How big of a 3d printer do i need

Shop the Best Large Format 3D Printers (Including Best Large 500mm 3D Printer)

Welcome to the Thomas guide to the best large format 3D printer 2023. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

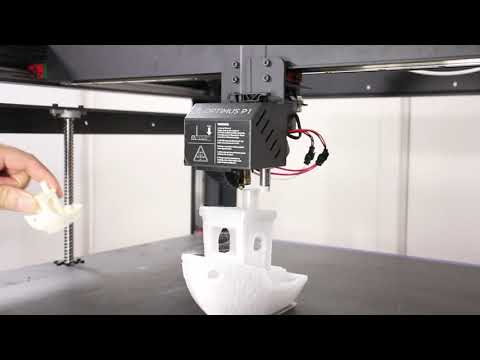

Printing larger items with most at-home or small-scale 3D printers is possible but consists of separately printing different parts of the project and then connecting them all together afterward to make a much larger finished product. In this way, many 3D printing enthusiasts, such as cosplayers, for instance, are able to get past the 3D printing size limitations and use their machines for much larger products than the print bed will allow.

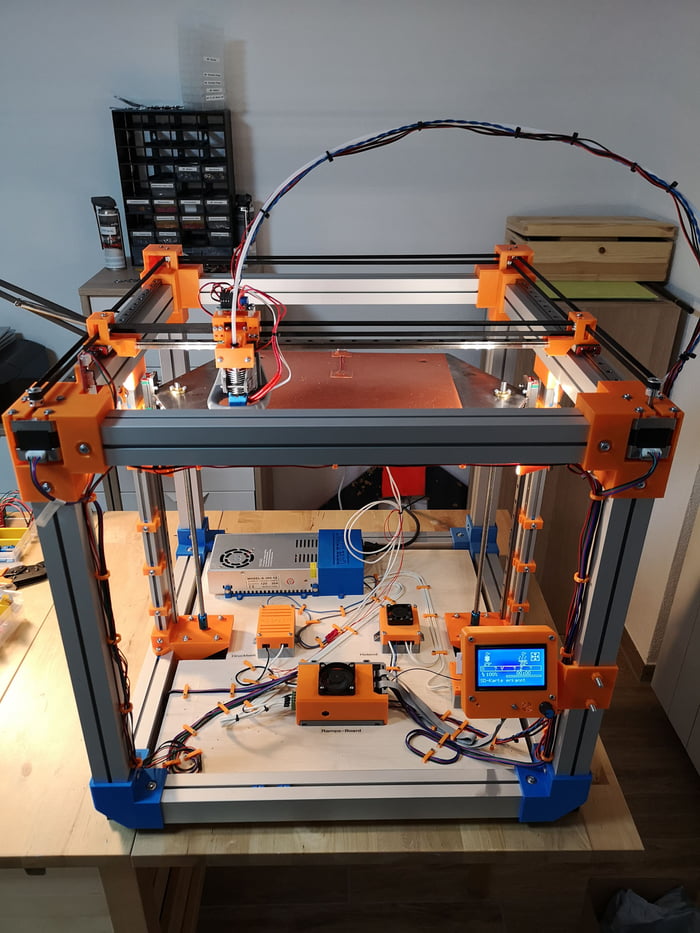

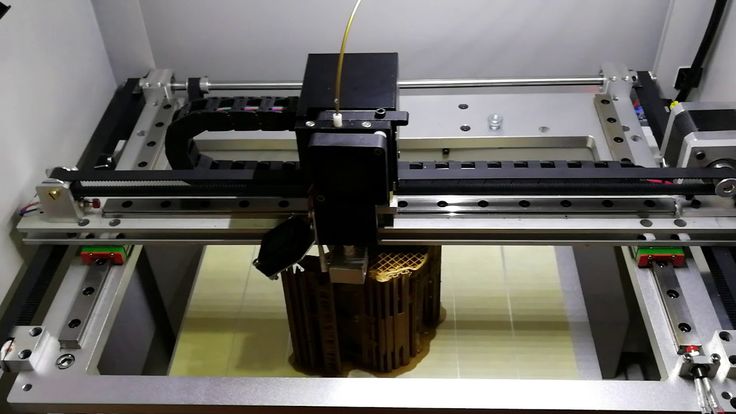

A large-format 3D printer in actionImage credit: Shutterstock/asharkyu

However, purchasing a large-format 3D printer can provide an increase in opportunities for creativity and a decrease in the amount of "putting together" necessary for those larger projects.

Here is a list of the best large-format 3D printers, followed by a buying guide to help you select the best large-format 3D printer for your needs.

Thomas’ Top Picks for the Best Large Format 3D Printer 2023

If you're ready to step up your 3D printing game and have a blast doing it, here are some of the best large-format 3D printers currently available to buy now.

Best Large 500mm 3D Printer: Creality CR-10 S5 Plus 3D Printer | Buy Now Best Large 400mm 3D Printer: ANYCUBIC Chiron 3D Printer | Buy Now Best Large 3D Printer Under US$1000: Creality Ender 5 Plus 3D Printer | Buy Now Best Industrial Large 3D Printer: Snapmaker 2.0 Modular 3-in-1 3D Printer | Buy Now Best Large 3D Printer under US$500: SUNLU S8 3D Printer | Buy Now Best Cheap Large 3D Printer: LONGER LK1 3D Printer | Buy NowScroll down to see more on our top picks for the best large format 3D printer, according to many happy buyers.

*Prices listed in this article were as shown in US$ on amazon.com (USA) and other online retailers as of February 2022

1. Best Large 500mm 3D Printer—Crealty Large 3D Printer 500x500x500mm

As one of the 3D printers with the largest printing beds currently available, the Creality CR-10 S5 3D printer has 500x500x500mm of printing space meaning you can really let your imagination run wild.

Installation is super quick and easy as the machine comes in three pre-assembled parts with clearly labeled wires and instructions. Other features include a resume-printing function in the event of loss of power, and you also get a one-year warranty from the manufacturer.

One buyer who gave this machine five stars helpfully mentioned that you need to have plenty of room to accommodate this huge printer, writing, "The main thing to consider is its sheer size. It requires over a yard, possibly a full meter of depth to move the build plate. "

"

2. Best Large 400mm 3D Printer—ANYCUBIC 3D Printer 400x400x450mm

A large-format 3D printer from a trusted brand, the ANYCUBIC Chiron is for anyone who doesn't mind spending some extra time and effort on leveling the bed or working out the settings.

Users have reported this as being rather tricky, but the trade-off is a great 400mm 3D printer with impressive capabilities, plus, a superb customer service department that helped with any and all issues pertaining to the printer, from setup to product completion. One fan wrote, "It took me a long time to dial in my settings and get high-quality prints but I was able to get the printer working and printing decent quality the same day I put it together."

Another happy user who has "completed more than 4,000 hours of printing" and "used many hundreds of rolls of filament," described, "The results I am getting are amazing even with some prints taking over 300 hours to complete. In fact, I have just started a seven-part 700-hour print which is going very well."

In fact, I have just started a seven-part 700-hour print which is going very well."

3. Best Large 3D Printer Under $1000—Creality Ender 5 Plus 3D Printer 350x350x400mm

With pretty much the same capabilities as its equally highly-rated sister model, the Creality Ender 5 Pro, including an automatic bed leveling sensor, bed stabilizer, color touch screen, and easy assembly, the Ender 5 Plus has one major difference; its huge size which accommodates its large build plate.

This sturdy thing works straight out of the box, and in addition to great customer support, there is also a massive Creality community to quickly get any answers and assistance you may require.

"I have printed several large helmets with great results," one happy purchaser wrote, and another added, "I love having the bigger print bed for very big projects. There is some fine-tuning you will have to do but after that, you are ready to rock and roll. "

"

4. Best Industrial Large 3D Printer—Snapmaker 3-in-1 3D Printer 320x350x330mm

For advanced hobbyists or pros who want to up their 3D printing game, the Snapmaker 2.0 will make a proud addition to your workspace and open up a world of 3D opportunity and creativity. In addition to its large printing capacity, it is fast, powerful, and also allows you to do much more than 3D printing, like engraving, cutting, and CNC carving.

At this price, it's a unit for those who are pretty serious about 3D printing, but for small businesses that rely on the craft, it will end up paying for itself in no time. One reviewer who bought this to enhance their graphic design business, wrote, "It's been a valuable asset so far. We are making our own business cards on metal which is super unique and our customers love the added services we can now offer."

Another happy buyer who raved about its versatility and build quality, added, "I have been making non-stop with this machine. .. [It] allows for the imagination to go absolutely wild with ideas!"

.. [It] allows for the imagination to go absolutely wild with ideas!"

5. Best Large 3D Printer under $500—SUNLU S8 3D Printer 310x310x400mm Upgraded

Another good printer with a large print bed, and a tiny price to boot, the upgraded SUNLO S8 only weighs around 26 pounds so is not as much of a task to move as some of the other large 3D printers.

At under US$300, you get many features like high stability, accurate printing, filament runout detection, a Z-axis dual linear rail, and simple assembly. There's also a resume printing function for power failures.

"This printer provides great value for the cost," one buyer explained. "Not only is the print size large enough to do just about anything you can think of, but at 310x310x400 it is the largest in its price class." Another happy customer wrote, "Awesome printer for the price. Can't beat it. It's open-source so it's super easy to add upgrades if you want. Huge build size."

Huge build size."

6. Best Cheap Large 3D Printer—LONGER LK1 3D Printer 300x300x400mm

With an even smaller price tag, the Longer LK1 3D printer is another option for those wanting to dabble in 3D printing but unsure whether to fork out the big bucks just yet.

It provides plenty of features to learn the art, and the customer service is helpful with any questions you may have. The leveling is not the best, but it is easy to assemble and users have been satisfied with the print quality.

"This is an awesome entry-level printer," one satisfied shopper explained. "I was pleasantly surprised, how easy it was to set up... If you're looking for bang for your buck and [to] familiarize yourself with 3D printing, then don't go wasting money on expensive printers; this one works great."

BUY NOW: US$270.39, WalmartThe Best Large Format 3D Printer—Summary

With one of the largest printing beds currently available for a non-industrial 3D printer, the Creality CR-10 S5 3D printer (US$719, Creality 3D) provides an impressive 500x500x500mm of printing space. The Anycubic Chiron (US$623.75, Amazon) is another large-format printer with impressive capabilities and has a superb customer service department too.

The Anycubic Chiron (US$623.75, Amazon) is another large-format printer with impressive capabilities and has a superb customer service department too.

Choosing the Best Large-Format 3D Printer—Buying Guide

With the average printing bed size of a 3D printer intended for general use being around 150–300mm, if you wanted to scale up the size of your 3D creations, a printer of 350mm–500mm would be ideal, and luckily, there are a few worthy large-scale models available on the market for you to choose from.

Benefits of a Large 3D Printer

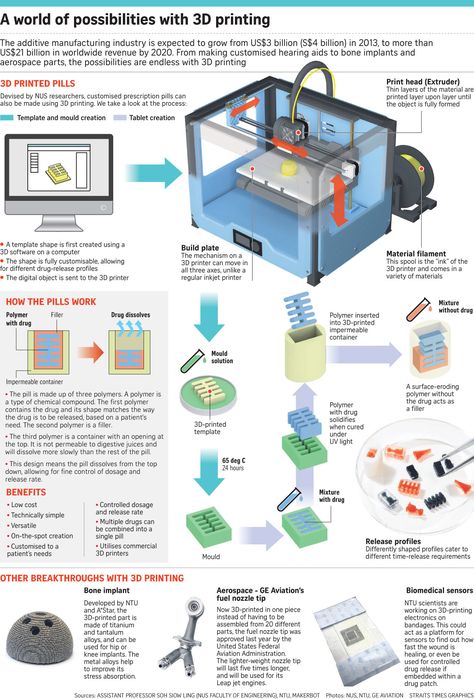

Development in 3D printing technology means that we've recently been presented with 3D-printed houses, cars, bikes, camper vans, life-size statues, and even sofas and other pieces of furniture.

Obviously, the "large format" we're referring to in this article is less about making grand-scale structures, and more about moving on from miniatures, ornaments, and other small objects or parts that an ordinary, non-industrial-sized 3D printer can produce.

Since you'll have a little more print bed area to play with, with a large-format 3D printer you can create detailed products that don't require a magnifying glass to really appreciate and also larger parts that would otherwise need to be printed in separate sections.

We hope our review of the best large-format 3D printer has been helpful. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

Other 3D Printing Articles- The Best 3D Printers under US$300

- The Best 3D Printers under US$200

- The Best 3D Printer Under US$1000

- The Best 3D Printer Under US$500

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

What manufacturers don't want you to know: The truth about 3D printer maximum print areas

One of the most fundamental decisions you can make when choosing a 3D printer is the size of the build area. While printer prices vary for many different reasons, it's pretty much a constant that the larger the build area, the more expensive the printer.

While printer prices vary for many different reasons, it's pretty much a constant that the larger the build area, the more expensive the printer.

In this edition of DIY-IT's 3D Printing Discovery Series on ZDNet, we'll take a hard look at the different build areas available for different 3D printers and then I'll take you into the dark underbelly of the 3D printing world to show you what manufacturers don't want you to know: the truth about 3D printer build areas.

This was a much bigger and more complex project than I expected and it took a whole lot of filament to produce the build area samples used in my testing. So before I get started on the details, I'd like to shout out a thank you to the folks at ColorFabb for providing the filament used in these examples. I'd also like to shout out to MakerBot, Ultimaker, Lulzbot, Dreammaker, and New Matter for providing unrestricted access to their printers so I could perform these tests.

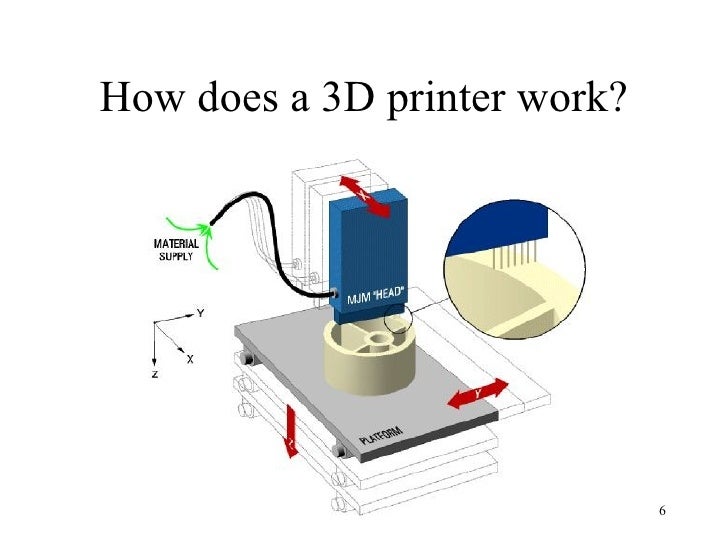

Put simply, when a manufacturer specifies a maximum print areas (also known as a build area), it's the maximum size of an object the printer can (theoretically) print. Technically, a 3D shape that's not equidistant on all sides isn't a cube, it's a cuboid or a convex polyhedron bounded by six quadrilateral faces.

Technically, a 3D shape that's not equidistant on all sides isn't a cube, it's a cuboid or a convex polyhedron bounded by six quadrilateral faces.

The accompanying video shows what the build areas look like for the five printers I have here in the shop. I designed and printed shapes that represent the maximum build areas for each of these printers. I've posted each of these on Thingiverse with links below, you can print your own sizing templates.

- MakerBot sizing template

- Ultimaker 3 sizing template

- LulzBot Mini sizing template

- Overlord Pro Plus sizing template

- New Matter MOD-t sizing template

Here they are in the printers. You can start to see how they relate to each other in size. From left to right, you're looking at the New Matter MOD-t (silver), the Dreammaker Overlord Pro Plus (blue), the LulzBot Mini (green), the Ultimaker 3 (white), and the MakerBot Replicator+ (red).

Image: David Gewirtz Another way to look at these is by stacking them together. In the video, you can really see how they differ in size when placed inside of each other.

In the video, you can really see how they differ in size when placed inside of each other.

Also, don't confuse what may look like available build area with actual, functional build area. For example, on the Overlord Pro, it looks like the model of the Vanderbilt Mansion would print. But if you compare the model with the actual buildable area, the mansion just won't fit. A mighty fine stack of three and half Yoda heads would easily fit in the Overlord's build area, but not the Vanderbilt Mansion. On the other hand, the mansion does easily fit in the build area of the Lulzbot.

As I alluded to at the beginning of this article, there's a lot about build areas that are misleading. Of the five vendors, not one specified a maximum print size that I was actually able to print.

On the MakerBot, the full cube I started to print began to disintegrate near the end, and I wasn't able to complete that print. On the Overlord, Cura wouldn't accept the dimensions specified on the Dreammaker site, except for the vertical Y-axis dimension. When I printed a test bar, the Overlord Pro wasn't able to actually meet that height and caused a very messy jam.

When I printed a test bar, the Overlord Pro wasn't able to actually meet that height and caused a very messy jam.

New Matter's slicer accepted a model for printing, but after two tries, you can see just how messy the results were. Once I reduced the model's size, it eventually printed. In the case of both the Lulzbot and the Ultimaker, Cura simply wouldn't accept a model sized for the maximum printable area described in the specs for each printer.

After a lot of test prints, here's what I found.

| Printer | Specified Width | Actual Width | Specified Depth | Actual Depth | Specified Height | Actual Height |

|---|---|---|---|---|---|---|

| MakerBot Replicator+ | 295 | 292 | 195 | 192 | 165 | 165 |

| Ultimaker 3 | 197 | 188 | 215 | 185 | 200 | 200 |

| LulzBot Mini | 152 | 152* | 152 | 152* | 158 | 158 |

| Dreammaker Overlord Pro Plus | 125 | 79 | 125 | 79 | 280 | 255 |

| New Matter MOD-t | 150 | 145 | 100 | 95 | 125 | 125 |

*There's a trick to making this work. See the article below.

See the article below.

On the MakerBot Replicator+, the specified maximum print size was 295 millimeters long by 195 millimeters deep by 165 millimeters high. Actual build area was 292 millimeters long by 192 millimeters deep by 165 millimeters high, so length and width were three millimeters smaller than specified.

On the Ultimaker 3, the specified maximum print size was 215 millimeters long by 215 millimeters deep by 200 millimeters high for a single extruder. This machine supports using two extruders at once. For a dual extruder setup, the specified maximum print size was 197 millimeters long by 215 millimeters deep by 200 millimeters high.

I tested with both extruders active, and my best results were 185 millimeters long by 188 millimeters deep by 200 millimeters high, so length and width were more than a centimeter smaller than specified, at least for a true rectangle. Ultimaker says that you can increase this a bit if you have longer areas in the middle, but you can't go all the way out in the corners. In any case, like the other vendors, the company didn't meet it's published spec.

In any case, like the other vendors, the company didn't meet it's published spec.

On the LulzBot Mini, the specified maximum print size was 152 millimeters long by 152 millimeters deep by 158 millimeters high. The actual max print area area allowed by Cura was 145 millimeters long by 145 millimeters deep by 158 millimeters high, so length and width were six millimeters smaller than specified.

UPDATE: The LulzBot folks reached out to me and described a trick (changing the Skirt Line Count in Cura) that lets it print to the full 152x152 spec. I tested it and it works. Here's a short video that shows how it's done. Very cool.

The Overlord is interesting, because the Delta architecture means it should print cylinders that have a large diameter than the length and width dimensions of a cuboid. That said, for consistency sake, I went with squared edges. Dreammaker specifies 125 millimeters long by 125 millimeters deep by 280 millimeters high. The width and height weren't even close, at 79 millimeters by 79 millimeters. Even though I'm using the taller Overlord Pro, this was the only printer that completely failed at its specified height. Instead of 280 millimeters, the best I got without making a mess was 255 millimeters. Essentially, the Overlord's maximum specified print area was about 25 percent more than reality.

The width and height weren't even close, at 79 millimeters by 79 millimeters. Even though I'm using the taller Overlord Pro, this was the only printer that completely failed at its specified height. Instead of 280 millimeters, the best I got without making a mess was 255 millimeters. Essentially, the Overlord's maximum specified print area was about 25 percent more than reality.

Finally, there's the New Matter MOD-t. Although the New Matter slicer accepted a print designed at its maximum print size of 150 millimeters long by 100 millimeters deep by 125 millimeters high, the results were a mess. I finally managed a print that was 145 millimeters long by 95 millimeters deep by 125 millimeters high, so the MOD-t lost about 5 millimeters off the X-and-Y axis.

What does it all mean?

So now that you've seen the results of my little study, what does it all mean?

My recommendation is that you do't freak out too much about the fact that the specified maximum build dimensions and the actual ones are slightly different. In most cases, the difference is a centimeter or less.

In most cases, the difference is a centimeter or less.

That said, if you're buying a 3D printer for a project that is tightly dependent on certain dimensions, you should make sure to factor into your decision the fact that the build area documented in the specs is lightly to be optimistic by about 5 or 10 percent. If you're particularly dependent on an exact size, ask the vendor to print a part sample to see what the machine will produce.

Beyond that, if you're in the market for a new 3D printer, think carefully about how much build area you really need. Since build area is one of the most fundamental drivers in printer price, you save money and get a lot more capabilities in a printer if you're willing to sacrifice some build area. Conversely, if you need to print larger objects, you'll definitely need to be aware that size does matter when it comes to your buying budget.

You can follow my day-to-day project updates on social media. Be sure to follow me on Twitter at @DavidGewirtz, on Facebook at Facebook. com/DavidGewirtz, on Instagram at Instagram.com/DavidGewirtz, and on YouTube at YouTube.com/DavidGewirtzTV.

com/DavidGewirtz, on Instagram at Instagram.com/DavidGewirtz, and on YouTube at YouTube.com/DavidGewirtzTV.

A small guide for choosing a 3D printer for beginners / Sudo Null IT News

The reason for writing this article was the article “ I wanted to buy an inexpensive 3D printer, but I looked at YouTube and got sick of ”, at the end of which the author asks to answer a few questions. I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

This article will not contain advice: “Buy a printer from manufacturer X - it is good, and manufacturer Y - do not take it in any case”, only general recommendations.

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it, I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

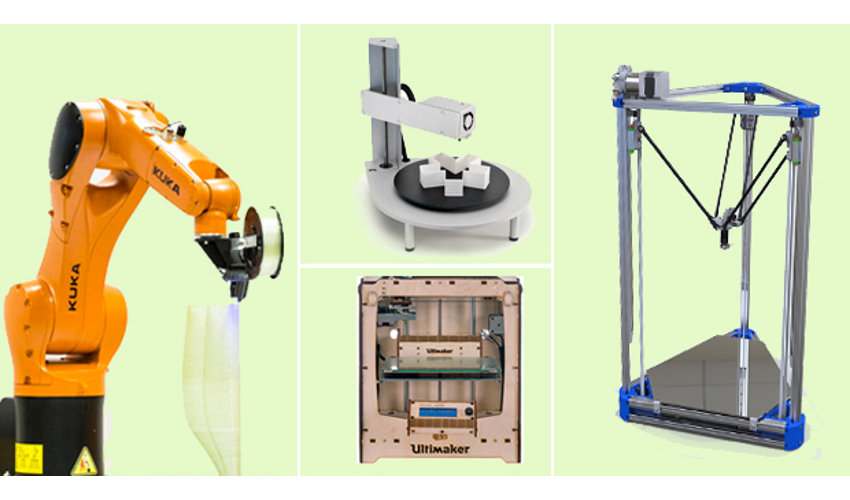

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusion, which is fed in the form of a rod and SLA (LCD) - printing with a photocuring polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

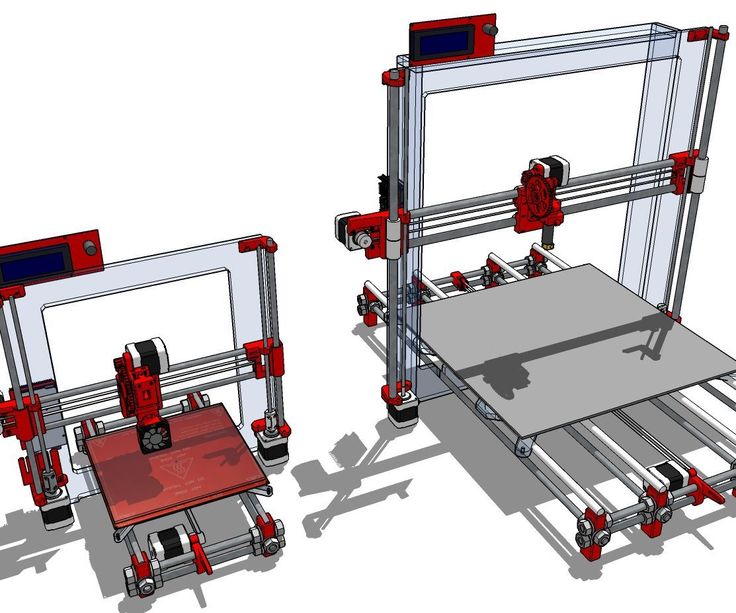

SLA and FDMTo be honest, I almost never did SLA printing and I still don’t have an LCD printer in my home zoo (but it may appear soon), so I will mainly talk about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

Dried tables - printers with a table that moves horizontally. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

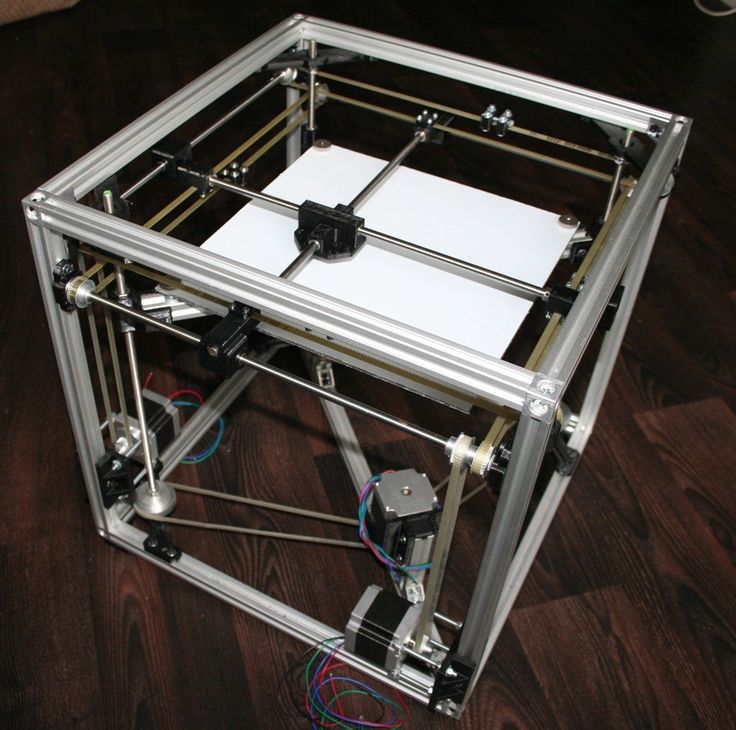

Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

Delta - printers with the so-called delta kinematics, when the print head is attached to the carriages moving along vertical guides using a system of rods. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement.

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

Typical deltasBy availability on the market, 3 main categories can also be distinguished:

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-

The advantages include low cost, wide distribution and uniformity, which allows you to buy failed parts in the nearest radio shop or on well-known Chinese sites.

Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation.

Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation. -

The disadvantages include the quality of components / assembly and the need to refine these printers to obtain acceptable quality / print speed. It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

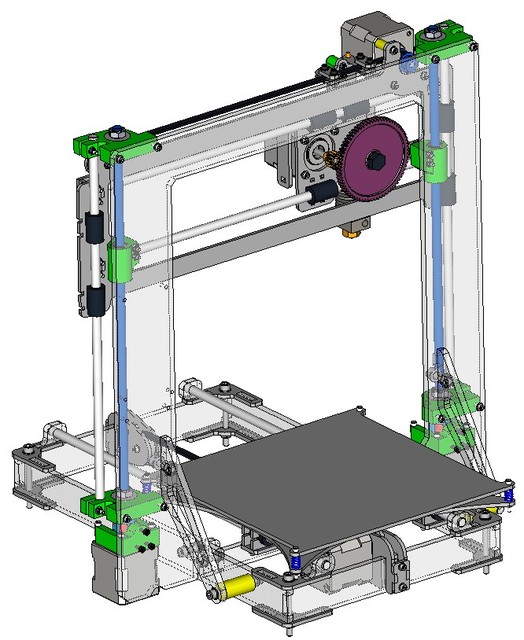

Kits (assembly kits, mainly domestic production) - google for the words “ ZAV ”, “ UlTi ”, “ UlTi ”, etc. Usually they are a set for assembling a plywood cube. Recently, options with metal cases have appeared. Supplied in different versions - from a kit for building a case with printed parts, ending with completely finished assembled products.

-

The pluses include a fairly good engineering study, the ability to choose the components for the mechanical and electronic parts and make the printer completely to your requirements. With good components, they provide fast, stable and high-quality printing. The price is somewhat more expensive than Chinese printers, but cheaper than semi-professional printers of domestic or European / American manufacturers.

-

The disadvantages include a decent amount of time spent on assembly and waiting for components if you decide to save money and order these components yourself from different sellers and assemble a printer from them. When assembling, direct hands are required.

Factory Printers (Semi-professional printers from domestic or American/European manufacturers). There are a lot of models, the designs are very different.

-

The advantage of this class of printers is printing with acceptable quality out of the box.

In addition, you get operational reliability and warranty support from the manufacturer.

In addition, you get operational reliability and warranty support from the manufacturer. -

The main disadvantage is the price. It is often not clear what factors it depends on. You can buy a high-quality printer relatively inexpensively, or you can take something incomprehensible for a high price. The second disadvantage is the presence of specific solutions that are incompatible with popular solutions on the market: these can be nozzles with their own thread pitch, special fans, electronics, belts, and even slicers. Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Now that we have decided on the classification of printers, we can proceed to the procedure for choosing a printer for yourself, your loved one. If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze several typical situations:

I want to do something for myself and my family - if you don't plan to print products from engineering plastics that can withstand decent loads and temperatures, a Chinese drygostol or a cube will suffice. If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

I can't do anything with my hands, but I have to. Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

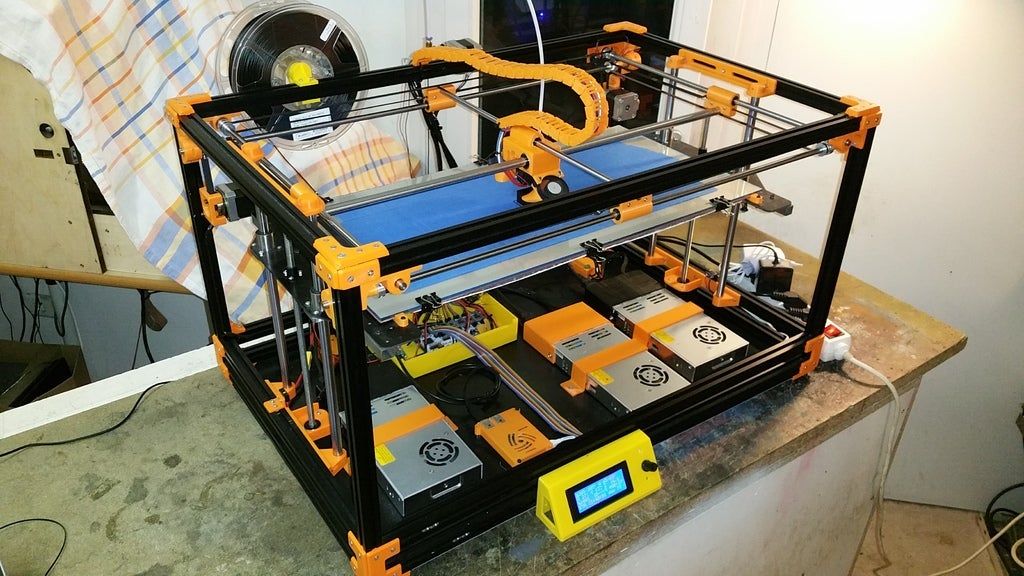

I want to print for sale - a farm of the same type of printers, depending on the budget. If there is no budget, but there are resources for regular tuning / repair - you can even from Chinese drygosts. Additionally - a printer with a large print area, a printer with a closed case and a heated table for printing engineering plastics, an SLA / LCD printer for printing products with a high degree of detail.

Whether at work or at home, the need arises to design and print enclosures and parts. If only small prototypes are planned - an LCD printer, if functional products - a closed cube with the ability to print with engineering plastics.

Kids are growing up and this is the technology of the future, I want you to master - see what printers are used in prototyping competitions in your area. Take the same one. May be used.

I want to make figurines for desktops, beautiful little things for home - LCD printer.

I want to figure out what kind of technology and how it works in general - a kit for assembling a domestic manufacturer. By the time you collect it, you will understand.

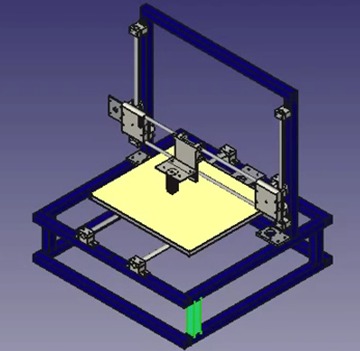

There is no money at all, but I want to print, I will collect it myself from scratch - it will turn out better and cheaper than the Chinese. Strange as it may seem, no. The cost of components with Ali will be more expensive than a printer with Ali. Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

If you want to completely build your printer from scratch, then it's better to treat it as a separate hobby and accept that it will not turn out very cheap. Well, or look in the direction of used printers.

I don’t know why I need a printer, but I want to try - a Chinese or a domestic assembly kit. Can be used. If it doesn't work, you can always resell.

Decided on the type of printer - what to look for first of all when buying ?

-

First of all - on the rigidity of the structure - the accuracy and speed of printing depend on it.

It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better.

It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better. -

Secondly - if the printer will be in the apartment - "silent" drivers for stepper motors. 3D printing is not a fast process, and having a constant loud enough buzzer under your ear is annoying.

-

Third - the presence of a heated table and ease of modification to a closed case. Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost.

-

Fourthly, the presence of a good plastic blowing system is also important.

-

Fifthly, when choosing printers with CoreXY, H-Bot or Delta mechanics, it is highly desirable to have a 32-bit control board, or you will encounter fading (freezes) at high print speeds.

-

In the sixth, seventh, etc. - there are many nuances in the design of printers. If something is unclear, feel free to ask the community.

In any case, if you are going to buy or have already bought a 3D printer, start learning some 3D editor. The easiest, in my opinion - https://www.tinkercad.com . You can simulate a washer in it or the well-known plate changer without much effort.

Over time, its capabilities will no longer be enough - then you can switch to more serious CAD systems. In my opinion, a printer should own two types of editors - a solid state for modeling technical products (CAD) and a polygonal tool (Blender, etc.) - for modeling artistic ones, but many printers consider this redundant and master only one.

On this, perhaps, I will round off - the article has already turned out to be quite voluminous, if you have questions, I will be happy to answer them in the comments or in a separate article. I’ll say right away - I won’t answer questions like: “ which is better: flying bear 5 or ender 3 ” - a lot of copies have already been broken on this topic on specialized resources, I don’t see the point in repeating.

Best regards, Maxim.

8 nuances worth paying attention to

Sooner or later, everyone will learn about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Nuance 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs.

They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0.3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials.

Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.