Nylon filament for 3d printer

1.75mm Nylon Filament | MatterHackers

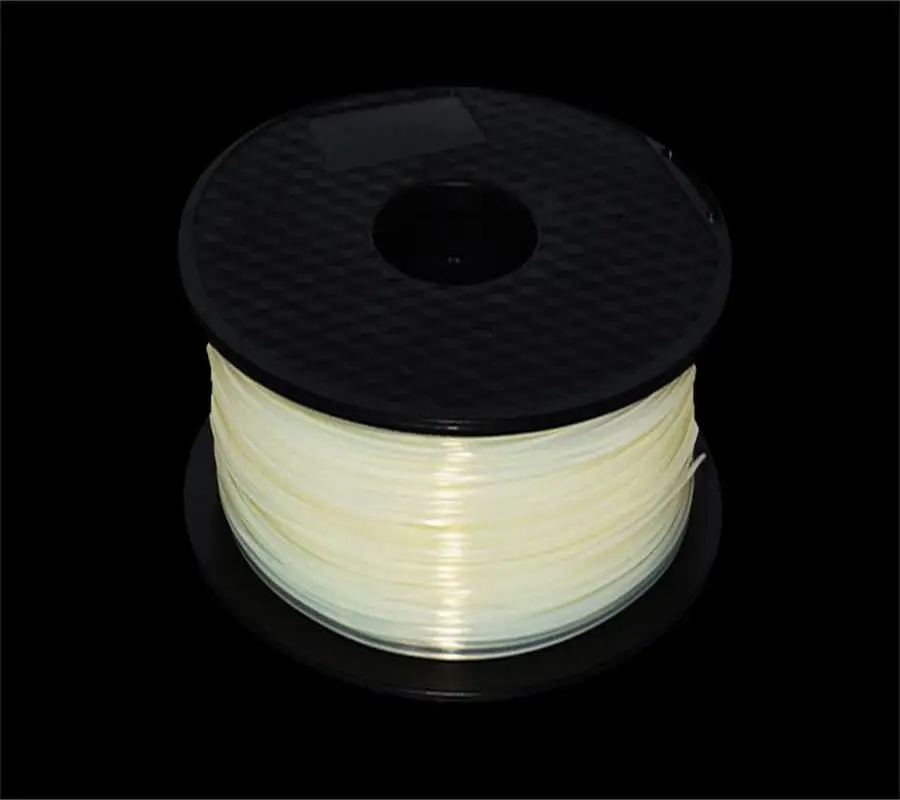

Nylon is an incredibly strong, durable, and versatile 3D printing material. Flexible when thin, but with very high inter-layer adhesion, nylon lends itself well to things like living hinges and other functional parts. Nylon filament prints as a bright natural white with a translucent surface, and can absorb color added post process with most common, acid-based clothing dyes or synthetic cloth specific dyes. Nylon filament is extremely sensitive to moisture, so taking drying measures during storage and immediately prior to printing (using desiccant, vacuum, or elevated temperature) is highly recommended for best results. For tips and tricks on 3D printing Nylon, check out How To Succeed When Printing With Nylon.

Nylon Filament

PRO Series Nylon

The strength and durability of Nylon now in vibrant colors.

NylonX

The durability of Nylon combined with the stiffness of carbon fiber

NylonG

Glass infused nylon for strong, functional prints

Ultimaker Nylon Filament

Get impact and abrasion resistance with Ultimaker Nylon filament

Kodak Nylon 3D Printing Filament

Kodak Nylon 3D Printing Filament

Taulman Nylon 645, 680, 230

eSUN Nylon Filament

Material designed for high tensile strength and heat resistance

DSM Novamid 3D Printing Filament

Advanced material for automotive and electrical 3D printing applications.

Guides & Articles

5 Reasons Why You Should Start 3D Printing with Nylon

It's time to start 3D printing with Nylon filament - embrace the unique characteristics that make this material so versatile in a wide range of applications.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

Living Hinge: Design Guidelines and Material Selection

Bring your prints to life by adding an additional degree of motion to your designs - living hinges are the foundation of expanded mechanical solutions.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

Retraction: Just say "No" to oozing

By understanding a little more about the 3D printing process, and how settings in MatterControl affect extrusion, we can help you reduce and even eliminate oozing and stringing from your 3D prints. This should be a part of the regular maintenance and calibration program for your 3d printer.

How To Clear and Prevent Jams on Your 3D Printer

At some point you may encounter a filament jam or a clogged nozzle where your 3D printer is not extruding. This guide is intended to help you prevent such jams, or fix with them as painlessly as possible.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

3D Printing Nylon Filament - Gizmo Dorks

Gizmo Dorks

$29. 95

95

Current stock: 0

The Gizmo Dorks 3D printing Nylon filament is a strong durable material that is not as brittle as ABS or PLA. Nylons are classified in the family of polyamides, which is a polymer consisting of amides joined together by peptide bonds. For Fused Deposition Modeling, FDM, Nylon filament is a great material to use for 3D printing. The strength of the Nylon filament is remarkable, especially when using a higher fill setting.

3D prints using Nylon filament are generally very wear resistant, and they are incredibly flexible as well. Many users prefer using Nylon filament when printing engineered parts such as gears. However, Nylon does have a considerable amount of warping when compared to ABS or PLA. Pyrolysis occurs around 350°C.

Tips When Printing With Nylon Filament

Nylon prints will stick to blue painter's tape. Because Nylon adheres to cellulose surfaces poplar wood can be used as a bed. Some users have used cardboard or hardboard (not to be confused with hardwood). Nylon also sticks extremely well to machinable garolite, but that may be hard to come by. Users have also said that using a glue stick on a glass bed works well. PVA glues (think of Elmer's white glue all) can also be diluted and applied on with a sponge head. Please use in a well ventilated area or in a closed ventilated system.

Nylon also sticks extremely well to machinable garolite, but that may be hard to come by. Users have also said that using a glue stick on a glass bed works well. PVA glues (think of Elmer's white glue all) can also be diluted and applied on with a sponge head. Please use in a well ventilated area or in a closed ventilated system.

Nylon filament absorbs a lot of moisture when left out in the open. Please bake the Nylon filament in the oven at 170°F for 3-6 hours just before printing to remove moisture.

- Net weight = 1 kg or 2.2 lbs

- Printing temperature : 230°C - 260°C depending on part and printer type

- Print speeds : 18 mm/s first layer, then 28mm/s - 34mm/s

- Heated bed of 110°C helps combat Nylon's warp

- No cooling fans

- Only use in well ventilated areas

- Store dry when not in use, absorbs moisture

Nylon Filament for 3D printing comes in 2 different sizes

- 1.75mm Nylon Filament

- 3mm (2.

85mm) Nylon Filament

85mm) Nylon Filament

Your shopping cart

Account

Log in

Email Address *

Password *

Forgot password?

New Customer

Create an account with us and you'll be able to:

- Check out faster

- Save multiple shipping addresses

- Access your order history

- Track new orders

- Save items to your wish list

Create Account

Forgot Password

Fill in your email below to request a new password. An email will be sent to the address below containing a link to verify your email address.

Email Address *

3D Printable Nylon

- 1 Description

- 2 Specifications

- 3 Advantages and disadvantages of nylon

- 3.

1 Features

1 Features - 3.2 Disadvantages

- 4 3D printing use

- 5 Use of available materials

Description

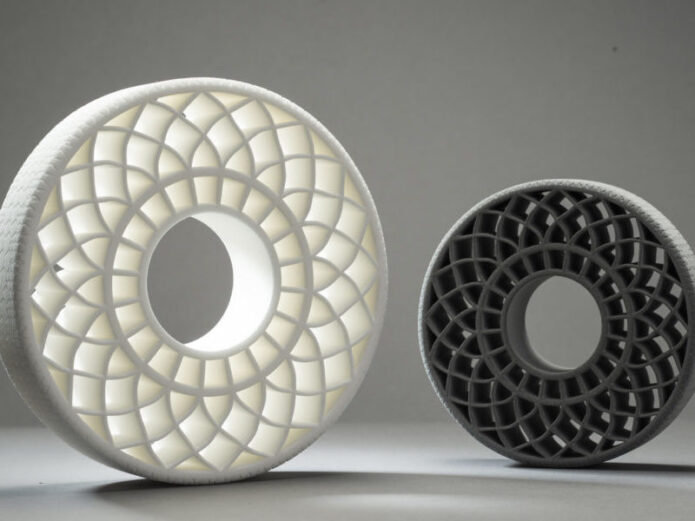

Nylon is attractive as a material for 3D printing due to its high wear resistance, affordability and excellent slip coefficient, which allows the use of nylon in bearings and other similar mechanisms, often without the use of lubricants. nine0025

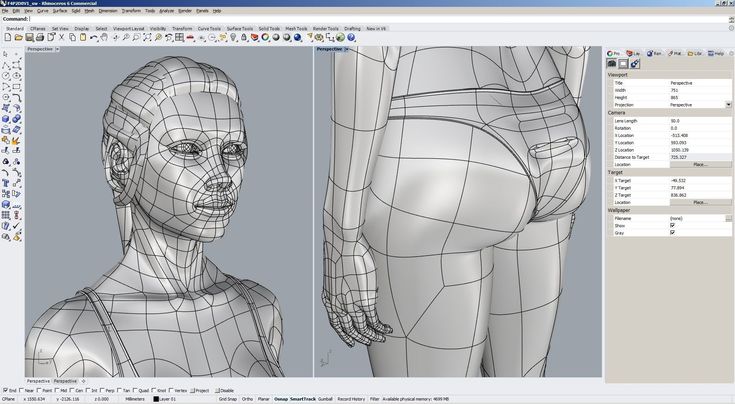

An example of a model created using Stratasys Nylon 12

Despite the widespread use of nylon in the industry, the use of this material in 3D printing is quite limited due to certain technological difficulties. However, in recent years, specialized nylon consumables have appeared, focused on use with SLS and FDM printers.

Taulman and Stratasys nylon threads are the most popular examples. nine0002

Specifications

| Taulman 618 | Taulman 645 | Stratasys Nylon 12 | |

| Density | 1. 134 g/cm³ 134 g/cm³ | – | – |

| Hygroscopicity | 3.09% | 3.09% | – | nine0048

| Tensile strength | 65.99 MPa | 85.68 MPa | 48.26-53 MPa |

| Elongation at Break | Over 300% | Over 300% | 9.5-30% |

| Melting point | 218°C | 214°C | 178°C | nine0048

| Glass transition temperature | 49.4°C | 68.2°C | – |

| Extrusion temperature | 235-260°C | 235-260°C | – |

| Pyrolysis temperature | 350-360°C | 350-360°C | – |

Stratasys Nylon 12 is designed for use with Fortus brand 360mc, 400mc and 9 professional rigs00mc, while Taulman's nylon filaments are designed to work with any home and office 3D printer optimized for the popular ABS plastic. In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

Advantages and disadvantages of nylon

Advantages of

- High wear resistance

- High elasticity

- Resistant to most organic solvents

- High temperature resistance

- Easy to machine

Disadvantages

- High hygroscopicity

- Release of toxic fumes during pyrolysis

- Taulman brand nylon threads available in 1.75mm and 3mm diameters

3D printing use

Taulman brand nylon filaments are available in 1.75mm and 3mm diameters

Nylon printing technology is similar to ABS printing, but with some differences. Like ABS, nylon is prone to twisting and warping when cooled unevenly, requiring the use of a heated bed.

The nylon layers have excellent adhesion, which minimizes the chance of delamination of models. Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding. nine0025

Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding. nine0025

Nylon is almost impossible to bond, which makes it difficult to manufacture large-sized parts from components. Alternatively, it is possible to connect nylon parts by melting the surfaces to be joined.

Nylon can be dyed with acid-based dyes.

Nylon does not adhere to glass or other smooth surfaces, so it is recommended to apply painter's tape to the desktop or use a wood backing when printing. nine0025

Due to the high hygroscopicity of nylon (the ability to absorb moisture), it is recommended to dry the nylon filament immediately before printing. Otherwise, water vapor may be released from the nozzle, which is not catastrophic for the extruder, but may affect print quality.

Use of scrap materials

Some hobbyists prefer to use inexpensive nylon line for printing, which is fraught with some unpleasant consequences. As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle. nine0025

As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle. nine0025

Go to the main page of the Encyclopedia of 3D Printing

Nylon plastic for 3D printing

December 5, 2021

Nylon is a versatile group of polyamide-based thermoplastic polymers originally developed to replace silk. Under the name "Nylon" you can actually buy different varieties of filaments, which are slightly different in composition and, as a result, have different properties. Nylon threads show great versatility in use and performance as they allow the production of both strong and flexible items with a good silky finish. nine0025

Under the name "Nylon" you can actually buy different varieties of filaments, which are slightly different in composition and, as a result, have different properties. Nylon threads show great versatility in use and performance as they allow the production of both strong and flexible items with a good silky finish. nine0025

All this explains why this type of plastic is most often used in such areas of 3D printing as: prosthetics, robotic, mechanical, functional non-metal parts, belts, gears, handles, waterproof products, housings. It is ideal for the manufacture of end-use parts. It is also a type of plastic that will be able to meet most of the requirements of engineers, designers and manufacturers. And it's easy to buy - it's fairly common.

Nylon has high impact and abrasion resistance and a low coefficient of friction. It is also characterized by corrosion resistance to alkalis and organic chemicals. nine0025

If nylon thread is used for thick structures with high fill density, the final object will be strong and wear resistant. When faced with a load, such parts will have excellent impact resistance. If you use this filament for thin details, then you will get flexible elastic objects.

When faced with a load, such parts will have excellent impact resistance. If you use this filament for thin details, then you will get flexible elastic objects.

Nylon fibers are harder to work with than PLA. But any 3D printer can print with this material, the print temperature of which is maintained at a higher level (220-270 ° C), a heated table and even a case to avoid deformation. The latter is a recommendation, but not a requirement. Please note that the nylon filament in the spool is flexible and can cause jams, especially if the 3D printer is programmed for high feed and print speeds. nine0025

Like powdered nylon, this filament absorbs quite a bit of moisture, which should be kept in mind when storing the filament or parts printed with it. On the other hand, this characteristic makes it easy to dye objects made of nylon with dyes for synthetic fabrics - the result will be durable.

The advantages of nylon include the following characteristics:

- High level of strength and durability.

Learn more