3D printing uiuc

What We Offer — Illinois MakerLab

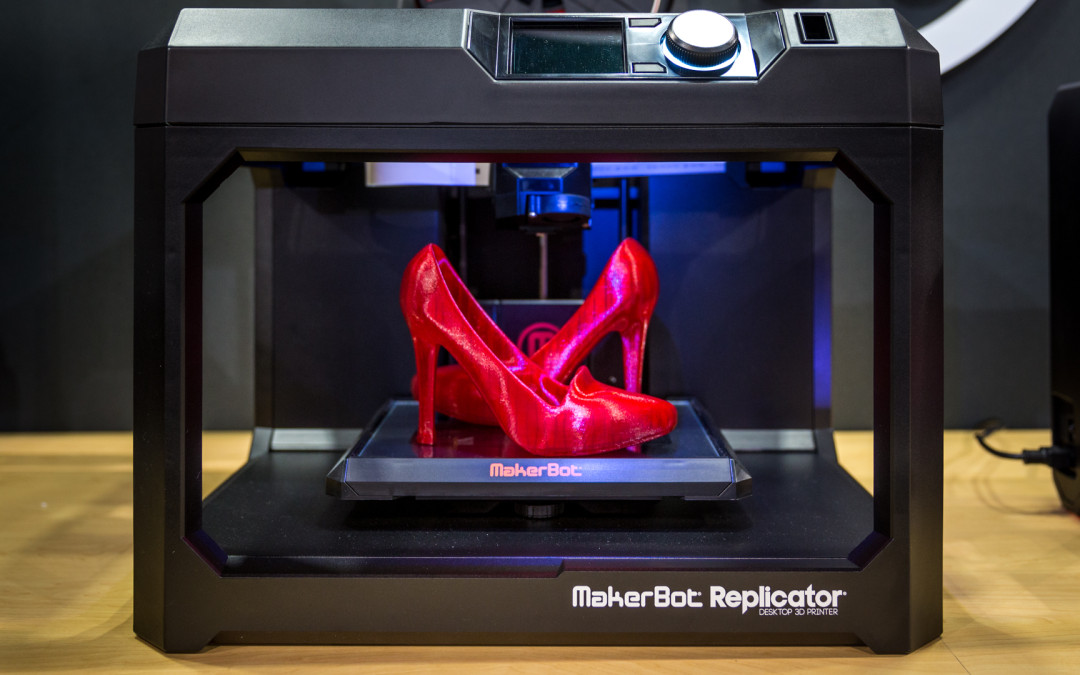

3D Printing: We have 19 Ultimaker 3D Printers that can be used to turn digital designs into physical objects. Specifications, build area and material options are listed on our Frequently asked questions page. . Material costs ($2 minimum) are paid by credit cards. There will be a 20% surcharge for all prints setup and managed by our Guru’s. Dual color or special filement prints have a 50% surcharge on base prices. Payments made with campus accounts require a minimum billing of $10, and will be charged at Illinois Faculty/Staff rates.

Free print hour: Choose a small print to print for free!!

11 am -1 pm on Friday

Check out the Things We’ve Made

User

Illinois Student

Illinois Faculty/Staff*

All Other Users

Walk-In Rates

15¢ per gram

25¢ per gram

35¢ per gram

Online Ordering Rates**

18¢ per gram

30¢ per gram

42¢ per gram

Online 3d Printing : We now have an online 3d printing service as well. More details on our online ordering page.

*Includes departments and alumni

**Online Orders incur a 20% surcharge

3D Design & Prototyping: If you need turnkey design services, our MakerLab Gurus are experts in 3D design and prototyping and are available to turn ideas into 3D designs and then into product prototypes. These services are available at the following rates (30 minute minimum + 30 minute increments + material costs). If you are interested in learning and designing things yourself, sign up for our workshops.

Read our Design Stories to get an idea of our work.

User

Illinois Student

Illinois Faculty/Staff

All Other Users

Cost

$15 per hour

$25 per hour

$50 per hour

1 to 1 Private Tutoring for 3D Modeling

Are you interested in improving your 3D Modeling skills or want to learn how to start? Individual tutoring sessions will be available for you to meet with one of our Gurus who have experience with diverse software. Online or in-person, our Gurus will ensure that you are effectively improving your skills after every lesson

Online or in-person, our Gurus will ensure that you are effectively improving your skills after every lesson

Price:

$25 for 30 minute session

Software:

Tinkercad

Fusion 360

Meet our Gurus and their diverse set of skills and backgrounds!

If you are interested, contact us.

Reserving MakerLab for a Private Session

In addition to our scheduled activities, the MakerLab may be reserved for private class sessions (up to 21 students at a time). These sessions can cover a variety of topics including 3D printing, 3D design, 3D scanning, product prototyping, and many others. Drop us a line.

Our Printing Policies

Illinois MakerLab’s 3D printers may be used only for lawful purposes. Individuals who choose to use any of Illinois MakerLab’s services will not create materials (digital or physical) that are:

Prohibited by local, state or federal law

Unsafe, harmful, dangerous, or pose a potential threat to the well-being of others

Obscene, inappropriate, or offensive in a public university environment

In violation of another individual’s intellectual property rights (i.

e., reproducing copyrighted, patented, or trademark protected materials)

e., reproducing copyrighted, patented, or trademark protected materials)

The Illinois MakerLab reserves the right to refuse the printing of materials. If you have questions concerning the nature of something you would like to create in the lab, please contact us.

3D Printing - School of Art & Design

Zortrax (FFF) 3D Printing –

- Prepare your file for printing in Z-Suite (available on all lab computers). For info on preparing the file, consult the Zortrax Quickstart Guide on the Tutorials & Templates page.

- Submit your Zortrax 3D print files to the queue by filling out the online form (you will be prompted to upload your file after you submit the form) or bringing your file on a USB stick to the Digital Output Support Lab Assistant in 235A.

- You will receive an email when your request has been processed and added to the queue. You will receive a second email when your print starts.

Form 2 (SLA) 3D Printing

- Request an estimate at go.

illinois.edu/art3DprintEstimate.

illinois.edu/art3DprintEstimate. - Immediatly after you submit this request, you will receive an automated email reply.

- A print estimate with the estimated cost and projected start time for your print should be expected within 1-2 business days.

- After you receive this estimate, you must confirm the estimate to reserve your place in the queue within 24 hours. If you confirm the estimate after 24 hours, the cost will likely remain accurate, but the projected start time may change. You will be notified of the revised start time, but it will be considered automatically confirmed, unless you respond with a cancellation prior to the start time of the print.

Table of Printer Specifications

| Zortrax M200+ | Formlabs Form 2 | |

|---|---|---|

| FFF: fused filament fabrication ABS Filament (black / white / first available) | SLA: stereolithography clear or flexible resin | |

| free | Varies by material ($. 25 - $.40/ml) 25 - $.40/ml) | |

| 7.9 x 7.9 x 7.1 in zortrax build volume | 5.7 × 5.7 × 6.9 in form2 build volume | |

| 90 microns [0.0035 in] | 25 microns [. 001 in] 001 in] | |

| breakaway ABS | breakaway resin | |

| submit a .zcodex file through the online form or bring your .zcodex file to the DOS lab assistant | submit . stl file(s) through the online form for estimate stl file(s) through the online form for estimate |

At Art & Design, we have several 3D printing options. Understanding the basics will help you to make an informed decision about what printing process is right for your project.

3D printers are considered to be “rapid prototyping devices” – but that doesn’t always mean that it is a quick process. Small models can often take hours or even days to print. Additionally, after it is printed, it may need to be cleaned in a chemical bath before it is ready for pick up. Also, keep in mind that the output of a 3D printer is a prototype – it is not usually considered to be a final product. Plan your project to allow for enough time to make multiple versions, and to allow for enough time to finish it by sanding and/or painting. All 3D prints require some level of finishing, and depending on what printer you use, the amount of finishing necessary may vary.

Types of Printers

Our Zortrax printers use a process call Fused Filament Fabrication (FFF). With FFF printing, plastic filament is melted and squeezed through a nozzle, laying down one layer of extruded plastic at a time. The model is built by printing many thin layers of plastic. The level of detail or smoothness of the print is determined by the height of each layer of plastic.

To avoid wasting plastic, and reduce print time, the interior space of a FFF print can be filled with a looser mesh of plastic. This interior structure of the model is called “infill”. Infill is usually described in percentages – a higher percentage of infill is a denser mesh. A denser mesh results in a stronger model, so, depending on how your model will be used, it may require a higher density of infill. If your model doesn’t need to support weight, handle tension, it will significantly reduce print time to use a lower percentage infill in printing.

Our Form 2 printer uses a process called Stereolithography (SLA). With SLA printing, a printing plate is submerged in a vat of resin that can be cured, or made solid, by being exposed to ultraviolet light. A laser traces the path to be cured, and successive layers are built by raising the printing plate slightly, and curing another layer of resin to the previous layer. In SLA printing, the level of detail or smoothness is determined by the size of the point of the laser, creating prints with finer detail than is typically possible with FFF printing. Unlike FFF printing, SLA prints typically have a solid infill to avoid liquid resin from being trapped inside the model.

Support Material

To build areas of a print that overhang, the printer builds scaffolding on which it builds the overhanging area. This scaffolding is called “support”. Both the Zortrax and the Form 2 printers use the same material that is used for the model for support that can be broken off and sanded away. All prints require the use of some amount of support.

All prints require the use of some amount of support.

Sometimes, a model can be printed in a way that minimizes the need for support, or places the support in areas that are easier to cut or break away, and sand cleanly. However, some models need to be printed at a particular angle for the printer to successfully build the model, and the support cannot be minimized. This is particularly true for SLA printing, where the model must be printed at an angle for the layers to be successfully cured to the print bed.

Success and Failure

There are many factors that determine the success of a print. All printers have limitations, and printing to the extent of the limitations often results in failure. For example, prints that come close to the maximum build volume of the printer, or that have extremely thin walls are prone to failure. Printers tend to create minor vibrations and movements that may affect the success of particularly delicate models.

Most 3D printing technology produces a model that is close to the specified size in the software, but some shrinkage should be expected. Because of this variance, it can often be difficult to 3D print parts that fit together accurately.

Because of this variance, it can often be difficult to 3D print parts that fit together accurately.

What is 3D printing and how it can be used! Interesting!

What is 3D printing

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used. nine0005

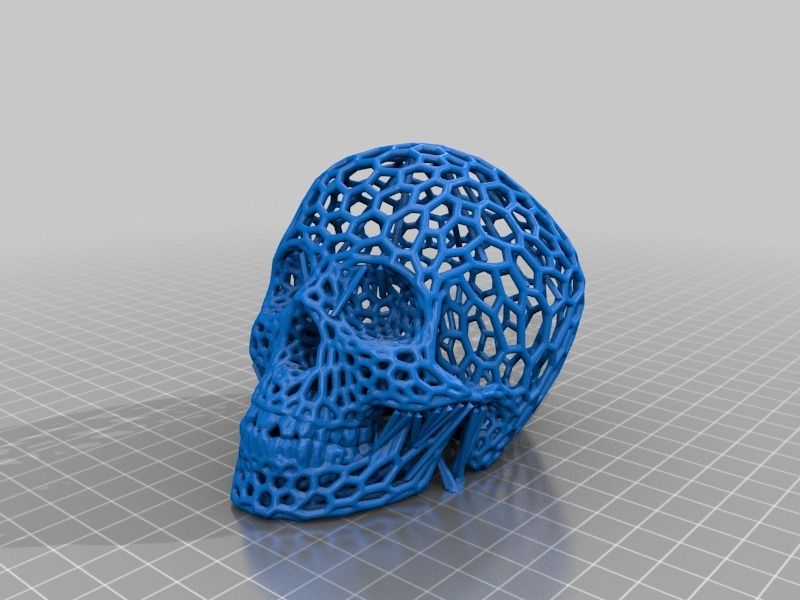

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies". nine0005

More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies". nine0005

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

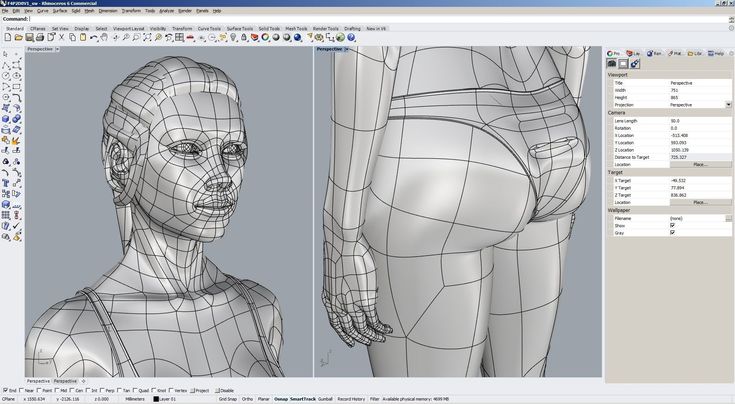

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to the 3D printer; nine0015

- 3D model reproduced.

Objects are reproduced gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique. nine0005

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Different 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) . One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic;

- Laser stereolithography (SLA) .

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; nine0015

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; nine0015 - Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

As you may have guessed by now, 3D printing is extremely versatile. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent. nine0005

In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent. nine0005

Well, that was a brief description of what 3D printing is. We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We also want to remind you about the possibility to order 3D printing, 3D scanning, 3D modeling services or purchase of related equipment and consumables with delivery throughout Ukraine in 3DDevice. If you have any questions, please contact us at one of the phone numbers listed here. We look forward to collaborating! nine0005

Return to the main page

3D printing on order in Nizhny Novgorod, cost of services

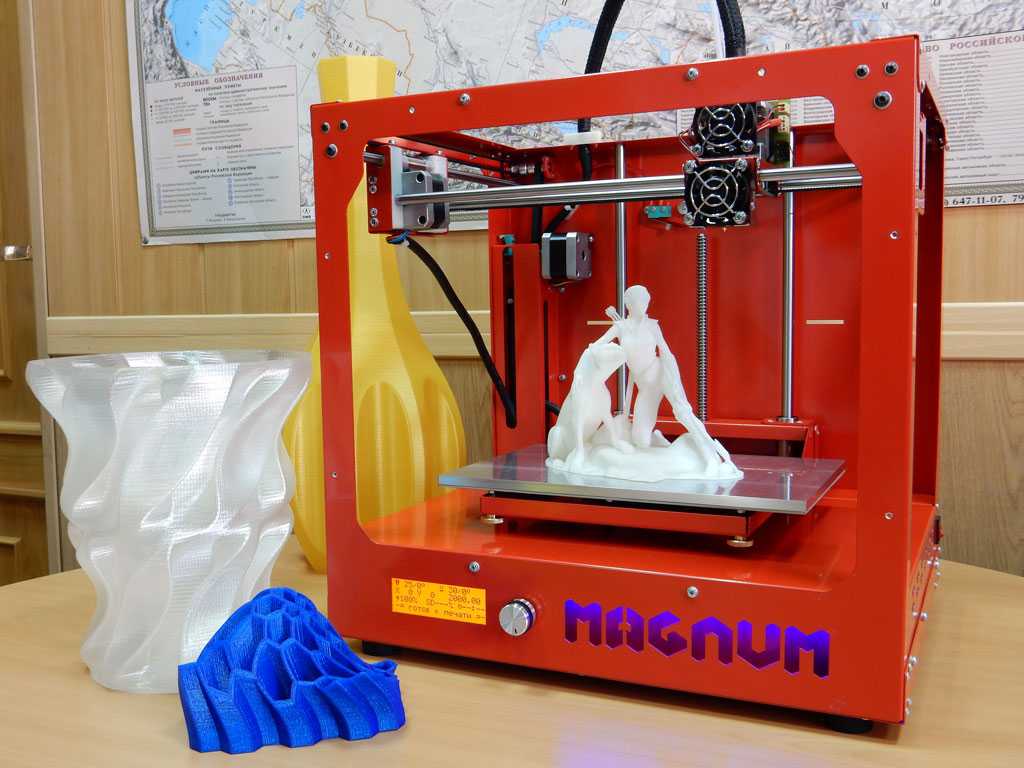

The cost of printing on a 3d printer allows you to use the service not only for commercial and state enterprises, but also for individuals - innovative production technologies have become widely available. Prototyping of 3d models is the reading of information from a computer program by special equipment and translation into a real object by successive building up layer by layer until the formation of a finished product. ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of ordered samples, the material from which they will be made and the method of prototyping.

3d printing and prototyping - the latest technologies in practice

The combination of computer technology with production allows you to multiply the speed of production, reduce the cost of creating the necessary items. Volumetric printing is developing at a rapid pace, from the realm of fantasy, it has become a familiar production process, which can be carried out using various methods. Order 3d printing in Nizhny Novgorod for one model or batch of products, just call Pro Plast-NN LLC at the numbers listed on the site. The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

Where created 3d models and prototypes are used

Prototyping on 3d printers allows you to quickly and at low cost get a sample of the desired part from a polymer material, made with a high degree of accuracy, without roughness or distortion. Depending on the technology used and the material from which the sample is made, the product acquires high-tech properties: ideal shape, strength, plasticity, temperature stability. Models have found application in many areas, so they make custom 3d printing companies of different specializations:

- medicine;

- automotive;

- serial industrial production: mechanical engineering, instrumentation, metallurgy;

- architecture - when creating models of buildings and complexes;

- designs;

- souvenir production.

How 3d prototyping is carried out

The basis for prototyping is a 3d image of an object, compiled by a computer program with three-dimensional modeling functions. nine0046 3d custom prototyping is performed with high accuracy of transferring an image into a physical object using one of several possible methods:

- FDM (Fused Deposition Modeling). A moving molten polymer thread forms an object of complex geometric shape in layers, which can subsequently withstand high mechanical and thermal loads.

- SLS (Eng. Selective Laser Sintering). This is the sintering of a powder in a container under the targeted action of a laser beam. nine0015

- MJM (from the English. Multi Jet Modeling - modeling with many nozzles). Multi-nozzle 3d printer prototyping , applying molten material with multiple inkjet heads, based on the principle of a laser printer.

- LOM (from the English Laminated Object Manufacturing - the production of an object by lamination). Bonding layer by layer of thin films, as is done with lamination. After reaching the desired volume with a laser tool, an object of the desired shape is cut out of the mass. nine0015

- SLM (from English Selective Laser Melting - selective laser melting). Selective fusion of metal with a targeted laser beam, resulting in a solid object.

- EBM (from the English Electron Beam Melting - electron beam melting). Creation of a product from a powder that is melted by a directed electron beam.

- STL (from English stereolithography - stereolithography). Purposeful formation of a solid object by a laser beam directed into a container with liquid polymer rubber. nine0015

Benefits of 3d printing and prototyping

What are the advantages and benefits for a customer who decides to order a 3D printing with a printer?

Before launching a new product into mass production, an enterprise can purchase a prototype, test it, make changes to avoid errors in the design development of the product, and reduce the cost of production.

If a private or public enterprise needs to produce a small batch of products, it is more profitable for him to apply for a small-scale prototyping service than to carry out design and engineering development and testing of prototypes, reconfigure production, use labor resources and equipment. nine0046 Printing on a 3D printer at affordable prices will save businesses a significant amount, reduce production costs.

The desired samples can be obtained in a short period, regardless of the degree of complexity of the object being created. Typically, the prototyping process lasts from one to ten days, depending on the specifics of the chosen manufacturing method. You can place an order for 3D printing at Pro Plast-NN LLC - we will answer your questions, calculate the cost, conclude an agreement and print products in a short time. nine0005

The cost of 3d printing with the printer is low, which allows customers to reduce their own costs for design development, testing and sample production. LLC "Pro Plast-NN" makes high-quality 3D printing - the price is calculated by managers individually, depending on the volume, complexity of the work, the chosen manufacturing method and the material from which the sample is printed.

The cost of prototyping and creating 3d models

Answer to question how much it costs to print on a 3d printer depends primarily on the number of ordered products, the material from which the product is made, the size of the object, and the technology of its manufacture.