Nextengine desktop 3d scanner

NextEngine 3D Laser Scanner

Hardware

Software

Accessories

Service

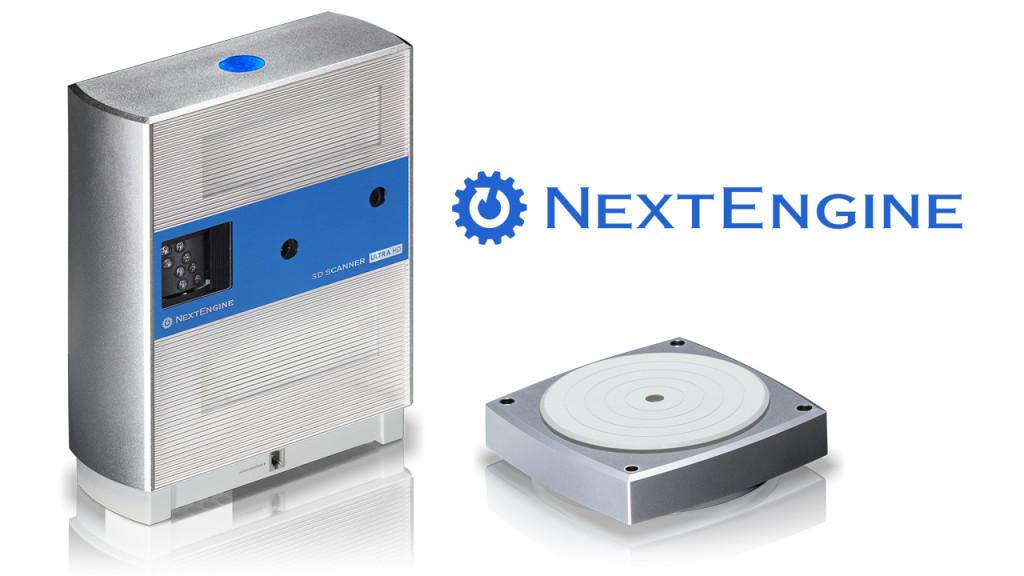

3D Scanner Ultra HD

Learn More

To capture all the stuff you work with, you want 3D input at your fingertips. NextEngine's exclusive Multi-Laser Technology delivers superior precision and fidelity. Find out what has made NextEngine's Desktop 3D Scanner the World's best-seller. New Ultra HD sensors deliver stunning resolution.

$2,995

Buy Now

30-Day Money-Back Guarantee

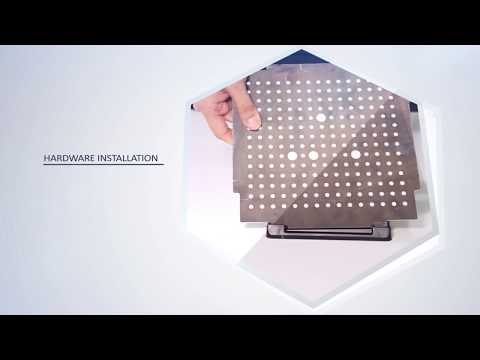

MultiDrive

Learn More

Fully automate alignment of multiple scans with tilt/rotary object positioning. Define multiple scan families and with one click execute creation of your 3D mesh model. Just trim unwanted overlapping scan

data, fuse, and polish. A new level of simplicity for NextEngine 3D

Scanner users.

$995

Buy Now

30-Day Money-Back Guarantee

ScanStudio

Learn More

Every NextEngine 3D Scanner comes equipped with high performance Scanning and Modeling Software at no extra charge. ScanStudio manages your scanner hardware, refines your data, and assembles it into a fully healed precise mesh model.

STANDARD

ScanStudio ProScan

Learn More

Increase your scanner performance with the ScanStudio ProScan upgrade. Double scan speed for faster cycle times and capture more surface area with Large Format mode.>

$995

Buy Now

30-Day Money-Back Guarantee

CAD TOOLS

Learn More

Want to convert your mesh model into a CAD model? Need spline outputs or NURBS surfaces? Want to quickly determine volume or surface area? ScanStudio CAD TOOLS gets the job done in one integrated and quick to learn package.

$995

Buy Now

30-Day Money-Back Guarantee

RapidWorks 4.0

Learn More

Are you a Solid Modeling CAD expert? If you need industrial-strength tools to convert Scans to CAD parts, RapidWorks is the World's state-of-the-art in Engineering Software for 3D scan data. Get robust full feature set design tools for under 3K!

Get robust full feature set design tools for under 3K!

$2,995

Buy Now

30-Day Money-Back Guarantee

QA-Scan 4.0

Learn More

Need fast verification that a physical sample meets design requirements?

QA-Scan provides easy-to-use tools for precisely comparing 3D scans with CAD models. Made for high volume applications, QA-Scan automatically aligns your data, checks tolerances, and produces detailed GD&T reports.

$1,995

Buy Now

3D Curriculum

Learn More

Ten simple lesson plans help students become proficient with the NextEngine 3D Scanner and RapidWorks reverse engineering software. Capture the imagination of your students as they explore the future of 3D design.

$995

Buy Now

Black Bases

Reduce trimming time, replace white platforms on your AutoDrive or MultiDrive positioner with black platforms nearly invisible to the scanner.

$10

Buy Now

AutoDrive Extension

24 inch extension between Scanner and AutoDrive increases flexibility to orientate large objects.

$10

Buy Now

PaintPens

Learn More

Scan your transparent or mirror-finish objects with these convenient valve-action paint pens. Coat parts with water-based white tempra paint for excellent scanability. Wipes off with a damp sponge. Use at your desk and store in a drawer. One set of PaintPens is included with your scanner.

$15

Buy Now

Extra PowderPen

Learn More

Scan shiny objects with handy pushbutton powder brush pen. Coat parts with microfine talc granules suspended with a trace of lanolin for mild clinging to surfaces. Wipes off easily with a tissue. One PowderPen is included with your scanner.

$10

Buy Now

Extra PartGripper

Learn More

Adjustable stainless steel part-holding fixture has soft silicone pads to protect and grip your part. Use additional Grippers for difficult objects, or to modify for special purpose jigs. One PartGripper is included with your scanner.

Use additional Grippers for difficult objects, or to modify for special purpose jigs. One PartGripper is included with your scanner.

$55

Buy Now

3 Year Extended Warranty

Total warranty coverage for your 3D scanner for repair/replacement of any defect for 3 full years. No charge for any parts, labor, or services.

$295

Buy Now

RapidWorks ProCare

Learn More

Talk with our engineers via phone or real-time NextWiki chat, and get one-on-one assistance from reverse engineering experts. 3 Years of Software upgrades for RapidWorks, plus phone support, priority real-time chat, priority e-mail support, and project-specific assistance.

$995

Buy Now

QA-Scan ProCare

Talk with our engineers via phone or real-time NextWiki chat, and get one-on-one assistance from experts. 3 Years of Software upgrades for QA-Scan, plus phone support, priority real-time chat, priority e-mail support, and project-specific assistance.

$795

Buy Now

ScanStudio ProCare

Learn More

Extends support for your Scanner and ScanStudio software for 3 full years. Includes unlimited support and all major software upgrades.

$295

Buy Now

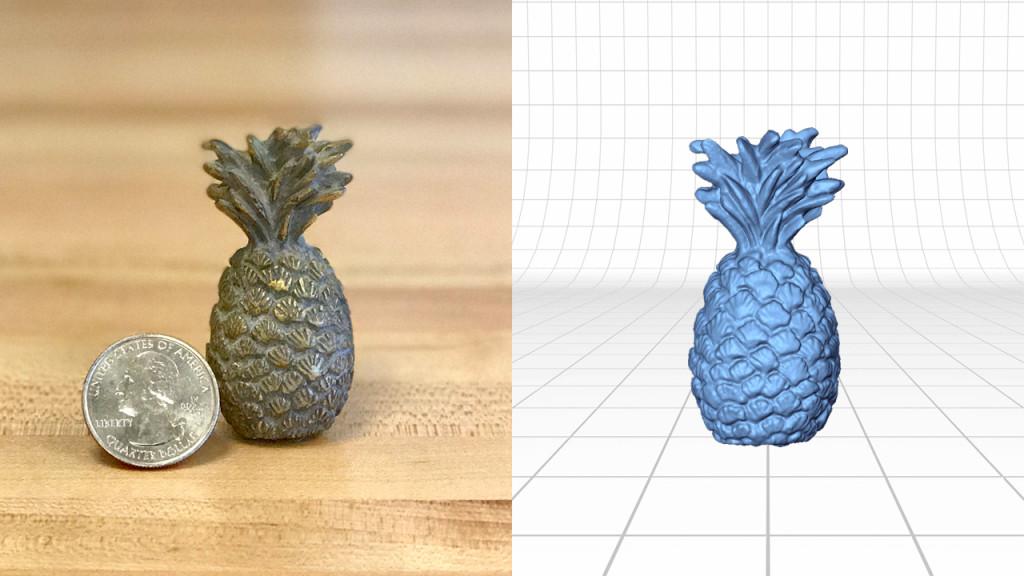

NextEngine Just Made 3D Scanning Cooler

By David Cohn

I get to review a lot of products, but I can’t think of many that I’ve waited more impatiently to receive than NextEngine’s Desktop 3DScanner. This compact peripheral was first unveiled last year in Las Vegas at SolidWorks World. With a price of $2,495, it takes a capability once available only to specialists using expensive equipment and puts it within reach of just about anyone.

> > The NextEngine Desktop 3D Scanner consists of the scanner,Auto Positioner platform, and Part Gripper. NextEngine also includes several water-soluble marking pens, modeling clay, and a small easily scanned object.

NextEngine also includes several water-soluble marking pens, modeling clay, and a small easily scanned object.

The Desktop 3D Scanner consists of a laser scanner — a self-contained aluminum and polycarbonate unit about the size of a box of cereal — as well as an Auto positioner platform to capture multiple surfaces of objects and a Part gripper. to secure objects during scanning. The scanner houses two arrays of four Class 1M 10mW solid-state lasers and two twin 3.0 mega pixel CMOS RGB image sensors — each optimized for scanning at one of two fixed distances — as well as a pair of lights that illuminate the object being scanned to highlight its color and texture.

The Setup

The entire package comes in an elegant box. Simply remove the components, place them on a desk, download the NextEngine ScanStudio software from the company’s website, and connect the scanner to a Windows XP-based workstation via the supplied USB 2.0 cable. The AutoPositioner’s built-in cable connects to the front of the scanner and also establishes the distance of the scanning platform from the scanner by fitting the cable into one of two slots on the underside of the Auto positioner

< < The scanner first illuminates the object and displays a preview image so you can adjust its position and select scanning options.

At the macro mode distance of 6.5 inches, the scanner has a field of view of 5.1 in. x 3.8 in. and an accuracy of 0.0005 in., with a maximum texture density of 400 samples (points) per inch. At the wide-angle mode distance of 15 inches, the scanner has a field of view of 13.5 in. x 10.1 in. and an accuracy of 0.015 in. and 150 samples per inch. Anything outside the field of view is not captured by the laser, but you can scan larger objects by doing multiple scans and then combining them using the ScanStudio software.

After setting up the scanner, you place the object you wish to scan on the Auto positioner and use the Part gripper., if necessary, to hold the object firmly in place. The Auto positioner can hold objects up to 20lbs.

Scan One

First, the scanner illuminates the object using the white lights and shows you a live onscreen image so that you can adjust the model on the scanning platform. (See the Image Gallery below for more.) You also determine the type of scan: a single scan,a bracket scan of three consecutive angles, or a 360-degree scan. For bracket and 360-degree scans, the Auto positioner automatically rotates after each scan. The angle of rotation between scans is dependent on the number of divisions you set. For example, selecting 8 divisions would rotate the object 45 degrees before each scan; a total of 8 scans for a 360-degree scan or 3 scans totaling a range of 135 degrees for a bracket scan.

For bracket and 360-degree scans, the Auto positioner automatically rotates after each scan. The angle of rotation between scans is dependent on the number of divisions you set. For example, selecting 8 divisions would rotate the object 45 degrees before each scan; a total of 8 scans for a 360-degree scan or 3 scans totaling a range of 135 degrees for a bracket scan.

> > You must place three or more virtual pins in order to align bracket or360 degree scans. Marking alignment points on the object before scanning can assist alignment.

You can also adjust the color and finish settings to obtain the best scan, and control decimation (down sampling of point data) and smoothing of texture data.

Proper preparation of the object being scanned is important. NextEngine recommends applying powder to shiny or dark objects and white paint to transparent surfaces, and provides applicators for this purpose.

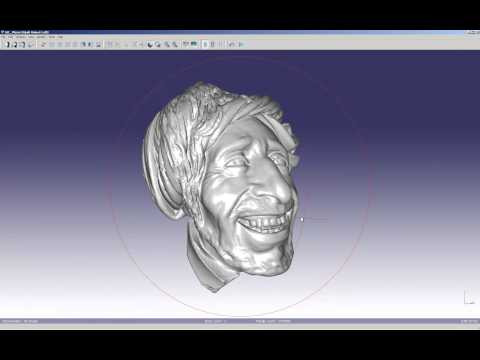

I scanned several different objects, including a bracketed scan of a bust of William Shakespeare and a 360-degree scan of a small toy car.It took approximately 15 minutes to do my initial scans: 2.5 minutes for each of six passes.

Aligning Scans

Once the scans were complete, I could rotate, pan, and zoom the resulting scans and use the various ScanStudio tools to trim away overlapping or unwanted areas and blend overlapping scans to better merge surfaces. I found that it was much easier to trim away the scanning platform and gripper from each individual scan before proceeding to the next step — aligning the individual scan passes to create a 3D model — although you can do some additional trimming after performing alignment. I also found that it was often easier to trim scans when looking at mesh or point cloud views rather than color textural images.

< < The ScanStudio software’s trim tools let you remove unwanted scan data. I found it helpful to work in the mesh view while performing this step.

I found it helpful to work in the mesh view while performing this step.

To align the individual passes, you use the software to place at least three virtual pins on two of the scans in the family. Using more pins may yield better accuracy. You can also improve alignment by placing alignment marks on the object before scanning. A red water-soluble pen is provided for this purpose, and NextEngine recommends 5 marks per facet of the object you’re scanning.

Once I had aligned the six scans, I repositioned the toy car and made additional scans of its top and bottom, trimmed away extraneous material, and then used the alignment tools again to align these additional scans.

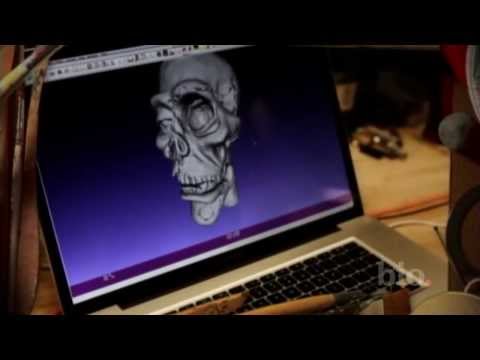

Wizards Help

When you’re satisfied with the scan, you can save it in a number of formats, including OBJ, PLY, STL, VRML, U3D, and SCN format. Files can then be loaded into various programs, but one of the most intriguing aspects of the NextEngine scanner is its integration with SolidWorks Office Premium 2007.

> > Each pass of the scanner takes a little more than two minutes, as the array of four lasers pass across the object being scanned.

SolidWork’s ScanTo3D add-in lets you start the ScanStudio software from within SolidWorks and load scan data directly into a SolidWorks part.You can also open mesh or point cloud scan data, prepare the data, and then convert it into a surface or solid model. Two wizards step you through the conversion process. The Mesh Prep wizard prepares and cleans up mesh or point-cloud files, producing a mesh feature from which you can create surfaces. You can simplify scan data by reducing the number of points or mesh vertices, smooth the mesh to eliminate jagged areas, and automatically detect and fill holes in the mesh.

< < Once all of the scans are aligned and blended, you can load the 3D scan data directly into SolidWorks Office Premium 2007 by clicking the SolidWorks button.

After preparing the mesh, you launch the Surface wizard, which has two modes of operation: Automatic or Guided. Automatic creation uses a single-step process to automatically create a solid model and works well for anatomical and organic shapes. Guided creation uses a multi-step process to create surfaces and is preferable for analytical surfaces or when you want to have more control over the resulting surfaces. Once the surface has been created, you can use other SolidWorks tools such as Trim, Knit, and Thicken to turn the surfaces into a solid model.

> > SolidWorks’ Mesh Prep and Surface wizards, part of the ScanTo3D add-in,helps prepare scan data for conversion into a solid model.

There’s no doubt that the NextEngine Desktop 3D Scanner is extremely cool, but be prepared to spend some time learning all the ins and outs. It took several attempts before I got the objects I wanted to scan prepared just right and several tries before I got the hang of aligning multiple scans. But for those willing to devote the effort, the NextEngine Desktop 3D Scanner is nothing short of amazing.

It took several attempts before I got the objects I wanted to scan prepared just right and several tries before I got the hang of aligning multiple scans. But for those willing to devote the effort, the NextEngine Desktop 3D Scanner is nothing short of amazing.

Image Gallery

Here is a series of additional images showing off the NextEngine Desktop 3D Scanner that we could not could not get in the hard copy version of this article. —DE Editors

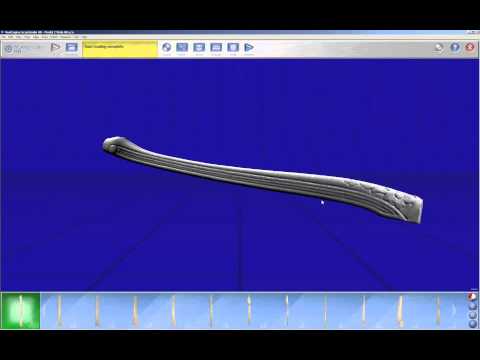

The image on the left is you what would see of the model car in the ScanStudio viewfinder as you beginning scanning. This view enables you to see exactly what you’re about to scan. On the right, the scanning has begun. The NextEngine leverages multi-laser stripes that sweep across the surface of the model to capture geometry details. The four laser stripes provide multiple readings for each point to cross-validate captured data.

The four laser stripes provide multiple readings for each point to cross-validate captured data.

On the left, you can see that to align bracket or 360 degree scans,you place three or more “virtual pins” onto corresponding spots on a pair of scans. Marking alignment points on the object before scanning assists alignment. On the right is an example of how the trim tools in ScanStudio let you remove unwanted scan data.

On the left, now it’s David’s turn to get the multi-laser stripes sweeping across its surface. On the right, the scanned model of Michelangelo’s David has been brought into SolidWorks 2007 Office Premium to process with ScanTo3D.

Here’s a mesh view of the bust inside ScanStudio after scan data has been combined and aligned.

NextEngine Desktop 3D Scanner—At a Glance

NextEngine, Inc.

Santa Monica, CA

> Price: $2,495

> Size: 8.8 in. x 3.6 in. x 10.9 in.

> Weight: 7 pounds

> Interface: USB 2.0 high-speed interface; USB cable included

> Power: 100-240VAC (built-in world-wide auto-switching power supply; AC cable included)

> System Requirements: 2GHz PC; 2GB RAM; 128MB graphics; Windows XP; powered USB hub recommended

David Cohn is a computer consultant and technical writer based in Bellingham, WA, and has been benchmarking PCs since 1984. He’s a contributing editor to Desktop Engineering, an applications engineer with The PPI Group, the former editor-in-chief of Engineering Automation Report and CADCAMNet, and the author of more than a dozen books. You can contact him via e-mail at [email protected] or visit his website at www.dscohn.com. Or send your comments about this article through e-mail by clicking here. Please reference “NextEngine” in your message.

You can contact him via e-mail at [email protected] or visit his website at www.dscohn.com. Or send your comments about this article through e-mail by clicking here. Please reference “NextEngine” in your message.

3D scanners NextEngine, Inc.

Filter

Designation

Designation

tabletop

manual

stationary

3D scanner type

3D scanner type

nine0005Dental

Industrial

Architectural

Manufacturer

Manufacturer

Creaform Inc.

24

MakerBot Industries, LLC

1

Open Technologies Srl

5

Fuel 3D Technologies Limited

1

DAVID 3D Solutions GbR

3

SHINING 3D TECH

44

AICON and Breuckmann

3

3D Systems

3

4DDynamics Bvba

8

Artec 3D

6

Volumetric technologies

1

Range Vision

9

Roland DGA Corporation

3

Rubicon Technologies

1

Solutionix Corp.

7

Dental Wings inc.

3

FARO Technologies UK Ltd

8

nextengine, inc.

1

Basis Software Inc.

10

LLC RIFTEK

1

Trimble Navigation Limited

5

LMI Technologies Inc. nine0005

3

smart optics Sensortechnik GmbH

7

DotProduct LLC

1

GOM mbH

9

Leica Geosystems

6

Texel

1

AGE Solutions

1

SMARTTECH 3D

7

XYZprinting

1

Thunk 3D Technology Co. , Ltd.

, Ltd.

Thor3D

1

ScanTech

6

Peel 3D

5

Reset filters

Filter

Sort: By price Rated

3D Scanner HD

NextEngine 3D Scanner HD is a desktop professional 3D scanner that uses tech...

No offers

What is a 3D printer?

Top 13 3D scanners on the market!・Cults

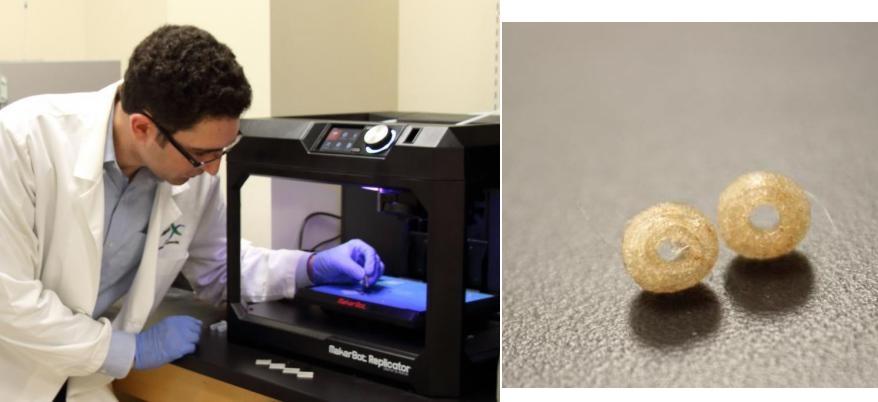

In the past, 3D scanners were mainly used for industrial and professional applications. For example, scanning architectural objects or creating digital models for films. As technology advances, the price continues to drop. Now, 3D scanning gives the average person the ability to custom-make just about anything they want. With more affordable prices, 3D scanning is becoming more accessible to consumers for personal use. nine0005

With more affordable prices, 3D scanning is becoming more accessible to consumers for personal use. nine0005

But first, a basic overview of 3D scanning:

A 3D scanner scans real objects and passes the image data to a 3D modeling program. The object can then be manipulated in the software and - if desired - exported and created on a 3D printer.

1. Select any object (or person!) you want to scan

Why is 3D scanning useful?

Imagine if you could scan your body and see how your clothes fit and look online before ordering them? 3D scanning technology can do just that. For example, bodylabs uses 3D scanning to understand how products will work for customers based on their body shape and posture. nine0005

2. Scan it and customize it in 3D modeling software

After scanning the object, you can reduce its size or edit it with free 3D design software. You can then choose to 3D print the edited file.

3. Export your model and print it in 3D!

After scanning the model and editing it to your liking, you can export it to . stl format and send it to a printer to bring it to life. nine0005

stl format and send it to a printer to bring it to life. nine0005

We have listed the 3D scanners below in ascending order of price (from cheapest to most expensive). Their rating does not necessarily reflect our judgment of the quality of the product. We've included some handy YouTube videos that go into more detail about each product.

1. XBox Kinect 3D Scanner - $95 USD

If you want to get by on the cheap, there are ways to use your old Xbox 360 or Xbox One Kinect device to get great results! If you have a Kinect. nine0005

2. iSense 3D Scanner for iPhone/iPad - $99

This scanner was developed by 3D Systems as part of the Cubify family. Although they don't sell 3D printers anymore, they keep their 3D scanner in the market. Like a structure sensor, iSense attaches to an iPad or iPhone. Its range of motion is 0.5m more than the Sense.

3. XYZprinting 3D Scanner - $139

XYZprinting 3D Scanner is the cheapest portable 3D scanner on the market. At under $200, it's perfect for anyone looking to get into 3D scanning on a budget. nine0005

At under $200, it's perfect for anyone looking to get into 3D scanning on a budget. nine0005

The size of the scanner is 60 cm x 60 cm x 30 cm, so it is best used for small items. It also uses the new Intel RealSense image capture software, which means it can connect to any Windows device with a 4th generation Intel processor.

4. BQ Ciclop 3D Scanner Kit - $199

This open source hardware project has been released under an open source license so that all mechanical design, electronics and software information is available to the community for further development . The full package costs about 199 USD. You can even download the design and print it in 3D!

5. Structure Sensor for iPad - $379

Arguably the best scanner on the market, the Structure Sensor was developed through a Kickstarter campaign that attracted over 3,500 people and raised $1.2 million. Structure Sensor turns your regular iPad into a 3D scanner that captures three streams of data at 30 frames per second.

6. Cubify Sense - $399 USD

Cubify Sense is a portable pen scanner that makes it easy to manually scan 3D objects. This makes it possible to use Sense in quite unique areas, with both advantages and disadvantages. Sense is compatible with Windows and Mac OS.

7. Matter And Form Desktop 3D Scanner MFS1V1 - $467 USD

The first ever crowdfunded 3D scanner, Matter and Form, is a Toronto-based company that has raised nearly half a million dollars to develop this product. It uses a 3D laser scanner with a movable camera head and a 360-degree rotating platform. nine0005

MFS1V1 generates a detailed point cloud, which again works very well in some scenarios and less well in others.

8. XYZprinting Da Vinci 1.0 Pro 3-in-1 3D Printer - $810

Da Vinci 1.0 Pro is both a 3D scanner and a 3D printer. It uses a laser diode module with a 2 megapixel camera (higher resolution than 1.2 megapixel iPad scanners). Please note that this machine uses proprietary 3D printing consumables. nine0005

nine0005

9. Einscan-S - $999

Einscan-S has two scanning modes: automatic and free. The first one is the easiest: just place an object on the rotating surface of the Einscan turntable and the machine will scan it in just 3 minutes with an accuracy of .1 mm. For large models, free scan mode works by rotating the scanner on a tripod around the object. Einscan-S generates one STL file that can be sent directly to your 3D printer. Einscan-S produces 3D printable models with greater accuracy (using "Light Structure Phase Shift Technology" instead of lasers) than competitors, providing industrial quality 3D scanning technology within a consumer's budget. nine0005

10. IIIDScan PrimeSense 3D Scanner - $1441 USD

Greater accuracy comes at a price. This tripod-mounted 3D scanner is unique in that it uses a short-range image sensor capable of scanning 3D objects in more detail and at a faster rate than other scanners on the market.

11. Fuel3D Scanify - US$1,500

This is a very high speed handheld 3D scanner capable of capturing an object in less than 1/10th of a second. In this regard, it differs significantly from the other 3D scanners on this list. In practice, it's more like taking a 3D photograph than manually scanning an object. Fuel3D Scanify uses a dual HD stereo laser camera combined with photometric data from three xenon flashes to create reasonably realistic 3D scans in the blink of an eye (so to speak). High tech. nine0005

In this regard, it differs significantly from the other 3D scanners on this list. In practice, it's more like taking a 3D photograph than manually scanning an object. Fuel3D Scanify uses a dual HD stereo laser camera combined with photometric data from three xenon flashes to create reasonably realistic 3D scans in the blink of an eye (so to speak). High tech. nine0005

12. NextEngine 3D Scanner HD - $2,995 USD

The NextEngine 3D Scanner HD combines portability with very high accuracy - much better than the scanners at the top of this list. Of course, the higher the accuracy, the higher the price! It uses an electro-optical system with a laser array that scans in tandem. The advantage is that the high-precision scanner has no size limits. The scanner comes with its own mesh creation software package, and you can also check out their NURBS and Solid modeling packages as options. nine0005

This is the scanner for those who want to get really serious results from their 3D scanning efforts.