How hard is it to 3d print

How Hard Is 3D Printing? 7 Things To Know – Printing It 3D

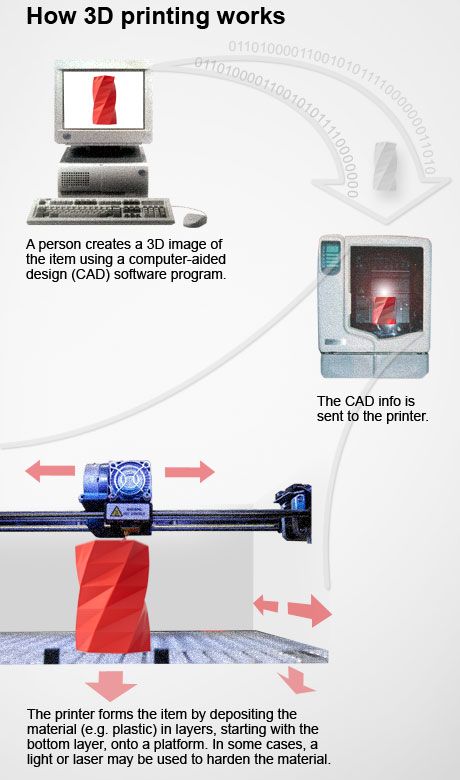

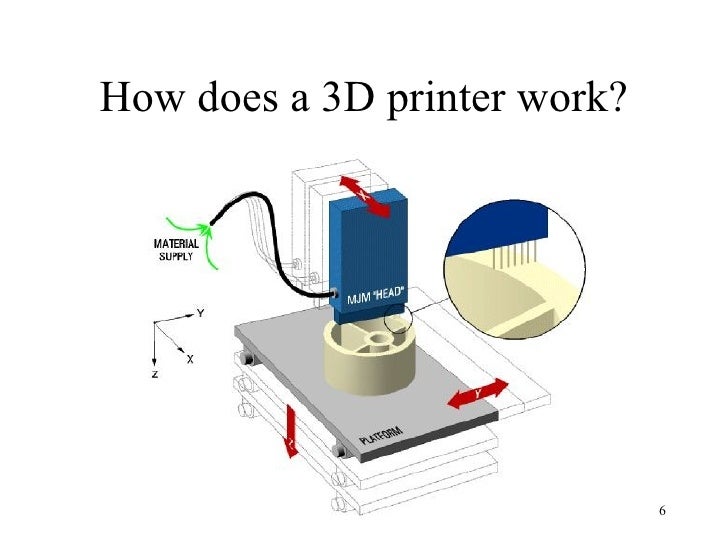

3D printing is the process of making 3-dimensional solid objects from a digital file. Although this technology has been around for more than 30 years, it has only recently gained popularity. That said, how hard is 3D printing?

3D printing is quite hard, especially for beginners. It requires creativity, math, and computer-aided design (CAD) skills to master. However, once you have the necessary hardware and software, modeling skills, and an understanding of how this technology works, 3D printing becomes easier.

This article will explain why 3D printing can be complex and the technology needed to do it. Read on for insights into these and the benefits and limitations of this technology.

Why 3D Printing Is Hard

3D printing is complex because it attempts to combine the processes of creating and assembling a physical object from start to finish. Before making a 3D printed product, one must first design it with CAD software. This process may require creativity, engineering, and math skills.

Even for simpler objects, designing takes time because there are no common standards when using CAD software. Every company has its ways of interacting with these programs, and designs vary from one program to another.

A lot more goes into 3D printing than just clicking “Print” on your computer screen. Different materials have different properties that must be taken into consideration before designing a product.

For example, the thickness of material matters when it comes to how its design will be printed, but it may also affect how the product works. If a material is too thin, it may snap or break easily when handled.

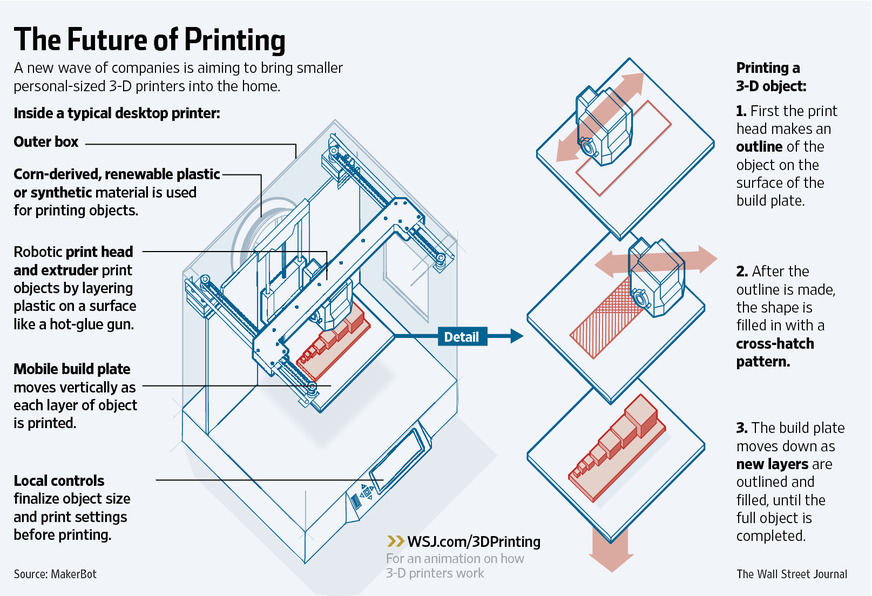

Once you have designed an object and selected the suitable material, the printing process is no longer as simple as clicking a button. The printer must be configured by choosing where to start and stop printing, called the build area.

There is also the build volume, or the size of an object one can create in a single printing session.

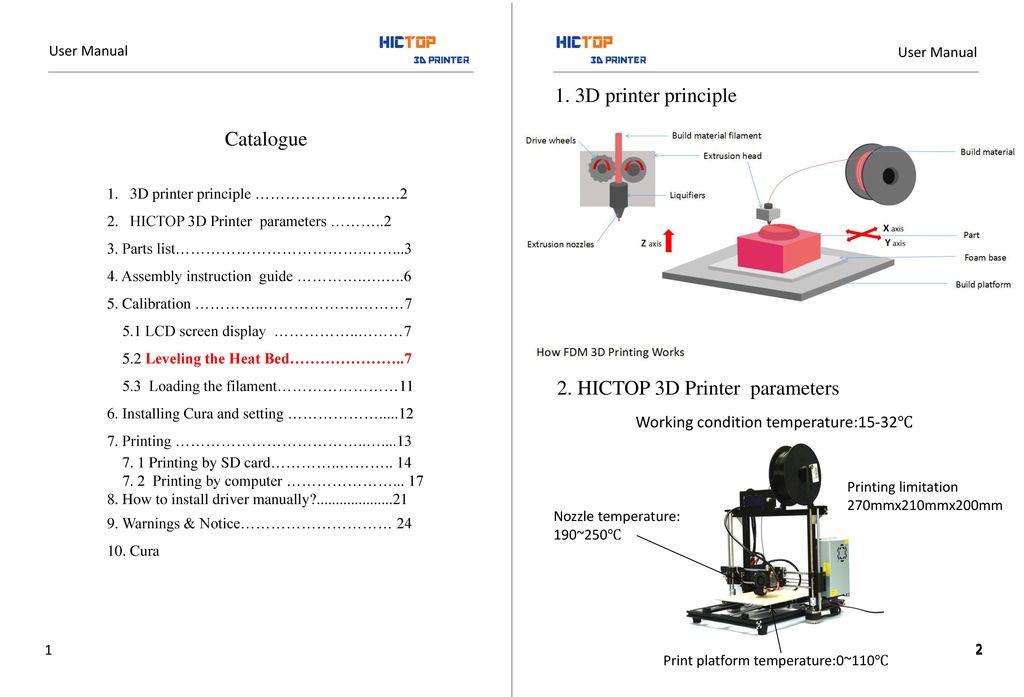

Here is a video summary of how 3D printing works:

7 Crucial Things To Know About 3D Printing

Here are 7 things every beginner should know about 3D printing.

1. What Is 3D Printing?

3D printing is the process of creating physical objects from digital models. A “file,” usually in STL format, is sent to a 3D printer that will build up the product layer by layer until it has been completely printed.

3D printing is the successor to CNC machining and has been around since 1984 when Chuck Hull invented stereolithography. Since then, 3D printers have been used for everything, from art-making to scientific research, but they are still gaining mainstream popularity.

2. The Software Needed

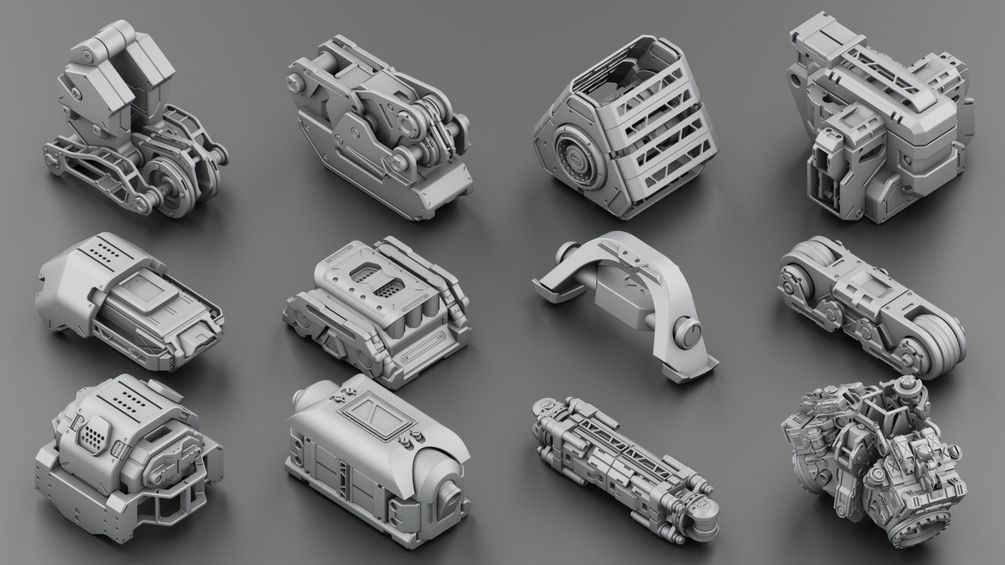

CAD software allows users to create and manipulate 3D models. It gives designers the ability to create things that have never existed before in a virtual environment, from simple shapes to complex structures.

CAD software is highly customizable and can allow users complete freedom of design when working on their projects. For example, the Autodesk Fusion 360 will enable users to share designs with others through cloud-sharing so that more people can participate or even improve on the initial design.

With so many CAD software options, choosing a program to get started with is difficult. Programs like SketchUp and Tinkercad are good introductions. However, they may be too basic for an experienced designer looking to do something more complex.

For something more advanced, you may have to pay for a commercial program like SolidWorks or AutoCAD.

3. The Hardware Needed

To create models and send them to a 3D printer, you need computer hardware. The most recent Mac and Windows computers have the power necessary for CAD software.

The most recent Mac and Windows computers have the power necessary for CAD software.

However, if you’re using an older system or want something better for your specific needs, there are alternatives.

If you’re working on an Apple computer, a good graphics card is essential. You can use the built-in graphics card for basic tasks like editing photos. However, for more complex activities such as 3D printing, you will need an additional graphics processing unit (GPU).

Quad-core processors are also recommended because they work faster and save time in some CAD programs.

Maybe you don’t work on a computer at all. With an app like Autodesk’s 123D Circuits, you can create 3D models of objects such as PCB boards without having to buy expensive equipment. Computer hardware is also available for Android phones, giving users the ability to design and print from anywhere.

4. The Skills Needed

As I mentioned, creativity, math, and engineering skills come in handy in ensuring you get the best results from 3D printing. In addition to these, beginners need CAD skills to master 3D printing.

In addition to these, beginners need CAD skills to master 3D printing.

CAD software is user-friendly, but it still takes time to learn its many nuances. While there are online resources and tutorials available, the best way to learn CAD is by using it every day.

There are usually a few different ways to design something, so don’t be afraid to experiment until you understand how your program works.

While CAD programs have user-friendly interfaces, 3D printers are far less intuitive. For instance, machines like MakerBot, FlashForge, and Anycubic may look simple.

However, they have complex inner workings that aren’t always easy to troubleshoot.

Learning basic mechanical engineering skills will help you diagnose problems with your printer and use it more effectively.

For more information on 3D printing, I recommend reading Getting Started with 3D Printing: A Hands-on Guide to the Hardware, Software, and Services That Make the 3D Printing Ecosystem (available on Amazon. com).

com).

As the title suggests, the book gives an overview of the nuances of 3D printing, the knowledge, skills, and technology required, making it a worthwhile starting point for any beginner.

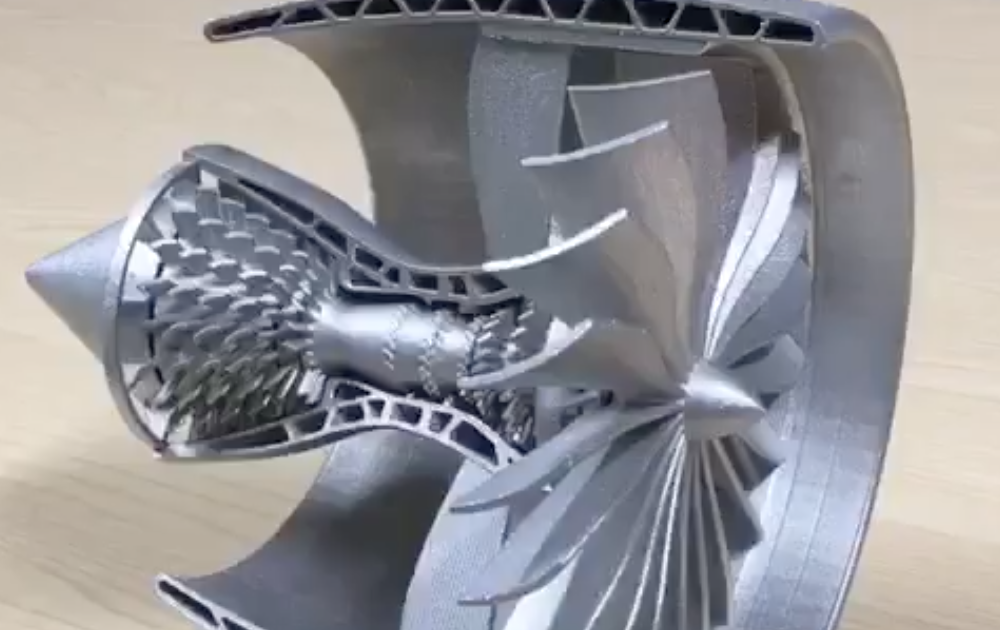

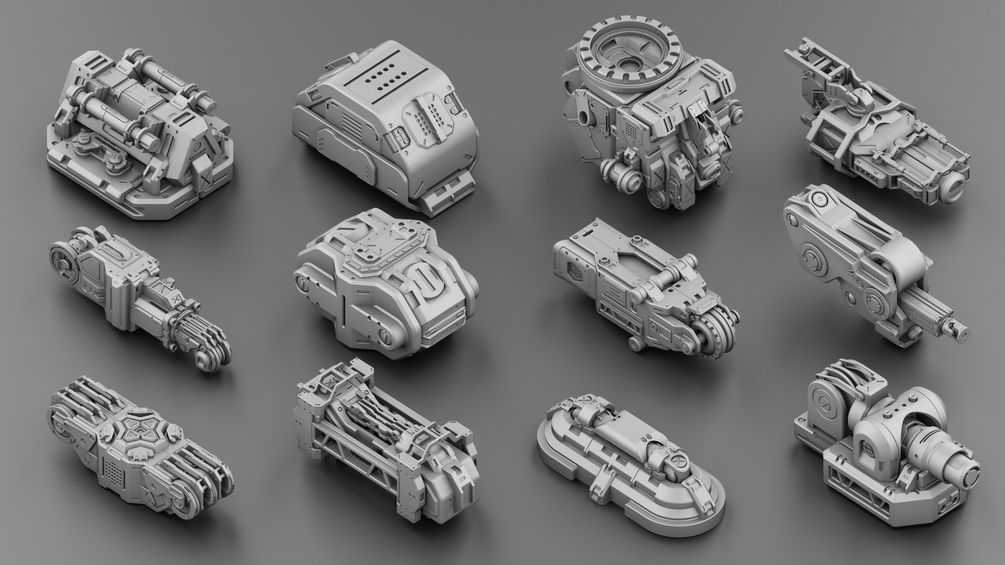

5. What 3D Printers Can Make

3D printers have been used to create just about anything, from jewelry and firearms to medical devices. They can even print food, like chocolate and marshmallows.

That being said, there are still some legal restrictions on what can be printed with these technologies. For instance, you can’t print some types of weapons, explosive devices, or patented substances or objects. Doing so could land you in trouble with law enforcement!

6. The Benefits of 3D Printing

3D printers have many practical applications, such as testing new products and making repairs on machinery.

They’re also a boon for medical professionals who can create custom prosthetics and better training models for surgeons.

Besides saving lives, they also save money by allowing designers to test things like shoe soles and aerodynamic helmets before making a large investment.

7. The Limitations of 3D Printing

The hype around 3D printing has made it seem like a miracle product that will revolutionize manufacturing and change our lives as we know it. While there is no doubt that 3D printing will eventually be used in countless ways, there are certain limitations to consider before you put one on your wishlist:

- Things take longer than you’d think. While a CAD file may look simple on the screen, it takes time to “slice” into thin layers for printing. As a result, objects that take only 30 minutes to print on FDM printers can sometimes take hours or even days when using more advanced techniques like DLP printing.

- Materials are pricier than they seem. There are many different types of plastics available for purchase, each with unique properties. If you don’t have a top-of-the-line brand printer, these plastics can be quite expensive.

- The print volume is limited. Some FDM printers can print items as large as a basketball, but most are much smaller for convenience.

It’s not always possible to scan an object and then print it perfectly scaled up.

It’s not always possible to scan an object and then print it perfectly scaled up.

- Downtime leads to lost income. Suppose your 3D printer fails during working hours. In that case, it may mean you lose money during a scheduled break or an important presentation.

- There are still many unknowns regarding 3D printing. With new technologies and materials being developed all the time, there may be hidden costs associated with maintenance or repairs of your printer. Because these printers are so complex, it’s not always easy to pinpoint what needs to be fixed when it breaks down.

Final Thoughts

For many, 3D printing is a challenging task to take on successfully from beginning to end. An artist’s creativity must be accompanied by math and engineering skills to accomplish a project. But with proper planning and an understanding of what your limitations are, 3D printing is a great technology to try.

Are 3D Printers Easy or Hard To Use? Learning How to Use Them – 3D Printerly

A key question with 3D printing is, just how hard or easy is it to print something in 3D? Do you need a ton of experience to get started? I decided to put together a quick article to try and help answer this important question.

With the right information, 3D printing is a very simple process. 3D printer manufacturers realize that ease of set-up is a big factor when it comes to 3D printing beginners, so most have specifically made it easy to function from start to finish. Set up can take minutes.

This does sound extremely easy, but for beginners there can be a few barriers that you have to overcome to get a smooth printing process. I will explain these and hopefully lessen your worries about 3D printing.

Are 3D Printers Hard to Use & Learn?

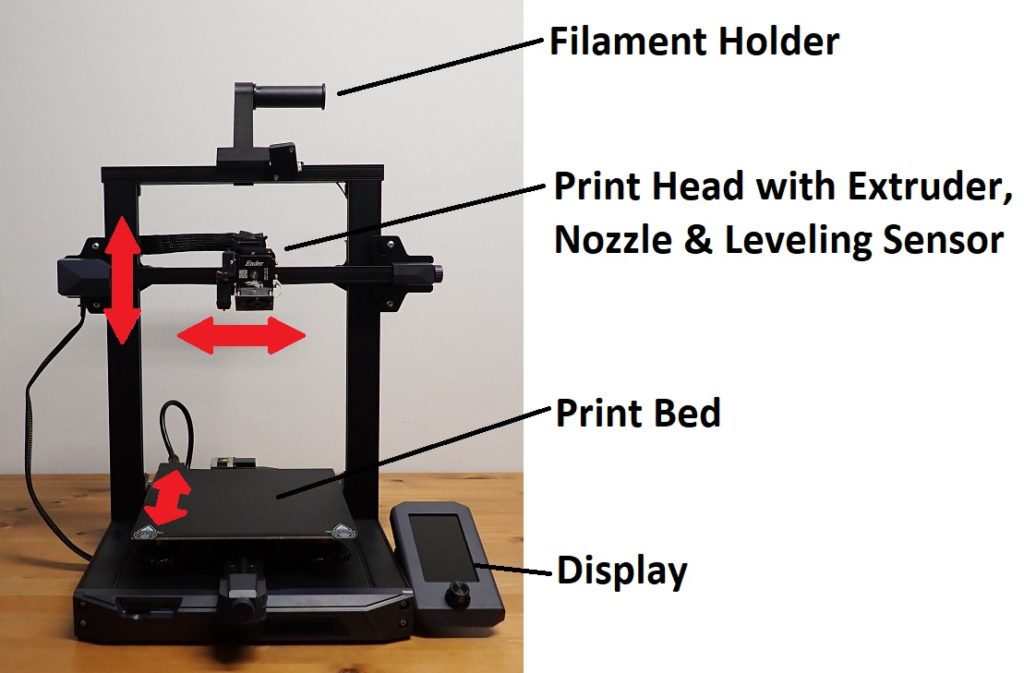

3D printers are not hard to use with a good, reputable brand of 3D printer since they are pre-assembled and have many useful instructions to follow to get them up and running. Slicers such as Cura have default profiles that allow you to 3D print models without much input from users. 3D printers are getting easy to use.

In the past, there was a lot of tinkering and user input that was necessary to get 3D printers to provide a somewhat accurate model from the build plate, but nowadays, even teenagers and kids can handle a 3D printer.

The assembly process is no different than a decent DIY project, only requiring you to put the frame together, along with parts such as the hotend, screen, spool holder, most of which are pre-assembled.

Some 3D printers come completely assembled and calibrated at the factory so you don’t actually need to do much, other than plugging it in and printing from the supplied USB stick.

Nowadays, there are plenty of YouTube videos and articles that you can find to help you with getting started with 3D printing, as well as troubleshooting help that makes things simpler.

Another thing that is making 3D printing easier is how manufacturers are stepping up their skills and making 3D printers easier to assemble and operate, with automatic features, touchscreens, good build surfaces that 3D printing materials stick to nicely, and much more.

Check out the video below for a complete beginners guide to 3D printing. It takes you from step 1 to having a fresh 3D print right off the build plate.

5 Steps to Easy 3D Printing

- Get a beginner-friendly 3D printer – this should have auto-features, easy navigation panels, be compatible with most software. Ideally a pre-assembled 3D printer

- Add your filament of choice – sometimes comes with your 3D printer, or bought separately. I’d recommend using PLA filament as this is the most common, and easy to use type.

- Pick your 3D printer slicing software (Cura is the most popular) and select your 3D printer to autofill settings – keep in mind some 3D printers have brand-specific software such as Makerbot.

- Choose a 3D CAD file of your liking to print – this is the actual design you want to print and the most common place would be Thingiverse.

- Start printing!

What’s the Hard Part About 3D Printing?

3D printing can be made very easy, or very hard depending on what your goals are, how technical you want to get and your experience with DIY.

As I’ve mentioned, setting up your 3D printer and starting the print process can be very easy, but once you start designing your own prints and make unique adjustments this is where things can get difficult.

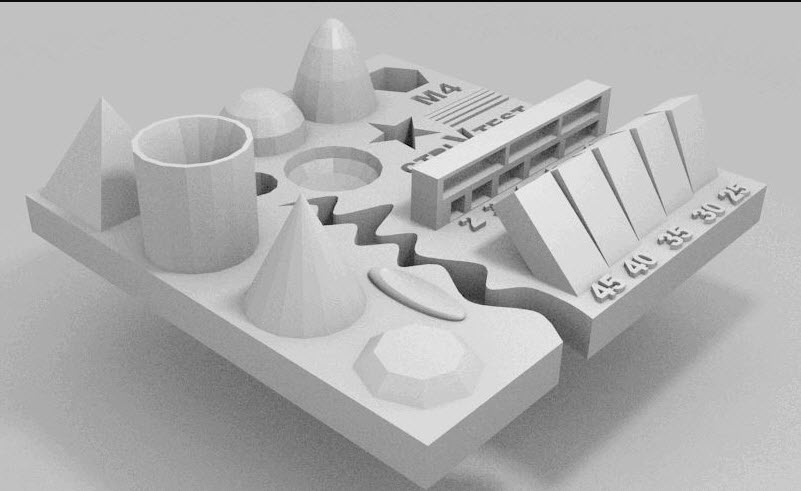

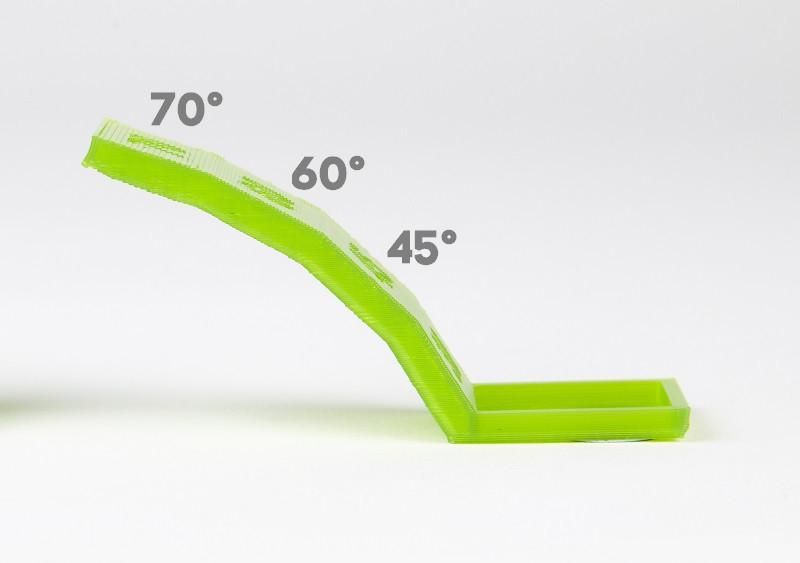

To get specific prints, it does take a unique understanding of how designs must be put together.

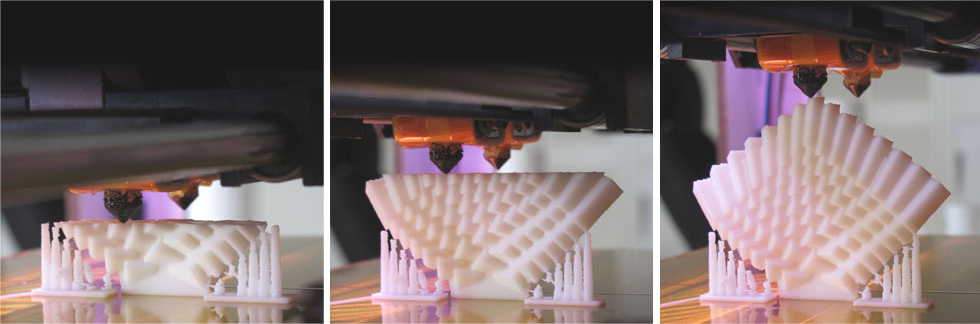

Designing prints can be a complicated process because you have to design your print in a way that it’s supported throughout the print, or it just won’t hold up.

Once you have that knowledge, it should be much easier to get designing and many programs have guides which tell you if your design is well-supported.

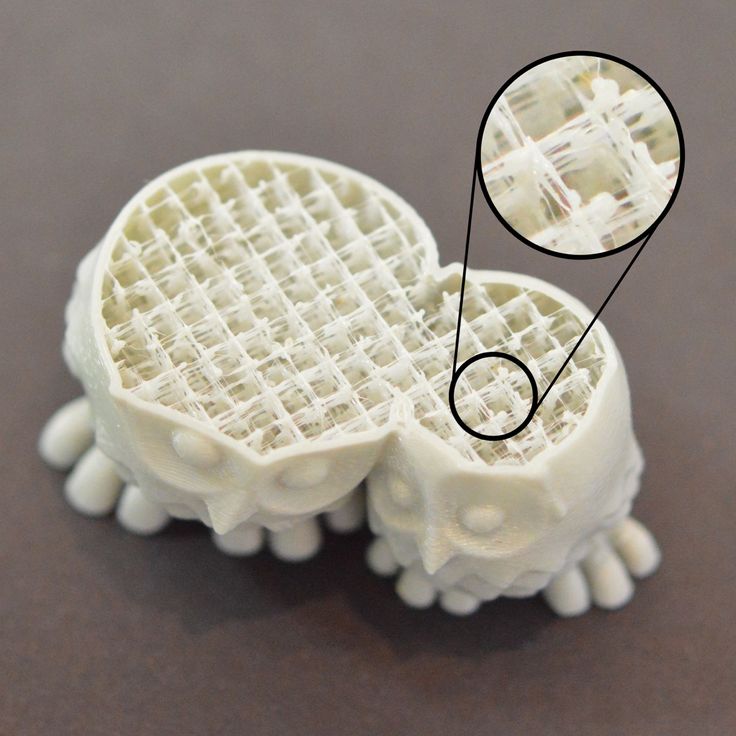

Having a high enough infill setting that your print won’t fall apart in the middle of the print is another important factor, so be aware of these things.

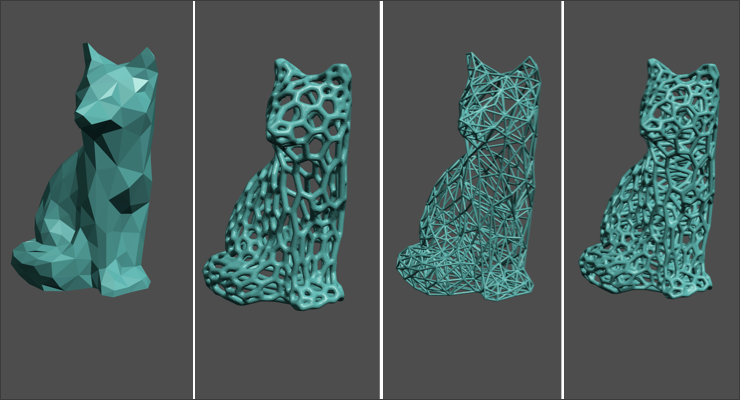

Luckily there are Computer-Aided Design (CAD) software out there that caters to different levels of expertise.

This ranges from simply putting shapes together in a program, to putting together small complex shapes to do anything from create a favorite action figure, to replacing a spare part on an appliance.

You can avoid this by taking a shortcut by just using designs from people who already have designs which are proven to work.

Thingiverse is a collective source of 3D print designs (STL files) which is available to everyone. A great thing you can do is look at a design from someone else and make adjustments in your own unique way, if you have the experience.

Like most things, with practice 3D printing will become very easy to do. There are things you can do which do get more complex, but the main process isn’t very hard to get started.

What If I Run Into Some Issues?

The main reason people run into issues is because they’ve jumped into things without doing research. If you bought a 3D printer kit from someone’s recommendation, a lot of the time they can be difficult to put together.

If you bought a 3D printer kit from someone’s recommendation, a lot of the time they can be difficult to put together.

They may also not have features which really help out beginners such as auto-levelling the nozzle to the print bed to ensure precise printing, or have compatibility with beginner-friendly software. This is why it’s important to know the basic stuff before you jump into 3D printing.

There are many troubleshooting issues that people have when it comes to 3D printing, as people get further into the field. This can range from the quality of your filament where it can break, filament material not sticking to the print bed, first layers being messy, prints leaning etc.

If you do run into some issues, the 3D printing community is an extremely helpful one and many questions you have, most likely have already been answered on the many forums that are out there.

In most cases, putting together a 3D printer isn’t too hard if necessary. An example of a simple 3D printer is the Creality3D CR-10, which comes in three parts and takes only 10 minutes to put together.

Once your 3D printer is put together, most settings can be autofilled when selecting your specific 3D printer within your software, so this is a pretty simple step.

After sorting out issues a few times, you should become confident in preventing those issues, and being able to quickly solve them in the future.

Final Thought

3D printers are being used in education at many levels, so if children can do it, I’m pretty sure you can too! There is some technical know-how but once things are up and running you should be printing away.

Mistakes will be made from time to time, but they are all learning experiences. Many times, it takes a few setting adjustments and prints should come out pretty smooth.

There are many levels of knowledge that you’ll need to get to a good level of 3D printing, but this mostly comes with practical experience, and just generally learning about the field. The first few times may seem difficult, but it should get easier as time goes on.

As time goes on, I can only imagine that 3D printer manufacturers and software developers will keep on aiming to make things simpler.

This along with the development in technology and research leads me to think that it will not only become more cost-efficient, but easier to create useful and complex designs.

13 notes about 3D printing, after 3 years of owning a 3D printer / Habr

This article will be, first of all, of interest both to those who have directly dealt with 3D printing, that is, who owns a 3D printer, but also to those who are just about to join the ranks of 3D printers and are thinking about buying their own printer.

In the framework of this article, I want to present my observations, as a direct owner of a 3D printer, for more than 3 years.

Despite the fact that 3D printers have been known for a long time and, in my memory, have become widely used, judging by the information on various resources, starting around 2010 (I may be wrong, these are my subjective observations), for a long time I ignored this area, it’s hard to say why…

Probably thought it was some kind of "childish pampering", another hype topic for which there is simply not enough time. ..

..

The turning point happened when one of the wheels on my travel suitcase wore out. You know, a big plastic suitcase, with four spinning wheels on the bottom. Unfortunately, it is a “rather disposable thing”, due to the lack of bearings on the wheels, which is why the wear of the friction point of the axle and wheel allows the suitcase to last no more than one or two seasons. nine0003

And it’s like “lightning flashed in the middle of the day: 3D printer!” It is with his help that I can fix this problem! Looking ahead, I’ll say that I didn’t succeed in fixing the suitcase in this way, so I had to use a different approach ...

As a result, I “upped” it - installing wheels from unnecessary roller skates. Thanks to this “up”, the suitcase has become a real all-terrain vehicle and, even being very loaded, it rides easily - pushed forward even with “one finger”. And even in the snow, 5-6 cm thick. A tank, not a suitcase turned out! By the way - I took spinning wheeled "units" in Leroy. Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

But this thought itself became a kind of trigger that allowed me to finally join the world of printers and buy my first 3D printer.

Like many, before buying it, I studied various forums and sites for a long time, delving into all the subtleties. And for some reason, I immediately liked the type of printer called the delta printer. Probably because during operation it looks like some kind of "alien device".

If at your leisure you like to sit “looking into the carpet”, then with the advent of such a printer you will have a much more interesting activity, even hypnotizing, one might say :-))

And this, in fact, is my delta (if anyone is interested), which went through, let's say, the "ultimate up": all the electronics are placed upstairs, on a self-made welded frame, covered with polyethylene and a magnetic door is made. The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

Well, yes, I won’t argue for a long time, let’s start reviewing the main facts that I have accumulated as a result of owning this car ... The facts are purely subjective and may differ from your vision. In any case, I will be glad to comments, clarifications, etc. nine0003

▍ NOTE 1. Delta is good, but...

Here I should give a number of my observations regarding the delta printer:

- It contains a completely finished frame of the future box, which makes it easy to form a heat chamber. I understand that many printers are made in the form factor of a “certain box” (but this point cannot be ignored), which greatly facilitates the process of wrapping this box with heat-insulating material.

In my case, as such a material, I used a plastic film. nine0032

In my case, as such a material, I used a plastic film. nine0032 - Already thanks to its design, delta allows you to work at much higher speeds than XY printers. By the way, it is on the delta principle that many modern high-speed industrial robots are built to sort various parts directly on the conveyor belt:

However, this plus does not allow to fully realize the occurrence of parasitic vibrations, even despite their suppressors:

Thus, accurate printing is possible, only at speeds (at least that was the case for me), no more than 60 mm per second. A complex procedure for aligning the movement of the head parallel to the table, which is why, for many, the so-called "lens" appears. People struggle with it with varying degrees of success, but I have not encountered this on my printer and for me, therefore, the “lens” has never been a problem. At the same point, it is worth noting the calibration of the table, which was initially absent on the first deltas, and I had to use an external third-party solution from one American do-it-yourselfer called EZBED. This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

▍ NOTE 2. "Size doesn't matter..." :-)

When I got the printer, I was impressed by the possibility of huge printouts, a la the handguards of some futuristic rifles, huge body parts, etc.

However, if you try to analyze the results of your many years of practice, it turns out that in most cases, rather small objects were printed that easily fit in the palm of your hand, a maximum of two palms. Despite such a seemingly small size, the printing of these details took a significant amount of time. Of course, this very much depends on which nozzle you print with. But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size. nine0003

But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size. nine0003

Therefore, to be honest, the need for a printer that allows you to print "Venus de Milo in life size" is not obvious.

Of course, you can object to me that “I’m going to buy a printer, I’ll get used to it a little and I’ll get started!!!”

One simple point must be taken into account here: there are no universal things. And in order to understand how much 3D printing in general and your printer, in particular, you will need to solve your problems, and how much it will be able to solve such problems, you just need to first try the 3D printing method personally and then a lot will become clear to you . nine0003

Therefore, for a beginner, I recommend taking a small printer that allows you to print extremely small items that fit in the palm of two. With such a device, you will definitely never lose, as it will always be needed. In addition, with its help you will be able to get used to the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

In addition, with its help you will be able to get used to the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

▍ NOTE 3. "What type of printer to get." nine0027

Based on the foregoing, I do not recommend taking a delta printer and this can be said right away.

Not because it is bad, in fact, it prints quite accurately, its main problem (in my opinion) is the inability to print rectangular flat, fairly large case components, as well as the inability to fully realize high-speed work, since the quality drops critically. Here it turns out to be a rather offensive situation - the printer can work quickly, but this cannot be done, since the quality will be “nothing”. nine0003

And then what kind to take? Depending on the budget and capabilities, I recommend taking any cube printer, for example, the same Core XY (the head moves, and the table goes down as the model “grows”, from top to bottom):

Image source: thingiverse. com

com

Such a printer allows you to easily print fairly large flat parts of cases, has good speed and accuracy. In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling. nine0003

However, the advantages of this printer will not be fully revealed if it has a direct extruder. On the one hand, it will allow printing with rubber-like materials, on the other -

large inertia and head weight. And these are parasitic vibrations, wear of the fur. parts, etc. (like everything in life, “we treat one thing and cripple another” :-))

At the initial stages, this may not be necessary, but in the future it may be necessary to print, for example, tires for your homemade car. And with this, the Bowden extruder has obvious problems. Although, in fairness, printing with such a rubber-like material is far from a daily need. However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so. nine0003

However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so. nine0003

By the way, there are printers of a cheaper type, the so-called "drygostol", printing by moving the table and head:

They are inexpensive, moderately accurate, but they require a sufficiently high-quality gluing of the printed model to the table, because the table moves, and the model can come off when the table is jerked sharply. When printing large models, this can be a problem.

▍ NOTE 4. What to print with?

It's only a matter of taste and purpose. That is, if your printout will only stand on a shelf and should differ in some kind of aesthetic appearance, these are some requirements, if the printout is an engineering part that will be operated under conditions of increased mechanical load, these are different requirements. That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties. nine0003

That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties. nine0003

For engineering parts, for example, I only use ABS. It combines high hardness, strength and low price. Although I understand that now this last statement will cause a storm of comments in the style of “no! - there is even stronger, even better, the same PETG, etc. ":-)

Just here I wanted to say that thanks to the low price and the practical experiments that I conducted with ABS plastic, I realized that it is completely meets all my requirements. nine0003

However, the fact that ABS plastic releases carcinogenic substances when heated is quite annoying and forces you to take measures to prevent poisoning. For this, my printer prints completely closed and on an open balcony. After printing, the printer chamber opens, and it remains open in this form until it is completely ventilated and cools down.

▍ NOTE 5. "ABS is difficult to type on, it flakes, peels off the table, etc.

.."

.." With a properly configured printer (in my case, at a print temperature of 205 degrees, a thermal chamber and a desktop temperature of 100 degrees), the use of auxiliary techniques, for example, among which, one can name the so-called ABS juice (which is ABS- plastic dissolved in acetone), you can create wear-resistant and durable things, without any hypothetical problems. nine0003

For example, my printer has been printing for many hours at temperatures well below freezing. And this happened more than once, not twice, not three! And the print quality was excellent:

12-hour ABS printing at -4 C

▍ NOTE 6. Acetone for post-processing and ABS juicing

At one time, I wrote a fairly detailed article on this topic and I will try to give the main excerpts from it. The essence of the issue here is as follows: due to the fact that different GOSTs are used for the production of acetone, acetone differs in quality. Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))). nine0003

Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))). nine0003

In contrast to it, there is a much higher quality acetone, which, however, is not found at all in any household stores, even large chain stores, such as Auchan or Leroy Merlin.

This type of acetone is found exclusively in shops that sell varnishes and paints for automotive work, i.e. these are highly specialized shops for car workshops:

Acetone, which can be purchased there, is of excellent quality, smells almost like alcohol, quickly disappears,

:-) - this is a joke, of course, don't even try it.

However, its main advantage, compared to household type acetone, is that it perfectly dissolves ABS plastic and does not allow it to precipitate. For me personally, it was a very surprising observation when the same ABS plastic was perfectly dissolved with acetone from an auto shop, and completely precipitated when I tried to use household acetone (I just ran out of good acetone, and I had to use "what is "). nine0003

Therefore, if you want your results to always be excellent, then here is the right acetone. It should be labeled "for professional use":

▍ NOTE 7. What about ABS juice?

"ABS juice" is what printers call a mixture of acetone and pieces of ABS plastic dissolved in it. This mixture is smeared on the surface of the desktop before printing and allowed to dry. Thanks to this spread, the model easily sticks to the desktop and does not peel off during the printing process. After printing is completed and the platen has cooled down, the model can be easily separated. nine0003

nine0003

All that needs to be said here is that, after trying different approaches over time, I settled on using flexible metal spatulas, also called "Japanese type spatulas":

According to the results of many tests, this method of spreading turned out to be one of the most convenient options, such spatulas can be cleaned very quickly and easily after work. In other words, highly recommended!

▍ NOTE 8. "Yes, nothing sensible can be done on it, I indulged a little and decided to sell it - you can't use it for anything good anyway"

I absolutely disagree with the statement above, which is periodically heard from newcomers to 3D printing. You can even say more: at the moment I can’t even imagine how I used to live without a 3D printer! Since it is he who makes it possible for any do-it-yourselfer to significantly expand their capabilities and make piece products, almost of factory quality! Of course, for this, appropriate hands must be applied to the 3D printer, but that’s another question… and take on things that I would never have thought to take on before! nine0003

For example, among my homemade products, the following can be listed:

- Heated sole for boots, which is a hose integrated into the insole (and filled with household silicone from a household store), through which water flows, heated with a catalytic type hand warmer.

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress. nine0032

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress. nine0032

- Centrifugal water pump mounted on the shaft of an internal combustion engine that drives a high pressure wearable air compressor with a pressure of 500 bar. The pump pumps coolant through the casing of the high pressure pump, or rather its second stage. Despite the fact that the pump is 3D printed and runs at over 6000 rpm, nothing “fell apart, fell apart, didn’t break.” As you can see in the photo, the pump is installed instead of the “starter”, that is, the armstarter. The compressor scheme as a whole is as follows: 2 engines. Connected by clutch. One is heavy duty. The second is modified and turned into a high pressure compressor:

Yes, before assembling this, I also did not believe that this was possible. Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

- I printed a number of Rank-Hilsch test tubes, the essence of which I have described in detail in this article.

- Printed mass of parts, more than 100 pieces, to create 10 web-controlled robots. There was also a detailed article about this here.

Well, and a bunch of all sorts of useful and not very crafts. As you can see from my crafts above, I have a special passion for creating some useful things, a utilitarian direction. That is, so that the printout is useful, and does not belong to the type “yyy breathe, Mikola, what am I doing here” :-), and then put it on the shelf and that's it. Although, engineers are also not alien to beauties, and this will be my next fact below. nine0003

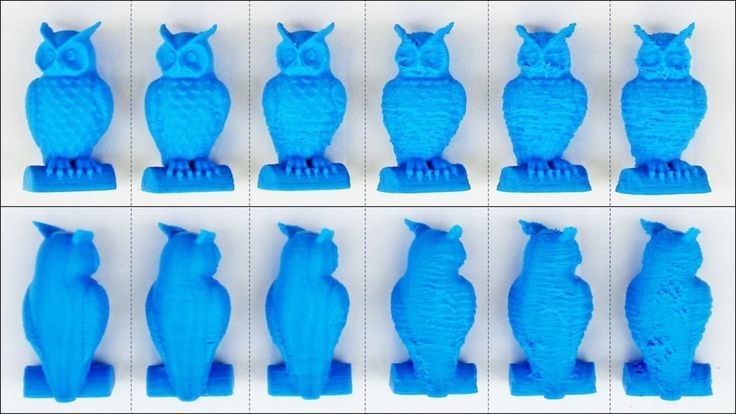

▍ NOTE 9 Proper placement of the model when printing is half the battle

It would seem an obvious fact, but many underestimate it. Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

This allows the layers in the printout to run at an angle of approximately 45-50 degrees to the model. The result of this is that the printed model is almost completely invisible layers and the model looks like it has been post-processed, but at the same time retains a deep matte color, which, to my personal taste, is more like a marble than a glossy result of processing in an acetone bath : nine0003

An additional advantage of this method is that the layers going at an angle of 45-50 ° to the model give it additional strength. This is especially true for printing statues, which contain many thin elements that are easily chipped when the statue is accidentally dropped from a table or shelf (learned from bitter experience, this happened to me many times, and ruined some fairly decent prints).

That is, the layers going across the model, if the model has a large length in height, does not allow it to maintain sufficient strength. For better understanding, I tried to illustrate this point in the figures below:

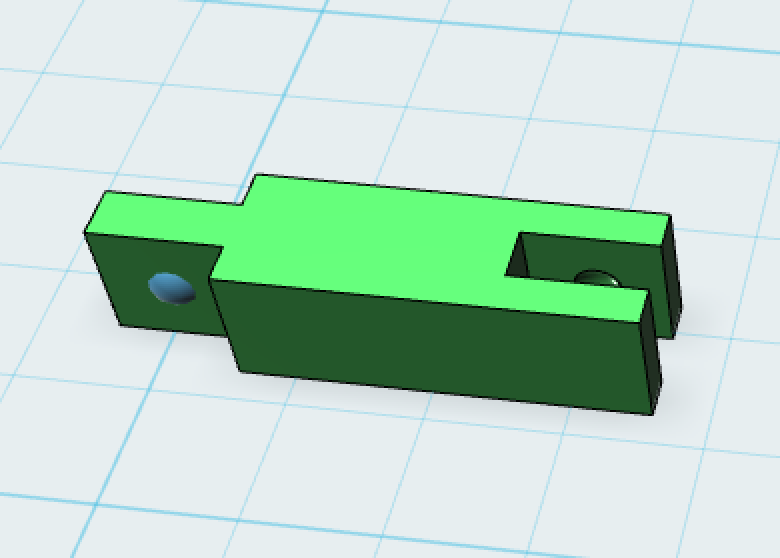

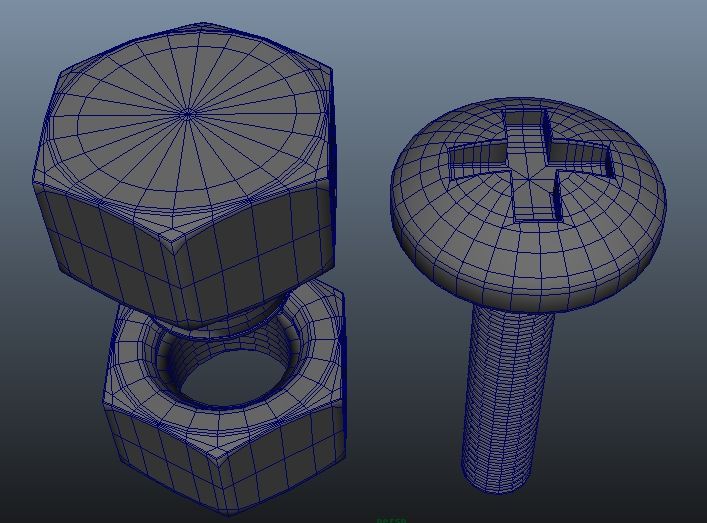

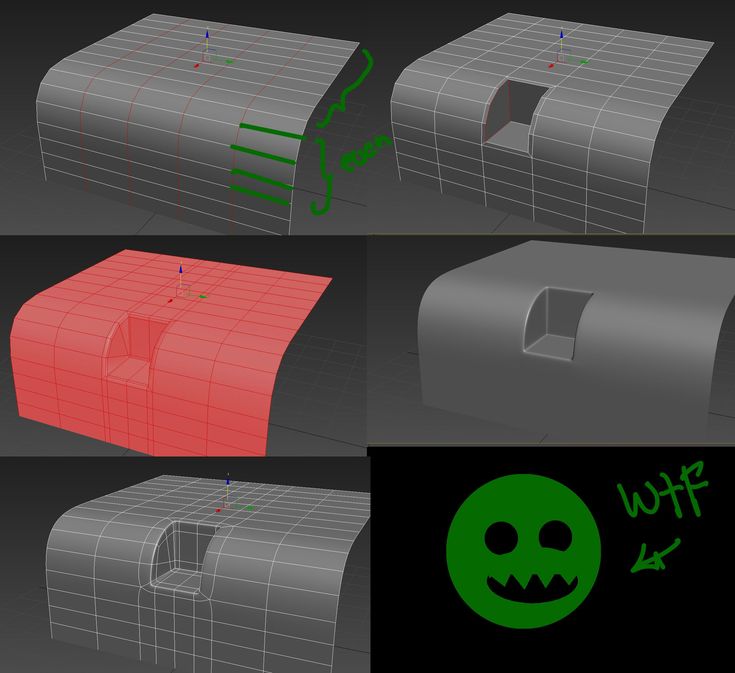

▍ NOTE 10. Bleeding must be taken into account when printing, especially if the model is composed of separate parts and must be assembled by joining these parts to each other, entering into each other, etc.

I tried to illustrate this point in the figures below. The implication here is that if you're printing a composite model, you need to correct for the amount of bleed on the plastic (I'm not sure what it's called, but at least I tried to convey what I mean). If this is not taken into account, then the model will not fit. nine0003

For example, in my case this correction is 0.2 mm per diameter - if I want the model to fit more tightly; if I need a free joint, without excessive density, then 0.3 mm per diameter:

That is, suppose that the blue part has a size of 10x10mm. So it must be modeled in a CAD program as 9.8x9.8 mm (if we want it to sit tight) or 9.7x9.7 mm (to sit freely). Well, or expand the hole in the green part, and leave the blue one as it is. nine0005 This is often a problem when you download a prefabricated model from the Internet - but it is not going to, even if you crack! And because no amendments have been made…

So it must be modeled in a CAD program as 9.8x9.8 mm (if we want it to sit tight) or 9.7x9.7 mm (to sit freely). Well, or expand the hole in the green part, and leave the blue one as it is. nine0005 This is often a problem when you download a prefabricated model from the Internet - but it is not going to, even if you crack! And because no amendments have been made…

For your particular case, the amendments may be different.

▍ NOTE 11. What if...

In fact, this note complements note number 8. Using a 3D printer allows you to create metal parts using a printed 3D model. For this, the casting method is used according to the lost wax or burnt model. In our case, we will deal mainly with metal casting on a burnt model. nine0003

Briefly, it looks like this: printing a 3D model (using PLA plastic) → pouring it with plaster → burning PLA plastic, simultaneously with burning the mold, in a conventional stove oven → pouring the resulting mold with molten metal (melted in a conventional microwave) .

Image source: 3dtopo.com

I told about a simple method of melting metals in a home microwave oven here.

There was even a good article about casting on Habré. nine0003

▍ NOTE 12. Durability?

Despite the fact that ABS plastic is called exposed to ultraviolet radiation and, accordingly, burns out, losing its strength in the sun, in my practice, even printouts that are constantly exposed to the sun have not lost their strength and color at all, continuing to be successfully used and Currently.

It should also be added here that printouts are constantly exposed not only to the rays of the sun, but also work continuously in damp conditions! nine0003

As such printouts, I can give an example of winglets for technical cranes, which I printed out, but, unfortunately, did not photograph this process; as well as fasteners on shoes that I use “both in the snow, and in the heat and in the pouring rain, and in general are always with me”:

▍ NOTE 13.

And what about the thread?

And what about the thread? Periodically, there is a need to print parts containing a particular thread. Modeling such products requires a good understanding of what a thread is in general, as well as what corrections need to be made in your particular case, which I have already described above. nine0003

But since I've owned a metal lathe for a long time, I'm not at all happy with the 3D printed carving that looks like "something very carving-like".

I am satisfied with an exceptionally perfect carving. Therefore, I keep in stock a large set of various taps and dies, with which I cut all my threads in plastic printouts:

I posted a photo of dies and taps not to brag, but to make the reader understand that serious carving requires a serious approach (unfortunately). And considerable costs for all this thread-cutting iron ...

To create your own threads (both threaded channels and threaded pins), I recommend the following reference materials: for holes, for pins.

Well, that's where I want to end my story and note that he does not claim to be exceptionally accurate and exhaustive. Nevertheless, I tried to state a number of my observations. It will be interesting to read yours, in the comments!

3D printer print size - 1.2 x 1.5 x 1.8 m. by Sprint 3D. nine0001

Rapid prototyping of large-scale art products

In the minds of many contemporaries, 3D printing is a technology capable of creating extremely small objects - spare parts, souvenirs, various kinds of models, and so on. Moreover, many believe that it takes many hours. In the meantime, a whole car has already been created through 3D printing. And it didn't take weeks. Let's consider what print size 3 D printer is possible today and what speed 3 D printing is currently being achieved. But first, a few words about prototyping.

Rapid prototyping of 3D models is a process of rapid creation of mock-ups of models (prototypes), which will later be used to improve and finalize design solutions. In some cases, such prototypes can also be used as finished products.

In some cases, such prototypes can also be used as finished products.

Satellite 3D printer 500x500x800 cm

Modern 3D printer capabilities

In recent years, 3D printing equipment has made a huge leap forward. One of the brightest representatives of the new generation of printers for rapid prototyping of dimensional art products is the 3D printers that we use in our work.

Main features of the equipment:

- Working area – up to 1.2x1.5x1.8 m.

- Speed 3 Print D Z-Axis (height) - 35 cm/h.

How do you achieve high print speeds and the ability to produce large items? First of all, due to the use of special photopolymer gel compositions with a high degree of viscosity, as well as due to the rationalization of the placement of supporting structures. The so-called GDP-technology (Gel Dispensed Printing) is used. It is based on the use of liquid light-sensitive compounds that quickly harden under the influence of ultraviolet lamps. Those are located directly above the print heads and act directly on the material. This system ensures fast curing. nine0003

It is based on the use of liquid light-sensitive compounds that quickly harden under the influence of ultraviolet lamps. Those are located directly above the print heads and act directly on the material. This system ensures fast curing. nine0003

Due to the fact that the GDP technology cures faster than other technologies, there is no need to use supports for horizontal surfaces. Obviously this saves time. And at the same time, the materials of production.

Also note that 3D printer models and some analogues use two printheads that work independently of each other. This allows you to create two objects at the same time in one workspace or separate components of one large product. Accordingly, print size 3 D of printer in this case, when gluing, it increases at least twice and can exceed 3 meters.

Large-scale 3D printing: how much more difficult it is than small-sized

If in older models of printers there could be cases when the material clogged the nozzle and the work done simply went down the drain, then modern equipment is devoid of such shortcomings. You don’t have to worry that something will go wrong in the many hours of printing and you will have to redo everything from the beginning, wasting time and a lot of resources. nine0003

You don’t have to worry that something will go wrong in the many hours of printing and you will have to redo everything from the beginning, wasting time and a lot of resources. nine0003

Separately, we note the simplicity of the post-processing process. After hardening, the gel lends itself perfectly to a wide variety of processing. It is perfectly painted and varnished, which opens up the widest possibilities for creating a wide variety of dimensional objects: stands, product models, models of equipment and much more. Everything is fast, convenient and at the same time quite inexpensive. The printing process itself and finished products meet the requirements of environmental friendliness and safety of use. During production, no harmful and dangerous substances are emitted, and the printed products fully comply with modern environmental standards and are hypoallergenic. This is a particularly important factor at the present time. nine0003

How does 3D prototyping work? A physical structure is built according to a previously prepared mathematical model.

The advantages of prototyping are obvious:

1. Visibility of the whole process;

2. Minimization of the time required for preparation of production;

3. Reduce engineering and design costs. nine0216

The first step in prototyping is mathematical modeling, which creates a mathematical model in STL format. After that, prototypes are finalized to create the necessary surface textures. Prototyping also includes the development of technologies, the production of specific models and their finishing. Everything is almost identical to small-sized printing, although products are made with many times larger sizes.

Advantages of rapid prototyping in large-scale printing:

- Accurate and fast verification of the conformity, function and form of the printed design.

- Extensive design flexibility and versatility with the ability to quickly transition between different stages of production.

- Increased speed 3 D printing and no waste of materials that are already used in large quantities.

Learn more