PID-00597-00 Categories: Resin, Consumables, Phrozen

- Description

- Additional information

- Reviews (0)

Description

Phrozen Nylon-Green resin is an excellent resin for producing prototypes and even functional parts that require both rigidity and flexibility. It is a tough resin that will suit many applications and can even be manipulated being able to return to it’s original shape and size.

Features

- Contents: 1kg

- XY Planar Resolution: 47 micron

- Z Resolution (Layer Height): 30-100um

- Normal layer time: 10 sec @ 50 um

- Property: High hardness, toughness and resolution.

- Cleaning: Clean with alcohol spray (or Phrozen wash). Dry with air gun or compressed air

- Suitable for: LCD 3D Printer

- Application: Prototyping/functional parts

- Colour: Transluscent Green

Key Performance

- Viscosity: 742cPa・s(25℃)

- Density: 1.10 g / cm3

- Hardness: Shore 68D

- Elongation: 130 %

- Break value: 19 MPa

- I-Zod Impact: 23.79 KJ/m2

About Resin Operation

- Avoid sunlight exposure.

- After printing, stored used resin in a closed and opaque bottle.

- DO NOT mix fresh resin and used resin.

- Shake or stir resin properly to avoid pigment separation.

- DO NOT dump resin. Please cured resin and treat/recycle it as general plastics garbage.

Safety Recommendation

- Do your best to wear glove, goggles, long sleeves shirt during usage of resin. Wash hands after every operation.

- DO NOT swallow resin. Go to the hospital if you do.

- Avoid eye contact with resin. Rinse with water and go to hospital if resin contacts eyes.

- The resin might cause slight skin irritation. Stop using it if allergy occurred.

- Resin smells. We strongly suggest you use it under ventilated condition.

- Keep resin in room temperature(15 – 35 Celsius) and dry condition.

- Keep resin away from children.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

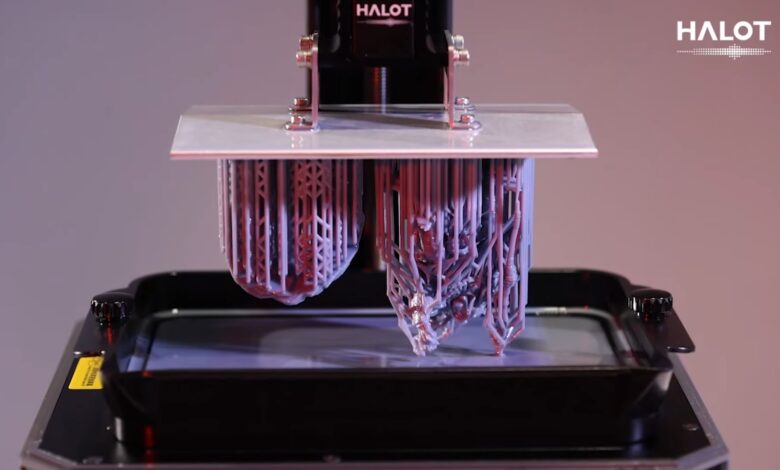

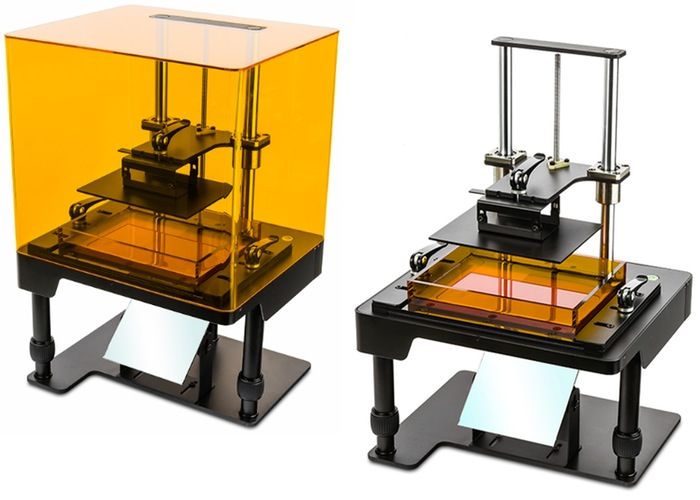

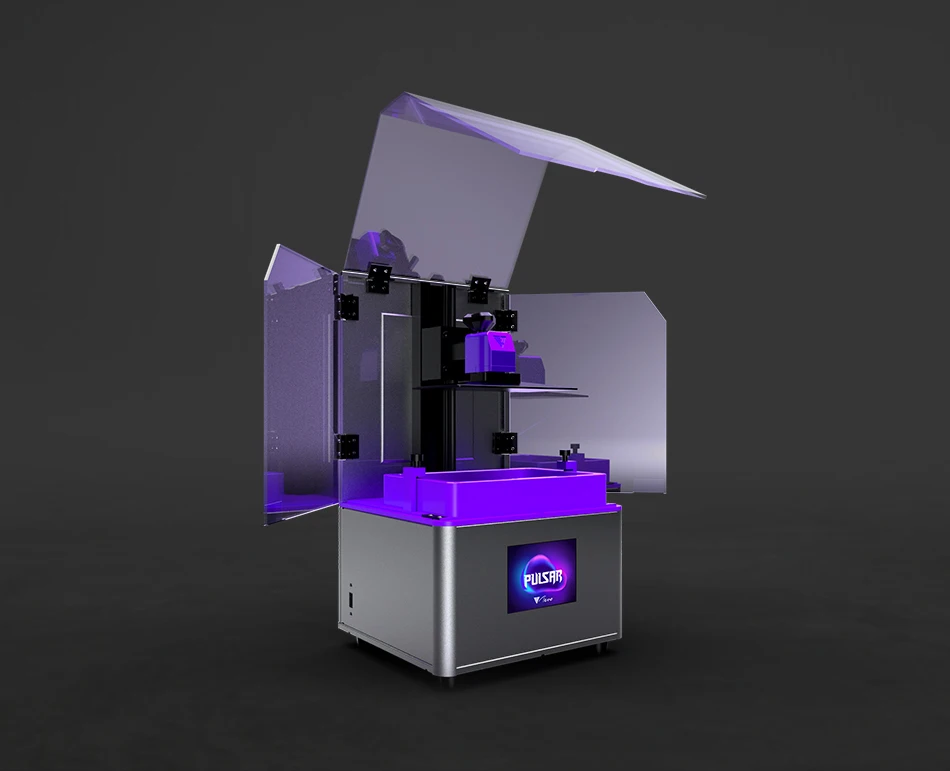

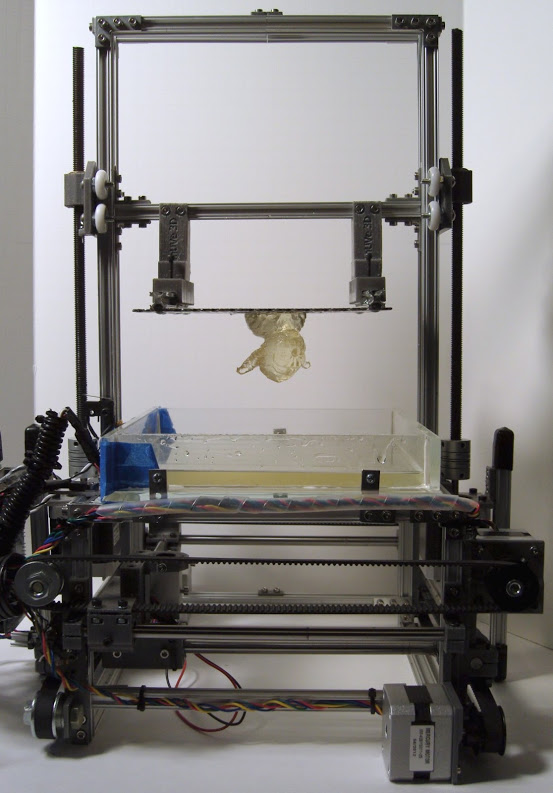

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

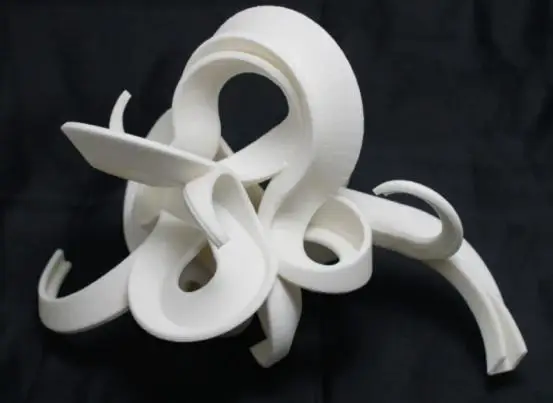

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

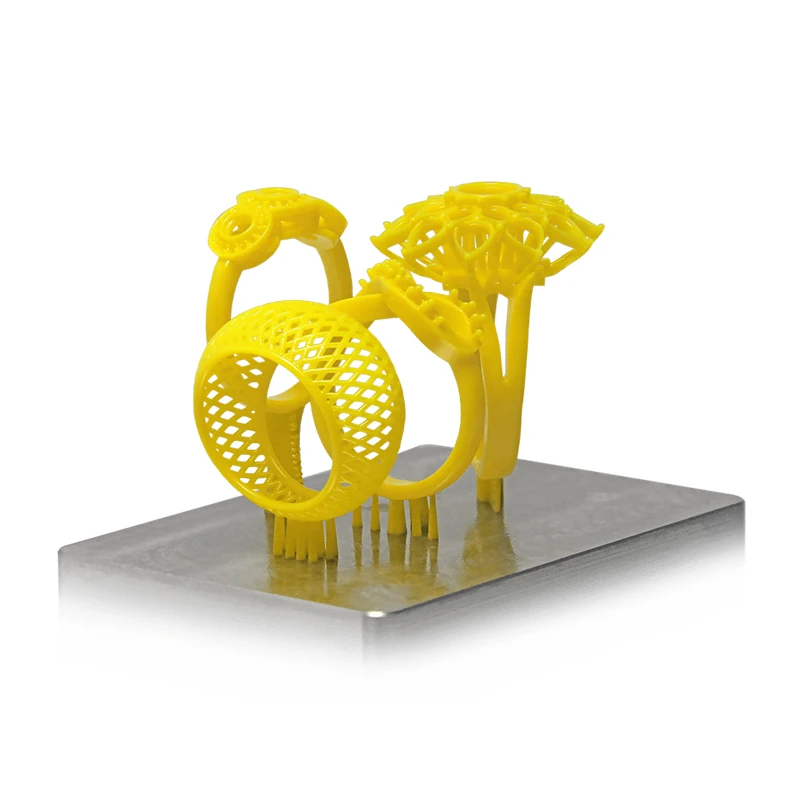

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Molding resin allows you to take the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you!

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

Types of resins for photopolymer 3D printer, characteristics, application

In recent years, the introduction of photopolymer printers in various areas of production is gaining more and more popularity. In order for the printer to reach its full potential, it is necessary to choose the right material - photopolymer resin.

In order for the printer to reach its full potential, it is necessary to choose the right material - photopolymer resin.

Now there is a wide variety of resins designed to solve a wide range of problems. Sometimes it can be difficult not to get confused in such a variety of materials. It is conditionally possible to divide photopolymer resins into several types - standard, engineering, dental, jewelry (burned).

Standard resins

Standard resins are well suited for making decorative models. They are strong and hard enough for making miniatures, master models, paintable figures or mock-ups, but their strength is usually not strong enough for functional products.

But standard resins are different from each other. Some of them can be washed not with alcohol, but with plain water, there are transparent types of resins or, for example, with a wide color palette.

Standard

Compared to other types of photopolymers, standard resins have a richer color palette. The main advantages are an inexpensive price, good detail and fast curing time.

The main advantages are an inexpensive price, good detail and fast curing time.

ESUN Standard

A good resin for professionals and beginners who are just getting acquainted with photopolymer printing. The advantages of ESUN Standard are a large palette of colors, no smell and fast printing speed.

ESUN Standard is suitable for printing decorative models or any other product that will not be subjected to heavy physical exertion.

Print technology: DLP/LCD/LED

UV wavelength: 395-405nm (transparent 395-410nm)

Shore hardness: 80-82 D

Impact strength according to Izod: 18 - 40 J/m

Bending strength: 46-72 Mpa

Modulus of elasticity: 1000 - 1400 MPa

Elongation at break: 28-35%

Exposure time per layer (recommended): 5-10 sec.

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 0. 5 kg, 1 liter.

5 kg, 1 liter.

Deadpool figurine

Bust of a military man

Moving castle, miniature

Users note good detailing, a good balance of strength and light elasticity, and excellent adhesion to the platform. The print time of the layer corresponds to the one declared by the manufacturer (5-10s) even on 3D printers with a weak UV source.

Of the minuses - sometimes the resin can be difficult to stir and a fine suspension comes across. This does not reduce print quality, but it does make me nervous. The gray color is slightly transparent, many users would like the color to be more “dense”.

ESUN eResin-PLA

eResin-PLA is based on PLA monomer, familiar to many from FDM printing. This makes the resin environmentally friendly and the finished product very tough and scratch resistant.

Resin is well suited for decorative items, master models or functional models without load.

Print technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 75-80 D

Elongation at break: 20-50%

Modulus of elasticity: 600 - 800 MPa

Impact strength according to Izod: 15 - 32 J/m

Tensile strength: 35-50 Mpa

Exposure time per layer (recommended): 15-20 sec.

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 1 liter

Shoe model

Figurine cartoon girl

Play miniature

Non-standard focusing rings for lens

Phrozen Aqua 4K

The Phrozen Aqua 4K is specifically designed to unlock the full potential of 4k resolution photopolymer printers. A pleasant bonus is the almost complete absence of shrinkage.

Resin is well suited for precision printing of decorative patterns. The manufacturer specifies that all properties of the resin are revealed when using printers with high resolution, such as Sonic Mini 4K / Sonic Mighty 4K.

The manufacturer specifies that all properties of the resin are revealed when using printers with high resolution, such as Sonic Mini 4K / Sonic Mighty 4K.

Print technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 77 D

Color palette: gray, ivory.

Volume: 1 kg

Armor printed in gray resin Phrozen Aqua 4K

Bust Predator

Figurine war with a bear, to demonstrate the capabilities of Phrozen Aqua 4K

Phrozen Beige Low Irritation

This resin is hypoallergenic. Phrozen Beige Low-Irritation has passed the ISO-10993 10 test, which means that the resin does not contain heavy metals and the finished models can directly contact the human body.

The resin can be used in dentistry or for products that will come into contact with the skin.

Print technology: DLP/LCD/LED

UV wavelength: 395-405nm

Color palette: beige

Volume: 0. 5 kg

5 kg

Decorative figurine

Jaw

ESUN Precession Model

Resin is designed for fast printing of high-precision models. In addition, finished products are tough and can withstand heat up to 80 degrees.

ESUN Precession Model is a good choice for models that need high detail.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85 D

Elongation at break: 12.1%

Bending strength: 77 Mpa

Tensile strength: 335-410 Mpa

Color palette: red.

Volume: 1 liter

DC Universe Riddler Head

Miniature model of ICE

Clear resins

Clear resins are present in other photopolymer ranges, but may become yellow or cloudy over time. If optical transparency without yellowness is important in the finished model, then you should pay attention to special polymers.

Phrozen SC-801 Clear

The main advantage of Phrozen SC-801 Clear is its optical transparency. Models made from Phrozen SC-801 Clear do not become cloudy or yellow during post-curing and during use.

This photopolymer is suitable for the manufacture of durable and accurate models for which optical transparency is important.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 70 D

Color palette: transparent

Volume: 1 liter

Material transparency model

Left product made of Phrozen SC-801 Clear, right RESINMAGIC3D High-Grade Clear

Figure printed with Phrozen SC-801 Clear

Miniature bottles printed for a articulated doll. Left made from Phrozen SC-801 Clear, right made from another polymer.

Washable

Finished models made on a photopolymer printer are recommended to be washed from photopolymer residues with alcohol. There are situations where this is not acceptable, such as when the printer is being used in schools. For such cases, manufacturers have created the Washable line. Washable are resins that can be washed with plain water.

There are situations where this is not acceptable, such as when the printer is being used in schools. For such cases, manufacturers have created the Washable line. Washable are resins that can be washed with plain water.

ESUN Water Washable

ESUN Water Washable is as strong and precise as ESUN Standard resins. The only difference is that the finished product can be washed not with alcohol, but with plain water.

ESUN Water Washable is well suited for printing at home or in educational institutions due to its low toxicity and odorlessness.

Print technology: DLP/LCD/LED

UV wavelength: 395-410 nm

Shore hardness: 76 D

Tensile strength: 68 MPa

Elongation at break: 5-10%

Bending strength: 45-70 MPa

Modulus of elasticity in bending: 900-1400 MPa

Izod impact strength: 18-39 J/m

Color palette: white, transparent, flesh, gray, black.

Volume: 0. 5 kg

5 kg

Rings and pendant printed in clear ESUN Water Washable

Fox figurine

Phrozen Water Washable

Phrozen Water Washable compares favorably with other water-washable resins in terms of strength, durability, and short flash-over time.

The resin is suitable for making prototypes and other models at home and in educational institutions where it is undesirable to use strong-smelling alcohols for washing.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80 D

Color palette: gray, black.

Volume: 1 kg

Bust made from Phrozen Water Washable

Alien printed from Phrozen Water Washable

Bust of Spiderman

Wanhao Water washable

It is a resin with high resolution and good hardness. Wanhao Water washable has very little shrinkage and a wide range of colors.

Wanhao Water washable has very little shrinkage and a wide range of colors.

Resin is well suited for printing master models and decorative models when it is not possible to use alcohol to wash the final product.

Print Technology: DLP/LCD/LED

UV wavelength: 395~420nm

Shore hardness: 75D

Color palette: white, transparent, black, gray

Volume: 0.5 kg, 1 kg

Han Solo in transparent Wanhao Water washable

Test model of transparent Wanhao Water washable

Test patterns in different colors Wanhao Water washable

Engineering

Previously, photopolymer printers were mainly used for making master models and products with high accuracy. Now they face a wider range of tasks. It is much more convenient to make a ready-made, functional model right away. For this, engineering photopolymer resins with improved characteristics have been developed. Depending on the application required, they can be harder, heat resistant and durable than standard resins.

Depending on the application required, they can be harder, heat resistant and durable than standard resins.

Reinforced

These are polymers with improved characteristics - for example, high heat resistance or impact strength. They can be used to produce functional prototypes, engineering models, etc.

Phrozen TR250-LV

The Phrozen TR250-LV has been specifically designed to meet engineering challenges. In addition to high strength and hardness, the resin has increased heat resistance and can withstand heating up to 150 degrees.

The Phrozen TR250-LV is suitable for the production of models for subsequent thermoforming or products that require increased heat resistance.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 79D

Tensile strength 25 MPa

Izod impact strength: 6.31 kJ/m2

Color palette: gray

Volume: 1 kg

Jaw Layout

Orc Bust

Phrozen ABS-like

This resin is similar in characteristics to ABS plastic, familiar to many from FDM printing. There is a white color in the palette, this allows, if necessary, to easily paint the finished product.

There is a white color in the palette, this allows, if necessary, to easily paint the finished product.

Phrozen ABS-like is suitable for printing functional models and prototypes.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 79D

Izod Impact Strength: 2.32 kJ/m2

Color palette: gray, white

Volume: 1 kg

Skull Model

Weapons for miniature figures

1/4 mask

Phrozen Rock-Black Stiff

When creating Rock-Black Stiff, emphasis was placed on strength, wear resistance and heat resistance (up to 97 degrees). Models are strong and slightly flexible to withstand shock loads.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 81D

Elongation at break: 4%

Izod impact strength: 2. 68 kJ/m2

68 kJ/m2

Color palette: black

Volume: 1 kg

Elf bust

Bust printed in Phrozen Rock-Black Stiff

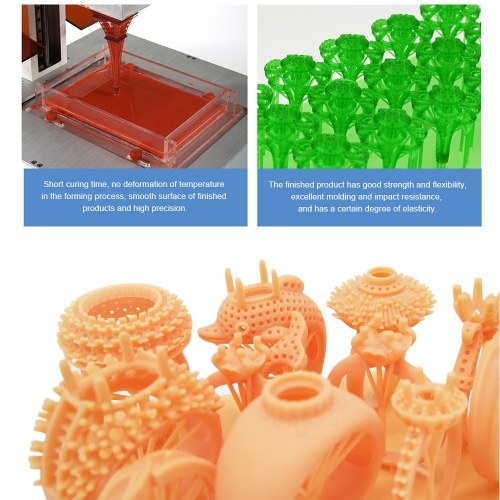

Phrozen Nylon Green Tough

Photopolymer is an analogue of nylon. Nylon is a very strong and wear-resistant material, familiar to many from FDM printing. Products are very durable and resistant to stress. Finished models printed in Nylon Green Tough can be folded.

Suitable for the manufacture of finished products or functional prototypes.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 68D

Elongation at break: 130%

Tensile strength: 19MPa

Izod impact strength: 23.79 kJ/m2

Color palette: green

Volume: 1 kg

Phrozen Nylon Green Tough Vase

Test model

Spectacle frame

Phrozen TR300 Ultra-High Temp

TR300 Ultra-High Temp allows you to quickly produce durable, shock and heat resistant products (up to 160 degrees). The photopolymer compares favorably with its competitors by its short exposure time (on 3D printers of the Phrozen Sonic series, 1.3 seconds per layer).

The photopolymer compares favorably with its competitors by its short exposure time (on 3D printers of the Phrozen Sonic series, 1.3 seconds per layer).

Phrozen TR300 is suitable for the manufacture of heat-resistant and durable products. For example, it can be a model for subsequent thermoforming or manufacturing an industrial layout.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80D

Tensile strength: 32 MPa

Izod impact strength: 8 kJ/m2

Elongation at break: 2%

Color palette: gray

Volume: 1 kg

Phrozen Onyx Rigid Pro410

The main properties of models made from Onyx Rigid Pro410 are amazing detailing and durability. The resin was developed in partnership with Henkel and is intended primarily for home workshops.

Photopolymer is perfect for models with an abundance of small details that need high detail. Or for engineering/functional models where high accuracy and strength are important.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Color Palette: Black

Volume: 1 kg

Tablet stand

Fruit vase

Wall mounted spice holder

Wall hanger

Flexible

Products made from such resins will look like silicone or rubber. Such photopolymers make it possible to obtain flexible and durable functional products resistant to tearing.

Phrozen Biege Flex

This is a resin designed for products that need to be strong and slightly flexible. Phrozen Biege Flex is suitable for functional models that need some flexibility.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 65D

Tensile strength: 40 MPa

Modulus of elasticity: 192 MPa

Color palette: beige

Volume: 0. 5 kg

5 kg

Bust of Harley Quinn

Miniature from Phrozen Biege Flex

Functional carabiner

HARZ Labs Industrial Flex

By its properties, finished products from HARZ Labs Industrial Flex resemble polyurethane. Products from it are elastic and very durable.

HARZ Labs Industrial Flex is suitable for the manufacture of gaskets or any other model where softness and tensile strength are important.

Industrial Flex can be used as an additive for other HARZ Labs resins. This allows you to increase the flexibility and strength of the finished model. Depending on the resin ratio, different degrees of flexibility can be achieved in the finished product.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 63D

Shrinkage: 0.5%

Elongation at break: 103%

Tensile strength: 13 N/mm2

Color palette: transparent

Volume: 0. 5kg 1kg

5kg 1kg

Various gaskets printed from HARZ Labs Industrial Flex

ESUN Flex

Flexible and durable material with good wear resistance. Good tear resistance and accuracy make ESUN Flex suitable for engineering models.

For example, products that must be strong and flexible at the same time. These can be engineering prototypes or functional models.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85-90 A

Shrinkage: 6.9%

Elongation at break: 100-150%

Bending strength: 77 Mpa

Tensile strength: 390-320 kN-m

Color palette: transparent yellow

Volume: 0.5 kg

Test model from ESUN Flex

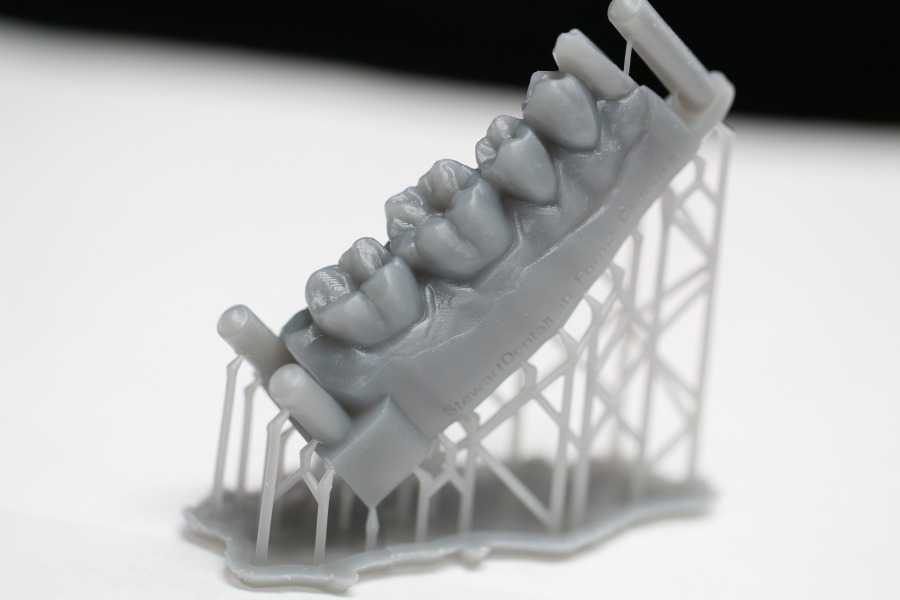

Dental resins

From the very beginning of its existence, photopolymer printers have taken the place of indispensable assistants in the dental industry, therefore, in the assortment of many companies that manufacture photopolymer resins, there are materials intended for use by dentists.

Special photopolymers

These are special polymers that are focused on solving specific problems. No one forbids using them for other than their intended purpose, but they fully reveal their potential precisely in the task for which they were created.

Harz Labs Dental Soft

Dental Soft was created as a material to simulate gums in demonstration models. The finished print is pink in color and has high strength and chemical resistance. Despite its flexibility, the finished model will be resistant to deformation. Harz Labs Dental Soft is certified for medical use.

The material is suitable for gum printing or other medical applications.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 87-90D

Shrinkage: <0.5%

Elongation at break: 68%

Tensile strength: 1.2 N/mm2

Color palette: pink

Volume: 0.5 kg, 1 kg

Gums from Harz Labs Dental Soft

Gums from Harz Labs Dental Soft

NextDent Gingiva Mask

Another gum simulation resin from NextDent. Gingiva Mask is a flexible and durable resin that blends beautifully with model material.

Gingiva Mask is a flexible and durable resin that blends beautifully with model material.

The resin is suitable for various models in the dental industry.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 60 - 75 A

Elongation at break: 40 - 60%

Color palette: pink

Volume: 1 kg

Gingiva made from NextDent Gingiva Mask

Part of the gum made from NextDent Gingiva Mask

Jaw Demo with NextDent Gingiva Mask Inserts

Harz Labs Dental Clear

Products from this resin are durable and hard. The main feature is the resin is transparent, without turbidity and yellowness. Harz Labs Dental Clear is certified for medical use.

This photopolymer is suitable for the manufacture of surgical templates, demonstration models and even aligners.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent

Volume: 0.5 kg, 1 kg

Jaw Demo Model

Piece of jaw printed from Harz Labs Dental Clear

Dental Yellow Clear

Very similar in its properties to Harz Labs Dental Clear - just as strong and hard. The only difference is that the color of the resin is not crystal clear, but yellow. The resin is certified for use in medicine.

Dental Yellow Clear is suitable for making aligners or demonstration models.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent yellow

Volume: 0. 5 kg, 1 kg

5 kg, 1 kg

Gingiva pad made of Dental Yellow Clear

Jaw models

Dental Yellow Clear Demonstration Product

Burnout

In addition to specialized resins in dentistry, low-ash burnable or smelted materials are needed for direct casting.

Before casting, be sure to read the instructions from the manufacturer. Each resin has its own burnout cycle in order to obtain a good casting quality.

ESUN Castable Dental

ESUN Castable is designed for direct casting in dentistry. Finished products are smooth and hard. When burning, the ash content is practically absent.

High precision allows ESUN Castable to be used for crowns, bridges and other castings.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80D

Elongation at break: 11-20%

Bending strength: 49-58 Mpa

Impact strength according to Izod: 44 - 49 J/m

Color palette: green

Volume: 1 kg

Crowns printed from ES

ESUN Castable jaw

Example of printed and molded model

Phrozen Wax-like Dental Green

Wax-like Dental Green is a waxy resin with low shrinkage and zero ash content. Due to the low shrinkage, the finished products are very accurate, and the matte surface will help to see even small imperfections.

Due to the low shrinkage, the finished products are very accurate, and the matte surface will help to see even small imperfections.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Color palette: green

Volume: 0.5 kg

Ring made from Phrozen Wax-like Dental Green

HARZ Labs Dental Cast Cherry

HARZ Labs Dental Cast Cherry was developed for direct casting of dental products. With the correct burnout cycle, it is possible to achieve almost zero ash content. The photopolymer is certified for medical use.

Dental Cast Cherry is suitable for casting metal or ceramic crowns and bridges.

The manufacturer recommends the use of phosphate-based phytomass, because they can be used at high temperatures, which are required for high-quality burning of the model.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 40-50D

Shrinkage: less than 1%

Color palette: red

Volume: 1 kg

Crown models printed with Dental Cast Cherry

Cast crowns

NextDent Cast

It is an easy-to-burn-out resin with zero ash content. Designed for the manufacture of burn-out dental models.

Designed for the manufacture of burn-out dental models.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80-90D:

Color palette: red

Volume: 1 kg

Crowns made from NextDent Cast

Demo Model

DETAX Freeprint cast UV

High precision resin designed for fast manufacturing of dental products. Finished products can be used for direct casting. DETAX Freeprint cast UV burns out ashless even with large casting volumes. For molding, it is recommended to use phosphate-based masses.

Print technology: DLP/LCD/LED

UV wavelength: 378-388 nm

Color palette: red

Volume: 1 kg

Overlay made of DETAX Freeprint cast UV

Crowns made from DETAX Freeprint cast UV

Burnout resins

In addition to dentistry, 3D printers have firmly established themselves in the jewelry industry. 3D printing allows you to create complex products much faster than classical methods (manual wax cutting, CNC machine). Burnt-out resins were created especially for jewelers.

3D printing allows you to create complex products much faster than classical methods (manual wax cutting, CNC machine). Burnt-out resins were created especially for jewelers.

ESUN Castable for jewelers

Photopolymer specially designed for printing and casting small models with high detail. Products from ESUN Castable are smooth, and almost zero ash content makes it easy to get the desired product in the metal.

The resin is suitable for printing jewelry - rings, pendants, earrings and for other burn-out models, in which accuracy and perfect surface quality are important.

Print technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 60 D

Color palette: yellow, green

Volume: 1 kg

Ring printed from ESUN Castable

Ring from ESUN Castable

Phrozen Wax-like Castable Violet

Waxy polymer with low shrinkage and zero ash content. Products made of Phrozen Wax-like Castable Violet have a nice matte surface, which will show the slightest imperfections.

Products made of Phrozen Wax-like Castable Violet have a nice matte surface, which will show the slightest imperfections.

Wax-like Castable is suitable for making any castable models.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Color palette: purple

Volume: 0.5 kg

Ring printed in Wax-like Castable and finished casting

Wax-like Castable Openwork Rings and Precast Castings

Wax-like Castable pendant and finished product

HARZ Labs Jewelry J-Cast

This is a photopolymer designed for the manufacture of burn-out models for subsequent casting in metal. High precision, low shrinkage (less than 1%) and low ash content (less than 0.1%) make it possible to print even very small products without distortion.

HARZ Labs Jewelry J-Cast is suitable for printing jewelry. Due to its high thermoplasticity, the photopolymer can be burned out over a wide temperature range.