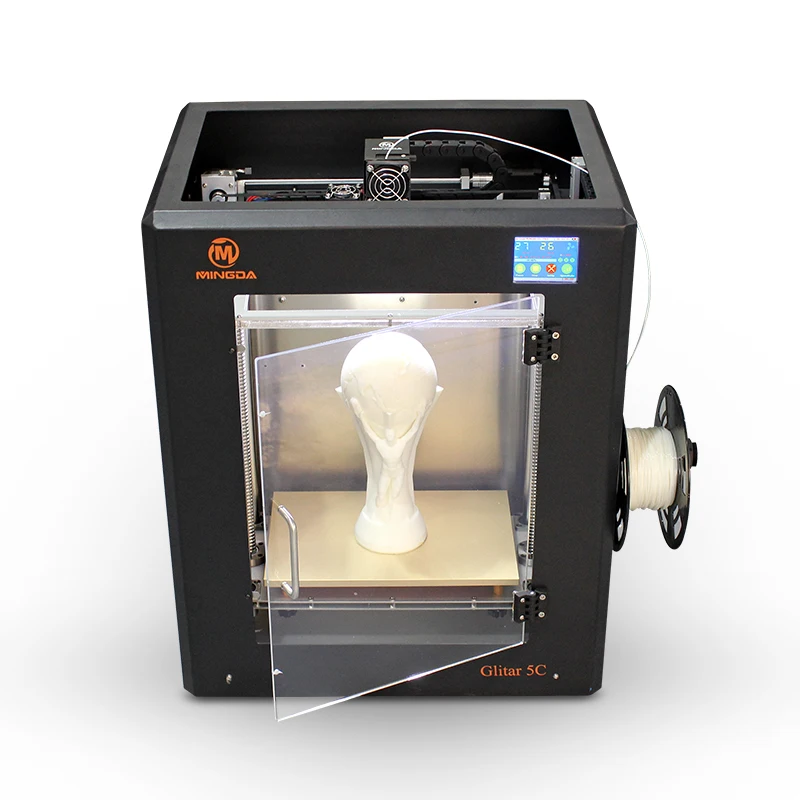

Medical grade 3d printer

3D Printing Medical Parts - Medical Grade 3D Printing Company

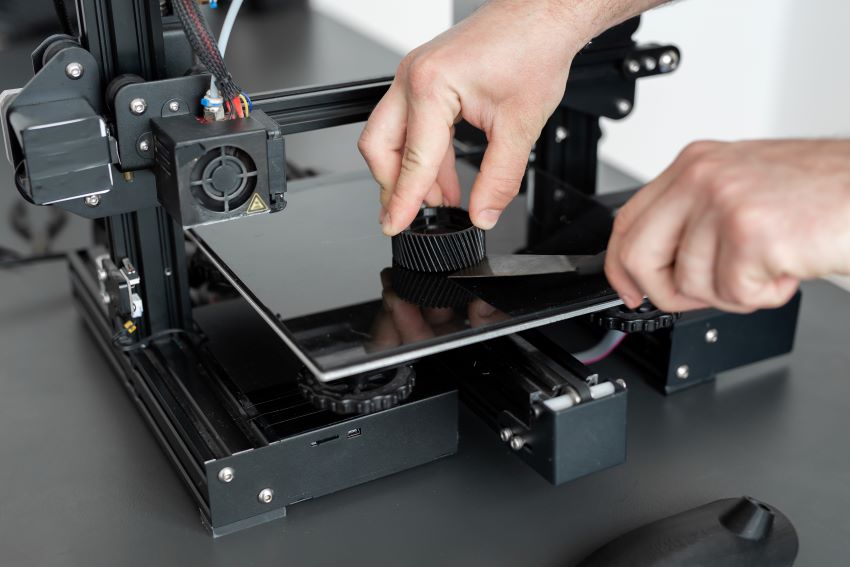

The medical industry―with its need for customizable, biocompatible and sterilizable plastic and metal components―is one of the most promising fields for 3D printing applications. It may sound like science fiction, but many types of medicine are already benefiting from additive manufacturing, with more applications being developed year after year.

Every day, 3D printing provides patients with affordable custom prostheses, implants, and devices; it enables doctors to perform their jobs more effectively with custom tools and models; and it helps medical device companies develop better products, faster. Some researchers are even working on technologies to 3D print living tissue and organs!

Keep reading to learn why 3D printing is such an effective tool for the medical industry and some of the ways it is helping medical professionals provide better care at less cost. For a general overview of 3D printing, check out our Complete 3D Printing Guide.

Advantages of Medical 3D Printing

So what makes 3D printing—also known as additive manufacturing—so useful in the medical industry? In many ways, the needs of modern medicine align perfectly with the capabilities of 3D printing.

Implants, prostheses, devices, anatomical models, and even some tools need to be designed for each patient. With traditional technologies, this customization is extremely expensive and time-consuming. 3D printing, on the other hand, can produce small runs of custom parts―even just one part at a time―at no extra cost and without any setup time or tooling. Additive manufacturing excels at highly customized applications, and the human body is about as custom as it gets!

However, it doesn’t stop there. Medical devices often require complex designs, internal geometries or organic forms. For example, think about the curves and hollow spaces in a hearing aid―or a heart! And did you know that implants are more likely to be accepted by a patient’s body if they have porous surfaces? These types of shapes are difficult or even impossible to make with traditional manufacturing.

3D printing can easily produce complex geometries in plastic or metal―all in one piece and with a high level of accuracy. This can allow for improved designs as well as reduced costs and production times. Eliminating crevices and gaps between multiple parts has the added benefit of making devices easier to sterilize and harder for bacteria to grow on.

When it comes to medical devices, the materials used in a device are at least as important as the design of the device itself. 3D printing is compatible with biocompatible and sterilizable plastics and metals that offer a range of mechanical, chemical and thermal properties. 3D printed components can be rigid or flexible, hard or soft, and smooth or textured. Whatever the demands of an application, 3D printed materials can meet them.

There’s also the unmatched production speed of 3D printing when compared to other technologies. Nowhere is this more important than when it comes to treating patients. The long timelines of traditional manufacturing often mean that patients are left waiting to begin their treatment program or have to go through multiple intrusive doctor visits over a long period of time to fit and re-fit medical devices. At best, this causes the patient inconvenience and additional discomfort. At worst, these delays can cause patients’ conditions to become more serious or even fatal.

The long timelines of traditional manufacturing often mean that patients are left waiting to begin their treatment program or have to go through multiple intrusive doctor visits over a long period of time to fit and re-fit medical devices. At best, this causes the patient inconvenience and additional discomfort. At worst, these delays can cause patients’ conditions to become more serious or even fatal.

Finally, 3D printers allow medical professionals to say goodbye to plaster casts by using 3D scanning and x-rays to quickly create detailed 3D models, eliminating the need to store countless physical casts for ongoing patient care. This does more than just save space—plaster casts can degrade over time or through mishandling. 3D images provide accurate, permanent models that can be accessed anywhere, saving medical professionals time and expense.

For more information on the unique design capabilities of 3D printing, take a look at our Design for Additive Manufacturing (DfAM) Guide.

Medical Applications for 3D Printing

3D Printed Prosthetics

The intense customization involved in prosthetic medicine makes prostheses famously expensive and time consuming to produce. This is largely due to the importance of getting a perfect fit to create a functional and comfortable prosthesis for the patient, as the devices and their sockets are subjected to rigorous use. For these reasons and more, 3D printed prostheses are revolutionizing the industry.

The prosthesis-fitting process typically consists of multiple castings and follow-up appointments to fine tune the fit. For patients, this is often more than just an inconvenience: having a cast made is uncomfortable, and the many fitting visits can be invasive to patients who may be sensitive about their condition. Not to mention, all of the time spent fitting and re-fitting is time spent without a properly fitted prosthesis.

With 3D printing, patients don’t even need to sit for a physical cast. Instead, technicians can use a 3D scanner to quickly create a precise 3D model of the patient’s residual limb. This 3D scan then serves as the basis for an accurate and affordable 3D printed socket that typically only requires a single fitting visit.

Instead, technicians can use a 3D scanner to quickly create a precise 3D model of the patient’s residual limb. This 3D scan then serves as the basis for an accurate and affordable 3D printed socket that typically only requires a single fitting visit.

Patient-Specific Devices and Implants

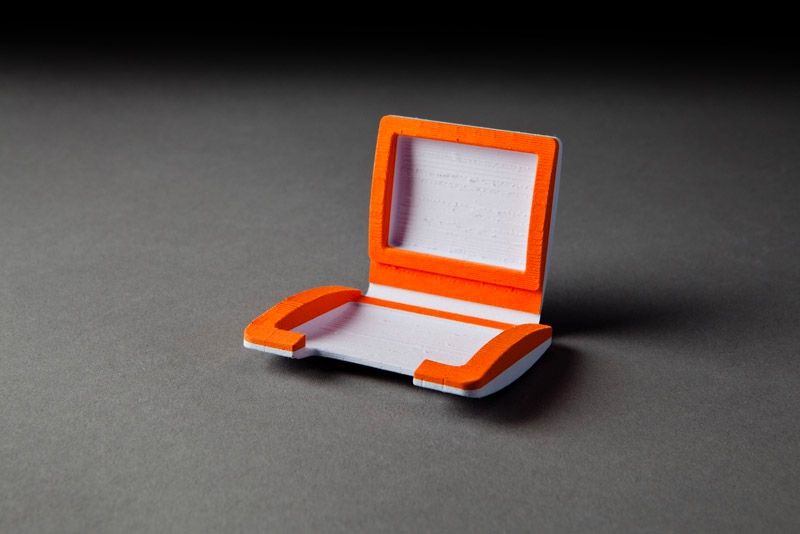

Prosthetic medicine is not the only medical field that requires a high degree of customization. Patient-specific devices (like hearing aids) and implants (like artificial joints, cranial plates and even heart valves) are rapidly converting to 3D printing for its easy customization and fast production.

Heart valves and hearing aids have traditionally required a full week of extensive, handmade adjustments by skilled workers. Prior to 3D printing, producing a hearing aid took nine steps from casting to fitting. Now, hearing aids can be 3D scanned and printed in a single day.

There are design advantages, too: 3D printed silicone heart valves provide an exact fit that rigid, traditionally manufactured heart valves simply can’t. For implants like titanium artificial joints or cranial plates, 3D printing can create complex, porous surfaces that make patients’ bodies less likely to reject the implants.

For implants like titanium artificial joints or cranial plates, 3D printing can create complex, porous surfaces that make patients’ bodies less likely to reject the implants.

Dentistry and Orthodontics

Like prostheses, dental implants and orthodontic devices require extensive customization with a high degree of accuracy. We rely on our teeth to stand up to heavy use day after day—as a result, dentures, crowns, implants and retainers need to be durable, precise and comfortable. On top of that, they need to be made of biocompatible materials like cobalt chrome and porcelain.

3D printing allows dental and orthodontic professionals to accomplish all of this faster and at less cost than traditional methods like machining. A combination of 3D scans and x-rays can be used to produce high-quality dental devices without any casting or setup time.

Even for devices like braces or expanders that do not require 3D printed components, 3D printed models made from sterilizable plastics can be used to measure form and fit, eliminating the need for lengthy patient fittings or multiple visits.

Medical Device Development

Research, development and certification for medical devices is extremely resource-intensive and time-consuming. Often, the high price of medical devices is due not to manufacturing costs but expensive product development. Because 3D printing offers a range of biocompatible and sterilizable materials, it helps medical device developers produce and test functional prototypes in a fraction of the time, leading to more iterations, better products and less expensive care.

Additive manufacturing shines in product development because of its fast turnaround, easy alterations and low cost for very small volumes of parts—it can easily save businesses hundreds of thousands of dollars and months of time in product development. Given the rigorous and lengthy certification process required for medical devices, these time and cost savings are especially valuable.

Personalized Surgical Instruments

In the operating room, precision and efficiency are everything. The unique challenges of each procedure cannot be understated—every patient’s body is different, as are every surgeon’s hands. When fine control is at a premium, why should surgeons be limited to one-size-fits-all surgical tools?

The unique challenges of each procedure cannot be understated—every patient’s body is different, as are every surgeon’s hands. When fine control is at a premium, why should surgeons be limited to one-size-fits-all surgical tools?

3D printing provides an affordable and timely method for producing personalized surgical tools that are tailored to the needs of each surgeon and each procedure. Made with sterilizable and biocompatible plastics and metals, these tools can be single-use or reusable. And because these tools can be produced in such a short time, hospitals don’t need to keep a large back stock of instruments and can instead order production as needed.

Surgical instruments that are personalized to the size and shape of each surgeon’s hands—plus additional customization for each application—can dramatically improve outcomes and efficiency. Moreover, surgical guides made specifically for each patient can increase accuracy while reducing the amount of time in the operating room by eliminating the need to consult diagrams and assistants.

Custom Anatomical Models

High-quality anatomical models are expensive, and even the best offer a finite range of options. Students and professionals alike regularly use models for education, training, surgery preparation and to provide visual aids for patients.

With 3D printing, medical professionals and educators can create affordable custom anatomical models for a range of purposes. For example, surgeons can practice for difficult surgeries using patient-specific models that precisely reproduce the conditions that they will encounter during surgeries.

Bioprinting

What if 3D printers could use cells and organic matter instead of plastic and metal? That’s the basic concept of bioprinting—the cutting edge of 3D printing in the medical industry.

Although most bioprinting technologies and applications are still in early development, researchers have had success printing bones, skin, and cartilage. One day, we may even be able to 3D print functioning organs.

Bioprinting works like other 3D printing technologies: using a range of methods, material is deposited or solidified in successive layers to build 3D objects. With bioprinting, however, printers use stem cells or cells cultivated from tissue samples. These cells are held together with a binding gel or collagen scaffold.

Bioprinted body parts and organs would allow patients’ natural tissue to grow over the 3D printed parts and eventually replace the cells with their own. And while we likely won’t be seeing functioning bioprinted organs anytime soon, the technology is already helping researchers carry out research on living tissues without having to acquire them from a living organism.

Medical-Grade 3D Printed Materials

When it comes to medical products, not all materials are created equal. Medical devices and implants need to be sterilizable, as the presence of microorganisms can lead to life-threatening infections. And any product that will be in contact with tissue must be biocompatible—meaning that it is not toxic to living tissue and will not produce harmful reactions if placed in a biological system. Implants in particular must be made of materials that are likely to be accepted by recipients’ bodies. Corrosion-resistance is equally as important, as our bodies’ fluids are surprisingly corrosive over time. And because implants need to stand up to heavy long-term use, these materials must be strong, durable and lightweight.

Implants in particular must be made of materials that are likely to be accepted by recipients’ bodies. Corrosion-resistance is equally as important, as our bodies’ fluids are surprisingly corrosive over time. And because implants need to stand up to heavy long-term use, these materials must be strong, durable and lightweight.

Fortunately, modern 3D printers are compatible with a number of plastics and metals that meet these qualifications. Below, we’ve outlined a few of the most commonly used 3D printed materials for the medical industry.

Nylon PA-12

This general-purpose plastic is lightweight, durable, corrosion-resistant and able to be sterilized with a steam autoclave. Nylon PA-12 offers good flexibility and chemical resistance. It is also among the fastest and most affordable medical-grade materials to print and is compatible with Multi Jet Fusion printing and SLS. Nylon PA-12 is USP Class I-VI and ISO 10993 certified. Read more about nylon PA-12.

PC-ISO

PC-ISO is a biocompatible polycarbonate (PC) engineering thermoplastic used in FDM 3D printing. It has a lower-quality finish than Nylon PA-12 but is commonly used for surgical guides, prototypes and molds. PC-ISO can be gamma or EtO sterilized and is USP Class I-VI and ISO 10993 certified. Read more about PC-ISO.

It has a lower-quality finish than Nylon PA-12 but is commonly used for surgical guides, prototypes and molds. PC-ISO can be gamma or EtO sterilized and is USP Class I-VI and ISO 10993 certified. Read more about PC-ISO.

ABS M30i

Like PC-ISO, ABS M30i is another biocompatible engineering thermoplastic for FDM. FDM prints are ideal for functional prototypes, form-fit tests and end-use parts. ABS M30i can be gamma or EtO sterilized and is also USP Class I-VI and ISO 10993 certified. Read more about ABS M30i.

Titanium

Titanium is the king of biocompatible metals and is the most popular material for medical implants. Replacement joints, pacemakers, cranial plates, dental implants and more are all regularly made from titanium. Titanium is extremely strong, lightweight, corrosion-resistant and non-reactive. It can be 3D printed using DMLS, one of the most expensive 3D printing technologies. Read more about titanium.

Cobalt Chrome

Like titanium, cobalt chrome has very high corrosion resistance and excellent biocompatibility. It offers additional strength and hardness over titanium and is commonly used for replacement teeth in addition to heavy-use replacement joints like knees, hips and shoulders. Cobalt chrome is also 3D printed using DMLS. Read more about cobalt chrome.

It offers additional strength and hardness over titanium and is commonly used for replacement teeth in addition to heavy-use replacement joints like knees, hips and shoulders. Cobalt chrome is also 3D printed using DMLS. Read more about cobalt chrome.

Stainless Steel

Stainless steel is strong, sterilizable and biocompatible; however, it does not offer the same long-term corrosion resistance as titanium or cobalt chrome. As a result, stainless steel is more commonly used for surgical tools and temporary implants like bone screws. Stainless steel parts can be 3D printed at a much lower cost than other metals with direct material printing. Different types of stainless steel offer varying levels of strength, rigidity and chemical resistance. Read more about stainless steel.

Silicone

Silicone is a flexible rubber material with a wide range of applications in the medical and food industries. It is heat-resistant and can be Class V or Class IV certified for biocompatibility. Silicone can be approved for both short- and long-term implants. Catheters, respiratory masks, medical tubing, and seals are all regularly made from silicone.

Silicone can be approved for both short- and long-term implants. Catheters, respiratory masks, medical tubing, and seals are all regularly made from silicone.

While silicone 3D printers are still in early development, silicone casting with 3D printed molds is a fast and affordable way to manufacture high-quality parts and products. Read more about silicone.

Given the unique needs of every patient and body, medical devices often require the most customization of any type of product in any industry. But, because of the high costs and long lead times of tooling for traditional manufacturing, these devices have historically been expensive and slow to produce. 3D printing—with its unmatched ability to produce small runs of highly customized parts—is redefining what is possible in medicine.

Tailoring medical solutions to patients and doctors improves outcomes; reducing costs and production times increases accessibility. Now, custom medical devices, implants and tools are more accessible than ever. As 3D printing technologies continue to develop, healthcare providers and researchers will continue to explore new applications—from implants and surgical tools to tissues and functioning organs.

.

3D printing for the medical industry

The medical field is a constantly changing environment in which medical professionals perpetually search for the most innovative tools. Prodways 3D printing solutions help create devices for practitioners (surgeons, prosthetists, technicians) such as highly customized medical or orthopedic devices specifically customized for the morphology of the patient, previewing models for surgery, or ceramic substitutes for bone reconstruction.

Through the use of medical-grade and biocompatible 3D printing materials, combined with high resolution 3D printers, we offer solutions tailored to your needs.

Applications

Case Studies & Customer References

3D PRINTERS AND MATERIALS FOR MEDICAL PRODWAYS

The team at Prodways Technologies are experts in the development of industrial 3D printers and additive manufacturing materials for the medical sector.

Our multi-technology offering enables prototyping to test your preclinical equipment, manufacturing of your medical intervention tools and implants adapted to the patients’ morphology.

3D PRINTING CERAMIC BONE SUBSTITUTES FOR RECONSTRUCTION

Thanks to the DLP® MOVINGLight® additive manufacturing technology of Prodways, you have access a unique solution for 3D printing of high resolution ceramic parts with up to 99% ceramic density after debinding and sintering.

Our industrial ceramic 3D printers ProMaker V6000 enables high-precision, direct 3D printing of unique, biocompatible bone substitutes in ceramics – hydroxyapatite (HA) or Tricalcium Phosphate (TCP) – for reconstructive surgery.

This technology eliminates the steps for tooling required for conventional CIM (Ceramic Injection Molding) technologies.

PREVIEW MODELS FOR SURGICAL INTERVENTION

Whether for training your teams to prepare for surgery or for demonstration to your patients, Prodways 3D printing technologies enable:

- 3D Printing of models representing a wide range of clinical conditions or pathologies from a 3D file

- Creating reconstructions of bone from 3D scanning

Our multi-technology offering allows for printing:

- Massive parts with complex shapes and high resolution via laser sintering technology, using polymer powders.

- Small parts requiring very high accuracy to identify pathologies at first glance via DLP® MOVINGLight® technology

ADDITIVE MANUFACTURING OF STERILE & ULTRA CUSTOM SURGICAL TOOLS

With our industrial plastic 3D printers using laser sintering Prodways offers a unique PA11 registered as “medical-grade” by the manufacturer, with USP Class VI certification: PA11-SX 1450. You can directly print small- or medium-sized series of pre-mounted, highly customized, shock-resistant and sterilizable by gamma sterilization instrumentation for single-use in implantation surgery – removing steps and minimizing conventional tooling costs.

3D DIRECT AND FAST PRINTING OF CUSTOM ORTHOTICS

Prodways laser sintering technology, combined with our medical grade PA11-S 1450 USP Class VI, allows for the 3D printing of temporary instrumentation such as highly customized mandibular orthotics – in a much shorter time and with a longer life than conventional thermoforming technologies – as well as more standard orthopedic medical devices.

CUSTOM PRODUCTION SOLES OR COMFORT ORTHOPEDIC

Prodways laser sintering 3D printing technology allows for the manufacturing of light orthopedic or comfort insoles, perfectly adapted to the morphology of the consumer and with the appropriate corrective shape.

The shoe soles are highly customized thanks to the precise scan of the shape and arch of the foot, with a lattice or honeycomb structure, which allows for individual adjustments to the density for each area of the foot.

Shoe soles can be printed in PA12 or PA11 medical-grade certified USP Class VI (medical equipment) according to the type of sole.

PRINTING HIGH-PRECISION CUSTOM CUTTING GUIDES

Prodways 3D printing technology allows you to print high-quality medical devices – with precision tolerances of just a few microns – such as cutting guides or surgical guides, perfectly adapted to the morphology of your patients, while reducing costly changes of your production tools .

Our range of medical, biocompatible 3D printing materials can meet your needs for the most demanding applications.

PRODWAYS PARTNERS WITH CERHUM

PART DESIGN & PRODUCTION

SLS 3D printers in medicine. Additive Manufacturing of Sterile and Customized Surgical Instruments

The medical industry is in a state of flux and looking for solutions to modernize current manufacturing processes. Profile specialists are interested in introducing the most efficient and innovative means of production to enterprises.

The French holding Prodways offers medical practitioners (surgeons, prosthetists) modern 3D printing technologies that allow them to create:

- Unique orthopedic products, taking into account the structural features of the body of a particular patient;

- Demonstration models of various parts of the skeleton

- Ceramic replacement components for bone reconstruction

Biocompatible 3D printing materials and high-precision 3D printers from Prodways are the answer to today's demands and needs of the medical industry.

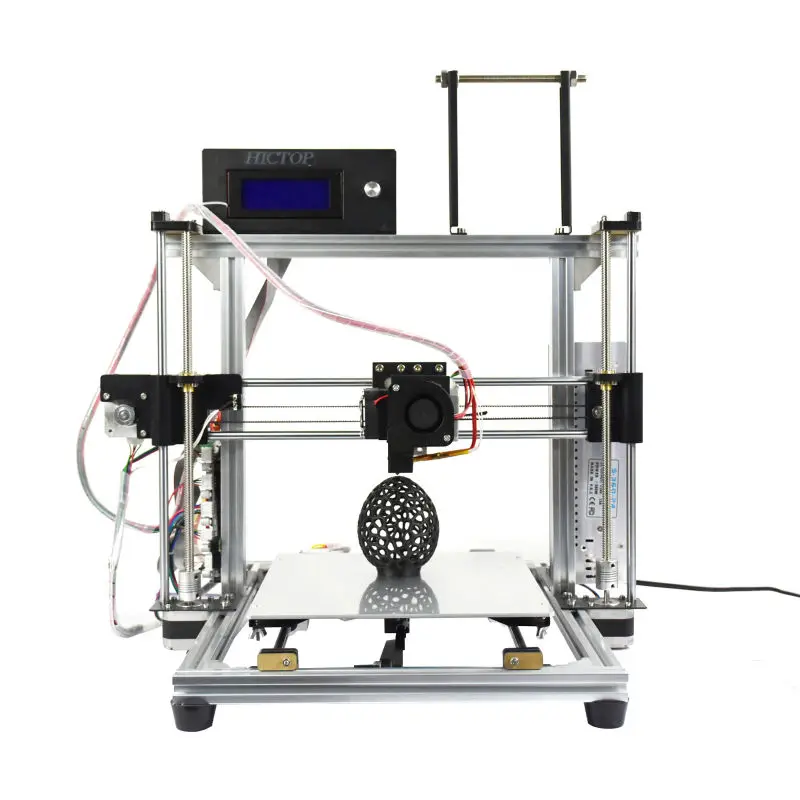

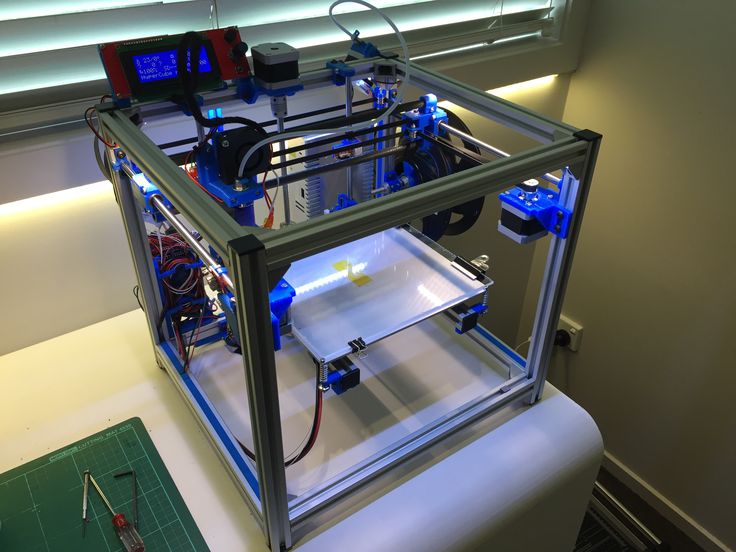

Industrial SLS 3D Printers Prodways

Prodways Technologies employees are experts in the production of industrial 3D printers and materials for the medical sector.

The company's offer includes equipment that uses the following 3D printing technologies:

- SLS - selective laser sintering of plastic powder

- DLP MOVINGLight ® digital curing photopolymer resin

Prodways printers can be used in prototyping for medical device testing, as well as in the production of customized end-use products and tools.

3D Print Ceramic Bone Substitutes

With DLP MOVINGLight ® you can 3D print high resolution ceramics with 99% ceramic density.

The Prodways ProMaker V10 industrial ceramic 3D printer enables direct 3D printing of unique bone replacement components made from biocompatible ceramics - hydroxylapatite or calcium orthophosphate.

DLP MOVINGLight ® eliminates the machining step that is part of traditional ceramic casting technology.

Production of surgical demonstration models

Prodways SLS and DLP 3D printers provide a wide range of imaging options for training healthcare professionals and presentations to patients. 3D technologies allow:

- Design and grow products that illustrate a wide variety of clinical diseases and pathologies

- Create a 3D model of a patient's bone using a 3D scan and then send the 3D file to a printer for printing

Solutions offered by Prodways will make it possible to grow:

Large models with complex geometric shapes in high resolution on SLS 3D printers. The plastic powder used during the operation of the printer can be recycled and used during the subsequent production cycle, which can significantly optimize the cost of creating products.

Small parts that require high detail and print accuracy to correctly identify existing pathologies using DLP MOVINGLight ® 3D printer.

Additive manufacturing of sterile and customized surgical instruments

Industrial SLS printers support printing with USP Class VI certified polyamide (PA 11-SX 1450). With this material it is possible to manufacture small and medium batches of products intended for single use in implant surgery. In this case, the products will be customized, impact-resistant and can be sterilized by means of gamma radiation.

With this material it is possible to manufacture small and medium batches of products intended for single use in implant surgery. In this case, the products will be customized, impact-resistant and can be sterilized by means of gamma radiation.

Fast 3D printing of orthopedic products

Prodways selective laser sintering technology allows you to create orthopedic corrective insoles that match the individual characteristics of the human foot.

Thanks to high-precision 3D scanning of the foot, it is possible to obtain a 3D model of the insole of the desired shape, with a lattice or honeycomb structure. Thus, it is possible to adjust the fit of the insole to different parts of the foot.

Orthotic insoles can be printed in either PA12 or PA11 powder depending on their type, both plastics are medical grade materials and are USP Class VI certified.

High Precision 3D Printing of Surgical Guides

With Prodways 3D printers it is possible to produce medical instruments of high quality and precision (with a tolerance level of a few microns). For example, individual surgical guides used to fix the patient's bone during surgery.

Prodways' wide range of medical, biocompatible materials greatly expands the scope of additive technologies and makes it possible to use them to solve the most complex and demanding problems.

Office Equipment Jetcom is the official distributor of Prodways 3D printers in the Russian Federation.

We provide comprehensive support to our customers at each stage of cooperation - from the correct selection of equipment to maintenance of installed equipment.

You can get acquainted with Prodways SLS 3D printers in our showroom in Moscow, we will also be happy to perform test printing for you and demonstrate the capabilities of the devices.

For detailed advice, please contact us in any way convenient for you:

Phone: + 7 (495) 739-09-09

E-mail – [email protected]

3D printing in medicine

Personalized and precise solutions in the medical field are becoming increasingly popular. New tools and advanced technologies bring doctors closer to patients by providing treatments and devices that meet the needs of each individual.

New tools and advanced technologies bring doctors closer to patients by providing treatments and devices that meet the needs of each individual.

The expansion of 3D printing technologies in healthcare has made a huge contribution to improving the quality of medical services. With new tools and treatment approaches developed using 3D printing, patients feel that their treatment becomes more comfortable and personal. For physicians, the new technology available allows them to better analyze complex cases and provides new tools that can ultimately raise standards of care.

Later in this article, you'll learn about five areas, from models for surgical planning to vascular systems and bioreactors, in which 3D printing is used in healthcare, and why many healthcare professionals see great potential in this technology.

In today's medical practice, 3D printed anatomical models based on patient body scans are becoming more indispensable tools, as they provide more personalized and accurate treatment. As cases become more complex and standard case times become more important, visual and tactile anatomical models are helping surgeons to better understand their task, communicate more effectively, and communicate with patients more easily.

As cases become more complex and standard case times become more important, visual and tactile anatomical models are helping surgeons to better understand their task, communicate more effectively, and communicate with patients more easily.

Medical professionals, hospitals and research institutions around the world use 3D printed anatomical models as a reference tool for preoperative planning, intraoperative imaging, and for sizing medical instruments or presetting equipment for both standard and very complex procedures, which is reflected in hundreds of scientific publications.

3D printing makes 3D printing affordable and easy to create customized patient anatomical models based on CT and MRI data. The peer-reviewed scientific literature demonstrates that they help clinicians better prepare for surgery, resulting in significant cost and time savings. At the same time, patient satisfaction is also increased through reduced anxiety and reduced recovery time.

Physicians can use individual patient anatomical models to explain the procedure to the patient, making it easier to obtain patient consent and reduce patient anxiety.

Preparation for surgery using preoperative models can also affect the effectiveness of the treatment. The experience of Dr. Michael Ames confirms this. After obtaining bone replications from the young patient's forearm, Dr. Ames realized that the injury was different from what he expected.

Based on this information, Dr. Ames chose a new soft tissue procedure that was much less invasive, reduced downtime, and resulted in much less scarring. Using imprinted bone replication, Dr. Ames explained the procedure to the young patient and his parents and obtained their consent.

Physicians can use patient-specific surgical models to explain the procedure beforehand, improving patient consent and lowering anxiety.

Result? The operation lasted less than 30 minutes instead of the originally planned three hours. With this reduction in operating time, the hospital avoided a cost of about $5,500 and the patient recovered faster.

According to Dr. Alexis Dang, Orthopedic Surgeon at UC San Francisco and Veterans Affairs Medical Center San Francisco: “All of our full-time orthopedic surgeons and nearly all of our full-time surgeons part-time, used 3D printed models to treat patients at a Veterans Medical Center in San Francisco. We could all see that 3D printing improves the efficiency of our work.”

We could all see that 3D printing improves the efficiency of our work.”

The advent of new biocompatible medical polymers for 3D printing has opened up opportunities for the development of new surgical instruments and techniques to further improve clinical operating procedures. These include sterilizable trays, contoured surgical guides, and implant models that can be used to determine the size of an implant prior to surgery, helping surgeons reduce time and improve accuracy in complex procedures.

Anatomical model of a hand with elastic resin skin for 3D printing.

Todd Goldstein, PhD, lecturer at the Feinstein Institute for Medical Research, is unequivocal about the importance of 3D printing technology to the work of his department. He estimates that if Northwell used 3D-printed models 10-15% of the time, it could save $1,750,000 a year.

“Whether it's prototyping medical devices, complex anatomical models for our children's hospital, designing training systems, or making surgical templates for dental clinics, [3D printing technology] has increased our capabilities and reduced our costs in a variety of areas. In doing so, we were able to produce instruments for treating patients that would be almost impossible to recreate without our sought-after stereolithography 3D printer,” says Goldstein.

In doing so, we were able to produce instruments for treating patients that would be almost impossible to recreate without our sought-after stereolithography 3D printer,” says Goldstein.

3D printing has become virtually synonymous with rapid prototyping. The ease of use and low cost of 3D printing in-house has also revolutionized product development, with many medical instrument manufacturers adapting the technology to produce entirely new medical devices and surgical instruments.

Over 90 percent of the top 50 medical device companies use 3D printing to create accurate medical device prototypes and fixtures and fittings to simplify testing.

According to Alex Drew, Principal Mechanical Engineer at DJO Surgical, an international medical device supplier, “Before DJO Surgical purchased [Formlabs' 3D printer], we printed nearly all of our prototypes outsourced. Today we are working with four Formlabs printers and are very pleased with the results. The speed of 3D printing has doubled, the cost has been reduced by 70%, and the level of detail allows you to effectively coordinate designs with orthopedic surgeons.

Medical companies such as Coalesce are using 3D printing to create accurate medical device prototypes.

3D printing helps speed up the design process by allowing complex designs to be iterated over in days instead of weeks. When Coalesce was tasked with building an inhaler device that could digitally evaluate an asthma patient's inspiratory flow profile, outsourcing would result in a significant increase in production time for each prototype. Before sending the project files to a third party company for the physical implementation of the project, they would have to be carefully developed and carried through various iterations.

Instead, desktop stereolithographic 3D printing allowed Coalesce to handle the entire prototyping process in-house. The prototypes were suitable for use in clinical trials and looked just like the finished product. Moreover, when the company demonstrated the device, its customers mistook the prototype for the final product.

Overall, the introduction of in-house manufacturing resulted in an exceptional reduction in prototyping time by 80–90%. In addition, the models took only eight hours to print and were finished and painted in a matter of days, while outsourcing the same process would take a week or two.

In addition, the models took only eight hours to print and were finished and painted in a matter of days, while outsourcing the same process would take a week or two.

Hundreds of thousands of people lose limbs every year, but only a fraction of them are able to restore limb function with a prosthesis.

Conventional dentures are only available in a few sizes, so patients must adjust to what fits best. On the other hand, custom bionic prostheses that mimic the movements and grips of a real limb based on the impulses of the surviving limb muscles are so expensive that they can only be used by patients living in developed countries with the best medical insurance. In the case of children's prostheses, the situation is aggravated even more. Children grow up and inevitably outgrow their prostheses, which, as a result, require costly modifications.

The difficulty lies in the lack of manufacturing processes that would allow for individual orders at an affordable price. But increasingly, prosthetists are looking to reduce these high financial barriers to rehabilitation with the flexible design capabilities of 3D printing.

But increasingly, prosthetists are looking to reduce these high financial barriers to rehabilitation with the flexible design capabilities of 3D printing.

Initiatives like e-NABLE allow people around the world to learn about the possibilities of 3D printed prostheses. They are driving an independent movement in the prosthesis industry by offering information and free open source projects so that patients can get a custom-designed prosthesis for as little as $50.

Other inventors, such as Lyman Connor, go even further. With only a small fleet of four desktop 3D printers, Lyman was able to fabricate and customize his first mass-produced prostheses. His ultimate goal? Create a customizable fully bionic arm that will cost incomparably less than similar prostheses that retail for tens of thousands of dollars.

Researchers at the Massachusetts Institute of Technology have also found that 3D printing is the best method for making more comfortable prosthetic sockets.

In addition, the low cost of manufacturing these prostheses, as well as the freedom that comes with being able to design custom designs, speak for themselves. 3D printed prostheses have a lead time of just two weeks, and then they can be tried and serviced at a much lower cost than traditional counterparts.

3D printed prostheses have a lead time of just two weeks, and then they can be tried and serviced at a much lower cost than traditional counterparts.

As costs continue to fall and material properties improve, the role of 3D printing in healthcare will no doubt become more important.

The same high financial barriers that are seen in prosthetics are common in orthoses and insoles. Like many other patient-specific medical devices, custom-made orthoses are often not available due to their high cost and take weeks or months to manufacture. 3D printing solves this problem.

Confirmation is the example of Matej and his son Nick. Nick was born in 2011. Complications during preterm birth led to the fact that he developed cerebral palsy, a pathology that affects nearly twenty million people worldwide. Matei was delighted with how determined his son was to overcome the limitations of his illness, but he was faced with a choice between a standard, off-the-shelf orthosis that would be uncomfortable for his son, or an expensive custom solution that would take weeks or months to manufacture and ship. , and from which the child would quickly grow.

, and from which the child would quickly grow.

He decided to take matters into his own hands and began to look for new ways to achieve his goal. Thanks to the opportunities provided by digital technologies, in particular 3D scanning and 3D printing, Matei and Nika's physiotherapists were able to develop a completely new innovative workflow for the manufacture of ankle orthoses through experiments.

The resulting 3D-printed, custom-fit orthosis that provides support, comfort, and motion correction helped Nick take his first steps on his own. This non-standard orthopedic device reproduced the functionality of the highest-class orthopedic products, at the same time it cost many times less and did not require any additional settings.

Professionals around the world are using 3D printing as a new method of manufacturing custom insoles and orthoses for patients and clients, as well as a range of other physiotherapy tools. In the past, undergoing a course of physiotherapy with the use of individual physiotherapy instruments carried many difficulties. Often there was a situation when patients had to wait a long time for a finished product, which at the same time did not provide proper comfort. 3D printing is step by step changing this status quo. Data confirms that 3D printed insoles and orthoses offer a more precise fit and lead to better therapeutic outcomes, which means greater comfort and benefit for patients.

Often there was a situation when patients had to wait a long time for a finished product, which at the same time did not provide proper comfort. 3D printing is step by step changing this status quo. Data confirms that 3D printed insoles and orthoses offer a more precise fit and lead to better therapeutic outcomes, which means greater comfort and benefit for patients.

The usual treatments for patients with severe organ damage today are autografts, transplantation of tissue from one area of the body to another, or transplantation of a donor organ. Researchers in bioprinting and tissue engineering hope to expand this list soon with on-demand fabrication of tissues, blood vessels, and organs.

3D bioprinting is an additive manufacturing process that uses materials known as bioink (a combination of living cells and a compatible substrate) to create tissue-like structures that can be used in medicine. Tissue engineering combines new technologies, including bioprinting, which make it possible to grow replacement tissues and organs in the laboratory for use in the treatment of injuries and diseases.

Using high-precision 3D printing, researchers such as Dr. Sam Pashne-Tala from the University of Sheffield are opening up new possibilities for tissue engineering.

In order to direct cell growth to form the necessary tissue, Dr. Pashne-Tala grows living cells on a laboratory scaffold that provides a template of the required shape, size and geometry. For example, to create a blood vessel for a patient with cardiovascular disease, a tubular structure is needed. The cells will multiply and cover the scaffold, taking on its shape. Then the scaffold is gradually destroyed, and the living cells take the form of the target tissue, which is cultured in a bioreactor - a chamber that contains the cultured tissue and can reproduce the internal environment of the body so that the cultured tissue acquires the mechanical and biological characteristics of organic tissue.

3D printed bioreactor chamber with tissue engineered aorta miniature inside. The tissue is cultured in a bioreactor to acquire the mechanical and biological characteristics of the organic tissue.

3D printed bioreactor chamber with tissue engineered aorta miniature inside. The tissue is cultured in a bioreactor to acquire the mechanical and biological characteristics of the organic tissue.

This will allow scientists to design patient-specific vascular grafts, expand surgical care, and provide a unique platform for testing new vascular medical devices for people suffering from cardiovascular disease, which is currently the leading cause of death worldwide. The ultimate goal is to create blood vessels that are ready for implantation in patients. Since tissue engineering uses cells taken from a patient in need of treatment, this eliminates the possibility of rejection by the immune system, which is the main problem of modern transplantology.

3D printing has proven its ability to solve the problems that exist in the production of synthetic blood vessels, in particular, the difficulty of recreating the required accuracy of the shape, size and geometry of the vessel. The ability of printed solutions to clearly reflect the specific characteristics of patients was a step forward.

The ability of printed solutions to clearly reflect the specific characteristics of patients was a step forward.

According to Dr. Pashne-Tal: “[Creating blood vessels using 3D printing] makes it possible to expand the possibilities of surgical care and even create designs of blood vessels for a specific patient. Without the existence of high-precision affordable 3D printing, the creation of such forms would not be possible.”

We are witnessing significant advances in the development of biological materials that can be used in 3D printers. Scientists are developing new hydrogel materials that have the same consistency as organ tissues present in the human brain and lungs, which can be used in a range of 3D printing processes. Scientists hope that they will be able to implant them into the body as a "scaffold" for cell growth.

Although bioprinting of fully functional internal organs such as the heart, kidneys and liver still looks futuristic, hybrid 3D printing at very high speed opens up more and more new horizons.

It is expected that sooner or later the creation of biological matter on laboratory printers will lead to the generation of new, fully functional 3D printed organs. In April 2019, scientists at Tel Aviv University 3D-printed the first heart using biological tissue from a patient. A tiny copy was created using the patient's own biological tissues, which made it possible to fully match the immunological, cellular, biochemical and anatomical profile of the patient.

“At this stage, the heart we printed is small, about the size of a rabbit heart, but normal-sized human hearts require the same technology,” says Prof. Tal Dvir.

The first 3D bioprinted heart created at Tel Aviv University.

Precise and affordable 3D printing processes, such as desktop stereolithography, are democratizing access to technology, enabling healthcare professionals to develop new clinical solutions and quickly produce medical devices with individual characteristics, and doctors around the world to offer new types of therapy.