Father of 3d printing

Chuck Hull: the father of 3D printing who shaped technology | 3D printing

Although measured and deliberate in his responses, there is one moment when the softly spoken Chuck Hull – known as the father of 3D printing – tells of his surprise about what exactly his creation was capable of achieving.

In 1996, surgeons at the Wilford Hall medical centre in Texas working to separate a pair of conjoined twins thought that only one would be able to walk after the operation. After a model of the girls' bone structure was generated using 3D printing, however, they found a shared upper leg bone to be bigger than expected and split it successfully, resulting in both twins being able to walk.

Hull said: "This is extremely difficult for surgeons, to figure out how they are going to separate the two twins so that you will have two separately living people. When some of those surgeries were first done using the help of our technology, it was really touching for me."

Now 75 and still working as chief technology officer of 3D Systems, the company he co-founded, Hull is enjoying some minor celebrity 31 years after he first printed a small black eye-wash cup using a new method of manufacturing called stereolithography, now known as 3D printing.

At the time, he was working for a company that used UV light to put thin layers of plastic veneers on tabletops and furniture. Like others within the industry, he was frustrated that the production of small plastic parts for prototyping new product designs could take up to two months.

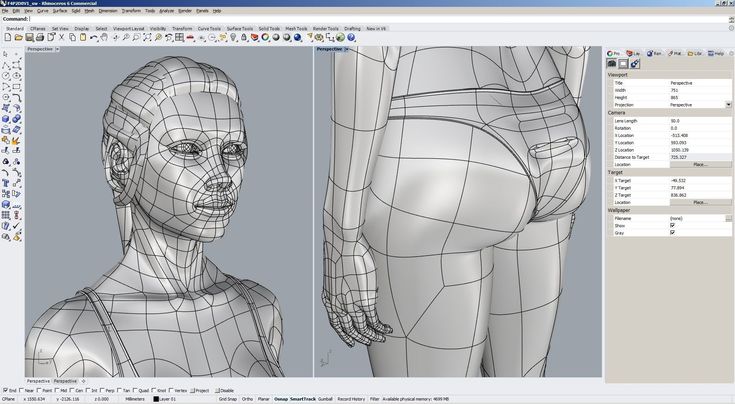

He had an idea that if he could place thousands of thin layers of plastic on top of each other and then etch their shape using light, he would be able to form three dimensional objects. After a year of tinkering with ideas in a backroom lab after hours, he developed a system where light was shone into a vat of photopolymer – a material which changes from liquid to plastic-like solid when light shines on it – and traces the shape of one level of the object. Subsequent layers are then printed until it is complete.

After patenting the invention in 1986, he set up 3D Systems in order to commercialise the new method of production and went on the road to secure both funding – eventually getting $6m (£3. 5m) from a Canadian investor – and customers, using videotapes to show the equipment. The first commercial product came out in 1988 and proved a hit among car manufacturers, in the aerospace sector and for companies designing medical equipment.

5m) from a Canadian investor – and customers, using videotapes to show the equipment. The first commercial product came out in 1988 and proved a hit among car manufacturers, in the aerospace sector and for companies designing medical equipment.

Soon General Motors and Mercedes-Benz were using 3D Systems' technology – the company sold printers, materials and software – to build prototypes, but it was developments in medicine that stunned him, such as when models in advance of surgery could be created. "That was just startling to me, that someone used the technology like that."

When Hull originally came up with his invention, he told his wife that it would take between 25 and 30 years before the technology would find its way into the home. That prediction proved correct as the realistic prospect of widespread commercial 3D printers has only emerged in recent years.

The possibilities appear endless – from home-printed food and pharmaceuticals to suggestions that pictures of ceramics will be able to be taken in shops and then recreated using plans downloaded from the internet.

Hull, an unassuming man who has 93 patents to his name in the US and 20 in Europe, says he is "humbled" by the possibilities but stops short of predicting what his technology could eventually deliver, although he is confident printers could soon be in every home.

"It's nice to get some recognition, it was a lot of hard work but other than that I just keep working," he said last week in Berlin, where he received a European Inventor Award.

Controversy has arisen with the possibility that guns will be able to be produced using 3D printing, again using blueprints downloaded from the internet. A group called Defense Distributed last year successfully tested a 3D printed gun in Texas. Hull said: "My first thought is that people messing with that – I hope they don't hurt themselves. Building and testing guns of that nature could be dangerous. I think the people doing that were trying to make a point.

"I don't know that people are going to be printing guns around the world but in any case our company, we are not the government or the police agencies. It is more their business and all technology, the governments and the police have to be aware [of], it is not just 3D printing."

It is more their business and all technology, the governments and the police have to be aware [of], it is not just 3D printing."

After finding that retirement was not for him, Hull returned to the company he co-founded and is now vice-president as well as chief technology officer, and holds shares worth $20m (£12m). Last year, 3D Systems brought in revenues of more than $500m (£294m) and has three bases in the UK, in Hemel Hempstead, High Wycombe and Clevedon. New systems of 3D printing have emerged over the years and various other firms have been added to the 3D Systems stable.

Last week the company launched the Ekocycle Cube printer in a collaboration with the singer Will.i.am, named chief creative officer in January, which is touted as being for everyday use and priced at $1,199 (£705).

Stepping down is not an option at the moment for Hull, who declares the products of 3D printing, now including ranges of jewellery, as "all his children". Future projects include working with Google on the company's next generation phone.

"We always say which room is it going to be in? I am not much of a futurist. It is really difficult for me to project. I sit there and work on the projects I have and I don't have a lot of say on where this is going."

What can be printed?

On a small plot in the north of Amsterdam, architects are building what they hope will be the first 3D-printed house. They are laying blocks that have been printed using a scaled-up version of an open-source 3D printer to be stacked like Lego bricks – one of the more elaborate examples of what can be produced using 3D printing.

The recent Consumer Electronics Show in Las Vegas showcased printers that could produce foods such as ravioli and chocolate printed patterns, while Harvard researchers have recently unveiled what they say is the first 3D printed battery, which can be constructed in minutes.

New in Tech this week

Will your next phone be 3D? Amazon's new Fire Phone uses a system of four cameras to constantly track its user's face and makes objects appear 3D using "dynamic perspective" – shifting the image around as the user tilts their head. Users can nod and use other gestures to navigate the phone too, which uses Amazon's own version of the Android software. But a camera on the back that can instantly recognise objects, books, art and goods is the killer feature for the online superstore. Point the phone at a book, snap a picture and buy it from Amazon with one tap. Yet another attack on the high street.

Users can nod and use other gestures to navigate the phone too, which uses Amazon's own version of the Android software. But a camera on the back that can instantly recognise objects, books, art and goods is the killer feature for the online superstore. Point the phone at a book, snap a picture and buy it from Amazon with one tap. Yet another attack on the high street.

Paranoid about drones watching your every move? The personal drone detection system could be for you. The black box, which claims to beep when a non-military drone flies within 15 metres of it, is available on the crowd funding site Kickstarter. What you actually do about a drone intruding on your airspace is left to you.

Yo! A single word that has gone viral thanks to a stupidly simple app. The Yo app for Android and iPhone literally just sends the word "yo" to friends, contacts or complete strangers. One word can mean so many things with the right context, enough to earn the free app's creators more than $1m (£588,000) in funding at least.

Microsoft has taken strides towards delivering longer battery life. The software giant has launched new wireless charging smart trousers that power up your phone while it's in your pocket. Designed by British fashion designer Adrien Sauvage for the "Modern Man" (what about the rest of us?), the trousers use inductive charging to power a Nokia Lumia smartphone without wires. Never be left with a dead phone battery again.

What do the Vulcan salute, a chipmunk and chilli have in common? They are all brand new emoji – small cartoons of objects that can be sent instead of words. More than 250 new emoji have been added to the Unicode 7 specification, which defines how text is handled or expressed in computer programs. The little characters could soon be winging their way across your chat apps, email, internet and Word documents.

Samuel Gibbs

Pioneers of Printing: Chuck Hull and the Beginning of 3D Printing

In this edition of Pioneers of Printing we focus on the ground-breaking achievements of Charles “Chuck” Hull. His success story of the “father of 3D printing” shaped the print industry forever. Nowadays, 3D printing is playing an important part in the future of our industry, manufacturing and medical printing.

His success story of the “father of 3D printing” shaped the print industry forever. Nowadays, 3D printing is playing an important part in the future of our industry, manufacturing and medical printing.

In this edition of Pioneers of Printing we take a look at the life of Charles “Chuck” Hull, the father of 3D printing. In 1983, Chuck Hull invented stereolithography, also known as 3D printing. That very year he created the first 3D printed part ever. His innovation has changed print forever and opened new doors to revolutionize not only our industry but also other fields like car manufacturing, the aerospace sector and medical printing.

Humble Beginnings

Chuck Hull was born as Charles W. Hull on May 12, 1939, in Clifton, Colorado. After graduating from Central High School in Grad Junction, Colorado, he went on to study engineering physics at the University of Colorado. In 1961 he received his Bachelor of Science and started out his career.

The Basic ‘Aha’

Hull says, he started out to solve a problem. In 1983, when he first came up with the idea of printed 3D parts, he was working at a company using UV light to harden tabletop coatings. During his work, he had to prototype plastic parts that had to be injected into a mold, which he called a “really tedious process”. Seeing the time and effort it took to fulfil this job, he thought about a way to not only speed up but simplify the process of occupying his workdays. There had to be a more efficient way to approach the task:

In 1983, when he first came up with the idea of printed 3D parts, he was working at a company using UV light to harden tabletop coatings. During his work, he had to prototype plastic parts that had to be injected into a mold, which he called a “really tedious process”. Seeing the time and effort it took to fulfil this job, he thought about a way to not only speed up but simplify the process of occupying his workdays. There had to be a more efficient way to approach the task:

“I saw it as a big impediment to design a plastic part because I had to design a plastic part now and then so I would get frustrated. I kind of put two and two together. If I could print lots of these layers, I can have a proper plastic part, so that was just the basic ‘aha’.”

Chuck Hull applied for his patent “Apparatus for production of three-dimensional objects by stereolithography” on August 8, 1984, coining the term stereolithography. The patent was granted on March 11, 1986, changing the print industry forever. It soon became a widely used technique in rapid prototyping and direct manufacturing. True to his occupancy at the time, Hull’s initial invention worked with thinly printed layers of ultraviolet curable materials stacked on top of each other.

It soon became a widely used technique in rapid prototyping and direct manufacturing. True to his occupancy at the time, Hull’s initial invention worked with thinly printed layers of ultraviolet curable materials stacked on top of each other.

After his patent was granted in the United States, he co-founded 3D Systems. At the beginning he was working with solid imaging technology only. Just one year later, in 1987, his company produced the first-ever 3D printer: the SLA-1 Stereolithography (SLA) printer.

His 3D printing technology was a sales hit among car manufacturers, the aerospace sector and companies designing medical equipment. Soon, industry giants like General Motors and Mercedes-Benz used his systems to build prototypes.

Today, Chuck Hull holds 93 US and 20 European patents to his name and was awarded the European Inventor Award in the Non-European countries category in 2014 by the European Patent Office and the Industrial Research Institute’s IRI Achievement Award in 2015 for his ground-breaking invention of stereolithography.

What the Future Holds

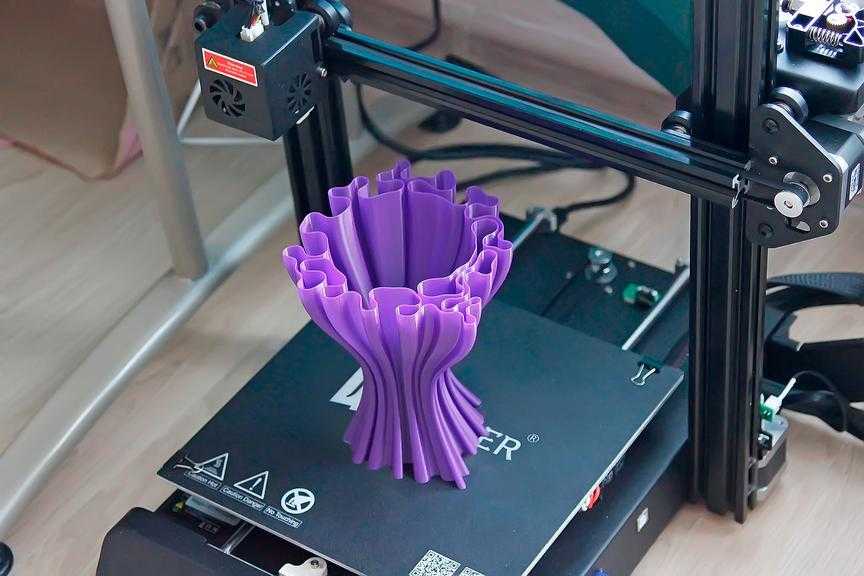

Around 2010, more than 20 years after Chuck Hull started out with his humble idea, 3D printers became a comparatively inexpensive product that even made its way into private households – a development the inventor predicted from the start, telling his wife it would take between 25 and 30 years before the technology would find its way into the home.

Talking to the father of 3D printing today, he is surprised about what exactly his own creation was capable of achievingand curious to see where the future will lead.

“If you’re innovative and creative there’s just a tremendous opportunity.”

In an interview with Industry Week Hull said:

“I always say, first disclaimer, I’m not much of a futurist. But certainly, the benefits are no tooling, customizable fasts, and so a lot of plastic parts will be automated and built with 3D-printing. It’s another step toward digital manufacturing, and it fits right into the whole movement. In the future, people won’t even think about it. It’ll be the recognized way to manufacture plastic parts. The same with metal parts, except right now the provision is that those tend to be more specialized parts. Maybe they’ll advance to the same level.

It’ll be the recognized way to manufacture plastic parts. The same with metal parts, except right now the provision is that those tend to be more specialized parts. Maybe they’ll advance to the same level.

The trend we’re on right now is more aerospace parts and medical parts.”

Do you have any predictions about the future of 3D printing?

3d3d print

A father made a prosthetic hand for his son on a 3D printer / Habr

Bernodot

3D printers

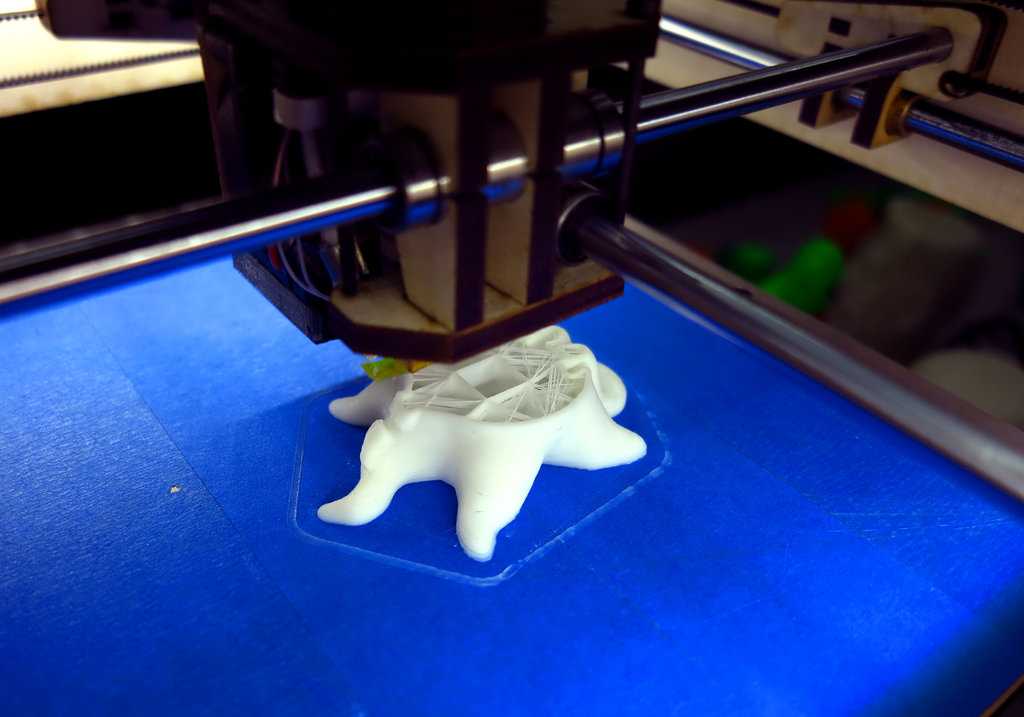

These are not one, but two very similar stories. In fact, there are already many such cases and there are additional links at the end of the article. With the advent of 3D printers in the consumer market, these stories are becoming mainstream.

Leon was born without fingers on his left hand, he has been living without a prosthesis for 12 years. Doctors say that the cause of the injury was the limited circulation in this limb, when the baby was still in the mother's womb ...

Doctors say that the cause of the injury was the limited circulation in this limb, when the baby was still in the mother's womb ...

His father Paul spent a long time trying to find an inexpensive and functional prosthesis, but the standard offers of orthopedic companies are traditionally very expensive - tens of thousands of dollars. Recently, Paul came across a video online showing inventor Ivan Owen from Washington State demonstrating a model of a prosthetic hand that anyone can download and 3D print. The prosthesis is attached to the forearm at the hand, the movement of the wrist controls the fingers: they can be squeezed and unclenched (all at the same time). nine0013 Paul is incredibly happy: having spent $2,000 on a printer, he can now print new prosthetics every day, experimenting with designs. The cost of plastic for printing one prosthesis is only about $10.

Carpenter Richard from South Africa lost four of his fingers in an accident at work. He poked around the Internet and found out that the prostheses sold online are not very functional and too expensive. Not discouraged, he began work on designing a prosthetic hand with functioning fingers, calling on 3D printing technology and a designer friend from Seattle to help. According to him, according to the cost of consumables, they met $ 150. From the frames of the video, you can understand why his model turned out to be more expensive - it is a much more complex mechanism than the prosthesis from the first video. A more complex mechanism provides finer functionality. nine0013 Thanks to the media, the interested public found out about Richard and it turned out that he can, and most importantly, wants to help many adults and children. Such children, for example, like little Liam, who in the same video demonstrates how skillfully he manages with his robotic arm.

Not discouraged, he began work on designing a prosthetic hand with functioning fingers, calling on 3D printing technology and a designer friend from Seattle to help. According to him, according to the cost of consumables, they met $ 150. From the frames of the video, you can understand why his model turned out to be more expensive - it is a much more complex mechanism than the prosthesis from the first video. A more complex mechanism provides finer functionality. nine0013 Thanks to the media, the interested public found out about Richard and it turned out that he can, and most importantly, wants to help many adults and children. Such children, for example, like little Liam, who in the same video demonstrates how skillfully he manages with his robotic arm.

Another video about Richard, shorter, but with Russian subtitles:

Related Links

- 3D Printed Child's Dream Hand (Ukraine) nine0027 We want to make a child prosthesis using 3D printing (Russia)

- 3D-printed implant replaced 75% of the patient's skull (in English)

- Printers now print even ears (in English)

- 3D printing gave a man a new face and a new life (in English)

tags:

- 3d prostheses

- prosthetic arm

- cool dads

hubs:

- 3d printers

Total votes 82: ↑79 and ↓3 +76

Views126K

Comments 51

Bernodot @Bernodot

President

Comments Comments 51

🙋♂️ Father's Day 3D Printed Gift Idea・Cults

🙋♂️ Father's Day 3D Printed Gift Idea

3D Printed Father's Day Gift Ideas

Every year you wonder The question of what to give dad, he already has all the classic gifts, why not choose an original 3D printed gift this year or even offer him a premium 3D file so he can make it on his 3D printer! nine0005

PRINT-IN-PLACE PHONE HOLDER - FOR SPACE?!

Free

Tripod smartphone

Free

Switcherang: Nintendo Switch Joy-Con Grip

Free

Question Switch box Cartridge case

Free

nine0074 Cable Gland for Desktop Sit-UpFree

Pokeball Switch Cartridge Case

Free

Clamp with hand screw

Free

Cable clip

Free

Adjustable sanding stick

Free

nine0074 PS4 controller wall holderFree

Bottle opener and cap GUN!

Free

CAN HANDLE (STANDARD AND TALL BOY)

Free

Splash Wine Holder

Free

Walnut cracker [my grandmother's design].

nine0075

nine0075 Free

GuitarPicks

Free

Mini Vise

Free

Optimized G-Clamp

Free

BCN3D MOVEO - open source 3D printed robotic arm

Free

nine0074 Self-aligning Gimballed drink holderFree

SMARS modular robot

Free

Splash Coaster - Small

Free

Print in Place Allen Key Holder Inspired by Wiha

Free

Joycon & Knuckles

Free

Vegetable signs/labels

Free

Pegstr - Pegboard Wizard

Free

Lens Cap Holder

Free

Father's Day Sculpture

Free

Lens Hood

Free

Gyro Motor Factory / Watch Factory

2. 50 €

50 €

Xbox One Steering Wheel for wired controllers

Free

Pizza Bottle Opener | Updated

Free

Veronique Frame

Free

Wallet Card Holder (Universal Pack)

1.28 €

iphone 5/5S/SE car holder

Free

12 in 1 Storage Cube for Nintendo Switch Game Cartridges and MicroSD Cards

1.99 €

Caliper

Free

Glue Gun Rest

Free

nine0074 Miter BoxFree

Swimbait Fishing Lure

Free

Watering Can A for PET Bottle Caps

Free

Desktop Gardening Tools

Free

Watering Bottle

Free

nine0074 Fly Fishing ReelFree

LiftPod - Multipurpose Foldable Stand

Free

CARDHOLDER-WALLET (ONLY BACK PLATE WITH LOGO CS:GO)

Free

Snes Mini Raspberry Pi

Free

Bokeh Kit

Free

nine0074 Slim - smart wallet 2. 14 €

14 €

Gyro Motor Factory / Clock Factory

Caliper

LiftPod - Multipurpose Foldable Stand

Wallet card holder (universal package)

Here is our guide to best 3D printer files for Father's Day , all of which are based on Platform Cults STL file platform and very are easy to 3D print .

Looking for an original gift idea for Father's Day? You have come to the right place. We've put together a great selection of 3D Printer 3D Files that should make your dad very happy. First of all, it is necessary to determine what he needs and what he would like. This guide collects DIY 3D Printables for your dad to spruce up his garage or print himself some new tools. He also has things to do with friends, sports or * get creative with your 3D printer**.