Miller 3d printing

Miller 3D Printing | 3d printing solutions for the construction industry

While 3D printing’s emergence in the construction industry is ongoing, some building aspects are poised for more growth than others. Specifically, concrete is making significant headway in the construction industry. In fact, the concrete 3D printing market is projected to be valued at $56.4 million, and growing from the amount of new, innovative projects that are being planned in construction.

3D printing concrete shows great potential, however it’s worth noting that the overall technology when it comes to the concrete material is still in its infancy. In fact, most 3D printers that process concrete are still being tested and tweaked, and they aren’t yet designed for general end-use applications. That being said, there are a few success stories for these projects, and there is potential to build everything from foundations to walls to individual cinder blocks to bridges in a faster, more affordable, and more environmentally-friendly manner as the technology continues to progress.

There is increasing pressure in the construction industry to meet tight schedules and budgets as architects are tasked to keep their designs competitive. As a result, construction companies are looking to introduce new innovations to support this sector. 3D printing in the construction industry offers a wide range of potential benefits to these robust applications including:

- Speed- 3D printers can construct a home or building in a matter of days, whereas conventional construction can take months for homes or even years to fully construct a commercial building. In fact, 3D printing for construction can save 60% in time and 80% in labor.

- Waste reduction- Worldwide construction waste currently totals more than 1 billion tons each year, which is expected to double by 2025. 3D printing won’t be able to solve construction waste problems entirely, but it can decrease the negative environmental impacts. Additive manufacturing works by laying material down in accordance to the designing parameters, so almost none of it is wasted.

It can also be paired with other waste-reducing processes and building methods. For example, prefabrication and lean construction work well with additive manufacturing to increase the potential of a zero-waste building.

It can also be paired with other waste-reducing processes and building methods. For example, prefabrication and lean construction work well with additive manufacturing to increase the potential of a zero-waste building. - Design freedom- Architects are able to create and build complex designs that would otherwise be unattainable, too expensive, or too labor-intensive to create through conventional construction methods. As a result, we are expecting to see a lot more innovation and creativity in the commercial construction space, especially with concrete designs. For example, Venice is now home to a 3D printed concrete bridge that was made out of a unique circular shape made out of disassembled and reused materials.

Reduce human error- According to OSHA, more than 5,000 workers are killed on the job each day. If 3D printing made construction more programmable and automated, worker injuries and fatalities would decrease.

Specific Additive Manufacturing Industry Solution

While 3D printing’s emergence in the construction industry is ongoing, some building aspects are poised for more growth than others. Specifically, concrete is making significant headway in the construction industry. In fact, the concrete 3D printing market is projected to be valued at $56.4 million, and growing from the amount of new, innovative projects that are being planned in construction.

Specifically, concrete is making significant headway in the construction industry. In fact, the concrete 3D printing market is projected to be valued at $56.4 million, and growing from the amount of new, innovative projects that are being planned in construction.

3D printing concrete shows great potential, however it’s worth noting that the overall technology when it comes to the concrete material is still in its infancy. In fact, most 3D printers that process concrete are still being tested and tweaked, and they aren’t yet designed for general end-use applications. That being said, there are a few success stories for these projects, and there is potential to build everything from foundations to walls to individual cinder blocks to bridges in a faster, more affordable, and more environmentally-friendly manner as the technology continues to progress.

3D Printer in Appleton - Dan Miller

Email yourself a 10% off coupon

Send

Coupon sent! Check your email

Proceed to checkout: €

Add more 3D models

Upload 3D model

get an instant quote

or

Find 3D models

files accepted: stl, obj, zip, step, stp, iges, igs, 3ds, wrl

files accepted: stl, obj, zip, step, stp, iges, igs, 3ds, wrl

Proceed to checkout: €

discount applied: was €

+ Upload more 3D models

Proceed to checkout: €

discount applied: was €

Appleton, WI 54915

3D printing €0. 76 /cm³

76 /cm³

CAD design €75.79 /hour

CNC €151.59 /hour

Ask Dan a question

Things I've Made

About me

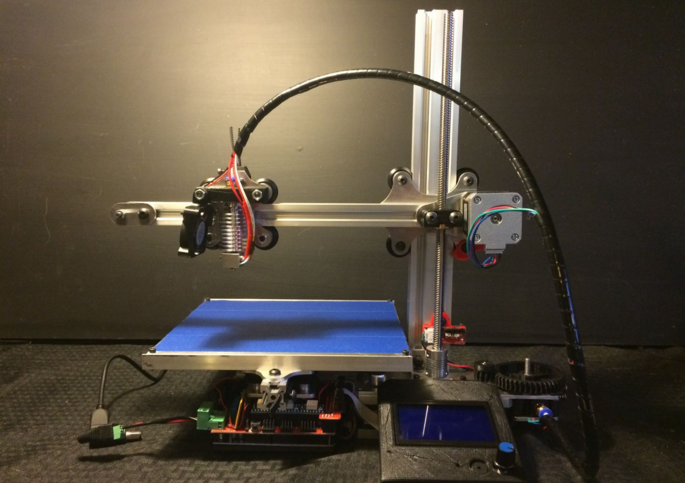

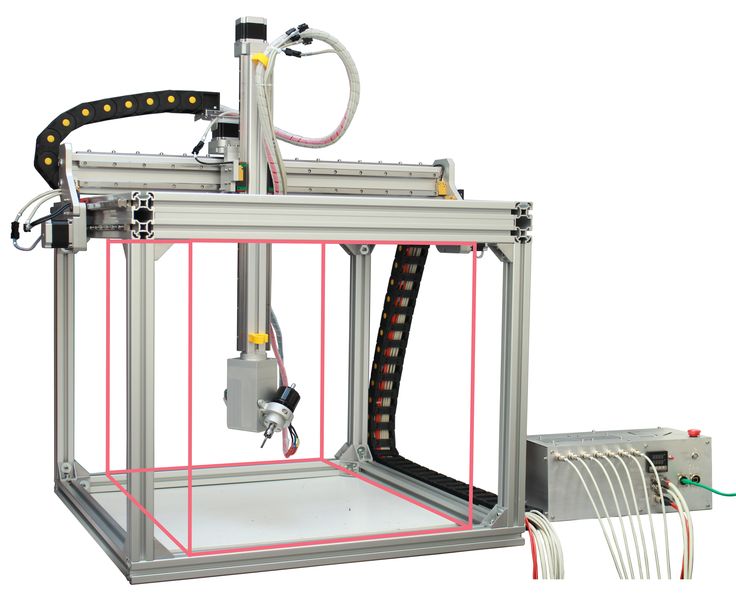

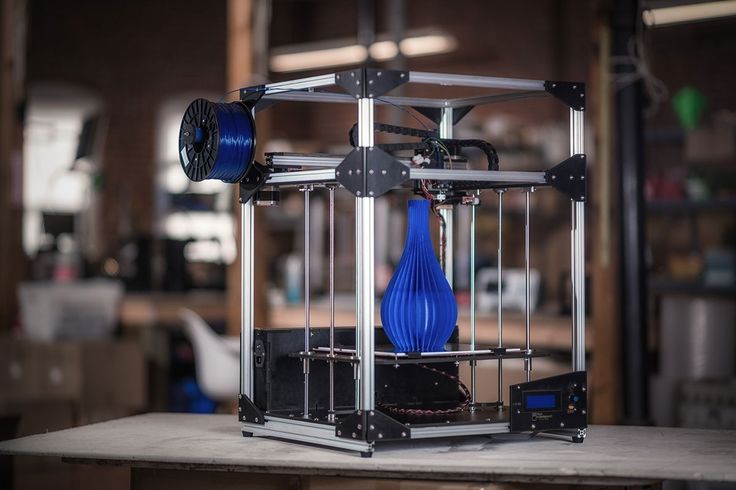

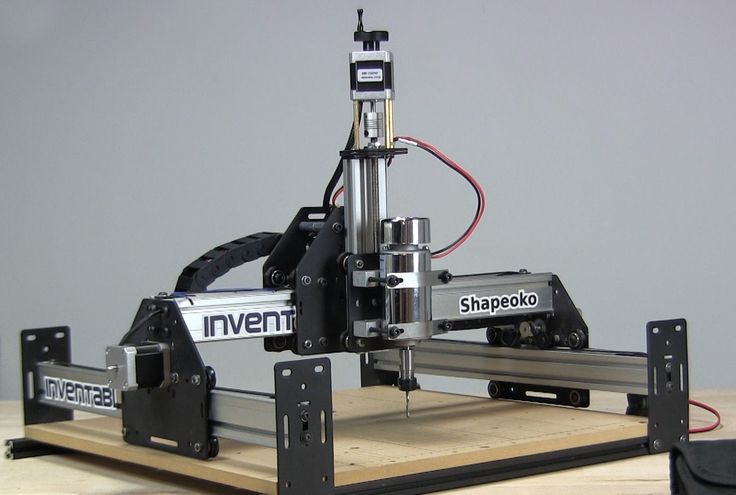

I run all the machines listed - Improved RepRap Prusa i3, CNC Machine, Small Wire Feed Welder, and basic wood working tools. I am a licensed Professional Mechanical Engineer that works full time, and manufactures during my free time. I am willing to take on complex projects. I will assess your project and will provide you with the best possible options considering your needs and my design and manufacturing capabilities. You can see some of my basic 3D Printing work on Thingiverse at: http://www.thingiverse.com/dacmill4/designs

I look forward to working with you!

My Services

Reprap Prusa I3

3D printer

Shoptask

CNC • €151.59 /hour

My Reviews

Seamus W.

Thorough, timely, and professional. Parts were great

Parts were great

5 out of 5

Erik R.

Outstanding! Dan was friendly, helpful, and great at communicating. He took the time to really figure out exactly what I was trying to accomplish and his knowledge of mechanical engineering offered valuable insight. Very impressed with his software design skills. Within the first hour he had created what would have taken me a week to make in the shop. Very reasonably priced, and the printing quality was fantastic! I would recommend Dan to anyone that wants 3D printing work done, especially if it is technically challenging. I plan on going through Dan for all of my 3D printing needs in the future.

5 out of 5

Jennifer G.

What a great experience! Needed a cookie cutter fast and he delivered the same day at a great price! Works perfect. Will recommend to anyone and everyone looking for a personalized cookie cutter! Oh the possibilities. ..

..

5 out of 5

Rebecca K.

None

5 out of 5

Nicholas M.

None

5 out of 5

Sara N.

Dan was very prompt when I contacted him, provided great service, very high quality product, and turned it around quicker than I ever could have imagined. I was extremely please with the entire experience!

5 out of 5

James L.

5 out of 5

Kevin E.

5 out of 5

Gone・Cults

Unfortunately, the job you are looking for has disappeared...

But don't panic!

Yes, this work is no more, it's sad... but you can always check the profile of the author matiasprocichiani who made this model, or even send him a direct message.

Otherwise, at Cults, we always have something to please your 3D printer. For example, look at these little hooligans:

For example, look at these little hooligans:

01

ARTICULATED CHRISTMAS DEER

2.97 €

02GOMERO Simpson

€1.99 -70% 0.60 €

Footlings

€2.78 -fifteen% 2.36€

AERODYNAMIC WIND TURBINE

22 € -fifty% 11 €

Hanging macrame planter 3

€4. 19

19

Cut-Man - PET bottle cutter with handle!

3.49 €

07Simple Christmas tree

Free

08Eiriss

€6.50 -25% 4.88 €

Gaboon viper-snake skull

Free

tenSacred Blade of Ludwig from Bloodborne (with scabbard)

15 €

elevenMini milk carton - handle cup

3.36 €

12Diego Luna as Cassian Andor

15. 38 €

38 €

"Cardboard" sheep!

Free

fourteenChibi Thor

5 €

fifteenRick the Thinker

Free

1678 Dome Zero Body Shell (Xmod & MiniZ)

Free

17Full 3D printed M142 Himars

9 €

eighteenYet Another Quick Change Toilet roll holder (fold-out)

1 €

19Cloud vases

1.28 €

twentyBiomimic pen holder 1

€6. -60% 2.50 €  26

26

What is the power of today's 3D printing

You are here

Home

The motto of modern 3D printing equipment is simpler, cheaper, better, faster. Especially for the 3Dtoday portal, Dmitry Miller, head of the REC consumables manufacturer and 3D printing studio, a resident of the Skolkovo Foundation, shared his opinion on how quality criteria are being transformed in the 3D printing industry today.

If a few years ago the use of 3D printing was affordable only for large companies with significant financial resources, today additive technologies have become widespread even in home use for personal needs.

Additive technologies are developing rapidly. The good news is that this growth is exponential. In fact, this means that every year developers in this area manage to achieve more than in previous years.

This has a significant impact on the range of applications for 3D printing and additive technologies in general. What is the effectiveness of modern 3D equipment?

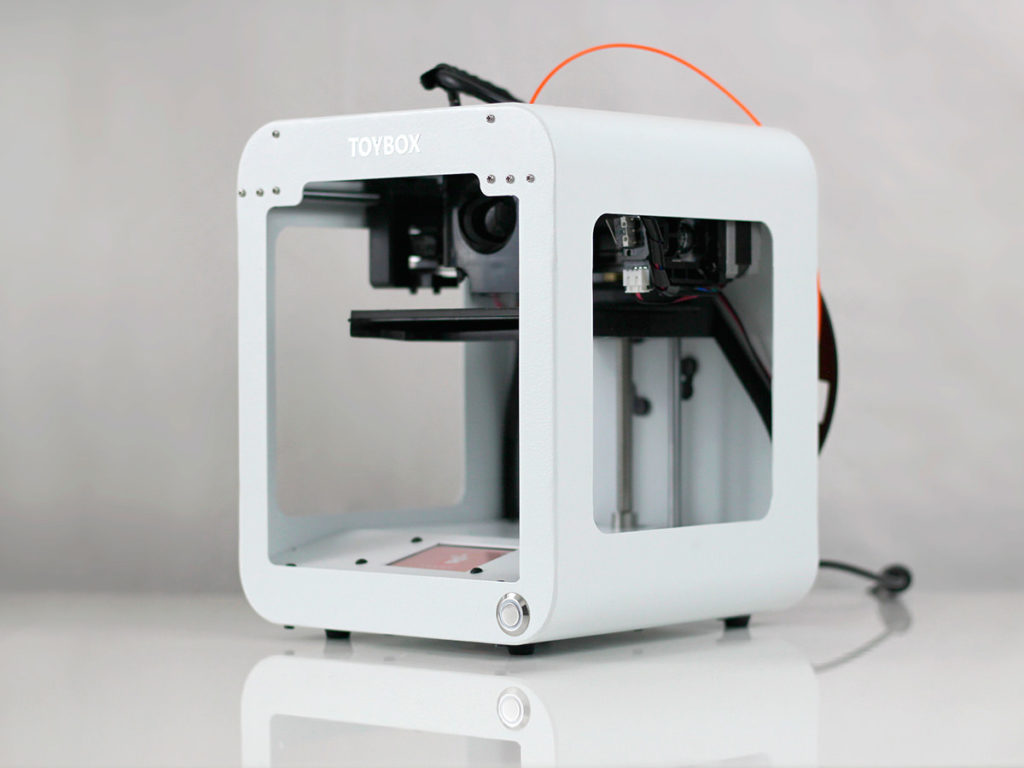

1. Simplicity

3D printing technology is really getting easier every year. If earlier, before using the equipment, it required a certain technical adjustment and proper maintenance by a specialist, today even many schoolchildren know how to use 3D printers. The simplification of equipment operation contributes to the popularization of additive technologies - their introduction to the general public and into various spheres of our life.

This explains the growing popularity of additive technologies not only in the commercial sector, but also in the private sector for home use. For example, according to official statistics in 2014, a total of 110 thousand 3D printers were shipped (but this does not mean that they were sold) all over the world. In 2018, over 400,000 home 3D printers were sold alone. In 2021, these figures increased by an order of magnitude.

In 2021, these figures increased by an order of magnitude.

2. Cheapness

In recent years, the final cost of 3D printing has dropped significantly. This opens up great prospects and makes it possible to use 3D printing technologies not only for an increasing number of companies and enterprises, but also in everyday life, privately. Today, 3D equipment and consumables often cost even less than popular branded gadgets.

Analysts cite as an example that ten years ago it was difficult to find 3D printers costing less than four or five thousand dollars, but today on the market you can find models costing about $100.

3. Quality

The quality of 3D printing is also on the rise: today's 3D printers are able to print with sub-millimeter accuracy, which allows to produce high quality final models that are not inferior to classical mass production in large enterprises. An illustrative example is Anycubic's new DLP 3D printer Photon Ultra. Although this printer has a nominal resolution of 720p, the print quality is superior even to that of 2K/4K monochrome LCD 3D printers. This is because DLP 3D printers use a different illumination technology than LCD mask 3D printers. DLP 3D printers use a projector that bounces light onto a pixel through a micro-mirror, resulting in no light convergence and sharper black and white contrast. LCD 3D mask printers condense all light into a pixel, which can result in jagged edges and shadows on the edges of models. DLP 3D printers deliver sharper fine lines and fine text than LCD mask 3D printers, with better color purity and richer layer saturation, resulting in finer textures and sharper corners.

This is because DLP 3D printers use a different illumination technology than LCD mask 3D printers. DLP 3D printers use a projector that bounces light onto a pixel through a micro-mirror, resulting in no light convergence and sharper black and white contrast. LCD 3D mask printers condense all light into a pixel, which can result in jagged edges and shadows on the edges of models. DLP 3D printers deliver sharper fine lines and fine text than LCD mask 3D printers, with better color purity and richer layer saturation, resulting in finer textures and sharper corners.

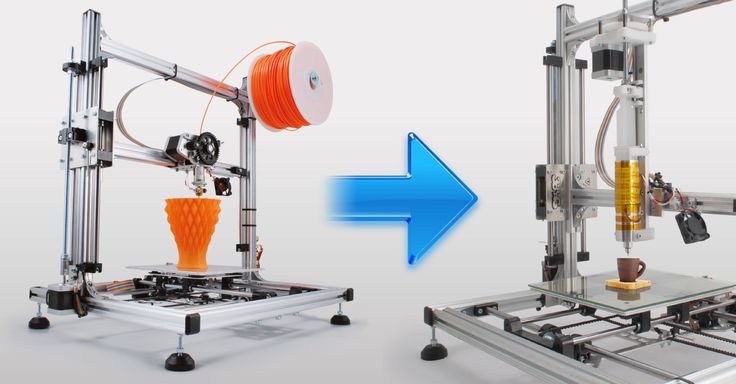

4. Speed

In many ways, it was the growth in the speed of 3D printing that enabled the ubiquitous commercial use of additive technologies. Modern 3D printers print at a high speed by the standards of past models. This allows you to put 3D printing on stream, carrying out both serial conveyor printing and operational piece production. The first FDM/FFF 3D printers in the mass market printed at speeds up to 35mm/s. Today, the print speed of, for example, the Ender 3 3D printer reaches 180 mm/s. According to official information from the manufacturer of 3D printers Creality (ed. note)

Today, the print speed of, for example, the Ender 3 3D printer reaches 180 mm/s. According to official information from the manufacturer of 3D printers Creality (ed. note)

5. Compactness

If the first devices were quite bulky, then today's printers stand out against their background with their compactness. For example, one of the early 3D printers, the Actua 2100, occupied an area of several square meters, and its dimensions were closer to a chest of drawers than to a printer. Today's 3D printers can easily fit on the desktop, while the usable working area of the printers themselves has increased, due to which users have the opportunity to print larger and more voluminous models.

Despite the fact that the market of additive technologies has made a real breakthrough lately, experts note that this is only the beginning. In the near future, 3D printing equipment will become an indispensable attribute of every home - as commonplace as, for example, a laptop or a refrigerator.