How to clean a 3d printer

How to Clean a 3D Printer Bed

By Sammy Ekaran

It's essential to keep your 3D printer's bed clean to ensure high-quality results and also prolong its lifespan. We show you how.

If you're using a 3D printer, you know that keeping the bed clean is essential for producing high-quality prints. If the bed isn't clean, your prints will be covered in streaks and smudges, which can ruin the overall look of your project. The steps below will show you how to clean your 3D printer bed quickly and effectively.

What Is a 3D Printer Bed?

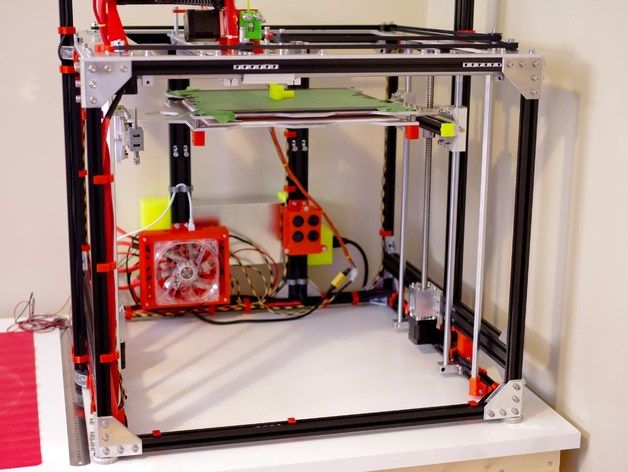

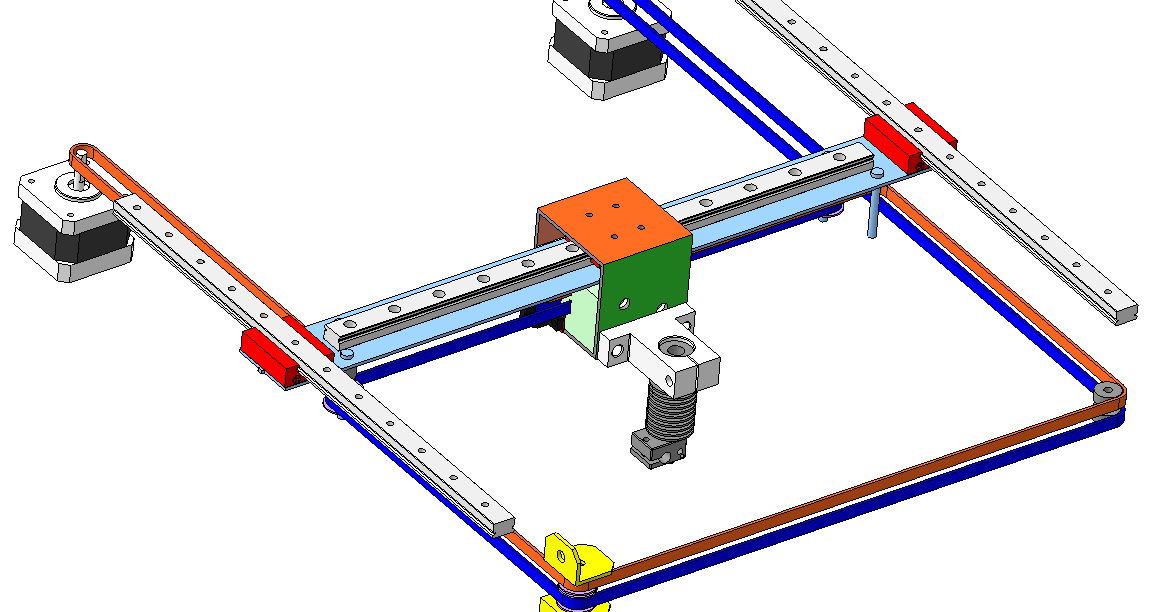

A 3D printer bed is a platform where the 3D object is built. It is made of glass, metal, or plastic. Each layer is bonded to the previous layer in the bed during 3D printing. The 3D printer bed must be clean and level for the object to be printed correctly, but if it’s not, you will experience first layer woes, and the object will be printed with distorted layers.

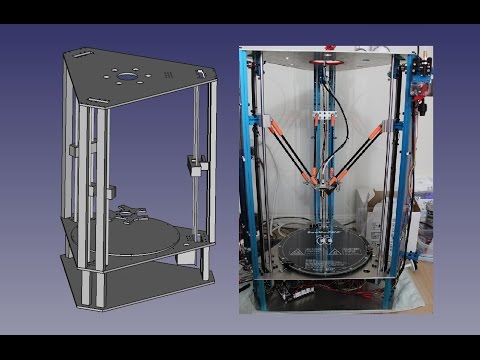

Most 3D printers have an automatic bed-leveling feature that makes it easy to keep the print bed level. Some 3D printers also have heated beds that help prevent filament warping during printing. Having looked at what a 3D printer bed is, let’s now look at what you need to have to clean it.

What You'll Need

Depending on your build plate's material, you need various things to clean your 3D printer bed. Here we will use a metal 3D printer bed to demonstrate how it’s cleaned. Below are the primary materials required:

- Isopropyl alcohol (IPA). Ensure the IPA is at least 99% pure—anything less won't be effective.

- A lint-free cloth—you can also use a pocket tissue or cotton wool.

- You'll also need something to scrape off any stubborn bits of a filament—a putty knife, or credit card works well for this.

- Painter's or masking tape is also necessary. Just use the low-tack variety so it won't damage your print bed.

Once you have all the materials, you can proceed with the cleaning process.

Step 1: Remove Any Debris or Dust on the Bed

You can remove debris or dust from the bed's surface using a brush or vacuum. If the dirt is clinging to the bed in clumps, you can use a brush, but a vacuum is helpful if the debris is spread more evenly across the bed. If debris is stacked below the bed, you can unscrew it completely, remove anything that might be stacked, and return it later.

To remove the bed, use a screwdriver to loosen the four screws on each corner. But remember that you will need to level your build plate after removing it because some materials like PLA can be difficult to stick to the bed if it's not level enough. Also, exercise caution so you don't damage the bed

Step 2: Apply Isopropyl Alcohol to the Cleaner

Take a lint-free cloth and dampen it with isopropyl alcohol. You can also use a cotton swab or a pocket tissue to do this job. To start cleaning, gently wipe down the entire surface of the build plate in a circular motion. This will remove residual oils and/or fingerprints and leave the build platform ready for your next print.

This will remove residual oils and/or fingerprints and leave the build platform ready for your next print.

Once you're done, remove any residue with a dry, lint-free cloth. It's essential to ensure the build plate is completely dry before using the 3D printer again. Any water or alcohol left on the surface could cause the filament not to stick correctly, resulting in poor print quality.

Step 3: Clean Further With Masking Tape

During the printing process, 3D printers often leave behind a trail of excess material, which can be challenging to remove, especially in the heated build plate that forms the base of the printed object. Even after cleaning using the two steps above, removing the excess materials attached to the 3D printer bed can be a tough job, and that’s where the masking tape comes in now.

The tape will adhere to the build plate and help lift any remaining bits of material. To use the tape, simply apply it to the build plate and then peel it away. With a bit of patience, you should be able to remove all the excess material and leave your build plate clean and ready for the next print job.

With a bit of patience, you should be able to remove all the excess material and leave your build plate clean and ready for the next print job.

Step 4: Wipe the Bed

After you have cleaned your 3D printer bed, it is important to wipe it with a dry cloth. This will help remove any residue left behind from the cleaning process.

Wiping the bed with a dry cloth helps prevent static electricity build-up which can damage sensitive electronic components. It also ensures the surface is adequately prepared for the next printing job.

Tips for Cleaning a 3D Printer Bed

A few more handy hints to help you keep your printer bed clean:

- Use isopropyl alcohol and a lint-free cloth. Avoid using abrasive materials like sandpaper, which can damage the build surface.

- If there is a stubborn residue that won't come off with alcohol and tape, you can try soaking the build plate in acetone overnight. However, be sure to ventilate the area well and take care not to damage any other parts of the printer.

- Rinse the bed off with water and dry thoroughly before printing again.

- Clean the bed regularly. This ensures that your prints are always coming out correctly and that your printer will last longer.

- It's also essential to clean the nozzle regularly. You can do this with a brass wire brush or needle, but be careful not to damage the nozzle opening.

- Use a soft cloth or brush to remove dirt or debris from the bed's surface.

- Once you've cleaned the bed, applying a thin layer of adhesive is vital before printing anything on it. This will help ensure that your prints adhere properly.

Get Quality Prints With a Clean Bed

Cleaning a 3D printer bed is essential for optimal printing results. If the bed is not cleaned, prints may be lower in quality or have imperfections, and the bed itself may become damaged over time if it is not cleaned correctly. Following the above steps will ensure your build plate is clean, and you won’t have a failed print due to a dirty 3D printer bed.

Methods for Cleaning 3D Printed Parts

Time to read: 7 min

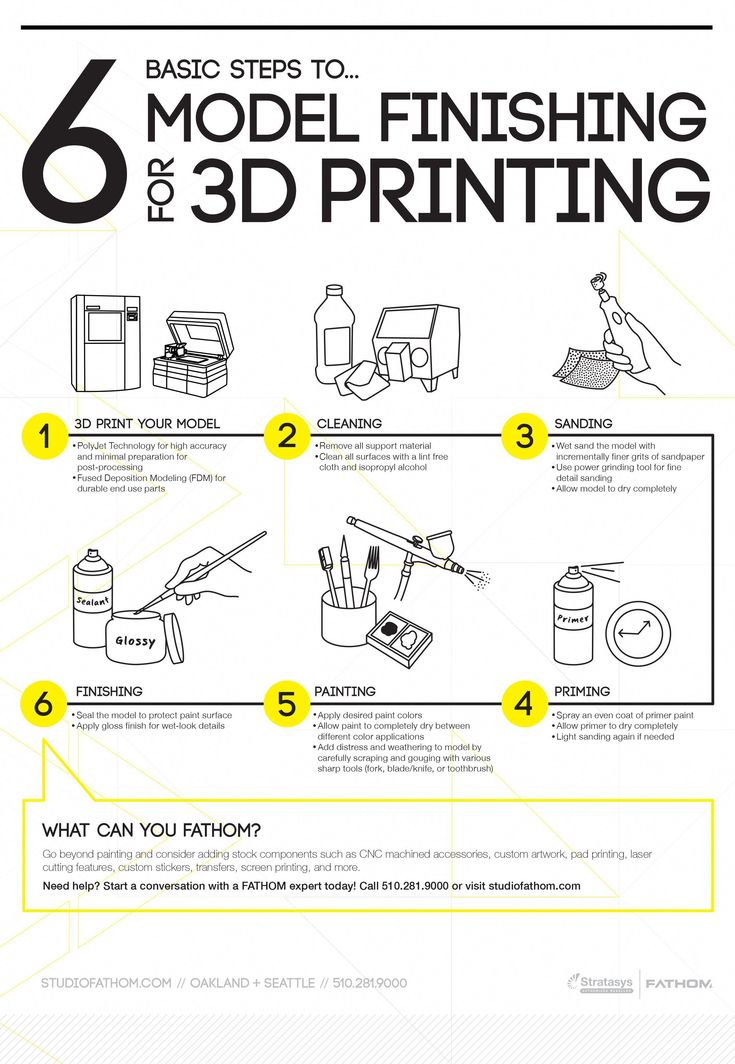

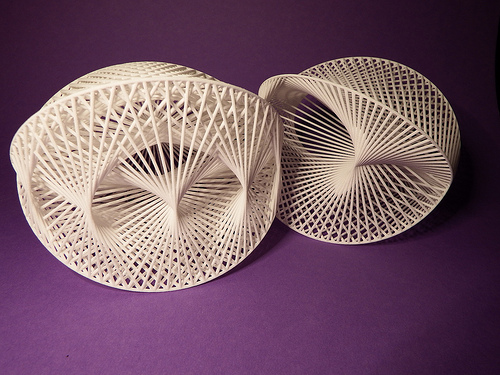

You’ve envisioned it, you’ve modeled it, and you’ve printed it. As it turns out, however, your newly printed prototype may need a bit more TLC before it appears, or functions as intended. 3D printed part finishing often involves a cleaning step to improve appearances or remove unwanted support material.

The purpose of this article is to investigate practical methods for cleaning up 3D printed parts, as well as the tools you should have at your workbench to make these processes as simple as possible. Even when outsourcing 3D printing to a partner such as Fictiv, you will likely want to perform some 3D printed part cleaning yourself.

Luckily, except for specialty appliances that can be used for dual-extruder printers with soluble support material, everything you need to get a great finish to your printed components can be conveniently found at your local hardware store.

Disclaimer: always utilize caution when performing 3D printed part cleaning. Always wear appropriate PPE to protect yourself when working with tools or chemicals of any type (for example goggles and gloves).

Always wear appropriate PPE to protect yourself when working with tools or chemicals of any type (for example goggles and gloves).

One of the most basic 3D print cleaning tools you should have in your 3D printing area is a simple putty knife. A putty knife can have many applications from the initial removal of a 3D printed part to the removal of residue from the print bed. For selecting, a putty knife, choose one with a thin, flexible metal blade to allow you to easily get between the plastic and the printer bed. This allows you to gently pry completed prints off the print bed while minimizing the risk of damage to the part.

Pro Tip: If you’re using a glass build bed with glue for adhesion, try placing your bed in the freezer for 15-20 min. The lower temperatures help to desolidify the bond of the PLA to the bed and your PLA part will pop right off!

Rough Cleaning and Part PreparationDepending on the type of part and printing method you’ve used, the first thing you’ll want to do is remove any support material adhering to the 3D printed part. There are several methods for removing this material.

There are several methods for removing this material.

If the printer you’re using creates part supports using a soluble material, soaking the part in hot water with a strong detergent (always following the manufacturer’s recommendations) for several hours, depending on the part size, may be sufficient for support removal.

A sodium hydroxide bath can also help dissolve support material such as HIPS.

Agitating the solution with a pump to ensure constant fluid movement over the surface of the part will also be important in processing these types of components.

Ultrasonic tanks are useful for cleaning soluble support material from complex components with a large surface area. These may clean components faster and with greater success than a simpler agitated bath because of the mechanical energy generated by the ultrasound waves. There are a variety of ultrasonic cleaners for 3D/resin printed parts. Ensure the ultrasonic cleaning chemical utilized will not attack the 3D printed base material, while effectively and completely removing support material.

Consult your 3D printer manufacturer or support material manufacturer for additional information regarding the necessary equipment or procedures to remove soluble support material from your 3D printed parts.

Single-Extruder SystemsFor single-extruder type 3D printers, where support material is printed using the same material that comprises the part itself, start by removing as much material as possible using your hands or a pair of needle-nose pliers.

Many common tools can be repurposed into 3D print cleaning tools. A small pair of flush-cutters, used for cutting wire, may also come in handy during this process.

Additionally, a small set of files and dental tools can help reach those nooks and crannies that are hard to reach. Or, even a rotary/multi-tool may be beneficial in removing excess support material. Try increasing the speed of the rotary tool before increasing the torque, as speed increases will yield better results. Rotary sanding tools are not recommended for PLA smoothing. When smoothing PLA, sandpaper with a manual approach is better.

When smoothing PLA, sandpaper with a manual approach is better.

Depending on your settings, the material, and the algorithms implemented in your printing software, the bulk removal of support material can be quite easy or possibly quite frustrating. So, patience and a desire to learn the optimal settings are key here.

Pro Tip: A simple handheld scratch awl can also be very useful for cleaning out small holes, channels, and crevices in printed parts.

Tackling the Crude ImperfectionsFollowing any major operations using pliers and cutting tools, many 3D printed parts will still have undesirable imperfections, including “strings” of material extending from the outer surfaces and rough edges where the support material has broken away from the part.

In these cases, consider carefully sanding the rough surfaces of the part using sandpaper. Start with a rough grit such as 150 to take care of major imperfections and work your way to 600 grit.

It’s worth it to use this sanding method as the finer paper generally isn’t suitable for treating coarse surface imperfections, yet coarse paper alone may leave deep scratches.

Wet-sanding plastic using 600 or 800 grit paper can produce a smooth finish on flat surfaces.

Pro Tip: Check out our Ultimate Guide to Finishing 3D Parts for more detail on how to create a perfect finish.

For more accuracy on smaller external features, use a set of micro files, often used for jewelry applications.

A rotary tool with sanding and polishing bits can also be very useful for hard-to-reach surfaces that require sanding.

Take care not to sand away areas of the part itself, particularly with electric tools! At high RPMs, you may risk slightly melting areas of the part due to heat generated from friction, so practice on spare parts first if possible.

For many engineers, cleaning your 3D printed parts can be time-consuming to get just right. Fictiv’s on-demand 3D printing services and network of highly vetted 3D printing operators deliver the highest quality parts that are printed, inspected, and ready to integrate into your next build or rapid prototyping cycle. To get an instant quote, create your free account here.

Fictiv’s on-demand 3D printing services and network of highly vetted 3D printing operators deliver the highest quality parts that are printed, inspected, and ready to integrate into your next build or rapid prototyping cycle. To get an instant quote, create your free account here.

After you’ve taken care of the major imperfections, you may be left with areas of the part which have sand marks or other discoloration. Depending on the material, there are several ways of cleaning up these areas.

Heat GunA heat gun is a useful tool for very slightly melting the part you’re cleaning. This can be used to clean up the discolored patches of material you might find, for example, in PLA or ABS after a sanding operation.

Be very careful here as you can deform or melt away features in your part when using any form of heat treatment as the melting temperatures of some 3D printing filament can be relatively low. Apply hot air from the heat gun in a sweeping motion several inches from the surface of the component, checking to be sure you aren’t causing damage.

Apply hot air from the heat gun in a sweeping motion several inches from the surface of the component, checking to be sure you aren’t causing damage.

You might also consider experimenting with polishing bits, used for buffing ceramics or metals, to smooth out surfaces on 3D printed parts.

AcetoneFinally, for ABS parts, acetone can be used to create a smooth, glossy finish. When placed in a jar containing acetone vapor, the exposed surfaces of the printed part will dissolve over time, reducing the appearance of layer lines. Please note acetone is not a recommended PETG smoothing chemical.

Note that the surface of an acetone vapor-treated part will continue to dissolve for some time after it’s been removed, so it’s a good idea to practice on a few spare parts before trying this method on production components.

Also, be sure to follow standard safety protocol when using acetone. Only handle it outside or in a well-ventilated space as the vapors are harmful and keep it away from flame or excessive heat since it’s also very flammable. Refer to an acetone MSDS for more details.

Refer to an acetone MSDS for more details.

Lastly, here’s a list of some of the recommended tools mentioned in this article to help you get started building your 3D part cleaning inventory:

- Wide and narrow flexible metal putty knives

- Needle-nose pliers

- Scratch awl

- A pair of small flush-cutters

- Sandpaper (150-800 grit)

- Micro file set

- Rotary tool with sanding/polishing bits

- Heat gun

- Acetone

- Wax carving tools

- 3D printed part cleaning can range from utilizing common tools for material removal, sanding/chemicals for smoothing, heat guns, or polishing bits. Generally, part cleaning includes mechanical removal, sanding, and polishing. Optimal methods depend on material usage. Always consult material-technical datasheets for information.

- PLA is a common filament and it is simple to clean with mechanical tools, files, heat guns, sandpaper, and polishing tools.

Resin or a clear spray paint may be utilized for an even smoother, shinier finish.

Resin or a clear spray paint may be utilized for an even smoother, shinier finish. - ABS is another commonly used filament and it can be smoothed with a process known as vapor smoothing. This process involves suspending the ABS printed part above an ABS bath in a well-ventilated area for around 15-20 minutes. The vapors physically smooth the prints.

- Keeping your 3D printing bed clean is optimal for subsequent printing. Cleaning will depend on the bed material as some will be easily cleaned with IPA (PEI beds) or acetone (PEI beds) and others will need to be mechanically scraped (glass beds) with tools.

As always, feel free to reach out to the Fictiv Team at [email protected] with any additional questions!

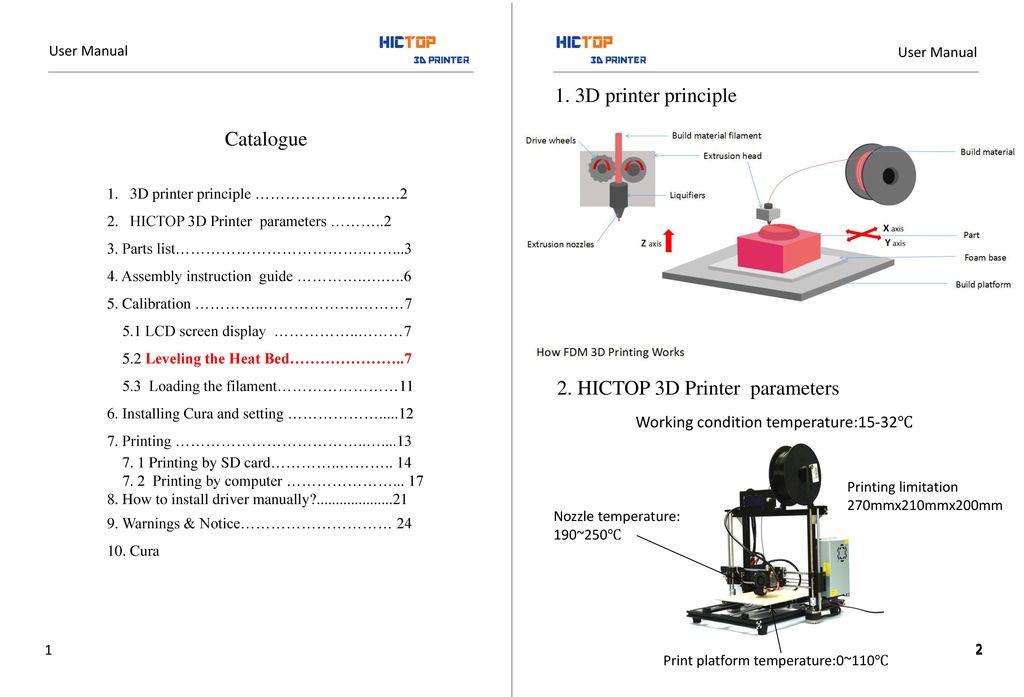

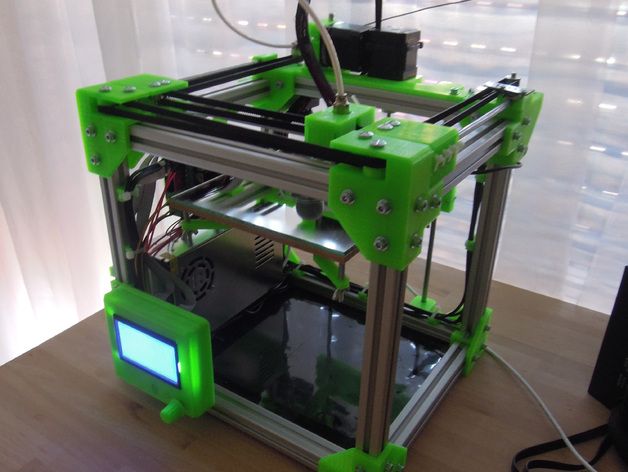

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

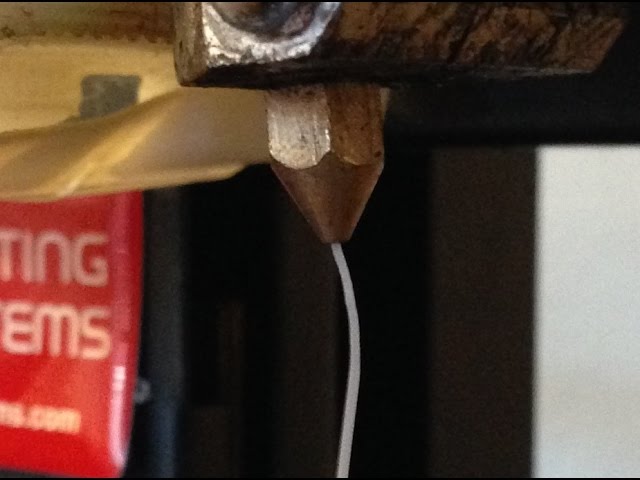

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

If you want to understand how this is done correctly, then read this article. Aceto Read more→

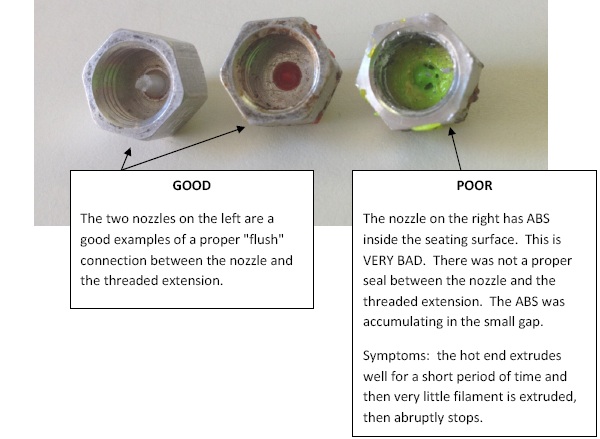

How to clean a 3D printer nozzle: clean the extruder from plastic

The extruder nozzle is one of the most problematic parts in a 3D printer. It can easily get clogged or clogged. Poor plastic feed will affect the quality of the finished model. Print defects will occur. Sometimes the job is completely stuck as the printer needs a nozzle cleaning.

Main Causes of Clogged Extruder

Regardless of the type of print head, it can become clogged. The reason for this is the filament or dirt that accumulates inside the knot. Most often, the nozzle becomes clogged when the printer is not used correctly in conditions:

- Overload, when the device works for a long time without stopping.

- In dusty areas. Sometimes the printing device is placed in a non-residential room or workshop, where cleaning is very rarely carried out.

- Incorrect print settings.

In particular, the use of an inappropriate filament or an erroneously set melting point.

In particular, the use of an inappropriate filament or an erroneously set melting point.

In some cases, the design of the nozzle itself can cause frequent clogging. For example, when the printer comes with an initially defective extruder. The geometry of the nozzle is broken. The device should be returned under warranty or the nozzle should be replaced separately. nine0003

Information! The filament itself can be the cause of litter. A common factory defect or a burr on the plastic can cause a cork.

Pieces of sintered filament

In any case, it is worth carefully studying the problem of blockage and only then proceed to prevention. If you are afraid to damage the device, it is better to take the printer to a service center.

Dust and debris trapped in the nozzle

The first cause is dirt or dust that has entered from outside. Most often, the nozzle becomes clogged with debris for a long time. Dirt can accumulate for months and even years. It sinters on the walls of the nozzle, plaque is formed. Over time, it can cause the filament to get stuck. nine0003

Dirt can accumulate for months and even years. It sinters on the walls of the nozzle, plaque is formed. Over time, it can cause the filament to get stuck. nine0003

Extruder temperature too high

Beginner 3D makers find that an excessively high melt temperature will help avoid clogging problems. This is an incorrect judgment. When working at an elevated temperature, the plastic is instantly sintered right inside the assembly. Filament jamming occurs. A bottleneck is formed.

Therefore, it is important to follow the temperature regime recommended by the filament manufacturer. Sometimes this figure may differ slightly. Somewhere at +/- 5 ° С. It all depends on the printer model, as well as the extruder itself. The optimum melting point is found experimentally. nine0003

How to clean the 3D printer extruder: step-by-step instructions

You can clean the printer yourself, without going to a specialized workshop. There are several working methods by which you can clean the nozzle. Let's consider each of them step by step.

There are several working methods by which you can clean the nozzle. Let's consider each of them step by step.

Clogged extruder nozzle

Manual

The roughest way to clean the extruder. Thin objects are used for it:

- drill with a diameter of up to 0.35 mm; nine0028

- guitar string up to 0.33 mm in diameter;

- leg from a diode or transistor.

Special nozzle cleaning tool for different diameters

Cleaning algorithm:

- Shut off the 3D printer. Wait until the nozzle cools down a bit.

- Remove filament residue from nozzle tip.

- Drill or chisel the hole slowly with the tools indicated. Be careful not to make a hole too deep. nine0028

- Turn on the printer, feed the plastic to print.

- Repeat the procedure several times until the filament comes out in an even layer.

Some experts advise you to clean the nozzle while the printer is on. This can be done if the primary rubbish has been eliminated.

This can be done if the primary rubbish has been eliminated.

Attention! Do not use a screwdriver or drill! So you can miscalculate the force and go through the extruder, damaging the plastic capture mechanism. It is better to use a thin drill clamped in pliers. nine0003

Cleaning with a thin tool

Thinner

Sometimes mechanical cleaning is only partially helpful. With a drill, you can remove the cause of the blockage, but there are still plaques or influxes of plastic inside the nozzle. This situation is often encountered when working with ABS. To remove the filament completely, you will need to clean the nozzle in an aggressive environment. For example, in acetone or dichloroethane.

Cleaning algorithm:

- Turn off the printer, let the extruder cool down a bit. nine0028

- Unscrew the nozzle, put it in a container with acetone or dichloroethane.

- Leave the part for 2-3 hours, then remove and clean the nozzle with a needle.

Screw the nozzle onto the printhead. Throw out the plastic.

Important! Spare nozzles can be stored in a jar of acetone. In this way, they will always be ready for use without pre-cleaning.

Filament

Filament cleaning is one of the safest methods that does not involve intervention in the design of the extruder or partial disassembly of this unit. Two types of plastic are used to clean the nozzle:

- Filament with higher melting point. A reel with refractory plastic is placed in the printer. It literally pushes the cork out of the extruder.

- Cleaning plastic. It is usually sold in the form of short sticks or small coils. Its structure resembles nylon. Cleaning filament is the safest way to remove plugs in an extruder.

We recommend using the latter method as an alternative to manual or dry cleaning.

Carbon deposits on the filament

Prevention of clogging - expert advice

To keep the extruder and nozzle in good condition, it is worth following a number of rules:

- Use the filament melting temperature specified by the manufacturer.

Learn more